T he unstoppable expansion drive of

30,000 items available from stock Over 1,000 incoming containers processed annually Additional 40,000 locations in new automated shuttle warehouse ERP system S/4H integrated with Dynaman WMS

30,000 items available from stock Over 1,000 incoming containers processed annually Additional 40,000 locations in new automated shuttle warehouse ERP system S/4H integrated with Dynaman WMS

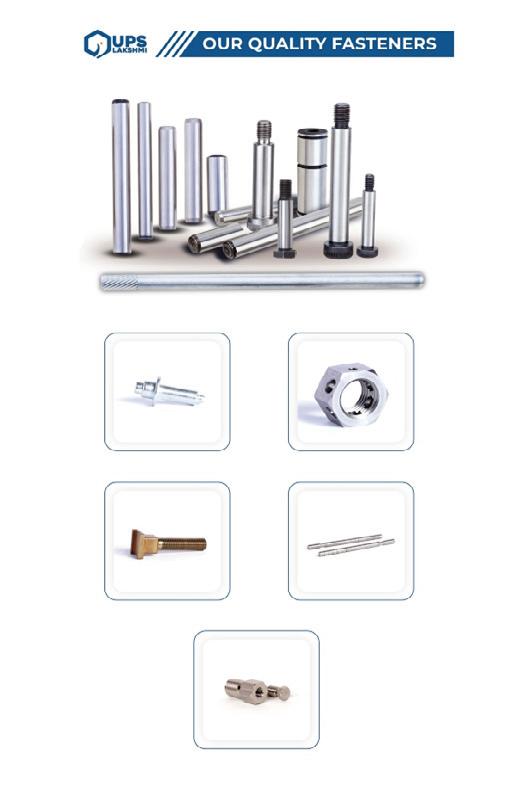

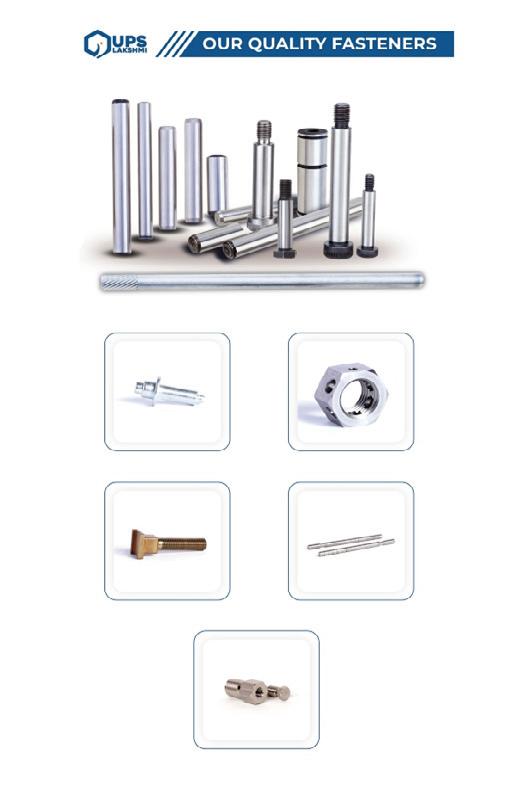

QUALITY SINCE 1951 OUR PRODUCT RANGE INCLUDES:

THE STANDARD DIN 912 | DIN 931 | DIN 933

HEXAGON HEAD DIN 6921 | ISO 4014 | ISO 4017 | DIN 960 | DIN 961

HEXAGON SOCKET HEAD DIN 7991 | ISO 10642 | DIN 6912 | DIN 7984 | ISO 7380 -1 & -2

THREADED SCREWS WITH HEXALOBULAR SOCKET ISO 14579 | ISO 14580 | ISO 14581 | ISO 14583

HEXAGON SOCKET SET SCREWS DIN 913/ISO 4026 | DIN 914/ISO 4027 | DIN 915/ISO 4028 | DIN 916/ISO 4029

THREAD ROLLING SCREWS DIN 7500 Form CE | DIN 7500 Form M

TAPPING AND DRILLING SCREWS DIN 7504 Form K | DIN 7981 | DIN 7982 | ISO 14585 |

HEXAGON NUTS DIN 934 | DIN 985 | DIN 980 | DIN 439 | DIN 6923 | ISO 4032 | ISO 7042

WASHERS DIN 125 | ISO 7089

PARALLEL PINS ISO 8734 | DIN 7979 Form D Achilles Seibert GmbH | Philipp-Reis-Straße 3 | D-24558 Henstedt-Ulzburg Phone +49 (0) 41 93 89 55 | sales@achill-fasteners.com

