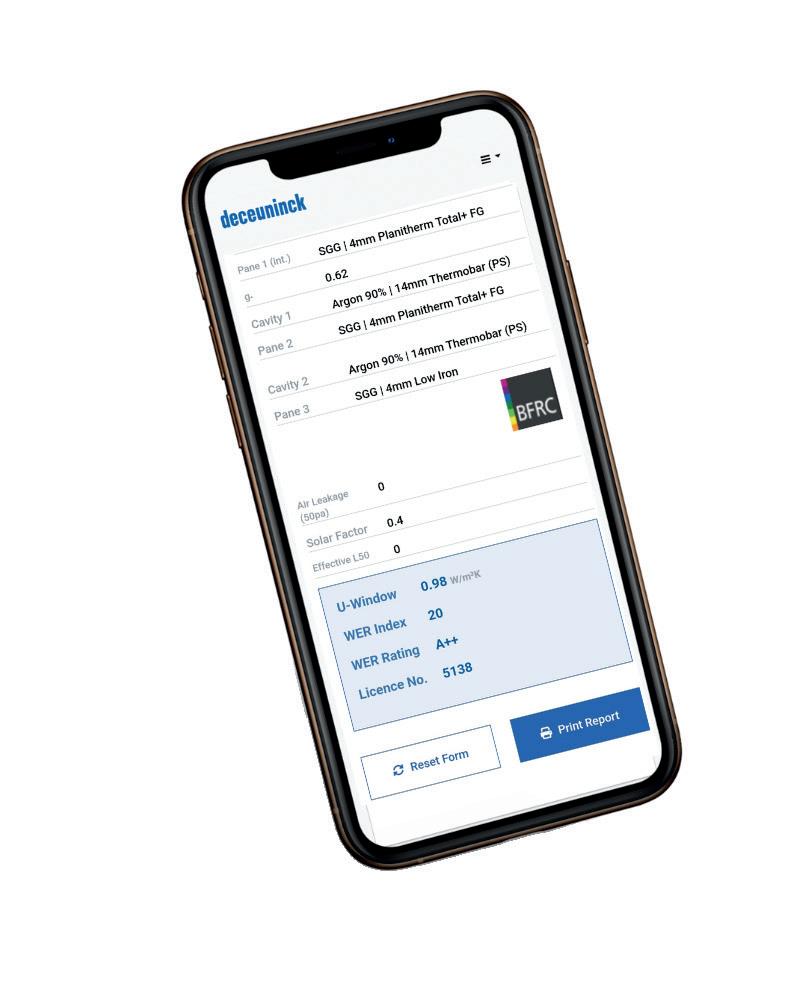

Powered by Deceuninck

Developed with Deceuninck fabricators & installers in mind, our Business Kit gives

FREE Leads & Lead Dashboard

Dedicated Subsites on 3 Websites

Media Centre

Product Configurator

Energy Savings Calculator

Energy Ratings Calculator

Award Winning Marketing

Brochures, Images, Videos, VR Tours & more!

John Cowie

Editor - Head of Online Content

E: john.cowie@windowsactive.co.uk

Jennie Shoglen - Graphic Designer

Emma McCormack - Sub-Editor

ADVERTISING SALES

Steve Gravestock Sales Director

Tel: 07990 671901

E: steve.gravestock@windowsactive.co.uk

Donna Crockatt

Publishing & Sales Executive

Tel: 07919 448809

E: donna@windowsactive.co.uk

PRODUCTION AND CIRCULATION

Tel: 07919 448809

E: production@windowsactive.co.uk

WINDOWS ACTIVE is published by: Active Magazines Limited PO Box 627

Rickmansworth Herts, WD3 0BQ

Stuga Machinery has confirmed an exciting new chapter as its parent company, Stürtz Group, becomes part of Voilàp Group. The move unites three wellestablished machinery names – Stuga, Stürtz and Voilàp and marks a significant step forward for UK fabricators. Customers can expect continuity from Stuga’s trusted UK team, combined with the additional strength, innovation and resources of a strategic global partner.

In his latest Podcast, Guy Hubble MD of RegaLead, sat down with the Managing Director of Portico Doors Tony Craggs.

The UK’s fenestration industry is navigating a phase of cautious consumer spending, with recent Google Trends data over the last three months revealing a market adjusting to persistent economic headwinds. The fenestration sector sees ‘flight to quality’ writes John Cowie

“What I value most is the way Heritage has expanded while staying true to the principles we were founded on. In the past five years we have doubled in size, which speaks to the strength of our team, the quality of our products and the loyalty of our customers.”

Paul Culshaw MD of Heritage Trade Frames

Our popular in-bound supplements are a must read. This month we bring you the Hardware Active edition - a look at all the locking and movement mechanisms for windows and doors.

Natasha Erskine, Marketing Director, UKO Group: “In today’s competitive landscape, businesses must do more than deliver quality products, there has to be a bigger focus on building and maintaining meaningful relationships with their customers. Our growth story is rooted in the simple but powerful principle of putting the customer at the heart of everything we do.”

The atmosphere at the recent Glazing Summit was, at times, difficult to shake. In a room where the prevailing tone leaned toward economic pessimism, it was hard not to be drawn into the wider narrative of slowdown, stagnation, and strain. With the UK economy faltering, the prospect of further tax rises in the autumn budget, and the looming burden of new employment legislation, the outlook for many sectors, fenestration included, appears fraught. Yet to remain mired in this downbeat trajectory is to miss the opportunity that remains present within the market. Yes, sales leads are falling. Yes, costs are rising. And yes, regulatory changes continue to add complexity. But beyond the headlines, there are encouraging signals, if the industry is prepared to pay attention to them.

One such signal emerged from the Summit itself: the notable absence of installers in the audience. Rather than suggesting disengagement, this absence could well reflect strong activity on the ground. Conversations with those in the field support this, with many installers reporting steady pipelines and rising order values, a reassuring counterpoint to the gloom that dominated the conference room.

What’s particularly striking is the profile of today’s customer. While the number of enquiries may be lower, the value of those that convert is increasing. Much of this spending is being driven by younger homeowners, aged 25 to 35, who are demonstrating a growing appetite for high-value installations. This shift in consumer behaviour hints at a broader cultural trend: the home as an investment, not just a place to live.

For an industry often geared toward traditional sales models and demographics, this represents both a challenge and an opportunity. Younger consumers are more informed, more discerning, and more technologically inclined. Their expectations differ and so must the industry’s response. Among the most under-leveraged opportunities is smart technology. Despite growing consumer interest in connected home solutions, the UK fenestration sector has been slow to embrace products such as smart locks, sensors, and integrated home security systems. Anecdotal resistance, often framed around mistrust of smart locks, persists, yet feels increasingly out of step with broader consumer behaviour. It is difficult to reconcile the widespread acceptance of digital

locks on cars and hotel rooms with the hesitancy around residential installations. The real issue may lie less with the consumer and more with how the trade is selling, or not selling , the benefits of smart technology.

In markets such as France, smart functionality is often integrated as standard, enhancing the value proposition and sustaining premium pricing. With the global smart windows market forecast to grow from $6.45bn in 2025 to $9.54bn by 2029, the UK risks falling behind if it continues to treat smart products as optional addons rather than essentials.

Another area ripe for re-evaluation is marketing. Too often, the industry leans heavily on pay-per-click and Google Ads, overlooking the value of brand-building at a local level. Homeowners trust names they recognise, a truth evident in sectors like kitchens and bathrooms. Fenestration should be no different. A strong local brand can rival and, in some cases, surpass a national competitors in securing consumer confidence. Visibility, reputation, and consistent messaging are vital. And with manufacturers investing heavily in innovation, from thermal performance to design aesthetics, the challenge is not a lack of compelling product, but a failure to communicate its value effectively.

As one speaker at the Summit put it: “What’s in your toolbox?” The answer, it seems, is more than many realise. From smart technology to advanced materials, from local brand equity to rising consumer demand, the industry has tools at its disposal. But using them requires clarity of purpose. Rather than diversifying into adjacent home improvement sectors, the fenestration industry might do better to focus on what it does best and do it better. Retrofit solutions, smart integration, and consumer-led product development should form the core of a renewed growth strategy.

In a sector often prone to introspection, it’s time to shift focus from problems to potential. The fundamentals are changing not collapsing. And those prepared to engage with the emerging demands of a younger, savvier, and more qualityconscious homeowner may yet find that the glass is, in fact, half full.

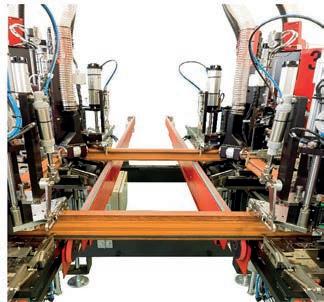

John Cowie Editor

Stuga Machinery has confirmed an exciting new chapter as its parent company, Stürtz Group, becomes part of Voilàp Group – the Italian-based global leader in automation and digitalisation. The move unites three well-established machinery names – Stuga, Stürtz and Voilàp – and marks a significant step forward for UK fabricators. Customers can expect continuity from Stuga’s trusted UK team, combined with the additional strength, innovation and resources of a strategic global partner. With Voilàp’s backing, our customers can now plan with confidence, knowing that Stuga and Stürtz have a stable, long-term foundation.

