Rheology:Concepts,Methods,andApplications3rd EditionAlexanderYa.Malkin

https://ebookmass.com/product/rheology-concepts-methods-andapplications-3rd-edition-alexander-ya-malkin/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Rheology: Concepts, Methods, and Applications Alexander Y. Malkin

https://ebookmass.com/product/rheology-concepts-methods-andapplications-alexander-y-malkin/

ebookmass.com

Quantum Mechanics 3rd Edition Nouredine Zettili

https://ebookmass.com/product/quantum-mechanics-3rd-edition-nouredinezettili/

ebookmass.com

Advances in Food Rheology and Its Applications: Development in Food Rheology 2nd Edition Jasim Ahmed (Editor)

https://ebookmass.com/product/advances-in-food-rheology-and-itsapplications-development-in-food-rheology-2nd-edition-jasim-ahmededitor/

ebookmass.com

US Presidents and the Destruction of the Native American Nations 1st ed. 2021 Edition Michael A. Genovese

https://ebookmass.com/product/us-presidents-and-the-destruction-ofthe-native-american-nations-1st-ed-2021-edition-michael-a-genovese/

ebookmass.com

AWS Certified Solutions Architect Associate All-in-One Exam Guide (Exam SAA-C02) Joyjeet Banerjee

https://ebookmass.com/product/aws-certified-solutions-architectassociate-all-in-one-exam-guide-exam-saa-c02-joyjeet-banerjee/

ebookmass.com

Practice Makes Perfect®: Advanced French Grammar, Second Edition Véronique Mazet

https://ebookmass.com/product/practice-makes-perfect-advanced-frenchgrammar-second-edition-veronique-mazet/

ebookmass.com

End of an Era: How China’s Authoritarian Revival is Undermining Its Rise 1st Edition Carl Minzner

https://ebookmass.com/product/end-of-an-era-how-chinas-authoritarianrevival-is-undermining-its-rise-1st-edition-carl-minzner/

ebookmass.com

Safe Maternity and Pediatric Nursing Care 1st Edition, (Ebook PDF)

https://ebookmass.com/product/safe-maternity-and-pediatric-nursingcare-1st-edition-ebook-pdf/

ebookmass.com

Oxford Handbook of Urology 4th Edition Edition John Reynard

https://ebookmass.com/product/oxford-handbook-of-urology-4th-editionedition-john-reynard/

ebookmass.com

https://ebookmass.com/product/local-economic-development-analysispractices-and-globalization/

ebookmass.com

Rheology

Concept, Methods, and Applications

3rd Edition

Prof. Dr. Alexander Ya. Malkin Academy od Sciences, Institute of Petrochemical Synthesis Moscow, Russia

Prof. Dr. Avraam Isayev

The University of Akron, Department of Polymer Engineering Akron, Ohio, USA

Published by ChemTec Publishing

38 Earswick Drive, Toronto, Ontario M1E 1C6, Canada

© ChemTec Publishing, 2005, 2012, 2017

ISBN 978-1-927885-21-5 (hard cover); ISBN 978-1-927885-22-2 (E-PUB)

All rights reserved. No part of this publication may be reproduced, stored or transmitted in any form or by any means without written permission of copyright owner. No responsibility is assumed by the Author and the Publisher for any injury or/and damage to persons or properties as a matter of products liability, negligence, use, or operation of any methods, product ideas, or instructions published or suggested in this book.

Library and Archives Canada Cataloguing in Publication

Malkin, Aleksandr IAkovlevich, author

Rheology : concepts, methods, and applications / Alexander Ya. Malkin, Avraam I. Isayev. -- 3rd edition.

Includes bibliographical references and index. Issued in print and electronic formats.

ISBN 978-1-927885-21-5 (hardcover).-ISBN 978-1-927885-22-2 (PDF)

