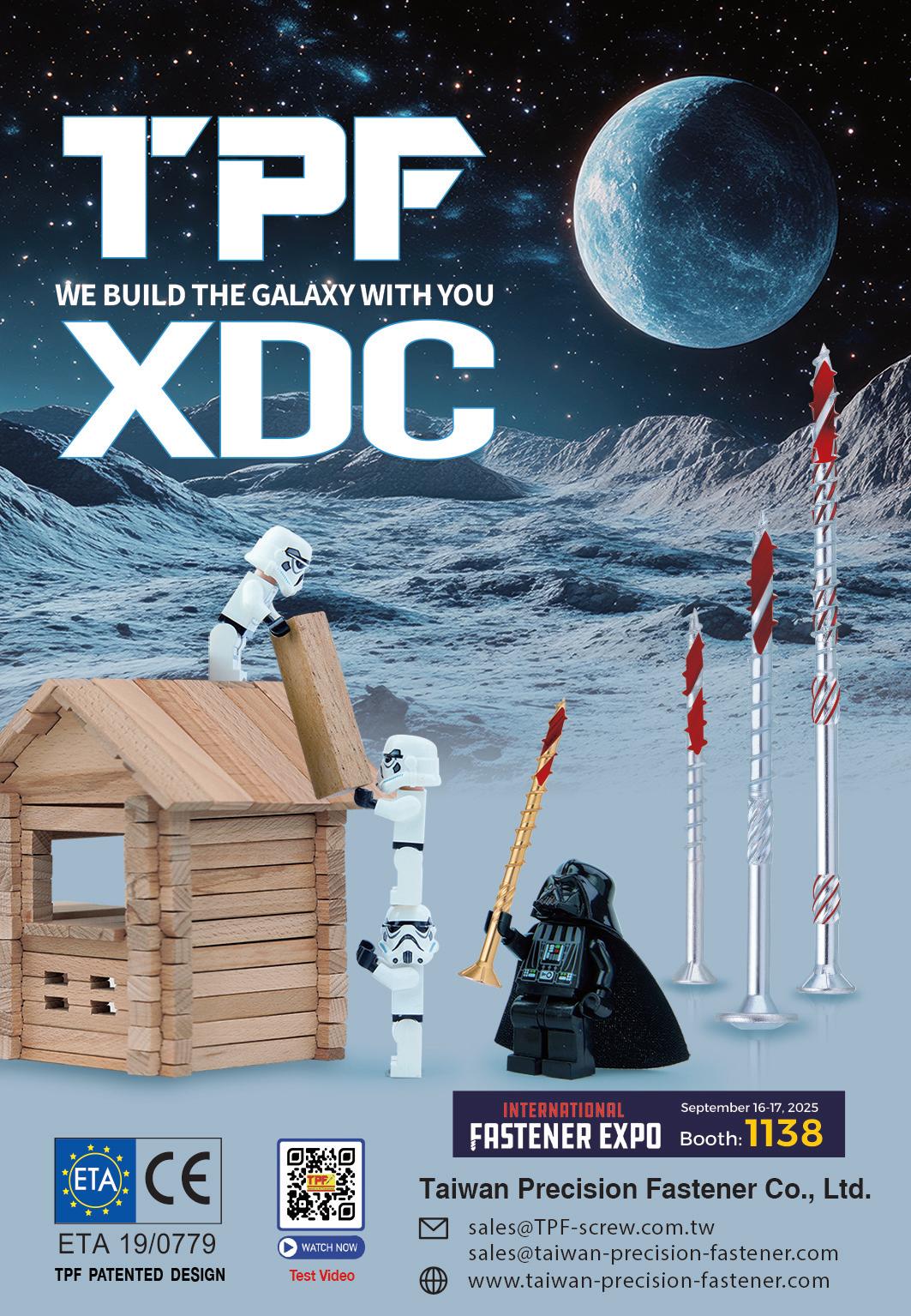

INTERNATIONAL FASTENER EXPO 16-17 September 2025

Booth 2059 | Las Vegas | USA | www.fastenershows.com

FASTENER POLAND 15-16 October 2025

Booth D7 | Krakow | Poland | www.fastenerpoland.pl

INTERNATIONAL FASTENER EXPO 16-17 September 2025

Booth 2059 | Las Vegas | USA | www.fastenershows.com

FASTENER POLAND 15-16 October 2025

Booth D7 | Krakow | Poland | www.fastenerpoland.pl

MUSTAFA TECDELIOĞLU, CHAIRMAN OF ÇETIN CIVATA, IS GUEST EDITOR OF THIS ISSUE OF TORQUE MAGAZINE

We’ve passed mid-2025 and market conditions remain tough after chaotic tariff wars, erratic energy costs, wars and geo-political stresses. Despite this challenging period, Cetin Civata has retained its market share in export and local markets, thanks to market experience, efficiency and sustainability improvement policies, our variety of standard and special products and our dynamic managerial organisation. We have retained our standing in standard products in central Europe distribution, while also acquiring a new B2C portfolio in automotive in South Europe. We’ve also increased our business volumes with automotive FSP companies domestically and in export markets.

// We expanded our surface coating facility by installing a new furnace which enables us to implement the whole process of Geomet zinc flake coating, so we can offer a new licenced brand to our customers //

In standard parts, we have seen clients demand more value-added parts with higher mechanical resistance values, additional functionality and with high corrosion protective surface coatings. Our position has also been maintained through

continuous investments, including state-of-the-art equipment and an advanced machine park. We expanded our surface coating facility by installing a new furnace which enables us to implement the whole process of Geomet zinc flake coating, so we can offer a new licenced brand to our customers. The other major investment has been realised in our factory’s sorting department by installing brand new automatic optical sorting machines and upgrading current machines: now we reach a higher quality control optimisation and a higher measurement control efficiency. Another major investment has been upgrading our level of digitalisation and automation along the production process and also in commercial and administrative departments of our factory.

The ability to take dynamic decisions, together with our flexible approach to new products for new business and advanced engineering structure of inhouse tooling and in-house production process enables us to produce a big variety of fasteners. This is a big advantage for Cetin’s sales force to serve and supply plenty of industries and markets.

One of our important plans – with respect to production – is technical specialisation with project management understanding on strategic products for specific client segments. Those include selftapping construction screws in the UK and North American markets, and hex screws with flange and locking teeth for the German market. With specific product categories in specific territories we plan to make Cetin a market leader in those categories.

We look forward to seeing you at our stand in Las Vegas at IFE and at Fastener Poland.

