Hello and welcome to the October edition of the DGB Digital Magazine

It is spooky season, and so far this year, our industry has seen its fair share of scary moments. A litany of business collapses has produced anxiety and a jumpy disposition to much of the sector. Confidence remains fragile as we all look for signs that things may be getting better.

The upcoming budget looks like it is going to do nothing to alleviate our frustration and concern.

That being said, we saw continued activity in the M&A part of our market, with Laumann Group completing its major acquisition of Epwin Group, and Thermoseal making a purchase of their own.

Mental health was in the spotlight this month as well, with reports that nearly three-quarters of freelancers are paid late, and suicide rates continuing to be a serious problem for the construction sector as a whole.

As we make a final push towards the end of the year, many of us will be aiming to finish on a high note to help create positive momentum as we drive on to 2026.

We hope you enjoy this month’s edition!

Team DGB

Energy efficiency has become one of the most important considerations in today’s housing market. Rising energy costs and evolving regulations mean homeowners are increasingly focused on balancing comfort with running costs and sustainability.

For installers, this creates opportunities. Offering quality products can set your business apart and help you meet demand. At Origin, energy performance is not an afterthought – it is engineered into everything we design. Every product in the Origin range is built to not only meet current and future building regulations, but to exceed them too. That means installers can specify our systems with confidence, knowing they are offering the most thermally efficient door and window systems on the market. This is made possible by our in-house research and development team, who are continually innovating our systems to deliver

more for our partners.

Aluminium, while inherently strong and lightweight, is not naturally thermally efficient. The reason Origin systems perform so well lies in the technology our R&D team has developed to unlock their full potential. By combining advanced materials with precision engineering, we have created doors and windows that balance strength, aesthetics, and best-in-class performance.

We are proud to be at the forefront of the drive for more thermally efficient glazing solutions, demonstrated clearly in our most recent product launch, the OS-29+ sliding door.

Innovation in action: Aerogel

One example of how we achieve outstanding efficiency is the use of Aerogel. When integrated into the polyamide break, it allows our OW-80 premium window to achieve U-Values as low

as 0.8 W/m2K. Aerogel is the least conductive material on earth and has even been used in space exploration to insulate astronauts’ suits. When applied in glazing systems, it provides remarkable thermal performance without increasing bulk or weight.

Alongside Aerogel, other technologies play a vital role. Thermal breaks within the aluminium frame interrupt heat transfer, which allows rooms to remain cool in summer and warm in winter. These design innovations mean our systems can deliver levels of efficiency that were once only possible with far heavier or less versatile constructions.

The OS-29+ is a clear example. Engineered to achieve U-Values as low as 0.78 W/m2K, it is the most thermally efficient aluminium sliding door available in the UK today. This level of performance allows installers to specify a statement product that also sets the benchmark for energy efficiency.

What sets Origin apart is not just efficiency, but the balance it finds between thermal performance and design. For example, our OW-

70 window achieves such impressive U-Values in a double-glazed unit that other manufacturers can only reach the same performance with triple glazing.

For homeowners, this means improved comfort without the higher material costs of an additional pane of glass. For installers, it is a powerful message to share: better performance, less complexity, and greater value.

The future of construction is clear. Homes must be built to use less energy, and glazing plays a central role in this. At Origin, our products already go beyond the standards of today and tomorrow, ensuring that every system installed is future-ready.

For our partners, this provides reassurance. They can show customers that their investment is not only stylish and durable, but also designed to keep their home efficient and comfortable for decades to come.

By working with Origin, partners can offer glazing solutions that help them meet market demand, build trust, and secure long-term success.

Ben Brocklesby, Director at Origin, leading manufacturer of premium aluminium doors and windows, discusses how installers can stand out in a crowded marketplace by offering homeowners exactly what they want.

Simply offering quality products isn’t enough to drive sustainable growth in today’s competitive fenestration industry. For installers to truly thrive, they must shift their focus from selling products to delivering a complete solution for homeowners.

For this to happen, installers must first understand what homeowners want. They are not just looking for functionality and aesthetics; they are also craving performance. One of the most pressing issues homeowners are facing at the moment is the price of energy. This means thermal efficiency is now increasingly important to them. Homeowners are actively seeking ways to save on bills. As a result, installers need to be able to recommend products that meet or even exceed current and future thermal efficiency regulations.

Home security also remains a top priority for homeowners. So, in order to stand out above the rest of the market, installers must be offering products that boast advanced locking systems

and innovative security features. These, in turn, offer homeowners greater peace of mind.

Homeowners take pride in their homes and want products that complement their home’s interior and exterior style, whether it’s modern, traditional, or something in between. Being unique is also something homeowners truly value. With this in mind, it’s vital that installers offer a wide range of colours, finishes, and customisation options in order to meet these diverse aesthetic needs.

With a greater understanding of what homeowner’s want, installers can tailor their offering to be much more targeted, speaking directly to a customer’s buying priority. This is vital in a saturated market.

For example, Origin’s newest product addition, the OS-29+, is a completely new sliding door system that combines minimalist design with cutting-edge performance. The system embodies these three key homeowner desires: thermal efficiency, security, and aesthetics.

The OS-29+ has been carefully engineered by our in-house research and development team to deliver exceptional thermal performance. Achieving U-Values as low as 0.78W/m2K, this system redefines what is possible for sliders and is the most thermally efficient aluminium sliding door available. This level of efficiency gives installers and specifiers a new option for customers looking to improve a home’s energy performance.