1. Rheology--Textbooks. 2. Textbooks. I. Isayev, Avraam I., 1942-, author II. Title.

QC189.5.M33 2017531'.1134

C2016-907346-7 C2016-907347-5

Printed in Australia, United Kingdom and United States of America

2.3

2.3.1

2.3.2 Complicated mechanical models differential rheological equations

2.4 Superposition The Boltzmann-Volterra Principle

2.4.1Integral formulation of the superposition principle

2.4.2 Superposition principle expressed via spectra

2.4.3 Simple transient modes of deformation

2.4.3.1 Relaxation after sudden deformation

2.4.3.2 Developing stresses at constant shear rate

2.4.3.3 Relaxation after steady shear flow

2.4.3.4 Relationship between relaxation and creep functions

2.4.3.5 Relaxation function and large deformations

2.5 Relationships among viscoelastic functions

2.5.1 Dynamic functions relaxation, creep, and spectra

2.5.2 Constants and viscoelastic functions

2.5.3 Calculation of a relaxation spectrum

2.5.3.1 Introduction general concept

2.5.3.2

2.5.3.3

2.6 Viscoelasticity and molecular models

2.6.1 Molecular movements of an individual chain

2.6.1.1 A spring-and-bead model (“free draining chain”)

2.6.1.2 Model of a non-draining coil

2.6.1.3 Model of a rotating coil

2.6.2

2.6.2.1

2.6.2.2

2.6.2.3

2.6.2.5

2.6.2.6

2.6.2.7

2.6.3

2.7 Time-temperature superposition. Reduced (“master”) viscoelastic

2.7.1

2.8.1

2.8.1.1

2.8.1.2

2.8.1.3

2.8.1.4

2.8.1.5 Non-linear periodic measurements

2.8.2 Linear-non-linear correlations

2.8.3 Rheological equations of state for non-linear viscoelastic behavior

2.8.3.1 The K-BKZ model

2.8.3.2The Wagner models

2.8.3.2 The Leonov model

2.8.3.4 The Marrucci models

2.8.4 Comments constructing non-linear constitutive equations and experiment

3 Liquids

3.1 Newtonian and non-Newtonian liquids. Definitions

3.2 Non-Newtonian shear flow

3.2.1 Non-Newtonian behavior of viscoelastic polymeric materials

3.2.2 Non-Newtonian behavior of structured systems plasticity of liquids

3.2.3 Viscosity of anisotropic liquids

3.3 Equations for viscosity and flow curves

3.3.1

3.3.2

3.3.3

3.3.4.3

3.3.4.4

3.4

3.4.1

3.4.2.2

3.4.4

3.5

3.5.1

3.5.2

3.5.3

3.6

3.6.1

3.6.2

3.6.3

3.6.3.1

3.6.3.2

3.6.3.3

3.7

3.7.1

3.7.5

3.7.5.1

3.7.5.2

3.7.5.3

3.8

4

4.4.2.2

4.4.2.3

4.5.3

4.5.4

4.5.4.1

4.5.4.2

5 Rheometry

5.1

5.2

5.2.1

5.2.2

5.2.2.6

5.2.2.7 Adsorption on a channel surface

5.2.3 Flow in incompletely filled capillary

5.2.3.1 Motion under action of gravitation forces

5.2.3.2 Motion caused by surface tension forces

5.2.4 Limits of capillary viscometry

5.2.5 Non-viscometric measurements using capillary viscometers

5.2.6 Capillary viscometers

5.2.6.1 Classification of the basic types of instruments

5.2.6.2 Viscometers with the assigned load

5.2.6.3 Cup viscometers

5.2.6.4 Glass viscometers

5.2.7 Viscometers with controlled flow rate

5.2.7.1 Instruments with a power drive

5.2.7.2 Instruments with hydraulic drive

5.2.7.3 Extrusion rheometers

5.2.7.4 Technological capillary tube viscometers

5.3 Rotational rheometry

5.3.1 Tasks and capabilities of the method

5.3.1.1 Viscometric and non-viscometric measurements

5.3.1.2 The method of a constant frequency of rotation

5.3.1.3

5.3.2

5.3.2.1

5.3.2.2

5.3.2.3 Bi-conical viscometers

5.3.2.4

5.3.2.5

5.3.2.6

5.3.2.7 On a role of rigidity of dynamometer

5.3.2.8

5.3.3Limitations of rotational viscometry

5.3.4 Rotational instruments

5.3.4.1

5.3.4.2 Rheogoniometers and elastoviscometers

5.3.4.3 Viscometers with assigned rotational

5.3.4.4 Rotational viscometers for special purposes

5.3.4.5 Rotational instruments for technological purposes

5.3.5 Measuring normal stresses

5.3.5.1 Cone-and-plate technique

5.3.5.2 Plate-and-plate technique

5.3.5.3 Coaxial cylinders technique

5.3.5.4 Hole-pressure effect

5.4 Plastometers

5.4.1. Shear flow plastometers

5.4.2 Squeezing flow plastometers

5.4.3

5.4.3.1

5.5.2Method of rolling

5.5.3 Viscometers with

5.5.4 Viscometers with

5.6 Extension

5.6.1

5.6.2.

5.6.2.1

5.6.2.2

5.6.2.3

5.6.2.4Flow

5.6.2.5 High strain rate methods

5.6.2.6

5.6.3 Biaxial

5.7 Measurement of viscoelastic

5.7.1

5.7.2

5.7.3

5.7.4

5.7.6

5.7.7

5.7.7.1

5.7.7.2

5.7.8

5.7.8.1

5.7.8.2

5.7.8.3

5.7.8.4

5.7.9

5.7.10

5.7.10.1

5.7.10.2

5.7.10.3

5.8

5.8.1

5.8.1.1

5.8.1.2

5.8.1.3

5.8.1.4

5.8.1.5

6

6.1

6.2

6.2.1

6.2.2Mineral

6.2.3

6.2.4

6.2.5

6.2.8

6.3

6.3.1

6.3.2

6.3.3

6.3.3.1

6.3.3.2

6.3.4

6.3.4.2

6.4

6.4.1

6.4.2

6.4.3

6.4.3.1

6.4.3.2

6.4.3.3

6.4.3.4

6.4.3.5

6.4.3.6

6.4.3.7

Preface

A number of books, devoted to different aspects of both theoretical and applied rheology, were published in the last 20 years. The keyword in the last sentence is “different aspects”. Rheology has a unique structure with its own language, fundamental principles, original concepts, rigorous experimental methods, and a set of well-documented observations with inherent interrelations between various branches of natural science and numerous practical applications.

By examining the enormous volume of rheological literature and meeting various people interested in rheology (university teachers, students, applied scientist, and engineers), the authors felt the need for a systematic presentation of the subject matter in one book a book that includes all components of rheology and presents them as an independent branch of natural science.

