https://ebookmass.com/product/steel-corrosion-induced-

Advanced Engineering Mathematics (Gujarat Technological University 2018) 4th Edition Ravish R Singh

https://ebookmass.com/product/advanced-engineering-mathematicsgujarat-technological-university-2018-4th-edition-ravish-r-singh/

ebookmass.com

SteelCorrosion-Induced ConcreteCracking Foreword Servicelifeofunreinforcedconcretestructurescanbeextremelylong.Many historicalstructuresfromtheRomanperioddemonstratethisfactconvincingly,suchasthePantheoninRome,whichisbuiltofhigh-strengthconcrete,normalconcrete,andacupolaofextremelylightweightconcrete,or RomanbridgesalloverEurope.Theyhavesurvivedthousandsofyears undertheeffectsofnaturalexposure,wars,andearthquakeswithoutprotectionormaintenance.

Ifsteelreinforcementisembeddedinconcrete,thenthesteelisprotected initiallybyasurfacepassivationlayerintheaqueousporesolutionbecause ofitshighpHvalue.Thispassivationlayer,however,isnotstableinaging concrete.Concreteisaporousmaterial.Atfirst,theporespaceispartially filledwithwaterandisinequilibriumwithhighrelativehumidity.However, thesurfaceofreinforcedconcretestructuresisoftenexposedtoanatmospherewithmuchlowerhumidity.Asaconsequence,along-lastingdrying processbeginsassoonastheformworkisremoved.Astheporespaceispartiallyemptied,gasesdilutedinthesurroundingairsuchasCO2 willslowly migrateintotheporespaceandreactwiththeyoungcement-basedmatrix. First,athinlayerofcarbonatedhydrationproductsisformednearthesurface.Whenthegrowingthicknessofthiscarbonatedlayerreachesthecover thickness,thepHvalueoftheporeliquidincontactwiththesteelreinforcementisloweredandtheprotectivepassivationlayeriseventuallydestroyed. Hence,corrosionisinitiated.

Ifthesurfaceofconcreteistemporarilyincontactwithanaqueouschloridesolutionsuchasseawaterorwatercontainingdissolveddeicingsalt, thenchlorideionscanpenetrateintotheporespaceoftheconcrete. Fortunately,thechlorideionsarefilteredoutofthesaltsolutionandtheyare enrichedclosetothesurface;however,thecleanwatermaypenetratedeep intotheporespacebycapillaryaction.Later,dissolvedchlorideionsmigrate deeperintothenanoporousmaterialbyslowdiffusion.Wheneverthechlorideconcentrationnearthesteelreinforcementreachesacriticalvalue,the protectivepassivationlayermaybelocallydestroyedandcorrosionofsteel begins.

Untilnow,durabilitydesignhadnotreachedthesophisticatedlevelof structuraldesign.Usuallyoneconsidersdifferentstages,forinstance,corrosioninitiation,crackformation,andspalling.Afterinitiation,therateof

corrosionmayberatherlow.Butafterthefirstcracksaregenerated,corrosionwillbesignificantlyaccelerated.Theauthorsofthisbookprimarily describetheformationofcorrosionproductsandthetime-dependentpressure builtupbythevoluminouscorrosionproducts.Theseareessentialprocesses thatmayserveasindicationsoftheendofservicelifeofreinforcedconcrete structures.

Themechanismsofsteelcorrosioninconcretearebrieflydescribed.The followingchaptersdescribeingreatdetailtheformationofcorrosionproductsattheinterfacebetweensteelandconcrete.Inparticular,thegradual fillingoftheporesofhardenedcementpasteandthegradualfillingofcracks withcorrosionproductsareconsidered.Finally,amodeldescribingconcrete crackingduetotheformationofcorrosionproductsispresented.This approachandtheresultsobtainedbythetwoauthorsofthisbookwillbe veryhelpfulformorerealisticpredictionoftheservicelifeofreinforced concretestructures.

Inthisbook,thecomplexprocessesthatcanbeobservedduringthecriticalperiodofagingconcretebetweencorrosioninitiationandcrackformation intheconcretecoverandthen,finally,spallingofthelayernearthesurface aredescribedingreatdetailforthefirsttime.Abetterunderstandingofthese complexprocesseswillcontributetothedevelopmentofmorereliablepredictionofservicelifeandofmoreefficientmethodsforprotectiveinterventions.Therefore,theservicelifeofreinforcedconcretestructurescanbe extendedsystematicallyandthecostofrepairmeasurescanbesubstantially reduced.ThisisofparticularimportanceforcountrieslikeChina,inwhicha nationwideinfrastructureisrapidlybeingbuilt.Innoothercountryismore concretebeingproducedatthismoment.