For more than 40 years, Stuga has designed and built its own range of sawing and machining centres in the UK, supported by a full in-house engineering, production and aftersales service operation. That specialism has made Stuga a trusted partner to fabricators of all sizes, helping them automate uPVC window and door production with reliable, UK-supported machinery. Since joining the Stürtz Group in 2022, Stuga customers have benefitted from a wider portfolio of welding and cleaning systems, giving them the ability to scale automation across the factory floor. Now, with Voilàp’s backing, Stuga is able to continue investing in service, innovation and long-term support – combining the stability of a trusted UK brand with Voilàp’s long-term vision, industry knowledge, technology expertise, and financial strength.

For UK fabricators, the message is clear: Stuga continues to operate with the same experienced management, engineering and service team in Great Yarmouth, but

now on a stronger foundation thanks to the scale and resources of Voilàp. The respected British brand retains its home-grown expertise while gaining the capabilities of a global industrial group, giving customers access to a wider range of automation solutions. Alongside Stuga’s UK-built machinery, fabricators can benefit from Stürtz’s proven product range and Voilàp’s advanced automation and digital innovation. Existing Stürtz users in the UK can remain confident in the local support they receive, now underpinned by enhanced global resources. Reinforced supply chains, ongoing investment in parts and product development, and a commitment to long-term reliability all add up to greater resilience for the future.

“By bringing Stürtz and Stuga into the Voilàp family, we combine proven machinery and customer focus with our global scale and vision for innovation,” says Valter Caiumi, President & CEO of Voilàp Group. “Together, we can deliver intelligent, connected production systems that make the factory of the future a reality.”

“Our customers know they can rely on Stuga’s UK team, and that hasn’t changed. They now benefit from the best of three worlds: Stuga’s local expertise, Stürtz’s proven technology, and Voilàp as a strategic partner,” adds Stuga’s Managing Director, Ed Williams. “This means we can invest in more service, innovation, and long-term support –helping our customers feel confident today and secure for the future.”

Nottingham-based window and door manufacturer Frame Trade UK Limited has entered liquidation after a turbulent period marked by the pandemic, operational setbacks, and severe factory flooding.

Richard Pinder and Sean Williams of Leonard Curtis were appointed Joint Liquidators on 10 July 2025, following the sale of the business and assets to Frame Trade Windows Ltd — a newly established subsidiary of the Regal Group.

Founded in 2003, Frame Trade UK specialised in PVC-U and aluminium manufacturing of double-glazed windows, doors, and conservatories, supplying customers across the East Midlands. The company employed 19 staff.

A series of challenges over recent years

led to its decline. “The business suffered a significant drop in trade due to the pandemic,” said a spokesperson familiar with the matter. “This was compounded by the costly replacement of critical machinery and major flooding at its Nottingham facility in 2023, which severely disrupted production.”

Ahead of liquidation, the company’s business and assets were sold to Frame Trade Windows Ltd. The transaction included the TUPE transfer of 17 employees, safeguarding the majority of jobs. Two directors were made redundant.

Richard Pinder, Joint Liquidator at Leonard Curtis, said: “After reviewing the circumstances of the sale, and obtaining valuation advice, the Joint Liquidators confirmed that the sale of the business and

assets was the best outcome for creditors. It maximised asset realisations and minimised preferential creditor claims as a result of the TUPE transfer.”

Jason Bamford, Managing Director of the Regal Group, expressed confidence in the acquisition: “We had worked with Frame Trade UK for years and felt it was a natural fit with our existing group of companies.

“With the current customer base and demand from within the group, I am confident the business can return to profitability and provide job security for years to come.”

The Regal Group, which operates a number of companies in the fenestration sector, has indicated it will invest in restoring and expanding the production capacity of the newly acquired operation.

ULTRA-SLIM SIGHTLINES OF JUST 29MM

OPTIONAL FLUSH STACKING EXCLUSIVE SIGNATURE KNURLED HANDLE

Organisers of the prestigious G25 Awards have unveiled this year’s shortlist, recognising standout achievements across the UK’s glazing and fenestration sector. The winners will be announced at a gala dinner on Friday 28 November, hosted at the London Hilton on Park Lane — marking the event’s 21st anniversary.

In a statement, event organiser Tony Higgin praised the calibre of this year’s submissions: “Congratulations to all those shortlisted. The judging panel had an incredibly difficult task given the volume and quality of entries. The innovation and passion on show has been remarkable — we look forward to celebrating together in November.”

The shortlist spans 14 categories, reflecting the sector’s breadth — from technical innovation and sustainability, to customer care and unsung contributions.

UAP, Glazpart and Sternfenster are among the most shortlisted, with nominations across multiple categories including Training & Development Initiative, Promotional Campaign, and Component Supplier of the Year.

Emerging talent is also spotlighted in the Rising Star category, with nominations for professionals across the supply chain, such as Craig Hopper (Ecoglass), Ella Glover (UKO Group) and Lara Coutinho (ERA). Meanwhile, the Unsung Heroshortlist pays tribute to dedicated individuals making quiet yet critical contributions, including Ken Boak (SWC Trade Frames) and Paul Ramsey (Shelforce).

Project-based excellence also features strongly. 30 Duke Street by Saint-Gobain Glass and Thames Valley Windows’ Cholbury Place development in Ascot lead the Commercial Project of the Year nominations, while sustainability commitments are acknowledged with entries from Pilkington UK, Saint-Gobain, and Glazpart.

As the sector continues to adapt to new regulatory pressures and shifting market demands, the G25 Awards serve as a timely barometer of resilience, creativity and leadership within the UK’s £4.6bn glazing industry.

Tickets for the black-tie dinner are now available via the official website www.gawards.com, with industry leaders expected to gather in force to honour peers and push for continued excellence in 2026.

Training & Development Initiative of the Year:

•FDM by UAP

•Glass and Glazing Federation

•Sternfenster

•Tyneside Home Improvements

•UKO Group

Promotional Campaign of the Year:

•AluK

GB

•Glazpart

•Hurst Doors

•Safeware Hardware

•Sternfenster

•Window Systems

•The Residence Collection

•Tyneside Home Improvements

•Window Ware

Unsung Hero:

•Ecoglass, Colin Sturdy

•UKO Group, Chris Bennett

•Epwin Window Systems, Lawson Price

•Forel UK, Pasquale Di Lello

•Glass Express Midlands, Kirsty Fortnam

•Go Glass. Clive Sparkes

•Shelforce, Paul Ramsey

•SWC Trade Frames, Ken Boak

Customer Care Initiative of the Year:

•Glaze Style

•ICAAL

•Glazpart

•The Window Company (Contracts)

•TWC Home Improvements

Component Supplier of the Year:

•Kenrick & Sons

•ERA

•Glazpart

•Safeware Hardware

•Thermoseal Group

•UAP

Rising Star:

•Craig Hopper, Ecoglass

•Ella Glover, UKO Group

•Jason Gostling, Direct Trade (Yorkshire)

•Josh Forrester-Rodway, Window Widgets

•Lara Coutinho, ERA

•Lee Brett, Emerald Windows and Doors

•Samuel Johnson, Liniar

•Sarah Whitaker, UKO Group

Commercial Project of the Year:

•Saint-Gobain Glass Bespoke

•Glazing Solution

•Thames Valley Windows

•Fenestration Solutions

•The Residence Collection

Sustainability Initiative of the Year:

•Glazpart

•Pilkington UK

•Saint-Gobain Glass

Machinery Innovation:

•Forel UK & Ireland

•Haffner

•Pilkington UK

New Product of the Year:

•AluK

•Crittall Windows

•Deceuninck

•Residence Collection

•UAP

•Ultraframe

•Universal Trade Frames

Best Business Initiative of the Year:

•Crittall Windows

•Glazepoint

•Sternfenster

•Supply2trade

•UK Doors Online

•Universal Trade Frames

Installer of the Year:

•Emerald Windows and Doors

•The Window Hub

•TWC Home Improvements

•Tyneside Home Improvements

Glass Company of the Year:

•Ecoglass

•Glass Express (Midlands)

Fabricator of the Year:

•Conservatory Outlet

•Direct Trade (Yorkshire)

•Emplas

•Hurst Doors

•Roseview Windows

•Sternfenster

•Victorian Sliders

CR Smith, the window and door specialist, has recruited two highly experienced figures from Scotland’s construction and manufacturing industries to its leadership team, reflecting the firm’s commitment to expanding its public sector operations alongside its long-established domestic customer base.