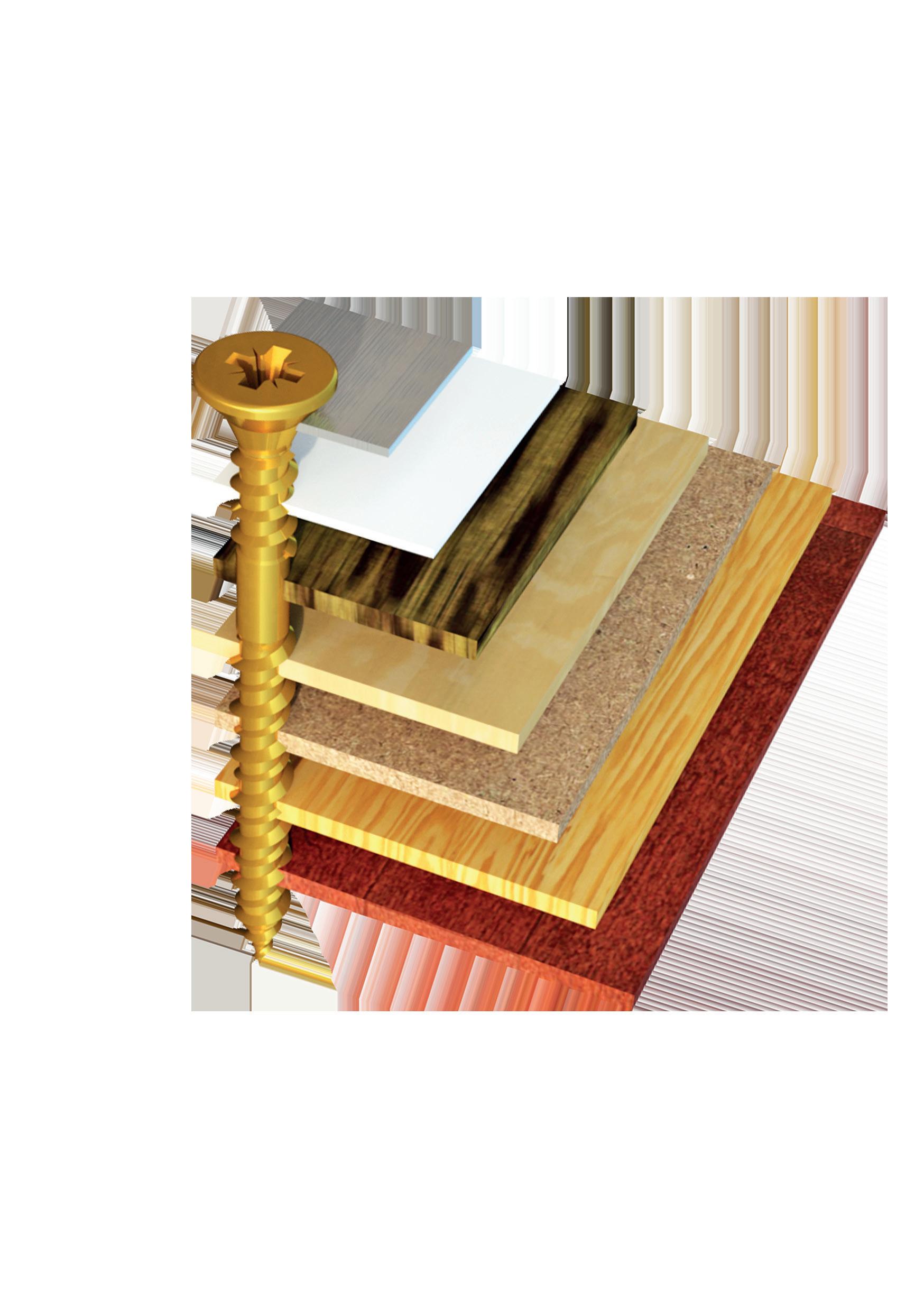

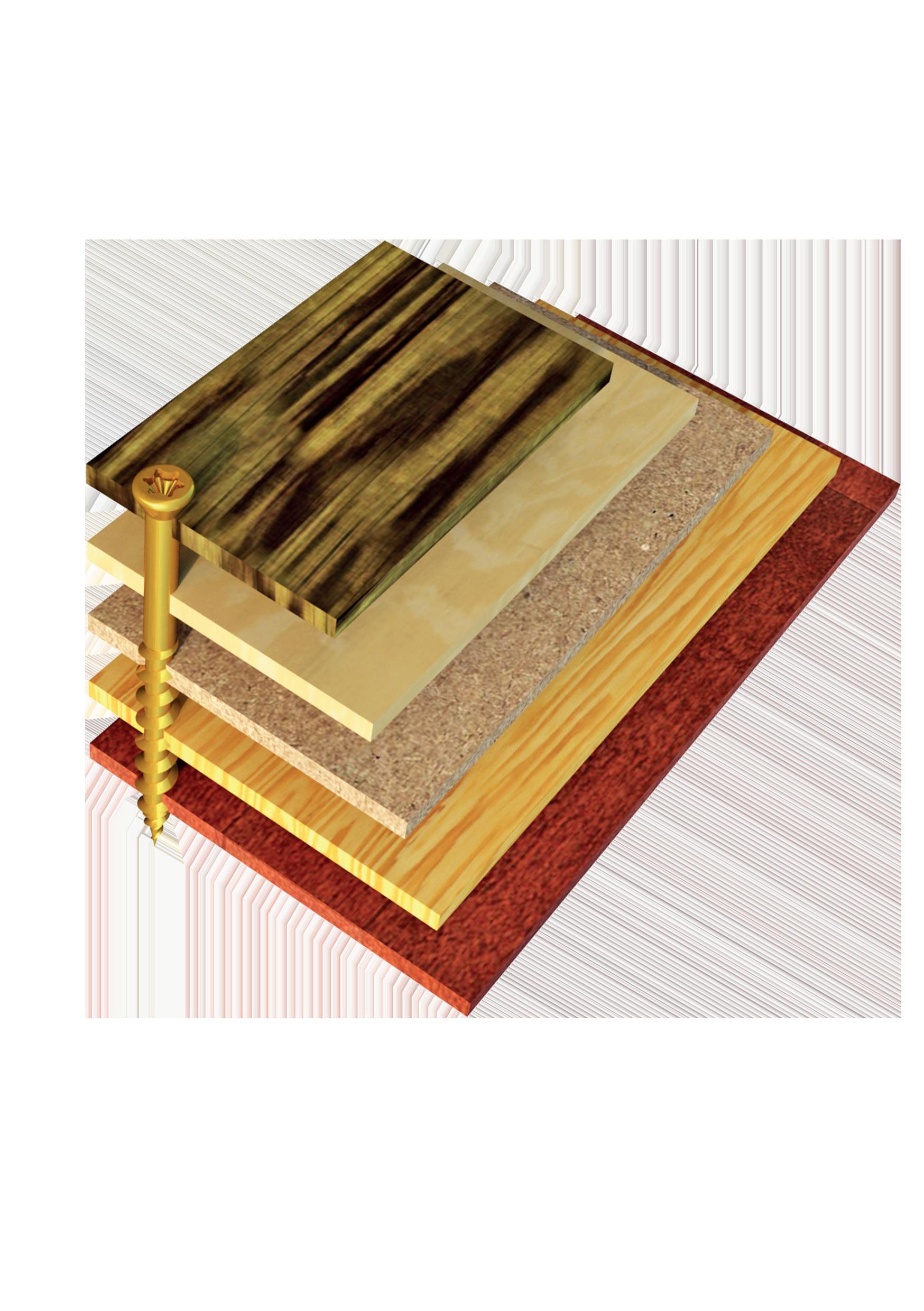

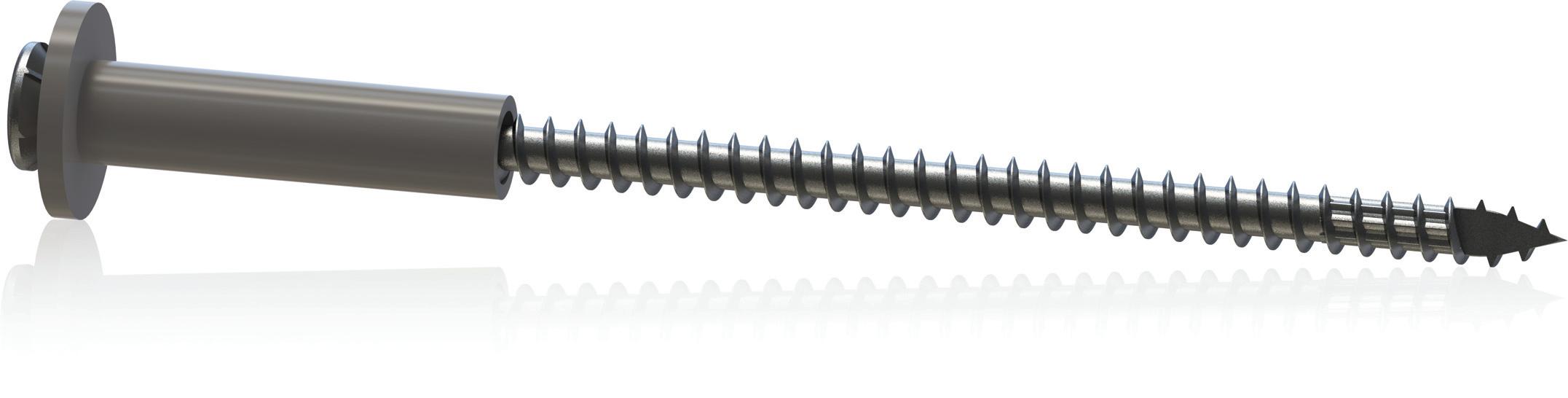

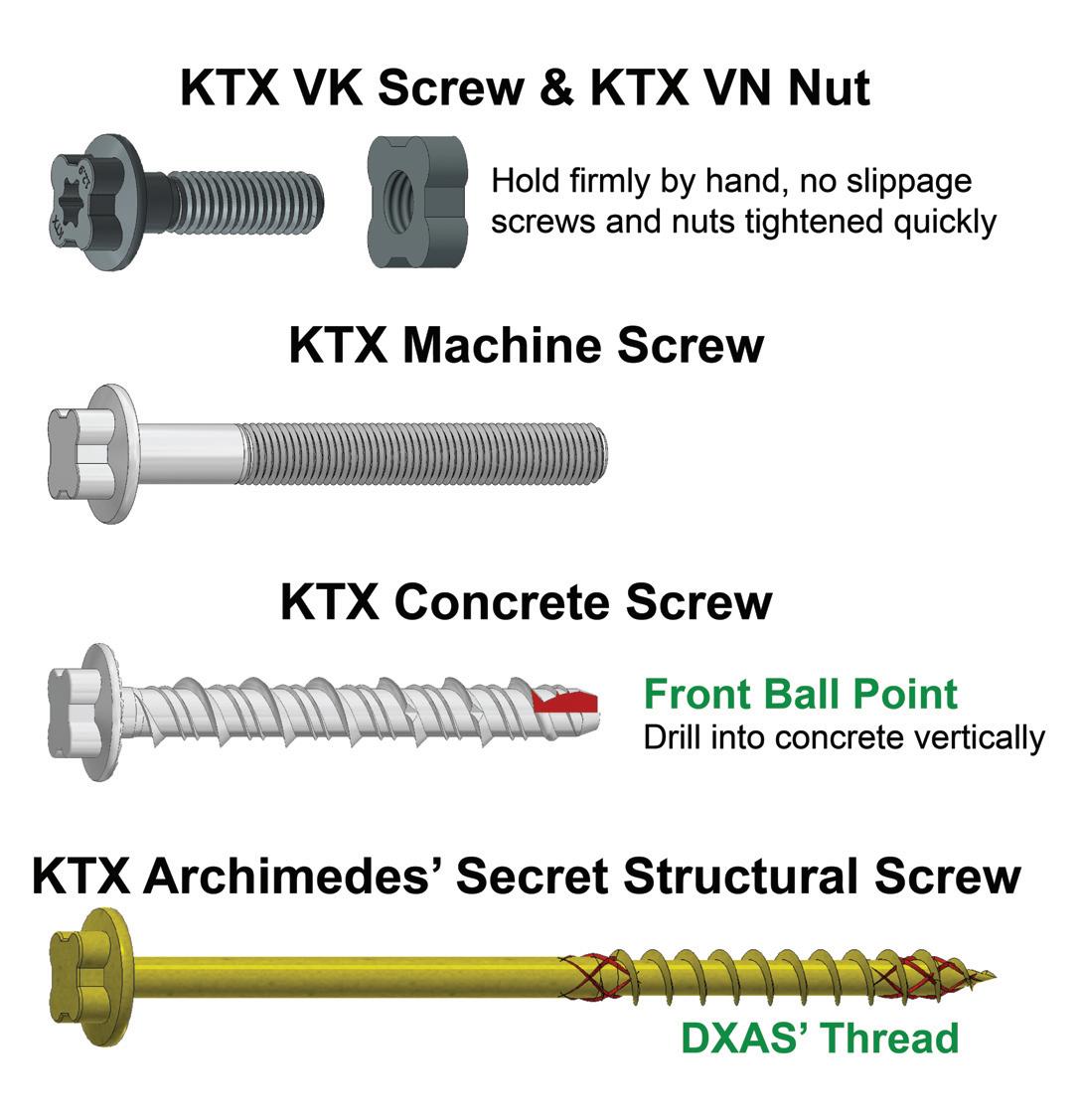

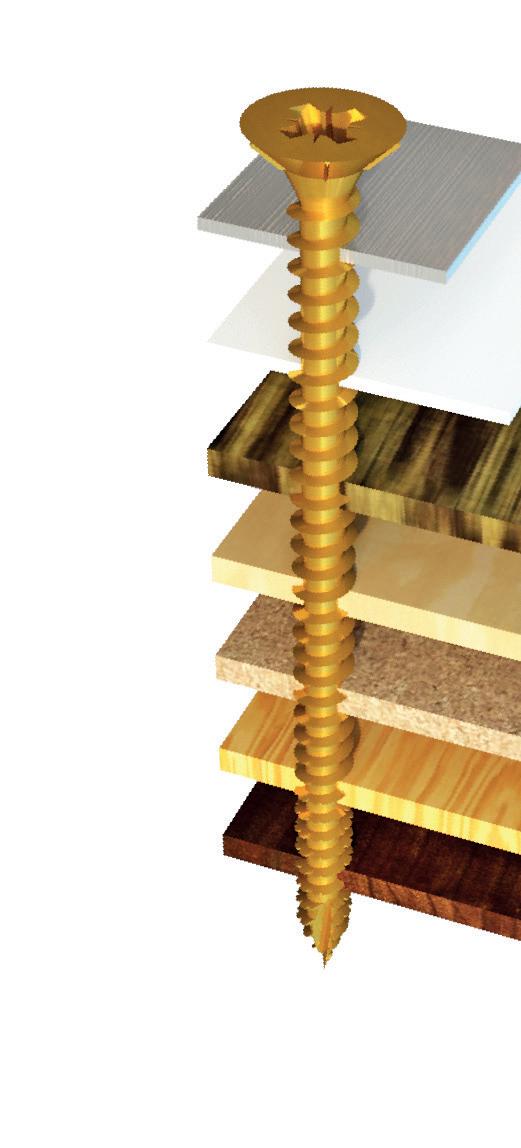

TIMBER DECK AND GARDEN ROOF FAÇADE CONCRETE

Whatever your requirements are, we provide you with everything from a single source. We produce in various processes such as stamping and stamping-bending technology, cold forming, injection moulding and extrusion technology.

From zinc to special solutions such as our special coating 1,000, everything is possible!

PRODUCTION POSSIBILITIES

· Screws with partial or full threads from 40 mm to 3,000 mm with a diameter of 3-14 mm are produced on fully automatic machines