Ifmodernconstructiondoesnotbecomemoresustainable,andiftheservicelifeofreinforcedconcretestructuresisnotsignificantlyextended,then furtherdevelopmentwillbeslowedbecauseoftheenormouscostsforrepair andmaintenanceoftheexistinginfrastructure.Thisbookmaycontributea greatdealtofindingrealisticandsustainablesolutionstothisworldwide problem.

Thisvolumedeserveswidedistributionandwillhopefullybestudiedin greatdetailbyscientistsandpractitioners.Withthisbook,theactualsituationconcerningdurabilityandservicelifeinconstructioncanbeimproved substantiallyworldwide.

FolkerH.Wittmann

Acknowledgments ContinuousfinancialsupportfromtheNationalScienceFoundationofChina (NSFC)throughgrants50538070,50920105806,50808157,and51278460is gratefullyacknowledged.Withoutthisfinancialsupport,itwouldbenotpossibletoperformalltheexperimentalwork,developtheanalyticalmodels, andfurthertheresearchinthisarea.

Theauthorsalsoexpresssinceregratitudetothegraduatestudentswho contributedtheirtalent,intelligence,effort,andhardworktothisresearch. TheyareHaiyangRen,JiangYu,BingyanHu,HongDai,YingyaoWu, HangjieDing,JianfengDong,andXiaowenZhang.Particularthanksare expressedtoHangjieDing,JianfengDong,andXiaowenZhang,whoalso helpedtoeditthecontents,improvetheformat,andmodifysomefiguresin thisbook.

WeappreciatethecommentsandencouragementfromProfessorFolker H.Wittmann,hiscommentsimprovethequalityofthebook,healsokindly wrotethe Foreword.Manythankstothereviewersofthisbookfortheir time.Theirhelpfulsuggestionshavestrengthenedthebookconsiderably. OurthanksalsogotothepublisherandtheeditorFanjieWu,whopatiently repliedtoallourquestionsandhelpedusasmuchaspossible.

Weapologizefornamingsuchasmallnumberofthemanypeoplewho helpedusandwithwhomwehadthepleasureofworking.Sincerethanksto allofthemfortheirwillingnesstosharetheirknowledgewithusandfor encouragingustogofurtherandfurtherinthisarea.

ListofFigures Figure1.1Comparisonofsteelcorrosionatconcretesurface crackingbetweentheempiricalmodel-predicted resultsandtheexperimentalresults.

Figure1.2Comparisonofconcretesurfacecrackwidth propagationbetweenthemodel-predictedresults andtheexperimentalresults. 7

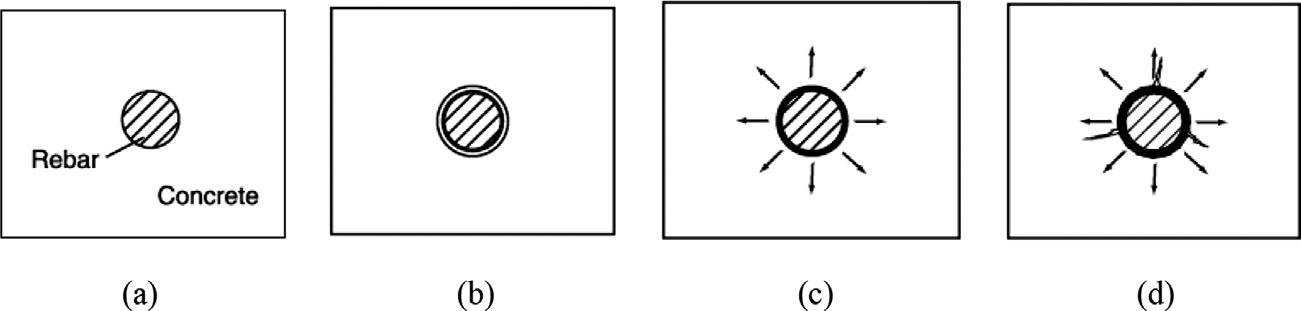

Figure1.3Three-stagecorrosion-inducedcrackingprocess. (a)Corrosioninitiated.(b)Stage1:filling. (c)Stage2:stressing.(d)Stage3:cracking. 8

Figure1.4BSEimagesshowing accumulationofcorrosion productsatthesteel–concreteinterface(S,steel; CL,corrosionlayer;CP,corrosionproducts-filledpaste; P,unalteredpaste;A,airvoid).

