Available Now – while supplies last

Leap into spring with the SATA BBQ promotion and get yourself a stylish, strong and functional BBQ apron as well as solid, innovative and multifunctional BBQ tongs in stainless steel. Whether at the next family gathering or at the camp site - with the SATA BBQ Kit you are perfectly set.

SATA customers will get the limited edition BBQ Kit along with the purchase of SATAjet X 5500 (any technologies or versions) as a gift. Available only from your local authorized participating SATA dealer –only while supplies last.

Classic Collision has announced the acquisition of Pinnacle CARSTAR Auto Body in Tomball, Texas, according to a press release.

Pinnacle CARSTAR Auto Body has served the area “for many years,” and values timely service that meets or exceeds customers’ expectations. Martin Russel, now former owner of Pinnacle CARSTAR Auto Body, believes that Classic Collision will uphold those same standards.

“We have specialized in keeping our customers’ vehicles looking as good as (or better than!) the day they bought them and believe that Classic Collision will continue our dedication to our craftsmanship,” Russel stated.

CEO of Classic Collision Toan Nguyen said that the company is “eager” for Pinnacle CARSTAR Auto Body to join their network and that “their high level of quality and performance standards” will be implemented across their Houston businesses.

12TH-ANNUAL

Caliber and its brands have launched the 12th annual Restoring You Food Drive to help address hungry youth nationwide, according to a press release.

“Non-perishable food and monetary donations” will be accepted at any Caliber location until May 26. Monetary donations may be sent online. Caliber’s nonprofit will “donate an additional $.25 for every dollar raised.” The donations to each Caliber location will go toward that location’s local food banks’ summer programs.

“This year’s goal is to donate

four million meals to local food banks across the country, and we believe that is achievable with the help of our incredible family of Caliber teammates, our customers and valued business partners,” Caliber Chief People Officer David Dart stated.

The Restoring You Food Drive was started by a “caring teammate” in 2011 and has since grown to “more than 1,600 Caliber centers across 41 states and 25,000-plus teammates” that have helped donate more than 24 million meals.

Fix Auto USA has announced the opening of a new location in Ogden, Utah, according to a press release.

Fix Auto Ogden is owned by Efrain Perez, who operates the store alongside his wife, Rebeca Perez. Efrain is from Colombia, where he got his start in the industry by helping his dad with work around his body shop. His family moved to the United States and Efrain soon started his own small body shop.

While Rebeca is new to the automotive industry, the same drive that motivated her background in healthcare working as a nurse helps her to connect and communicate with customers.

The 10,500-square-foot facility will employ eight individuals. Efrain said he is “optimistic about taking this location to the next level,” with it set to gain I-CAR Gold certification soon and plans to earn more OEM certifications sometime this year.

Quality Collision Group (QCG) has completed an acquisition of Schaefer Autobody Centers, according to a press release.

Schaefer Autobody is based in St. Louis, Missouri, and has been in business since 1985. They have 14 locations that will begin to be shifted to the QCG network “immediately.”

QCG CEO Jerod Guerin was compelled to approach owner Scott Schaefer because of the company’s “leadership position in the market” and saw a potential growth opportunity.

Following the merger, Schaefer will be joining QCG’s executive team, and plans for Schaefer Autobody to keep its identity.

“The Schaefer way of doing things isn’t going away; it’s only getting better,” Schaefer stated. “Joining Quality Collision Group allows us to expand and deliver the best results for our customers and clients.”

ProColor Collision has announced the opening of its newest location in North Hollywood, California, according to a press release.

The 17,000-square-foot shop at 6872 Lankershim Blvd aims to provide collision repair to the greater Los Angeles area. It has also recently been given I-CAR Gold certification.

The store will be owned and operated by Pargev Adamyan, who has more than 20 years in the collision repair industry.

“We offer the best customer service with 50 years of shop and insurance experience as we strive to do a better and cleaner job every time,” Adamyan stated.

Adamyan wishes to continue in the footsteps of his father, who worked in the collision repair industry for 30 years. Adamyan made the decision to join ProColor Collision to have access to

resources such as “the most upto-date technology, strong history and proven network support.”

Classic Collision has announced the acquisition of two new locations: a Colorado and a Florida location, according to a press release.

BJ’s Auto Theft & Collision in Commerce City, Colorado has been in business for 30 years and values timely service with professional results. BJ Penrod, who had owned the shop, is confident it will be in good hands after being acquired by Classic.