Danny McArthur, formerly managing partner at Hardies Property & Construction Consultants, joins CR Smith as Director of Commercial to lead the firm’s social housing and commercial activities. A qualified quantity surveyor, CDM principal designer, and project manager, Danny brings a wealth of expertise, having delivered major social housing development projects across Scotland.

Alistair Mercer has been appointed Director of Manufacturing, bringing over a decade of leadership experience in manufacturing operations management. Skilled in lean manufacturing, Six Sigma, and project management, Alistair will oversee the CR Smith state-of-the-art manufacturing facility in Fife. He will drive process innovation and workforce development, ensuring the facility continues to meet the complex demands of made-to-order and made-to-measure production.

CR Smith, which designs, manufactures, and installs high-quality windows, doors, and home extensions, reported a 30% increase in revenues during Q1 2025, following several major contracts to upgrade social housing stock. As local authorities and housing associations implement ambitious plans to meet new sustainability standards, the firm is increasingly being

chosen as a trusted partner, building on more than 50 years of success in the private housing, commercial house builder and public sector markets.

The addition of Danny and Alistair to the CR Smith management team follows the recent appointments of Sharon Glass as Director of Finance and Michael Leggiero as Director of IT.

Gerard Eadie, Chairman of CR Smith, commented: “The appointments of Danny and Alistair mark a significant step in our growth strategy. Both bring exceptional expertise and proven track records in their respective fields, which will be instrumental as we scale our operations to meet growing demand from both the public and private sectors. Their leadership will strengthen our ability to deliver high-quality, energyefficient solutions for our customers across Scotland.”

CR Smith, which has offices in Glasgow, Inverness, and Aberdeen, as well as its head office and manufacturing plant in Fife, has been a cornerstone of Scottish business since Gerard Eadie CBE took over in 1974, consistently investing in its people and innovation. The firm became one of Scotland’s most recognised brands in 1984 when it simultaneously sponsored both Rangers and Celtic.

With delivery reliability now one of the biggest issues facing glass buyers, Topline Glass in Somerset is stepping up to highlight how its unique approach is setting new standards for customer service in the sector. As reports grow of fabricators and installers struggling with inconsistent dropoffs and driver shortages, Topline has doubled down on the three elements it believes make the difference - professional drivers who customers actually like having on site, safer and more flexible van-based deliveries, and intelligent route optimisation software that makes every mile count.

MD Jeremy Bartlett said: “Our customers tell us time and again that deliveries are one of the biggest factors in choosing a supplier. Too many still experience a ‘drop and go’ culture, where drivers see their job as simply getting glass off the lorry. At Topline, we see it differently - our drivers are part of the customer’s team on site. From their professionalism to our safer ground-level van drops and our investment in MaxOptra technology, every decision we make is designed to make deliveries easier, smarter, and more reliable.”

Dave Barter, who has been part of the Topline team for more than five years, said: “As a driver, I pride myself on the communication I have with all my customers and the relationships we build to

make sure I’m delivering a great service for them and their customers. It’s about more than just dropping off glass - it’s about trust and making sure every job runs smoothly. And of course, there’s always time for a quick chat about Chelsea!”

Unlike traditional large trucks, Topline’s Sprinter vans allow glass to be unloaded safely at ground level, improving turnaround times on site and avoiding the access issues that can derail tight schedules.

The adoption of MaxOptra software adds further efficiency, with timed delivery slots, dynamic routing, and a fully paperless proof-of-delivery system that reduces both emissions and admin. Jeremy added: “Ultimately, we want to be the supplier that customers trust not just for quality glass, but for the peace of mind that comes with knowing the delivery will be on time, handled safely, and backed up by the right technology.”

100% RECYCLED POST-CONSUMER ALUMINIUM, MANUFACTURED IN OUR OWN FOUNDRIES

BUREAU VERITAS certification

OVER 30 YEARS RECYCLING ALUMINIUM

with unique replaceable glass unit

Fitted in minutes

PAS24:2020 Security as standard

Bespoke sizes up to 3m2

28mm double or 44mm triple glazed options

Replaceable glass unit

3 stock colour options: Grey matt, Black matt or White gloss. Bespoke RAL or BS colours also available

Free site delivery*

Andrew Scott, Managing Director of Purplex Marketing and Insight Data, delivered a compelling address at this year’s Glazing Summit highlighting the key challenges and opportunities shaping the future of the UK fenestration industry.

Speaking to a packed audience of business leaders and industry professionals at the Coventry Building Society Arena, Andrew shared exclusive data and analysis drawn from Insight Data’s market intelligence platform Salestracker, which now tracks around 50,000 companies and 80,000 industry contacts across the glazing supply chain. According to Insight Data’s latest findings, there are currently 13,479 companies active across the sector. The number of PVC fabricators has fallen sharply from around 4,000 two decades ago to about 1,100 today while aluminium continues to rise as the material of choice.

For this year’s Glazing Summit, Insight Data also conducted an industry survey to over 2,000 installers to understand how they feel about current market conditions. A key finding revealed that while order values look positive on the surface, with 33 per cent reporting an increase in the last year, a third of installers (31 per cent) admitted they are fighting harder to win new business as competition within the industry has grown year-on-year. Andrew also warned that the sector’s growing reliance on Google Ads is unsustainable with around £100 million now being spent annually within the glazing

sector on digital advertising. “During COVID, many installers who had never used Google Ads before turned to it as their traditional sales routes closed,” he explained. “That demand doubled the cost per click and now only Google is winning.”

Instead, Andrew urged companies to “return to the art of marketing” emphasising that long-term success depends on brand building, customer trust and diversification. “Too many installers depend entirely on Google Ads or cheap lead generation services,” he said. “The industry must focus on creating genuine desire and reputation,

while suppliers must support installers in learning how to market themselves rather than just feeding them leads. That is the only sustainable way forward.”

He also pointed to diversification as a key strategy for resilience. Installers, he said, should explore related sectors such as renewables and energy-efficient home technologies while trade suppliers could pursue commercial and retail opportunities. “Those who adapt, evolve and invest in true marketing will thrive,” Andrew added. “The future still offers opportunity but only for those willing to change.”

West Midlands installer Hayley Windows is marking more than a decade of success with long-term supply partner CWG Choices, praising the fabricator’s premium products, dependable logistics, and unrivalled customer support.

Directors Laura Molineux and Kelly Easthope say the relationship has become an essential part of their business: “We’ve worked with CWG for 12 years now and they feel like an extension of our team,” says Laura. “From day one they’ve invested in our success, not just processed our orders.”

The partnership spans CWG’s Kömmerling PVC-U systems and The Residence Collection, product ranges that have helped Hayley Windows stand out in a competitive Midlands market.

Reliable service and streamlined logistics are key. “As soon as we place an order, we receive a delivery date

within hours – and everything runs like clockwork,” Kelly explains. “That reliability means our installers and customers can plan with confidence.”

Hayley Windows also credits CWG with exceptional aftercare. “If an issue arises, CWG’s technicians get involved until it’s resolved. They never just ship a spare part and walk away,” says Kelly.

Beyond products and service, CWG has supported Hayley Windows with marketing and lead generation, including website development that continues to generate enquiries.

CWG Choices Sales Director Dean Hague adds: “Hayley Windows is a fantastic example of a business making the most of what we offer. From our premium products to ongoing marketing support, it’s a genuine partnership built on trust and collaboration.”

For Hayley Windows, that partnership continues to be a key advantage.

“CWG isn’t just a supplier,” Laura concludes. “They’re part of our team and a vital part of our growth.”

www.hayleywindows.co.uk

Two years after stepping into the role of Managing Director at Glass Express Midlands, Arun Photay is keen to emphasise just how complex – and collaborative – the glass industry really is.

Speaking candidly about his journey, Photay describes his entry into the Birmingham-based IGU (insulated glass units) manufacturer as “something of an accident”, spurred by a conversation with a retiring friend over a curry. But what began as a career detour has become a mission to support and strengthen an industry he’s grown to admire.

“This is not ‘just a pane of glass’,” says Photay. “It’s an ecosystem of research, investment and precision – a sector that blends technical challenge with innovation.”

Over the past two years, Glass Express Midlands has ramped up investment in machinery, vehicles, and staff to meet rising

demand. But Photay insists that financial investment alone isn’t enough. The industry, he argues, needs to attract fresh talent if it’s to sustain its momentum.

“Succession is our biggest challenge,” he says. “We must do more to show

young people that this is a sector full of opportunity – not just in manufacturing, but in design, engineering, and leadership.”

Photay praises the culture of openness he’s encountered across the supply chain – from competitors offering advice to suppliers acting as true partners. Yet he is clear-eyed about the road ahead. He urges greater collaboration to raise standards in performance, sustainability, and safety, and to engage government on the regulatory frameworks required for long-term success.

“We all have a duty to leave this industry stronger than we found it,” he says. “That means investing not just in equipment, but in people, values, and shared knowledge.”