9

Figure1.5Corrosion-inducedconcretecrackingmodel. (a)Thick-walledcylindermodel.(b)Double-layer thick-walledcylindermodel. 12

Figure2.1Theanodicandcathodicreactions.20

Figure2.2Initiationandpropagationperiodsforsteel corrosioninconcrete. 23

Figure2.3Pittingattackinasteelbar.24

Figure2.4Transformationofironoxides.27

Figure2.5Stagesincorrosion-induceddamage.(a)Passive rebar.(b)Corrosioninitiationandgrowth. (c)Furthercorrosionandcrackingpropagation. (d)Spalling/delamination.

28

Figure3.1XRDpatternofeightdifferentrustsamples.36

Figure3.2TGcurvesofallrustsamples.37

Figure3.3DTAcurvesofallrustsamples.38

Figure3.4XRDpatternsoftheoriginalandheatedsample1.40

Figure3.5ImprovedXRDpatternsofeightrustsamples.41

Figure3.6Theconcreteportandthesteelcorrosionproducts. (a)TheconcreteportinYokosuka.(b)Thecorroded steelbarintheconcretebeam.(c)Thecorrosion productpeeledfromthecorrodedsteelbar. (d)Flakyrustsamples.

47

Figure6.7Averagethicknessofthecorrosionproducts-filled paste(CP)fordifferentthicknessesofthecorrosion layer(CL).

Figure6.8RustdistributioninsliceR-6.(a)SliceR-6. (b)Area1.(c)Area2.(d)Area3.(e)Area4.

Figure6.9Crackatthesteel–concreteinterfaceofsliceM-14 (6897μm 3 6155μm).

Figure6.10SliceL-4withthemoreseverecorrodedsteelbar.104

Figure6.11Rustdistributedinacrackpenetratingtheconcrete coverinsampleL-9.(a)BSEimageofthecorrosioninducedcrackandananalyticallineacrossthe crack.(b)ThedistributionofFeacrossthecrack analyzedbyEDSalongtheanalyticalline.

Figure6.12RustdistributedinaninnercrackinsampleR-7. (a)BSEimageofthecorrosion-inducedcrackand ananalyticallineacrossthecrack.(b)The distributionofFeacrossthecrackanalyzedbyEDS alongtheanalyticalline.

Figure6.13Schematicdiagramofcrackpropagationandrust development.(a)Beforesurfacecracking. (b)Surfacecracking.(c)Aftersurfacecracking.

Figure7.1Steelcorrosionvarieswiththedistancetothefront ofspecimenR.

Figure7.2Typicalcracksandrustlayerofslicesfrom specimenR.

Figure7.3Measuredthicknessoftherustlayeraroundthe rebarperimeter.

Figure7.4Polarcoordinatesystemdefinedforthecornerand middlerebars.

Figure7.5Polarcoordinatesystemformeasurementandfitting oftherustlayer.

Figure7.6Theregressionanalysisoftheproposedmodelsfor thetesteddata.

Figure7.7 R2 offourmodels.120

Figure7.8Physicalmeaningof λ3.(a)Partialcorrosion (λ3 5 0).(b)Wholecross-sectioncorrosion (λ3 5 Tr;min ).

Figure7.9Twopartsoftherustlayerwhensteelcorrosion spreadsthroughouttheentirecircumference. 122

Figure7.10Areaofcorrosionpeaksgrowwiththeincreaseof λ1.122

Figure7.11Peakareaofpartialcorrosion.123

Figure7.12Relationshipbetween λ1 and ρ.

ListofFigures xxi

Figure7.13Nonuniformcorrosionspreadingwidelywiththe increaseof λ2

Figure8.1Layoutdetailsofspecimens(dimensionsare inmm).

Figure8.2Wettinganddryingcyclescombinedwitha constantcurrent.

Figure8.3Schematicdiagramofpreparationofsamplesfor digitalmicroscopyobservation.(a)Crackedpartsof specimenswerecastinepoxyresin.(b)Asample preparedfordigitalmicroscopyobservation.