“Our goal has been to maintain communication with our customers to guarantee that we make it a positive experience during difficult times and know that Classic Collision will continue that same approach,” Penrod stated.

Irish Mike’s Collision located in Orlando, Florida has been a family-owned and operated store known for reliable service at an affordable price. Owner Michael Flynn described the shop as a “fixture in the neighborhood” and that even those who moved out of the area have still returned.

Classic Collision CEO Toan Nguyen said that the two stores’ great service combined with customer satisfaction is why the company thought they were the next step for growth.

“Both BJ’s Auto Theft & Collision and Irish Mike’s Collision have been high performers along with customer focused, and we look forward to welcoming them to the Classic family as we continue to expand our footprint across Colorado and Florida,” Nguyen stated.

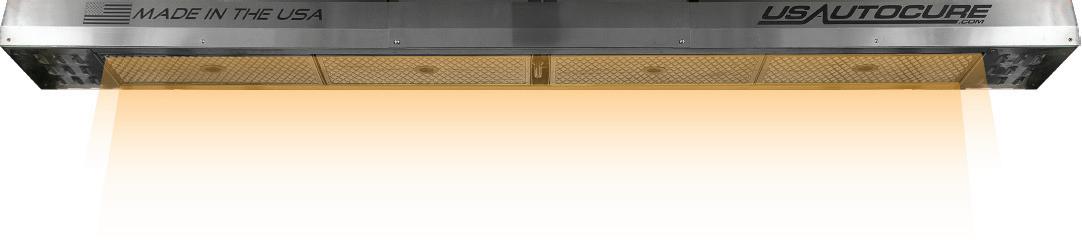

Gas-catalytic, medium-wave infrared curing is adaptable to a broad range of applications.

1

PAINT: Our chemist will review a list of the coatings products and other technologies you use and their response to infrared curing.

2

To determine how US Autocure systems can help you, we start with 3 simple steps: 3

PROFITABILITY: We’ll work with you to determine the areas of savings and gains that infrared curing can provide.

BOOTH: Some basic spray booth information is all that is needed to help us determine the best system for you.

There are no costs associated with these steps and we will not share this information with anyone but you. These activities can be completed quickly, but we won’t rush you.

We believe in our technology.

We want you to be comfortable that it’s right for you. 480.268.9703

THIS MONTH’S FEATURE SUBJECT BENEFITTED FROM SMART MANAGEMENT AT THE START

Our cover story subject, Jason Wong, has a pretty cool origin story for his shop ownership. He says that years ago, he started working at a shop for free as long as he could fix his car there. Eventually, he matriculated through other roles in the shop, including bookkeeping and customer service. After years of putting in work, the shop owners sold to Wong, who has now been in the business for nearly 30 years.

Of course, it’s great to see a shop owner who has worked their way up to the position. But what I like the most about this story is that Wong’s bosses seemed intent to place him in the best position suited to his skills. Maybe it wasn’t just putting Wong wherever there was an open position, rather it was more about putting him in the best place to succeed.

And just look at the results. I mentioned his tenure in business ownership, and CARSTAR recognized him as the 2022 Franchisee of the Year. Around the same time, Wong joined the ranks of MSOs and opened a second shop.

There’s a ton more to check out in this month’s profile story, including how he has cemented his brand in the marketplace, and how he maintains a healthy culture of transparency in the operation. “We hired 10 employees recently, and they’re all about 26 years old,” he says in the story.

Whether you’re a small MSO or a sprawling shop network, there’s lots to glean in this month’s edition. Thanks for reading.

Matt Hudson Content Director

It’s officially 2023 . While the modern world may not look quite like the one predicted by “The Jetsons” television show, technology has still crafted much of today’s society and that certainly includes the automotive aftermarket. Just because flying cars aren’t the norm, that doesn’t mean vehicle technology isn’t vastly different than it was even just a few years ago, and shops are paying attention.

As the industry settles into a new year, these responses have the potential to become an especially vital component of the approach to automotive repair. That’s because innovative technologies are not going to stop emerging. The way vehicles are repaired will continue to shift, and it is important to stay informed.

So, what exactly is the forecast for vehicle trends and technology for 2023? The MSO Project reached out to a few industry experts to hear their thoughts.