With a greater understanding of what homeowner’s want, installers can tailor their offering to be much more targeted, speaking directly to a customer’s buying priority. This is vital in a saturated market. For example,

Origin’s newest product addition, the OS-29+, is a completely new sliding door system that combines minimalist design with cutting-edge performance. The system embodies these three key homeowners’ desires: thermal efficiency, security, and aesthetics.

Our sleek, tactile, high-end signature knurled handles tie perfectly into our full product suite, allowing installers to offer a cohesive look across bi-folds, internal doors, windows and sliders.

The new Sliding Door exceeds all required security accreditations and achieves PAS:24, providing homeowners with ultimate confidence in their investment. With a multi-point lock and 3-Star Diamond Cylinder, it delivers unrivalled home security. Therefore, no matter the priority, the OS-29+ delivers a superior and future-ready solution for modern glazing requirements.

Installers can also offer clients significant design flexibility. With over 150 RAL colours available, the OS-29+ can be fully customised to suit a wide range of styles. Combined with Origin’s own in-house powder coating facility, accredited by Qualicoat, every door benefits from a

flawless and long-lasting finish. Our 10-stage pre-treatment process ensures the aluminium is thoroughly prepared before coating, giving the product the durability and level of finish our Trade Partners expect.

It has never been more important for installers to stand out. To do this, they need to truly understand what homeowners want, tailor their offering, and deliver on the promise.

By aligning with Origin, installers get the unique combination of unrivalled thermal efficiency, design flexibility, and guaranteed quality, which helps them be relevant for more projects and close more leads.

It’s never been more important for installers to stand out. understanding the homeowner’s wants, tailoring the offering and delivering on promises is key. By aligning with Origin, installers get the unique combination of unrivalled thermal efficiency, design flexibility, and guaranteed quality, which helps them be relevant for more projects and close more leads. Find out more about becoming an Origin partner.

Reflecting its continuing growth and evolving offer, Endurance® Aluminium has launched an extensively updated sales brochure.

The new brochure builds on the success of a version published earlier this year and has been produced to accommodate a number of recently introduced product lines.

This includes Endurance® Aluminium’s new sash windows, which combine heritage looks with modern materials and design innovations, as well as its new tilt and turn windows. These latter products continue to be a sought-after choice, especially in modern homes, thanks to their versatility and functionality.

In addition, the latest brochure provides in-depth information on Endurance’s new contemporary aluminium front doors, which can add extra kerb appeal to any property, and on its lift and slide patio doors.

These new doors complement a wider door offering that already features French, bifold and heritage doors. They also deliver the same trademark levels of aesthetic appeal, security and thermal efficiency.

Another new product detailed in the updated Endurance® Aluminium brochure is roof lanterns. The fabricator has introduced these

increasingly popular fenestration solutions to ensure installer partners and homeowners alike can enjoy their many benefits.

This includes the ability to flood an area with natural light, creating a sense of openness and space.

Finally, the new brochure also outlines the growing range of design options offered by Endurance® Aluminium such as a new woodgrain foil finish. This is now available across its entire range.

Scott Foster, marketing director at the Endurance group, comments: “The publication of the new Endurance® Aluminium brochure is indicative of the strength of our commitment to our installer partners.

“Our willingness to publish this latest edition so soon after our previous version stems from our unrelenting desire to offer our installers the most up-to-date and factually correct sales aids.

“It joins an already comprehensive tool kit of other assets and items, such as social media templates, high-quality photography and online designers, all created with one simple aim.

“To help our installer partners maximise their success.”

Following on from the news that VEKA parent company Laumann Group was to launch a bid to acquire Epwin Group Plc, the company has now announced that the acquisition has been completed.

This mega-merger was part of a frenzied period of M&A activity within the sector during the summer period.

The announcement was made via a press release on the Laumann Group website:

The German-based Laumann Group SE is pleased to announce the successful acquisition of the UK-based Epwin Group plc, a formerly publicly listed and successful business within the UK construction industry. This acquisition represents a key milestone in Laumann’s long-term growth strategy, which focuses on expanding its geographic and product footprint, strengthening technical and service capabilities, and reinforcing its position as an innovative and dependable partner to the international construction sector.

The UK is considered an attractive and strategically important market for Laumann

Group, which is characterized by strong demand in the repair, maintenance and improvement (RMI) sector, an active housing market and upcoming public investment programs. Epwin’s established brands, specialized product portfolio and nationwide distribution network complement Laumann’s existing operations, which create opportunities for cross-selling, operational synergies, and diversification across multiple market segments.

The integration process will be managed collaboratively by Laumann Group, with all companies continuing to operate under their established brands and management structures, ensuring continuity for customers and partners.

Jon Bednall, CEO of Epwin Group, comments: “We are excited to join forces with Laumann Group, and we look forward to working collaboratively to ensure the smooth integration of Epwin into the Laumann Group of companies. This partnership will strengthen our ability to deliver high-quality products and services to our customers.”

Laumann Group has significant experience in successfully identifying, executing, and integrating acquisitions by leveraging synergies and combining expertise across its global network. The company will once again apply its well-established integration principle: “as much as necessary, as little as possible.” This approach, designed to preserve the strengths and individuality of each business, has already proven effective in previous integrations such as GEALAN (2014), Vinylit (2021), Syscon (2023) and PROCURAL (2023). The focus remains on creating value through collaboration while maintaining the unique capabilities that make each company successful.