Figure8.4Measurementandcalculationofthecrackwidth, Wi,atradius Ri.(a)Measurementofcrackwidth. (b)Totalcrackwidth, Wi

Figure8.5Measureddataandthefittinglineofthecrack width.(a)SliceR000-1-8,representingtheinner crackingscenario.(b)SliceR000-2-8,representing thecracksthathadpenetratedtheconcretecover.

Figure8.6Schematiccrackshapemodel.136

Figure8.7Relationshipbetweenparameter a1 andcorrosion layerthickness TCL

Figure8.8Relationshipbetweenparameter a2 andcorrosion layerthickness TCL

Figure8.9Relationshipbetweencrackwidthonconcrete surface, Ws,andcorrosionlayerthickness, TCL.

Figure8.10Schematicdiagramofcorrosion-inducedcrack propagation.

Figure9.1InfluenceofcracksonCPdevelopment.(a–c)Inner crack.(d,e)Outercrack. CP,corrosionproductsfilledpaste; CL,corrosionlayer; TCP,thicknessof CP; TCL,thicknessofCL.

Figure9.2Schematicofmeasuredregionsattheconcrete–steelinterface.

Figure9.3Thicknessofthecorrosionproducts-filledpaste(CP) versusthicknessesofthecorrosionlayer(CL) excludingtheregionsoftheinnercracksforR000. (a)Measureddata.(b)Apartofthedatamapafter groupingintherangeof20 μmforR067.

148

150

150

Figure9.4Relationshipbetween TCP and TCL excludingthe regionsoftheinnercracks.(a)R000.(b)R033. (c)R067.(d)R100. 151

Figure9.5 TCP TCL modelsforfourtypesofconcrete (excludingtheeffectofinnercracks).

152

Figure9.6Effectofconcretequalityon TCP.152

xxiv ListofTables

Table9.1FittingValuesof kT and T max CP (µm)151

Table9.2Average TCP and TCL ofEachSample,MeanValuesof TCP,andTheirMeanSquareDeviationofEachType ofConcreteSpecimens(µm) 155

Table9.3Valuesof kT ConsideringtheEffectofInnerCracks156

Chapter1 Introduction ChapterOutline

1.1Background1

1.2EmpiricalModels2

1.2.1CriticalSteelCorrosion atSurfaceCracking2

1.2.2CrackWidthatthe ConcreteSurface4

1.2.3Discussiononthe EmpiricalModels6

1.3AnalyticalModels7

1.3.1Three-StageCorrosionInducedCrackingModel7

1.1BACKGROUND

1.3.2CorrosionProductsFilling Stage8

1.3.3ConcreteCoverStressing andCracking10

1.3.4RustFillingin Corrosion-Induced Cracks13

1.4ContentsofthisBook13 References15

SincePortlandcementwasinventedin1824,ithasbeenthemostwidely usedconstructionmaterialintheworld.Untilthemid-1970s,concretewas viewedasbeingmaintenance-freeandhavingapracticallyunlimitedlife. However,sincethen,anumberofdurability-relatedproblems,suchascorrosionofreinforcement,alkali-silicareactions,andsulfateattacks,have emergedandstimulatedresearchinvestigatingthekeyfactorsthatrelateto concretedurabilityindevelopedanddevelopingcountries.

Amongalldurabilityproblems,reinforcementcorrosionhasbeenidentified astheprimarycauseofdeteriorationinconcretestructures [1].Theincreased incidenceofreinforcementcorrosionisprimarilyduetotwoindependentreasons.Thefirstreasonisthecarbonationofthecoverconcreteand,thus,theloss ofalkalinity.Thesecondreasonisthepresenceofchlorideionsinsufficient amountsatthesteelsurface.Chlorideionsaretheprimarycauseoftheinitiationofreinforcementcorrosion,andexposingconcretestructurestoenvironmentsrichinthisionsignificantlyenhancestheriskofstructuraldegradation.

Aftertheonsetofcorrosion,becausetheferrousorferricionsmightform complexes,mostofwhichoccupyalargervolumethantheoriginalmetal, theresultingincreaseinvolumeassociatedwiththeformationofcorrosion productswillexertoutwardexpansivepressureonthesurroundingconcrete,

200mm,andlargerthan200mm,respectively. Ec and fc aretheelasticmodulusandcompressivestrengthoftheconcrete,respectively.