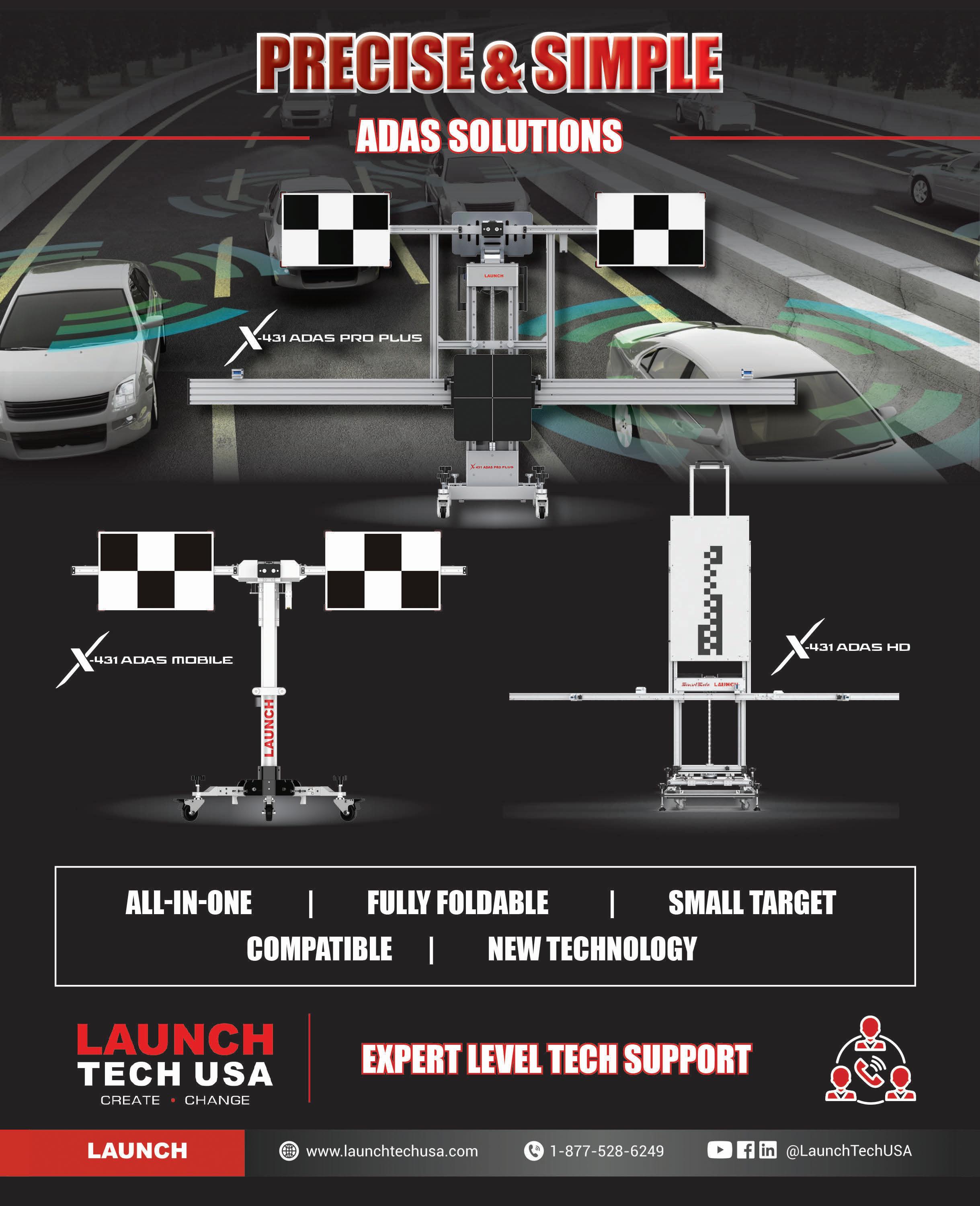

“I think the challenges facing shops in the next year will include how to service new energy vehicles such as electric and hybrids and enabling technicians to access the education, training, and tools needed. Another challenge will be servicing the increasing number of vehicles with advanced driverassistance systems such as automatic

emergency braking, lane keep assist, and blind spot monitoring.

Calibrating the input devices (camera, LiDar, Radar) inherent in these systems requires a shop to have significant space and a comprehensive calibration frame system, and skilled technicians.”

