Ohio Mulch Success Strategy: Changing With The Times

By P.J. Heller

By P.J. Heller

Jim Weber has come a long way since he was a 19-year-old running a lawn service business out of the garage at his parents’ home.

Today, some 38 years later, Weber is owner and president of Ohio Mulch, one of the largest mulch manufacturing companies in Ohio. The company, headquartered on a 56-acre site in Columbus, has 20 locations in Ohio, Georgia and Kentucky, some 350 employees at the height of the mulch season, and produces some 1 million cubic yards of mulch annually.

That’s a far cry from when the teen-age Weber had to drive around to numerous locations trying to find bags of mulch for his lawn service business.

“I was doing a lot of landscaping and one of the things I needed back then was mulch,” he recalls. “It was very difficult to get 40 years ago. Hardly anyone used mulch. The typical garden center back then didn’t exist. They probably went through one or two semi loads a year and not every store carried it. I would assume that the margins were significantly greater back then than they are today, but the volume was significantly less.”

Weber eventually got the names of some mulch manufacturers off the bottom of the bags and realized he could purchase semi-trailer loads to meet his needs.

“At the time, I knew I couldn’t have semi loads of mulch delivered to my parents’ home,” he says. “So, I had to find a place to store the product.”

He found a facility to rent where he could store equipment and the bagged mulch. He set up a little storefront where he could sell mulch and began promoting and advertising the business. He also quickly realized that he could sell some of the mulch to other landscapers and retailers.

“Back then, the home and garden section in newspapers came out on Sunday. The first day I opened for business was Sunday, April 1, 1984. That first day I did $1,500,” he remembers. “Wow. It was better than I thought.”

In his first year in business, he sold 99 semi-trailer loads of mulch. He ended up selling his lawn service business to concentrate on the mulch business.

By his third year in business, he says he was having difficulty getting enough product, including from local sawmills. Consistency was also an issue.

That prompted him to purchase a grinder “to make my own premium bulk product,” Weber says.

By 1990, however, the grinder couldn’t keep up with the volume of material. So Weber modified the grinder, replacing lightweight and trouble-

Continued on page 3 NEWSServing Soil, Mulch, Compost & Wood Pellet Producers Vol. XVI No. 5 September / October 2022 www.SoilandMulchProducerNews.com

Ohio Mulch main facility, Columbus, OH

Photo / Ohio Mulch

Kathy & Jim Weber

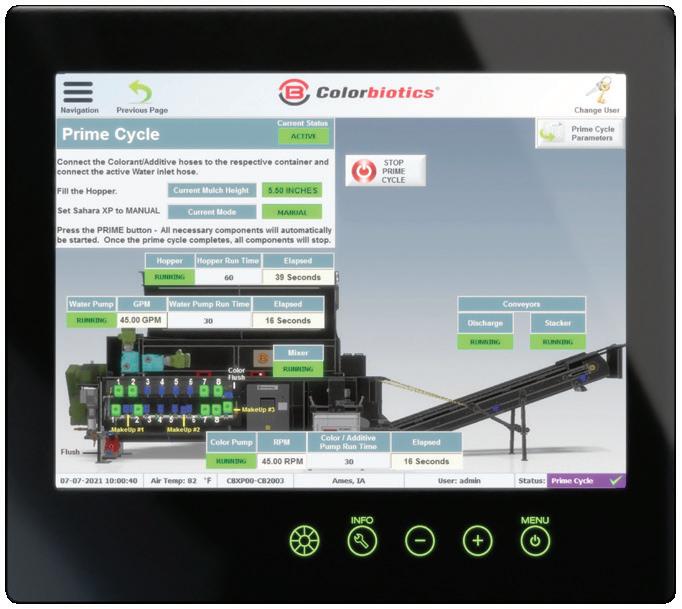

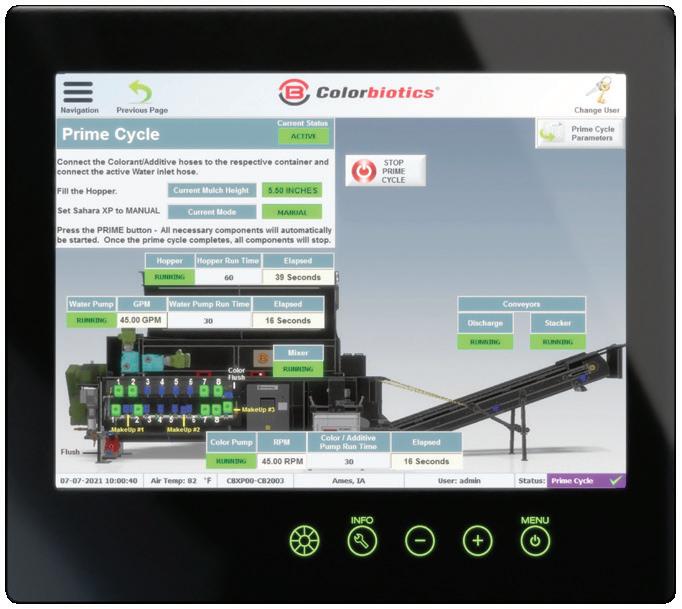

Goodbye, guesswork.

2 Soil & Mulch Producer News September / October 2022 The Sahara® XP comes equipped with GEM Studiov4 Colorbiotics and Sahara are registered trademarks of MBCC Group. © 2022 MBCC Group. All rights reserved.