Ohetal. [9] measuredtheconcretestraintodeterminethecrackingstate oftheconcretecover.Oncetheconcretestrainreachedtheultimatevalue, theconcretecoverwasthoughttobecracked.Thefollowingmodelwasproposedtocalculatesteelsectionlossatsurfacecracking:

Webster [10] conductedregressionanalysison50setsofexperimental datafromotherresearchersandproposedthefollowingsimplemodelforan approximateestimationofthecriticalcorrosiondepth:

Forsomeexcitingempiricalmodelsaboutcriticalsteelcorrosion,their predictableperformance,andacomparisonofthesemodelsarediscussedin Section1.2.3.

1.2.2CrackWidthattheConcreteSurface Theinitialcracksprovideapathforrapidingressofaggressiveagentstothe reinforcement,whichcanacceleratethesteelcorrosionprocessandcause damagesuchasdelaminationorspallingoftheconcretecover.Inpractice, manyownersofconcreteinfrastructuresusetheappearanceofvisiblecracks asanindicationtoexecuteanappropriateintervention.Therefore,the corrosion-inducedcrackwidthisusedasanimportantparametertoassess theserviceabilityanddurabilityofthereinforcedconcretestructures.

Alonsoetal. [3] observedthat15 50 μmofsteelcorrosionpenetration cangeneratea0.05 0.1mmcrackwidthatthecoversurface,whereasa 0.2 0.3mmcrackwidthneeds50 200 μmofsteelcorrosionpenetration.

Consideringthelocationofsteelbarsinbeams,Rodriguezetal. [6] proposedthefollowingmodeltocalculatethecrackwidthontheconcretesurface, Ws (inmm):

where δ (in μm)issteelradiallossinducedbycorrosion, β 5 0.0100forthe steelbarsatthetopofthebeam,and β 5 0.0125forthesteelbarsatthebottom.

Wang [11] proposedthefollowingmodel:

Vuetal. [12] definedthe concretequality,whichistheratiobetweenthe coverthickness, C,andthewater-to-cementratio, w/c,or C/(w/c),and observedthatthereisanonlinearlineofbestfitbeforethecrackwidthlimit isreached.Theseresearchersproposedthefollowingmodel:

whereAandBareconstants.Additionally,Vu [12] proposedamodeltopredictthetimetocrackingwhenextrapolatingtheacceleratedcorrosiontest resultstothebehaviorofrealreinforcedconcretestructures.Thetimetocrack initiationandcrackpropagationforrealreinforcedconcretestructures, t(real), withanyvalueofcorrosionrate, icorr(real),is:

where t(exp) and icorr(exp) arethetimetocrackinitiationandcrackingpropagationandthecorrosionratefortheaccelerationcorrosiontests,respectively. kR istherateofloadingcorrectionfactor,whichcanbecalculatedas:

Mullardetal. [13] investigatedreinforcedconcreteslabstostudycover crackingpropagationconsideringtheeffectoftheconcretestrength,cover thickness,reinforcementbardiameter,andconcreteconfinement.Citingthe resultsfromVu [12],thefollowingnewmodelwasproposed:

where kR hasbeenshownin Eq.(1.11) and kc istheconfinementfactorthat representsanincreaseincrackpropagationduetothelackofconcreteconfinementaroundtheexternalreinforcingbar. kc 5 1forasteelbarintheinternallocation. Eq.(1.12) issuitablefor0.1 # C/(d ft) # 1and Ws # 1.0mm.

Vidaletal. [14] investigatedtwobeamsnaturallycorrodedinasaline environmentandsubjectedtowetting dryingcyclesoverperiodsof14and 17years.Theresultsshowthatthecover/diameterratio(C/d)andthebar diameter, d,seemtohavenoeffectonthecrackwidthevolutionasafunctionofsteelcross-sectionloss,andthefollowingmodelwasproposed:

where ΔAs (inmm2)isthesteellossofthecross-sectionand ΔAs0 (inmm2) isthesteelcross-sectionlossattheinitialcrackingmoment.Thesefactors canbecalculatedas:

FIGURE1.3 Three-stagecorrosion-inducedcrackingprocess.(a)Corrosioninitiated.(b)Stage 1:filling.(c)Stage2:stressing.(d)Stage3:cracking. 8 SteelCorrosion-InducedConcreteCracking

stage [16].Asthecorrosionproductsfurtherincrease,expansivepressurein thesurroundingconcreteisgenerated.Thispressureincreaseswiththecorrosionproductsandcreatesextrastressesandstrainsintheconcretecoversurroundingthereinforcingsteel.Whentheinternaltensilestressesexceedthe tensilestrengthoftheconcretecover,crackswillstartintheconcretecover startingfromthesteelsurfacetowardtheconcretesurface.Duringtheprocessofthecrackingpropagation,thecorrosionproductswillalsofillthe spacewithinthecracksduringthisstage.

