Study Suggests Livestock Manure Compost Can Help Remediate Heavy Metal-Contaminated Soils

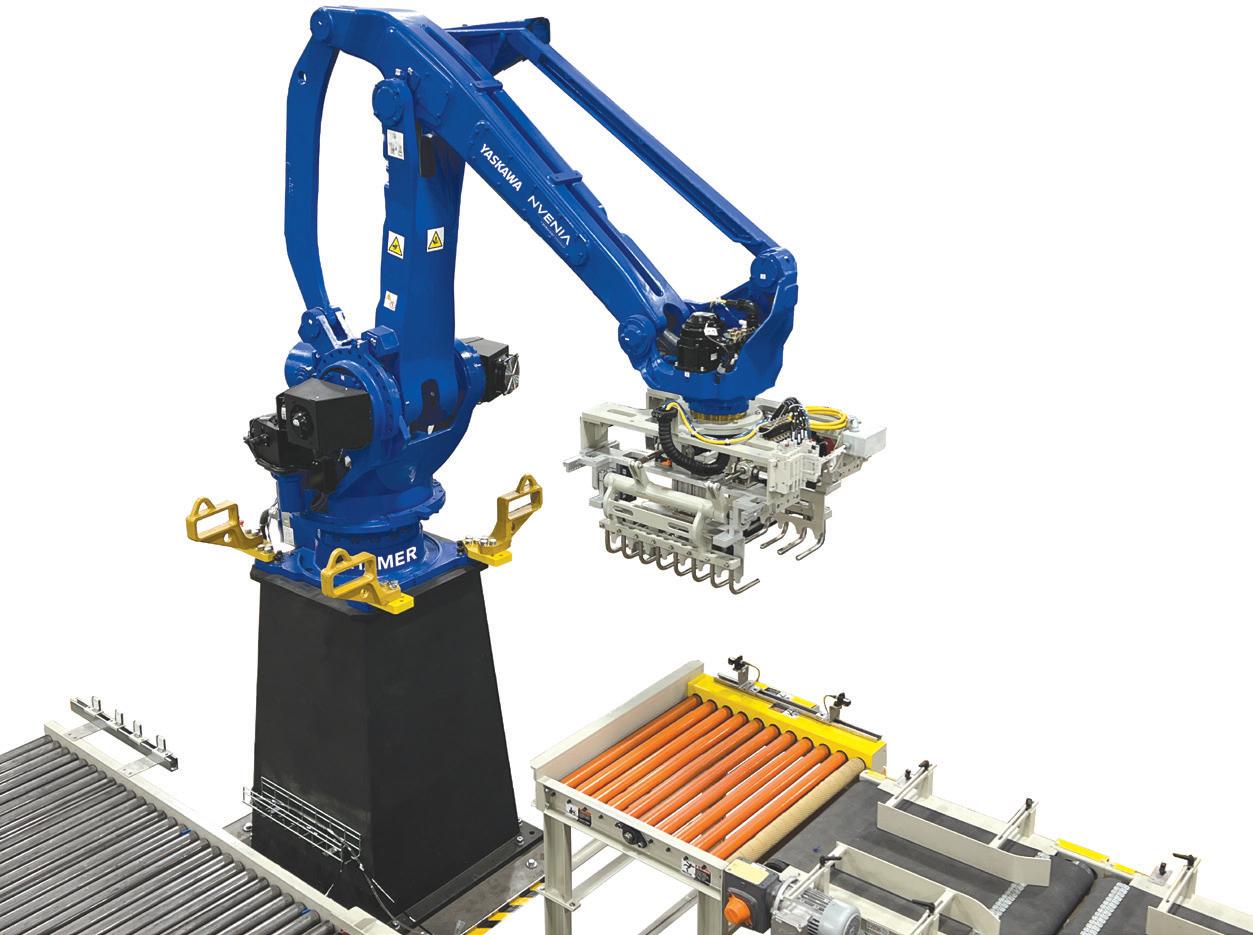

BAgging / PAlletizing equiPment

Amadas industries – pg 20

nVenia – pg 4

comPoSt turner

resource machinery & engineering – pg 22

conVeyorS & conVeyor PArtS

Amadas industries – pg 20

Smalis conveyors – pg 7

equiPment SAleS grindertrader.com – pg 4

grinderS, chiPPerS & Screening SyStemS

Amadas industries – pg 20

Bandit – pg 11

diamond z – pg 18

hogzilla – pg 8

Precision husky – pg 5

rotochopper – pg 13

Sundance grinders – 14

Vermeer corporation – 7

Viably – pg 17

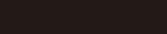

mulch coloring equiPment / colorAntS

Agricoatings – pg 9

Amerimulch – pg 15

Britton industries – pg 6

cmc – pg 23

colorbiotics – pg 2

Faltech – pg 10

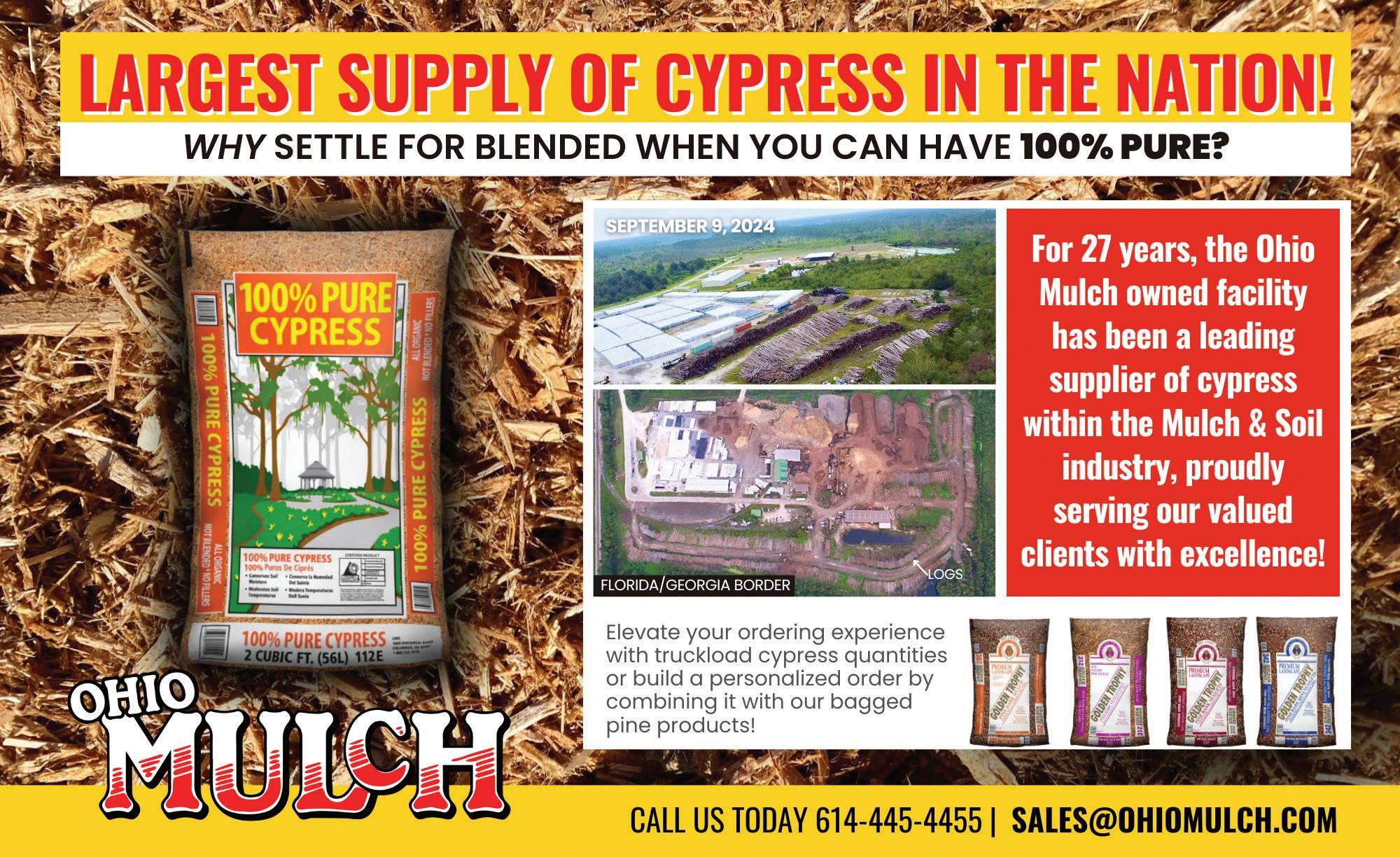

Florida coastal colors – 19

milagro rubber inc – pg 12

t.h. glennon co – pg 24

mulch SuPPlierS

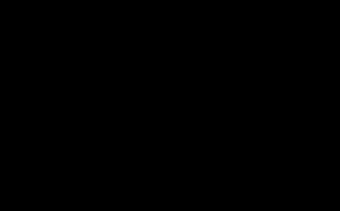

ohio mulch – pg 16

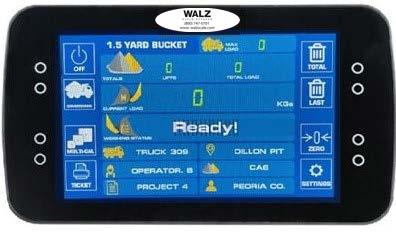

PAyloAd Weighing & meASuring SyStemS

Walz Scale – pg 21

trAilerS

Weaver Systems – pg 14

trommel BruSheS

Power Brushes inc – pg 4

WeAr PArtS

Armorhog – pg 10

Soil contamination by heavy metals (HMs) is a growing environmental concern, particularly in areas affected by industrial activities such as mining and metallurgy. These pollutants persist in the environment, posing risks to agricultural productivity, soil health, and human safety. One promising method for mitigating heavy metal contamination is the use of organic amendments, such as livestock manure compost, to stabilize metals and improve soil quality.

Human activities like non-ferrous metal mining and industrial operations contribute to soil pollution by introducing heavy metals such as lead (Pb), cadmium (Cd), zinc (Zn), and copper (Cu) into agricultural lands. Once in the soil, these metals cannot be biodegraded and may accumulate over time, leading to reduced soil fertility, lower crop yields, and potential health hazards through the food chain.