|

|

Publisher Jerry Ramsdale jerry@torque-expo.com

Editor Jonathon Harker jonathon@torque-expo.com

Deputy Editor Rachel King rachel@torque-expo.com

Deputy Editor Simon Yuen simon@torque-expo.com

Sales Manager – UK Claire Warman claire@torque-expo.co.uk

Sales Manager – International Harry Whyte harry.whyte@torque-expo.com

Sales Managers – Tools

David Pattison dpattison@torque-expo.com

Lloyd Ramsdale lloyd@torque-expo.com

Circulation Tracy Howell tracy@torque-expo.com

Head of Production Luke Wikner luke@torque-expo.com

Designers

Dan Bennett

Victoria Arellano

Published by

Stag Publications Ltd

18 Alban Park Hatfield Road

St Albans

Herts AL4 0JJ

tel: +44 (0)1727 739160

fax: +44 (0)1727 739169

Email: info@torque-expo.com

Web: www.torque-expo.com

Disclaimer

Although the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or of Stag Publications Ltd.

06 NEWS

12 WOMEN IN FASTENERS & TOOLS > JAYNE SHEPPARD, HARRISON & CLOUGH

14 COVER PROFILE > PGB-EUROPE

18 SHOW REVIEW > BAU 2025

24 OPINION > FASTENER FAIR GLOBAL 2025

26 REPORT > OPTIMAS CELEBRATING EXCELLENCE AWARDS

28 FOCUS > NYLON AND PLASTIC FIXINGS AND FASTENERS

36 SPOTLIGHT > MKT

38 FOCUS > HIGH TENSILE AND BOLT ASSEMBLIES

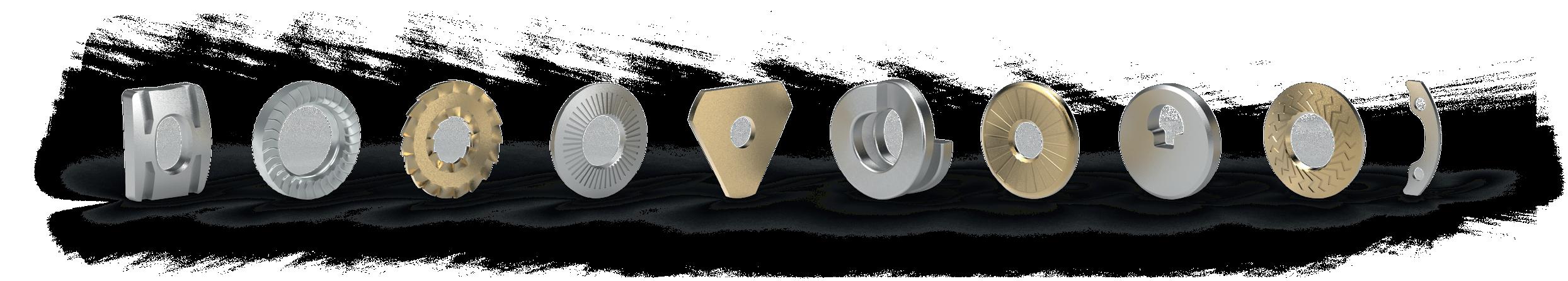

44 SPOTLIGHT > GROWERMETAL

46 TERRITORY FOCUS > UK

64 TERRITORY FOCUS > SPAIN & PORTUGAL

68 SPOTLIGHT > GOLDENGATE HARDWARE

70 SHOW PREVIEW > INTERNATIONAL FASTENER SHOW CHINA

72 SHOW PREVIEW > +INDUSTRY

To subscribe to Torque Magazine visit: torque-expo.com/subscribe/ or scan this QR code...

Such is trading in modern times, that the ink is barely dry on the page and there’s another new supply chain upset to grapple with.