The integration will follow a deliberate, step-bystep process. Both Laumann Group and Epwin Group are in excellent financial and operational health, allowing for a thoughtful and sustainable transition. Andreas Hartleif, CEO of Laumann Group, states:

“There is no need to rush. Both companies are strong and well-positioned. Our priority is to ensure a smooth integration that benefits employees, customers and partners alike.

Throughout this process, both companies will continue to operate on a ‘business as usual’ basis, ensuring stability for all stakeholders”.

The statement by Laumann Group gives some indication as to how the companies under their umbrella will operate. There was some speculation when this news broke that VEKA and Epwin could have been merged into one entity. That seems not to be the case, judging by the language in this press release. However, that doesn’t rule out it not happening in the future should Laumann decide that is what is best for their business. Both VEKA and Epwin have large and loyal customer bases. That would be a difficult sell to each of their own client bases.

This is clearly one of the biggest acquisitions of the year within our sector. There may well be others before the year is out, but it is highly unlikely we will see another deal of this size this year.

Read the original press release from Laumann Group here: https://www.laumann-group.com/ news/laumann-group-successfully-completesacquisition-of-epwin-group-plc.html

Major M&A news once again, this time in the aluminium part of our market, as it is announced that the European arm of Kawneer has been acquired by Munich-based Mutares Group.

This continues a string of acquisitions in the aluminium space as both the UK and European markets see further consolidation in the face of stagnant economic conditions.

A statement on the Kawneer website announced the following:

Mutares SE & Co. KGaA has successfully completed the acquisition of Kawneer EU. The transaction strengthens the Mutares Engineering & Technology segment as a new platform acquisition.

As of the 1st of October, Kawneer Europe, combining the strengths of our teams in UK, France and the Netherlands, has become a standalone company within the portfolio of the investment firm Mutares. This marks the beginning of an exciting new chapter. One that builds on Kawneer’s strong foundation while embracing fresh energy, ideas, and long-term growth.

We will continue to design, manufacture, and supply industry-leading aluminium systems across the UK, France and the Netherlands, now with the added strength of Mutares alongside us. Company profile of Mutares SE & Co. KGaA, Munich, a listed private equity holding company with offices in Munich (HQ), Amsterdam, Bad Wiessee, Chicago, Frankfurt, Helsinki, London, Madrid, Milan, Mumbai, Paris,

Shanghai, Stockholm, Vienna and Warsaw, acquires companies in special situations which show significant operational improvement potential and are sold again after undergoing a repositioning and stabilization process.

Read the original article here: www.kawneer.co.uk/news/kawneer-eu-now-partof-the-mutares-group/

A statement from Mutares was also released via their website:

Mutares SE & Co. KGaA (ISIN: DE000A2NB650) has successfully completed the acquisition of the European business of Kawneer (“Kawneer EU”). The transaction strengthens the Mutares Engineering & Technology segment as a new platform acquisition.

Kawneer EU is a leading designer, manufacturer, supplier, and distributor of aluminium window and façade systems, operating through three country-focused business units in the Netherlands, France, and the UK, each with deep market penetration and long-standing customer relationships. The company employs over 400 people. With over 450 customers and four highly efficient facilities, the platform delivers comprehensive building envelope solutions, including windows, doors, sliders, curtain walls, and framing systems in residential and non-residential markets, making it a onestop shop for customers.

Read the original article here: mutares.com/en/mutares-has-completed-theacquisition-of-kawneer-eu/

The next generation of door is here. The new Origin OB-36+ system is available in 2 di erent collections. The Soho aesthetic is perfect for replicating a sought-a er steel-look design, whilst the Contemporary style o ers an elegant way to maximise light levels in a home. Both systems are 2025 Future Homes compliant for thermal e ciency and feature sightlines of just 36mm.

Don’t get le behind. Stand out from the competition and futureproof your business by opening an account with Origin today. Call 0808 192 0042 or visit origin-global.com/partner-with-origin

After the success of its previous plan (“Grow & Impact”), Saint-Gobain, the worldwide leader in light and sustainable construction, launches its new strategic plan, “Lead & Grow”. With #1 positions in every region and its country-based operating model, well-adapted to its local markets and a deglobalised world, the Group is raising its profitable growth trajectory, targeting:

• Outperformance thanks to an unrivalled suite of solutions, delivering performance and sustainability for buildings and enabling the Group to increase its exposure to nonresidential and infrastructure.

• A strategy focused on growth and value creation with:

o Around €12bn in growth capex and acquisitions over the period 2026-2030

o Continued optimisation of the Group’s profile with asset rotation expected to represent over 20% of sales by 2030

• An ambitious financial trajectory over the period 2026-2030, with targets raised:

o Mid-single-digit sales growth on average in local currencies with market outperformance of 1 to 2 points

• EBITDA margin of between 15% and 18%

• Free cash flow conversion ratio above 50%

• ROCE above 13%

• Attractive shareholder returns with around

€8bn expected to be distributed in dividends and share buybacks by 2030

Benoit Bazin, Chairman and Chief Executive Officer, commented:

As the worldwide leader in light and sustainable construction, Saint-Gobain is best positioned to address the key challenges of the construction sector thanks to its full suite of innovative and sustainable solutions. Over the last few years, the Group has demonstrated the strength of its new profile and its capacity for execution with its “Grow & Impact” plan. With “Lead & Grow”, the Group further elevates its trajectory for growth, profitability and value creation for its shareholders and customers. In the current geopolitical context, Saint-Gobain benefits from the powerful operating model it has established and optimised countryby-country, based on local value chains.