However, it became obvious from the early planning stages that some information would need to be omitted to provide a clear presentation of the concepts, methods, and applications which constitute the essence of efforts that created this science. The wish to present all aspects of rheology will inevitably lead to a book of enormous size. Every attempt to write a scientific book is personal and objective; objective because science benefits from objective assessments and personal because our experiences make us feel that certain aspects are more important than others. In our case, we are university teachers and researchers primarily in the field of applied rheology. An attentive reader will most likely find some reflections of our personal preferences.

Considering the goals and the tasks of the book, the authors tried to limit the choice of references to the first publications on a particular subject, also including reviews and papers providing the most expressive examples and illustrations of the topics under discussion. Accordingly, a great number of original publications are not mentioned. It is regrettable because any serious publication is worth mentioning.

The authors hope that the readers of the book will benefit from our presentation of rheology as an interrelated system of concepts, principal phenomena, experimental methods, and directions of their application. Our rheology is also a science interwoven with other branches of theoretical and applied sciences. We take many opportunities to emphasize these links because they enrich science, make it easier to understand and apply, and this also helps to fulfil our goals concisely expressed in the book title. To amplify its usefulness as a teaching tool, all chapters of the book contain questions to be used by readers to assess their knowledge of particular subject. Answers to these questions are included as the last part of the book.

Finally, the authors are glad to fulfil their pleasing duty to thank Dr. Andrei Andrianov (Moscow State University) for his technical assistance in preparing the computer

versions of many figures and realizing the liaison between the authors. The authors are also grateful to Dr. Sayata Ghose for painstaking proofreading and making corrections for this book.

Special gratitude goes to Professor J.L. White who read the manuscript of the book and made many valuable comments, which helped to enrich the presented text.

We express our deep gratitude to publishers of various journals (Advances in Polymer Science, Colloid Journal, European Polymer Journal, International Journal of Polymeric Materials, Journal of Applied Polymer Science, Journal of Macromolecular Science, Journal of Non-Newtonian Fluid Mechanics, Journal of Polymer Science, Journal of Rheology, Macromolecular Chemie, Polymer, Polymer Engineering and Science, Polymer Science USSR, Reviews of Scientific Instruments, Rheologica Acta) and books (Rheology of Elastomers by P. Mason and N. Wookey (eds), A Practical Approach to Rheology and Rheometry by G. Schramm for permission to use figures from their publications.

Alexander Ya. Malkin, Moscow, Russia

Avraam I. Isayev Akron, Ohio, USA

July, 2005

Preface to the 3rd Edition

In the 3rd edition of the book, we updated the material paying special attention to the issues which have become the hot spots of rheology during last decade. These are such topics as the rheology of polymeric materials containing fillers, the concept of heterogeneity of the flow including the effect of shear-banding, and new ideas in understanding the visco-plastic media. We have added references to the mosty up-to-date publications in these fields.

We are grateful to readers who were kind to bring to our attention some misprints and not quite clear explanations used in the former editions. Necessary corrections have been implemented.

We hope that this book is continued to be used by students and young researchers who only start their career in the intriguing world of the rheology of real materials surrounding us in our life.

Alexander Ya. Malkin, Moscow, Russia

Avraam I. Isayev Akron, Ohio, USA

December 2016

Rheology: Subject and Goals

Rheology, as an independent branch of natural sciences, emerged more than 70 years ago. It originated from observations of “strange” or abnormal behavior of many well-known materials and difficulties in answering some “simple” questions. For example:

•paints are evidently liquids because they can be poured into containers, but why do they remain on vertical walls without sagging down, unlike many other liquids?

•clays look solid but they can be molded into a shape; they may occupy vessels the way any liquid does; why do clays behave like many liquids?

•yogurt does not flow out of a container (it has high viscosity), but after intensive mixing its viscosity decreases, and then increases again when left to rest, so which value of viscosity should be considered?

•concrete mix appears to be solid and rigid, but when subjected to an external force it changes its shape similar to liquids; what are the reasons for such behavior?

•parts made out of polymeric materials (plastics) look solid and hard, similar to parts made out of metal, but they are noticeably different: when force is applied to a metallic part it slightly changes its shape and maintains its new shape for a long time; this is not the case with plastics which also change their shape after force is applied but they continue to change shape; if this material is solid, why does it “creep”?

•pharmaceutical pastes (for example, toothpaste or body lotion) must be “liquids” when applied and they should immediately become “solids” to remain on skin; are they liquids or solids?

•sealants widely used in construction must be fluid-like to seal all spaces and to fill cavities, but then sealant must rapidly “solidify” to prevent sagging; is sealant liquid or solid?

•metals are definitely solids, but how is it possible to change their initial form by punching and stamping as if metal was liquid?

These are just few examples. It is common for them that they represent properties of many real materials and that they exhibit a mixture of liquid-like and solid-like properties. This shows that commonly used words “liquid” and “solid” are insufficient to describe their properties, and new concepts are need to understand properties of many real materials. A new terminology emerges from discoveries and description of new features of mate-

rials. New methods are needed to characterize and measure their properties. New fields of application can be expected from the application of new concepts and the results of studies. All these are the essence of rheology.

Superposition of liquid-like and solid-like features in behavior of technological materials is directly regarded as the consequence of time effects, i.e., the results of observations depend on a time scale. Possibly, this is the most common feature of the materials, which were listed above. Time by itself has no meaning, but time is a reflection of changes in material structure taking place during the period of observation (or experiment).