One of the latest points is container prices (again) which look to be heading for instability as the flow of containers from Asia to the US likely decreases. It’s just one of a number of implications the world is grappling with in light of controversial policies enacted in the second term of US President Trump. Even those who don’t export directly to the US know all too well that the indirect knock-on effects might impact them. There’s even talk that UK mortgage rates may lower as the UK tries to mitigate the ill economic effects. Will that give consumers more spending cash? That remains to be seen.

The short point is that the full effects are yet to be fully appreciated. And inconsistent messaging on said tariffs from the US doesn’t exactly help.

The broader point might be something along the lines of ‘here we go again’ in the sense that the supply chain hasn’t exactly been straightforward for at least the last five years. Importers, wholesalers, distributors and – to a point – end consumers have been buffeted by various supply challenges and considerations of late, some a result of hugely impactful one-off events like Covid and others the result of policy changes, including well-meaning ones like CBAM and more protectionist ones…

This issue includes territory reports covering the UK, Spain and Portugal. Maybe there is a phrase in those languages to sum things up, but there's a French phrase that probably says it best: “Plus ça change.”

Jonathon Harker

Editor

jonathon@torque-expo.com

As part of our commitment to the environment, Torque Magazine is fully recyclable.

Change is good for keeping you active, and I can say that being active is definitely the case at Ambrovit. Screws symbolize the construction of something new, maintaining a constant balance between people and technology.

Daniele Warehouseman specialized in automation AMBROVIT HAS ALWAYS PLACED PEOPLE AT ITS CORE

Bufab celebrated a significant cut in emissions with the publication of its latest (2024) Sustainability Report.

Transitioning to electric and hybrid vehicles, investments in solar systems and the adoption of green certificates helped Bufab achieve a 25% reduction in total emissions since the 2021 base year.

Scope 1 and 2 emissions decreased 22% compared to 2021. Every Bufab company has a structured plan to achieve netzero internal emissions by 2030.

Looking ahead, Bufab has set an ambitious target to cut its carbon footprint by 55% by 2031. As an intermediate milestone, it aims to have 70% of its

purchases and suppliers contributing to emission reductions in line with its climate goals. Currently, 47% of Bufab’s suppliers have already committed to reducing their emissions at the same pace as the company.

www.bufab.com

The organisers behind the NMBS Exhibition praised the “strong relationships” that the sector enjoys, with independent merchants and suppliers taking part in the 2025 edition in early April.

1,125 visitors attended while 280 exhibitors showcased goods and services

at the key event. This year’s show was the first since the demise of engineering buying group Troy (UK), which ran successful trade event Troy Means Business. NMBS previously reached out to former Troy supplier and merchant members to offer support.

Chris Hayward, chief executive officer

Anochrome Group has noted renewed interest in advanced coating techniques – especially thermal diffusion coating, particularly in oil and gas, wind energy and defence.

Thermal diffusion is an advanced solution that offers superior protection, extending the lifespan of metal parts and enhancing performance, said the firm.

Steve Norman, Group UK Divisional Director at Anochrome Group, said: “In industries where metal components face harsh environments, safeguarding

against corrosion and wear is paramount.

“If parts last longer, that ultimately leads to a more sustainable product – and that is a core consideration for decision makers across most sectors. It also, of course, reduces maintenance costs and helps to ensure optimum performance.

“We have definitely seen a noticeable uptick in thermal diffusion enquiries from right across Europe. This specialised coating is extremely difficult to come by, so we would expect demand to continue to increase.”

at NMBS, said: “This year’s event has once again demonstrated the strong relationships that make up our sector. We remain committed to supporting merchants and suppliers as they navigate the opportunities that this year will hopefully bring.”

www.nmbs.co.uk

The process diffuses zinc into steel at elevated temperatures, forming a robust anticorrosive alloy layer on the metal's surface. This method, also known as thermal diffusion galvanizing, utilises a zinc alloy powder to create a protective coating for ferrousbased parts.