As he looks to the next two years, Photay’s vision is one of steady evolution: “driving quality, strengthening relationships, and ensuring that the glass sector is recognised for both its products and its principles.”

Star invest £250,000 in its

One of Worcestershire’s leading home improvement specialists has pledged its commitment to the city and surrounding areas by investing £250,000 into its showroom. 5 Star Windows & Conservatories, which celebrates a decade of being open in Carden Street this month, has extended its lease for another ten years and, to mark this milestone, has channelled fresh spending into new customer service technology and installing new demonstrations for consumers.

This has seen the launch of the latest forte door collection and the opening of a comprehensive ‘hup!’ display that showcases the latest modular build technology promising to make building conservatories, orangeries and living spaces quicker, easier and more energy efficient.

Several new jobs have also been created in Worcester in the last twelve months as the company sets course for its best year. Richard Manser, MD of 5 Star Windows & Conservatories, commented:

“We wanted to celebrate 10 years of our showroom being open in Worcester and what better way to do that than by giving it a facelift, adding exciting new ranges and, importantly, reinforcing our commitment by extending our lease until 2035. Worcestershire is a fantastic place for home improvements, with an eclectic mix of housing and consumers who are keen to try new styles, whilst marrying traditional features. Customers are very loyal - once they receive a high-quality service and the trust is in place then they will keep coming back and back. Our sales tend to be 65% repeat business. Our 5000

ft² Carden Street showroom showcases bifolding doors, French doors, Juliet balconies, a comprehensive range of windows, six fully furnished living spaces and the entire ‘Ultraframe’ collection of roofs. There’s also lots of design technology in place to make the buying and selection process as easier and enjoyable as possible.”

5 Star Windows & Conservatories has established a strong reputation across its showrooms in Worcester and Kidderminster, having completed more than 40,000 successful installations during the last twenty-three years.

The company, which offers an industryleading 20-year guarantee, provides a complete end-to-end service for clients, from initial consultation and support with designs to installations being completed by one of its dedicated fitting teams and access to an extensive aftercare package. A dedicated training centre ensures all its 80-strong team keep up to date with the latest legislation and construction techniques, whilst the firm continues to leverage its involvement as one of the most successful retailers in the Conservatory Outlet Network.

North-East-based aluminium fabrication business, Made For Trade, has become the latest new member to join the Council for Aluminium in Building (CAB). Set up in 1979, Made for Trade is a leading UK manufacturer and supplier of innovative aluminium fenestration products, delivering multi-award-winning solutions to the trade.

From the pioneering Korniche Roof Lantern to its high-performance bi-folding doors, patio doors and rooflights, MFT combines precision engineering with exceptional service, helping installers and resellers grow their businesses with confidence.

Gavin Herdman, Head of Engineering, Made for Trade, said that CAB membership offered Made for Trade access to increased technical support as well as opportunities to work in partnership with colleagues in the industry on key issues impacting the sector. “Made for Trade is committed to being an active member of the aluminium building products industry and supporting our customers by giving them a voice on key issues. CAB membership opens up a wealth of networking opportunities and supports us in staying on top of regulatory change so that our offer to our customers is ready for all current and future changes.”

CAB membership offers a host of benefits including access to technical

support and CAB Technical Committees, regulatory updates, government advocacy, plus networking and an active events programme.

In the last 12-months it’s pushed its Closed-Loop Recycling Scheme which supports industry sustainability by isolating waste streams so that higher value aluminium alloys used in construction are ring-fenced. This also means that manufacturers can command a higher price, from recycling specialists.

Its new U-Value Charter which brings in new standard methodologies for u-value calculations, generating a unique

opportunity for qualifying CAB members to evidence transparency and win more business through compliance.

It also offers an extensive training programme including the CAB Apprenticeship Toolbox. Developed in partnership with training provider GFTS, it’s been designed to help members recruit and encourage students and school leavers to join the industry as well as providing guidance on training and how to access funding. Nigel Headford, Chief Executive, CAB, said: “Made for Trade are an exciting and innovative business. Their decision to join CAB reflects the growing recognition that our technical, regulatory and legislative work is crucial for companies operating in today’s market. Membership gives them a seat at the table on issues shaping the future of the industry from regulatory frameworks to product performance standards.By joining CAB, companies gain more than a badge - they gain access to technical committees, working groups, and opportunities to shape the industry response to regulation”, Nigel continued.

“It’s also a chance to network with peers and competitors on shared challenges. For a company with Made for Trade’s profile, this is a strategic move that will ensure they remain ahead of the curve.”

E: enquiries@c-a-b.org.uk

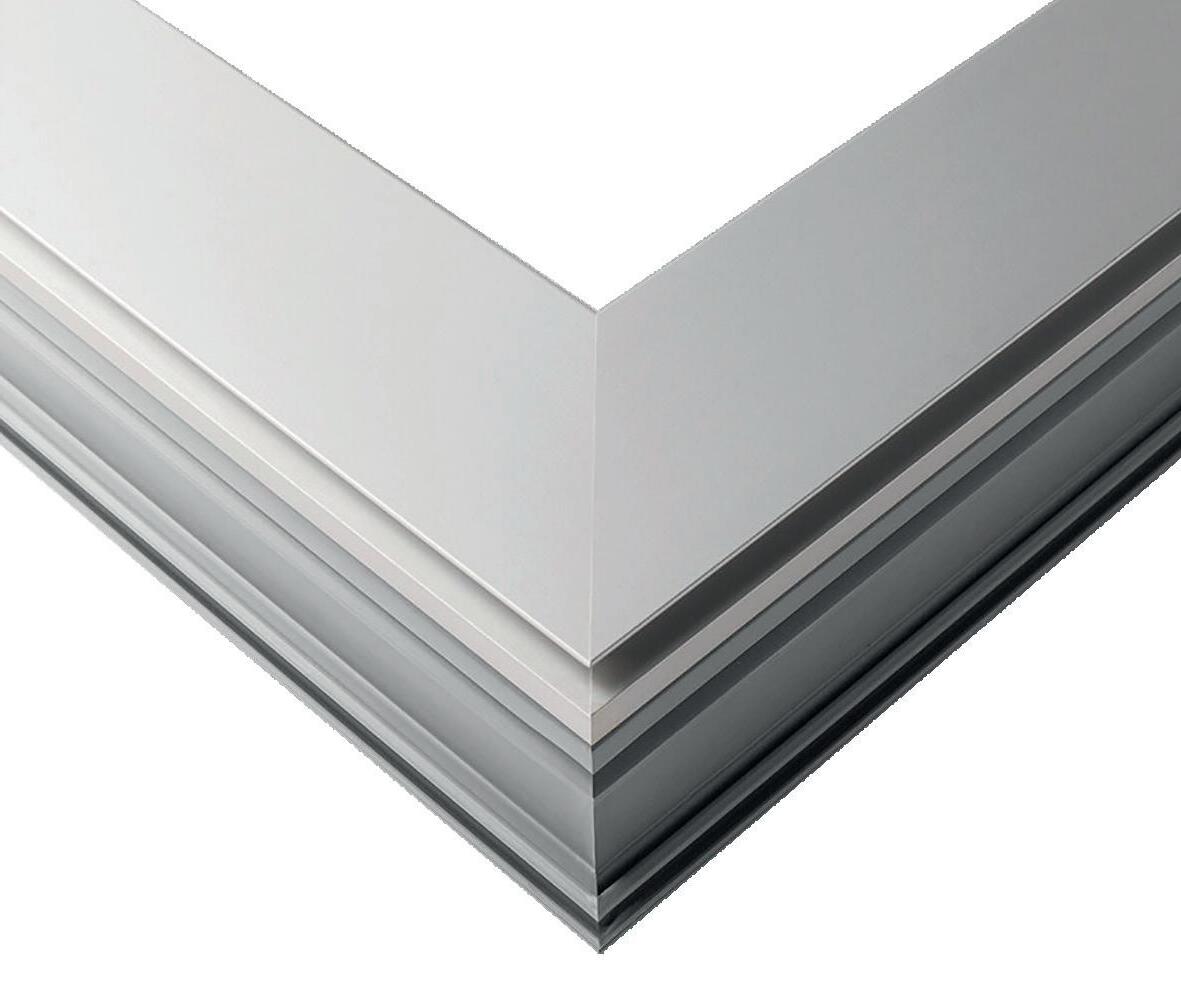

As the UK’s window and door industry braces for the sweeping regulatory changes under the Future Homes Standard (FHS), one manufacturer is already delivering products that exceed forthcoming requirements. The Residence Collection, known for its heritage-inspired PVC-U window and door systems, is positioning itself as a frontrunner in the race to meet the government’s ambitious carbon targets.

