Attention Readers !

AutoMAtIC Floor SySteMS

Keith Manufacturing Co – pg 16

BAggINg/PAlletIzINg equIPMeNt

Amadas Industries – pg 3

Charter Next generation (CNg) – pg 13

CoMPoSt turNer resource Machinery & engineering – pg 12

CoNVeyorS & CoNVeyor PArtS

Action Conveyors – pg 12

Amadas Industries – pg 3

Barford – pg 20

Maverick environmental equipment – pg 6

Smalis Conveyors – pg 20

equIPMeNt SAleS

grindertrader.com – pg 22

grINderS, ChIPPerS & SCreeNINg SySteMS

Action Conveyors – pg 12

Amadas Industries – pg 3

Bandit – pg 5

Barford – pg 20

diamond z – pg 7

hogzilla – pg 18

Maverick environmental equipment – pg 6

McCourt equipment – pg 14

Precision husky – pg 17

Premier tech – insert

Spaleck uSA – pg 8

MulCh ColorINg equIPMeNt/ ColorANtS

AgriCoatings – pg 9

Amerimulch – pg 21

Britton Industries – pg 4

CMC – pg 19

Colorbiotics – pg 2

Faltech – pg 6

Florida Coastal Colors – pg 11

Milagro rubber Inc – pg 18

Münzing Corporation – pg 15

t h glennon Co – pg 24

PAyloAd WeIghINg & MeASurINg SySteMS

Walz Scale – pg 23

tree & StuMP SPlItterS

u.S. Pride Products – pg 10

troMMel BruSheS

Power Brushes Inc – pg 22

WeAr PArtS

Armorhog – pg 14

Chef of Compost Industry Serves Up Custom Blends

By P.J. Heller

If someone was to co-opt the Burger King slogan of “Have It Your Way,” it would likely be the crew at Full Circle Soils & Compost. Not content to produce just a standard compost that can be marketed to customers, Full Circle offers a complete menu of items that can be added to compost to create a blend geared specifically to a particular soil type.

“We are 100 percent focused on the actual growability and usefulness and efficacy of the end product by not just making compost, but making compost with minerals and nutrients that work correctly,” explains Cody Witt of Full Circle.

Witt sounds more like a master chef whipping up recipes of compost blends from the company’s pantry than the part owner and main site manager of a 40-acre compost facility in Carson City, NV.

“We have very specific recipes for the compost itself with very specific ratios of what materials go into each pile based on the compost we’re making,” he says. “After that, we have a pantry of minerals and nutrients that we would add, again for our product line and for custom soil amendments that we would make.

“We’re kind of the chef of the compost industry, where we take a large amount of our time

figuring out what’s the best product and usage for every specific project were working on for the best growth . . . from landscape to turf to garden to agriculture production to food production.”

The concept for the compost recipes started with Witt’s father, Craig Witt, a fourth generation Nevada dairy farmer. He began seriously looking into soil nutrient density after becoming concerned about a decrease in overall crop growth and milk production in cows on lands typically treated with straight manure and chemical fertilizers.

In the mid-1980s, Craig Witt began making some compost for his farm and in 1997 launched Full Circle to create large scale composting for the 500-acre farm. Before long, people in the area began coming to the farm to purchase his compost. In 2003, Full Circle moved to a new location in Carson City and began its composting operation one year later.

The company has done intensive soil analysis profiles along the eastern Sierra Front, which includes northern Nevada and the Lake Tahoe area. The area stretches about 200 miles from the compost facility.

“We have one of the largest databases of northern Nevada-eastern Sierra Front soil tests,”

NEWS Serving Soil, Mulch, Compost & Wood Pellet Producers www.SoilandMulchProducerNews.com Vol. XVII No. 4 July / August 2023 Continued on page 3

Are you looking for Products, Equipment or Services for your business? If so, check out these leading companies advertised inside:

2 Soil & Mulch Producer News July / August 2023 See the newest coloring system from Colorbiotics at SaharaXP.com Colorbiotics® and Sahara® are trademarks of Colorbiotics LLC in the U.S. and other countries. © 2023 Colorbiotics LLC. All Rights Reserved.

Chef of Compost Industry Serves Up Custom Blends

Continued from page 1

Cody Witt says. “We have more than 3,000 profiles done over the last 27 years. From that, the consumer product line started to get very intensive. We started blending up to 20 different organic soil amendment into the compost.”

Full Circle encourages its customers of any size to submit a soil sample to International Ag Labs in Fairmont, MN. Full Circle then interprets the results and provides recommendations on how to improve soil health. Customers can also arrange for Craig Witt to visit their site, take a soil sample for the lab and provide more detailed recommendations, including information on creating what Full Circle says is “a custom blend to address all of your soil’s needs in one product, a service very few companies are capable of offering.”

“We’ll actually make custom products based on site-specific soil conditions to create compost with minerals and nutrients,” Cody Witt says. “We’ll blend in these minerals and nutrients to create these custom fertility solutions.”

Witt says it makes sense for customers to do a soil test. He is seeing more big projects, such as large housing developments and Department of Transportation projects, requiring site soil testing.

“It’s just like going to the doctor,” he says by way of comparison. “You wouldn’t just start taking medication without a blood test. So we do push most of our customers to understand their soil a little better.”