And hello, GEM Studiov4 Thanks to this do-it-all interface, the all-new Sahara® XP coloring system is as simple as push to start. Plenty smart enough to follow the flow of material and find hidden dollars in every drop. Get to know the new GEM at SaharaXP.com.

Ohio Mulch Success Strategy: Changing With The Times

prone parts with heavy-duty components to make

The transformation was so dramatic that he had people knocking on his door to purchase the machines. That prompted him to buy old machines from farmers, modify them and then resell them. He eventually sold about 40 of the reconfigured Webermill Bark Grinders.

Weber says being able to change with the times has kept Ohio Mulch a competitive force. Among those changes: in the late ‘90s, the company opened a facility in South Georgia to produce cypress, pine and cedar mulch, which is then shipped to Ohio. It began offering colored mulch (black, brown, red and golden). And it led to Ohio Mulch planting an 1,100-acre tree plantation, using biosolids -- sewage sludge -- as a fertilizer to enhance the growth of the trees. Those trees lately have been used to make pallets for the company, with the scraps ground up for mulch.

The same is true for cypress trees and logs, with the wood being used to make lumber for fencing and the scraps being used for mulch.

‘We’re taking a 50-year-old tree and making a 50-year product out of it,” Weber explains. “We are taking the tree to make

lumber and the byproduct is mulch.”

The company also takes in green waste at a majority of its facilities as a convenience to its customer base.

“They can drop off their yard waste and pick up mulch at the same time,” Weber says.

Those kinds of innovative ideas have allowed Ohio Mulch to continue to expand its client base throughout Ohio and its contiguous states. Today, its products can be found in its own retail outlets as well as in garden centers, nurseries, landscape companies and stores, including Home Depot, Ace Hardware, True Value, Lowes and Walmart.

Despite its success, the company, like many others, has faced challenges.

“Transportation is the biggest challenge,” Weber says, citing supply and demand for trucks, their hours of service and a shortage of drivers.

“Do you know any person whose child says, ‘I want to grow up to be a truck driver,’” he asks. “It’s not a sexy business to be in. Today’s generation of kids think they can have a full-time job just making TikTok videos.”

Labor is also an issue, especially coming out of the coronavirus pandemic when all types of businesses are scrambling to attract workers.

“I’ve never seen it as bad as I’ve seen it this year,” Weber says. “We used to place an ad in the paper and applicants who came through stuck around for a year or two or three. Today you’re lucky if you hire someone and they come back after lunch. It’s that bad.”

Even so, Weber says the “biggest asset” for the company is its employees. He recently had one employee retire at age 70, who had worked at Ohio Mulch for 31 years.

“I certainly encourage longevity,” Weber says, citing among other things the company’s excellent vacation benefit.

Ohio Mulch’s customer base is pretty evenly split between landscapers and homeowners. In 2020, during the pandemic, however, homeowners accounted for about 70 to 75 percent of sales.

“The governor would go on the news on TV and tell people to stay home and work in their garden” he said. “People took the advice literally.”

Bulk and bagged mulch products account for about 90 percent of the company’s sales. Soils make up the remaining 10 percent.

Looking ahead, Weber says the focus will likely be on expanding into areas utilizing smaller mulch manufacturing facilities, rather than having a large distant plant and having to ship product a long way.

And he is optimistic that the mulch market will continue to grow, not only for landscaping purposes but also for such things as erosion control.

“I do see it continuing to grow,” he says.

EQUIPMENT & PRODUCT SHOWCASE

www.GrinderTrader.com

Sell your products / equipment here, call 440-257-6453.

3September / October 2022 Soil & Mulch Producer News Soil & Mulch Producer NEWS Continued from page 1 Publisher / Editor Rick Downing Contributing Editors / Writers P.J. Heller • Dr. Brian E. Jackson Robert L. LaGasse • Sandy Woodthorpe Production & Layout Christine Mantush Advertising Sales Rick Downing Subscription / Circulation Donna Downing Editorial, Circulation & Advertising Office 6075 Hopkins Road, Mentor, OH 44060 Ph: 440-257-6453 • Fax: 440-257-6459 Email: downassoc2@oh.rr.com Subscription information, call 440-257-6453. Soil & Mulch Producer News is published bimonthly by Downing & Associates. Reproductions or transmission in whole or in part, without written permission of the publisher, is prohibited. Annual subscription rate U.S. is $19.95. Outside of the U.S. add $10 ($29.95). Contact our main office, or mail-in the subscription form with payment. ©Copyright 2022 by Downing & Associates www.SoilandMulchProducerNews.com PUBLICATION STAFF Printed on Post-Consumer Recycled Paper

it more reliable.

330-323-1146 • GrinderTrader.com Market & Sell Your Tub or Horizontal Grinder!Market & Sell Your Tub or Horizontal Grinder!

Growers Facing Supply & Demand Challenges for Growing Media

Dr. Brian e. Jackson

Once upon a time growers could call their growing media supplier(s) and have product ordered, shipped, and delivered within days. It is no mystery to anyone today that “those days” are gone, at least for the foreseeable future. The global growing media industry, like so many others in horticulture, has experienced unprecedented product demand which has led to product shortages, long delivery times, or in many instances the inability to take or fill product orders from new, low volume, or sporadic customers.