Set for full implementation by 2025, the FHS will mandate new homes to reduce carbon emissions by 75–80% compared with 2013 standards. A key element of this push involves more stringent building fabric requirements, particularly for windows and doors, which must now achieve u-values of 1.2 W/m²K or lower alongside improved airtightness and sustainability credentials. Launched in 2011 with its flagship Residence 9 (R9) system, The Residence Collection has steadily expanded its offering to include the Residence 7 (R7) and Residence² (R²) ranges. Each combines traditional aesthetics with modern engineering, delivering u-values as low as

0.74 W/m²K with triple glazing and A++ energy ratings as standard.

“Our systems are already exceeding the performance targets,” said Sarah Hitchings, Sales and Marketing Director at The Residence Collection. “We see the Future Homes Standard not just as a regulatory milestone but as a chance to push

the boundaries of what our industry can achieve.”

Beyond windows, the brand recently introduced a new open-in entrance door compatible across its entire product suite. Available in multiple configurations, including French doors, the system mirrors the visual appeal of timber while delivering on performance. It supports both double and triple glazing, meets PAS 24 and Secured by Design standards, and includes features such as low thresholds for accessibility and a patent-pending timber-look panel trim.

With full compliance to Part L and Part F of Building Regulations and solutions designed for both new builds and conservation projects, The Residence Collection is positioning itself not only as FHS-ready but as a benchmark for the future of fenestration in the UK.

As industry players adapt to the new standards, The Residence Collection’s approach underscores a growing consensus: energy efficiency and design excellence are no longer mutually exclusive—they are essential partners in building homes for the future.

36 colours with a staggering 3330 possible combinations. Delivered from our in-house lamination hall featuring cutting-edge wrapping technology.

A PARTNER IN YOUR SUCCESS FUTURE-READY PERFORMANCE SMARTER FABRICATION, BETTER MARGINS SINGLE-SOURCE BUILDING PRODUCT SOLUTIONS SCALABLE, RELIABLE SUPPLY

SCAN QR TO BECOME A LINIAR CUSTOMER TODAY

Polymer solutions manufacturer

Rehau has reported that UK commercial new-build project enquiries have more than doubled year-on-year for the first six months of 2025, defying wider construction industry pressures and revised-down forecasts. From January to June 2025, Rehau saw double the number of active projects that the company’s commercial team is currently engaging with and progressing compared to 2024. The growth is underpinned by an 85% conversion rate on commercial project enquiries to eventual completion, demonstrating an ability to deliver at scale even as demand has increased.

The company’s performance comes at a time when the wider construction sector has faced significant headwinds. These challenges include rising inflation, delays in the planning process and weakened investor confidence, which were all highlighted by the Construction Products Association as reasons for downgrading their earlier H1 2025 forecasts. “Many in the industry have reported a cautious market in the first half of 2025,” says Barry Gilligan, Sales Director at Rehau UK. “But demand for technically robust solutions hasn’t disappeared. Instead, specifiers are becoming more selective in what they want, particularly in areas such as windows and doors. The introduction of legislation such as the Building Safety Act means that businesses are increasingly looking to reliable and responsible suppliers that can demonstrate technical support and a proven track record of professionalism.

“These stakeholders expect suppliers to deliver exceptional service alongside quality products, especially as they look to identify solutions that align with specific project goals such as thermal performance. This isn’t only limited to housing either, as we’re also seeing a spending uptick in other

sectors, including school construction.”

Following a turbulent first half of the year, the outlook for the second half of 2025 is more optimistic, with the Government pledging £39 billion to construct social and affordable housing in England alone. The uplift in funding is expected to stimulate new projects and accelerate planning activity across the housing sector, placing further pressure on building fabric and component manufacturers to meet rising demand levels.

According to Barry, this pressure also opens up interesting opportunities for developers and the wider supply chain, provided that all relevant project stakeholders prioritise greater collaboration.

He is confident Rehau’s H1 uplift can continue into the second half of the year, as the business continues to work to secure long-term projects in sectors buoyed by

further financial support.

“As funding commitments begin to translate into real-world projects, the challenge for the industry will be to deliver at pace without compromising on quality,” Barry concludes. “That means closer collaboration between developers, specifiers and suppliers, and a renewed focus on longterm value, not just short-term cost.

“The need for these closer working relationships isn’t just limited to housing projects either. We’re also seeing a construction spending uptick in multiple other areas, including for hotels and schools. For the latter, we believe it is likely due to funding allocated by the School Rebuilding Programme starting to come through, and underlines why it is vital the supply chain collaborates to meet growing, policy-driven demand in this instance and beyond.”

Sheerline can reveal it has been named a 2025 WIRED Trailblazer. The awards, which were launched by HSBC UK and WIRED Consulting, recognise midsized scale-ups that are growing quickly and using innovation to tackle social, economic, and environmental challenges.

Receiving this award highlights what Sheerline has achieved in a relatively short space of time thanks to the right strategy, investment, people, and products. The result has been a range of perfectly matched, fullysuited products, an OTIF consistently above 99%, and multiple award wins.

A special event was held at Cleaver & Wake in Nottingham to celebrate the East Midlands-based recipients of this year’s awards. It provided an opportunity to meet with likeminded business leaders from the region who share the same values and growth mindset.

Ross Hartshorn, Sheerline’s Technical Production Director, attended the event and said: “It was fantastic to meet so many likeminded and inspiring business professionals from across the East Midlands who are driving real change in multiple industries.”

“Being named a 2025 Trailblazer is rewarding for everyone at Sheerline – it reflects our commitment to innovation,

continuous improvement, and strategic, sustainable development. Thank you to WIRED Consulting and HSBC UK,” he added.

Now in its fourth year, the WIRED Trailblazer awards have built a community comprising of inspiring entrepreneurs and business leaders. This year, a total of 17 companies in the East Midlands region were recognised for their commitment to innovation.

2025 is shaping up to be a fantastic award-winning year for Sheerline, having received Best Technical Innovation for the third time at the GGP Installer Awards earlier in the year and a King’s Award for Innovation 2025, which recognises unique benefits of the Sheerline system.

To find out what makes Sheerline standout, visit the website: www.sheerline. com, call 01332 978 000, or email info@ sheerline.com.

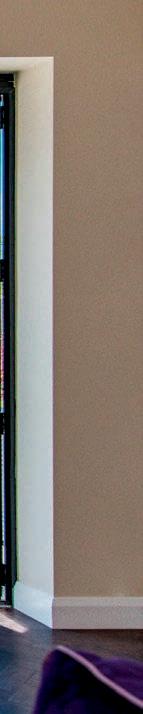

Don’t get left behind - homeowners nationwide are falling in love with the charm of heritage styles.

Our authentic flush sash window system captures the heart of traditional design, while cutting-edge uPVC construction delivers outstanding performance. Get in touch today to become a Timberlook installer!

• Heritage flush sash style

• Timberweld joints for heritage style

• Elegant woodgrain foils

• Heritage cill & hardware options

• U-Values as low as 1.2

• Concealed trickle vents

• Complementing flush French & single door

• Available on Tommy Trinder Framepoint®

• Free leads in your area

Powered by Deceuninck

• FREE Leads & Lead Dashboard

• Dedicated Subsites on 3 Websites

• Media Centre

• Product Configurator

• Energy Savings Calculator

• NEW Energy Ratings Calculator

• Award Winning Marketing

• Brochures, Images, Videos, VR Tours & more!

In today’s-built environment, aluminium has become the material of choice for forward-thinking architects and contractors who demand a balance of design freedom, technical performance, and sustainability. At Midori Aluminium, we have built our reputation on delivering advanced aluminium systems that support both striking aesthetics and robust functionality — whether for commercial, residential, or bespoke architectural projects.

Architects are increasingly looking for systems that offer slim sightlines, versatile configurations, and modern finishes without compromising performance. Midori’s product range has been developed to meet these exacting standards, offering window, door, and curtain walling solutions that can adapt seamlessly to contemporary and traditional projects alike. From minimalistic frameless styles to bold, structural designs, our aluminium systems provide the flexibility needed to transform architectural concepts into reality.

For contractors, performance is more than a design aspiration — it’s a practical necessity. Ease of fabrication, installation efficiency, and reliability all play a crucial role in project delivery. Midori Aluminium understands these pressures, which is why our systems are engineered to ensure smooth assembly and consistent quality across every application. The result is a product that not only meets specifications but also saves valuable time and reduces risk on-site.

Durability and performance are at the heart of every Midori system. Aluminium is naturally strong and corrosion-resistant,

and our designs incorporate advanced thermal break technology to maximise energy efficiency. In a climate where building regulations are becoming more stringent, Midori products help customers achieve compliance without compromising on design.

Sustainability is no longer an optional extra; it’s a requirement of modern construction. Aluminium is infinitely recyclable, and at Midori, we are committed to reducing the environmental footprint of our products. By working with trade customers, contractors and architects, we aim to support the transition towards more sustainable building practices while still delivering the high performance the market

demands.

What sets Midori Aluminium apart is not just our products but our partnership approach. We work closely with customers from design through to completion, offering technical support and tailored solutions for projects of any scale. Our team’s deep industry knowledge ensures that clients can rely on us not just as a supplier, but as a long-term partner invested in their success.