Continued on page 4

www.SoilandMulchProducerNews.com

PUBLICATION STAFF

Publisher / Editor

Rick Downing

Contributing Editors / Writers

P. J. Heller • Robert LaGasse

Sandy Woodthorpe

Production & Layout

Christine Mantush

Advertising Sales

Rick Downing

Subscription / Circulation

Donna Downing

Editorial, Circulation & Advertising Office 6075 Hopkins Road, Mentor, OH 44060 Ph: 440-257-6453 • Fax: 440-257-6459

Email: downassoc2@oh.rr.com

Subscription information, call 440-257-6453.

Soil & Mulch Producer News is published bimonthly by Downing & Associates. Reproductions or transmission in whole or in part, without written permission of the publisher, is prohibited.

Annual subscription rate U.S. is $19.95. Outside of the U.S. add $10 ($29.95). Contact our main office, or mail-in the subscription form with payment.

©Copyright 2023 by Downing & Associates

Printed on Post-Consumer Recycled Paper

3 July / August 2023 Soil & Mulch Producer News Soil & Mulch Producer NEWS

Chef of Compost Industry Serves Up Custom Blends

Continued from page 3

All is not lost, however, for customers who may balk at doing the soil test, which costs about $66.

“Again, because we’ve done so much work on our own and understanding different soils within different areas of northern Nevada, we can point people in the right direction if they don’t want to do a soil test,” Witt says.

In many cases, the company’s signature Boost soil amendment product –compost plus a 20-ingredient mineral and nutrient package specifically designed for the area – may suffice. In other cases, Witt says, compost may not be the answer.

If someone used too much manure in their backyard and they have too much potassium and sodium in their soil, Witt says Full Circle is “one of the only composters who might say compost may not work for you. Maybe you only need minerals and nutrients. We will help people look at their soil and come up with best program for long term growth. Sometimes that means we only blend up nutrients and don’t blend any compost into it.”

Witt hesitates to call Boost and the company’s other products “generic” because of all the soil analysis profiling that has been done over the years.

The custom blends offered by Full Circle, as well as its line of bagged and bulk products, including compost and dirt products, potting, gardening and landscape soils and mulches, can be especially important in northern Nevada’s high desert climate and harsh growing environment. The company makes more than 40 products, Witt says.

“You can only grow a garden [here] for about four months of the year,” he notes. “We will have freezes up until June, and it will freeze again in September. So you only have June to September to grow.”

Even so, he reports the company’s test garden averages up to 150 pounds of tomatoes per 12-foot-tall plants with its products.

“So we do a very good job of growing, achieving big yields in a very short period of time by focusing on the soil nutrient side,” he says.

Full Circle sells its products within a 200-mile radius of its facility through wholesalers as well as direct to consumers. Its products can be found in garden centers, rock yards and grocery stores; it does not sell through big box stores or, as yet, do private labelling.

“Our customer base is pretty local because we are known for making very

high-end products that have a huge growth result,” he says. “A lot of people want to buy locally and they want to buy from people who know the area and know how soils work. We have done very well keeping that market.”

The only other composting site in Nevada that sells direct to consumers is Terra Firma Organics in Las Vegas, which in 2018 purchased Full Circle. Dane Buk, who owns Terra Firma operations in both Las Vegas and Jackson, WY., also is the primary owner of Full Circle. At Full Circle, Craig Witt, described as a “soil and compost mixologist,” remains on staff and Cody Witt is part owner and overall site manager. The company has about 25 to 30 employees.

The sale of Full Circle came about when the company was growing so fast between 2015 and 2017 that it began looking for a partner. Craig Witt had known and consulted with Buk previously and Buk opted to create a secondary company.

“We’re kind of like a multifaceted site with three different locations,” Cody Witt notes. “We share equipment across all the sites. We have done huge investments since 2018 into our current composting operation with equipment and the amount of materials we process. That was the whole goal, to sell and grow but still be involved in the operation.”

Witt says Full Circle takes in about 70,000 cubic yards of material annually and sells about 35,000 cubic yards which includes compost, soils and mulches. Based on Environmental Protection Agency calculations, keeping that much material out of the landfill is the equivalent of taking 30,000 cars worth of carbon dioxide (CO2) off the road annually, he says.

“Pretty much everything that comes into my facility goes out on an annual basis,” Witt says. “Right now, we sell so much product that I’m running out of product. We actually need more organics.

“We sell so much because the product works so well,” he adds. “Every year we literally run out of product.”

Full Circle mainly takes in forestry products, due to its proximity to Lake Tahoe and its regulations for fire prevention and lake clarity. It also takes in pine needles and woody biomass recycling. Residential green waste collection is limited since there are no state mandates for collection; the city of Carson launched a green waste collection program in 2019 and two small towns nearby also have similar

Continued on page 18

www.keithwalkingfloor.com/j-max

4 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS

» Diverse line of models ranging from 14” to 45” capacity

» Cuttermill processes material utilizing less fuel

» Wide variety of teeth and screen sizes available

» Produces a high-quality end product

» Top notch aftermarket support

WATCH IT RUN!

40 YEARS OF QUALITY TREE CARE AND RECYCLING EQUIPMENT

5 July / August 2023 Soil & Mulch Producer News

MODEL 3680T 35” Capacity Horizontal Grinder

Study Finds Plastic Substitutes Don’t Break Down

La Jolla, CA – Referring to compostable plastics as biodegradable plastics is misleading, according to a team of oceanographers, reports Scitechdaily. com

According to the study findings published in the open-access journal, PLOS One, the term “biodegradable” can be deceptive when applied to certain plastic substitutes. Rather than disintegrating, so-called compostable plastic remains unchanged in marine environments for at least 14 months. This is the first-time researchers have tracked the ability of natural, synthetic, and blended fabrics to biodegrade directly in the ocean.