The impact that the pandemic has had on horticulture is pretty well documented, experienced, and understood at this point as we near the end of 2022. Increased sales, increased crop production, increased profits (to most), increased everything. Everything, including fuel, plastics, fertilizers, labels, labor and growing media! In addition to the recent demand for soilless growing media, there are a couple of other underlying factors that have contributed to what we are now experiencing in the supply chain of the growing media industry.

First, is the projected future demand of all types of soilless growing media between now and 2050. This demand, expected to increase at least four-fold, is driven by many factors. The accelerated increase in soilless growing systems (and acreage) in China alone can account for huge volumes of growing media being diverted to that emerging market. Secondly, here in North America as well as Europe and South America, the everincreasing adoption of many soft fruit crops to soilless growing systems (which need soilless substrates), the continued success and expansion of the Cannabis industry, record-breaking development and construction of vertical farming systems and other controlled environment spaces…all of which grow crops on/with some type of organic or inorganic soilless substrate material.

Throughout most of the pandemic, most growing media suppliers were working to fulfill customer orders using the existing raw material resources that had met demand successfully prior to 2020. The sourcing of new or larger volumes of raw materials was challenging for many (most) suppliers due to competition of raw materials from other markets, transport issues of materials, or the need of capital investments to scale up processing, harvesting, or transport of materials. In the period since demand drastically spiked, most suppliers have initiated the needed investments to increase raw material acquisition, raw material processing and handling processes, mix formulation, and overall production output.

Peat producers in Canada have progressively sought to properly license and open new peat bogs (from Alberta to New Brunswick) to enhance raw

material access and harvested volumes while also employing all possible practices to keep their processing (mix manufacturing) facilities fully staffed and operational around the clock despite the pandemic. Manufacturers of engineered wood fiber, most of whom are some of the largest peat producers in Europe, have installed over a dozen new refining facilities (disc refers and screw extruders) across Europe in the last two years to help cope with product demand. Wood fiber manufacturing in North America has not kept up as well or been as progressive therefore the opportunity for wood product development and commercialization grows greater by the day. While some increase in production has occurred, the need for more products, higher volume, and more suppliers remains high. The use of bark (fresh, aged, or composted) remains exceptionally high in North America and thanks to aggressive timber harvesting to keep up with the construction boom at home and abroad, raw bark from the timber/ lumber industry remains abundant which is good for bark processors and suppliers to the horticultural market. Other organic materials including rice hulls, recycled organics (i.e. PittMoss), composts, anaerobically digested materials, and other forestry or agronomic-based fiber have also greatly enhanced production capacities and product offerings.

Transport of substrate components as well as finished ready-to-use growing media have been hampered by the historic transportation gridlock that has strangled supply chains across the world. Namely, products like perlite ore (Greece is a primary source), coconut coir (Sri Lank, South India, Philippine’s and Mexico are primary sources), vermiculite (North America and South Africa), some rock wools (many sources in Europe), and European peat and wood fiber have been especially hard hit. Not exempt from the transportation issues, Canadian peat delivery to points across the US have also struggled to keep up with demand.

Even with abundant raw material resources, major challenges have contributed to the supply chain issues of many growing media products. First, pandemic-related personnel issues (illness, quarantine, care for family, education of at-home children, etc.) faced by substrate suppliers was often crippling to these businesses trying to make and export products. Even as the pandemic effects on personnel have lessened, the economic climate and severe labor shortages that followed have remained burdensome to many. In conversations with many growing media suppliers, one of the other realities that became clear is that despite having raw materials on-site to use in substrate formulation, they were limited by the processing capacities of existing equipment or facilities. Perlite is a good example. A super popular

4 Soil & Mulch Producer News September / October 2022

Continued on page 6

BORN TO GRIND.

Precision Husky Corporation leads the forest products industry, building the most rugged equipment available.

Our horizontal and tub grinders are the most powerful, easiest to use grinders in the industry. They are designed with innovative features and advanced technologies to give you the power and production needed

to tackle the most demanding grinding operations.

We are a family-owned, family-operated company, and we’ve earned our position in the industry by building the highest-quality, most reliable equipment since 1964. Contact us to learn more about our products and to discuss your needs.

Leeds, AL

5September / October 2022 Soil & Mulch Producer News P.O. Drawer 507,

35094 • 205-640-5181 • www.precisionhusky.com • sales@precisionhusky.com

H3060 Horizontal Grinder

MAY WE INTRODUCE SOME OTHER MEMBERS OF OUR FAMILY... Precision Husky PG-5200 / Horizontal FP S&M Producer News Mar-Apr 2022.indd 1 3/14/22 9:37 AM

Growers Facing Supply & Demand Challenges for Growing Media

Continued

growing media component saw severe supply shortages this past year, but in many cases that was not due to perlite ore running out or being unavailable as a result of shipping backlogs, but instead it was due to the limited “popping” capabilities at perlite and growing media manufacturer facilities. Perlite ore is a rock that must be “popped” in kiln-like machines at super high temperatures to be transformed into the lightweight puffy aggregates you are familiar with seeing in your substrates.

Looking ahead, many growers are also adopting new business strategies, production practices, marketing plans, sustainability polices, and collaborative initiatives as some means by which to evolve their operations into successful businesses of the future. For example, there is evidence of increasing demand (by growers) for sustainable automation-ready substrates, peat free or reduced substrates, pledges to have plastic free growing operations within the next decade, plans for carbon neutral operations, resilient crop production systems, and other sustainable business practices of importance to specific regions of the country.