The main method of rheology consists of constructing models, which are useful in qualitative or (better) quantitative description of experimental results of mechanical behavior of different materials. Any natural science pretends to deal with reality and does so by means of phenomenological models. Any model is created not to reflect all, but the most important, characteristic features of an object. The concepts of liquids and solids are also models and their formal (mathematical) representation originated from the classical works by Isaac Newton and Robert Hooke.

Newton (1687) reflected upon a resistance of liquids to a cylinder rotating in a vessel. His ideas were converted to a more accurate form by Stokes, who formulated a general law of liquid-like behavior, known as the Newton-Stokes law. According to this concept, the deformation rate is expected to be proportional to stress and the constant coefficient of proportionality is called viscosity, which is a material parameter of liquid. This law assumes that, in flow of liquids, a force (or resistance to flow) is proportional to a velocity (of movement).

Hooke (1676) formulated a similar proposal concerning properties of solids. The law, named after him, was translated to modern form by Bernoulli and then by Euler. Hooke’s law states that in deformation of solids, stress is proportional to deformation. The coefficient of proportionality is called Young’s modulus

Both models represent properties of many real materials and work well in describing their behavior with a considerably high degree of accuracy. However, there are many other materials which are not described by the Newton-Stokes and the Hooke laws. Rheology relies on the concept that non-Newtonian and non-Hookean materials exist in reality. These materials are interesting from both theoretical and applied aspects, and that is why such materials must be the objects of investigation.

It is important to emphasize that every model describes properties of real materials with a different degree of approximation. The Newton-Stokes and Hooke laws are not exceptions, and more strict and complex laws and equations give much better approximation of reality than the classical Newton-Stokes and Hooke laws known from school years. Both basic phenomenological (i.e., taken as probable assumptions, but only assumptions) relationships (the Newton-Stokes and Hooke laws) do not include inherent structure of matter. Because matter consists of molecules and intermolecular empty spaces, every material is heterogeneous. At the same time, an observer sees a body as a homogeneous continuous mass without holes and empty spaces. The obvious way out of these contradictory evidences lies in the idea of the space scale of observation. This scale can be small enough to distinguish individual molecules or their parts. Then, molecules can be combined in regular arrangements, such as crystals, and then crystals can be organized in super-crystalline (or super-molecular) arrangements. All this leads to the concept of mate-

rial structure, i.e., more or less well-organized and regularly spaced shapes. The structure might be well determined. This is the case, for example, of reinforced plastics and monocrystals. In other cases, “structure” can mean complex intermolecular interactions, which cannot be observed by direct methods. Rheology is specially interested in structured materials, because their properties change due to the influence of applied forces on the structure of matter.

The definition of rheology as a branch of natural science and the subject of rheological studies can be formulated based on the following argument. Traditionally, rheology is defined as “the study of deformations and flow of matter” (College Dictionary). However, this definition is ambiguous. The definition is close to mechanics of continuum, and does not distinguish special features of rheology.

The following points should be emphasized:

•Rheological studies are not about “deformation and flow” but about properties of matter determining its behavior, i.e., its reaction to deformation and flow.

•Rheology deals with materials having properties not described by the models of Newton-Stokes and Hooke. It is a negative statement (the rule of contraries). The positive statement is that rheology studies materials having properties described by any relationship between force and deformation. In this sense, the NewtonStokes and Hooke laws are limiting cases formally lying on the border of rheology. The subject of rheology is not about all matters, but only those for which non-linear dependencies between forces and deformations or rates of deformations are main characteristics.

•Rheology is interested in materials, deformation of which results in superposition of viscous and elastic effects.

•Rheology studies materials with structure changes under the influence of applied forces.

One of the key words in rheology is the behavior of various real continuous media. What is the meaning of: “behavior”? For a body of finite size, it is a relationship between external action (forces applied to a body) and internal reaction (changes of a body shape). For continuous media this approach is extrapolated to a point and the relationship between forces and deformations at this point (i.e., changes of distance between two arbitrary points in a body) is examined. Thus, by discussing what happens in a body at a point of reference, the problem of a geometrical form of a body as such is avoided, but the subject of investigations are only its substantial, inherent properties.

The first main goal of rheology consists of establishing the relationship between applied forces and geometrical effects induced by these forces at a point. The mathematical form of this relationship is called the rheological equation of state, or the constitutive equation. The Newton-Stokes and Hooke laws are the simplest examples of such equations. Rheological equations of state can be (and they are!) very different for numerous real materials. The rheological equations of state found for different materials are used to solve macroscopic problems related to continuum mechanics of these materials. Any equation is just a model of physical reality.

The independent second goal of rheology consists of establishing relationships between rheological properties of material and its molecular structure (composition). This is related to estimating quality of materials, understanding laws of molecular movements

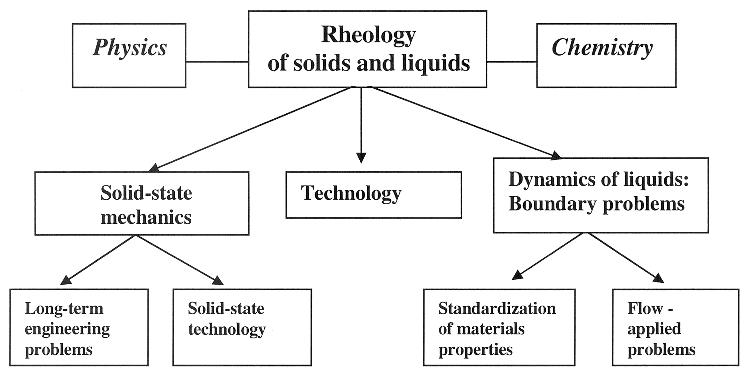

Fig. 1. Rheology as an interdisciplinary science its place among other sciences.

and intermolecular interactions. The term microrheology, related to classical works by Einstein (1906, 1911), devoted to viscous properties of suspensions, is sometimes used in this line of thought. It means that the key interest is devoted not only to movements of physical points but also to what happens inside a point during deformation of medium. Therefore, it is a search for rheological equations of state of different materials based on the basic physical concepts. Then, the constants entering these models are related to various molecular parameters of material.