The team of researchers from the Scripps Institution of Oceanography at the University of California, San Diego found that PLA, which is derived from fermented sugars and starches, will break down to its constituent polymer, lactic acid, only at very high temperatures. The findings have implications for the use of PLA, which has been adopted as a replacement for oil-based plastics to reduce both fossil fuel use in manufacturing processes and non-biodegradable waste.

Although PLA does break down, it only does so when composted in industrial grade composting processes where high temperatures are reached and maintained. The material does not break down in colder conditions.

The researchers conducted an experiment in coastal waters off the coast of Southern California in which they compared degradation of PLA, oil-based plastics, cellulose-based materials, and a blend of cellulose-based and oil-based materials. Samples were examined weekly for evidence of disintegration and returned to the ocean after a few hours.

The authors found that the cellulose-based material degraded quickly, in less than one month. In contrast, neither the oil-based plastic, the blend, nor the PLA showed signs of degradation throughout the 14 months of the experiment.

The study shows the need for standardizing tests to see if materials promoted as compostable or biodegradable such as PLA do biodegrade in a natural environment. In this case, consumers who are concerned about microfiber plastic pollution should be informed, knowledgeable, and mindful of the materials they are buying, the authors summarized.

6 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS erick ENVIRONMENTALEQUIPMENT www.maverickenvironmentalequipment.com SALES-RENTAL-PARTS-SERVICE-HEAVYHAUL NOWCARRYING:

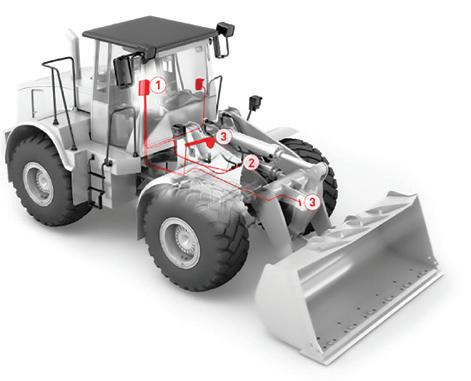

DZH4000TK-THEMULCHMASTER

Spring time is mulch time, and all about productivity. You need to produce tonnage and you need to produce it now. That’s what the Diamond Z DZH4000TK is designed for ... and does.

The DZH4000TK will out grind competitor’s comparably sized machines. The C18 Caterpillar engine combined with our aggressive down-cut mill delivers production rates up to 120 tons per hour. The smaller stature offers easy transportability. Friendly operation, ease of maintenance and attention to detail are throughout ... hallmark traits for all Diamond Z grinders.

As a track-mounted horizontal grinder, the DZH4000TK allows you to operate just about anywhere a portable grinder cannot. With up to 755 horsepower, production capacities up to 120 tons per hour, and an innovative, operator-friendly design, the DZH4000TK is the simple horizontal-tracked choice for your most difficult jobs.

7 July / August 2023 Soil & Mulch Producer News

GRINDINGSIMPLIFIED

DIAMOND Z GRINDERS Caldwell, Idaho 208.585.2929 www.diamondz.com Visit www.diamondz.com to see these tub and horizontal grinders and our complete line: 1352B 1463B DZH3000 1248BTK DZ800TKT DZH6000 ® ™ Soil Producer.indd 1 1/29/2020 2:00:45 PM

News From The Mulch & Soil Council

By RoBeRt

By RoBeRt

WOTUS Update

LaGasse,

By David Crow, The CROW Political Report

In a significant ruling, the Supreme Court delivered a welcome blow to the Environmental Protection Agency’s (EPA) overreach of authority in May. The court’s decision curtailed the EPA’s ability to regulate vast expanses of wetlands, which will help combat unnecessary government intrusion and bolster property rights. Justice Samuel A. Alito Jr., writing for five justices, aptly pointed out that the Clean Water Act does not grant the agency the power to regulate discharges into wetlands unless they possess a “continuous surface connection” to bodies of water.

This latest decision marks a second setback for the EPA’s authority and a broader challenge to the power of administrative agencies. In the previous year, the court already limited the EPA’s jurisdiction to address climate change under the Clean Air Act, again reining in the agency’s overreach.

Although the decision was technically unanimous, all the justices agreed that the homeowners who initiated the case should not have been subjected to the agency’s oversight since the wetlands on their property were not subject to regulation in any event. However, there was a divergence of opinion concerning the majority’s establishment of a new test to determine the coverage of wetlands under the law.

Interestingly, Justice Brett M. Kavanaugh,

By RoBeRt LaGasse, executive DiRectoR

By RoBeRt LaGasse, executive DiRectoR

executive DiRectoR

executive DiRectoR

joined by three liberal justices in a concurring opinion, expressed concerns that the decision might hinder the federal government’s ability to address pollution and flooding. His argument, while well-intentioned, fails to recognize the potential adverse consequences of the Clean Water Act’s expansive reach. By narrowing the act’s coverage to only adjoining wetlands, as per the court’s new test, some long-regulated adjacent wetlands will no longer fall under the Clean Water Act. This adjustment has significant benefits for water quality and flood control throughout the United States.

The case, Sackett v. Environmental Protection Agency, No. 21-454, centered around an Idaho couple, Michael and Chantell Sackett, who sought to build a house on a wet residential lot near Priest Lake in the state’s panhandle. The couple faced obstruction from the agency after adding sand, gravel, and fill to their property in preparation for construction. Instead of accommodating the homeowners, the EPA ordered them to cease work and restore the property to its original state, even threatening substantial fines. Consequently, the couple took legal action against the agency, leading to a dispute that reached the Supreme Court in an earlier appeal. In 2012, the justices ruled in favor of the Sacketts, determining that their lawsuit could proceed.