In mining regions, such as the Taojia River Basin in China, long-term industrial activities have resulted in heavy metal contamination in both vegetable fields and rice paddies. Contaminants from mining waste and industrial runoff can degrade soil structure, alter microbial communities, and increase the mobility of toxic metals, threatening both agriculture and the ecosystem.

Organic amendments, such as composted livestock manure, offer an effective and sustainable way to remediate contaminated soils. These materials can enhance soil fertility by improving organic matter content, modifying soil pH, and promoting microbial activity,

which in turn influences the bioavailability of heavy metals.

Research indicates that both sheep manure (SM) and chicken manure (CM) composts can help stabilize lead and other heavy metals in contaminated soils. The key mechanisms through which organic amendments aid in remediation include:

1. Soil p h m odification: Compost applications generally increase soil pH, creating conditions that reduce heavy metal mobility.

2. o rganic m atter e nhancement: Higher organic matter levels improve soil structure and enhance the immobilization of heavy metals by binding them to organic compounds.

3. m icrobial Activity Support: The presence of organic materials fosters beneficial microbial growth, which can influence heavy metal transformation and stabilization.

Field studies have demonstrated that compost application can lead to significant improvements in soil quality and reductions in heavy metal availability. In vegetablegrowing soils, the application of 10% CM compost resulted in the most effective Pb immobilization, reducing its bioavailable content to 11.561 mg/kg. Similarly, in rice paddies, 10% CM compost application improved soil fertility and decreased Pb and Cd uptake by plants, reducing their transfer to edible crops.

