Are you looking for Products, Equipment or Services for your business? If so, check out these leading companies advertised inside:

AUTOMATIC FLOOR SYSTEMS

Keith Manufacturing Co – pg 4

BAGGING/PALLETIZING EQUIPMENT

Amadas Industries – pg 8

nVenia – pg 16

COMPOST TURNER

Resource Machinery & Engineering – pg 20

CONVEYORS & CONVEYOR PARTS

Amadas Industries – pg 8

Smalis Conveyors – pg 13

EQUIPMENT SALES

GrinderTrader.com – pg 3

GRINDERS, CHIPPERS & SCREENING SYSTEMS

Amadas Industries – pg 8

Diamond Z – pg 6

HogZilla – pg 22

Maverick Environmental Equipment – pg 20

Precision Husky – pg 15

Viably – pg 5

MULCH COLORING EQUIPMENT/ COLORANTS

AgriCoatings – pg 21

Amerimulch – pg 7

Britton Industries – pg 9

CMC – pg 17

Colorbiotics – pg 2

Faltech – pg 18

Milagro Rubber Inc – pg 10

Münzing Corporation – pg 11

T.H. Glennon Co – pg 24

MULCH SUPPLIERS

Lambert Peat – pg 3

Ohio Mulch – pg 12

PAYLOAD WEIGHING & MEASURING SYSTEMS

Walz Scale – pg 19

SOIL AMENDMENT

Green Solutions LLC – pg 4

TRAILERS

Weaver Systems – pg 14

TROMMEL BRUSHES

Power Brushes Inc – pg 3

WEAR PARTS

ArmorHog – pg 3

BY STAFF

hen devastating floods swept through the Texas Hill Country in early July, claiming the lives of over 130 people, a wave of grief was quickly followed by controversy. Some blamed the tragedy on a cloud seeding operation that took place more than 100 miles away, pointing fingers at Rainmaker Technology Corporation and its CEO, Augustus Doricko. Though experts and officials say there is no evidence linking the weather modification effort to the flooding, the event has reignited public interest—and concern—over a technology that’s been used for decades to enhance rainfall.

A recent article on www.theepochtimes. com explores how cloud seeding, once seen as a niche tool, is now becoming part of a broader conversation about how we manage water in an era of increasing droughts, water shortages, and extreme weather.

Despite some misconceptions, cloud seeding does not create storms or clouds from scratch. Instead, it enhances the rain potential of existing clouds. The process involves dispersing substances—typically silver iodide or table salt—into clouds to encourage the formation of raindrops or snowflakes. These particles act as nuclei that attract moisture, hastening the cloud’s natural precipitation process.

“The vast majority of water that traverses the troposphere in the United States just gets recycled by the ocean,” says Doricko. “Cloud seeding takes a small percent more of that water and helps it fall over land, where it can be used.”

A Technology with Deep Roots

Cloud seeding isn’t new. The technology dates back to the 1940s when scientists first experimented with weather modification to increase snowfall in upstate New York. Since then, states including Texas, Utah, California, and North Dakota have used the method to combat drought, enhance snowpack, and replenish aquifers.

In Texas, for instance, programs have operated for decades across tens of millions of acres. However, due to the recent rains and public outcry following the Hill Country floods, all cloud seeding efforts in the state have been temporarily suspended.

Doricko insists that operations like the one his company conducted on July 2—well south of the flood zone—had no impact on the storm system that caused the deadly floods. “It’s unfortunate that people link the two,” he says, “but I welcome the opportunity to educate the public.”

Cloud seeding is typically employed in regions suffering from prolonged dry spells or those that depend heavily on snowmelt. Doricko’s company works in multiple states, including Utah, Colorado, Oregon, and parts of California. In Utah, operations run from October to April to help build up the winter snowpack, which is crucial for water supply during the dry season.

“The snow we generate acts like a natural battery,” Doricko explains. “It melts slowly, releasing water into rivers and aquifers.”

Why is Colorbiotics the choice of more mulch producers than any other name in the industry?

A. Large stock of colorant for on-time delivery

B. Entire lineup of mulch coloring equipment

C. Complete inventory of replacement parts

D. Coast-to-coast fleet of service vehicles

Answer: All of the above

Because water flows across state lines, cloud seeding has implications for regional water management. For example, states like California and Arizona help fund seeding projects in upstream areas like Colorado, recognizing the downstream benefits.

However, Doricko emphasizes that safety measures are built into every program. If there’s any threat of flooding or dangerous storms, operations must be halted—even if local communities are eager for rain.

In the U.S., cloud seeding operates under a mix of federal and state oversight. Operators must notify the National Oceanic and Atmospheric Administration (NOAA) at least 10 days before a seeding event, though NOAA has no power to approve or deny these actions.

In Texas, cloud seeding requires a stateissued license, and applicants must demonstrate meteorological expertise and meet specific safety and financial criteria. But while permits are mandatory, reporting after the fact is minimal. Doricko argues that more federal oversight could help ensure transparency and public trust.

“Right now, people have to rely on trust,” he says. “We need better data collection and public reporting to show how effective and safe cloud seeding really is.”

Research on cloud seeding’s effectiveness and environmental impact has grown steadily since the mid-20th century. So far, studies suggest the practice is relatively low risk. The Texas

Department of Licensing and Regulation, for example, says that after decades of monitoring, no significant environmental impacts have been found from seeding projects.