Justice Alito had previously expressed concerns about the EPA’s overreaching authority in a concurring

opinion. He highlighted the ambiguous nature of the Clean Water Act, stating that any piece of land with intermittent wetness is at risk of being classified by EPA employees as wetlands subject to the act. This ambiguity grants the agency unprecedented control, leaving property owners vulnerable and at the mercy of bureaucratic discretion. In the end, all nine justices agreed that the EPA had exceeded its bounds in attempting to regulate the Sacketts’

Florida Suspends Changes to Seasonal Fertilizer Bans

According to the Tampa Bay Times, Florida Governor Ron DeSantis allowed his recently approved budget to include a provision to prevent cities or counties from adopting new fertilizer bans which environmentalists claim are a necessary water quality tool designed to curb the type of toxic algae currently flaring up on Lake Okeechobee. Fertilizer is nutrient-heavy, so when it runs off into nearby waterways it can act as fuel for algal blooms. Fertilizer bans in summer months are meant to prevent that from happening – but do they actually do that?

Despite the public outcry from dozens of Florida environment groups, Gov. DeSantis declined to use his line-item veto on a measure that will suspend cities or counties from adopting or amending

8 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS Sales: 412-294-2494 Email: info@spaleck-us.com Continued on page 10

9 July / August 2023 Soil & Mulch Producer News Our Vision Colors Yours! 615-443-0345 Ext 103 OHIO | TENNESSEE | TEXAS | info@agricoatings.com | www.agricoatings.com All the mulch colorant companies are saying the same thing: Ours has better coverage, Ours has better weatherability, Ours is more brilliant, looks better...blah..blah..blah We at Truly believe WE make THE Best High Performance Mulch Colorant! Prove it to yourself. Contact us to set-up a trial run. Blah...Blah...Blah...

Innovation = Splitting Productivity

At U.S. Pride, we strive to bring our customers BIG wood splitting solutions that save time and money! We’re changing the game with the release of the new HF-800 + rotating grapple combo. The HF-800 has always been an absolute monster at splitting BIG logs quickly. Combining the two attachments into one package allows one operator to split, move and position logs without changing attachments or getting help from a second machine and operator. The new U.S.A. made 52” grapple rotates 360 degrees allowing easy loading and positioning of logs for stacking or further processing in a tub or horizontal grinder, chipper, shredder or firewood splitter.

The new package includes excavator mounting brackets, HF-800 splitter, 360 degree rotating grapple, and hydraulic control valve with switch & wiring. Installation and operation are straightforward. Our hydraulic control valve is plumbed into your excavator’s standard auxiliary hydraulic ports and allows switching between the cone splitter and grapple from the operator seat. HF-500, HF-600 & HF-800 owners can buy the Retrofit Kit to upgrade their splitter with the new grapple. (Integrated Splitter & Grapple is Patent Pending)

News From MSC

Continued from page 8

seasonal fertilizer restrictions after June 30 and until July 1, 2024. During that year-long period, University of Florida researchers will use $250,000 to study the effectiveness of rainy season bans and submit their findings by the end of this year, before the start of next year’s wet season.

In a text message, DeSantis spokesperson Jeremy Redfern underscored that existing bans are still in place, but said pausing new bans “ensures that fewer variables are introduced during the study period.”

As a result of the legislation, the University of Florida’s Institute of Food and Agricultural Sciences will focus on a literature review of more recent studies looking into urban fertilizer and environmental impact, according to Michael Dukes, director of the UF Institute’s Center for Land Use Efficiency.

Dukes said he anticipates their findings will show more studies are needed to determine the relationship between nutrient losses and the use of fertilizer in urban areas. Existing studies on the effects of fertilizer leaving landscapes during the rainy season or otherwise, “are lacking,” Dukes said in a statement.

“If science-based information is to be used to make policy, this needs to be understood in order to understand the effect of ordinances related to fertilizer,” Dukes said. “Also, this work will define gaps in knowledge and further research questions.” More than 100 municipalities across Florida, including more than 20 local governments in Pinellas, have used rainy season fertilizer bans as a tool to prevent souring the state’s waters.

Labor Law Alert

Federal Pregnant Workers Fairness Act Takes Effect: Federal employment law is about to give birth to some long-overdue requirements. As of June 27, 2023, employers with 15 or more employees must provide pregnancy-related accommodations to employees and applicants under the federal Pregnant Workers Fairness Act (PWFA). Below we’ll refer to employees and applicants collectively as “employees.”

Pregnancy Related Accommodations

Under the PWFA, employees are entitled to accommodations for a condition related to or affected by pregnancy, childbirth, or a related medical condition. The condition can be physical or mental. Pregnancy-related conditions include, among others, morning sickness, gestational diabetes, post-partum depression, and lactation.

This law expands employer obligations beyond what is already required by the Americans with Disabilities Act (ADA) in that being entitled to a pregnancy-related accommodation does not require that the employee’s condition rise to the level of disability. Also, employees are entitled to accommodations even if they can’t perform their essential job functions on a temporary basis.

Possible accommodations include but aren’t limited to:

• Providing more frequent or longer breaks

• Modifying a food or drink policy

• Providing seating or allowing the employee to sit more frequently if their job requires standing

• Observing limits on lifting

• Providing job restructuring, light duty, or a modified work schedule

Employers can’t require an employee to take leave if a reasonable on-thejob accommodation is available. Like the ADA, the employer and employee should engage in the interactive process to determine what reasonable accommodations can be provided. However, if the employer is willing to grant the employee’s request, the interactive process is not required.