Thanks to the know-how and commitment of our teams, I am confident we will outperform in each geography and seize major opportunities: in Asia and high-growth countries driven by demographics and urbanisation, in North America with strong structural needs, and in Europe with significant potential for recovery. We will also expand into new growth markets: in infrastructure, particularly thanks to our established leading position in construction chemicals, and in nonresidential, where the Group holds key advantages. We are building the world of today and tomorrow with ambition and responsibility.

Thermoseal, a leading manufacturer and distributor of insulating glass components and part of the Fenzi Group, is proud to announce the acquisition of Solutions UK, a respected British sales agency serving the glass and glazing sector. This strategic move strengthens Thermoseal’s commercial network across the UK and Northern Ireland, reinforcing the Fenzi Group’s commitment to customer proximity and market responsiveness.

Solutions UK has long been recognised for its deep industry expertise and strong relationships with glass processors. By joining Thermoseal, the agency will gain access to a broader portfolio of high-performance products and benefit from the resources and global reach of the Fenzi Group.

“Solutions UK brings exceptional market insight and customer service capabilities. Together, we’ll be even better positioned to support our clients with tailored solutions and faster response times,” said Mark Hickox, Sales Director of Thermoseal

Solutions UK will continue operating under its established name and team. As part of Thermoseal and the wider Fenzi Group, it will play a key role in expanding commercial operations and delivering integrated support to customers across the region.

The acquisition reflects Fenzi Group’s strategic vision to build a robust, customer-centric global network that drives innovation and excellence in glass processing.

Thermoseal is a leading UK-based manufacturer and distributor of components for insulating glass units, including spacer bars, sealants, and desiccants. As part of the Fenzi Group, Thermoseal combines local expertise with global innovation to serve customers across Europe and beyond.

Founded in Milan, Fenzi Group is a global leader in chemical products for secondary glass processing, including mirror backing paints, sealants for insulating glass, and decorative paints. With operations in over 90 countries, Fenzi is known for its commitment to quality, innovation, and sustainability.

Solutions UK is a specialist sales agency serving the glass and glazing industry. With a strong network and deep market knowledge, the company provides commercial representation and strategic support to manufacturers and suppliers across the UK and Europe.

Read the original article here: www.fenzigroup. com/en/fenzi-group/news-events/thermosealacquires-solutions-uk-expanding-fenzi-groupscommercial-reach-in-the-gla

Endurance® Doors is taking steps to ensure its

of specialist tutors from the CMI and require significant commitment from students.

The Level 5 course entails 370 hours of learning and usually takes a year to complete.

The Level 7 course, meanwhile, involves 557 hours of learning and typically involves around 15 months of studying.

Sharleen Lawless, HR Director at the Endurance

“To ensure these issues do not restrict the Endurance Group’s ambitious plans for the future, we are adopting a similar approach to many other large and progressive employers.

“We are creating our own internal talent pipelines by offering our team extensive scope for personal and professional growth as well as further opportunities to develop through internal mobility.”

The new Endurance training initiative enables staff to gain either a CMI (Chartered Management Institute) Level 5 or Level 7 Diploma in Management and Leadership. Completing either course also enables participants to earn Chartered Manager status. The courses are delivered online by a team

To date, three members of the Endurance team have completed the Level 5 course, with two of those students being awarded distinctions. One individual from the business has so far obtained the Level 7 qualification.

“The interest from the team in our CMI Level 5 and 7 training has been amazing” says Sharleen.

“Participants have come from all areas of the business, including operations, production, marketing, customer experience, technical, manufacturing and engineering.

“We’ve long recognised that our wider success stems from having engaged employees who feel empowered about their own development and career goals.

“The implementation of this latest initiative stems from that understanding and reflects our commitment to being an organisation that places its people first.”

Direct Trade (Yorkshire) Ltd is expanding its trade portfolio with the addition of the Entrance Composite Door Solutions range, providing installers with a high-quality, in-demand product designed to meet both homeowner expectations and building regulations.

The new doors combine cutting-edge engineering with installer-friendly features, offering the perfect balance of performance, aesthetics, and reliability.

• Highly customisable – Over 9,000 style combinations, including colours, hardware, and glazing options, making them easy to sell to a wide variety of customers.

• Market-leading security – PAS-24 certified with multi-point locking and Ultion cylinder options, giving installers a strong security selling point.

• Energy efficiency – High-density foam core and advanced construction for excellent thermal performance, helping properties meet Part L regulations.

• Installer peace of mind – 25-year structural guarantee and 10-year surface finish guarantee, reducing aftercare and callback risks.

• Low maintenance – GRP skins resist warping, fading, and weathering, ensuring long-term performance with minimal upkeep.

• Acoustic performance – Double or tripleglazed options provide sound insulation, ideal for urban or busy environments.

• Durability – Laminated timber frame and robust composite build for long-lasting quality.

Mark Powell – Sales Director at Direct Trade (Yorkshire) Ltd, commented: “We know our

trade partners want products that not only perform technically but are also straightforward to sell and install. The Entrance Composite Door delivers exactly that – a high-demand, specification-driven product that homeowners love, and installers can supply with confidence.”

The Entrance Composite Door Solutions range is now available to order through Direct Trade (Yorkshire) Ltd, complete with marketing support and technical guidance.

For trade enquiries, please contact:

Mark Powell (Sales Director)

Direct Trade (Yorkshire) Ltd

Email: mark.powell@directtradeltd.co.uk

Phone: 07800 585416

Web: directtradeltd.co.uk

Two Tradespeople Lose Their Lives to Suicide Every Day as Mental Health Crisis Deepens in Construction

Key Stats:

2 tradespeople take their own lives every day in the UK (Office for National Statistics, 2024).