In its origin, the term “rheology” applies to flowing media, since the main root of the word means “to flow” (rheo in Greek). But it is very difficult to classify material as solid or fluid and, therefore, this term is now used for any material. As a result, many analytical methods used for solids and liquids are very similar. The majority of publications devoted to rheology and, consequently, the largest part of this book deal with flowing materials, whereas rheology of solids is frequently treated as a part of the mechanics of solids and discussed as a separate branch of science.

The place of rheology among other natural sciences and applied problems is shown in Figure 1. Rheology is a multi-disciplinary science having many relationships with fundamental physics and chemistry, as well as many applications in technology and engineering of materials and many fields of biological sciences.

Indeed, the connection between rheology and physics consists of explanation and predictions of rheological properties, based on knowledge of molecular structure and fundamental laws of physics (molecular physics, statistical physics, thermodynamics, and so on). The connection between rheology and chemistry consists of existing experimental evidences of direct correlation between chemical parameters (molecular mass and molecular mass distribution, chemical structure, intermolecular interactions, etc.) and rheological properties; therefore, it is possible to synthesize materials with desirable properties.

The second layer of interrelations consists of connection between rheology and mechanics of continuum. The results of rheological studies give the background for formulation of boundary problems in solid-state mechanics as well as in dynamics of liquids.

This includes governing equations and their solutions to find numerical values of macroparameters, such as pressure, forces, displacements, etc.

In the framework of solid-state mechanics, such effects as a long-term behavior, engineering properties of materials as well as their technological properties are the direct objects of rheological analysis. Solutions of boundary problems in dynamics of liquids are used for analysis of flow in technology (calculation of pressure and output, resistance to movement of solid bodies in liquids, and so on), as well as for standardization of the methods of quality control in technology of liquid products.

It is worthwhile to list materials, for which the rheological analysis is the most important. In fact, such a list should include all materials, because the Newton-Stokes and Hooke laws are the limiting cases only. However, the following list gives an impression of fields that cannot be developed without participation of rheological studies:

•metals, alloys, and composites at large deformations and different technological operations

•concrete, ceramics, glass, and rigid plastics (including reinforced plastics) at long periods of loading

•polymer melts and solutions, including filled composites, rubbers

•foodstuffs

•lubricants, greases, sealants

•pharmaceuticals and cosmetics

•colloid systems including emulsions and detergents of any types

•paints and printing inks

•mud, coal, mineral dispersions, and pulps

•soils, glaciers and other geological formations

•biological materials such as bones, muscles and body liquids (blood, saliva, synovial liquid, and others).

It is worth mentioning that polymers and plastics continue to be the main object of rheological studies, and at least half of the publications on rheology are devoted to them.

To recapitulate, it seems useful to point out that the main ideas of the Introduction permit us to compose a dictionary of rheology.

Rheology is a science concerned with mechanical properties of various solid-like, liquid-like, and intermediate technological and natural products. It accomplishes its goals by means of models representing principal peculiarities of behavior of these materials. The behavior of material is a relationship between forces and changes of shape. A model gives a mathematical formulation of such relationship. Rheological properties are expressed by the model structure (i.e., its mathematical image) and values of constants included in the model are characteristics of material.

Rheological models are related to a point, which is a physical object including a sufficient number of molecules in order to neglect the molecular structure of matter and to treat it as a continuum. The rheological analysis is based on the use of continuum theories, meaning that the following is assumed:

•there is no discontinuity in transition from one geometrical point to another, and the mathematical analysis of infinitesimal quantities can be used; discontinuities appear only at boundaries

•properties of material may change in space (due to the gradient of concentration in multi-component mixtures, temperature distribution, or other reasons) but such changes occur gradually; these changes are reflected in space dependencies of material properties entering equations of continuum theories which must be formulated separately for any part of material surrounded by the boundary surfaces at which discontinuity takes place

•continuity theories may include an idea of anisotropy of properties of material along different directions.

Rheological behavior of material depends on time and space scales of observation (experiment). The former is important as a measure of the ratio of the (time) rate of inherent processes in a material to the time of experiment and/or observation; the latter determines the necessity to treat a material as homo- or heterogeneous.

The results of macroscopic description of behavior of real engineering and biological media, based on their rheological properties, are used in numerous applications related to technology of synthesis, processing, and shaping various materials listed above.

LITERATURE

Many books devoted to rheology were published during the 70 year history of this science. It is not possible to list all of them. The most important books which gave the input to development of rheology and reviewed results of principal rheological schools are cited in the text of this book. The same concerns many historically important and original publications.