Accordingtothethree-stagecorrosion-inducedcrackingmodel,thetotal radiallossofthesteelbarwhentheconcretecoverhascrackscanbetaken asapproximatelythesummationofthreecomponents [16].Thefirstisthe radiallossofthesteelbar, δ pore,producedduringstage1.Thesecondisthe radiallossofthesteelbar, δ stress,producedbetweenthestressinitiationin theconcretecoverandthesurfacecrackingoftheconcretecover.Thethird istheradiallossofthesteelbar, δ crack,inwhichthecorrosionproductsfill thespaceinthecracksintheconcretecover.Mathematically,thiscanbe expressedasfollows:

1.3.2CorrosionProductsFillingStage Duringtherust-freeexpansionstage,theconceptoftheso-calledporous zoneisassumedtoaccommodatethesteelcorrosion,whichisgenerated freelyinthisstagewithoutstressingthesurroundings.However,itspresent formishighlyquestionablebecauseitisnotcertainwhetheranyreliable valuecanbeassociatedwithit [17].

Previousstudies [18 25] haveobservedtheareaofconcretearoundthe rebarpenetratedbycorrosionproducts.Wongetal. [23] observedthisarea (Fig.1.4)andcalleditcorrosionproducts-filledpaste(CP),whichwasalso calledthecorrosion-accommodatingregionbyMichel [24].CPisusedto describetheareaofconcretearoundtherebarpenetratedbycorrosionproductsinthischapter.TheexistenceofCPhasbeenverifiedforreinforced concretemembersthathaddeterioratedinthenaturalenvironment [18 20],

FIGURE1.4 BSEimagesshowingaccumulationofcorrosionproductsatthesteel concrete interface(S,steel;CL,corrosionlayer;CP,corrosionproducts-filledpaste;P,unalteredpaste; A,airvoid) [23]

TABLE1.1 ExperimentalStudyofCorrosionProducts-FilledPaste

ReferenceCorrosion Method Stage1:CorrosionProducts-FilledPaste

Care ´ etal. [21] External current Theexistenceofcorrosionproducts-filledpaste wasverified.Itwaspointedoutthatthecorrosion products-filledpastewasnotinthewholearea aroundthesteel.Whentherustfilledthepores,it producedpressureonthepastelayerbutwasnot studiedquantitatively.

Wongetal. [23] Dry wet cycle

Theaveragedepthofcorrosionproducts-filled pastewithdifferentcorrosiondegreesissimilar, approximately100 200 μm,andisdistributed onthesideofserioussteelcorrosion.

Micheletal. [24] External current Corrosionproducts-filledpasteincreasesalong withthecorrosion-inducedcrackingprocess,and themaximumvaluecanreach0.6mmwhenthe corrosion-inducedcrackoccurs.

Zhaoetal. [25] External current

Zhaoetal. [26] Dry wet cycle

Zhaoetal. [27] External current

Thecorrosionproducts-filledpastewasobserved bySEMbutnotstudiedquantitatively.

Thepenetrationofcorrosionproductsintothe porouszoneofconcreteandtheformationofa corrosionlayeratthesteel concreteinterface mayoccursimultaneously.

Provedthatthepenetrationofcorrosionproducts intotheporouszoneofconcreteandtheformation ofacorrosionlayeratthesteel concreteinterface mayoccursimultaneously

duringtheartificialcyclicwet drytests [22,24,26],andinelectrochemical corrosionconditions [21,24,25,27].

Table1.1 presentsexperimentalstudiesofCP.Forexample,Micheletal. [24] investigatedtheamountofcorrosionproductspenetratingconcreteand producedasemi-quantitativedescriptionoftheirchangesduringtheelectrochemicalcorrosionprocess.TheseresultsindicatedthatthedepthoftheCP