Why is Colorbiotics the choice of more mulch producers than any other name in the industry?

A. Large stock of colorant for on-time delivery

B. Entire lineup of mulch coloring equipment

C. Complete inventory of replacement parts

D. Coast-to-coast fleet of service vehicles

Answer: All of the above

EPA Will Review “Waters of the United States”

The Environmental Protection Agency (EPA) announced in March that it will be reviewing the definition of “waters of the United States” in light of the 2023 Supreme Court ruling in Sackett v. EPA, reports justthenews.com. This review aims to simplify regulations and reduce the costs associated with permitting.

The goal of the EPA’s review is to streamline the process, making it easier for businesses, farmers, and landowners to navigate while ensuring that water resources remain protected. EPA Administrator Lee Zeldin emphasized that the agency seeks to maintain clean water for all Americans while providing clear, consistent regulations across states, particularly benefiting farmers and small businesses.

The definition of “waters of the United States” determines when federal permits are required for activities that may impact bodies of water. Under the previous, broader definition, farmers, landowners, and businesses often had to obtain expensive federal permits or face penalties for failing to do so, even on private property.

However, following the Sackett v. EPA ruling, the Supreme Court narrowed the scope of what qualifies as “waters of the United States” to include only relatively permanent bodies of water, such as streams, rivers, lakes, and oceans, rather than a wider range of waters. This shift is expected to reduce the number of situations requiring federal oversight and regulation.

Oldcastle APG

Acquires Mulch & Soil Division of H&H General Excavating

Atlanta (BUSINESS WIRE)

Oldcastle APG, a CRH Company, recently announced its acquisition of the bagged and bulk mulch and soil assets of H&H General Excavating. The addition of the mulch and soil assets and facilities located in Spring Grove and York, Pa., enables Oldcastle APG to extend its offerings, enhance its service abilities, and widen customer access to a broader range and variety of products.

“We are pleased to welcome H&H’s mulch and soil business to the Oldcastle APG family, extending our Lawn & Garden capabilities in the Northeast,” says Tim Ortman, President, Oldcastle APG. “The addition of its highquality product lines will help us better serve our customers and advance our mission to help others Live Well Outside.”

These products will be integrated into Oldcastle APG’s Lawn & Garden business, aligning with APG’s other recent acquisitions, reinforcing its growing presence in key areas along the East Coast, and supporting efforts to build the most comprehensive portfolio of outdoor solutions.

VISIT BOOTH 1243

When the Elements Fight Back, We Power Through

For packaging materials like mulch and soil, equipment must be durable, abrasion-resistant, and efficient to handle tough production environments. Our machinery is built to meet these challenges head-on.

From bagging to bulk in-feed, filling, automation, palletizing, and load securing, our equipment offers:

• Superior Durability: Designed for harsh environments.

• Abrasion-Resistant Steel: Withstands tough materials

• Efficient Performance: Keeps production lines running smoothly

• Versatile Applications: Ideal for industrial and natural materials.

For packaging solutions that perform under pressure, trust nVenia to deliver

Minneapolis

to Become First City in North America to Own and Operate Biochar Facility

Minneapolis is making history by becoming the first city in North America to own and operate a biochar facility.

Biochar is a specialized charcoal created by heating wood waste to 700 degrees in a lowoxygen environment. The Minneapolis biochar facility will be located at 670 25th Ave. SE and have the capacity to annually:

• Process over 3,000 tons of wood waste

• Produce over 500 tons of biochar

• Remove nearly 3,700 tons of carbon dioxide which is the equivalent of taking over 789 cars off the road

Construction on the facility is expected to begin this spring with biochar production beginning in the summer or early fall.

“Seeing this project come to life has been many years in the making and is currently the City’s only existing carbon-negative project,” said Jim Doten, Carbon Sequestration Program Manager. “Biochar is a versatile product that will benefit the green infrastructure of our city and its soil by creating drought resistance and improving nutrient delivery. I’m thrilled about the positive impact this facility and biochar will have on Minneapolis.”

Xcel Energy recently signed an agreement with the City of Minneapolis to supply wood waste for biochar production at the facility. The agreement allows Xcel Energy to provide tree trimmings and other vegetation from its power line maintenance operations to help produce the biochar.

“Minneapolis is at the forefront of biochar production, and partnerships like this are crucial to our mission of achieving carbon neutrality by 2050,” said Mayor Jacob Frey. “Collaborating with Xcel to repurpose tree trimming and vegetation into biochar not only strengthens our sustainability efforts but also accelerates our progress toward a greener future.”

Xcel Energy conducts routine tree trimming and other vegetation management services to minimize the risk of interference with electrical equipment. In 2024 alone, crews worked on more than 50 miles of distribution lines and 20 miles of transmission lines in Minneapolis, leaving an abundance of wood waste in need of disposal.

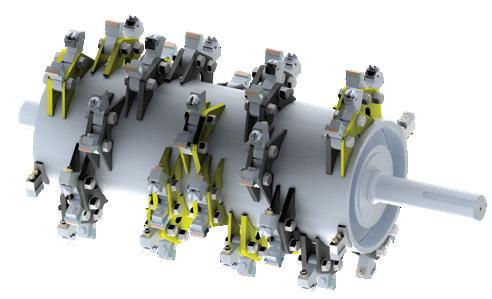

WHEN GENTLE PERSUASION JUST ISN’T ENOUGH.

For sixty years, the industry has relied on Precision Husky Corporation to produce the highest quality, most rugged equipment. Today’s products are ready to lead the way for the next sixty years.

Our horizontal and tub grinders are just one example. They are the most powerful, easiest to use grinders in the industry, designed with innovative

features and advanced technologies to give you the power and production needed to tackle the most demanding grinding operations.

You can invest in our equipment with confidence, and know it will do the job for many years to come. Call us today to discuss your needs and learn more about our high-performance products.