Rainwater samples from seeded clouds show only trace amounts of silver—well below federal health guidelines. In fact, the iodine used in table salt far exceeds what’s found in rain from seeded clouds.

Cost-wise, cloud seeding has shown promising returns. Utah’s water agency estimates it costs between $5 and $10 per acre-foot to boost snowfall by 5 to 15 percent. And in North Dakota, a 2019 study showed cloud seeding increased farm rainfall and significantly reduced crop damage from hail, delivering up to $53 in benefits for every $1 spent.

Still, results can vary based on geography and climate. “It doesn’t work just anywhere,” cautions the Utah Division of Water Resources. “The conditions have to be right.”

Weather Modification vs. Geoengineering

Cloud seeding is sometimes confused with other atmospheric interventions, such as geoengineering or so-called “chemtrails.” However, scientists distinguish cloud seeding as a localized, short-term method to stimulate rain, whereas geoengineering involves altering global climate patterns—such as reflecting sunlight to cool the Earth.

Doricko agrees that more scrutiny is warranted for large-scale climate engineering. “Dimming the sun is a real technology that we need to take very seriously,” he says. “But it’s not the same as cloud seeding.”

Annual subscription rate U.S. is $19.95. Outside of the U.S. add $10 ($29.95). Contact our main office, or mail-in the subscription form with payment. ©Copyright 2025 by Downing & Associates

U.S. Secretary of Agriculture Brooke L. Rollins also recently announced the U. S. Department of Agriculture (USDA) is revising National Environmental Policy Act (NEPA) regulations to reduce unnecessary red tape that is killing jobs and raising prices for Americans. This reform allows the Department to efficiently deliver the critical services and funds America’s ranchers, farmers, loggers, and rural communities rely on and corrects the harms caused by decades of unnecessarily lengthy, cumbersome NEPA reviews.

“President Trump is reforming government to be more responsive to the needs of the American people. We have been hamstrung by overly burdensome regulations for decades. USDA is updating and modernizing NEPA so projects critical to the health of our forests and prosperity of rural America are not stymied and delayed for years. So many beneficial and commonsense infrastructure and energy projects have been stymied and delayed in litigation and endless reviews. Overregulation has morphed the NEPA process into bureaucratic overreach on American innovation,” said Secretary Rollins.

USDA is making common sense reforms to ensure the NEPA process does not cause unnecessary delays or stands in the way of American free enterprise. This move institutes reasonable considerations for environmental impacts and streamlines operations.

USDA is issuing one set of department-wide NEPA regulations by rescinding seven agency-specific regulations, resulting in a 66% reduction in regulations. This will allow USDA officials to concentrate resources on projects the public needs while also ensuring that it honors the Department’s legacy of land stewardship.

The Komptech Lacero 8010 is a powerful, high-speed, horizontal grinder purpose-engineered and built for the demanding North American wood waste, biomass, mulch, orchard/land clearing, and organics markets.

/ Feed large waste volumes into the versatile 7'10" open-front hopper / Leverage all-day grinding with a huge 41" diameter downswing drum / Track chassis with optional 3-axle dolly for quick on-road transport

Explore Your Next Opportunity In Wood Waste and Green Waste Grinding thinkviably.com/lacero

www.thinkviably.com/lacero

Anew large-scale composting facility has opened its doors just southwest of the Twin Cities, bringing with it a major boost to local sustainability efforts and an affirmation of Indigenous environmental values, reports www. mprnews.org

On Tuesday, the Shakopee Mdewakanton Sioux Community (SMSC) officially launched Dakota Prairie Composting with a grand opening ceremony. The facility replaces the tribe’s former compost site, the SMSC Organics Recycling Facility, which had been operating since 2011.

The new site is more than an upgrade—it represents a significant step forward in the region’s approach to organic waste. Dakota Prairie Composting is designed to process up to twice as much material as its predecessor and is expected to divert 25,000 tons of food scraps from area landfills every year. The waste will be transformed into nutrient-rich compost and mulch, offering a practical and sustainable alternative to dumping organic matter in landfills.

For Tribal Chairman Cole Miller, the project is rooted in long-held cultural values. “We make decisions for our values as a people, and we’re always going to do that,” Miller said during the ceremony. “We’re going to do the right thing for the environment and our neighbors.”

The expanded facility is already drawing attention not just for its capacity, but also for its technology. Dakota Prairie Composting is one of only two metro-area compost sites equipped with advanced machinery that can separate compostable food waste from non-compostable packaging. Without this system, managing packaged food waste would often lead to contamination and unusable compost.

“Once you have packaged food waste, there’s really no way to compost that effectively without specialized equipment,” said Dustin Montey, director of the facility.

The Minnesota Pollution Control Agency has set an ambitious goal: recycle 75% of waste generated in the metro area by 2030. The launch of Dakota Prairie Composting is expected to play a key role in reaching that target.

“This history-making facility is really going to help our state reduce its reliance on landfills, conserve energy and natural resources, and cut pollution and greenhouse gas emissions,” said Thad Hellman, the tribe’s economic development administrator.

Looking ahead, Dakota Prairie Composting already has the necessary permits in place to expand further, with the long-term goal of processing three times more organic waste than the former site.

“The hope is to leave this world a better place than what we were given,” Miller said. “There’s a lot of landfills, and we’re able to reduce the amount of waste that ends up there. We’re going to put it to good use.”