“With this surge in electric vehicles, automotive repair shop owners and technicians will need to make decisions on electric vehicle-related training and tools/ equipment. Of course, these decisions are not easy and whatever a shop owner decides will be based on many factors including the following:

Does investing in EV tools and equipment make sense for my market/ customer base?

An automotive repair shop in California, the state with the largest density of EV drivers, will most likely consider investing in tools and equipment given electric vehicles are likely to come through the shop. On the flip side, a shop in a rural region/state, where there are far fewer electric vehicles on the road, may not have to invest in certain resources until EVs become more prominent in that area.

When we view automotive technology historically, there is no shortage of shifts that challenged shop owners to adapt to new norms. For instance, when ADAS was first introduced, many shop owners across the country viewed it as a niche. Today, pretty much every new vehicle

sold has some level of ADAS and it has become vital technicians are trained and up to date with tools and techniques.

Electric vehicles will be the norm one day and for many automotive repair shops, especially in rural areas, it may be smart to invest resources into technician training and equipment that’s applicable to EVs and gas-powered vehicles–highcapacity lifting tables for instance are a perfect example of equipment that is essential for EV repairs yet can be used in gas-powered vehicle repairs.

Being capable of servicing electric vehicles is very niche, however, the market for it is there. Servicing and providing amenities to EV owners–including offering charging stations–could be used as a way to attract and retain new customers.

Cars are becoming more like computers every year, which means shop owners will have to pay attention to tool and equipment updates, as well as make sure their technicians are properly trained and up to date with new technology.

If shop owners aren’t up to date on industry news, tool updates, and new requirements from OEMs then they run the risk of missing out on vital information which could directly correlate to how they service their customers. For instance, ADAS recalibration is becoming ever more important, but the processes can change with new vehicle models and are not the same across manufacturers. That’s why it’s important to have technicians of all skill levels to be enrolled in multiple training sessions a year.”

“In my opinion, the same two trends we started 2022 with will be the same two trends that will be prominent in 2023: The continued growth of electric vehicles (BEV, HEV, PHEV) and vehicles equipped with ADAS coming into the shop.

For ADAS, the realization has to come that whether a shop knows it or not, they are working on ADAS just by doing routine thrust angle alignments and many other ‘non-ADAS-specific' types of repairs. In addition to those, vehicles equipped with ADAS features are now aging to the point we should begin to see some sensor failures, etc. Shops are going to have to ask themselves how they are going to ensure these vehicles are returned to their owners in proper operating condition.

Regarding electric vehicles, again, while the popularity of these vehicles varies regionally, shops need to understand it’s not a question of ‘if;’ it’s a question of ‘when’ these vehicles start showing up in your service bays. Turning them away is not a solution for growth. Addressing them, like many other emerging technologies we’ve dealt with over the years, will require some training and some gear, but most of the repairs are going to be repairs we’re used to (brakes, suspension, steering, CV joints etc.)

To summarize, I would say the challenges are really, as they’ve always been, for the shop owner to accept and embrace that new technologies mean new opportunities. Ignoring them has never been a good business decision. Embrace them and reap the long-term rewards!”

By Carol Badaracco Padgett

Mark Serr Photography

By Carol Badaracco Padgett

Mark Serr Photography

when owner and operator Jason Wong turned his collision repair shop in San Francisco into a CARSTAR franchise, he didn’t necessarily have a firm feel for running the business. But he did love cars— and he was loaded with more than 25 years of experience in the collision repair industry.

At the time, CARSTAR was new to the California market. “Nobody knew who they were,” as Wong puts it. “They had no insurance support.”

Yet, for Wong, CARSTAR simply stood out as a franchise option that aligned well with his business—so well that Wong’s shop, under a new five-year contract, became CARSTAR Auto World Collision.

“The reason I actually signed a contract with them is because they asked what I wanted,” Wong states. And what he wanted was for CARSTAR’s operational team to teach him how to run a collision repair shop—even more successfully than he had in the years prior to becoming a franchisee. He didn’t even want the CARSTAR team to actually

bring him business—just teach him the operations side of things.

Then, with his foot on the pedal, Wong opened a second CARSTAR Auto World Collision location in San Jose in 2022.

With two stores in operation, the newfound multi-shop owner began to hit some serious milestones: whereas a little over five years ago he was doing about $2 million a year in sales, in a short

time he saw those sales figures nearly double.