H-3060T Horizontal Grinder

OUR RECIPE

COLORANT SUCCESS Trump Administration Moves to Strengthen U.S. Lumber and Timber Industries

On March 1, 2025, President Donald Trump signed an executive order and a memorandum aimed at bolstering the U.S. timber and lumber industries, addressing what the White House has described as a significant crisis in both supply and demand, reports theepochtimes.com . These actions are part of a broader strategy to revitalize domestic production, enhance forest management, and reduce dependency on foreign lumber imports.

The executive order, titled “Freeing Our Forest,” directs federal agencies to reverse policies that have hindered timber production and outlines steps to accelerate the growth of the U.S. lumber industry. Specifically, it calls on federal departments and agencies to collaborate in finding ways to expedite the timber production process, improve forest management, and increase the availability of lumber for domestic use.

The order highlights that timber production should be paired with better land and forest management practices. It also places a strong emphasis on ensuring that federal actions align with important environmental laws, including the Endangered Species Act (ESA) and the Tribal Forestry Protection Act.

The executive order calls for a coordinated effort across several key federal agencies, including the U.S. Department of the Interior, the U.S. Department of Agriculture, the Bureau of Land Management, the U.S. Forest Service, the U.S. Fish and Wildlife Service, and the Department of Commerce. These agencies are tasked with submitting plans and recommendations to increase timber production while improving forest health and wildlife habitat. The agencies are also expected to identify and eliminate unnecessary delays in the permitting process related to timber production.

Importantly, the executive order directs agencies to review existing regulations, policies, and actions that may be impeding timber production, with the goal of removing any burdens that could slow down the industry’s growth.

One of the key goals of the executive order is to improve forest management practices. The order stresses that forest management not only helps increase timber supply but also plays a critical role in wildfire prevention and habitat preservation for wildlife. By better managing forests, the administration aims to reduce the risks of devastating wildfires and enhance the overall health of ecosystems.

The White House has emphasized that the timber industry should not be limited to the cutting of new trees but also include the salvaging of fallen trees. This process can lower the costs of construction materials and reduce the environmental impact of unmanaged forests, while also improving the habitat for fish and wildlife.

In addition to the executive order, a memorandum directs U.S. Secretary of Commerce Howard Lutnick to investigate the potential national security risks associated with the importation of lumber. The memorandum outlines a comprehensive review of the timber and lumber importation system, including an assessment of the current and projected domestic demand for timber and lumber, as well as foreign supply chains.

Lutnick is tasked with evaluating whether the influx of lumber imports—particularly from countries like Canada, Germany, and Brazil— could pose a threat to U.S. national security. The investigation will focus on the impact of foreign government subsidies and unfair trade practices, such as the dumping of subsidized lumber into U.S. markets, which can undermine domestic production and drive up prices.

The investigation is also expected to explore ways to strengthen the U.S. timber and lumber supply chain, potentially through measures like tariffs, export controls, or incentives aimed at boosting domestic production.

Continued on next page

The Trump administration has argued that increasing domestic timber and lumber production could have significant economic benefits, including job creation. The timber industry in the U.S. has the potential to support nearly 1 million jobs, a number that could rise as domestic production expands to meet growing demand.

Currently, the U.S. imports a substantial portion of its lumber, with the volume of imported lumber increasing nearly elevenfold from the early 1990s to the present day. Reducing reliance on foreign imports is seen as a critical step in ensuring that the U.S. remains competitive in the global lumber market and maintains control over its supply chain.

Through this executive order and memorandum, the Trump administration is working to address both supply and demand challenges in the U.S. timber and lumber industries. By improving forest management, streamlining timber production processes, and reducing dependence on foreign imports, the administration aims to create a more sustainable and competitive domestic lumber market. The policy shift also seeks to strengthen U.S. national security by minimizing the risks posed by foreign imports and supporting job growth within the industry.

News From the Mulch & Soil Council

By RoBeRt LaGasse, executive DiRectoR

Certification Committee Report

The Certification Committee convened On February 3 for its scheduled meeting at the New York – New York Hotel in Las Vegas.

Over the past year, the program has seen significant growth, with 302 certified products as of January 2025—a notable increase from 256 products at the same time the previous year. The program was also in the process of reviewing applications for two more mulch products, reinforcing an upward trend in participation.

Financially, the program is in a strong position. Revenues have increased due to a rise in application and testing fees, and while licensing fees had taken a dip the previous year, they had since rebounded. Efforts to reduce costs, particularly in audit-related travel, have paid off, contributing to a net operating surplus. However, there were still obligations tied to these funds, particularly for testing requirements associated with renewals.

Field audits for the 2025 season were also on the agenda. The team planned to conduct inspections across different regions, starting in the Southeast in March, moving to the South, and continuing through the Western, Northeast and Central regions by mid-year as the gardening season rolls out across the country.

Due to supply shortages, some of the plant species traditionally used in growth tests — basil, impatiens, and zinnias — had become unavailable for the first time in twenty years. After consulting industry experts, the committee settled on substitute varieties: Genovese basil, Beacon Bright Red impatiens, and Magellan Yellow zinnia. The changes were

previously voted by mail ballot and formally re-approved to ensure testing could continue without disruption.

The meeting then shifted focus to the All-Natural Certification program, an initiative designed to establish clear guidelines for mulch products free from synthetic or recycled wood materials. After reviewing public feedback collected during the open public comment period, the committee made minor adjustments to the proposed guidelines, including clarifying product definitions and removing any weight-based measures from the standards. Pine straw was officially included as a recognized mulch type under the certification. The committee also reviewed the certification application, which required manufacturers to confirm their products did not contain any synthetic or reprocessed wood, chemical additives, or unnatural stains. To strengthen oversight, a verification process was added, allowing the committee to request video inspections of manufacturing sites to confirm compliance.