U.S. Secretary of Agriculture Brooke L. Rollins recently announced the U.S. Forest Service is investing $106 million to support state and landowner efforts to conserve private working forestlands across the country. Funded through the Forest Legacy Program, these projects will protect forests vital to the economic and social fabric of local communities – ensuring they remain productive, working forests for Americans and tourists to use and enjoy.

In total, the Forest Service will fund 10 projects across 177,000 acres of stateand privately owned forestlands in Arkansas, Hawaii, Iowa, Michigan, Mississippi, New York, Oregon and South Carolina.

The Forest Legacy Program is authorized by the Cooperative Forestry Assistance Act Of 1978 (16 U.S.C. 2103c) and operates through voluntary partnerships with states and landowners with the goal of conserving these lands while balancing other local uses and goals. Projects are selected through competitive state and national processes and carried out through conservation easements or fee-simple acquisitions. Lands conserved through the program either remain in private ownership with longterm protections or become new public lands managed by state or local governments.

Privately owned forests represent 60% of the nation’s 704 million forested acres. These lands are essential to the social, economic, cultural, and ecological fabric of local communities and play a critical role in national timber production, supplying 88% of all domestic timber. To date, the Forest Legacy Program has conserved more than 3.1 million acres of forestland nationwide.

Continued from page 3

A Shifting Public and Political Landscape

As interest in cloud seeding grows, so does opposition. In May, Florida banned all forms of weather modification, despite previously allowing cloud seeding under state oversight. The legislation reflects growing public wariness about human interference with the environment.

Some federal lawmakers are also calling for bans. Rep. Marjorie Taylor Greene (R-Ga.) recently declared on social media that no entity should be allowed to modify weather “by any means possible.”

But for Doricko, the future of cloud seeding lies not in fear, but in informed discussion and innovation.

“I believe this technology can help transform our water landscape,” he says. “If we can harness just a bit more of the atmosphere’s moisture, we can not only end drought, but green deserts and make more land viable for farming.”

As climate pressures mount, cloud seeding may yet prove to be one of the tools humanity turns to—not to control nature, but to live more sustainably within it.

To read the full article visit: https://www.theepochtimes.com/us/whatto-know-about-cloud-seeding-5885087.

According to an article on denverite.com, Denver is now home to its first commercial composting facility within city limits, and it’s tucked away in an unlikely spot—a small parking lot near the National Western Center.

At first glance, it might not look like much: two large shipping containers sitting quietly side by side. But inside, food scraps and yard waste are undergoing a high-tech transformation into rich, usable compost. On Wednesday, Compost Colorado officially unveiled the site during a ribbon-cutting ceremony attended by community members and environmental advocates.

“It’s like a metabolism,” said Vann Fussell, the founder of Compost Colorado, as he opened one of the containers to reveal three feet of decomposing organic matter. The air filled with the earthy scent of vinegar and soil—not overwhelming, thanks to a built-in odor control system. “If we were at a larger compost facility, you’d be smelling a lot more smells than you’re smelling right now,” he added.

While most of Colorado’s composting happens in massive facilities far from urban centers, this micro-composting site is something new. Designed to work in small spaces, it uses a smart airflow system that pumps oxygen through food waste and wood chips, encouraging microbes to work faster. Meanwhile, pipes funnel any unpleasant gases into a mulch-and-biochar mix that neutralizes odors.

In just 7 to 14 days, the contents of the container become usable compost. Inside, a conveyor-like system slowly shifts the material to aid the process. The compact system could be a game-changer for urban areas that lack the space for large composting operations.

Fussell hopes the model can be replicated across Denver, with smallscale facilities embedded into neighborhoods. “It’s localized, distributed infrastructure,” he explained—an alternative to trucking waste across long distances.

Compost Colorado was founded in 2018 with the mission of serving Denver residents and businesses that didn’t have access to city composting services. The company now picks up food waste from over 2,000 residential customers and hundreds of businesses—from restaurants to radio stations.

Until recently, all of that waste had to be transported nearly 40 miles to a large facility in Bennet, Colorado. The journey was costly and less than ideal from an environmental perspective. In 2022, Compost Colorado received a $224,000 state grant to create its own facility in the Globeville neighborhood. But after running into permitting problems and lease issues, the plan was scrapped.

“We almost went out of business,” Fussell said.

The vision got a second chance thanks to a partnership with the National Western Center, which offered the company space outside one of its offices for free. In exchange, Compost Colorado will process all the organic waste generated by the sprawling campus and provide 10% of the finished compost to nearby residents in Globeville and Elyria-Swansea—two neighborhoods historically impacted by industrial pollution.

The project received additional funding in the form of a $374,000 grant from the Colorado Department of Public Health and Environment, helping it become a reality.

Currently, the site can process about half of the material collected by Compost Colorado, with the rest still headed to the Bennet facility. But that may soon change.

In 2022, Denver voters passed a ballot initiative called “Waste No More,” which requires apartment buildings and restaurants to offer composting and recycling services. Implementation of the law has been delayed, however, as city council members consider exemptions for small businesses.

At the ribbon-cutting, Brian Loma of the environmental group Green Latinos urged attendees to speak out against weakening the new law. “This partnership is amazing,” Loma said. “It sends a message to our city, where the Colorado Restaurant Association is saying it’s too expensive to divert organic waste.”

With the right support, Compost Colorado could become a model for how cities deal with food waste—cleanly, efficiently, and close to home.