Note that many states have already implemented pregnancy accommodation laws, some of which may be more generous than the PWFA. Employers need to apply the law—or the aspect of each law—that is most favorable to employees.

Undue Hardship Exception

Employers don’t have to provide an accommodation if doing so would cause an undue hardship on the operation of the employer’s business. Undue hardship is defined as “an action requiring significant difficulty or expense,” the same as under the ADA. This is a high standard for employers to meet. Action items

• Add a pregnancy accommodations policy to your handbook if you don’t already have one

• If you’re subject to a state law that provides similar accommodations, make sure your policy captures the most employee-friendly aspects of the applicable laws

• Ensure that managers are aware of the law and types of accommodations that may be required

Continued on page 12

10 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS

CONE SCREW SPLITTERS Scan With Your Phone Contact Charlie VanDusartz 715-760-0907 Charlie@USPrideProducts.com Visit our website for more details. See Our Entire Cone Splitter Lineup At: www.USPrideProducts.com

11 July / August 2023 Soil & Mulch Producer News

News From MSC

Continued from page 10

“Comp Time” Caution

Can we use comp time with our employees? It depends. For nonexempt employees of a private employer, no. The Fair Labor Standards Act (FLSA) doesn’t permit private employers to offer compensatory time (“comp time”) in lieu of overtime pay.

You could offer time off to your exempt employees as a reward for working more than their typical work week, which is considered a form of “flex time,” but there are downsides to doing this. First, your exempt employees may grow accustomed to being able to take time off when they work extra hours, and this may not be a desirable or sustainable practice for your organization. Second, tracking the hours of your exempt employees so you can reward them may be extra work for you and them. Third, formalizing a flex time system for exempt employees could create confusion about what they’re owed because it could create a perception that they’re compensated on an hourly basis.

Instead of creating a formal flex time system for exempt employees, it may be simpler to find other ways to reward them for working extra hours when needed.

APHIS Importing/Exporting?

The U.S. Department of Agriculture’s (USDA) Animal Plant Health Inspection Service (APHIS) reminds brokers, filers, forwarders, carriers, and other members of the importing community that an APhIS Core Message Set for clearance must be filed prior to moving cargo to Plant Inspection Stations (PIS) for inspection.

When submitting electronic information through the Automated Commercial Environment (ACE), a properly filed APHIS Core message set is required to be submitted along with any required documents in the ACE Document Imaging System (DIS). Failure to provide this information in the appropriate manner (electronic or paper) will result in cargo delays.

If the cargo is exempt from electronic submission, or a non-electronic means of clearance is being used, and the cargo must go to an APHIS PIS for clearance, then a properly completed PPQ 368 paper form and accompanying paper documents must be submitted for clearance of cargo.

Continued on page 14

12 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS www.actionconveyors.com | 503.537.1111 Manufacturer of custom vibratory equipment since 1972 VIBRA-SNAP® Flip-Flow Screen DENSE-OUT® Vibratory AIR Separator Remove rocks & stones for a higher quality product with our Screen your material for a consistent & desirable size product with our Clean and Screen Your Compost, Mulch & Soil

13 July / August 2023 Soil & Mulch Producer News

News From MSC

Continued from page 12

APHIS recommends that importers submit both electronic information or paper documentation in advance of the cargo’s arrival, including products that meet U.S. Customs and Border Protection (CBP) requirements for de minimis exemptions. ACE and the APHIS Core message set provides for faster clearance. APHIS accepts the use of test Entry Type 86 for cargo meeting the requirements of CBP’s de minimis exemptions.

For more on how to file an APHIS Core message set, please visit our website at www.aphis.usda.gov/ ace. For information about entry types and their APHIS Core requirements, go to “When to Submit an APHIS Core message set, by Entry Type, in ACE”.

The APHIS Core Message Set Help Desk operates Monday through Friday, 8:00 am to 7:00 pm Eastern Time. You can reach the Help Desk by calling 1-833-481-2102 or e-mailing ace.itds@usda.gov. If you are inquiring about a rejection or error for your message set, please be ready with any error codes or a copy of the message set that was filed.

Michigan Quarantine

If you are recycling landscape and yard waste in Michigan, effective immediately, the U.S. Department of Agriculture’s Animal and Plant Health Inspection Service (APHIS), in cooperation with the Michigan Department of Agriculture and Rural Development (MDARD), is establishing a quarantine for the box tree moth (BTM) in all of Lenawee and Washtenaw Counties and parts of Jackson and Monroe Counties, Michigan. BTM is a destructive pest of boxwood (Buxus species). APHIS is taking this action in response to

confirmed detections of BTM larvae in Lenawee County, Michigan. BTM was first detected in Michigan on November 2, 2022. Since the detection in late fall 2022, APHIS has worked with MDARD to restrict host movement, delimit the infestation, engage stakeholders, and conduct outreach. APHIS, MDARD, industry, and research partners are working closely to develop useful pest control tools.

APHIS is prohibiting the interstate movement of regulated articles of Buxus spp. from the entire Counties of Lenawee and Washtenaw, the County of Monroe west of US-23 and north of River Raisin, and the County of Jackson south of I-94 and east of US-127.

Regulated articles include the whole plant, all plant parts, pieces, cuttings, clippings, debris, and any portion of the plant, alive or dead. APHIS is taking this action to prevent the spread of BTM to the rest of the United States. These measures parallel the intrastate quarantine that MDARD established on April 10, 2023.