Setting appropriate fees for the add-on All-Natural Mulch Certification program was a crucial topic of discussion. The committee settled on a $200 application fee, a $200 testing fee, and a $650 licensing fee, with an annual renewal fee of $650. These fees were added to the current MSC Certified Mulch program and structured to cover the additional costs of reviewing special applications, conducting more detailed inspections, and maintaining oversight while keeping the program accessible to participants. The current MSC Certified Mulch program will continue unchanged for those who wish to certify old or new products at that level.

Continued on page 10

News From MSC

Continued from page 8

A particularly lively debate arose over the certification of all-natural bulk mulch, a topic that raised concerns over maintaining product integrity once it left the manufacturer’s control. Some members pointed out that other certifying agencies had special requirements that allowed them to certify bulk materials leading to questions about whether a similar approach could be taken for the MSCs all-natural mulch. The discussion ended with a consensus that further research would be done before making a final decision.

Standards Committee Report

The Standards Committee met on Feb. 3 in Las Vegas to review updates to the Uniform Voluntary Product Guidelines for Horticultural Mulches, Growing Media & Landscape Soils and Amendments (UVPG). Discussions centered on updating product labeling standards, including the removal of the term “Canadian Sphagnum Peat Moss” due to regulatory changes. The committee also debated the inclusion of foreign matter allowances, as provided in the new all-natural mulch guidelines.

Further deliberations addressed the removal of suitability statements from the UVPG as they

refer to test protocols that had been removed from the Guidelines previously. The committee agreed to submit the proposed changes to the board and membership for approval, following industry protocol. Additionally, a motion was passed to revisit the definition of wetting agents in July, particularly in light of emerging natural alternatives like yucca and aloe-based products. Looking ahead, the committee prioritized securing approval for the all-natural mulch standard before presenting additional amendments at the annual meeting. A special membership vote was considered necessary to implement the new standard, with members agreeing that splitting focus between multiple proposals could delay progress. The meeting concluded with planning for future discussions and setting a tentative review schedule.

Statistics Committee Report

The Industry Statistics Committee also met in Las Vegas to assess past survey initiatives and determine priorities for upcoming industry studies. Members reviewed previous survey topics, including consumer purchasing trends, sales growth, safety, and operational benchmarks. The committee

Continued on page 12

Which method is best suited for your application? Contact a Bandit sales specialist or visit www.banditchippers.com today for more details.

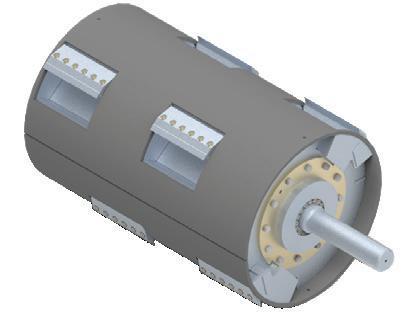

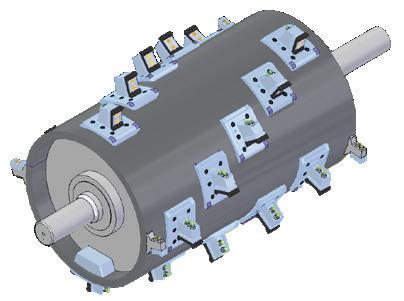

Hammermill (Model HM6420)

Concrete Shaft

Paddle Shaft

Chipper Drum

Cuttermill

News From MSC

Continued from page 10

emphasized the value of industry surveys in regulatory discussions and benchmarking, despite a limited sample size due to the small industry population.

For the upcoming year, the committee proposed repeating several key surveys, including the annual meeting topic survey, a national consumer mulch buying survey, a national consumer soil buying survey, and the year-over-year sales growth study. A potential industry-wide accident and injury survey was considered but deemed unlikely to gain traction due to low past participation.

Members also discussed broader industry challenges, particularly the financial burden of after-treatment systems in diesel-powered trucks and heavy equipment. The increasing costs and operational disruptions caused by diesel exhaust fluid (DEF) regulations were highlighted as significant concerns, with some companies reporting expenses in the hundreds of thousands dollars annually. The committee explored the possibility of requesting the Board of Directors to form a dedicated subcommittee or lobbying effort to address these issues, potentially in collaboration with other industry groups.

The meeting wrapped up with a focus on finalizing survey plans and securing member engagement, while also exploring avenues to address industry-wide regulatory burdens.

AAPFCO Report

The Association of American Plant Food Control Officials (AAPFCO) met in New Orleans on February 16-19. There were 29 states represented by 46 regulatory officials and almost 100 industry representatives were present to discuss issues regarding agricultural and specialty fertilizers; soil amendments and conditioners; liming materials; and potting mixes.

Overview on Fertilizers in U.S.

The meeting started with a presentation from Ed Thomas, VP Regulatory Affairs at The Fertilizer Institute (TFI). Ed gave highlights of key policy, industry, and environmental challenges affecting U.S. fertilizer production. Tax credits from the Inflation Reduction Act are driving investments in low-carbon ammonia and carbon capture, with $2.4 billion allocated annually. Meanwhile, a Republicanled government is pushing for energy expansion and tax cuts, shaping agricultural policy.

Trade concerns center on critical minerals like phosphorus and potash, essential for fertilizers, with 90% of U.S. potash sourced from Canada. Recent tariff disputes have caused disruptions, prompting industry concerns. Additionally, fertilizer pricing transparency is under scrutiny, leading to calls for an independent USDA economist to monitor trends.

Sustainability efforts include a low-carbon fertilizer certification system, allowing companies to trade carbon credits. Demand is rising as food producers and consumers push for greener agriculture. However, new EPA regulations on formaldehyde threaten urea-based fertilizers, adding uncertainty.

To improve industry oversight, AAPFCO is developing a fertilizer reporting system, backed by USDA funding. With 40+ states expected to participate, this initiative aims to enhance regulatory transparency and efficiency, ensuring better data for policymakers, growers, and manufacturers.

Beneficial Substances Labeling

States continue to change their fertilizer laws and/or adopt the model beneficial substances definitions and labeling regulations ahead of official state changes. Be cautious of the new format requirements and double check what states are now classifying as fertilizers or beneficial substances.