· Simple thread

· Double thread

· Reduced thread

· Different materials

· Different coatings

· Different tip geometries

· Individual customer requirements

· Materials from hardened steel to stainless steel are possible

· Different types of drive

The specialist for fastening technology FOR FURTHER INSIGHTS SCAN HERE

Publisher Jerry Ramsdale jerry@torque-expo.com

Editor Jonathon Harker jonathon@torque-expo.com

Deputy Editor Rachel King rachel@torque-expo.com

Deputy Editor Simon Yuen simon@torque-expo.com

Sales Manager – UK Claire Warman claire@torque-expo.co.uk

Sales Manager – International Harry Whyte harry.whyte@torque-expo.com

UK Sales Manager – Tools Lloyd Ramsdale lloyd@torque-expo.com

Circulation Tracy Howell tracy@torque-expo.com

Head of Production Luke Wikner luke@torque-expo.com

Designers Dan Bennett Victoria Arellano

Published by

Stag Publications Ltd 18 Alban Park

Hatfield Road

St Albans Herts AL4 0JJ

tel: +44 (0)1727 739160

fax: +44 (0)1727 739169

Email: info@torque-expo.com Web: www.torque-expo.com

Disclaimer

Although the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions

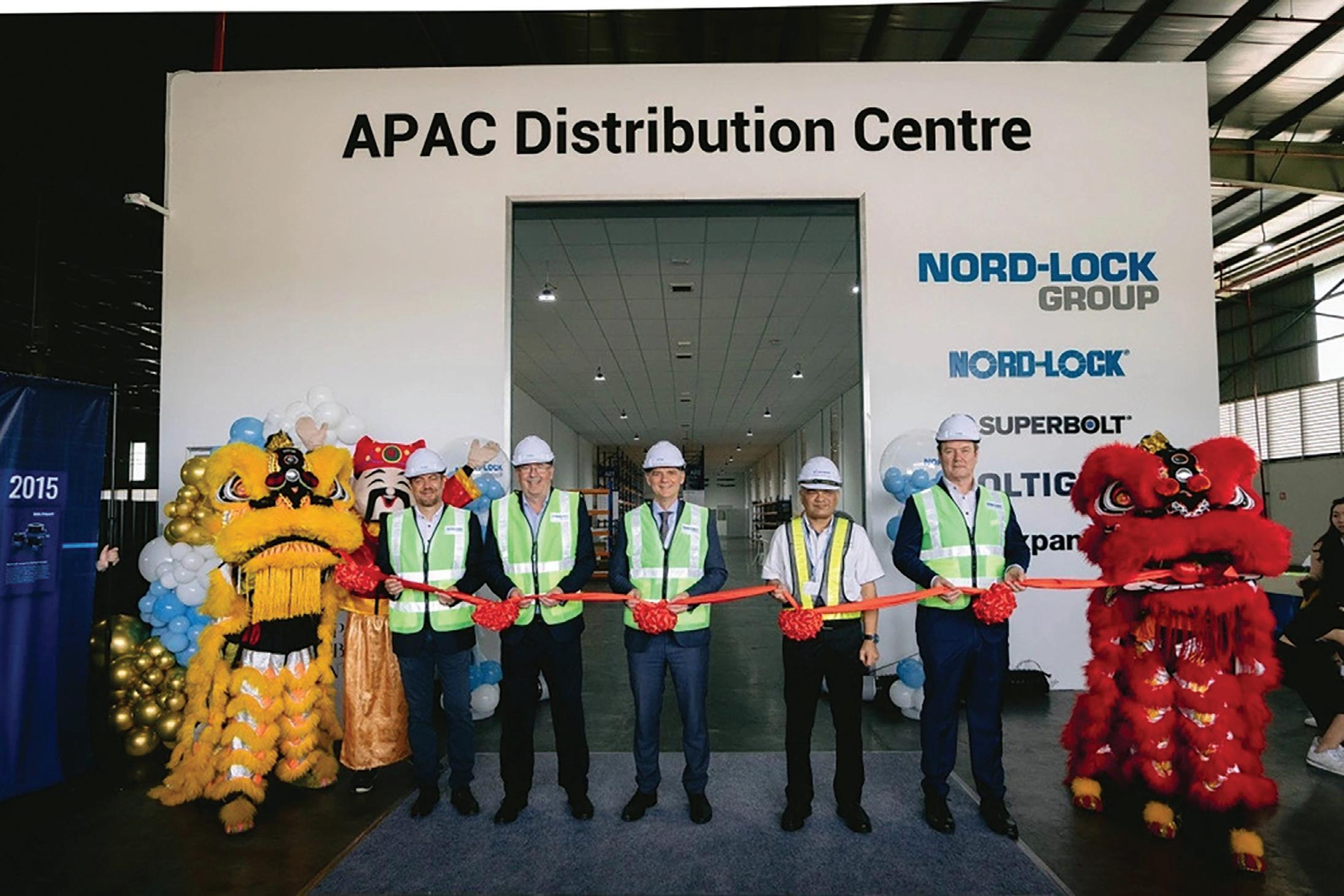

16 COVER PROFILE > SUNCO

18 FOCUS > QC LABORATORIES

24 FOCUS > OILS, SPRAYS & LUBRICANTS

28 SPOTLIGHT > DOERKEN

30 FASTENER TRAINING ACADEMIES

34 OPINION > NORM FASTENERS

36 BUILDING & CONSTRUCTION > TIMBER ENGINEERING

46 SHOW PREVIEW > INTERNATIONAL FASTENER EXPO 2025

49 SPOTLIGHT > HARRISON & CLOUGH

50 TERRITORY FOCUS > ASEAN/ASIA/PACIFIC

66 SHOW PREVIEW > FASTENER POLAND 2025

68 SHOW PREVIEW > HUSUM WIND 2025

Judging by discussions I had in early Q1, expectations for the year were not exactly optimistic. Many predicted a flat economy and were devising strategies to gain share in order for their businesses to grow. Now we’re over halfway through the year and a few financial statements have come through. So, have those expectations proved correct?

It's a mixed bag. There’s plenty of evidence of stability, but predictably scant indication of a boom.

Huge international fastener player Würth Group noted “the business climate appears to be improving slightly, despite erratic US economic policy”.

Meanwhile Fastenal noted that industrial production was “still sluggish” in Q2, affecting the performance of its fastener product line compared to non-fastener ranges. But: “The fastener category experienced improved growth in Q2 2025, compared to Q2 2024.”

Undoubtedly those are cherry picked points that only tell half the story (you can delve into some of the detail on www.torque-expo.com or sign up to our newsletters to stay in the loop).

How to sum up the above? There’s an argument to be made that larger players are a bellwether for the wider industry, so let’s end with the words of the Würth Group: “Overall, the business climate appears to be improving slightly… The number of orders… points to an acceleration in growth in the second half of 2025. For now, the Würth Group is entering the coming months with cautious optimism.” To subscribe to Torque Magazine visit: torque-expo.com/subscribe/ or scan this QR code...

Jonathon Harker

Editor jonathon@torque-expo.com

Würth is once again supporting the United Nations Children’s Fund (UNICEF) as part of its worldwide campaign week. The donation of €400,000 will be used to establish and expand integrated children shelters in Ecuador.

“Children in Ecuador grow up in an environment characterised by armed violence and insecurity. With this donation, we are supporting UNICEF in providing safe havens for children and adolescents in Ecuador, thus giving them a place where they can grow up protected and discover new perspectives,” said Bettina Würth, Member of the Supervisory Board of the Würth Group and Member of the Board of UNICEF Germany.

www.wuerth.com

“PUSHING

Winners of the WorldSkills UK’s Designathon took their concept from idea to reality during a handson experience at the Manufacturing Technology Centre (MTC) Training in Coventry.

The Designathon, part of WorldSkills UK’s competitionbased learning programme, challenged students to tackle realworld engineering problems

with creative, practical solutions. The winning team from New College Lanarkshire in Scotland impressed judges with their robotic grabber design, a precision tool for automated picking and placing, that showed strong potential for realworld application.

Hosted at MTC Training, the students collaborated with engineers, CAD

specialists, and manufacturing experts to bring their concept to life.

Kyle, a student at New College Lanarkshire said: “The designathon definitely pushed the limits of what I thought I was able to do. It was great fun and to find out that me and my teammate, Michael, were joint winners was hugely exciting.”

Apex Stainless Fasteners Ltd has appointed Steve Forbes as the new Managing Director for the company. Steve brings a strong track record of leadership across multiple international roles.

Commenting on the appointment, Steve said: “It’s an exciting time to be joining the business with so many large projects delivered, such as the new warehouse facility at Wednesbury, recent web shop launch and other projects. I want to take this opportunity to thank David for putting some strong foundations in place, which I hope to build on as we look to put Apex in a stronger position for future growth.”

www.apexstainless.com

Agenerational change is happening at GESIPA® as Sales Manager Jörg Penzel leaves the company and hands over the baton to Michael Münker, an SFS Group Germany GmbH employee.

After 12 years of dedicated service and a career spanning almost 40 years, Jörg Penzel will not be retiring but will instead start a fulltime position in the Federal Voluntary Service for a year.

In August 2025, Michael Münker will take over as Head of Sales at SFS Group Germany GmbH GESIPA®, succeeding Jörg Penzel. Michael Münker is a trained plant mechanic and studied mechanical engineering. He has been with the company since 2020, during which time he has gained extensive management and sales experience as a plant manager, particularly in the industrial and automotive sectors.

www.gesipa.de

Fastener Training Institute (FTI) will host Fastener Platings, Coatings and Corrosion, a fullday workshop during the International Fastener Expo (IFE). The training is on 15 September at the Mandalay Bay in Las Vegas. Carmen Vertullo, FTI instructor, and owner and founder of Carver Labs, will lead the workshop. Attendees who invest in this professional development will gain extensive knowledge about corrosion in fasteners.

DEWALT SUPPORTS FURTHER US TRADESPEOPLE THROUGH PARTNERSHIP >

DEWALT has formed a partnership with SkillsUSA, a studentled workforce development organisation in the US, to support future tradespeople across the country. As part of the partnership, DEWALT donated US$100,000 in tools to the SkillsUSA Championships, a gathering of the US’ future skilled workforce taking place in late June. DEWALT also collaborated with SkillsUSA to distribute the tools utilised during the competitions to aspiring tradespeople across the US. Looking ahead, DEWALT will commit US$30 million by 2027 to close the skilled trades gap by helping provide greater accessibility and resources for trades training.

NEW CEO OF NMBS >

MACH 2026 TO FEATURE SMART INDUSTRY SOLUTIONS ZONE > MACH 2026 will include the Smart Industry Solutions Zone, showcasing the latest advancements, products and technologies in manufacturing. The zone will highlight cuttingedge solutions that enhance productivity, sustainability and competitiveness in the manufacturing sector. It will also be the hub for discovering “transformative technologies and exploring their realworld applications”. MACH 2026 will take place in NEC Birmingham between 20 and 24 April 2026. Coorganised by the Manufacturing Technologies Association (MTA) and MTC Events, MACH 2026 aims to revitalise the UK manufacturing sector and bring renewed value to events hosted by both organisations.

Kevin Williams will join NMBS as the new CEO on 1 August 2025. He brings more than 30 years’ experience in building materials and construction distribution, having progressed through a variety of leadership roles at Travis Perkins and, most recently, as managing director at Headlam PLC. He will succeed Chris Hayward, who became CEO of NMBS in 2022, following more than 20 years as managing director and more than 47 years’ service in total at NMBS. Hayward will officially step away from NMBS early next year, allowing a smooth transition process through the rest of 2025.

OPTIMAS SOLUTIONS ANNOUNCES NEW EUROPEAN HQ >

Optimas Solutions has announced the opening of its new European Headquarters in Hambach, France, relocating from its current facility in Sarreguemines. Optimas’ new facility has a 6,000m² warehouse that can hold up to 9,500 pallets and 1,500m² of modern office space. Hambach is home to over 70 employees for sourcing, supply chain, engineering, quality, sales and operations teams, as well as a dedicated team providing products and services to the tunnel industry. Optimas said this decision can enhance its investment in Europe while strengthening supply chain security and operational efficiency.

To subscribe to Torque Magazine and receive the newsletter visit: www.torque-expo.com/subscribe/ or scan this QR code...

NEW BROCHURES AND GUIDES FROM RIVIT >

Rivit has launched the new brochures and updated guides, offering an overview of the entire Rivit range. For example, the Fastening Tools guide encompasses more than 30 models and comparative diagrams, allowing customers to find the most suitable riveting tool for operational needs. The Rivet Selection Guide is compiled based on materials and technical specifications, enabling customers to choose the bestperforming rivet type.

INNOTRANS EXPANDS TO SINGAPORE IN 2027 >

Messe Berlin will launch InnoTrans Asia, the first Asian edition of the transport technology trade fair, in Singapore, following the signing of a Memorandum of Understanding (MoU) with the Singapore Tourism Board (STB). Taking place from 7 to 9 September 2027 at the Singapore EXPO, this inaugural event will serve as a central platform for Asia’s rapidly growing transport sector. The trade fair will showcase Railway Technology, Railway Infrastructure, Public Transport, Interiors and Tunnel Construction.

HILTI’S PLANT IN INDIA ACHIEVES DGNB TOP RATINGS >

Hilti has been awarded the top ratings from the German Sustainable Building Council (DGNB) for its plants in India. Located in Vadodara, the plant and multipurpose building both received the Gold Rating from DGNB, becoming the first building in India to achieve the rating. Sustainability features include an energyefficient heating, ventilation and airconditioning system, a rainwater harvesting and treatment system, a photovoltaic system that can generate 1500MWh of power, to name a few.

Fiona

Beattie, National Commercial Manager at Owlett-Jaton, has worked in the fastener industry for over 20 years. She has witnessed not only technological advancements but also a shift in the role of women within the sector. However, she believes more still needs to be done to challenge the enduring stereotype of the industry as “a

man’s world”…

How did you get into the industry?

Like many people in this sector, I fell into the fastener industry rather than actively seeking it out. My first role was with Harrison & Clough, where I started as a junior in the sales office, but what began as just a job quickly turned into a longterm career.

I’ve always had a passion for sales, especially external sales. I remember saying in my interview that I wanted to be out on the road, selling facetoface, generating sales and building relationships. I was only 16 and couldn’t even drive yet, but I just knew that’s what I wanted to do! By the time I was 18, I was the youngest external representative, and I absolutely loved it.

I quickly realised how much I enjoyed the blend of working with people, applying product knowledge and solving problems. Once you’re in this industry, it really draws you in – and for me, it’s been 20 years now!

// Do not be afraid to ask the question! If you’re unsure, ask. It’s all part of learning, and no one expects you to know everything //

What does your day-to-day job involve?

As National Commercial Manager at OwlettJaton, I primarily focus on the builders merchant sector, working closely with the national buying groups. My role is quite broad and involves everything from highlevel commercial planning, pricing, exhibitions, customer relationship management and working closely with our sales and marketing team. There’s a nice mix of daytoday activities and strategic focus.

No two days are ever the same, and that is one of the things that I love most about the role. It definitely keeps things interesting!

What are the biggest changes you have seen in the industry and company since you started?

The industry has become much more datadriven and customerfocused. There’s been a real shift in expectations around service levels. Customers want more than just a product. They now expect support, insight and reliability as standard.

One of the most significant changes is the rise in online ordering. When I first started, everything was done over the phone or by fax. Today, it’s standard for customers to expect realtime access to stock levels, online ordering and account management – all done quickly and efficiently. This digital shift has fundamentally changed how we work and how we support our customers.

At the company level, OwlettJaton has significantly expanded its offerings and strengthened its position in the market. That’s come through continued investment in stock, systems and service, all with the aim of delivering more value to our customers.

Can you share some of your career highlights and milestones so far?

Moving from Harrison & Clough, where I was the National Sales Manager, to OwlettJaton as National Commercial Manager was a major milestone in my career. I’d been at my previous company for 19 years, so making the move was a huge decision, exciting but also a bit daunting. That said, I can honestly say it was the best decision I could have made.

OwlettJaton is a fantastic company with strong values, a great team and a real commitment to the industry. I feel proud to work here.

Both roles have allowed me to work with some of the largest accounts in the UK and have really helped shape my understanding of the sector from both an industrial and a merchant perspective. Along the way, I’ve been fortunate to have had great mentors who have taught me so much and continue to do so. I will always be grateful for that. However, honestly, the biggest highlight for me has been the relationships I’ve built along the way. Many of them have lasted for decades.

I’m a passionate person, and I’ve always thrown myself into everything I do, so seeing those connections turn into genuine, longterm partnerships is something I am incredibly proud of.