The demands of today’s construction industry are evolving rapidly, with aesthetics, performance, and sustainability at the core of every project. Midori Aluminium is proud to provide solutions that meet these challenges head-on, helping architects to design with freedom, contractors to build with confidence, and trade customers to deliver buildings that stand the test of time.

www.midorialuminium.co.uk

Heritage Trade Frames continues to reinforce its position as one of the UK’s leading trade fabricators with a composite door offer that combines style, strength and smart innovation. Producing an average of 450 composite doors per week, Heritage offers one of the most comprehensive door collections in the market, including standard GRP composite doors, stable doors and double/French door options. The range features the full Distinction Signature, Contemporary and Nxt-Gen collections, with an impressive 92 styles and 33 colour options, plus the flexibility to colour-match to any RAL or BS number.

While Anthracite Grey (7016) continues to lead in popularity, Heritage has seen a significant rise in demand for Agate Grey and Pebble Grey since adding the colours across its PVC-U window and door collections.

Every composite door from Heritage comes fitted as standard with the new Ultion 3-Star ALPS (Always Locked Protection

System) cylinder, reinforcing the company’s long-standing commitment to high-security products, a standard it has maintained for over nine years. Heritage also offers the Yale SensCheck™ Smart Lock, providing seamless integration with its PVC-U window and door range. Responding to customer feedback, Heritage has also launched a new range of marine-grade hardware for enhanced durability in coastal locations.

Lee Darcy, Sales and Marketing Manager at Heritage Trade Frames, said: “Our composite door offer has grown into one of the strongest in the trade. We’ve combined design versatility, colour choice, security and smart technology to give installers a door range that’s easy to sell, easy to fit and designed to last.”

Established in 1989, Heritage Trade Frames continues to deliver proven quality with a forward-thinking approach offering installers a complete composite door solution.

Lee, concluded: “Composite doors continue to be one of our most successful product lines and we’ve manufactured and supplied more than 100,000 in the past five years, and demand just keeps growing. Customers value the range for its choice, quality and reliability, and it remains a key part of our commitment to delivering products that help our customers stay competitive in the market.” E:

Clarity Doors & Windows, one of the North West’s fastest-growing glazing suppliers, has highlighted the power of persistence and client support in a recent project featuring Resurgence Flush PVC-U windows in an Anteak finish. The installation, which revitalises a dated residential building, demonstrates the company’s commitment to service-led growth in a competitive sector.

Head of Trade Sales, Barry Stanton, shared details of the project on social media, describing it as “an installation we’re truly proud of” following delays caused by a protracted council approval process. Though the contract had been secured months prior, developers faced setbacks in securing permission for replacement windows — a familiar challenge in sensitive planning zones.

Rather than wait out the delays, Clarity took a hands-on role, liaising directly with local authority planners, submitting a suite of technical documents, and making repeated site visits alongside the developer. The result was a green light for the project and a successful installation that balances modern energy efficiency with a sympathetic, timber-look aesthetic.

“This wasn’t just about supplying windows,” Stanton wrote. “We worked alongside

the client and the council to make sure every detail was right. That’s the kind of partnership we believe in.”

Clarity’s collaborative approach reflects its wider strategy: 100% of the company’s growth to date has been organic, built on repeat business and referrals. Serving both trade and retail customers — from schools and care homes to homeowners and managing agents — the firm has carved out a

strong regional presence with a reputation for reliability and proactive service.

Flush PVC-U systems, such as those used in the project, continue to gain popularity for their blend of heritage style and low-maintenance performance. With growing demand for energy-efficient retrofits, particularly in older housing stock, Clarity’s latest project underlines the value of technical expertise and responsive client service in navigating regulatory complexity.

Manufacturer and recycler of PVC-U windows and doors, Eurocell, is playing a central role in Energy House 2.0, one of the world’s most advanced building performance research facilities at the University of Salford, that is reshaping how the industry tests and improves homes for net-zero.

The £16m Energy House 2.0 facility is the only climate-controlled research chamber of its kind in the world. Here, homes are tested in real-world weather conditions ranging from snowstorms at –23°C to extreme heatwaves of +51.5°C, providing vital insights into how construction products perform under the pressures of climate change and future energy demands.

As part of the project’s latest phase, Eurocell’s Modus triple-glazed window system has replaced the original double-glazing in the concept research homes. This upgrade is set to raise the bar for energy efficiency, thermal comfort, and sustainability.

Ian Kernaghan, Head of Product, Design and Development at Eurocell said: “Triple glazing is a key step in futureproofing homes. Being part of Energy House 2.0 lets us show just how much impact design-led, high-performance products like Modus can

have. We’re not just testing windows, we’re demonstrating solutions that can help deliver lower carbon homes at scale.”

Energy House 2.0 is designed to help the construction industry and its supply chain prepare for zero carbon housing. The integration of Eurocell’s Modus system into the Energy House 2.0 homes complements pioneering research already being carried

out within the project. In earlier phases, testing demonstrated that innovative low-carbon construction methods could deliver significant reductions in embodied carbon emissions and maintain comfortable indoor temperatures for less than £2 per day in winter conditions.

By adding high-performance triple glazing to the test homes, Eurocell is helping the test homes meet very high levels of thermal efficiency, providing valuable real-world data for housebuilders, policymakers, and homeowners alike.

Ian added: “Energy House 2.0 is about more than research; it’s about reimagining the way we build homes. Eurocell is proud to be contributing solutions that help reduce environmental impact while delivering comfort and affordability for the people who live in them.”

Eurocell’s involvement in Energy House 2.0 underlines its ongoing commitment to sustainability and innovation across the construction sector. As the industry faces the dual challenges of climate change and the demand for large-scale housing growth, partnerships like this are crucial in proving that low-carbon, high-performance homes are not only possible but achievable at scale.

UK Glaze has opened its doors on a new glass production unit with a showroom in Royston, featuring a premium Gerda door alongside its range of decorative glazing products such as splashbacks, mirrors, balustrading and wall panels. Director Mohammad Kaboutari has invested £400,000 in setting up the unit.

When Mohammad Kaboutari arrived in the UK he had just £27 in his pocket. But he also had something else more valuable – his skills and knowledge as a master glazier, learned alongside his father back in Iran.

This allowed him to eventually open up his first business – MK Glass on the Caledonian Road in London, which grew into Empire of Glass 18 months later as his reputation for quality workmanship and as a master glazier spread among property owners in the neighbourhood and beyond. As the business name grew, so did requests for related products, and Mohammad soon started supplying windows and doors.

And it was whilst running Empire Glass that Mohammad first came across the Gerda front door, which Pioneer Trading Company’s Managing Director Danny Williams had recently brought across to the UK from Poland back in 2023.

Mohammad quickly became one of Pioneer’s top sellers of the Gerda door.

“My client base was becoming more demanding in their expectations around performance, safety and added value, and my existing door supplier just wasn’t delivering that level of quality that we wanted to sell,” said Mohammad.

“Even though the Gerda doors were coming in at a slightly more expensive rate, my customers were loving them – the aesthetics, the enhanced security features,

the lower U-values – and definitely the ‘thunk’.”

But more than that, the Gerda door appealed to the demographic of Mohammad’s core customer base – looking for premium decorative glazing products at the higher end of the market. This realisation came at a time when Mohammad and his brother were keen to concentrate their business on this more niche sector, leading to the decision to sell Empire of Glass as a going concern, and open a brand new business venture – UK Glaze.

“We reinvested everything we had in setting up this new unit,” continued Mohammad. “The glass factory has every

piece of kit we need to cut, process and transport the glass. And the showroom is evolving into a living, breathing example of what we can offer through our glass cutting services – from staircases and wall panels to bespoke furniture. The Gerda door sits proudly in the showroom as a focal point.”

The support Mohammad has received from Gerda has been instrumental in the transition out of central London to Royston, and Mohammad is consistently grateful for (and surprised by) the level of personal service he receives from Gerda.

“There are always going to be issues with suppliers no matter how brilliant they are, but it is by the quality of the response that we judge them,” continued Mohammad.

“With previous door suppliers we have had problems on site which had evolved into weeks of going round in circles and leaving jobs half finished. On the rare occasion we have had an issue with a Gerda door, all it took was a phone call to Keith Arm (Gerda’s sales manager), and the missing piece was in a taxi en route to the installation site. It is for this reason that we feel completely confident in Gerda’s commitment to partnering with us in building UK Glaze into a premium home decoratives supplier to high end homes.”

“Gerda’s values always align with quality above all else, and when it meets an installation business with similar values everything just seems to slot into place – just as it did with UK Glaze,” added Pioneer’s managing director Danny Williams.

“Mohammad is starting this new venture at the most challenging time economically, but in truth it is probably the best time in terms of building growth in the coming weeks and months. Pioneer values are based on a deep seated commitment to those who work hard, and we will be there to support Mohammad at every stage”.