Continued on page 14

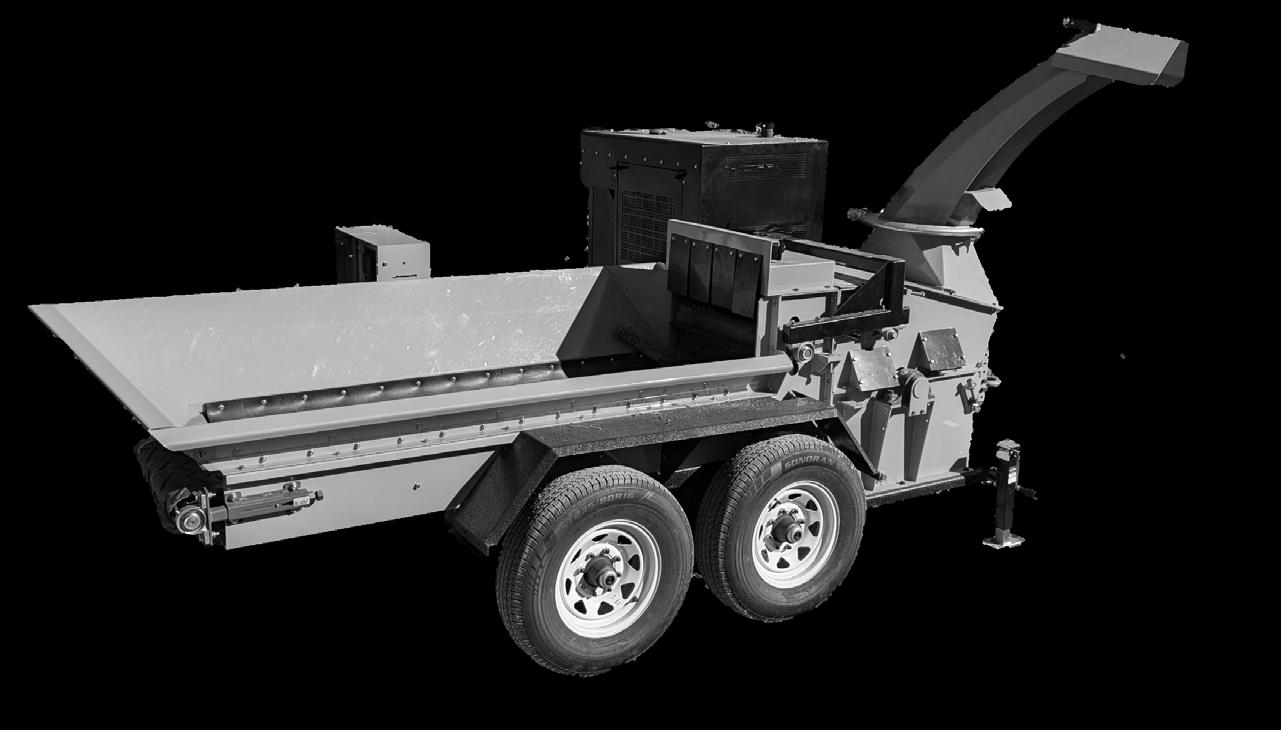

• Applications include compost and mulch production

• Compact, mobile, and highway ready

• Simpli : ied design and easy to maintain

• Conveyor-fed with multiple discharge options

• Process landscaping waste, compost, and wood tailings

Continued from page 12

• 5 states have amended their fertilizer laws to adopt AAPFCO beneficials substances model law.

• 26 states have agreed to accept beneficial substance labeling format under “regulatory discretion” which is not statutory – so check first.

• 29 states + Canada say they already accept or may change legislation to accept beneficial substances definition.

Other Activities

The existing Model Soil Amendment Law was removed from the AAPFCO Official Publication and referred to the new Beneficial Substances Model Law.

Silicon remained tentative as a secondary and micro plant nutrient. A working group was created to determine if silicon is a (micro) nutrient or beneficial substance and how it should be labeled on products.

A claim MI Compost is Fertilizer was Clarified. MI is NOT requiring compost to be registered as a fertilizer unless fertilizer claims are made. Standard registration is as a soil amendment/conditioner under Part 85 of the MI fertilizer bill.

MSC requested consideration of the Uniform Package Labeling Regulation (UPLR) street address exemption as an AAPFCO SUIP to prevent further State vs Federal regulatory conflicts on product labels. The Council is awaiting comment from the AAPFCO Board of Directors on the request.

This is a short report on very complex issues. For further information, call MSC office for details.

For more information about MSC, visit www.mulchandsoilcouncil.org or call 806-832-1810.

Viably Expands Distributorship of Scott Equipment Company’s Turbo Separator Food Waste Depackagers To California

Denver, CO – Viably (formerly Komptech Americas), a supplier of innovative waste processing solutions in North America, recently announced its expansion as the nationwide distributor for Scott Equipment Company’s Turbo Separator food waste depackaging systems within organics recycling for the commercial composting market. With the addition of California to its territory, Viably now offers this state-of-the-art food waste recycling technology across the entire United States and Canada, further empowering businesses to pursue sustainable organics waste management solutions.

The Turbo Separator is designed to help commercial compost facilities, food manufacturers, waste haulers, landfills, and other environmental organizations efficiently process packaged food waste and recover valuable organic material. Featuring multiple stationary models and a newly introduced mobile unit, the Turbo Separator provides a flexible and powerful solution for commercial compost facilities. Additional technology, known as Cleansweep, works in conjunction with the Turbo Separator as a secondary system to remove microplastics and other small contaminants from organic materials.

In addition to the four stationary product models of Turbo Separator, Viably will also begin offering its new mobile Turbo Separator unit. This mobile tool is ideal for commercial compost facilities, waste haulers, landfills, and other environmental organizations looking to introduce efficient food waste depackaging solutions across multiple locations or without investment in permanent infrastructure.