The modern history of rheology began with the publication of several books in the 1940s which had a great impact on the education of future generations of rheologists. Among them it is necessary to recall:

T. Alfrey, Mechanical Behavior of High Polymers, Interscience, N.Y. 1948.

M. Reiner, Twelve Lectures on Theoretical Rheology, North Holland Publ. Co., Amsterdam. 1949.

G.W. Scott Blair, A Survey of General and Applied Rheology, Pitman, London, 1949. Those who are interested in special aspects of rheology may like to pay attention to the following books published more recently.

1Deepak Doraiswamy, The origin of rheology: For a short historical excursion see http://sydney.edu.au/engineering/aeromech/rheology/Origin_of_Rheology.pdf

The development of rheology including sketches devoted to people who played the most important role in rheology can be found in a monograph:

R.I. Tanner, K. Walters, Rheology: A Historical Perspective, Elsevier, Amsterdam, 1998.

2The state of rheology and the main results obtained until 1969 were summarized in a five volume book Rheology. Theory and Applications, Ed. F.R. Eirich, v. 1-5, Academic Press, London, 1956-1959. One can find comprehensive analysis of rheology in the following books: J. D. Ferry, Viscoelastic Properties of Polymers, Wiley, NY, 1980.

C.W. Macosko, Rheology: Principles. Measurements and Applications, VCH, New York, 1993.

F.A. Morrison, Understanding Rheology, Oxford University Press, New York, 2001.

3The following books are devoted to the general theoretical background of rheology:

G. Astarita, G. Marucci, Principles of Non-Newtonian Fluid Mechanics, McGraw-Hill, New York, 1974.

R.B. Bird, R.C. Armstrong, O. Hassager, Dynamics of Polymeric Liquids, v. 1-2, Wiley, New York, 1987.

M. Doi, S.F. Edwards, The Theory of Polymer Dynamics, Oxford Science Publisher, Oxford, 1986. J. Furukawa, Physical Chemistry of Polymer Rheology, Springer, Berlin, 2003.

H. Giesekus, Phänomenologische Rheologie: Eine einführung, Springer, Berlin, 1995.

R.R. Huilgol, N. Phan-Thien, Fluid Mechanics of Viscoelasticity, Elsevier, Amsterdam, 1997.

G.D.C. Kuiken, Thermodynamics of Irreversible Processes: Application to Diffusion and Rheology, Wiley, New York, 1994.

R.G. Larson, Constitutive Equations for Polymer Melts and Solutions, Butterworths, Boston, 1988.

R.G. Larson, The Structure and Rheology of Complex Fluids, Oxford University Press, New York, 1999.

A.I. Leonov, A.N. Prokunin, Nonlinear Phenomena in Flows of Viscoelastic Polymer Fluids, Chapman and Hall, London, 1994.

A.S. Lodge, Elastic Liquids, Academic Press, London, 1960.

H.C. Öttinger, Stochastic Processes in Polymer Fluids, Springer, Berlin, 1996.

W. R. Schowalter, Mechanics of Non-Newtonian Fluids, Pergamon, 1978.

N.W. Tschoegl, The Phenomenological Theory of Linear Viscoelasticity, Springer, Berlin, 1989.

A.S. Wineman, K.R. Rajagopal, Mechanical Response of Polymers: Introduction, Cambridge University Press, Cambridge, 2000.

4The following monographs were devoted to different materials extensively studied by rheological methods: D. Acierno, A.A. Collyer (Eds.), Rheology and Processing of Liquid Crystal Polymers, Chapman and Hall, London, 1996.

J.M.V. Blanshard, P. Lillford, Food Structure and Behavior, Academic Press, London, 1987.

O.E. Briskoe, Asphalt Rheology: Relationship to Mixture, ASTM, Philadelphia, 1987.

P. Coussot, Mudflow Rheology and Dynamics, A.A. Balkema, Rotterdam, 1997.

D.A. Drew, D.D. Joseph, S.L. Pasman (Eds.), Particulate Flows: Processing and Rheology, Springer, New York, 1998.

H.A. Faradi, J.M. Faubion (Eds.), Dough Rheology and Baked Products Texture, Van Nostrand Reinhold, New York, 1990.

Y.C. Fung, Biomechanics: Mechanical Properties of Living Tissues, Springer, New York, 1993.

R.K. Gupta, Polymer and Composite Rheology, Marcel Dekker, New York, 2000.

B.G. Higgins, Coating Fundamentals: Suspension Rheology for Coating, TAPPI Press, Atlanta, 1988.

M.J. Keedwell, Rheology and Soil Mechanics, Elsevier Science, London, 1984.

D. Laba (Ed.), Rheological Properties of Cosmetics and Toiletries, Marcel Dekker, New York, 1993.

G.D.O Lowe (Ed.), Clinical Blood Rheology, CRC Press, Boca Raton, 1988.

J.M. Mazumdar, Biofluids Mechanics, World Scientific, Singapore, 1992.

W.B. Russel, D.A. Saville, W.R. Schowalter, Colloidal Dispersion, Cambridge University Press, Cambridge, 1989.

A.V. Shenoy, Rheology of Filled Polymer Systems, Kluwer, Dordrecht, 1999.

G.V. Vinogradov, A.Ya. Malkin, Rheology of Polymers, Springer, Berlin, 1980.

5Applied problems of rheology are presented (in addition to the above listed monographs) in the books:

V. Capasso, Mathematical Modeling of Polymer Processing, Springer, Berlin, 2003.

J.M. Dealy, K.F. Wissbrun, Melt Rheology and Its Role in Plastics Processing, Van Nostrand, New York, 1990.