“I’m at $10 million this year,” Wong states of his shop’s continued sales growth. And yet, he points straight back to CARSTAR when you ask him to name the major driver for his success. In addition, he’s quick to note that whereas the franchise was relatively unknown when he first signed on with the company, it’s now the country’s largest individually owned MSO.

“It’s amazing,” he states. “Since I came onboard the [CARSTAR] company has nearly tripled in size.”

Long before becoming a CARSTAR MSO, Wong had what it takes—innate talent and ability—that could be channeled into business success in the collision repair industry. But it took some time for him to develop his strengths to their fullest.

“I have two older sisters … I’m the youngest,” he says of his background growing up in San Francisco. While his sisters went to Ivy League schools, formal education didn’t really jive with their little brother.

“I’m a naturally lazy person, but Dad said either go to school or go to work,” Wong says, smiling. “I worked at a restaurant, and they promoted me to dishwasher, so I left.”

To add another dent in his selfesteem, the young man’s car kept breaking down.

“The shop was charging me hundreds and hundreds of dollars,” he reminisces. “And I said, ‘Hey, are you guys hiring? Can I just work here? I’ll work for free as long as I can fix my car here.’”

To his good fortune, Wong secured an invaluable crash course. “So I worked at a mechanical shop washing and detailing cars for free,” he states.

Then, after a few months, the shop’s owners noticed something especially admirable about their

young newcomer: he was a natural with customers.

“They put me into a service role because they said I’m good with people,” Wong notes. “Then they put me in the body shop, where I did the books, old-school.”

Eventually, the owners sold the shop—to Wong.

“I spent 19 or 20 years running the shop,” he shares. “Now I’m 49 and I’ve been in the business for close to 30 years.”

Wong’s hard work in the field he loves has paid off: recently he was recognized as CARSTAR’s 2022 Franchisee of the Year.

“I was absolutely shocked that I got this award,” he states. “It was strange because I go to work every day and still run my stores as an owner and operator.”

He jokes that he got an award just for going to work each day.

But when asked to seriously consider the traits he brings to the business that got him in the driver’s seat for award recognition as an MSO, he truly ponders.

“I follow rules; I’m getting older now,” he finds. “If I talk to insurance company X or Y, there’s not a whole lot of negotiation. I say, ‘What are the rules of your program?’ and I go to my guys and say, ‘This is where we’re at. Do you think you can do this?’”

He adds, “I don’t make a whole lot of the decisions solely. It’s not me, personally. I get a tremendous amount of support internally.”

CARSTAR, too, has been an immense support to Wong on an ongoing basis, over time, and he considers the company to be a true partner in his success.

“I’ve been with them for over five years now, and I’ve never met a group of people like them who are constantly

trying to come up with new procedures and processes to help the operators do better,” he states.

Today, as an MSO with serious time in the industry, Wong continues to be energetic and engaged in his businesses. And although he hits obstacles, he finds solutions and workarounds with the same dogged determination he had as a kid who was willing to work for free just to get his car fixed.

“The biggest obstacle I have to overcome, and it’s probably true in any industry, is going to be people,” he notes.

And yet … “I think I’m super blessed where I don’t have retention problems. I don’t have employee problems or technician problems. Others do, but I don’t have them.”

He does give himself just a bit of credit in the area of employee retention, saying, “If the transparency isn’t there in the leadership, it’s hard to have good people. Oftentimes, how well the operators do is a reflection on the owner of the company.”

Putting it all in big-picture perspective, he adds, “We’re fixing cars and putting them back on the road. Families and kids are using these cars. Without transparency, the business won’t work.”

Another way Wong addresses the challenge of finding and keeping good people is by recognizing generational differences.

“We hired 10 employees recently, and they’re all about 26 years old,” he states. “You can’t talk to people in their 20s like you can people in their 40s.” The 20-somethings “need constant motivation and vision, and they have to want to do it more than you do for it to happen. Generations are different.”

As an MSO looking to grow his business and succeed, Wong seeks out the knowledge of others in the industry.

“Everyone should have mentors and reach out to those they think they want to be,” he notes, saying that he does.

“I reach out to people across the country, people I meet at conferences—FenderBender’s was the first conference I went to three years ago, and I sat in a room with independent owners of all shapes and sizes. Everyone was so excited to be there. I’ve never had that experience in my life.”

He finds it of great benefit to keep tightly connected with CARSTAR, as well, saying, “I’m an advisory board member for the brand.”