Duravant to Acquire Pattyn, Provider of Packaging Automation Systems for Bulk and Industrial Applications

Downers Grove, IL – Duravant LLC (“Duravant”), a global engineered equipment and automation solutions provider to the food processing, packaging and material handling sectors, announced recently that it has entered into a definitive agreement to acquire the Pattyn Group BV (‘Pattyn”), a designer and manufacturer of automation systems specializing in B2B packaging. Pattyn is recognized for delivering comprehensive automation solutions and value-added services for bag-in-box packaging applications. Headquartered in Bruges, Belgium, Pattyn has over 70 years of expertise in machinery design and turnkey systems for counting, weighing, filling, and packing technologies for food, ingredients, and various non-food sectors.

“We are extremely excited to partner with Pattyn,” said Mike Kachmer, Chairman and CEO of Duravant. “Pattyn has a rich history delivering high quality solutions to a global customer base in over 80 countries.

Pattyn operates out of six specialized manufacturing sites in Belgium, France and Spain and has sales and service divisions in North America and Asia. Founded by Jean Pattyn in 1952 and expanded through the vision of Paul Pattyn in 1976, the company grew from a local business to a worldwide supplier of packaging automation.

“Pattyn has had a strong track record of solid performance, and we know that our potential to grow faster will happen alongside a strong partner,” said Stan Pattyn.

The transaction, which remains subject to customary regulatory approvals, is expected to close in the second quarter of 2025. Following the close of the transaction, Pattyn will be a distinct Operating Company within Duravant’s Packaging Solutions Group. The current Pattyn Group management team will continue to oversee operations after the completion of the sale, and Pattyn’s 550 employees will join Duravant’s 3600 employees around the globe.

Serious Grinding Built For North America

/ Feed large waste volumes into the versatile 7'10" open-front hopper / Leverage all-day grinding with the huge 41" diameter downswing drum / Track chassis with optional 3-axle dolly for quick on-road transport

The Komptech Lacero 8010 is a powerful, high-speed, horizontal grinder purpose-engineered for the demanding North American wood waste, biomass, mulch, orchard/land clearing, and organics markets. Explore

www.thinkviably.com/lacero

Enhancing Compost Quality: The Role of Biochar and Zeolite in Nitrogen Transformation and Retention

As urbanization and population growth accelerate, the production of kitchen waste continues to rise. Studies predict that from 2005 to 2025, global kitchen waste production will increase by approximately 44% (Liu et al., 2022). This surge presents significant environmental challenges, as improper disposal can lead to pollution, foul odors, and greenhouse gas emissions such as nitrous oxide (N2O) (Wang et al., 2022b).

Currently, kitchen waste is often mixed with other waste materials and either incinerated or landfilled, both of which have drawbacks. Landfilling consumes valuable

land resources and poses risks of leachate contamination, which can cause irreversible soil damage (Jin et al., 2021). Composting provides a more sustainable alternative by converting organic waste into nutrient-rich biofertilizer through microbial processes (Apori et al., 2021).

Nitrogen is a fundamental component of biological molecules such as proteins, nucleic acids, and peptides. It plays a crucial role in microbial metabolism and significantly influences compost quality (Zhu et al., 2019). During composting, organic nitrogen undergoes various transformations, including

Diamond Z is making some BIG changes for 2025, with new Grinder, Trommel, Screener and Stacker models. Whatever the job demands, Diamond Z has it covered. All machines are built our diamond standard, assuring you that nothing outworks a Diamond Z!

hydrolysis into oligopeptides and amino acids. Some of these compounds are converted into ammonium ions (NH4+), while others volatilize as ammonia (NH3) (Hochroth & Pfister, 2024). Under aerobic conditions, ammonia nitrogen can be further transformed into nitrate nitrogen by nitrifying bacteria (Caceres et al., 2018). However, composting materials tend to compact and form aggregates, leading to oxygen depletion and triggering denitrification, which results in nitrogen loss (Wang et al., 2019).

To improve nitrogen retention and enhance compost quality, researchers have explored the addition of functional additives such as biochar and zeolite. These materials exhibit strong adsorption capacities that help reduce nitrogen losses (Chen et al., 2020a; Liu et al., 2023b). Studies have shown that adding 8–12% biochar to sludge compost enhances its nutrient content and shortens composting time (Awasthi et al., 2017). Similarly, zeolite has been found to increase nitrogen content in compost piles, effectively aiding nitrogen fixation (Latifah et al., 2015).

A recent study, as reported in sciencedirect. com, conducted by Mi et al. investigated the effects of biochar and zeolite on nitrogen transformation and retention in composting. The researchers used kitchen waste mixed with rice straw as composting material and conducted a controlled 60-day composting experiment. The study aimed to:

1. Analyze changes in total nitrogen, ammonia nitrogen, nitrate nitrogen, and organic nitrogen during composting.

2. Examine microbial community dynamics associated with nitrogen transformation.

3. Identify key functional genes involved in nitrogen metabolism.

4. Explore the influence of biochar and zeolite on nitrifying and denitrifying microbial populations.

The study demonstrated that biochar and zeolite enhance nitrogen retention in composting by adsorbing inorganic nitrogen fractions and reducing nitrogen losses. Additionally, their porous structure provides habitats for beneficial microbes, influencing microbial succession and nitrogen transformation pathways. Overall, these findings support the use of biochar and zeolite as effective composting amendments to improve nutrient availability and mitigate nitrogen loss.

This article is based on the research conducted by Jiaying Mi, Linlin Hou, Yiming Hou, Caihong Song, Lina Pan, and Zimin Wei. Their contributions to the study include conceptualization, methodology, investigation, data analysis, and manuscript preparation. Their work provides valuable insights into sustainable composting practices and the role of biochar and zeolite in enhancing compost quality.