Construction workers are 4x more likely to die by suicide than the national average (ONS, 2024).

84% of tradespeople have experienced work-related stress, anxiety, or depression (IronmongeryDirect, 2024).

58% have never spoken to anyone about their mental health (Chartered Institute of Building, 2024).

Fix Radio’s Clive Holland, host of The Clive Holland Show, is calling for urgent action as new figures expose a worsening mental health crisis

within the construction industry.

National helpline The Big Brew reports that one in three texts it receives are from construction workers contemplating suicide, with 80% of messages sent during the working week.

Clive Holland said the issue runs deep:

“There are several underlying reasons why the rate of suicide in the construction trades is so high. Firstly, there is a macho image in the industry and men are not brilliant at ‘opening up’. But I feel this is changing – slowly but surely. Secondly, there is a lot of stress involved in running a small business –long hours, few holidays, slow payers, and cash flow issues. Rising material costs, energy prices, and a worsening skills shortage have ramped up pressures even further. Many tradespeople will tell you they’ve never been this busy.”

MONET Money: 71% of Freelancers Paid Late as £26bn Backlog Triggers Mental Health Emergency

Key Points:

71% of UK freelancers were paid late in 2024; 55% said this directly harmed their mental health.

The UK’s £26 billion late-payment backlog is driving anxiety, burnout, and business failures –with 1 in 20 UK business closures now a creative agency.

Chronic financial stress is reducing creative performance and focus, while 69% of women in creative industries report bullying or harassment compounding mental strain.

“Late payments are not just an inconvenience. They drive insolvency in agencies, sap confidence from freelancers, and trigger a cycle of anxiety and burnout. If we continue to tolerate a £26 billion backlog, the UK risks eroding both the resilience of its creative economy and the well-being of the people who power it.”

– Jacob Casson, CEO, MONET Money

I believe that many of us within this sector will feel passionately about this subject, including myself. Many of us who operate in our sector are small

businesses. There are plenty of installers out there who are single teams operating out of a single van and from home. Cash flow to individuals and companies of this size is absolutely vital. There is great emotional investment and commitment when it comes to small businesses, so when bills are paid late, it causes great mental stress on the person/persons running that business.

I have said on here, and on the DGB social channels in the past that larger companies need to pull their finger out and pay people on time. I am firmly of the belief that insane payment terms, such as 30/60/90 days, or 30 days end-of-month ought to be consigned to the bin. It is simply a way for larger businesses to drag out paying people the money they are owed.

Our industry constantly beats the drum for mental health, but in all honesty, I fear a lot of it is PR rather than meaningful action. One way to solve a lot of people’s stresses and strains is to ensure they are paid promptly, without delay, in full and without fuss. It is amazing how much less stressed you can feel when there is a decent bit of cash in an account, knowing all the bills will be paid. Like a weight being lifted from your shoulders.

Glass Futures is proud to announce a significant breakthrough in the commissioning of its worldfirst experimental glass furnace. At the start of this week, the team successfully rolled the first glass from the furnace, marking a pivotal moment in the journey to deliver a transformative R&D asset for the global glass industry.

Glass Futures is a global innovation platform that brings together industry, academia, and government to turn ambition into action. At the heart of its pilot facility is an innovative 30-tonneper-day oxy-fired pilot furnace, designed to showcase sustainable technologies and approaches.

From pioneering the world’s first multi-fuel hybrid pilot-scale glass furnace, to enabling circular supply chains and smarter manufacturing, Glass Futures delivers real-world solutions at scale. This achievement follows months of meticulous planning, engineering, and collaboration. The furnace, lit in June of this year, is designed to enable advanced analysis of glass flow and composition.

After overcoming commissioning challenges, including melting glass in an area near the furnace exit where directing heat is more difficult, the team successfully achieved full commissioning of the furnace and began rolling glass through both the rolled plate line and annealing lehr.

“This is a huge step forward,” said Justin Kelly, CEO of Glass Futures. “This milestone brings to life the investment in this national research and innovation asset with globally unique innovation capability. Along with the fantastic team at Glass Futures and our members, we are now fully open and actively collaborating.”

Support from our members, who contributed their expertise, played a vital role in this success. Glass Futures will now begin its formal trial programmes, with this milestone paving the way

for groundbreaking research and innovation in sustainable glass manufacturing.

Several such pioneering programmes are funded under the UK government’s Industrial Fuel Switching (IFS) initiative from the Department of Energy Security and Net Zero. These programmes will explore alternative energy sources such as waste-derived biofuels, electrical boosting, and hydrogen, aiming to revolutionise hightemperature industrial processes and reduce reliance on fossil fuels.

Aston Fuller, General Manager at Glass Futures said, “Having been part of Glass Futures since the very beginning, seeing the first glass roll from our furnace is a moment I’ll never forget”

Aston added, “It’s the result of years of vision, planning, and relentless hard work from an incredible team. This milestone isn’t just about commissioning a line, it’s about proving that innovation, collaboration, and perseverance can reshape the future of glass manufacturing and beyond.”

“Witnessing the first piece of glass was an incredible moment for the whole team” said Andy Pink, Head of Operations at Glass Futures. “This has been a complex and demanding commissioning process, and I’m immensely proud of the tireless work, resilience, and collaboration that got us here. We’ve overcome real technical challenges, and while there’s still more to do, this milestone proves what’s possible when a team of great people come together with a shared purpose.”