The attached Federal Order outlines the safeguarding measures required for protecting the industry from this pest. The Federal Order and additional information about BTM may be found at: https://www.aphis.usda.gov/aphis/ourfocus/ planthealth/plant-pest-and-diseaseprograms/pestsand-diseases/box-tree-moth.

For additional information, please contact the National Policy Manager, Allen Proxmire, at 480-3928754 or allen.proxmire@usda.gov.

For more information about Mulch & Soil Council, visit mulchandsoilcouncil.org or call 806-832-1810.

14 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS

Putting Sargassum Seaweed to Good Use

Florida’s Atlantic coastal cities and a number of entrepreneurs are trying to come up with new solutions for the tons of foul-smelling sargassum seaweed that wash up on their beaches during spring and summer, according to articles in NewsNationNow.com, IslanderNews.com, and Axios.com

Sargassum “blooms” have become a major nuisance, a tourism disruptor –and an expensive waste that requires special disposal methods. It does have some health hazards, as well. Tiny sea creatures that live in it can cause skin rashes or blisters in humans, and during decomposition, the seaweed releases hydrogen sulfide and other toxic gases which can cause respiratory difficulty in some individuals.

The Great Atlantic Sargassum Belt, first detected by NASA observation satellites in 2011 and now known to be the world’s largest bloom of seaweed, stretches for 5,500 miles from the Gulf of Mexico to the western coast of Africa, according to a 2020 article published in The Guardian Seaweed blooms are exacerbated by agricultural discharge of fertilizers, which travel in waterways to oceans, as well as by warming sea temperatures, according to a University of Exeter and Plymouth Marine Laboratory researcher interviewed by the Guardian in 2020. In May of that year, 9.5 tons of Sargassum were observed across the Atlantic.

A research team led by the universities of Exeter and Bath has been experimenting with a cheap and simple way to pre-process seaweed on an industrial scale before converting it into high-quality, low-cost sustainable fertilizer, fuels and chemicals. Using acidic and basic catalysts, the process releases sugars that can be used to feed a yeast that produces a palm oil substitute.

The same method also prepares the residual seaweed for the next stage of processing, called hydrothermal liquefaction. The experimental work provides a crucial missing step towards a true salt-based marine biorefinery by establishing the initial fractionation step. Once the seaweed is subjected to high temperature and pressure, it transforms into a bio-oil that can be processed further into fuels, and high-quality, low-cost fertilizer.

A team of researchers at the University of North Carolina at Chapel Hill has been examining nitrogen fixation among diazotrophs – microorganisms that can convert nitrogen into usable form for other plants and animals – living among sargassum.

More nitrogen in the ocean means greater biological productivity and growth. The discovery helps explain the sargassum blooms. Sargassum mats provide an important habitat for organisms to perform nitrogen fixation, but few studies have measured it in sargassum communities.

Over the past 30 years, studies have overlooked diazotrophs associated with sargassum, which could mean a historical underestimation of nitrogen fixation in the Atlantic nitrogen budget. The latest study, published in the open access journal, PLOS ONE, found that nitrogen fixation in sargassum communities was significant.

The peak seaweed blooming season is in June and July. This year, crews in Fort Lauderdale have collected 170% more sargassum compared to 2022, a costly endeavor. Encouraged by the findings of a recent University of South Florida (USF) study, Fort Lauderdale city officials are considering composting. Officials say diverting the seaweed from landfill and turning it into compost has a potential savings estimated at $300K-$350K.

Miami has been removing and disposing of the seaweed in landfills after drying and shrinking it. The process cost the county $4.2 million in 2022, according to a Miami-Dade County official. Although composting sargassum was considered, the official noted, the idea is being shelved due to Florida Department of Environmental Protection regulations protecting against contamination in ground and drinking water.

At the University of the West Indies in St. Augustine, Trinidad and Tobago, a research team is formulating biofertilizer and other products from sargassum in the laboratory. Industrial-scale seaweed collection and commercialization is a way off, however, because of the need for wildlife risk assessments and the complexity of international environmental and marine regulations.

Carbonwave, a Boston-based startup that “upcycles” sargassum seaweed into biomaterials wants to farm the seaweed and convert it into biomaterials. This spring, however, the company turned its focus to beach clean-up contracts with several Florida resorts.

The Miami-Dade Innovation Authority (MDIA), a nonprofit public-private incubator, is looking for groups offering a solution for the sargassum issue. Three global start-ups will receive a $100,000 equity investment to go towards more research and development for their proposed solution.

The deadline to submit proposals is Friday, September 29, 2023. More information can be found at the MDIA website: http://mdia.miami/sargassum.

15 July / August 2023 Soil & Mulch Producer News Soil & Mulch Producer NEWS AGITAN® DEE FO® Visit us at the Mulch & Soil Council Annual Conference. INTRODUCING MÜNZING’S ADDITIVES For Water-Based Mulch Colorants EDAPLAN® METOLAT® Defoamers Highly effective in reducing foam Fast foam break Dispersants Excellent viscosity stabilization No separate wetting agent required www.munzing.com info@munzing.us

Department of Defense Investigates Recycled Wood Building Material

Washington, D.C. – According to the U.S. Army Corps of Engineers, more than 80% of solid waste produced on Department of Defense (DoD) military bases consists of scrap wood, cardboard, and paper.