AGITAN® and DEE FO® Defoamers: Fast-Acting, Highly Effective Foam Control

EDAPLAN® and METOLAT® Dispersants: Providing excellent viscosity stabilization, eliminating the need for a separate wetting agent

www.munzing.com

As climate concerns grow, so does the hope that renewable electricity, especially from wind and solar, can one day replace fossil fuels entirely. It’s an inspiring vision, one rooted in our shared desire to reduce greenhouse gas emissions and protect the planet. A recent article on www. americaoutloud.news wonders if it is truly realistic to expect wind and solar to power every part of modern life?

While wind and solar energy have made impressive strides, many experts say these technologies are not yet capable of sustaining an advanced industrial society on their own. That’s because electricity from these sources is intermittent. The sun doesn’t always shine, and the wind doesn’t always blow. And for a world that relies on constant, dependable electricity to power hospitals, factories, transit systems, and more, that presents a major challenge.

Modern energy use goes far beyond electricity. Fossil fuels play a critical role in making many of the everyday products we rely on — from plastics and fertilizers to medical supplies and electronics. Oil and natural gas are also essential raw materials for industrial processes like steelmaking and cement production.

It’s easy to forget just how deeply embedded fossil fuels are in our daily lives. More than 6,000 products are made using petroleum, including clothing, packaging, detergents, cosmetics, and even some medications. Our global transportation system — with its fleets of planes, ships, and over a billion vehicles — is also powered mostly by oil-based fuels. These fuels are energy-dense, easy to transport, and relatively affordable — advantages that wind, solar, and batteries have yet to match at scale.

Wind and solar energy are clean and renewable, but they come with limitations. They depend on weather and daylight, which means they can’t consistently provide “base-load” power — the steady, 24/7 electricity supply needed to keep essential systems running.

Battery storage can help smooth out the gaps, but it’s still expensive, limited in capacity, and energy-intensive to manufacture. In fact, building

and maintaining wind turbines, solar panels, and batteries requires materials like rare earth metals, copper, and aluminum — all of which must be mined, refined, and transported using fossil fuels.

Even electric vehicles (EVs), often seen as the future of green transportation, have hidden fossil fuel footprints. Their batteries require large amounts of energy to produce, and the electricity they run on often still comes from natural gas or coal.

Aiming for a low-carbon future is essential — but moving too fast, without reliable alternatives in place, could have serious downsides. In many developing countries, fossil fuels remain the most practical and affordable way to provide energy for cooking, heating, and transportation. Rapidly phasing them out could risk worsening poverty and health outcomes.

We’ve already seen what can happen when energy policy moves faster than infrastructure can handle. In recent years, some European countries that moved aggressively away from fossil fuels were forced to restart coal-fired power plants when renewable energy fell short. The global race for liquefied natural gas (LNG) during energy shortages showed just how fragile our energy systems can be when pushed too hard, too fast.

To make smart decisions about our energy future, we need a better understanding of how energy systems actually work. Fossil fuels aren’t just “dirty fuels” — they’re also vital building blocks of our modern economy. And while renewables are an important piece of the puzzle, they aren’t a silver bullet.

A sustainable transition will likely include a mix of solutions: cleaner fossil fuel technologies, expanded renewables, nuclear power, and emerging options like hydrogen, carbon capture, and geothermal. No one technology can do it all. That’s why energy literacy — knowing how our energy is produced, used, and interconnected — is so important. When citizens understand the trade-offs and complexities involved, they can better evaluate policies and support realistic, long-term strategies.

The trade dispute between the United States and Canada over softwood lumber has resurfaced in 2025, reigniting one of the longest-standing economic tensions between the neighboring countries. The conflict, which dates back to the early 1980s, centers on accusations of unfair competition and differing approaches to forest management. A recent article on theepochtimes.com (https://www. theepochtimes.com/article/whats-behind-theus-canada-lumber-feud-5887689) explores this dispute. Here is a summary:

What’s at the Heart of the Disagreement?

The core of the dispute lies in the contrasting ways the two countries manage their timber resources. In Canada, around 90 percent of forests are publicly owned, with provincial governments setting the prices and issuing logging rights. In contrast, about 90 percent of timberland in the U.S. is privately owned, where landowners determine when and how much to harvest and set market-based prices.

American lumber producers argue that Canadian timber is subsidized through artificially low stumpage fees—what companies pay to harvest trees on public land. They claim this allows Canadian producers to sell softwood lumber in the U.S. at prices that undercut American competitors, a practice commonly referred to as “dumping.”

In response to these concerns, the U.S. government has periodically imposed duties on Canadian softwood lumber imports. While Canadian lumber is exempt from tariffs under the United States-Mexico-Canada Agreement (USMCA), it is still subject to anti-dumping and countervailing duties.

As of mid-2025, the U.S. Department of Commerce has set a combined duty rate of 14.4 percent on Canadian lumber imports, which could rise to 34.45 percent following a pending administrative review. These duties are intended to counterbalance what U.S. officials view as an unfair cost advantage enjoyed by Canadian exporters.

The lumber trade tension is not new. The U.S. first investigated Canada’s stumpage system in 1982. Since then, the two countries have engaged in numerous legal battles through organizations such as the World Trade Organization (WTO) and, formerly, under the North American Free Trade Agreement (NAFTA). They have also signed several softwood lumber agreements in attempts to resolve the conflict, none of which have led to a permanent solution.