Glass Futures extends its sincere thanks to all of its funders for their invaluable support, including Innovate UK, Liverpool City Region Combined Authority and St Helens Council.

Read the original article here: www.glass-futures.org/

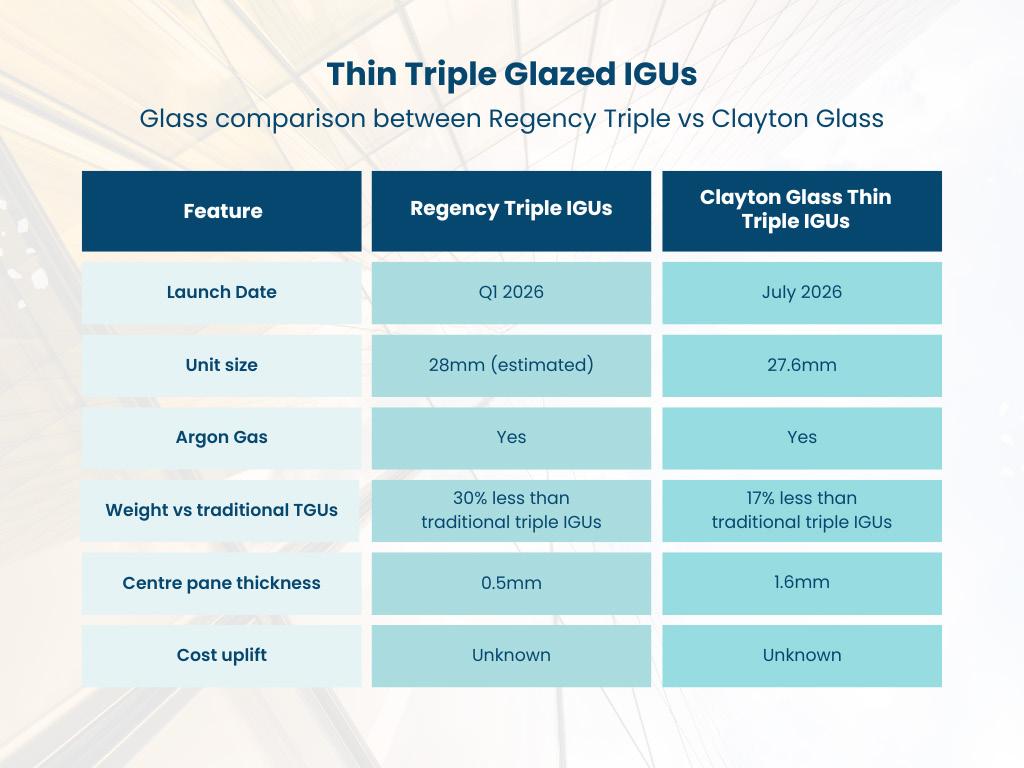

I think it is fair to say that triple glazing has had a pretty mixed performance over the past ten to fifteen years. Once billed as the next generational change in IGU technology, it has failed to gain the traction some had hoped it would.

Progress for triple-glazed units has been held back by a number of issues, including cost, weight, profile limitations, transport and hardware. Although demand for lower U-Values from homeowners and clients undertaking large renovation projects or self-builds has seen the use of triple glazing increase.

Things might be about to change, however, as two leading IGU producers are about to bring to market new triple-glazed units which may well address a number of those issues just stated. One of which has the backing of US glass and tech giants Corning Incorporated.

The two companies in question are Regency Glass and Clayton Glass. Those of you who follow these companies on social media, especially LinkedIn, will have seen both these businesses announce new innovations in the triple glazing space.

For now, based on a LinkedIn post by Clayton Glass, they are calling theirs Thin Triple IGUs. Regency have branded theirs Regency Triple. There is more information publicly available about the Regency Triple product, with limited information on the Clayton Glass product. But for the sake of communicating what is known as clearly as possible, below is a comparison table to help us understand the differences between the two technologies:

According to the information that is available,

Regency Triple is going to be the first to market, with the company saying its product will be available from Q1 2026. That puts it anywhere between January and March of next year. Clayton Glass have stated in a short video interview, which you can see further below, that theirs will be available from July 2026.

Regency Glass have partnered with Corning Incorporated, which is a glass and tech giant in the US. You’re likely to be reading this article via a Corning glass product. They are the company behind Gorilla® Glass, which is the glass used on billions of smartphones and other devices around the world. However, it is their Enlighten™ Glass, which is a technology that has been around in various iterations since the 1960s, that is used as the razor-thin centre pane in the Regency Triple product. The 1.6mm centrepane product appears to be a UK-developed innovation from Clayton Glass – something which will become clearer the more that is known about the product.

Thermal performance is not yet known for both products, but I think it is safe to assume that U-values for both are going to be lower than

regular double-glazed units and perhaps tripleglazed ones as well. I welcome comments from Regency and Clayton in the section below if they want to elaborate further.

In terms of weight performance, Regency Triple appears to be the frontrunner, with a 30% reduction in weight compared to conventional triple-glazed units. Cost uplifts for these products are not yet known either. But again, we can assume that they are going to cost more than regular DGUs.

Both companies have released videos on their new thin triple-glazed products. Regency have also published an article which expands further on their new product and partnership with Corning:

Additional information provided by Regency Glass:

The company will introduce the “Regency Triple” featuring Corning® Enlighten™ Glass in early 2026.