On average, each soldier on a strategically located forward operational base (FOB) generates close to 13 pounds of waste daily. A FOB may contain an airfield, hospital, machine shop, or other logistical facilities. The current practice is to send the waste to landfills or bury it on-site.

Under the Waste Upcycling for Defense (WUD) program, Defense Advanced Research Project Agency (DARPA) aims to research and develop an end-to-end process for turning scrap wood and other cellulosic waste such as cardboard and paper into lightweight, strong, and sustainable materials that can be used in multiple DoD environments. If successful, WUD will help mitigate the DoD waste disposal burden, alleviate supply chain logistics, and reduce the overall carbon footprint associated with DoD construction and defense, while simultaneously providing a pathway for sustainable building materials.

In 2018, researchers at the Department of Mechanical Engineering, University of Maryland demonstrated that with chemical treatment and pressing, wood can be densified. The study, done with small batches of virgin lumber, produced a material with greater strength-to-weight than steel.

Early results indicate that the process could be used to turn wood chips and scrap lumber into densified wood-like products. Researchers have been investigating biological processes that may replace or supplement the harsh chemical processes needed to modify the source material.

Beyond enhanced mechanical properties, however, the wood product must be fire resistant, water resistant, and have corrosion/weather durability. WUD aims to determine the potential of using combinations of various cellulosic waste types (scrap wood, cardboard, paper) to produce DoD-relevant materials.

DARPA is seeking proposals for further research and development. Responses are due by mid-September this year. WUD performers will engage with U.S. government and defense stakeholders, as well as appropriate regulatory authorities, to ensure safety and efficacy. This program will have a single phase and take 24 months to complete.

A Special Program Announcement solicitation with additional details is available at: sam.gov/opp/58b5a1daeb7e4358aeccae496a8f6d16/view.

University-Composter Partnership Diverts 28K Pounds of Food Waste from Landfill

Waco, TX – Baylor University is partnering with a Texas–based compost company to turn scraps from its Penland Dining Hall into a rich soil amendment, reports KWtX-tV

Since April of this year, more than 28,000 pounds of food have been collected and transported by Moonshot Compost and delivered to a compost facility in Austin. Anything that was grown or harvested, plus meat, poultry, and seafood is accepted, according to Moonshot’s website.

Based on the success of the Penland waste collection program, Baylor is expanding its subscription with the compost company to include two more dining halls on campus.

Moonshot offers a variety of commercial and residential composting plans which, like the one with Baylor, include distribution of collection bins. The company also has incentive programs with rewards for referrals. Subscribers can receive weekly reminder texts for pick up, but they also have the option of dropping off their food waste.

Waco’s landfill is predicted to reach capacity in July 2025. Plans are underway for the city to build a new landfill in Axtell, which is about 15 miles to the northeast. According to a Waco solid waste district official, construction on the new landfill is scheduled for this fall with completion projected to take two years. The landfill is set to start taking waste in February 2025.

Baylor is Moonshot’s only subscriber in the Central Texas area, but the company is looking to establish partnerships with businesses and institutions. The innovative Houston-based composter has developed “The Diversion Dashboard” app and website that allows subscribers to track their food waste collection progress.

16 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS

www.keithwalkingfloor.com/j-max

BORN TO GRIND.

Precision Husky Corporation leads the forest products industry, building the most rugged equipment available.

Our horizontal and tub grinders are the most powerful, easiest to use grinders in the industry. They are designed with innovative features and advanced technologies to give you the power and production needed

to tackle the most demanding grinding operations.

We are a family-owned, family-operated company, and we’ve earned our position in the industry by building the highest-quality, most reliable equipment since 1964. Contact us to learn more about our products and to discuss your needs.

MAY WE INTRODUCE SOME OTHER MEMBERS OF OUR FAMILY...

17 July / August 2023 Soil & Mulch Producer News P.O. Drawer 507, Leeds, AL 35094 • 205-640-5181 • www.precisionhusky.com • sales@precisionhusky.com

H3060 Horizontal Grinder

Precision Husky PG-5200 / Horizontal FP S&M Producer News Mar-Apr 2022.indd 1 3/14/22 9:37 AM

Chef of Compost Industry Serves Up Custom Blends

Continued from page 4

programs. A small amount of food waste is collected, most of which comes from California due to that state’s recycling mandates. Full Circle is the only company in Nevada that accepts food waste for composting. (Witt says there are fewer than 10 composting sites in Nevada).

“Nevada is very far behind in green initiatives,” Witt laments. “In the state of Nevada, there is no waste diversion mandate or recycling mandate. There is none. Because Nevada is so behind in organics recycling . . . we’re probably only capturing 5 percent of the organic material going to the landfill.”

He says the company’s long-term growth strategy is to “hopefully help Nevada get more material flowing to the compost industry so we can make more product and get it back out into the Nevada environment. Because of Nevada’s high desert arid climate, it’s the perfect location for the use of compost. There’s plenty of opportunity in the state for us to continue to grow composting to be very big and a very useful part of climate change and soil health.”

Continued on page 20

H18 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS

19 Soil & Mulch Producer News

Mulch Colorants

Chef of Compost Industry

Continued from page 18

The challenges, he says, include the fact that Nevada has no mandates for organic diversion and has extremely low landfill rates, making it much less expensive to go to the landfill than to a composting site.

“We get very minimal amounts of revenue from the inbound revenue stream, so we had to focus on product quality,” Witt says. “We are 100 percent product focused.”