Currently, the U.S. lumber industry is pursuing a fifth round of trade cases, pressing for stronger enforcement of duties and trade rules.

Canada remains a major global exporter of softwood lumber, with forestry products making up 7.5 percent of its total exports—about $33.4 billion annually. Nearly 70 percent of those forestry exports are sent to the U.S., making the American market critical to the Canadian industry.

However, U.S. officials have recently begun examining whether these imports could pose a national security risk. A Section 232 investigation, launched in July, aims to determine if foreign subsidies and import practices are harming America’s wood supply chain. A report is expected by the end of 2025.

The dispute also highlights divisions within the U.S. economy. Lumber producers, represented by the U.S. Lumber Coalition, support tariffs and trade duties to protect domestic jobs and encourage investment in American sawmills.

Meanwhile, groups like the National Association of Home Builders (NAHB) argue that these policies inflate lumber prices and harm housing affordability. NAHB representatives say the tariffs act as a tax on builders and consumers, contributing to rising home prices.

The U.S. Lumber Coalition counters that lumber makes up only a small portion of a home’s total cost and that lumber prices have fallen sharply since their peak in 2021, even as housing prices have continued to rise.

Supporters of trade restrictions also argue that reducing Canadian imports is helping the U.S. lumber industry expand. Since 2016, American sawmill capacity has grown by about 9 million board feet, while Canadian capacity has shrunk by about 3 million. Advocates say this proves the U.S. can become more self-sufficient if Canadian dumping is curbed.

Despite decades of negotiations, legal battles, and temporary agreements, the U.S.–Canada softwood lumber dispute remains unresolved. With new investigations underway and tariffs increasing, both nations continue to grapple with how to balance fair trade, economic growth, and industry protection.

As the debate continues, the outcome will have far-reaching implications not just for lumber producers and homebuilders, but also for international trade relations and the North American economy.

BY ROBERT LAGASSE, EXECUTIVE DIRECTOR

For several years, the MSC Certification Committee has been investigating consumer interest in all-natural/organic garden products. While other organizations may address the need to identify inputs for USDA Certified Organic farming and crop production, a national consumer survey conducted in 2023 showed only about 4% of consumers could identify or even had a vague understanding of existing “organic” products in retail markets.

In that same survey, the Certification Committee discovered that the majority of lawn & garden consumers view “all-natural” and “organic” as equal/the same. What most consumers want is simply products with all-natural ingredients and no chemicals or pesticides.

The committee began investigating the development of a standard for all-natural garden soils which turned out to be complex due to the multiple ingredients used in various types of growing media and landscape soils and the extensive number of alternative and synthetic inputs to define and qualify. The committee hopes to have an all-natural soil standard soon.

At the same time, the Certification Committee took a new approach last year and began developing a standard for all-natural mulch. The committee draft was sent to the Board last summer. After Board review, the draft guideline was sent to the entire MSC membership, announced to over 4,000 industry stakeholders and submitted to all 50 state agriculture departments for review and comment. The review period ended in January 2025, changes were made and resubmitted to the Certification Committee and then the Board of Directors in February.

On March 25, the Mulch & Soil Council held a Special Membership

Meeting via ZOOM. The meeting was called by Council President Jim Weber (Ohio Mulch) following the MSC Board of Directors’ vote in February to submit the final draft of the new standard for Product Guidelines for Certified All-Natural Horticultural Mulches (CANM) to the Council membership for adoption. The guideline was unanimously approved. The CANM will now serve as the basis for expanding the MSC Product Certification Program through the creation of an ADD-ON certification for “Mulch & Soil Council Certified All-Natural” mulch products. In addition to creating the CANM, the Certification Committee concurrently defined new all-natural testing protocols, a redesigned application process, an add-on license agreement, and a special Certified All-Natural” logo to help consumers identify next level MSC Certified products in the marketplace. Final preparations are being made to launch the new Certified All-Natural Horticultural Mulch product category in August.

CANM certification is in addition to (not instead of) MSC Mulch Product Certification under the Uniform Voluntary Product Guidelines for Horticultural Mulches, Growing Media and Landscape Soils and Amendments (UVPG).

• If you have an existing MSC Certified Mulch product that would qualify as all-natural under the CANM guideline, you can apply to ADD-ON CANM certification.

• If you have a mulch that is NOT currently certified by MSC and you would like to certify it under the CANM guideline, you must first certify the product under the UVPG standard and then add the CANM certification.

More information will be available in August. If you have any questions, please contact the MSC office.

The scrolling floor system uses a wide belt that stores extra belting on a front drive roll which rolls onto a rear drive roll during unloading, just like a scroll. After the product is unloaded, the belt is quickly returned to the front roll, completing the process in just minutes!