Wong also suggests that part of being a successful MSO is simply recognizing valuable opportunities when they come along. And personally, he watches for them.

“People should do the best they can,” he smiles. “Because opportunity doesn’t always come along, you know?”

Injuries to clients and auto shop employees, as well as other accidents at your shop and the potential lawsuits that could accompany those accidents, are an unpleasant but all-toocommon reality facing the automotive repair industry.

According to data from U.S. Bureau of Labor Statistics, 6,770 auto repair shop employees suffered an on-the-job injury in 2020, the most recent year for which data is available. An article from FindLaw.com also suggests that retail injuries, or injuries that occur in a place of business, “account for thousands of personal injury claims each year in the U.S.”

Ryan Byers, an attorney with the Jacksonville, Illinois-based law firm Rammelkamp Bradney, says owners and managers need to be prepared and protect themselves in the case that someone were to get hurt at their shop.

“You certainly want to plan for the rare and extreme case to make sure you’re protected,” he says.

It’s an all-too-common trope that has been played out across TV and pop culture: A customer at a store hurts themselves and, whether it was the store’s fault or not, threatens to sue. The business owner, for one reason or another, offers to settle with the customer right then and there to avoid any legal action. Everyone walks away happy and can go about their business as usual.

Though that scenario seems like it should be a win-win, Byers says it fails to take into account several important factors and could ultimately do more harm than good for a shop and its owner.

The first, and arguably most blatant, inaccuracy of that scenario is liability. Byers says that just because someone is injured on the premises of a shop, it doesn’t mean that shop is necessarily liable.

“The business or one of its agents is going to have to have done something negligent that results in the accident occurring,” Byers says. “Effectively, if you do something negligent that results in someone’s injury, you’re going to be liable.”

The legal definition for negligence is purposely broad and varies from state to state, Byers says, in order to cover a wide

base of negligence claims. Essentially, a person is considered negligible “if they did not act as a reasonable person would have acted under the circumstances.” For example, if an employee spills oil or another fluid on the ground and does not clean it up right away, that would be classified as a negligent act if a customer or other employee slipped on that puddle and hurt themselves.

“You might think that’s an open definition, and that’s because it is,” Byers says. “It’s intended to allow a court or a jury to look at all the circumstances of a particular case.”

Byers says the best way to make sure your business is protected is through a Commercial General Liability insurance policy, which The Hartford insurance company says “helps protect your business from claims that it caused bodily injuries or damage to another person’s property.”

A $1 million CGL policy through the Hartford costs “a few hundred to $1,000 annually” per the company’s website, though costs can vary based on several factors such as payroll size and claims history. The company also points out that its

CGL does not cover damage to your own property or injuries to employees.

On top of differences between a company’s policies, Byers also points out there are different rules state to state about what kinds of incidents your shop could be liable for, and what plaintiffs can and cannot recover through a lawsuit. He recommends staying in regular communication with your insurance agent to make sure that your policy is the right fit for your business.

“Most CGL policies renew annually,” Byers says. “It wouldn’t be a bad idea whenever that renewal comes up to check in with the agent and say ‘hey, these are the changes that my business has had –what changes are you aware of and do we need to change our coverage as a result?’”

Byers says there shouldn’t be a one-sizefits-all approach to dealing with an onsite customer injury; how you respond depends on the nature and severity of the injury. If the injury was caused by a dangerous condition and the injured party is still imminently in harm’s way, Byers says you can and should help them move out of that area if possible.

If the person is able to “leave the site of the accident under their own power … and are not at risk for further harm by doing so,” Byers says you should let them be the one to decide when they’re going to get up.

“The last thing you want is somebody who’s injured, maybe don’t realize the extent to which they’re injured, and you encourage them to move or physically move them and you cause further injury,” he says.

If your shop has security cameras, Byers says preserving that footage as quickly as possible can help exonerate you of some negligence claims. It can also look bad if you have cameras but don’t preserve the footage.

“That could be used by an opportunistic plaintiff to make you look more guilty than you actually were,” Byers says.

In addition, making sure you contact your insurance provider to start a claim as quickly as possible will also help according to Byers, as most CGL policies include a provision that says your shop will provide any notice of potential claims, and waiting to contact them might give the insurance company an argument that your shop has waived its coverage.

Similarly, Byers advises not to try to settle with the injured party by yourself. Most CGL policies will place the power to settle with the insurer, and settling without your insurance agent or an attor-

ney present might leave your shop without the necessary releases of liability.