Regency Glass Ltd, in collaboration with Corning Incorporated, one of the world’s leading innovators in glass, ceramics, and materials science, will soon launch its highly anticipated, next-generation triple-glazed unit: Regency Triple featuring Corning® Enlighten™ Glass. This revolutionary product is set to launch in Q1 2026, and today marks the first time its name is shared publicly.

At the heart of the Regency Triple lies an innovation not yet seen in the UK market: a 0.5mm piece of Corning® Enlighten™ Glass. The collaboration between Regency Glass and Corning brings to life an ultra-thin glass tripleglazed unit that delivers all the performance of a traditional triple-glazed unit without the bulk, weight, or compromise.

The Regency Triple is not just another tripleglazed unit; it is a leap forward in insulated-glass unit (IGU) technology, offering real-world benefits across fabrication, installation, and performance, including:

Ultra-thin profile: Provides the benefits of triple glazing whilst fitting seamlessly into a 28mm cavity, making the Regency Triple an ideal solution for the replacement window market. Lightweight design: Features a 30% decrease from conventional triple-glazed units and only a 5% weight increase compared to conventional double-glazed units, making product handling easier for installation teams.

Enhanced thermal performance: Delivers impressively strong thermal insulation, helping homeowners improve energy efficiency without costly or bulky frame modifications.

Design flexibility: Offers custom cavity widths available to suit any specification due to the use of a Thermo Plastic Spacer bar, also known as TPS®.

Thermal durability without tempering: Corning® Enlighten™ Glass delivers high thermal durability, offering protection from field thermal breakage.

READ FULL ARTICLE HERE: https://www. regencyglass.co.uk/our-next-generation-tgu-

regency-triple-featuring-corning-enlighten-glass/

READ LINKEDIN CLAYTON GLASS POST HERE: https://www.linkedin.com/feed/update/ urn:li:activity:7381267035747532800/

Some of the biggest barriers to traditional triple-glazed units have been excessive weight, storage, pressure on hardware and installers, amongst other things. But if we are looking at triple-glazed units that are 30% lighter, can achieve U-values that reach or surpass current Building Regulation requirements, that can fit into 28mm cavities across all profiles, which puts less strain on installers and fabricators alike, then we have products which look like they could have huge potential.

On the surface, both these products appear to solve problems that our industry has chewed over for some time. Obviously, there is more to be discovered about these products. We do not know their official U-values and cost. Once we do, we’ll have a better understanding of the potential of these products.

In his video interview, Clayon Glass Director Ryan Green thought it could take 5-10 years for this product to take off properly. I think that is a slightly conservative estimate, perhaps intentionally. If these products can nail solid U-values, or perhaps even better than what we can achieve now, and is at a price-point that doesn’t make the product prohibitive to installers and consumers, then I think we could be looking at a new glass technology that is going to be in high-demand.

In a LinkedIn post about this subject, there were a number of other questions that were posed by DGB followers. Size limitations were one point that was raised, another being questions around handling and processing, max sizes, etc. All of these, I am sure, will be answered as more information is provided.

I will continue to follow the progress of both these products over the coming months. I am eager to see how it is going to transform the triple-glazed market and fenestration as a whole.

Modern energy-efficient windows are designed to reduce thermal transfer between indoors and outdoors. While this improves comfort and lowers heating and cooling demand, it also creates a counterintuitive effect: external condensation. This phenomenon, most noticeable during spring and autumn mornings, can be explained through the interplay of surface temperature, ambient humidity, and thermodynamics.

Condensation occurs when air temperature drops to its dew point—the temperature at which air becomes saturated and can no longer hold all its water vapor. At this point, vapor condenses onto nearby cooler surfaces.

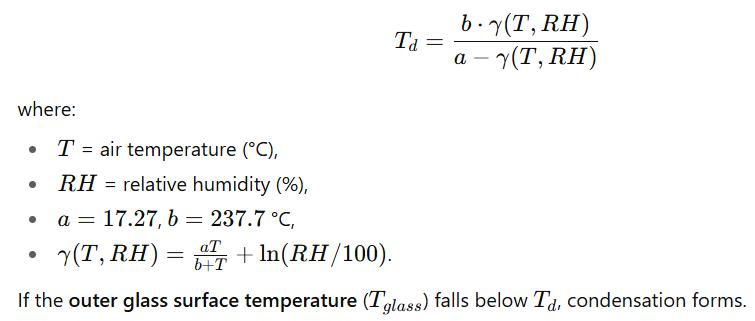

The dew point TdT_dTd can be approximated by the Magnus-Tetens formula:

Double- and triple-glazed units contain lowemissivity coatings and inert gas fills (argon, krypton).

These reduce U-values (overall heat transfer coefficients), typically to 0.7–1.2 W/m²K compared with 2.5–3.0 W/m²K for single glazing.

Result: little indoor heat is conducted outward. The external pane remains colder, closer to ambient outdoor temperature.

Glass radiates heat to the night sky, especially under clear conditions, often cooling below ambient air temperature.

Older, less efficient windows gain compensating heat leakage from indoors, reducing the chance of condensation.

Nights are cool, days are warming, and relative humidity is often high (80–95% at dawn).

These conditions place below the morning dew point for several hours, encouraging droplet formation.

Spring: Rapid transitions from cool nights to warmer, moist mornings.

Autumn: Cooler surfaces from nighttime radiative cooling, combined with moist air as temperatures fall.

In summer, outdoor temperatures remain high enough that dew points rarely exceed glass surface temperatures.