Silka says homeowners are rethinking their priorities and budgets after the latest ADT Burglary Report revealed 245,284 break-ins were recorded across England and Wales in the year up to March 2025 – the equivalent of more than 670 per day. Published in mid-September, the report confirms the front entrance door was the most common point of forced entry, with 67% happening this way.

“When a household name like ADT confirms that two-thirds of break-ins are forced through the front door, it qualifies the urgency we’re hearing from homeowners, and that security is driving their decisions,” says Managing Director at Silka, Asa McGillian.

“But if they decide to upgrade, they don’t want to settle for a purely functional product. They want an entrance door that looks exceptional and performs for the longterm, and it’s this customer we had front of mind when we created the Silka Kärben Collection.”

The Kärben Collection is Silka’s ultimate entrance door, with its carbon fibrereinforced Thermafill® core and bonded Italian porcelain panels in four textured tones (Corten Rust, Ghost Grey, Dark Shadow and Ivory Coast). Select styles like Angelo and Canova have the option to include slimline LED panels that light up

on approach, while smart features such as fingerprint recognition, keypad entry and smartphone app control are fully integrated at the factory. It’s a door built to deliver strength, security and standout design.

SILKA says the newly-released burglary figures highlight a major sales opportunity for installers, with higher-end homeowners actively putting more of their budget towards entrance doors that go beyond the standard.

“For installers, this report should be a clear signal,” Asa adds. “Kärben combines strength, design and technology in a way that helps secure premium projects and build lasting trust – and that’s exactly where the money is in today’s tougher economy.”

Available to customise through Silka’s online Doorbuilder tool, the Kärben Collection comes complete with matching sidelights and handle options, making it even simpler to specify and quote.

AluK’s MD Russell Yates has been appointed as President for the Council for Aluminium in Building (CAB). Having been a long-time supporter and advocate of the CAB, Russell is now working alongside the rest of the dynamic board and the professional team to help the CAB become an even more powerful voice for aluminium.Russell explained his objectives: “The CAB already has an impressive track record when it comes to advancing the cause of aluminium in construction – from ensuring that aluminium was A-rated in the BRE Green Guide back in the ‘90s, to formulating the new Closed Loop Recycling scheme.

“It has even more ambitious plans now and the current team are doing some really impressive work in key areas such as training, technical consultancy and lobbying. I want to use my position as President to support that work and raise the profile of the CAB even further in the places that matter most. We want to be talking to government and regulators to help shape upcoming and future legislation and engaging with other groups within the industry to ensure that aluminium

becomes the undisputed material of choice. We’re already seeing plenty of evidence of success particularly on material sourcing and recycling, where the CAB’s Closed Loop Recycling scheme looks set to shift the focus from cradle-to-gate to a cradle-to-

cradle approach and reinforce aluminium’s sustainability credentials. I’m passionate about this sector and will do all I can during my tenure to support the CAB’s mission. I am looking forward to a challenging but ultimately very rewarding year ahead.”

The working at height safety system that changed the game just got better

Now spanning up to 5 metres wide and supporting three engineers at once, Stronghold® delivers more capability without compromising what matters most.

Why installation businesses love Stronghold®:

SAFETY FIRST.

Secure harness anchor points, full mobility, no need for external access

SAVE SERIOUS TIME.

Assemble in under 10 minutes with no tools or fixings; wider spans mean more productivity

SLASH YOUR COSTS.

Forget scaffold hire. One system, endless jobs, fast ROI.

Make every install safer. Faster. More profitable. Hire Stronghold® today, call 01992 302 133 or visit www.stronghold-anchor.com

The new Kömmerling vertical sliding sash window is packed with technical and practical features. These include:

Wide range of single and dual colours available on a 10-day lead time. Six different hardware finishes.

Achieves a U-value of 1.2 W/(m2K)

Quick release tilt arms for speedy removal of sashes as standard. Deep bottom rail, run-through sash horn option and SBD complaint security are other key features.

Contact us today for a Technically Better sliding sash window. enquiries@profine-group.com | 01623 579200 | www.kommerling.co.uk

FUSION WELD OPTION

TILT OPTION FOR CLEANING

RUN THROUGH SASH HORNS

PREMIUM HARDWARE OPTIONS

One of the UK’s leading home improvement specialists is marking its 20th birthday in style by setting out a four-year growth plan to achieve £100m in sales. Conservatory Outlet, which is headed up by CEO Greg Kane and Managing Director Mick Giscombe, has unveiled an exciting strategy that will see it invest heavily in diversifying its manufacturing operations and further expansion of its hugely successful home improvement offering.

The Wakefield-based company is also marking the major anniversary by introducing a new corporate structure that will involve the introduction of Conservatory Outlet Group as the holding business, with CO Manufacturing and CO Home Improvements reflecting its two main areas of operation.

New websites and branding have been introduced to support the name change, kickstarting a £1m investment drive that will involve the installation of state-of-theart CNC machining at its Cutting Room facility, a fleet of commercial vehicles, new IT infrastructure and the creation of 20 new apprenticeships.

“We’ve had a fantastic two decades in business, enjoying significant growth across both our manufacturing and retail arms - so much so that we are now generating £62m of annual revenues and employing more than 400 people,” explained Greg Kane, CEO of Conservatory Outlet Group.

“This is just the start. You can’t stand still in our world, and we want to continue to meet customer expectations when it comes to new home improvement products and improving their experience.”

He continued: “That’s why we’ve outlined a new four-year growth plan that will look to accelerate us towards £100m and, to do this, we required a clear business structure that clearly celebrated our history but also paved

the way for the future.

“Our group will now comprise CO Home Improvements (covering the six retail businesses we own – Clearview, Orion, Planet, Trent Valley Windows, West Yorkshire Windows and Yorkshire Windows) and CO Manufacturing.

“The latter reflects our commitment to delivering the highest quality windows, doors and living spaces to our vitally important Premium retailers, but also the growth opportunities we see in other markets.”

CO Manufacturing has identified strong expansion possibilities in its fledgling trade products business in the North West and Yorkshire, as well as with housing companies through its dedicated new build offer.

The firm has developed a specialist collection of windows and doors for both

areas and is investing £1m in 4-axis CNC machines to give it greater capacity and repeatable quality across its production facility.

Similar levels of investment are being channelled into boosting the skills of its workforce, with 10 apprentices currently being recruited and the launch of its tailored Manufacturing Degree pathway that aims to create the production leaders of the future.

Greg went on to add: “We’re currently generating over £30m of revenues across manufacturing and we believe, with the right backing and diversification, we can take this figure up to £50m.

“The market is changing and we’re helping push the boundaries of innovation when it comes to thermally efficient products and utilising new materials for achieving different aesthetics.”

CO Home Improvements will work closely with the company’s network of 22 independently owned retailers, which span all of England and Scotland.

These firms have worked with the business for many years and share its values of excellent customer service and trust, with an appetite to embrace the latest technology to improve the client journey.

The network complements the firm’s six retail brands that operate predominantly in the East Midlands, North West and Yorkshire.

Greg concluded: “We are expecting similar growth in retail as we are in manufacturing and, together, we’ll hopefully hit the £100m target by 2029.

“Our aim is to enhance the support we give to our network even further so they can collectively achieve great things, as well as looking at the opening of four new showrooms in Derbyshire, South Yorkshire, the Lakes and one in either Liverpool or Manchester.”

Xladeco stands out for its innovative Quickfit manufacturing concept that allows for a quick and easy fabrication, avoiding CNC complex operations and punching tools.

Its ultra-slim sightlines of only 30 mm and its stepped profile design make Xladeco the ideal choice for any heritage replacement or contemporary steel-inspired project.

hinged pivoting sliding

Compatible with: Laminated glass 5+5 / 4+4 / 3+3 Monolithic glass 12 / 10 / 8 / 6

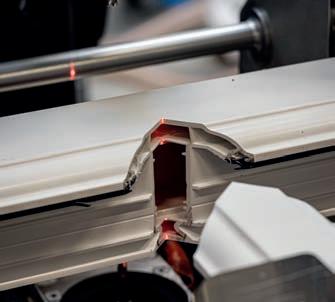

Manufacturer of windows and doors Listers has achieved significant productivity and sustainability improvements in its manufacturing operations following the adoption of machine monitoring technology from FourJaw Manufacturing Analytics.

Listers, which produces more than 3,000 windows a week, decided to install FourJaw’s plug-and-play machine monitoring system on six production lines in its factory in Staffordshire to gain real-time data on machine utilisation, downtime and energy consumption. Since going live, the data has helped Listers improve productivity by 10% and increase machine utilisation by 12%, enabling it to produce more than 250 additional windows each week using its existing assets and workforce.