“You don’t want to potentially void your coverage by doing something that impedes your insurance company’s rights,” Byers says.

Dealing with injuries in your shop –especially to customers – can be a nervewracking and intense process, but Byers says dealing with the affected party fairly and with respect can go a long way in making sure the situation plays out as well as it can. Checking in on the customer and making sure they feel thought of – while not say-

ing anything that sounds like an admission of fault – can be the difference in deciding whether your shop has a court date.

However, Byers says the best way to avoid liability claims is to make sure that your shop has policies and best practices in place that prevent an injury from happening in the first place.

“An ounce of prevention is worth a pound of cure,” Byers says. “Nobody is going to be 100 percent perfect in that regard, but the more preventative steps you can take, the better you’ll be in the long run.”

Effectively navigating vehicle technology is a task on nearly every shop’s to-do list. Staying educated and trained on what’s new and emerging is not a solo journey. The entire automotive aftermarket is facing these changes together.

While the various steps to understanding these shifts can’t necessarily be checked off all at once, technician training and educational opportunities for shops can be implemented in order to help.

Dirk Fuchs is the director of technical programs and services at I-CAR, and he understands the need for resources in this vein. Fuchs notes that I-CAR coined the term “technology tsunami” several years ago to describe the influx of technological advancements within the industry.

“There’s so much technology coming to our industry, and we need to stay on top of it and really be capable of repairing that … and do the right repair and a quality repair,” Fuchs said.

Fuchs says another reason that understanding technology and electric vehicles is important is safety. On the technician's side, he mentions the risk of someone getting hurt if the repair process is not well understood.

Fuchs says I-CAR thoroughly supports the notion that education is a crucial component of success in this industry, and there are many areas that can be impacted by this.

“You want to perform a quality repair, you want to have the best end result for your customer, you want to have your technicians safe and on and on,” Fuchs says.

The importance of training for electric vehicles may be clear, but many shops may be wondering how to get started. I-CAR has resources applicable for all kinds of collision repair shops, including seven online training courses available and a five-day EV Hands-On Skills Development course that is held at I-CAR's new Chicago Technical Center.

“When you really [want to] learn and want to have a completely educational

experience when it comes to high voltage technology, then we have … [an] educational path. You go first in those seven online training courses and then you come to our … brand new facility in Chicago and go through those five days,” Fuchs says.

At the end of the 5-day course, Fuchs says there is a written and practical exam to ensure the knowledge is being effectively passed along to participants. Recently, this course was recognized with the SEMA Global Media Award at the 2022 SEMA Show.

Beyond electric vehicles, I-CAR has other training resources for technology as well. This includes advanced driver assistance system training. One component is a Static ADAS Calibration 3-day Hands-On Skills Development general course that is focused on static calibration.

Additionally, there is a Ford ADAS Calibration two-day hands-on skills development course that allows participants to learn more about Ford Service Information (PTS) and the Ford Diagnostic & Repair System in a hands-on environment. This course and the threeday course are also taught at the stateof-the-art Chicago center. But educational courses are just the beginning of the work being done at this new facility.

“Research is a [big] topic for this building as well. We have all the capabilities of … general collision-related research [and] we can verify repair procedures,” Fuchs says. “We [also have] a welding lab in there … there [are] a lot of things going on around this building right now.”

Innovative technology is part of the research being conducted at the Chicago Technical Center right now. Fuchs mentions that Learning and Innovative Technology Manger Mike Mertes is spearheading what Fuchs calls “the cool stuff.”

“Mike is responsible for everything with new learning technologies,” Fuchs says. “We call it … ‘gamification.’”

Fuchs says I-CAR looks to the younger generation of “gamers” to see how they can make training and the overall industry more attractive and fun for potential future technicians to pursue.

Additionally, Fuchs points to the work being led by Mertes involving augmented and virtual reality. Mertes spoke about some of this work during the ADAPT Summit back in September.

“We [want to] also look into how we can use those modern technologies to create a safe environment,” Fuchs says. “In training topics like high voltage, [which] is a pretty dangerous technology for technicians, you could make a mistake in a virtual environment … and learn from this mistake.”

Fuchs mentions that I-CAR offers a vast catalog of online course options as well, all of which are all detailed on the I-CAR website. Fuchs sees the value of in-person training as well as online.