In winter, cold outdoor air holds little moisture, so dew points are too low for condensation to form.

External surface condensation: Normal, seasonal, evidence of low U-value glazing. Internal surface condensation (indoors): Caused by high indoor humidity and poor ventilation.

Interstitial condensation (between panes): Indicates IGU seal failure—argon gas has escaped and moisture has penetrated.

Although harmless, condensation may obscure views temporarily. Solutions include:

Hydrophobic coatings (e.g., TiO₂-based nanocoatings) to accelerate droplet dispersion.

Window placement considerations: North-facing and shaded elevations are more prone due to reduced solar gain.

Microclimate control: Reducing vegetation near windows lowers localized humidity.

External condensation on high-performance glazing during spring and autumn is a byproduct of physics, not a defect. It arises when the outer pane cools below the dew point due to:

• suppressed conductive heat transfer (low U-values),

• strong nocturnal radiative cooling, and

• elevated morning humidity.

Rather than being a problem, this phenomenon confirms that the window unit is minimising heat loss, functioning as designed, and delivering the thermal insulation benefits that older glazing systems cannot.

The latest Builders Merchant Building Index (BMBI) report, published in October, shows builders’ merchants’ total value sales in August 2025 were down -5.0% compared to the same month a year before. Year-on-year volume decreased -4.1% while prices were also down -1.0%. With one less trading day in 2025, likefor-like value sales for August (which take trading days into account) were -0.3% lower. Only one of the twelve categories sold more in terms of value compared to August 2024 – Workwear & Safetywear – which was up +2.7%. The worst performing categories were Ironmongery (-6.4%), Heavy Building Materials (-6.6%) and Decorating (-7.8%), but Timber & Joinery Products (-3.0%) performed better than Total Builders Merchants.

Looking month-on-month, value sales in August were -12.7% lower than in July. Volume sales were down -13.4% and prices increased +0.8%. All categories sold less, but Ironmongery (-14.5%) and Miscellaneous (-15.0%) declined more than the rest. With three fewer trading days in August, like-for-like value sales were +0.3% higher.

Total value sales in the 12 months from September 2024 – August 2025 were up +0.1% compared to the previous 12-month period (September 2023 – August 2024). Volume sales were up +1.9% but prices decreased -1.8%. Five categories sold more by value, with Services (+3.1%), Tools (+2.9%) and Landscaping (+2.3%) performing best. Timber & Joinery Products, one of the

two largest categories, fell by 0.6%. Decorating (-2.7%) was the weakest category. With one less trading day in the most recent period, like-for-like value sales increased +0.5%.

Total value sales year-to-date (January to August 2025) were up +0.8% compared to the first eight months of 2024.

Mike Rigby, Managing Director of MRA Research, which produces the BMBI report, says: “August was an extra quiet month for Britain’s builders’ merchants and their builder and trade customers, with volumes down yearon-year and month-on-month. How much of the drop can be blamed on the weather and how much on hesitancy among consumers and businesses as the economic landscape looks uncertain is anyone’s guess. But 2025 has pushed the famous summer of 1976 out of the UK’s top five hottest summers on record. An August heatwave brought temperatures of 33.4C in parts of England with 31.6C the highest in Scotland. The weather was also variable and varied by region, with hosepipe bans across large parts of England, while Storm Floris brought gusts of over 80mph to parts of the UK and widespread disruption in Scotland. Not ideal for external work!

“But confidence in the economy and in the Government’s handling of it is undoubtedly playing a part, with almost daily references in the news to the Chancellor’s delayed Autumn budget and the bad news it may bring. The Institute of Directors announced in October that business confidence was at a record low

according to its Economic Confidence Index, while consumer confidence dropped two points to -19 in September according to the longrunning GfK Consumer Confidence Index. With grocery inflation rising to +5.2% in October, and official UK inflation data expected to follow, there is no let-up in the squeeze on already stretched budgets.

“That said, there is good news for merchants, in the chancellor’s pre-budget announcement, with Rachel Reeves expected to unveil a new raft of planning changes to make it easier for developers to press ahead with housebuilding and infrastructure projects. This could be the shot in the arm the construction industry needs to get building again, but the government may need to do more to revive consumer and business confidence.”

Set up and run by MRA Research, the BMBI – a brand of the Builders Merchants Federation – is a monthly index of builders’ merchant sales, and the most reliable, up-to-date measure of Repair, Maintenance and Improvement (RMI) activity in the UK. The index is based on actual sales from GfK’s Builders’ Merchant Point of Sale Tracking Data, which captures value sales out to builders from generalist builders’ merchants, accounting for 88% of total sales from builders’ merchants throughout Great Britain. An in-depth review, which includes commentary by sector experts, is provided each quarter.

August’s BMBI report is available to download at www.bmbi.co.uk.

T a c k l i n g g e n u i n e , t h o u g h t p r o v o k i n g

U K g l a z i n g i n d u s t r y i s s u e s o n a d a i l y

a n d i n d e p e n d e n t b a s i s

S e t t o b e r e a d b y o v e r a q u a r t e r o f a m i l l i o n p e o p l e , c r e a t i n g o v e r

3 5 0 , 0 0 0 p a g e v i e w s

( e s t i m a t e d 2 0 2 5 s t a t s )

LATEST NEWS FIRST

R e a d t h e m o s t i m p o r t a n t b r e a k i n g

n e w s , f e a t u r e s , o p i n i o n a n d P R l o n g

b e f o r e y o u ' l l s e e t h e m i n p r i n t