What is your favourite thing about the fastener industry?

The people, without a doubt. It’s a downtoearth industry with a lot of integrity, and I’ve made lifelong friends and contacts. There’s a real sense of community and mutual respect, and that makes a huge difference in your daytoday work.

What do you think needs to be done to encourage more women to get involved in the fastener industry?

Visibility is so important. There are already so many brilliant women doing amazing work in this industry, but we need to be more vocal in highlighting their stories. There are multiple roles available, from technical to commercial and leadership, and we need to break the old stereotype that this is “a man’s world”. It really isn’t anymore. The more we challenge that perception, the

more inclusive and appealing the industry will become.

I also think it’s about showing the human side of the industry, the relationships, the career development and the genuine satisfaction that comes from a job you love. Once people see that, they realise this is a place where anyone can thrive regardless of gender.

What piece of advice would you give your younger self when starting out in this field?

Believe in your voice and back yourself. Confidence doesn’t appear overnight as it builds with experience. However, if you stay curious, work hard and focus on building genuine relationships, everything else tends to fall into place. Moreover, never underestimate the power of listening since it’s one of the most valuable tools you have in business.

I’ve always considered myself a good listener, and I truly believe that’s helped me connect with people and understand what they need. That said, anyone who knows me will tell you I’m never short of something to say! It’s all about finding the right balance between listening and knowing when to speak up.

Also, do not be afraid to ask the question! If you’re unsure, ask. It’s all part of learning, and no one expects you to know everything. If you don’t ask, you may never know, and chances are, someone else is wondering the same thing.

Any final thoughts?

I genuinely love what I do. I’m a passionate person by nature, and I believe it’s so important to enjoy your job. Let’s face it: We spend a huge part of our lives at work! For me, it’s about constantly learning, building relationships and being part of something that’s always evolving. The fastener industry has given me all of that and more.

To any women or men thinking about joining the industry, I say, do it. This industry is full of opportunities and great people, and you won’t look back!

www.owlett-jaton.com

“I quickly realised how much I enjoyed the blend of working with people, applying product knowledge and solving problems”

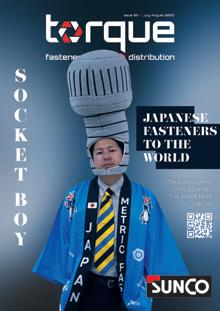

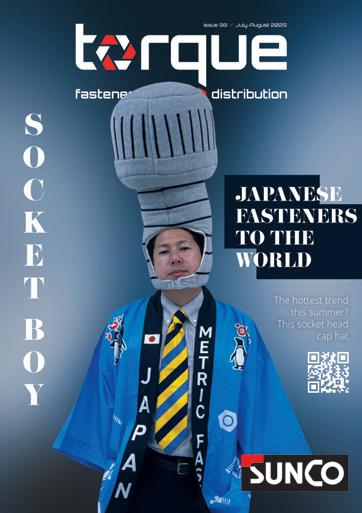

Sunco specialises in high-quality fasteners. Speaking with Torque Magazine, the company shares insights into its history, media strategy, the creation of its mascot, Socket Boy and its future plans. This firsthand information offers a deeper look at Sunco’s unique approach and vision for the industry...

Can you give us an overview of Sunco Industries and its core areas of expertise?

Since its founding in 1946, Sunco Industries has been at the forefront of the screw industry, pioneering the use of IT to manage plated product inventory and introduce trivalent plating products. In recent years, we have enhanced our capability to deliver products in small boxes or smaller quantities, including singlepiece shipments, to flexibly meet the diverse needs of our customers.

At our logistics centre, we utilise a proprietary mathematical model to operate a logistics system that is both highly automated and laboursaving, setting a new standard in the industry. We are also expanding the business model developed in Japan to overseas markets, building a system that enables fast and secure crossborder deliveries.

Sunco currently works with around 1,300 suppliers and 6,000 customers in Japan, along with 70 customers overseas.

What are the key industries and markets Sunco currently serves in Japan and abroad?

As a primary distributor, we sell mainly through wholesalers and retailers. More than 98% of our business is, and will continue to be, within the Japanese market.

Overseas, we are focusing on addressing minor issues related to JIS screws and replacement parts for cars and motorcycles manufactured in Japan. Although the market is not large, we believe this is the area where we can first leverage our strengths to support customers around the world.

How does Sunco differentiate itself in the competitive Japanese manufacturing and fastener industry?

Our biggest differentiating factor is our product lineup of over two million types, mainly JIS products, with 300,000 of them kept in stock for immediate delivery. While JIS screws are not widely distributed globally, there is demand for them in countries where Japanese manufacturers are active.

In this context, we are increasingly able to address issues faced by local corporations and screw trading companies, such as the inability to obtain JIS screws promptly or insufficient quantities for production. For companies looking to expand their product range, we offer flexible support, including nonJIS standard items.

We also develop and stock products based on customer feedback, and in some cases, these items are already held in general stock by the time of the next inquiry.

Under the slogan "Your special is our standard", we have built this business in Japan and are now expanding it overseas.

What are the company's strategic priorities for the next three to five years?

Our goal is to bring the convenience and quality of Sunco Industries to screw distributors worldwide, and to introduce Made in Japan screws to the global market. To achieve this, we will invest in enhancing our logistics capabilities, as well as in systems such as multicurrency payment and Englishlanguage standard naming.

In the Japanese market, we will continue to pursue our longstanding product and

customer expansion strategy, built on the principle of risk management that does not rely on a single industry or customer. We will further broaden our product lineup by offering items tailored to customer needs.

How has Sunco responded to recent global supply chain challenges?

Due to CBAM (Carbon Border Adjustment Mechanism) and restrictions on Russian materials, an increasing number of companies are finding their existing procurement channels at risk. From the perspective of supply chain stability, we have been highlighting the advantages of Japan in terms of location, quality and delivery management.

Our network of over 1,300 screwrelated manufacturers in Japan ensures a stable supply of our core products, which are consistently kept in stock. In addition, the weak yen has enhanced our price competitiveness.

Sunco aims to be the preferred partner in the global supply chain and is committed to building trusted relationships with customers worldwide, guided by our management philosophy of continuously doing work for which our customers can always say thank you.

How many copies of Socket Boy Magazine are distributed per issue?

We currently publish 10,000 copies of Socket Boy Magazine, which we distribute free of charge to customers and prospective customers by post and at trade shows around the world. A web version is scheduled to launch around August this year, offering readers worldwide insights into the Japanese screw industry and the history and culture of HigashiOsaka City, a hub of manufacturing.

The content will cover not only the screw industry but also Japanese manufacturing, history, culture and a variety of other topics. If you are interested, please subscribe using the QR code.

Why did Sunco decide to launch a digital version of Socket Boy Magazine in addition to the print edition?

The print version of Socket Boy Magazine was published in January 2024. The web version will feature more indepth articles and original content exclusive to the digital edition that could not be included in print. We hope you will enjoy the web version as much as the print edition.

How has Socket Boy Magazine contributed to Sunco's business and brand recognition so far?

We have received inquiries through social media posts related to Socket Boy Magazine, and we believe this has significantly increased our company's visibility. We have received subscription requests via social networking sites, and in some cases, even requests for quotes from people interested in Socket Boy Magazine

In addition to the magazine, the original character Socket Boy is also gaining attention, and at trade shows we are often approached by people who say, "SUNCO is the company that created Socket Boy, right?"

Can you introduce the magazine's editorial team?

What is your process for curating content?

Socket Boy Magazine is currently produced by a team of three and focuses on the Japanese screw industry, as well as the history and culture of HigashiOsaka City, home to many screw manufacturers.

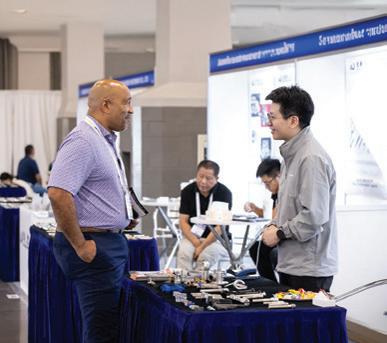

Aiming to communicate the appeal of Japan’s screw industry worldwide, the magazine actively covers fastenerrelated exhi

bitions and events held in Japan.

Recently, we launched a new section called "NEJIDO," which spotlights the management of our domestic suppliers through interviews about their life journeys and future prospects.

The content is highly readable and offers insights into the experiences of those who have transitioned from other industries to the screw industry, as well as those working hard to strengthen the sector.

It appears that Sunco is active on social media, which is not always common for B2B companies. Tell us about your strategy and what results you are hoping to achieve. We use social media to increase awareness of our company. Social media is a tool widely used by people of all ages and from many countries, and we believe it is an effective way to share information.

We hope this will be a good opportunity to introduce Sunco as an interesting company in Japan and to spark some interest in what we do.

Through our character Socket Boy, we aim to make the world of screws more familiar to people and to provide information in a fun and engaging way.

What communication channels does Sunco prioritise, such as industry media, social media, and trade shows, and why? Currently, our primary focus is the production of Socket Boy Magazine. In Japan, there are no magazines specialising in the screw industry, unlike in the UK, the US and Taiwan. Through Socket Boy Magazine, we hope to raise awareness of the appeal of the Japanese screw industry and of HigashiOsaka, a city renowned for its manufacturing.

In addition to domestic and international fastenerrelated exhibitions, the magazine was distributed at Smart Manufacturing Week in the UK in June 2024. We also distributed it at the JTown Cruise event in the US, running from late July to November 2024.

Is there anything else you would like to add?

We will be offering free international shipping again this year for the threemonth period from September to November. All international orders placed during this time will be eligible, so please take advantage of this opportunity.

In addition, our "BARA Service" allows you to order from a single screw, making it easy to use even for small quantities. Furthermore, customers who order from our online catalogue, 3QNET, during this period will receive a small but delightful gift.

Don’t miss out on this special offer!

www.jisscrew.com

Quality is a chief concern for any fastener business, whether a manufacturer, wholesaler, merchant or at any other level. Regardless of the trading challenges of the day, QC labs, procedures and equipment are vital elements...