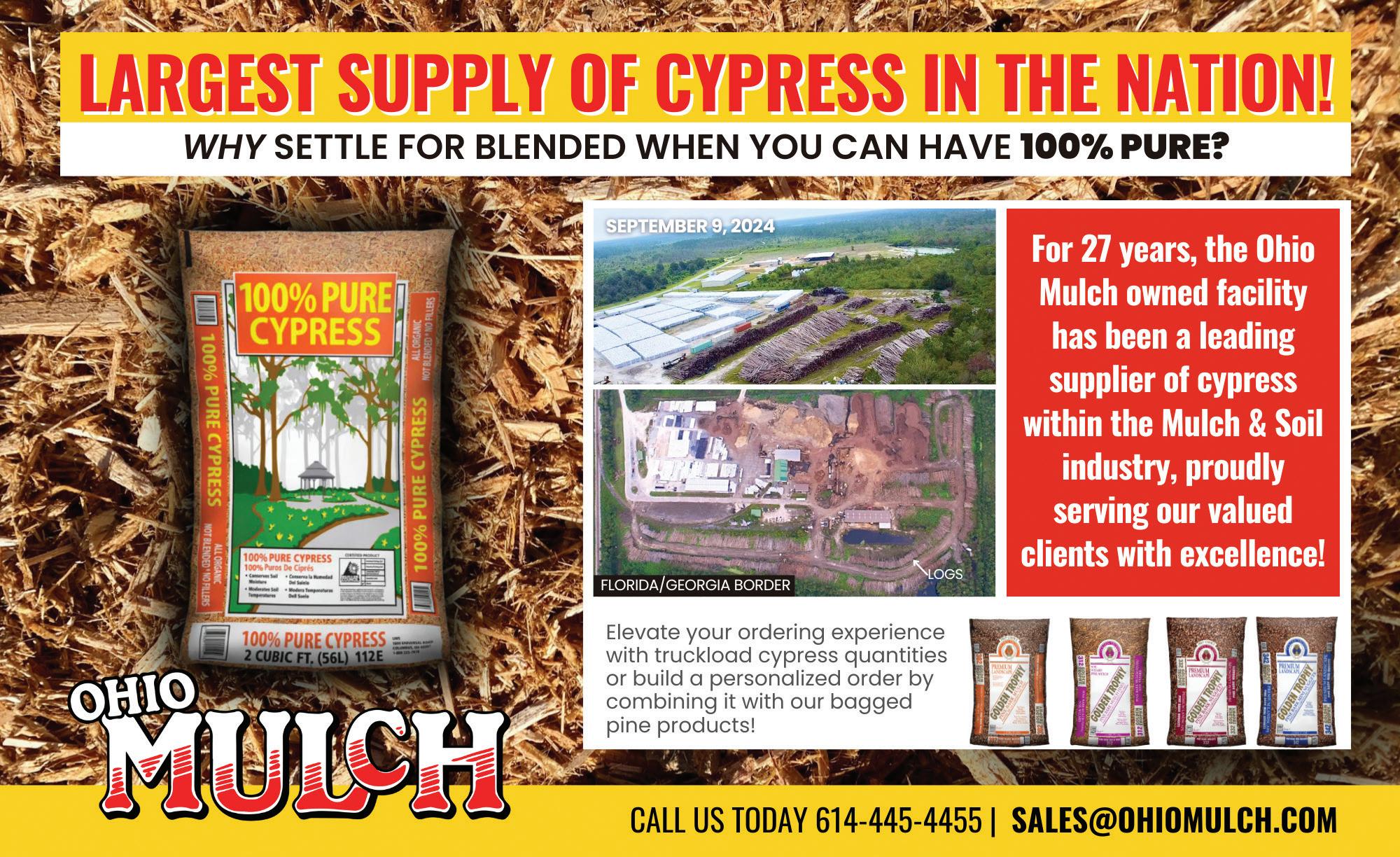

The industry has long relied on Precision Husky Corporation to produce the highest quality, most rugged equipment. Our High Volume Chip Screens are just one example. Precision HV Series Screens have heavyduty tubular steel support frames, and a TEFC motor which rotates the screening surface up to 300 RPM, supported by U-joints at each

corner. They are available in sizes from 5' x 10' to 10' x 20'.

You can invest in our equipment with confidence, and know it will perform for many years to come. Call us today to discuss your needs, as well as the newest options available for our line of sawmill, logging and wood waste recycling equipment.

Continued from page 14

Extended Producer Responsibility (EPR) is quickly reshaping the landscape of packaging and waste management in the U.S. As more states adopt or propose sweeping EPR laws, it’s crucial for businesses in every sector — including the mulch and soil industry — to understand how these changes may affect their operations and bottom line.

What is EPR? EPR shifts the financial and operational responsibility for packaging waste away from municipalities and taxpayers to the producers of packaged products. While earlier

EPR programs targeted niche items like paint or mattresses, new legislation aims to cover all packaging materials, regardless of product type or industry.

Under these new frameworks, businesses must fund the collection, recycling, composting, or disposal of the packaging they place into the market. This fundamentally changes the cost structure of waste management, with producers expected to pay annual fees based on the type and volume of packaging used.

Who is a “Producer”? In most cases, the “producer” is defined as the brand owner (the company whose name appears on the packaging) not necessarily the manufacturer of the packaging itself.

Fill It. Bag It. Palletize It. Protect It. One Seamless Solution.

Mulch, soil, aggregates — no problem. nVenia’s equipment handles abrasive products and harsh conditions with: Durability Abrasion Resistance Efficiency Full Line Systems

Tough jobs. Proven performance. Trust nVenia to deliver.

Key Features of Packaging EPR Laws:

• Mandatory Reporting: Businesses must report packaging types and volumes to a Producer Responsibility Organization (PRO).

• Fee Payments: Producers fund the system via payments to a PRO, which manages recycling and waste processes.

• State Recycling Targets: Many laws include aggressive recycling goals (e.g., California mandates a 65% recycling rate by 2032).