For customers, this translates into more reliable delivery times, consistent quality, and the assurance that their supply chain partner is actively reducing its carbon footprint. Listers has already achieved a 10% reduction in wasted energy by using FourJaw to identify opportunities to run its machines more sustainably. These improvements strengthen Listers’ operational resilience and support customers’ own sustainability commitments, making Listers a partner of choice in a competitive marketplace.

FourJaw’s technology has also become a key component of Listers’ sustainability initiatives, providing machine-level energy data to support its ISO 14001 and ISO 50001 certifications and highlight machines and production processes where energy is potentially wasted. FourJaw has already helped Listers reduce its carbon emissions and save thousands of pounds a month in energy expenditure by identifying a compressor that was using more power than

it should due to air leaks.

Listers plans to expand its use of FourJaw to gather data from other critical pieces of equipment in its factory and to integrate FourJaw with its maintenance management system, using real-time data to trigger automated maintenance requests the moment a machine goes down.

The system also empowers Listers’ workforce, giving operators real-time data that helps them quickly diagnose issues, reduce downtime, and develop new digital skills. By integrating technology with teamwork, Listers is building a culture of continuous improvement that benefits both people and processes. Stuart Pickersgill, Director of Manufacturing and Operations at Listers, comments: “FourJaw has been a breath of fresh air for Listers. It has become the heartbeat of the business, enabling us

to take a proactive and targeted approach to continuous improvement that benefits our people, customers and bottom line. In just a few short months, FourJaw has changed the way decisions are made at Listers and delivered productivity and sustainability gains that are already saving us thousands of pounds a week.”

Chris Iveson, CEO at FourJaw Manufacturing Analytics, comments: “Our work with Listers perfectly illustrates the tangible and immediate impact that smart technologies like FourJaw can have on manufacturing businesses. We are turning machine data into actionable insight fast and making it simple for manufacturers of all sizes to understand their operations, unlock significant productivity gains, reduce energy costs, and accelerate their journey toward a more sustainable future.”

Senior Architectural Systems is set to introduce a new waste reduction initiative as part of its commitment to circularity and working towards a fully closed-loop recycling process. The new initiative will see all polyurethane foam waste generated during the manufacture of the patented thermal break in Senior’s low U-value PURe® aluminium windows and doors collected and reused.

Each year, approximately 80 tonnes of polyurethane foam waste is produced as part of the PURe® manufacturing process. This occurs when extra polyols and isocyanate chemicals are injected into the thermal breaks to prevent cold spots during curing. The result is a unique thermal barrier that delivers lower U-values and improved energy performance compared to traditional systems.

However, the process also creates excess cured foam and although this waste has

always had the potential to be reused, it has previously been difficult to manage at scale. Senior is now working with a specialist waste partner to chemically break down the expanded and cured polyurethane foam into its original raw components—polyols and isocyanates. These recovered materials will be reintroduced into Senior’s own manufacturing processes, creating a circular

system that eliminates landfill disposal.

The initiative is scheduled to be fully operational by the end of the year and once implemented, the recovered materials from the manufacture of Senior’s PURe® windows and doors will be reused internally. This approach is expected to reduce carbon emissions, cut waste, and lessen demand for virgin raw materials.

Available in a variety of configurations, including aluminium casement windows, tilt and turn windows, and both commercial and domestic style doors, the patented PURe® system has been used across the sectors, specifically in the education and residential markets.

Senior’s investment in advanced recycling initiatives builds on the company’s ongoing commitment to reducing the environmental impact of its operations and supporting customers to make more informed choices.

Aself-build project near Coldstream in the Scottish Borders has become the latest to benefit from Passive House-certified glazing, following the installation of high-performance windows and doors by Glasgow-based Accent Doors and Windows.

The family-run firm supplied and fitted its Euro94 Timber Aluclad Triple-Glazed Windows and Doors – a product certified to meet the stringent demands of the Passive House standard and fully PAS 24 security tested. The installation forms part of a growing shift towards ultra-low energy homes in rural areas, where heat retention and durability are increasingly vital.

Available in pine, meranti, or oak finishes, the Euro94 range combines thermal efficiency with robust design, targeting the needs of self-builders and architects seeking both sustainability and aesthetic quality. Accent’s glazing products are known for achieving low U-values, and can be supplied either with full Passive House certification or engineered to meet its standards without formal accreditation.

“This project reflects a clear direction of travel in the UK’s building landscape – homeowners want future-proofed properties that deliver on comfort, energy

performance and security,” said Graham Ferguson, director of Accent Doors and Windows. “We’re proud to support that goal with tailored, certified solutions.”

With demand rising across Scotland and beyond, Accent continues to expand its footprint among trade professionals and self-build clients seeking reliable, highperformance joinery and glazing products at competitive prices – a market increasingly shaped by energy standards and climateconscious design.

www.accentdoor.co.uk

As part of its ongoing programme of continuous improvement, Hurst Doors has installed two new high-efficiency glue application machines at its manufacturing facility, supporting its long-term commitment to sustainable operations and continued investment in plant and machinery.

The new equipment delivers a more precise and consistent glue bead, significantly reducing adhesive waste and the release of harmful VOCs (volatile organic compounds) into the atmosphere. The upgrade has also enhanced production line efficiency, improving bonding quality while reducing manual handling on the shop floor.

“This investment is another step forward in our drive to improve manufacturing performance while reducing our environmental footprint,” said Kevin Wheatman, Director and General Manager at Hurst Doors. “By using adhesive more efficiently, we’re not only cutting waste, but

also creating a safer and cleaner working environment for our team.”

The installation follows a series of upgrades across Hurst’s operations over the last two years, including the rollout of new machinery, enhancements to material storage and handling, and significant investment in a new paint plant and supporting infrastructure. Together, these improvements support a more streamlined, responsive manufacturing process, helping to reduce downtime, improve throughput,

and deliver consistent quality at scale.

“We’re focused on making practical, measurable improvements that support both our sustainability goals and the performance expectations of our customers,” Kevin added. “This includes how we manufacture, how we reduce waste, and how we continue to design products like the Securicore™ PAS24 panel with recyclability and efficiency in mind.”

In addition to improving production processes, Hurst maintains closed-loop recycling partnerships for materials such as glass, MDF, polystyrene, and PVC-U, ensuring waste is diverted from landfill wherever possible. The company also invests in the energy performance of its door panels, contributing to lower carbon emissions and reduced heating bills for homeowners. Kevin concluded: “We’re committed to building a manufacturing environment that reflects the standards we set for our products - efficient, responsible, and built for the future.”

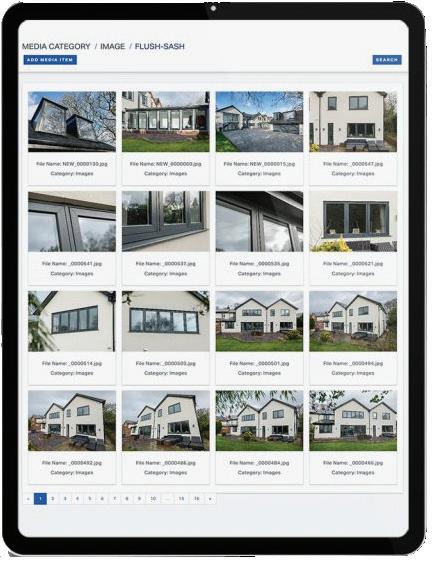

Software pioneers Tommy Trinder are celebrating as the total number of window companies using the sales platform passes 700.

“Making a decent return is getting tougher for installers,” says Chris Brunsdon, founder and CEO of Tommy Trinder. “Firms who are thinking smart and not just working harder, are the ones who are pulling ahead, and Tommy is helping to power that shift.”

From one-man bands to nationals and from the highlands to the Channel Islands, Tommy Trinder has established itself as go to app for installers looking to energise their sales process.

At the heart of the platform is its unique Framepoint Technology®. This patented system lets users free draw PVC-U, aluminium, and timber windows and doors with all the ease of sketching on a pad. Switching colours, ironmongery, bars and finishes is a doddle, and in a couple of taps installers can give homeowners a lifelike preview of how the products will look on their home. Says Chris:

“Even if you’re not exactly tech-savvy, Tommy makes it easy to wow clients,” says Chris. “In a competitive market, you have to stand out; you have to give homeowners something that makes them sit up and take notice.”

The value of work quoted by installers on Tommy Trinder is on the rise too. Every month an eye-watering £300 million pounds worth of work is quoted to homeowners via the platform. High average quote values are also a feature with quote values climbing towards £7900 over the last six months. According to Chris, premium products are playing a key role in that uplift; “Aluminium and timber now represent nearly half of all quotes generated through the platform,” says Chris. “For PVC-U, our users are seeing a bump in job value by making it easy to showcase premium features - foils, dual colour options, flush casements, peg-stays and decorative bars - all brought to life in a visual and compelling way for the homeowner.”

The firm reports that more than 14,000 homeowners receive a quote generated by Tommy Trinder every month and, notably, around half of them are provided with visualisations to accompany their quote;