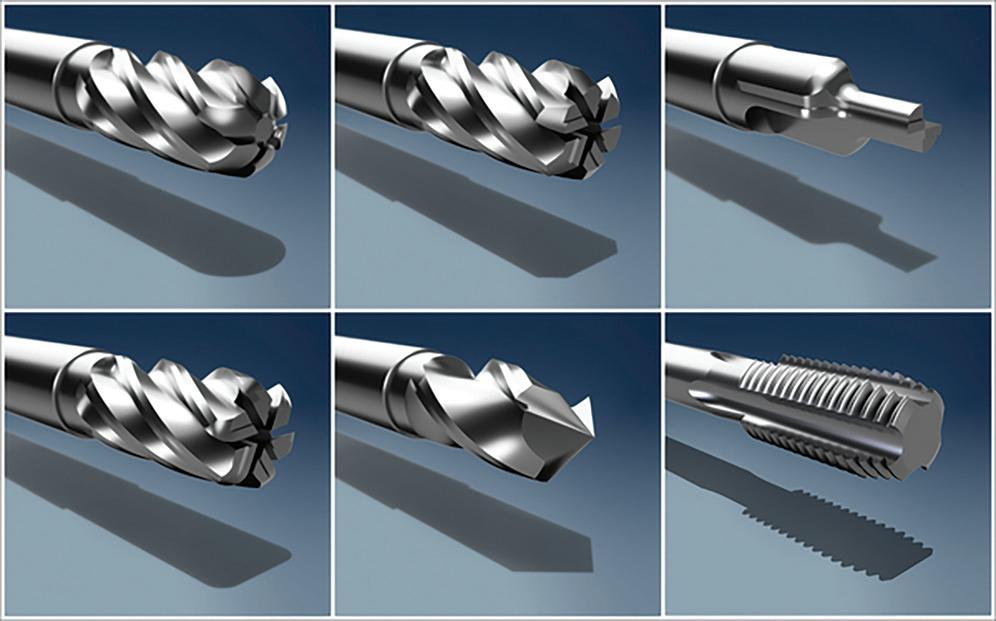

WERTH: FLEXIBLE VOLUME CUT & TOOL MEASUREMENT >

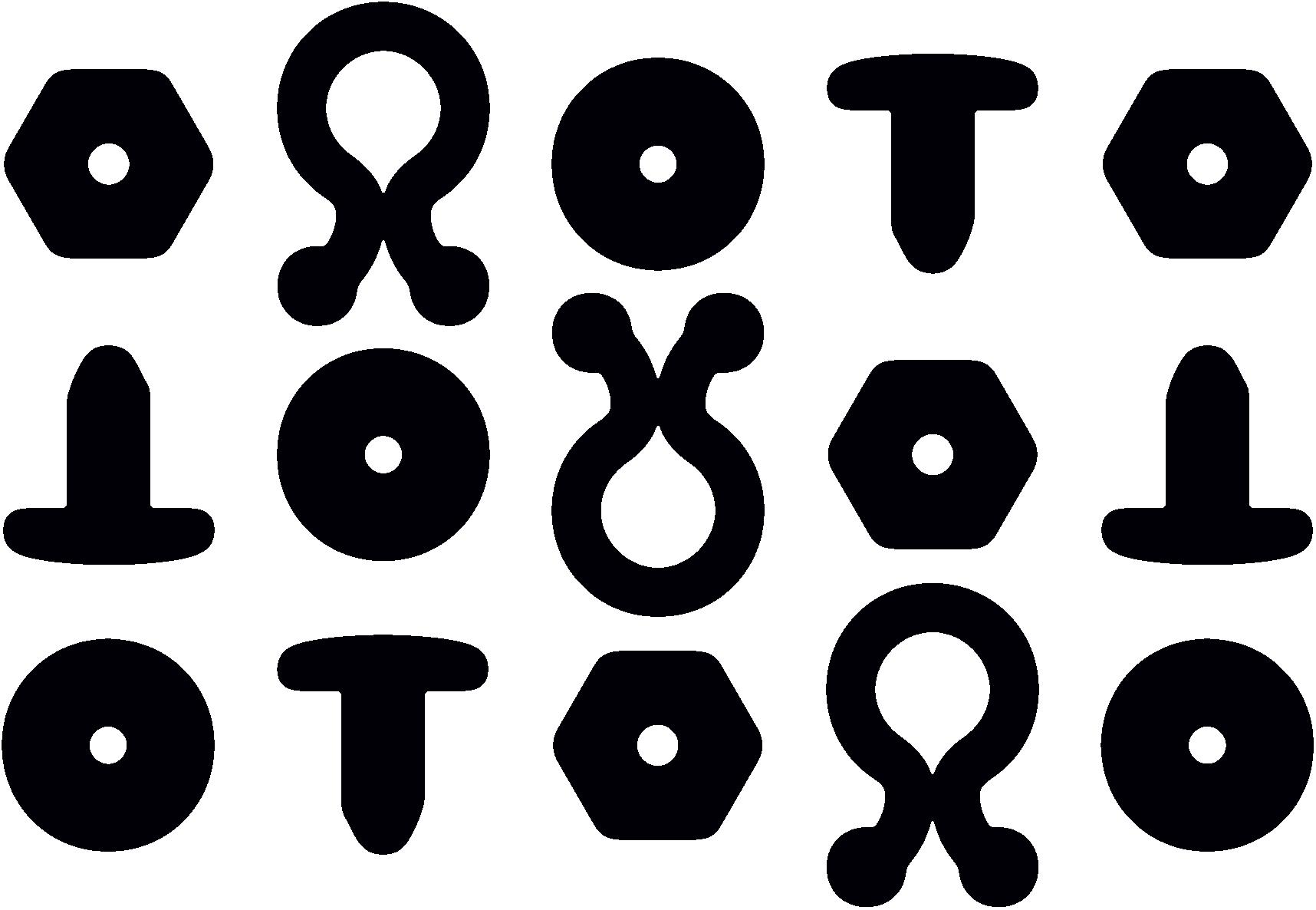

With the new WinWerth® Flexible Volume Cut option, it’s possible to produce cylindrical cross sections for specific analyses of complex geometries such as threads, seals or weld seams in the CT volume fully automatically.

With the Volume Section Sensor, Werth contour image processing has been possible in any sectional plane of CT volumes for several years. This allows reliable detection of material transitions, especially for workpieces made of several materials. It is also possible to filter images and capture contours at material transitions with subvoxel accuracy. The measured contours consist of many contiguous points. The information about the neighbourhood of the points to each other is retained and can subsequently be used when applying proven contour filters.

In addition to planar volume sections, cylindrical volume sections are now also possible. The base area of the cylinder is not limited to circles and can take on any mould. The specification of the cutting cylinder is defined by a cutting contour of the base surface, its height and orientation. The contours required for this can be determined, for example, by measurement with patch selection, segmentation or using a CAD model. The size of the base surface can be subsequently adjusted. The result is both a 3D view of the cut surface and the unrolled 2D surface of the cutting cylinder.

Like all measurement methods at Werth, the new process is fully integrated into the WinWerth measurement software and can also be used in automated series measurements. One application example is the thread measurement of bottle caps to determine lead angles and distances. Freeform cross sections through water pump housings, for example, enable the inspection of weld seams, gap dimensions and the fit of seals.

Meanwhile, the Werth Precision Tool Pro tool measurement program enables simple tool measurement with proven and standardised measurement sequences on all machines in the

ScopeCheck® and VideoCheck® series. The intuitive operation and operatorindependent measurement results aid successful integration into quality assurance systems as the high level of flexibility thanks to the many tool types available for measurement.

A standardised software concept across different machine types and well thoughtout user management enable flexible use of Werth”s tool measuring machines. The intuitive user guidance supports both the trained metrology technician in the laboratory and the grinder directly on the shop floor; it makes no difference whether it is a quick measurement of the outer contour in the Werth Messtechnik or complete tool measurements on machines with four or even five axes – the operation remains the same.

The optimised use of multisensor systems with sensors tailored to the measuring task in the modular Werth system also offers security for the future thanks to numerous expansion options. The ability to seamlessly connect to existing or planned automation solutions and a wide range of interfaces for data import and export are a matter of course for Werth. For example, the extensive connectivity to SPC and CAQ systems and automation solutions allows automatic correction of the grinding paths in one to two iterations.

With the latest version, you benefit from:

Extended selection of tool types

Automated measurement programme creation

Simplified operation

Full connectivity for integration into your quality assurance

Automatic grinding path correction with one to two iterations

werth-metrology.com

The Werth Precision Tool Pro tool measurement programme has a comprehensive and clear selection of different tool types

The high quality SMART insulation plugs from pgb are the perfect combination of plug and expansion nail in one handy product.

Your one-stop shop for all insulation work

The high quality SMART insulation plugs from pgb are the perfect combination of plug and expansion nail in one handy product. The plastic insulation plug prevents thermal bridges and is ideal for use in hollow and solid building materials.

Two types of pins available:

Plastic hammer-in pin

Metal hammer-in pin with plastic coating

The steel pin carries high loads, while the plastic component provides thermal insulation

Building materials

Our insulation fxings are suitable for fxing thermal

The insulation fxings are an ETA assessed fxing with high load-bearing capacity for a wide range of building materials.

AVAILABLE LENGTHS: from 140 mm to 300 mm

www.cetin.com.tr

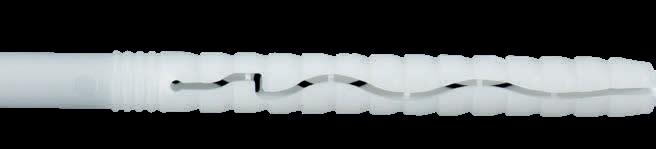

DIMAC: HOW AI IS ENHANCING EXTERNAL THREAD INSPECTION IN SCREWS AND BOLTS >

EDimac's multi-side camera station is equipped with three or four side surface cameras positioned to look at the threaded shank surface all around

xternal thread inspection in screws and bolts is crucial for ensuring product quality and reducing false rejections, thereby lowering selection costs. Various technologies are employed for this purpose, each with specific characteristics suited to different situations.

The traditional method for thread inspection is profile control using backlighting, derived from automating manual profilometer checks. While precise, this method is limited to a single thread section. Glass slide sorters capture a crosssectional image of the piece during its fall, allowing for an economical yet limited inspection. With the introduction of metal disk tables, it became possible to implement piece rotation in front of the dimensional camera, capturing multiple images. This method reduces false positives but increases inspection time and costs.

The profile analysis solution with a rotating station has two main limitations: the piece is not inspected over its entire surface despite the increased number of captured images, and the rotation entails higher machine costs and longer selection times.

To address these needs, Dimac has developed three advanced inspection stations.

The first solution uses a line surface scanning camera that grabs a line of pixel for each trigger while the piece turns 360°, the grabbed surface lines are joined together to obtain the unrolled image of the cylindrical side surface of the thread. The surface line scanning camera is triggered by the 360° rotation station”s encoder to cover the entire piece surface, the resolution of the trigger pulses can be set to improve the accuracy of the surface inspection. The vision software analyses the thread, identifying irregularities like "zthread" or foreign hits and dents or excess of surface coating between crests. The high quality of the acquired side surface image allows the detection of minimal defects, including those quite invisible to the

human eye, such as head fine cracks. This method is very accurate but does not perform dimensional measurements as well as its scanning cycle time limits the output rates. It’s a method recommended when high quality controls are required, such as in the aerospace applications.

Metal disk tables make piece rotation in front of the dimensional camera possible

A second solution, presented at Wire Düsseldorf 2024, is a multiside camera station equipped with three or four side surface cameras positioned 90° or 120° one another to look at the threaded shank surface all around. Although the image quality is lower than the above mentioned line scanning version, the multicamera station doesn”t require the piece rotation, allowing high productivity (up to 700 pieces per minute for M6 screws). Artificial Intelligence tools are used with this station to detect macroscopic defects such as dents, scratches, open cracks, and radial holes. This is an excellent solution to examine the entire external surface of the piece with high production rates.

A third technology, patented by Dimac in 2023, is electromechanical inspection using a gauging roller station, where a threaded master roller gauges the thread’s compliance. A group of two gripping rollers keeps the piece in rotation while the third threaded roller gauges the threaded shank simultaneously. The roller gauge sliding axis movement is checked to stay into a threshold envelope by a special sensor. Any defect affecting the roller gauging effort to spike out of the envelope is immediately identified, to define the thread quality. This solution is reliable for fasteners used in automatic assembly lines, because it helps to removing small burrs or dirt in the thread. Thanks to a special control algorithm, the system is insensitive to core ovalisation. The output rate is lower than the above mentioned solutions, but this station ensures the screwability of the conformed parts.

With four different thread inspection technologies, Dimac offers customers a suitable solution for their specific needs. Recent applications of Artificial Intelligence algorithms show promising results, paving the way for a defectfree future. The

success of the La Mille sorter, presented at Wire, demonstrates this. However, the field of electromechanical inspections continues to pose significant challenges, where Dimac’s experience and expertise make a difference internationally.

Dimac does not exclude the possibility of equipping its range of machines with more than one of these inspection stations, working sequentially on the same piece. This flexibility allows for comprehensive and precise control, adaptable to various industrial contexts.

Artificial Intelligence applications in Dimac’s solutions are opening new possibilities for quality control. These algorithms enable more sophisticated defect detection, ensuring defectfree products, says the firm. The La Mille 100% inspection & sorting machine developed with ITW France is an example of how these advanced technologies can be successfully applied. The field of electromechanical inspections continues to present significant challenges. Dimac’s experience and expertise are crucial in addressing these challenges and continuing to innovate. Dimac is committed to providing quality control solutions that meet the highest customer standards, maintaining its leadership in the sector, it says.

By offering advanced solutions and leveraging innovative technologies, Dimac aims to be a benchmark in external thread inspection for screws and bolts. Combining precision, efficiency and the ability to adapt to different production needs, Dimac’s solutions ensure highquality, defectfree products. With a constant focus on innovation and quality, Dimac is an industry leader helping move towards a more efficient and defectfree future, maintaining its international leadership in external thread inspection for screws and bolts. The challenges in electromechanical inspection highlight the value of Dimac’s mechanical expertise.

www.dimacsrl.com

Recent AI applications show promising results “paving the way for a defect-free future”