• Material Incentives: Higher fees are levied for hard-to-recycle materials, while discounts may be offered for packaging that incorporates recycled content or is fully recyclable or compostable.

Where Is EPR Happening?

• Enacted Laws: California, Colorado, Maine, Maryland, Minnesota, Oregon, and Washington have already enacted EPR legislation, with varying implementation timelines starting as soon as June 2025.

• Proposed Legislation: Connecticut, Hawaii, Massachusetts, New Jersey, New York, North Carolina, Rhode Island, and Tennessee — are actively considering similar bills.

Industry Concerns: The broad scope of these new laws introduces significant challenges:

• Cost Shifting: Businesses will ultimately pass new compliance costs on to consumers in the form of higher prices.

• Delegated Authority: Many laws hand regulatory powers to nongovernmental PROs, raising concerns about transparency and accountability.

• Regulatory Complexity: Businesses must navigate a growing patchwork of state specific requirements.

MSC Recommendations: The Mulch & Soil Council (MSC) advises members to actively monitor and oppose EPR legislation in their states. The Council warns that the expansive application of these laws creates new financial burdens and regulatory uncertainty, with unclear long-term environmental benefits.

Steps to Prepare: If your products are sold in EPR states, MSC recommends the following actions:

1. Assign a compliance lead within your organization.

2. Catalog all packaging materials used across product lines.

3. Document sustainability efforts related to packaging. Continued on page 18

Continued from page 16

4. Register with state-recognized PROs, such as the Circular Action Alliance (CAA) for CA, OR, and CO.

5. Stay informed through MSC’s Weekly State & Federal Legislative Reports.

Stay Engaged: For more resources and guidance, MSC members can access detailed tracking reports through the MSC Legislative Monitoring section. As the regulatory environment continues to evolve, staying informed and prepared is critical to managing compliance and mitigating costs. For questions or further assistance, contact the MSC office at info@ mulchandsoilcouncil.org.

Consistent with the U.S. Department of the Treasury’s March 2, 2025 announcement, the Financial Crimes Enforcement Network (FinCEN) has issued an interim final rule that removes the requirement for U.S. companies and U.S. persons to report beneficial ownership information (BOI) to FinCEN under the Corporate Transparency Act.

In that interim final rule, FinCEN revises the definition of “reporting company” in its implementing regulations to mean only those entities that are formed under the law of a foreign country and that have registered to do business in any U.S. State or Tribal jurisdiction by the filing of a document with a secretary of state or similar office (formerly known as “foreign reporting companies”). FinCEN also exempts entities previously known as “domestic reporting companies” from BOI reporting requirements.

Thus, through this interim final rule, all entities created in the United States — including those previously known as “domestic reporting companies” — and their beneficial owners will be exempt from the requirement to report

BOI to FinCEN. Foreign entities that meet the new definition of a “reporting company” and do not qualify for an exemption from the reporting requirements must report their BOI to FinCEN under new deadlines, detailed below. These foreign entities, however, will not be required to report any U.S. persons as beneficial owners, and U.S. persons will not be required to report BOI with respect to any such entity for which they are a beneficial owner.

Under the interim final rule, the following deadlines apply for foreign entities that are reporting companies:

• Reporting companies registered to do business in the United States before the date of publication of the IFR must file BOI reports no later than 30 days from that date.

• Reporting companies registered to do business in the United States on or after the date of publication of the IFR have 30 calendar days to file an initial BOI report after receiving notice that their registration is effective.

For more information, see Interim Final Rule: Questions and Answers at https://www.fincen.gov/boi/ifr-qa.

Anew hybrid termite — a cross between Asian subterranean and Formosan species — is spreading across Florida, raising alarms among scientists and homeowners alike.

Researchers at the University of Florida’s Institute of Food and Agricultural Sciences (UF/IFAS) first noticed the hybrid in 2021. “We saw winged termites that didn’t look right,” said Dr. Thomas Chouvenc, a UF/

Continued on page 20

Continued from page 18

IFAS entomologist. “Now, we’ve confirmed these hybrids are forming their own colonies.”

At UF/IFAS’s Fort Lauderdale lab, home to 20–25 million termites, researchers are working to understand and control this threat. “You must first learn how to keep termites alive to learn how to kill them,” Dr. Chouvenc explains.

The hybrids pose serious risks: their ability to form independent colonies suggests both parent species have likely been present for over a decade, possibly causing unseen damage. Even more concerning, the hybrids may now survive in new regions, potentially expanding across Florida and beyond.

Dr. Chouvenc urges early action. Correct identification is key, as drywood and subterranean termites require different treatments. Partnering with licensed pest control professionals is advised. Homeowners and businesses can visit the UF Termite Distribution Map and the UF/IFAS website for the latest information and sample submission guidance.

Caution for Mulch Producers: With hybrid termites expanding, horticultural mulch producers should expect a potential rise in consumer complaints. Proper identification of insect infestations and their source is essential to avoid misattributed issues and protect product reputation.

The 2025 Garden Trends Report by the Garden Media Group (gardenmediagroup.com/trends) highlights a dynamic shift in consumer gardening preferences that offers timely opportunities for producers of garden mulch and soil products.

A central theme, the urban green renaissance, signals increased demand for products that support soil health and natural aesthetics in heavily paved environments. As cities and HOAs move to reintegrate greenery—seen in initiatives like Philadelphia’s transformation of vacant lots—highquality mulches and living soils will play a vital role in stormwater management, urban cooling, and biodiversity support.