Like all other horticultural producers and industries, the growing media industry is responding as quickly and responsibly as possible to adjust to today’s new norms, adjusted customer expectations, transportation nightmares (realities) and expanding markets. Looking forward into 2023 growers are encouraged to build and maintain strong relationships with growing media suppliers, place product orders months in advance, order more volume than you have in the past in case of increased production decisions, and be willing to trial or adopt new growing media components or formulations that may require changes in production cultural practices. As national and global demand increases and growing media becomes more essential to more crops and more markets, the future may never go back to “the way it used to be” in regard to substrate prices and availability, but things will eventually improve from the peak demand and supply chain gridlock seen during the past few years.

Dr. Brian E. Jackson is a Professor of Substrate Science and Director of the Horticultural Substrates Laboratory at NC State University. Brian can be reached at Brian_Jackson@ncsu.edu.

There are better ways to bag

The next level of industrial automation is here and it’s designed to be the workhorse of your production floor. Our HAMER Brand form, fill & seal and open mouth bagging machines are the most capable and flexible available, improving machine uptime and reducing annual maintenance costs by almost 60%. There’s a reason why we are the industry’s first choice for reliable bagging automation.

Trust HAMER Brand automation to get the job done, better.

Hamer-Fischbein is now nVenia. With over 300 years of combined packaging machinery experience, Hamer brand equipment is still your trusted source for better bagging automation.

www.nVenia.com/betterway

6 Soil & Mulch Producer News September / October 2022 Soil & Mulch Producer NEWS

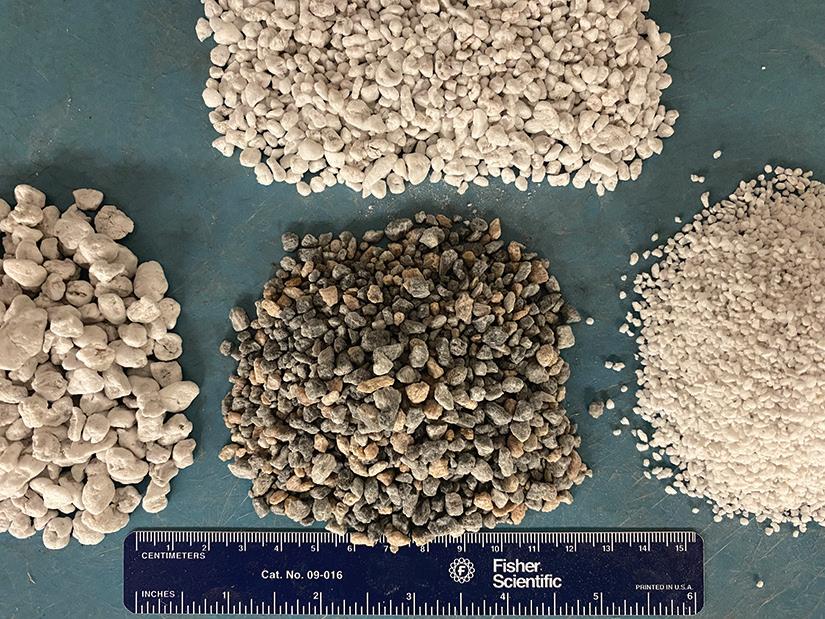

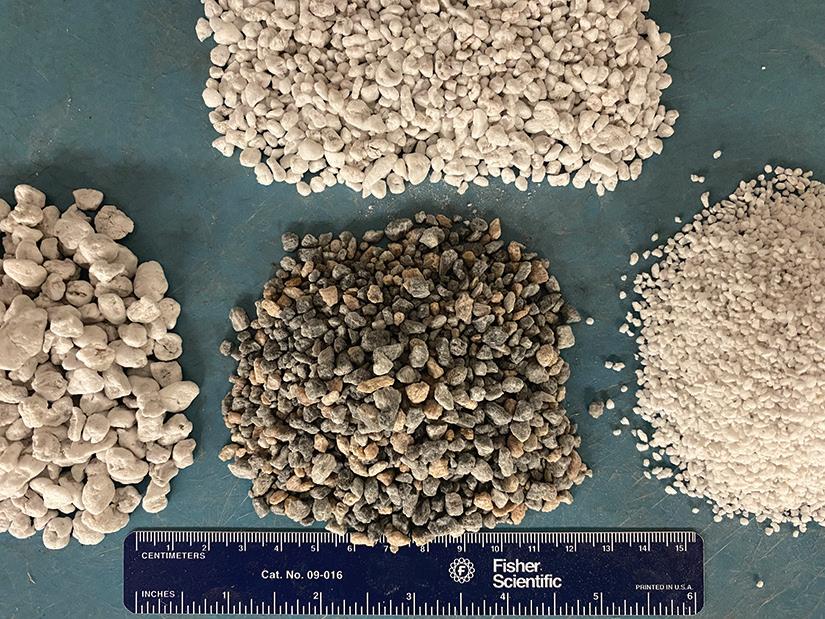

Growing media components have all been in extremely high demand since 2020, a trend that will continue. Photo/Brian Jackson

Perlite is a primary growing media component with supply issues due to processing constraints, transit delays, and unprecedented product demand. Photo/Brian Jackson

from page 4

HAMER Brand Model 2090

7September / October 2022 Soil & Mulch Producer News Our Vision Colors Yours! 615-443-0345 Ext 103 OHIO | TENNESSEE | TEXAS | info@agricoatings.com | www.agricoatings.com All the mulch colorant companies are saying the same thing: Ours has better coverage, Ours has better weatherability, Ours is more brilliant, looks better...blah..blah..blah We at Truly believe WE make THE Best High Performance Mulch Colorant! Prove it to yourself. Contact us to set-up a trial run. Blah...Blah...Blah...