C.D. Han, Rheology in Polymer Processing, Academic Press, NY, 1976.

C.D. Han, Multiphase Flow in Polymer Processing, Academic Press, NY, 1981.

A.I. Isayev (Ed.), Injection and Compression Molding Fundamentals, Marcel Dekker, New York, 1987.

A.I. Isayev (Ed.), Modeling of Polymer Processing. Recent Developments, Hanser, Munich, 1991.

J.M. Piau, J.F. Agassant (Eds), Rheology for Polymer Melt Processing, Elsevier, Amsterdam, 1996.

R.I. Tanner, Engineering Rheology, 2nd Edition, Oxford University Press, Oxford, 2000.

M.R. Kamal, A.I. Isayev and S.-J. Liu (Eds.), Injection Molding Technology and Fundamentals, Hanser, Munich, 2009.

J.F. Steffe, Rheological Methods in Food Process Engineering, 2nd Edition, Freeman Press, East Lansing, 1996.

J.L. White, Principles of Polymer Engineering Rheology, Wiley, New York, 1990.

6Experimental methods of rheology are discussed in the following books:

H.A. Barnes, J. F. Hutton, K. Walter, An Introduction to Rheology, Elsevier, Amsterdam, 1989.

D.V. Boger, K. Walters, Rheological Phenomena in Focus, Elsevier, Amsterdam, 1993.

A. Collyer, D.W. Clegg (Eds), Rheological Measurement, Chapman and Hall, London, 1998.

A. Collyer (Ed.), Techniques in Rheological Measurement, Chapman and Hall, London, 1993.

J.M. Dealy, Rheometers for Molten Plastics. A Practical Guide to Testing and Property Measurement, Van Nostrand Reinhold, New York, 1982.

J.M. Dealy, P.C. Saucier, Rheology in Plastics Quality Control, Hanser, Munich, 2000.

G.F. Fuller, Optical Rheometry of Complex Liquids, Oxford University Press, New York, 1995.

H. Janeschitz-Kriegl, Polymer Melt Rheology and Flow Birefringence, Springer, Berlin, 1983.

W.-M. Kulicke, B.C. Clasen, Viscometry in Polymers and Polyelectrolytes, Springer, Berlin, 2004.

V.I. Levitas, Large Deformation of Materials with Complex Rheological Properties at Normal and High Pressures, Nova Science, New York, 1996.

A.Ya. Malkin, A.A. Askadsky, V.V. Kovriga, A.E. Chalykh, Experimental Methods of Polymer Physics, Prentice-Hall, Englewood Cliffs, 1983.

K. Walters, Rheometry, Chapman and Hall, London, 1975.

R.W. Whorlow, Rheological Techniques, Ellis Harwood, New York, 1992.

7Computational methods are very important in applications of rheology, because of rather complicated equations used in calculation. However, although many papers in journals have been published only a very limited number of books are devoted to this problem, for example:

T. J. Chung, Computational Fluid Dynamics, Cambridge University Press, New York, 2002.

M. J. Crochet, A. R. Davies, K. Walters, Numerical Stimulation of Non-Newtonian Flow, Elsevier, Amsterdam, 1984.

R.G. Owens, T.N. Phillips, Computational Rheology, Imperial College Press, London, 2002.

J.R.A. Pearson, S.M. Richardson (Eds), Computational Analysis in Polymer Processing, Applied Science Publishers, London, 1983.

C. Pozdrikidis, Fluid Dynamics. Theory, Computation and Numerical Simulation, Kluwer Academic Publisher, Dordrecht, 2001.

C.L. Tucker (Ed.), Computer Modeling for Polymer Processing, Hanser, Munich, 1989.

Papers devoted to rheology appear in a large number of journals, but there are six special journals devoted to rheology, as follows:

Journal of Rheology

Journal of Non-Newtonian Fluid Mechanics

Nihon Reorogi Gakkaishi (Journal of Society of Rheology Japan)

Rheologica Acta

Applied Rheology

Korea-Australia Rheology Journal

New results in different branches of rheology can be found in these journals.

Continuum Mechanics as a Foundation of Rheology

Rheology is a science dealing with deformation and flow of matter. Relationships between stresses and deformations are the fundamental concepts of continuum mechanics, which are discussed in this chapter. The modern history of rheology was marked by the publication of several books1 in the 1940s, which impacted the education of future generations of rheologists.

1.1 STRESSES

Internal stresses are directly related to forces applied to a body regardless of their origin. Only in special cases do internal stresses exist in the absence of external forces. These are, for example, thermal stresses caused by temperature inhomogeneity throughout a body or frozen stresses stored as a result of thermal and/or mechanical history of a body treatment caused by its heterogeneity.

1.1.1 GENERAL THEORY

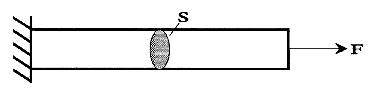

Figure 1.1.1. A bar loaded with a normal force.