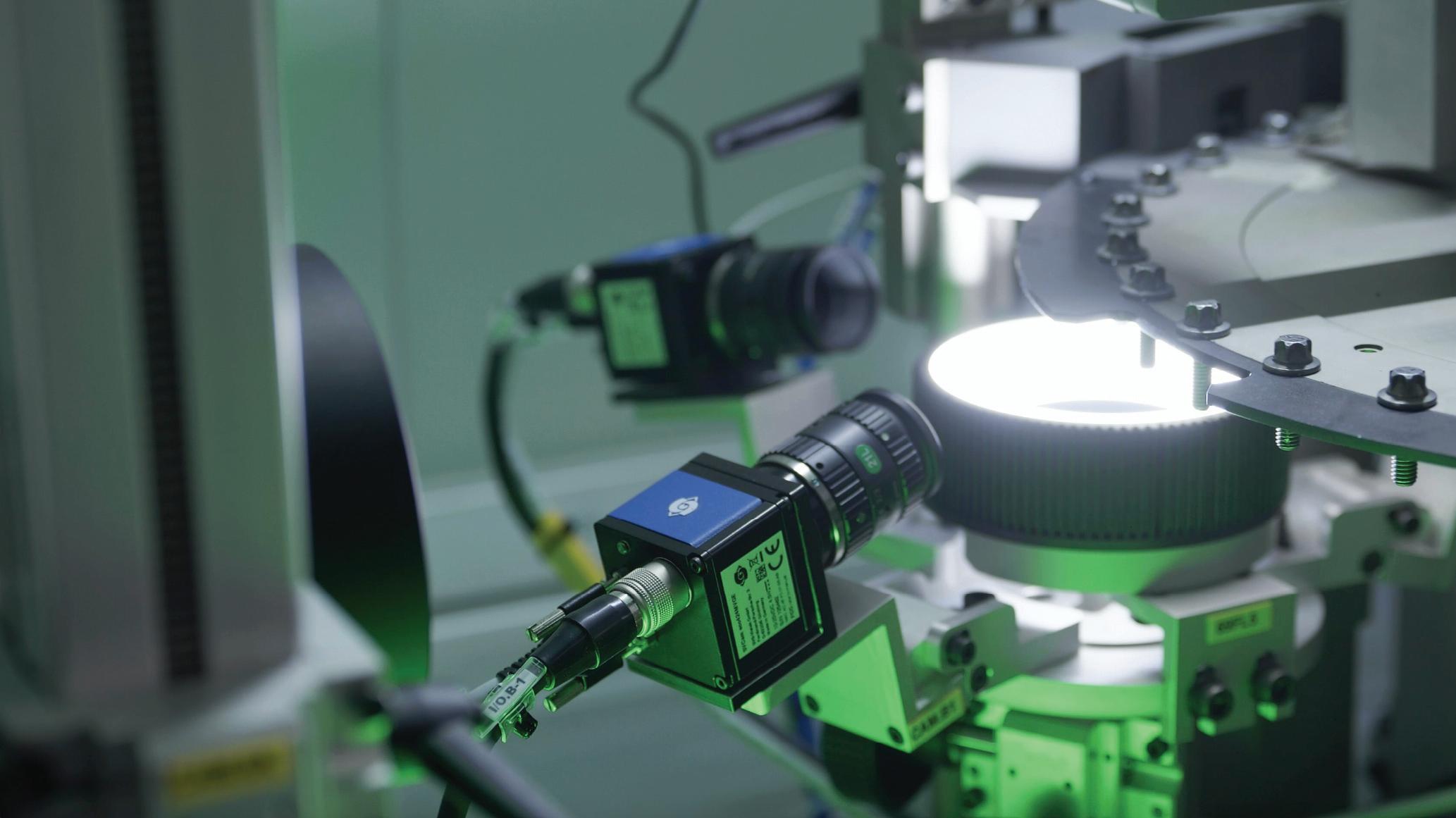

Kistler presented the KVC 821 vision inspection system at Control 2025 with a pocket plate for the complete inspection of screws for the first time

Whether connectors, screws or safetyrelevant parts in industrial production: manufacturing companies need to thoroughly analyse their processes to meet the highest quality standards and ensure continuous process optimisation. An endofline inspection of individual components provides additional assurance that no faulty part leaves the production line. The modular KVC 821 Vision Inspection System is a solution for this purpose. Recently showcased at Control 2025, it allows comprehensive inspection of safetyrelevant parts in a shorter cycle time.

KVC 821: system for optical quality assurance in a new configuration

Visitors to Control will have seen the KVC 821 inspection and sorting system as it transported suspended screws to the camera stations for inspection. The cameras capture both the thread and the entire screw head. The Multicapture Device from Kistler inspects the drive and the side edges. Equipped with eight cameras, the Multicapture Device generates highresolution images of the entire lateral surface without having to mechanically move the screws. Thanks to the additional 2.5D and 3D measurements and the precise evaluation by the KiVision software, every single screw can be checked for scratches, dents and dimensional accuracy – even at cycle times of up to 800 parts per minute. Kistler additionally uses artificial intelligence to detect previously unknown or rarely occurring anomalies.

The measured values can be imported directly into the software which performs the statistical evaluation and visualises it simultaneously on an external terminal. Thanks to the modular design of the testing system, it can also be adapted to other

test objects and inspection requirements in quality assurance – for example for connector components – in collaboration with Kistler”s experts.

Reliable bolting in production: caliTEST-B and cerTEST

With caliTESTB and cerTEST, Kistler presents two solutions from the field of fastening technology. They are designed for use in screw assembly and the calibration of the required tools. The caliTESTB calibration device is suitable for torque wrenches or torque tools with an effective length of up to 1320mm. Thanks to individually applicable sensors, these can be calibrated in a range between 0.2 and 1,000 N·m in accordance with DIN EN ISO 6789.

With up to four integrated screwdriving simulators and a measuring range between 0.2 and 500 N·m – or up to 6000 N·m when using external simulators – the cerTEST test system is designed for mobile use in production. Users can test their torque tools such as cordless, rotary and impulse screwdrivers in accordance with VDI/VDE 2645 Sheet 2, VDI/VDE 2647 or DIN EN ISO 5393 directly on the assembly line. With both solutions, the userfriendly CEUS software guides users step by step through the measurement, saves various measurement settings and histories, and automatically creates test reports.

The caliTEST-B calibration device calibrates torque ranges up to 1320mm and 1 000 N·m precisely and in accordance with DIN EN ISO 6789

The AkvisIO IME (Injection Molding Edition) process data analysis software allows users to evaluate production-related process and machine data with a focus on quality

management and statistical evaluation in the plastics sector: AkvisIO IME

The AkvisIO IME (Injection Molding Edition) process data analysis software demonstrates how comprehensive data analysis and statistical evaluation can be achieved in injection molding processes. AkvisIO can be easily connected to Kistler’s process monitoring and control solutions such as ComoNeo and ComoScout. This allows users to correlate their process and machine data for quality assurance and create process reports based on established methods of classical statistics with just one click. Thanks to communication standards such as the Ethernetbased Euromap 77, the machine itself becomes the data source – and AkvisIO the single source of truth for reliable production data. At the booth, Kistler uses its contact element, a demonstration kit, to show how data from ComoNeo can be recorded in high resolution and transferred to AkvisIO for archiving and display.

With the latest version of its data analysis software jBEAM, Kistler presents a solution that supports users in setting up and controlling rapidly changing processes in their value chain

of jBEAM and MaDaM at

Kistler’s portfolio is rounded off by the jBEAM software for measurement data analysis and MaDaM software for measurement data management. With the latest version of jBEAM, Kistler presents a solution that supports users in setting up and monitoring rapidly changing processes. It can be used to merge measurement data from different process steps and brings to light sources of error. Users benefit from uncomplicated operation via drag and drop.

www.kistler.com

Steelgard’s renowned corrosion-preventative solutions are now available through Molyslip...

Steelgard is now part of the Molyslip family, thanks to a strategic acquisition that means Molyslip can offer the quality corrosion prevention products to the market, gaining a suite of advanced protection solutions, tailored to meet the rigorous demands of various industrial sectors.

Steelgard is a range renowned for its exceptional corrosionpreventative solutions and brings over 50plus years of trusted performance and innovative technology to Molyslip’s portfolio. The brand’s essence, “Advanced Protection, Uncomplicated Application,” aligns with Molyslip’s commitment to delivering highquality, reliable products.

A trusted name within the industry, utilised in Ministry of Defence contracts, across global markets and relied on by thousands, this latest acquisition ensures that Molyslip customers will receive some of the best corrosion technology in the industry from a trusted name in the market, we're told.

As part of the Molyslip family, Steelgard will continue to be a standard setter for protection with its unique, advanced formulas that ensure clean, hasslefree application and longlasting durability without the mess. Designed for ease and efficiency, Steelgard’s lubricant solutions safeguard the integrity and extend

the life of valuable assets across a diverse range of industries. From Steelgard Export –the specialised shipping and export protection, to the range of OCTG protections for the oil and gas industry and VCI solutions for closed systems with Vaporol and Aquavap.

The range values include reliability, ensuring robust protection and preservation against rust and corrosion. Innovation, continuously advancing in corrosion preventative technology for better, faster, and more effective solutions. Simplicity, offering products that are straightforward to apply and maintain, designed for the busy professional.

Molyslip’s Steelgard range provides engineers with comprehensive, technically advanced, products ensuring that components are protected against corrosion. Corrosion causes considerable damage to components and has a major impact on the continued operation of machinery, so this is clearly an industry that requires the very best protections and products.

“Molyslip Steelgard represents the future of corrosion protection and we are excited to elevate corrosion prevention across the globe.”

molyslip.co.uk

Nylok’s ranges are now available to several territories through a partnership with Anochrome…

Tuflok, NySeal and NySeal 2.0 are now available through Anochrome Group in certain territories

At the tail end of last year, Nylok entered into a partnership in the UK, Poland and Czech Republic with Anochrome Group. The partnership meant that Anochrome Group was given access to the technology to support and run Tuflok, NySeal® and NySeal®2.0 in its facilities.

Nylok is a valueadded solutions provider of resin, adhesive and lubricant coatings for threaded fastener applications. Since 1942, Nylok has accumulated more than 150 patents, each representing solutions to the everchanging needs of its customers. Nylok’s core market segments are automotive, aerospace/defence, electronics, industrial and international.

Tuflok

Nylok® Blue Nylon TorqPatch® Tuflok® is a selflocking element comprised of nylon permanently bonded onto the threads of a fastener. When the Nylok Blue Nylon TorqPatch Tuflok is engaged, it creates a wedge between the fastener and mating part compressing the nylon and creating metal to metal contact opposite the patch. This

metaltometal contact results in a positive resistance to vibration and loosening. Since nylon has great memory characteristics, this locking element can be reused several times.

NYSEAL: Under Head Sealant (resistant to automotive fluids)

NYSEAL® creates a gaskettype seal, preventing leakage of fluids and gases under pressure. The coating is permanently fused on the bearing surface of the fastener. As the screw is seated to its final position against the mating part, the NYSEAL element compresses slightly and fills the void between the bearing surface of the head and the counter sink/counter bore.

Advantages:

• Eliminates timeconsuming, inhouse applications of Orings, gasket seals and sealant compounds

• Permanently bonded to the bearing surface

• Eliminates the leak path

• Prevents galvanic corrosion between dissimilar materials

• Reusable

NySeal®2.0: “The King of Under Head Sealants”

NySeal® 2.0 is durable and meets sealing requirements after multiple installations. NySeal 2.0 allows for setting a more consistent tightening strategy, since the material does not squeeze out of the joint/application.

• Z1: Nylok NySeal 2.0

• Z2: Material: Polyacrylate (purple)

• Z3: Hardness: Median hardness 62 shore D (approx. 95 shore A) per ASTM D2240

• Z4: Volume swell in IRM 903 oil at 100 c for 70hrs: <15% per ASTM D471

• Z5: Elongation: 3050% per ASTM D412

• Z6: Minimum tensile strength: 14MPA per ASTM D412

nylok.com anochrome.com

Earlier this year, Stafa secured exclusive dealership for Friedberg HV in the Benelux and France territories…

Stafa has taken a significant step in strengthening its market position. The company has acquired the exclusive dealership for the highquality HV bolts, nuts and washers from August Friedberg GmbH in the Benelux and France. This collaboration provides customers access to a premium and sustainable product range that is entirely manufactured in Germany.

Friedberg's HV products stand out for their innovative technology and reliability. They are fully produced in Europe and comply with all stringent European standards. Moreover, these products feature the unique AF Pro® lubrication, which ensures easy and consistent assembly. Weather conditions like rain, cold or heat no longer affect the tightening torque, and

the nuts are dirtrepellent: even after contact with sand, they can be easily rinsed and reused. This offers a major advantage during assembly.

With standard sizes up to M36 and larger sizes (up to M72) available on request, Stafa offers a wide range of possibilities. Additionally, an experienced technical team is ready to assist customers with complex challenges. Thanks to the exclusive partnership with Friedberg, customers can also rely on additional expertise when needed.

This exclusive dealership aligns with Stafa’s strategy to offer customers a comprehensive package that meets the

growing demand for European quality and sustainability. By combining Friedberg’s innovative products with Stafa’s logistical expertise, the market can count on reliability, userfriendliness, and availability.

Founded in 1977 and headquartered in Maarheeze, the Netherlands, Stafa is a specialist in fasteners, specials, and assemblies. With an extensive range of over 75,000 products, the company serves clients in sectors such as construction, engineering, infrastructure and wholesale.

This exclusive dealership strengthens Stafa’s position as a market leader and further expands its ability to serve customers in the Benelux and France, the firm said.

www.stafa.nl info@stafa.nl

Friedberg’s HV products feature AF Pro lubrication

Loctite 55 has earned itself two Red Dot Awards 2025, following an initial two awards for the product.

Loctite 55 earned a German Packaging Award 2024, followed by the WorldStar Global Packaging Award earlier this year.

The two Red Dot Awards were in the categories of ‘Product Design’ and ‘Sustainable Design’, for the robust and convenient design as well as for the sustainability improvements of the packaging of the 160m pack for its leading thread sealant cord.

In terms of the Product Design gong, the jury pointed out the ‘robust design and wellthoughtout production from a monomaterial both contribute to the sustainability of Loctite 55’. While for the Sustainable Design award – a new category granted in 2025 for the first time – the jury noted that ‘the Loctite 55 applicator boasts an ergonomic design with a number of userfriendly and environmentally conscious features.’