Biomass Energy Outlook: Capacity to Remain Steady, Woody Biomass Consumption to Increase

According to an article on biomassmagazine.com , the latest Short - Term Energy Outlook released by the U.S. Energy Information Administration (EIA) on March 11, renewable energy is expected to play an increasing role in the U.S. electricity sector. The agency projects that renewables will account for 25% of electricity generation in 2025, rising to 27% by 2026. This marks a steady increase from the 23% share recorded in 2024.

Biomass Energy Contribution

Biomass energy, which includes waste and wood biomass, is projected to represent a small but consistent portion of renewable electricity generation. In 2024, biomass accounted for 2.16% of renewable electricity production. However, this share is expected to decline slightly to 2% in 2025 and further to 1.81% in 2026.

Electricity generation from biomass reached approximately 20.5 billion kilowatt hours (kWh) in 2024 and is forecasted to rise to 21 billion kWh in 2025 before slightly decreasing to 20.7 billion kWh in 2026.

Biomass Capacity Forecast

The total biomass electricity generation capacity is expected to remain stable through 2026. At the end of 2024, the electric power sector had 2.7 gigawatts (GW) of waste biomass capacity and 2.3 GW of wood biomass capacity, both of which are projected to stay unchanged in the coming years. Similarly, the industrial and commercial sectors had 5.4 GW of wood biomass capacity and 1.4 GW of waste biomass capacity, with no anticipated changes through 2026.

Biomass Consumption Trends

While biomass capacity remains steady, consumption patterns vary across sectors.

• Electric Power Sector: Waste biomass consumption is expected to decline slightly from 0.156 quadrillion British thermal units (quad) in 2024 to 0.155 quad in 2025 and 2026. Wood biomass consumption, however, is expected to grow from 0.162 quad in 2024 to 0.172 quad in 2025 before dropping slightly to 0.167 quad in 2026.

• Industrial Sector: Waste biomass consumption is projected to decline from 0.154 quad in 2024 to 0.152 quad in both 2025 and 2026. However, wood biomass consumption in this sector is expected to increase from 1.227 quad in 2024 to 1.343 quad in 2025 and further to 1.378 quad in 2026.

• Commercial Sector: Waste biomass consumption is expected to remain relatively stable, decreasing slightly from 0.07 quad in 2024 to 0.069 quad in 2025 and 2026. Wood biomass consumption is projected to hold steady at 0.072 quad throughout the forecast period.

• Residential Sector: Wood biomass consumption in the residential sector is expected to remain unchanged at 0.406 quad through 2026.

Overall Biomass Consumption Outlook

When considering all sectors, waste biomass consumption is projected to decline from 0.381 quad in 2024 to 0.376 quad in 2025, maintaining that level in 2026. In contrast, total wood biomass consumption is expected to rise from 1.867 quad in 2024 to 1.993 quad in 2025, reaching 2.023 quad in 2026.

While biomass remains a relatively small contributor to the overall renewable energy mix, the steady consumption of wood biomass suggests its continued role in industrial, commercial, and residential applications. As renewable energy adoption grows, biomass will continue to play a niche but important role in the energy landscape.

Livestock Manure Compost Study

Continued from page 1

Additional observations include:

• CM compost enhanced soil organic matter more effectively than SM compost.

• SM compost showed a threshold effect, where Pb stabilization improved at 5% application but diminished at higher concentrations.

• Soil pH had a limited direct effect on Pb immobilization, with organic matter and phosphorus content playing a more significant role.

The use of organic amendments in soil remediation provides a dual benefit: reducing heavy metal contamination and enhancing soil fertility. However, long-term application must be carefully managed to prevent excessive accumulation of elements such as Zn and Cu, which could pose additional risks. For sustainable soil management, farmers and policymakers should consider:

• optimized compost Application: Using appropriate compost types and dosages to maximize heavy metal stabilization while avoiding nutrient imbalances.

• long-term monitoring: Tracking soil and crop conditions over time to ensure continued effectiveness and prevent potential secondary contamination.

• integration with other remediation Strategies: Combining organic amendments with physical and chemical remediation techniques to enhance overall soil recovery.

Organic-based remediation using livestock manure compost presents a viable strategy for mitigating heavy metal contamination in agricultural soils. While chicken manure compost showed the highest efficiency in Pb stabilization, both SM and CM amendments contributed to improved soil health. Future studies should focus on the long-term effects of continuous compost application to ensure sustainable and safe agricultural practices in heavy metal-contaminated regions.

Full study: www.frontiersin.org (title: Organic-Based Remediation of Heavy Metal-Contaminated Soils in the Taojia River Basin Affected by Long-Term Non-Ferrous Mining and Logging Activities)

Conference: May 5-8, 2025 Expo Hall: May 6-8, 2025

Las Vegas Convention Center, Las Vegas, NV

Attend the WasteExpo Welcome Reception, hosted at The Theater at Virgin Hotels Las Vegas- featuring complimentary food, open bars, expanded networking, and live music!

Learn from 100+ expert-led conference sessions over 3.5 days packed with insights to keep you ahead in the industry.

CEO Spotlight Session: Join GFL’s Founder & CEO, Patrick Dovigi, as he discusses the company’s path to success.

Connect with 550+ exhibitors in the expo hall ready to help you find the perfect products and solutions for your business.

Join one of our new workshops including our Achieving Sustainability & Zero Waste Goals

Register today with code SMPN25 to save 25% off. Learn

– The TRUE Approach Workshop and Food Waste Diversion Program Development Workshop.

www.SoilandmulchProducernews.com

Ins I de Th I s Issue

Study Suggests Livestock Manure Compost Can Help Remediate Heavy Metal-Contaminated Soils PAGe 1

Minneapolis to Become First City in North America to Own and Operate Biochar Facility PAGe 4

Trump Administration Moves to Strengthen U.S. Lumber and Timber Industries PAGe 6

News From The Mulch & Soil Council PAGe 8

Enhancing Compost Quality: The Role of Biochar and Zeolite in Nitrogen Transformation and Retention PAGe 18

Biomass Energy Outlook: Capacity to Remain Steady, Woody Biomass Consumption to Increase PAGe 20