News From The Mulch & Soil Council

By RoBeRt LaGasse, executive DiRectoR

By RoBeRt LaGasse, executive DiRectoR

Legislative & Regulatory News

In early July, APHIS confirmed the identification of emerald ash borer in Washington County, Oregon. The Oregon Department of Agriculture believes that the infestation has been in Washington County at least 3-5 years. Regulatory efforts to stop the spread of emerald ash borer were not effective and it has spread through much of the United States. Emerald ash borer is now in 36 States and the District of Columbia.

APHIS’ goal is to maintain ash in the North American landscape. We will continue to work with our state partners to provide biological control options and integrated pest management methods, as well as ongoing public outreach support, to mitigate impacts from this pest. The biocontrol effort involves releasing tiny, stingless wasps into known infested areas. The wasp larvae feed on early life stages of the emerald ash borer, killing the beetle. Recent research shows that biocontrol is helping reduce emerald ash borer populations and can help the survival of young ash trees as forests recover from outbreaks. We look forward to continued collaboration with all our partners on the effort to combat emerald ash borer infestations.

APHIS encourages the public to be on the lookout and report emerald ash borer, and has outreach materials including videos, photos, factsheets, and online reporting available at: www.aphis.usda.gov/plant-health/eab. You can also sign up to receive the emerald ash borer program report through our Stakeholder Registry, by visiting: https://www.aphis.usda. gov/plant_health/downloads/eab-report-sign-up.pdf.

Industry News

CFS Appeals USDA Organic Certification of Hydroponics: According to reports from the websites LAW360 and AgriPulse, the question of whether hydroponic production can be certified as organic now rests with a panel of federal appeals court judges, who seemed to be inclined to affirm a lower court decision allowing such certification.

Since 2020, the Center for Food Safety (CFS) and a coalition of organic farming operations have been challenging the USDA/NOP’s decision to allow products from hydroponic operations to attain organic certification. Plaintiffs’ claim their cause for action is that soil fertility is an integral, and required, element of organic farming, and not requiring it for hydroponic operations gives them an advantage over organic growers who must meet a raft of requirements to be certified. However, past statements by the plaintiff organizations emphasized more of the economic advantages hydroponics have in yield/acre than the “organic soil” claim currently offered in court. Last year, a federal district court judge backed USDA.

During a July 27 hearing in San Francisco, U.S. Circuit Court Judge Susan Graber told Sylvia Wu, counsel representing CFS, repeatedly that the Organic Foods Production Act doesn’t appear to specify that food must be grown in soil — it just lays out various requirements if the food is grown in soil.

“There is kind of a catch-all [in the statute] that if it’s not prohibited it’s ok, so where [on the statute] is production in water, or in other media other than soil, prohibited?” Judge Graber asked. “Where is there a restriction?

Continued on page 10

8 Soil & Mulch Producer News September / October 2022 Soil & Mulch Producer NEWS

www.keithwalkingfloor.com/j-max

9September / October 2022 Soil & Mulch Producer News

News From The MSC

Where has Congress said, ‘You can’t do this.’ Or ‘You only can do this if you do something special in the water’?”

Wu conceded that the statute doesn’t explicitly prohibit water-grown food from organic labeling, but she pointed out that the statute mandates certain soil fertility and production requirements, so she argued that “soil building was understood to be synonymous with organic farming.”

To that, Garber replied, “It looks to me like they’re just setting out alternatives. It doesn’t seem to say that these are the only options.”

During the hearing, Judge Garber pointed out that the USDA didn’t issue a rule that is currently being challenged. Instead, the agency refused a request to issue a rule, and so she questioned whether such a refusal would even be subject to the notice and comment requirement under the Administrative Procedure Act.

Judge Garber also questioned whether hydroponic food operations constitute a “farm” under the statute. USDA Counsel Daniel Winik noted that the OFPA does not define “farm, “ but “does provide a very good indication of what is meant by the word “farm” standing alone, which is that when it defines a certified organic farm as a term of art, it defines it to mean “a farm, or portion of a farm, or site where agricultural products or livestock are produced.”

His conclusion: “If you were thinking about in which of those buckets a hydroponic operation fits, it’s obviously far more natural to consider it a site where agricultural products are produced than to consider it a farm.” Therefore, Winik argued that the trial court’s decision (in favor of USDA) should be affirmed, and the agency’s decision deserves deference, particularly since it is a policy issue that has been “hotly contested” for many years.

The case is Center for Food Safety et al. v. Thomas Vilsack et al., case number 2115883, in the U.S. Court of Appeals for the Ninth Circuit.

NOTE: MSC joined with the Coalition for Sustainable Organics (CSO) and other supporters of the greenhouse growing industry to file an Amicus Curiae in support of USDA in this case.

Home Pellet Supply Warning:

An estimated 0.8% of U.S. households have a wood stove as a primary or secondary heating source, but wood pellet manufacturers are urging the homeowners to secure their pellet fuel early this year as the global pellet market works to fill a significant supply hole created by the Russian invasion of Ukraine.