That results in 70 percent of the company’s revenues coming from the product side, and only 30 percent coming from inbound materials. In contrast, he says, some large compost sites are highly focused on the inbound material revenue stream and less on the quality of the product going out. Those sites, he says, may be making 70 percent of revenue from the inbound stream and 30 percent from the outbound product.

“We do this [composting] a lot out of the goodness of our heart, to save Mother Nature,” Witt says. “Our main mission is to save Mother Earth by diverting as much organics as possible and making great products for the health of Nevada soils so people can grow in an environment that’s really hard to grow in.

“And we’re trying to push Nevada. . . It needs to turn the corner and really push sustainable alternatives for people to recycle their organics.”

20 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS P.O. Box 412 • 223 Marginal Road New Stanton, PA 15672 PHONE: (724) 925-8500 FAX: (724) 925-6421 800-348-0765 Email: dsmalis@mac.com Web site: www.radialstackers.com CONVEYOR REPLACEMENT PARTS • Pulleys • Belts • Idlers • Motors • Gearboxes • Hood Covers • Fasteners Nationwide Availability Reasonable Prices CONVEYORS RADIAL

STACKERS CONVEYOR PARTS

Photos courtesy of Cody Witt.

21 July / August 2023 Soil & Mulch Producer News www.chromascape.com service@chromascape.com *Three Sites in South Carolina Warehouses Arizona Texas South Carolina* Pennsylvania Ohio

US Maintains Duties Against Canadian Lumber Imports

Washington, D.C. – The U.S. Department of Commerce will stay the course on taxing Canadian softwood lumber imports, reports Northern Ontario Business. A statement issued by Canada’s Mary Ng, Minister of Export Promotion, International Trade and Economic Development expressed disappointment over the United States’ review regarding anti-dumping and countervailing duty orders on certain softwood lumber products.

The U.S. Department of Commerce conducts this review annually. Although similar to initial investigations, it applies only to companies that are subject to review.

The new combined “all others” duty rate that will apply to most softwood lumber exports is 7.99%, compared to the previous rate of 8.59% from the third administrative reviews. These new rates will apply on a going-forward basis to exports of softwood lumber products to the United States from companies that were subject to the fourth administrative reviews. These duty rates will apply retroactively to softwood lumber exports to the United States made in calendar year 2021.

U.S. duties were imposed on Canadian producers in April 2017. Ontario’s forest sector created nearly $21 billion a year in revenue from the sale of manufactured goods and services. Canada’s forestry industry directly and indirectly employs 142,000 people.

Minister Ng is calling for an “immediate negotiated solution” to the protracted dispute, noting that Canada is losing market share in the States as duties have led to a bump in lumber imports from offshore suppliers.

Maverick Environmental Announces Merger with Grand Equipment Company

Maverick Environmental Equipment recently announced that it has merged with Grand Equipment Company of Hudsonville, MI, a portfolio company of Cognitive Capital Partners (CCP).

Headquartered in Alma, MI, Maverick is a leading equipment dealer of aggregate processing, waste recycling and environmental equipment, parts, attachments, and services. Spanning four locations across Michigan, Ohio and California, Maverick offers multiple products from leading OEM’s of material processing and handling equipment.

Tim Smith and Charlie Stahl, co-founders of Maverick: “Our business has experienced tremendous growth during our first seven years, directly attributable to our top of line OEMs and our incredible team of employees. The quality of our brands along with the people we have supporting them will continue to be imperative to our continued success. Our new partnership with Grand Equipment Company not only improves our footprint, offerings, and service, but lays the groundwork for continued success in the equipment industry.”

22 Soil & Mulch Producer News July / August 2023 Soil & Mulch Producer NEWS Celebrating 52 Years Savannah Join us in this historic southern city for MSC’s 52nd Annual Meeting! This year’s meeting topics will include: • The Crow Report: What’s Going on in Washington D.C. • What About Biochar? • Technology That Works • Canadian Peat: Ideal for Growing, For Generations to Come • Other industry related sessions Keynote Speaker: Ken Schmidt Authentic Leadership and Customer Loyalty Expert Senior Role in Harley-Davidson Turnaround Author, Make Some Noise: The Unconventional Road to Dominance Mulch & Soil Council 2023 Annual Meeting October 10 - 12, 2023 The DeSoto Hotel Savannah, GA We Hope To See You There! For more info, go to www.mulchandsoilcouncil.org EQUIPMENT

PRODUCT SHOWCASE Sell your products / equipment here, call 440-257-6453.

&

23 July / August 2023 Soil & Mulch Producer News NTEP CERTIFIED WALZ SCANNER SYSTEMS Legal-for-Trade NTEP Certi�ied Volumetric Walz Scanner System Skid Steer/Lift Truck Scales Wheel Loader Scales Truck Scales (800) 747-0701 - www.walzscale.com 656 High Point Lane, East Peoria, IL 61611-9369

Ins I de Th I s Issue

Chef of Compost Industry Serves Up Custom Blends

PAGe 1

Study Finds Plastic Substitutes Don’t Break Down

PAGe 6

News From The Mulch & Soil Council

PAGe 8

Putting Sargassum Seaweed to Good Use

PAGe 15

Department of Defense Investigates Recycled Wood Building Material

PAGe 16

US Maintains Duties Against Canadian Lumber Imports

PAGe 22

PRSRT STD U.S. Postage PAID Cleveland, OH PeRmIT #1737 6075 Hopkins Road • Mentor, OH 44060 Ph: 440-257-6453 • Fax: 440-257-6459 Email: downassoc2@oh.rr.com Vol . XVII N o. 4 J ul / Aug 2023 www.SoilandMulchProducerNews.com