“Winning two Red Dot Awards is a powerful validation of the deep expertise and entrepreneurial spirit that drives our innovation culture at Henkel,” says Niamh O’Reilly, Vice President Innovation for

General Manufacturing and Maintenance at Henkel Adhesive Technologies. “This achievement reflects the outstanding collaboration across our specialist teams, who worked closely to understand and anticipate customer needs, translating insights into a solution that sets a new benchmark in both usability and sustainability. The jury’s recognition of Loctite 55’s enhanced handling and its sustainability improvements – such as reduced waste and improved recyclability –underscores our commitment to advancing the circular economy. We are especially grateful to our strategic design partner, Dolmen, whose creativity and partnership were instrumental in bringing this customercentric innovation to life.”

Thread sealant cord

Loctite 55 is used by numerous professional fitters and plumbers to seal pipe threads and fittings made of metal and plastic. It is suitable for sealing hot and cold water, natural gas, hydrogen gas and other common media found in traditional plumbing systems. In 2024, Henkel launched a new 160m package that has

been developed and improved based on an extensive customer survey. The new packaging design combines improved functionality for the easier, quicker and more ergonomic application of the thread sealant cord, and advanced sustainability by using monomaterial made of 70 percent postconsumer recycled plastic. An ideal choice for sealing metal and plastic threaded joints, Loctite 55 replaces hemp, paste, and PTFE tapes and proves to be an essential item for any toolbox. The product requires no curing time and results in an immediate, full pressure seal. Simply wind the proper amount onto the thread with tension and then cut the thread sealant with the integrated cutter. Unlike PTFE tape, Loctite 55 can be reliably readjusted to align fittings and measuring devices without the risk of tearing and causing leaks. This gives users more flexibility during installation and saves time for cleaning and resealing.

Loctite 55 is available from specialist distributors.

www.henkel-adhesives.com

DÖRKEN’s hybrid topcoat DELTAPROTEKT® TC 502 GZ offers an option for manufacturers seeking high-performance surface protection for fasteners…

DELTAPROTEKT® TC 502 GZ is a hybrid topcoat designed specifically for metric components such as screws and nuts

Coatings specialist DÖRKEN has introduced a hybrid topcoat designed specifically for metric components such as screws and nuts.

The product, DELTAPROTEKT® TC 502 GZ, is a silverfinished topcoat formulated to work in conjunction with a zinc flake basecoat or other metallic substrates, offering a broad range of multifunctional performance benefits.

Developed with OEM requirements in mind, the coating delivers a precisely defined coefficient of friction (COF) window, making it ideal for threaded components where controlled friction behaviour is critical. It meets the friction specifications of a wide array of manufacturers, including GMW 3359, Scania 3950, Ford WX 100, FCA PS 11036, VW 01131 and the VDA 235101 standard.

“With this topcoat, we have developed a coating that is ideal for components with metric threads,” said Emre Kocak, Product Engineer at DÖRKEN. “In doing so, we have aligned ourselves with the requirements of the market. DELTAPROTEKT® TC 502 GZ fulfils a large number of friction coefficient windows that are required in the specifications of various OEMs.”

The topcoat is completely free from PFAS and harmful heavy metals, offering a more sustainable solution without compromising on performance. Coating weight ranges from 2–10 g/m², and suitable application methods include spray and dipspin, depending on the geometry of the component. For best results, surfaces must be clean, dry and free from rust, dust, oils, grease and silicones before coating.

With its environmentally friendly formulation and compliance with industryspecific standards, DELTAPROTEKT® TC 502 GZ offers a new option for manufacturers seeking consistent, highperformance surface protection for fasteners in demanding applications.

www.doerken.com

The topcoat is completely free from PFAS and harmful heavy metals

As the world‘s leading manufacturer of high-performance corrosion protection systems DÖRKEN consistently focuses on sustainability and environmental protection. In line with the current developments around the possible PFAS ban, we already o er our main products completely PFAS-free.

You can rely on innovative solutions that combine maximum performance and ecological responsibility.

Contact us.

Gesipa’s training courses provide specialist knowledge on maintenance and servicing

Industry practitioners and dealers spent two days at Gesipa’s headquarters to learn more about its blind riveting technology, as well as boosting their in-depth knowledge for use when advising customers...

Gesipa recently hosted a training event for around 50 tool industry practitioners from 20 countries, featuring a wide range of activities.

The event took place at the company’s headquarters in MörfeldenWalldorf, Hesse, with a focus on developing consulting skills in the field of blind riveting technology.

Participating dealers learned about the advantages of blind rivet technology from experienced specialists, as well as the specific strengths of Gesipa products, enabling them to gain indepth knowledge before advising customers.

Additionally, the dealers and industrial customers visited the Gesipa Demonstration & Training Centre, where they received handson introductions to the handling of Gesipa setting tools and technologies.

Gesipa Demonstration & Training Centre

The training courses for industrial customers also provided specialist knowledge on maintenance and servicing, allowing them to carry out necessary service work independently and extend the service life of their devices.

The programme included a welcome dinner on the day of arrival, offering participants the chance to exchange ideas in a more relaxed setting. At the conclusion of the training, all participants received a certificate confirming their newly acquired knowledge in the field of "Fundamentals of Blind Riveting Technology."

In addition to this event, Gesipa will offer another training session in Thal, Thuringia, in November this year. Looking ahead, the company is considering launching a similar training event next year due to the high demand experienced this year.

www.gesipa.de

Operating 48 advanced machines across three dedicated manufacturing sites.

“Doing what we say, when we say”.

Manufacturing standard fasteners and bespoke components in all material grades that are often not available “off the shelf”.

The programme will cover multiple topics, including consensus standards organisations, IFI resources and torque tension, to name a few…

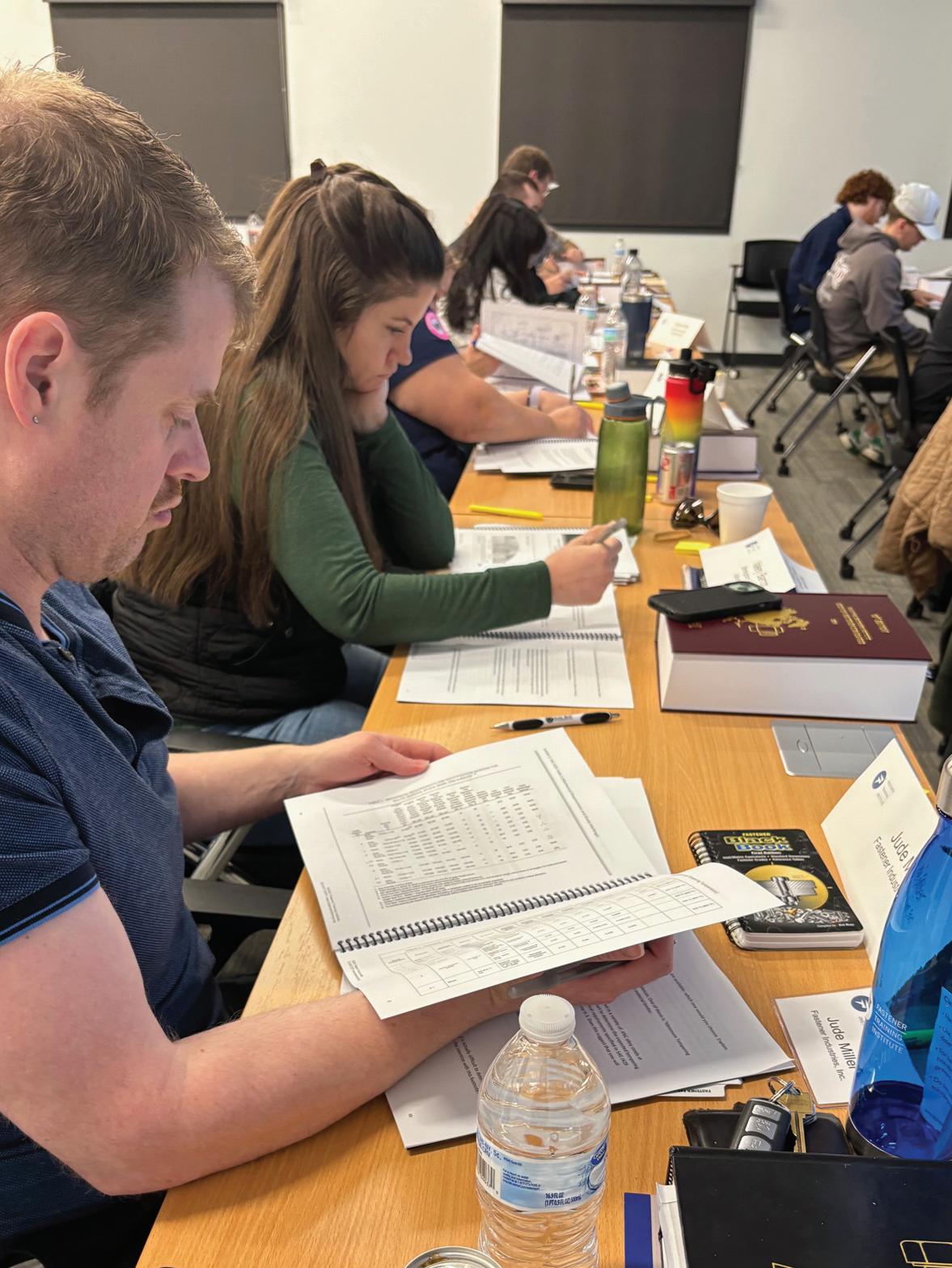

Fastener Training Institute (FTI) will host the next Fastener Training Week in Chicago, the US between 25 and 29 August.

As part of MidWest Fastener Association’s FSTNR Week, Fastener Training Week, sponsored in 2025 by Birmingham Fastener, is FTI’s flagship training programme, where students can gain Certified Fastener Specialist™ (CFS) designation by completing the weeklong training and passing a final exam.

The upcoming Fastener Training Week will cover a broad spectrum of topics led by Laurence Claus and Salim Brahimi from the Industrial Fasteners Institute. Subjects include consensus standards organisations, IFI resources, torquetension principles, quality assurance systems and sampling plans, thread technology and gauging issues, print reading and tolerances, material specifications for steel fasteners and the causes of fastener failure.

These topics will be complemented by case studies, handson demonstrations, learning labs, general classroom instruction and plant tours, enabling students to gain deeper insights.

“Keeping our industry safe and reliable through training is our mission. Fastener Training Week is challenging but the benefits, for both individuals and companies, are well worth the investment. It’s a great opportunity for industry professionals to complete Fastener Training Week while having the chance to engage with the MWFA (MidWest Fastener Association),” says Jo Morris, Managing Director of FTI.

Bob Baer, President of Abbott Interfast, adds: “Getting my CFS designation with Fastener Training Institute was a gamechanger — not just for me, but for our entire company. Customers visiting our facility immediately noticed the plaques displayed throughout the building and appreciated our commitment to quality and professionalism. That inspired us to invest in our people, making sure every Purchasing and Quality team member earned their CFS designation.”

www.fastenertraining.org

By completing the weeklong training and passing a final exam, students can earn the Certified Fastener Specialist™ (CFS) designation

Bosch focuses on agentic AI in manufacturing

Bosch is enhancing its AI capabilities to accelerate innovation and support other companies in developing their own multi-agent systems to reduce costs and improve efficiency…

Bosch is investing more than €2.5 billion by the end of 2027 in the application and development in AI. Part of this plan is its AI Academy, where more than 65,000 associates have received training since 2019.

Currently, about 5,000 AI specialists are working on intelligent AI solutions in Bosch. AI is an innovation booster for Bosch across different areas. For example, AI can help with DIY

Bosch invests heavily in AI and offers training to its employees

wall scanners that can look inside walls and detect electrical cables, metal beams and empty spaces.

“The breakthroughs in AI make it possible to open up completely new chapters in technology, accelerate the development of innovations and turn these into business,” says Stefan Hartung, chairman of the Bosch board of management.

In manufacturing, Bosch is already focusing on agentic AI, which is able to make its own decisions and carry out its own actions. This technology enables multiple processes to run in parallel. Several AI agents can work together as a team, forming a multiagent system that is overseen by either a human supervisor or a coordinating agent. Bosch is already applying this approach internally: its multiagent systems monitor manufacturing equipment, predict maintenance needs and optimise personnel scheduling.

“We’ve now reached the next level. The result is a reduction in unplanned downtime and an increase in productivity overall,” says Tanja Rueckert, member of the Bosch board of management.

Bosch is also developing a platform that will be made available to other companies in autumn 2025, enabling them to create their own multiagent systems with little or even no programming knowledge. Therefore, manufacturing can be more efficient, reduce costs and be able to react more flexibly to market requirements.