Russia contributed at least 2 million tons of wood pellets to global pellet markets, mostly to European buyers. According to the Pellet Fuels Institute (PFI), the demand to fill these missing tons is being felt throughout the world, including here in the United States. In preparation for the coming heating season, wood pellet producers are urging consumers to stock up now.

PFI notes that heating oil and propane prices are currently very high which historically leads to the increased use of the wood pellets with consumers who have both oil and pellet appliances in their homes. According to data captured by the U.S. Energy Information Administration, annual pellet sales have fluctuated between 1.7 million and 2.2 million tons within the last five years.

While pellet inventories in the United States are strong right now, pellet producers highlight the importance of keeping inventory moving through the system in the run up to the heating season. Strong late summer sales allow producers to run at full throttle and build inventory before usage begins to outpace production in the depths of winter.

PFI states that wood pellets are used as primary or secondary space heat in over 1 million homes, creating annual demand for nearly 2 million tons of premium heating pellets.

The Mulch & Soil Council began in 1972 and is the national association of producers of horticultural mulches, consumer potting soils and commercial growing media. Its mission is to define quality products and promote an open market and fair competition. To learn more about The Mulch & Soil Council, visit mulchandsoilcouncil.org or call 806-832-1810.

10 Soil & Mulch Producer News September / October 2022 Soil & Mulch Producer NEWS

Continued from page 8

With time being so valuable, it is more important than ever to invest in equipment that will save time and money. At Bandit, we pride ourselves by producing tough, reliable, easy to maintain equipment that will serve you on a consistent basis reducing manual labor and unnecessary downtime. Therefore, allowing you to move on to the next job quicker or enjoy some well-deserved time off.

11September / October 2022 Soil & Mulch Producer News

If you haven’t tried a Bandit unit for your operation, please contact a local Bandit dealer, email marketing@banditchippers.com or visit our website www.banditchippers.com and we will be happy to assist you! A highly trained dealer network with dedicated parts, sales, and service personnel are committed to providing top notch support from the initial purchase through the entire life cycle of the machine increasing uptime and reducing downtime. THE BEAST® 2460XP 24” Capacity Horizontal Grinder

Wood Prices Remain Mostly Up

According to the Wood Resource Quarterly, current profit levels are the highest in at least 25 years, with Canadian and the US forest industry seeing healthy gains.

Even though lumber prices in Canada and the US fell by about 50% from March to July 2022, they hovered near their five-year averages. Sawmills worldwide have benefited from historically high profits due to record-high lumber prices and limited increases in wood raw-material costs.

The Global Sawlog Price Index (GSPI), representing 20 regions, has increased 34% in two years, while sawlog prices increased in the 2Q/22 worldwide except for Oceania and Northern Europe. Overall, prices have continued an upward trend that started in early 2020.

As global wood fiber markets are enduring tight wood fiber supply and low pulp inventories, record high market pulp prices have increased the costs for pulp logs and wood chips, making outlays significantly higher than last year.

The global Hardwood Fiber Price Index (HFPI) jumped 5.3% q-o-q in the 2Q/22 and was 13% higher than a year ago, while the global Softwood Fiber Price Index (SFPI) has gone up relatively less (+7%) since the 2Q/21.

Prices for all the primary pulp grades reached new highs in the 2Q/22. Higher pulp prices paired with only modest increases in wood fiber costs have resulted in record gross margins for pulp companies worldwide. Global trade of market pulp fell slightly during the first half of 2022, driven by lower demand in China, Germany, and Italy. The United States stood out as the only market with substantial importation expansion mostly because of continued strong demand for a variety of paper products.

Global timber markets saw a 20% decline in international softwood log trade in the first half of 2022, thanks to a halt in Russian log exports sparked by an international boycott and reduced wood demand in China. Global trade of softwood lumber fell about 10% in the first half of 2022, for the most part driven by lower lumber demand in China, the US, and Germany. Lumber imports to China fell 44% during 2020-21, and shipments are on pace to reach their lowest levels in ten years in 2022. In Europe, lumber prices softened in early summer

The tumultuous energy market in Europe brought wood pellet prices in the second and third quarters to extremely high levels never seen before. The European pellet supply has been shrinking and is expected to dry up by the end of this year. Pre-war shipments from Belarus, Russia, and Ukraine totaled about 3.5 million tons in 2021, about 30% of total imports to the continent.

Composting Resumes in New York City

New York, NY — A no-signup organic materials recycling program is underway in the Big Apple, reports The Epoch Times

Although previous programs were canceled due to lack of participation and operational inefficiency, city officials are hoping people view the new options as user friendly and adopt composting as a routine. The simplified approach, which includes 250 drop-off sites as well as curbside pickup, cuts collection costs to half that of other programs by devising fleet, routing, and workforce efficiencies.

Residents can set out their waste on the assigned day using their own compost bins or the specially designed ones they can request the Department of Sanitation (DSNY) to deliver. Buildings with ten or more units automatically receive compost bins from the city.

Residents will need to separate leaf and yard waste, placing it in a separate bin or bag from regular trash and it needs to be marked as yard waste. Food scraps and food-soiled paper products can be put in any bin with a maximum size of 55 gallons and a secure lid. The bin should be marked with a free composting bin decal, which can be ordered from DSNY.