Any external force applied to a body leads either to a movement of the body as a whole or to a change of its initial shape. Both may occur simultaneously. The movement of a body in space and/or its rotation around its center of gravity, with no change to its shape is a subject of study by mechanics, and as such is not discussed in this book. The principal focus of our discussion here are changes which occur inside a body on application of an external force. The applied forces create dynamic reactions at any point of a body, which are characterized by a physical factor called stress. Stress can be explained using a simple example. Let us consider a body (a bar). The area of its normal cross-section is S (Fig. 1.1.1). The force, F, is normal to the surface, S. The specific force at any point of the cross-section equals F/S. The ratio is a normal stress or a tensile stress, σE:

[1.1.1]

i.e., stress is the force per unit of the surface area. The force at any surface may not be constant, i.e., be a function of coordinates. For example, a train moving on rails presses

rails at local zones (where wheels touch the rail). The force is then distributed within the rail according to a complex pattern of stress distribution.

In our case, we do not consider force distribution because we have selected a small surface area, ΔS. A relative (specific) force, ΔF, acting on the area of ΔS is used to calculate the ratio ΔF/ΔS. By decreasing the surface area, we eventually come to its limiting form, as follows:

This is a more general and exact definition of stress than given by Eq. 1.1.1 because it is related to a reference point, such as the surface area, ΔS. However, the definition is still not complete. A force at the area ΔS can have any direction, therefore a force is, in fact, a vector F. This vector can be decomposed into three components along three coordinate axes, in particular it can be decomposed to one perpendicular and two tangential components. The perpendicular component is normal stress, and tangential components are shear stresses

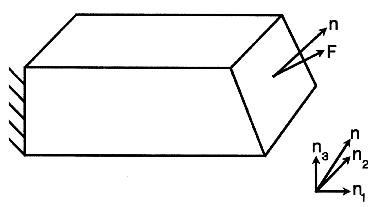

Figure 1.1.2. Definition of the stress tensor two vectors: force, F, and orientation of a surface, n

The selection of a small area ΔS is arbitrary, therefore it is better expressed by vector n, which determines orientation of ΔS to the normal orientation. The stress is described by a combination of two vectors, F and n, defined at any reference point. This is shown in Fig. 1.1.2. The stress is a derivative dF/dn, and it is independent of coordinate axis. Any vector is a physical object existing regardless of the choice of a coordinate system.

In practical applications, it is more convenient to operate with its projections on the coordinate axes rather than with a vector itself. Any vector can be decomposed into its three projections on the orthogonal coordinate axes; let it be Cartesian coordinates, x1, x2, and x3.2

It follows from the above explanations that a complete characterization of stress as a physical object requires identification of two vectors: a force and a normal orientation to the surface to which this vector is applied. The physical objects determined in such a manner are called tensors, and that is why stress is a value of tensor nature.

Let both vectors, F and n, defined at any reference point, be represented by their three projections along the orthogonal coordinate axes:

n = n(n1, n2, n3)

F = F(F1, F2, F3)

Nine values can be obtained from three projections of force on the surfaces determined by the three coordinate vectors. All values of force, Fi (i = 1, 2, 3), must be divided by the surface area to give the components of a stress tensor, σij. The first index gives the orientation of a force, and the second index designates the orientation of a surface.

The result is written in the table form (matrix), as follows:

where the components of the stress tensor, σij, mean the following: the first column represents components of a force (a force vector) acts on the plane normal to the x1 axis, the second column gives the same for x2 axis, and the third for x3 axis. The directions to the normal are indicated by the second indices.

The matrix contains all components (projections) of a force vector applied to different planes at an arbitrary point inside a body. In order to emphasize that this set of parameters presents a single physical object, i.e., stress tensor,3 it is usual to put the table between the brackets.

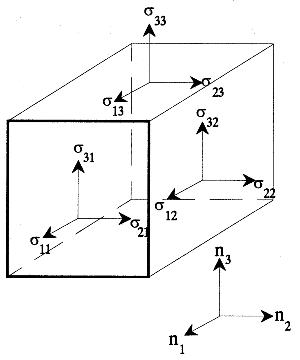

Figure 1.1.3. Three-dimensional stress state, a definition of the stress tensor components.

Fig. 1.1.3 shows all components of the stress tensor acting on a selected point. The components having the same numbers in their index are normal stresses, which are equivalent to the initial definition of the normal stress in Eq. 1.1.1, and all values with different numbers in the index are shear stresses.

All components of the stress tensor are determined at a point, and they can be constant or variable in space (inside a medium). It all depends on the distribution of external forces applied to a body. For example, the force field is homogeneous in Fig. 1.1.1, and thus a stress tensor is constant (inside a body). But the stress field (or stress distribution) is very complex in many other cases, for example, in a liquid flowing inside a channel or in the case of a roof covered with snow.

The values of the stress tensor components depend on the orientation of coordinate axes. They change with rotation of the coordinate axes in space, though the stress state at this point is the same. It is important to remember that, regardless of the choice of the coordinate axes, this is the same physical object, invariant to the choice of the coordinate axis.

Some fundamental facts concerning the stress tensor (and any other tensor) are discussed below.

Comments operations with tensors

There are several general rules concerning operations with objects of tensor nature.4 Two of them will be used in this chapter.

The first is the rule of summation of tensors. Tensor A is the sum of tensors B and C if components of A, aij, are the sum of components bij and cij with the same indices, i.e., the equality A = B + C means that aij = bij + cij

The second is the rule of multiplication of a tensor by a constant. Tensor A equals to the product of a scalar constant k and a tensor B if components of A, aij, are equal to kbij, i.e., the equality A = kB means that aij = kbij

The unit tensor (also called the Kronecker delta, δij) will be used below. This object is defined as a tensor, for which all diagonal (normal) components are equal to 1 and all shear components (when ) are equal zero.