“In Germany, 72% believe that AI will be the dominant technology of the next decade in their country. Bosch is already well equipped for the dawning age of AI,” says Hartung.

www.bosch.co.uk

M. SELIM GOKSU HEAD OF FASTENERS NORM FASTENERS

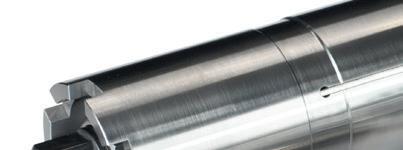

In today’s fast-paced industrial landscape, the demand for high-performance, reliable and costeffective components has never been greater. Fasteners – though small in size – play a critical role in the integrity and performance of countless applications across industries. At the core of modern fastener production lies hot forging, a manufacturing method that has proven to be essential in delivering superior strength, precision and efficiency.

Hot forging offers numerous advantages that make it an ideal choice for fastener production. When metal is heated above its recrystallisation temperature, it becomes more malleable and easier to shape, allowing for the creation of complex geometries with high dimensional accuracy. This method results in increased strength, higher density with fewer defects, the ability to form complex shapes, reduced need for further machining, minimal material waste and lower internal stresses – all contributing to enhanced performance and manufacturing efficiency.

These benefits make hot forging not only a technically superior process but also a highly costeffective solution, particularly for high-strength fastener applications.

Hot forging is widely used across various industries due to its versatility and performance advantages. In the automotive and aerospace sectors, it enables the production of high-strength, precision parts such as engine components and fasteners. The energy industry benefits from its durability in oil, gas, and power applications, while machinery and construction sectors rely on forged parts for heavy-duty equipment. It also plays a key role in marine industries, providing reliable, corrosion-resistant components. Additionally, it supports the steel and construction industries with strong structural parts and fasteners.

Norm Fasteners is committed to producing highquality fasteners tailored to client needs. Services include standard and custom fastener production, engineering support for customised solutions, ISO-compliant quality control and flexible, highvolume manufacturing with fast delivery

Offering comprehensive solutions in hot forging, Norm Forging provides production services for industries such as automotive, aerospace and energy. Its capabilities include custom part and prototype manufacturing, support in material selection and design optimisation, advanced testing methods like X-ray and ultrasonic inspection, and efficient delivery of both high-volume and rapid production orders

Forged parts ranging from 0.20 kg to 25 kg are produced with precision and consistency. Additionally, the facility manufactures fasteners such as bolts and nuts from M24 to M64, including bolts up to 1 meter in length, meeting the needs of heavy-duty applications.

Hot forging continues to play a vital role in modern manufacturing, especially in the fastener industry where strength, reliability and precision are nonnegotiable. Norm Fasteners and Norm Forging stand at the forefront of this innovation, delivering quality, performance and trust in every component they produce. As industries evolve, the strength of forged solutions remains a foundation for progress.

In addition to hot forging, we also produce fasteners using stamping, machining and cold forging methods. These alternative manufacturing techniques allow us to offer a broader range of solutions tailored to specific application needs, material requirements and production volumes – ensuring optimal performance, cost-efficiency and precision across all projects.

www.normfasteners.com

Halfmann Schrauben GmbH

Welkerhude 37, D-45356 Essen

+49(0)201 36484 0 info@halfmann-schrauben.de www.halfmann-schrauben.de

The planning and implementation of large timber construction projects presents architects and contractors with a variety of challenges. The quality of the truss nodes plays a key role in determining the durability and safety of the entire structure. In this context, the use of selfdrilling rod dowels, such as the HECOWS, offers significant advantages over conventional methods.

When planning and implementing truss intersections with slotted steel sheets, architects and contractors are faced with the challenge of ensuring stability, precision and durability. Precise holes must be drilled through the timber and steel. Traditionally, this requires three separate work steps: First the timber is predrilled, then the steel sheet, and finally the rod dowel is inserted. This process is not only timeconsuming, but also prone to tolerance problems caused by shrinkage and swelling of the wood or inaccuracies during drilling. With the HECOWS selfdrilling rod dowel, HECO offers an innovative solution that combines these three steps into one. Thanks to its special design, the rod dowel drills through wood and steel in a single operation, which speeds up and simplifies the installation process. This leads to time savings of up to 40% and at the same time increases the precision of the connection.

With an underhead thread length of 14mm, the HECOWS is ideal for up to three sheets of metal for slot installation in one process. With its small diameter of just 7mm, it enables small edge and centre distances, making it particularly versatile. With a drilling capacity for S235 grade steel,

it can easily process slotted sheets up to 10mm thick for one sheet and up to 5mm thick for two or three sheets. In addition, the underhead thread ensures that the anchor is reliably secured in position.

These properties make the HECOWS ideal for a wide range of applications, such as assembly butt joints, connection of mullion and transom constructions, support nodes, beam renovations, frame corners and tensioned support bases. Efficiency is further increased by the use of a pneumatic setting tool, which enables fast and ergonomic processing particularly advantageous for projects with a large number of connections.

HECO offers a highly efficient complete solution from a single source. The package includes not only the product itself, but also rental installation equipment, comprehensive advice, BIM/CAD data and tender texts for every project. This comprehensive support makes the planning and implementation of timber construction projects much easier.

For planners and contractors in timber construction, this innovative solution offers the opportunity to implement projects much more efficiently and with high quality at the same time. The combination of selfdrilling rod dowel and suitable assembly device optimizes the entire workflow for the production of truss intersections and thus contributes to an increase in competitiveness in modern timber construction.

www.heco-schrauben.com

As sustainable timber construction grows worldwide, innovative fastening solutions are key to efficient, environmentally responsible, and highperformance building. BECK, the Austrian fastening specialist and familyowned business since 1904, continues to lead these developments. With over 120 years of expertise, BECK presents significant 2025 product advancements addressing both ecological and practical challenges in modern timber engineering.

LIGNOLOC® Wooden Nailing System: Certified Sustainability and New Interior Applications

At the core of the innovations by BECK is the LIGNOLOC® Wooden Nailing System –an awardwinning technology enabling woodtowood connections without metal or fullsurface glueing. Made from European compressed beech wood, LIGNOLOC®

BECK’s LIGNOLOC Wooden Nailing System has new applications

BECK has released its 2025 Innovations with sustainability in mind...

Complementing timber connection solutions, the family company introduces the SCRAIL® CHIPBOARD Nail Screw Fasteners. Featuring a specially formed needlepoint tip, they ensure optimal driving and allow postadjustment. Their readjustability makes them ideal for temporary uses in softwoods and engineered wood, like crate manufacturing or chipboard fastening. Thanks to their thread geometry, warped or cupped boards can be corrected. Available in stainless steel, optionally with black oxidisation for aesthetic facades, these fasteners are highly versatile.

Responding to increasing automation, BECK presents the FASCO® INMOTION handheld slide, allowing controlled stapling and nailing with adjustable drive intervals. This provides manufacturers with a reliable entry into semiautomated production of woodbased components. For fully automated production, BECK offers FASCO® Nailing Heads, developed for multifunctional manufacturing bridges. They enable automated processing of LIGNOLOC® wooden nails, SCRAIL® Nail Screw Fasteners, and other BECK fasteners in the production of prefabricated timber elements, pallets, crates, and more.

Wooden Nails reduce thermal bridging and enable recyclable, ecofriendly timber structures. Compared to steel fasteners, CO₂ emissions can be reduced by up to 66%. An official Environmental Product Declaration (EPD) now offers architects and engineers verifiable sustainability data.

BECK has expanded the LIGNOLOC® range to include stepped shaft nails in 25mm and 37mm lengths. The 25mm version allows safe fastening in very thin timber elements while minimising splitting risk. These wooden nails are ideal for fine joinery, furniture, interior fittings, and kitchen construction where thin materials require careful fastening without compromising surfaces. Combined with the FASCO® F33 Coil Nailer by BECK, users achieve precision and efficiency.

SCRAIL® CHIPBOARD Nail Screw Fasteners: Precision and Versatility

To assist design professionals, BECK has now released the LIGNOLOC® Technical Handbook, tailored to structural engineers and planners. It provides detailed engineering principles, calculation methods, formulas, and verification models for timber connections using LIGNOLOC® wooden nails, serving as a practical tool for technically advanced timber construction.

With these 2025 innovations, BECK reinforces its mission: empowering technically advanced timber construction with sustainable, efficient fastening technologies – built on more than a century of familydriven expertise.

beck-fastening.com

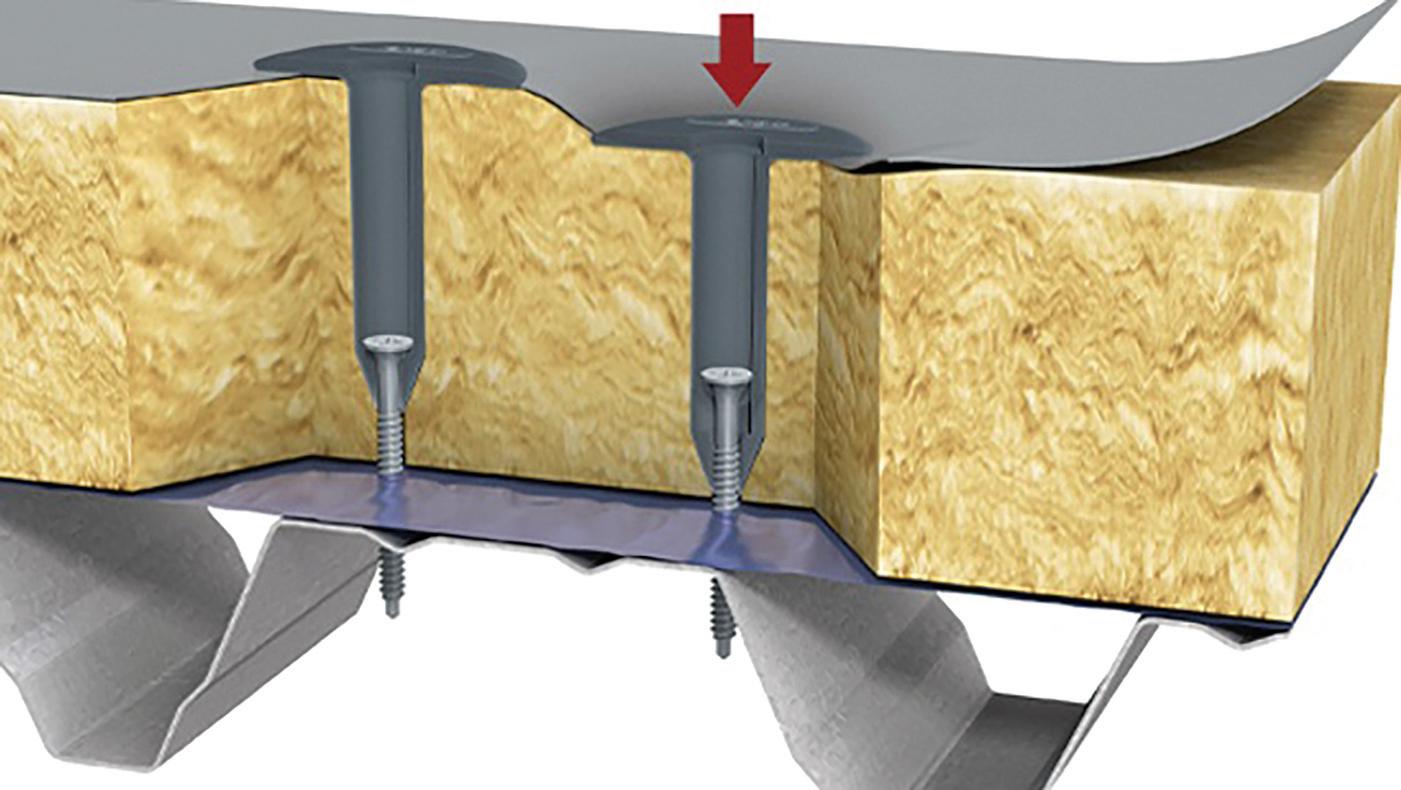

One of the oldest building materials is experiencing a renaissance, as wood is more popular than ever in construction. fischer offers the ideal fastening innovations for processing this popular building material…

Wood is a popular choice of building material, including for multistorey buildings. This renewable resource is climate neutral and offers excellent physical properties, strength combined with low weight, a high degree of prefabrication, fast processing, excellent insulating properties, a healthy indoor climate and a unique look. fischer fixing innovations allow wood to be processed in all its shapes and sizes, utilising the material to the fullest extent. In addition to this, fischer offers solar systems for various fixing situations when installing solar systems on roofs.

A new general design approval (aBG)/technical approval (abZ)/European Technical Assessment (ETA) is advancing timber engineering. The fischer FIS EM Plus injection system for compliant bonding of FIS A anchor rods or FIS IG internal threaded anchors now enables a multitude of connections and reinforcements in timber, including concealed connections. The injection system allows high loads to be transferred and enables a wide range of timber engineering applications. A comprehensive range of accessories and system components made of zincplated and stainless steel in various sizes enable various indoor and outdoor applications with the FIS EM Plus. Flush fastening points can be created with the innovative FIS IG internal thread solution, which prevents anchor rods from protruding during transport, which could be bent or take up space for other components. Together with the FIS EM Plus, the FIS IG can be dismantled flush with the surface, allowing the fastening point to be reused with ease.