The Lived-In Gardens trend further underlines this need. Consumers now embrace layered, mature plantings and naturalistic landscapes where soil vitality and mulch selection enhance both visual richness and ecological value. Encouraging moss lawns and dense, multi-layered planting means mulch producers can market products that promote moisture retention, soil health, and a naturally aged look.

Living Fences represent another growth area. With homeowners seeking biodiversity-rich borders instead of traditional fences, there is a clear call for soil blends that support dense, long-term planting and mulches that suppress weeds while enriching the soil. The cost savings and ecological benefits of living fences—highlighted by the report—make this trend particularly appealing.

Additionally, the Foraged movement points to increased consumer interest in native plants and wildflower meadows, where natural mulches and minimally processed soils can meet the demand for authenticity and sustainability.

Finally, the No Vacancy trend—reclaiming urban spaces for nature— encourages producers to promote soil products that remediate compacted, degraded urban soils and mulches that restore ecological function.

In summary, this year’s trends open multiple avenues for mulch and soil producers to innovate and market products aligned with evolving consumer values: sustainability, aesthetics, biodiversity, and climate resilience. Aligning offerings with these priorities will position brands as essential partners in the growing movement toward greener, healthier urban and suburban landscapes.

The Mulch & Soil Council is the national association of producers of horticultural mulches, consumer potting soils and commercial growing media. Its mission is to define quality products and promote an open market and fair competition. For more information about MSC, visit www. mulchandsoilcouncil.org or call 806-832-1810.

Stay

Durability

Invest

WriggleBrew, an Orlando-based biotech startup, has been awarded a $1.2 million Phase II grant from the National Science Foundation (NSF) to further develop a groundbreaking new process for turning dirty plastic waste into safe, nutrient-rich fertilizer using earthworms and beneficial microbes. The process eliminates all traces of micro and nano-plastics, and leaves behind a useful, organic fertilizer precursor.

Founded in 2022, WriggleBrew produces OMRI-listed organic liquid fertilizer made from worm castings, chitin, mycorrhizae, and rhizobacteria. Its flagship product is a novel organic fertilizer that is safe for people, pets, pollinators, and waterways. But behind the scenes, the company has also been developing a revolutionary method to deal with one of the planet’s most persistent environmental problems: plastic.

Utilizing the same earthworms the company is currently farming en-masse for its fertilizer production, the new process, named “Poly-composting” enables the rapid disintegration and effective destruction of plastic waste and enables its conversion into fertilizer.

The new NSF-funding will support a scaled-up research endeavor that will pilot plastic collection and bioconversion in several locations around the state of Florida. The novel system breaks down common plastic wastes such as polystyrene foam and plastic bags (currently recycled at low rates) into compounds that can be digested by earthworms. The process not only keeps plastic out of landfills and waterways but also converts it into a safe, microplastic-free soil amendment that can regenerate degraded farmland.

“This grant allows us to scale a system that doesn’t just recycle or sequester plastic waste, but actively eliminates it,” said Sam Baker, CEO of WriggleBrew. “We’re honored to receive NSF’s support to advance a technology - it’s funding that’s going to change the way things work”.

The grant will fund new research, equipment purchases, and expanded pilot production at WriggleBrew’s facility. The company is also expanding its own worm farming operation and in-house microbe lab to fully vertically integrate the process from waste input to final fertilizer output.

RUSSELLVILLE, AR, May 1, 2025 Denali, one of the nation’s largest organic recycling companies, recently announced the acquisition of Wallace Farm, Inc., a family-owned composting, soil, and mulch products company operating two large-scale facilities in North Carolina. Wallace Farm recycles food waste, green waste, and other organics into high-quality compost, mulch, and soil products.

The acquisition strengthens Denali’s large and growing organic collection operations in the Southeast by adding organics processing capacity through the two Wallace compost sites. Additionally, the move will support expanded production and distribution of Denali’s sustainable soil products, including the ReCirculate® bagged compost and soil product line.

Wallace Farm began commercial composting on the family’s farm 30 years ago. The company has two facilities, a 75-acre operation in Huntersville, near Charlotte, and a 162-acre facility in Advance, near Greensboro/Winston Salem.

“We’re pleased to welcome Wallace Farm and its team to the Denali family,” said Todd Mathes, CEO of Denali. “We look forward to continuing their operational excellence and building on their strong regional presence to further our commitment to building a resilient circular economy by transforming organic waste into renewable products.

With the addition of Wallace Farm’s facilities, Denali now operates a network of 26 composting sites across the U.S., leveraging innovative technology to maximize organic waste landfill diversion. The acquisition also reflects Denali’s broader strategy of building a robust, integrated system as the market leader in organics recycling.

“I’m proud of my family’s legacy in the communities we serve and joining Denali, which shares our family values, goals, and high standards of quality and customer service,” said Eric Wallace, President of Wallace Farm, Inc.

Cloud Seeding: The 80-Year-Old Weather Technology That’s Sparking New Debate PAGE 1

Secretary Rollins Rolls Back Overly Burdensome Environmental Regulations to Unleash American Innovation PAGE 4

USDA Invests $106M to Keep Working Forests Working PAGE 8

Understanding the Long-Running U.S.–Canada Lumber Dispute PAGE 13

News From The Mulch & Soil Council PAGE 14

$1.2M Grant Awarded to Company Destroying Plastic with Earthworms PAGE 22