“You can cover a lot of knowledge areas online, and that’s great,” Fuchs says.

He says online options can help save money on travel costs because people don’t have to leave home to complete them. With shops navigating parts shortages and other industry challenges, Fuchs says the accessibility of online training can be a great solution in many circumstances.

On the other hand, Fuchs points out that you lose the hands-on component of training when things are done online, so some courses are simply better taught inperson. He cites areas like ADAS with components that require unique processes such as calibration.

Those skills tend to be best developed in an environment that allows participants to practice in realtime with the equipment. But overall, Fuchs says I-CAR believes it is important to offer in-person and online training options alike. Fuchs says it goes beyond that as well, with I-CAR offering other avenues to access training, and planning for more opportunities to come.

“We try to bring training in-house with our in-shop team,” Fuchs says. “They’re going out for welding and other things to really make training accessible at the point where our customer is … and that’s the workshop. We have our Chicago training center … for me, a barrier is not everybody wants to fly to Chicago … it’s maybe also a little far, so [we are] already looking into expansion plans [and] how we can bring training into other areas when it comes to ADAS and EVs, for example.”

In the post-pandemic world, the way that people prioritize their lives has changed. Now more than ever, people are recognizing the importance of a healthy work-life balance. They are putting up more boundaries between their work and day-to-day life and aren’t overextending themselves in their jobs like they used to. This behavior change in the workplace can be seen across industries, including the automotive aftermarket, and it has led to the coining of the term “quiet quitting.” Although the term is often used negatively, it is important to note that this behavior is not necessarily bad.

Deanna Baumgardner, HR expert and president at Employers Advantage LLC, believes that such behavior shouldn’t be called quiet quitting because of that negative connotation.

“People aren’t quitting their jobs,” she says. “They’re just protecting their time more and themselves.”

This trend is not something to shirk within the shop. Instead, it should be embraced. Because even though quiet quitting is not initially negative, it may lead to negative patterns if it’s not handled correctly. Baumgardner believes that these negative patterns become especially noticeable.

“If [employees] do not feel that they’re getting support, validation or recognition from the organization,” she says.

Add onto that the low wages and repetitive work that quick lube technicians deal with every day and the odds of avoiding negative behavior are not in an auto-shop employer’s favor. But fret not—Baumgardner has provided three easy ways to avoid the negative sideeffects of quiet quitting.

At Baumgardner’s company, individual check-ins with employees occur bi-weekly. Baumgardner takes this time to talk to everyone about their role and what they’re looking for from their job.

“I really think people need to be transparent,” she says. “Be open with your employees. Have the one-on-one conversations with them, ask them how they’re doing.”

Having transparent conversations between shop-owners and employees can help an employee feel supported and ensure that the shop owner can help the

employee meet their career goals. It also helps the employee feel comfortable going to the shop owner with problems, which in turn prevents job dissatisfaction.

Shop owners can provide recognition to their employees in many ways. For example, Baumgardner ensures that her team feels recognized for their work through a Kudos channel. Here anyone is allowed to post about a customer’s positive feedback or an employee’s positive actions. Recognition could also be verbal appreciation from an auto shop owner to an employee,

or a shout-out about a hard-working employee in a team meeting. Regardless of how it happens, providing recognition is essential. Letting employees know that their diligence does not go unnoticed helps them to feel validated and encourages them to continue working hard.

Baumgardner provides weekly coffee breaks for her employees where the only rule is that they are not allowed to discuss work. Instead, they can talk about whatever they want. This provides the opportunity for team bonding and creates an open line of peer-to-peer conversation. Baumgardner’s company also has a monthly event where they meet up outside of work to just talk and catch up. Team-building activities prevent the development of negative patterns because they help employees feel seen and heard. These activities offer employees an outlet to express their discontent about work, or life, with others who understand and can validate their feelings. In addition, the meetings give employees a reprieve from their long workdays, helping them with work-life balance.

When asked what advice she would pass on to shop owners, Baumgardner stressed that even in the fast-paced environment of the shop, owners can still find meaningful opportunities for transparent communication.

The pandemic has created a huge shift in the way people view work, and how business is done. As a result, automotive companies don’t have the grounds to force their employees to do things the way that they used to. To guarantee continued success, it is necessary for automotive businesses to develop a forwardmoving plan. As the workplace continues to shift and change, auto shop owners should make sure that they too are evolving with their business.