The city also is piloting widely distributed “smart bin” technology using a key card or digital app. New Yorkers can bring their food scraps to any of the 200+ public food scrap drop-off sites that are currently open 24 hours a day, 7 days per week. across the five boroughs. All food scraps are processed locally at community scale compost sites.

12 Soil & Mulch Producer News September / October 2022 Soil & Mulch Producer NEWS

13September / October 2022 Soil & Mulch Producer News www.chromascape.com service@chromascape.com

Poor Weather Conditions Impact Canadian Harvest of Horticultural Peat Moss

Ottawa, Ontario, Canada, September 21, 2022 — The Canadian Sphagnum Peat Moss Association (CSPMA), whose members currently represent approximately 83 per cent of North America’s horticultural peat production, recently announced its annual level of harvest for the 2022 season. A survey of members was conducted on the status of their 2022 Actual Harvest as a percentage of their 2022 Expected Harvest as of August 31 (the season may continue in some regions, weather dependant). The harvest overall varied regionally, but significantly poor weather conditions across all regions meant that harvest, unfortunately, was well below expected levels.

Regional Results

In Western Canada (Manitoba [MB], Saskatchewan [SK] and Alberta [AB]), all regions were below the targeted volumes (56% in MB; 75% in SK; 81% in AB). In some cases, record breaking rain and floods significantly delayed the harvest season, a situation that extended through much of the summer. The end of summer saw more favorable conditions, but they were insufficient to enable target volumes to be reached. In Manitoba, weather conditions, specifically the spring 2022 flooding, limited harvest and plant operations, constraining capacity. To date, some facilities are continuing to recover from the flood damage.

In New Brunswick, both North and South regions were below expected harvest volumes (65% in NB North, 70% in NB South). Varied weather patterns combined with the late start constrained harvest throughout the Maritimes. The harvest on Québec’s South Shore (73%) and North Shore (61%) were also below expectations. Several summer storms, particularly on the North Shore, did not permit either region to achieve its targeted

volumes. Similar weather patterns affected the Ontario (57%) harvest.

South of the border, Minnesota (34%) experienced a lower-thanexpected harvest because of unique weather patterns.

The CSPMA stated that the Canadian horticultural peat producers are committed to working cooperatively with their commercial business partners. CSPMA members continue to harvest and manage horticultural peat in a sustainable and responsible way that delivers social and economic benefits to many communities across North America, all while applying world-leading environmental practices. In addition, Canadian horticultural peat producers are engaged in increasing harvesting capacity through investments in plant infrastructure, harvesting equipment, bog openings, and personnel training, while partnering with Academia to limit the environmental footprint. Producers, through the CSPMA, are also working with provincial governments to improve the regulatory environment to ensure the critical resource continues to deliver on the benefits of food security and well-being for generations to come.

Definitions

Actual Harvest 2022: The volume of cubic feet (CFT) of harvest that was achieved as of August 31, plus, what can reasonably be expected to be harvested for the last few weeks of the season considering (normal) harvesting conditions.

Expected Harvest 2022: The volume of CFT that equates to 1) market needs, plus, 2) anticipated buffer as at the end of the 2022 season, minus, 3) inventory on hand at the start of the 2022 season (what was left of the 2021 buffer).

14 Soil & Mulch Producer News September / October 2022 Soil & Mulch Producer NEWS

15September / October 2022 Soil & Mulch Producer News

Iowans Send a Half Million Tons of Food Waste to Landfill Each Year

Iowa City, IA — With just two sites in the state authorized to accept more than two tons of food scrap and other organic waste per week, the bulk of this waste is going to landfill where it releases methane gas as it decomposes, reports wqad.com

According to recent estimates, food scraps make up 20% of Iowa’s waste stream. Iowans are sending an estimated a billion pounds of food to landfills each year, a situation that is unlikely to improve until the state legislators change the rules that are discouraging the business of composting.

The Iowa City Landfill and Recycling Center, which began collecting food scraps in 2017 now has 4,000 households that participate in a curbside pickup program. The facility produces 2,500 to 4,000 tons of compost per year. Composting advocates would like to see consistently higher volumes, which translate to sustainable revenue. The problem is state law puts a limit at two tons for food waste recycling.

According to the program manager at the Iowa Waste Reduction Center (who also is vice president of the U.S. Composting Council), Iowa City and Cedar Rapids are the only two composting sites that accept food waste.

The Iowa Department of Natural Resources has begun a study to identify some of the problems in the rules and start a rewrite of state regulations for food waste recycling. The City of Davenport, for example, has considered food waste recycling, but the existing composting process would need an overhaul. According to officials, the current process uses biosolids from wastewater and yard waste and adding food wastes to the mix would require additional expenditures and space to accommodate the waste stream, process it, and store it.

Scrappy State-Registered Food Waste Composter Reaps Profits

Fort Plain, NY — The RapidRoots Compost Facility here has cornered the composting and compost sales market as the area’s only site registered with the state food scrap program, reports RecorderNews.com

RapidRoots registered with the New York State Department of Environmental Conservation (DEC) as a composting facility soon after a state law went into effect on Jan. 1. The law requires businesses and institutions to recycle if they generate in excess of two tons of food scraps per week on average and are located within 25 miles of an organic recycler. RapidRoots receives food scraps from both Montgomery and Fulton County providers that are located within a 25-mile radius of the compost farm.

The family business sold approximately 2,500 yards of compost in the last year, with prime customers being homeowners and big vegetable farmers. One no-till organic farm purchases approximately 250 yards of compost per year from the Fort Plain compost farm. Prior to RapidRoot opening its organic compost facility three years ago, the organic farmer sourced Schenectady municipal compost, which was lower quality and needed additional amendment.

RapidRoot also is registered for composting roadkill. mortalities, so the Fort Plain compost facility can recycle animals killed on local roadways. The animal remains are then spread onto the farm’s field and not included in the compost sold to the public.

16 Soil & Mulch Producer News September / October 2022 Soil & Mulch Producer NEWS

17September / October 2022 Soil & Mulch Producer News SAVE MONEY MEASURE YOUR VOLUME! WA LZ S C A L E • S C A N N E R (800) 747-0701 656 High Point Ln., East Peoria, IL 61611-9369 www.walzscale.com Volumetric Belt Scanner / Volumetric Truck Scanner Axle Scales/Truck Scales Starting @ $23,600.00 Starting @ $1,620.00 Skid Steer / Lift Truck Scales Starting @ $995.00 Wheel Loader Scales Starting @ $3,250.00

ADVERTISER NEWS Rotochopper Welcomes Chad Angeli

Rotochopper recently announced the addition of Chad Angeli to the Rotochopper team as Vice President of Customer Experience.

In this newly created executive role, Chad will lead the sales, marketing, and customer service functions, strengthening the Rotochopper brand and aligning customer touchpoints. As a strategic partner to the CEO, he will develop and implement strategies that lead to continued growth, market development, and profitability.

Rayco® Forestry Selects Maverick Environmental Equipment As Authorized Dealer in Ohio

Morbark, LLC, a manufacturer of tree care, forestry, and wood recycling equipment, announced today that Maverick Environmental Equipment is the new, exclusive dealer of Rayco Forestry Mulchers in Ohio. With two branches in Newbury and Bremen, Ohio, Maverick is also an authorized dealer for Morbark’s industrial equipment product lines, which include horizontal and tub grinders, whole tree drum and disc chippers, and flails.

Maverick began operations in 2016 when equipment industry veterans Tim Smith and Charlie Stahl joined forces to build their own company. The company focuses on providing machinery-based solutions for environmental applications, including aggregate processing, waste recycling, forestry, and biomass.

“We are dedicated to bringing our customers the highest quality products. This means partnering with top-tier manufacturers, like Rayco and Morbark, whose products work hard and take on the toughest materials,” said Tim Smith, managing partner, Maverick Environmental Equipment.

John Balogh, director of Rayco Forestry sales, said, “We are excited for Maverick to represent our forestry mulcher line in Ohio. We definitely know what Maverick provides and having them on board will ensure that our Ohio customers experience minimum downtime and maximum productivity.

Chad brings 18 years of business experience from an impressive resume at Tennant Company, a leading designer and manufacturer of cleaning equipment with annual revenue exceeding $1.1 billion. He began his career as a sales specialist in Indiana. From there, he was promoted into roles with more responsibility, eventually holding General Manager and sales leadership roles in Minneapolis, New York City, Toronto, Shanghai, and Sydney. He has a track record of building teams that collaborate around a compelling vision – teams that then execute and over-deliver on results.

“I am excited to welcome Chad to the Rotochopper leadership team,” said Tosh Brinkerhoff, CEO of Rotochopper. “His global experience and general management background will provide an important perspective as we grow the company, and his frequent interaction with customers throughout his career will be invaluable as we strengthen our mission to keep our customers happy.”

Chad earned both his bachelor’s degree and his MBA at the University of Wisconsin-Milwaukee. In college, he played basketball on a scholarship, serving as a four-year team captain and receiving the UW-Milwaukee Student-Athlete of the Year award in 1999. As his career took him around the world, Chad volunteered with organizations such as Heart to Heart China and New Wales South Food Bank.

“I am thrilled and grateful to be joining a team that has such a strong reputation for taking care of their people and their customers,” said Chad.

18 Soil & Mulch Producer News September / October 2022 Soil & Mulch Producer NEWS

Reach More Than 5,000 Mulch, Soil & Compost Producers & Resellers ... Advertise in Soil & Mulch Producer News! Contact Rick or Donna Downing at 440-257-6453

COLORED MULCH SOLUTIONS

19September / October 2022 Soil & Mulch Producer News Factory Direct • Employee Owned • Global Support Contact us today: 320-548-3586 • www.rotochopper.com

We were the first company to offer “Perfect In One Pass”® grind and color technology, and today through continuous innovations, that system remains the standard for producing colored mulch while maximizing productivity and minimized costs.

Email:

Ins I de Th I s Issue PRSRT STD U.S. Postage PAID Cleveland, OH PeRmIT #1737 6075 Hopkins Road • Mentor, OH 44060 Ph: 440-257-6453 • Fax: 440-257-6459

downassoc2@oh.rr.com VOL. XVI NO. 5 SEPT / OCT 2022 www.SoilandMulchProducerNews.com Ohio Mulch Success Strategy: Changing With The Times PAGe 1 Growers Facing Supply & Demand Challenges for Growing Media PAGe 4 News From The Mulch & Soil Council PAGe 8 Wood Prices Remain Mostly Up PAGe 12 Poor Weather Conditions Impact Canadian Harvest of Horticultural Peat Moss PAGe 14 Iowans Send a Half Million Tons of Food Waste to Landfill Each Year PAGe 16 Advertiser News PAGe 18

By P.J. Heller

By P.J. Heller