The result is a hard, nonmagnetic coating that provides exceptional resistance to corrosion, oxidation and abrasion, outperforming traditional protection methods.

www.anochrome.com

OwlettJaton’s Chief Executive Ian Doherty has retired, with his departure taking effect on 31 March 2025. Doherty joined the company in 2016 and has played a pivotal role in shaping its direction. One of his most significant achievements was the consolidation of multiple trading divisions under the single OwlettJaton brand. Moving forward, Doherty will continue to support the business in a nonexecutive capacity.

Following his retirement, Andrew Ballantine, Chief Operating Officer of Newbury Investments, will assume the role of interim Managing Director while the search for a permanent successor is underway.

owlett-jaton.com

Optimas has appointed Julia Anukam as Head of Sustainability for the International Region, covering the UK, Europe, India and APAC.

In her new position, Anukam is responsible for the company’s Net Zero targets validated by the ScienceBased Targets Initiative (SPTi) in September 2024. Based on the targets, Optimas needs to cut Scope 1 and 2 emissions by 42% and Scope 3 emissions by 51.6% by 2030. Aside from carbon reduction, she is spearheading a global sustainability strategy to integrate sustainable practices across Optimas’ people and processes.

The new Rivit catalogue has arrived number 11 !

More than 4500 products, including blind rivets, rivet nuts, lockbolts, tools for fasteners and many other service references, to fulfil even better all requirements.

Increasingly effective and efficient sales support tool, essential for choosing and browsing our comprehensive product range.

FTI will be holding training sessions at Fastener Fair USA this May, to help attendees learn the nuances of fastener applications and design concepts, equipping them with knowledge of head styles, drive features, thread forms, materials, heat treatments and plating and coating. Sponsored by Star Stainless, the all day class welcomes engineers, sales professionals, quality assurance professionals, purchasers and practitioners in OEM, sourcing and quoting, marketing or management.

AIRBUS >

US manufacturer TriMas has announced that TriMas Aerospace’s Monogram Aerospace Fasteners™, Allfast Fastening Systems® and Mac Fasteners™ brands have been awarded a multiyear global contract with European aerospace corporation Airbus. The contract features nextgeneration fastening solutions and newly certified products tailored to streamline robotic assembly processes for aerostructures and key aircraft components, underscoring TriMas Aerospace’s dedication to innovation in the aerospace sector. Additionally, the company continues to invest in cuttingedge manufacturing equipment and advanced processes to enhance performance and expand capabilities.

UK CONSTRUCTION WEEK ANNOUNCES PARTNERSHIP WITH CPI >

UK Construction Week (UKCW) has announced a partnership with independently governed notforprofit organisation CPI Ltd, which will debut at the London show in May. The partnership stems from a shared ambition to drive cultural change in the built environment sector, enhancing quality, promoting greater transparency in product information and raising marketing standards.

NMBS CEO CHRIS HAYWARD TO STEP DOWN NEXT YEAR >

UK buying society for Independent Builders, Plumbers, Hardware, Timber and Engineering Merchants NMBS has announced that CEO Chris Hayward will step down from his current role in 2026. Hayward became CEO of NMBS in 2022 after more than 20 years as managing director. During his tenure in senior positions, Hayward has focused on the strategic development of NMBS, including the amalgamation with United Merchants in 2014, which doubled the annual turnover while simultaneously driving up member returns.

FISCHER TO EXPAND FIXING SYSTEMS DIVISION >

After fischer sold fischer Automotive in April 2024, the group began investing in the former fischer Automotive site in Horb, expanding the fischer Fixing Systems division with renovation and maintenance of existing structures and fire protection systems.

Aside from the expansion, fischer announced that its revenue for the 2024 financial year reached €1.11 billion, representing a 1% increase.

To subscribe to Torque Magazine and receive the newsletter visit: www.torque-expo.com/subscribe/ or scan this QR code...

KELLER & KALMBACH LAUNCHES JV FOR FASTENER QUALITY MANAGEMENT >

German fastener and fastening technology supplier Keller & Kalmbach has formed a joint venture with speciality engineering company LAW NDT. The joint venture, MEXS Vertriebs GmbH, is 40% owned by Keller & Kalmbach. It aims to set new standards in modular measurement and testing technology for fasteners with the MEXS 400 testing system, a modular inspection system designed to inspect fasteners and other highprecision components.

MOWILEX

CERTIFICATION >

PT Mowilex Indonesia (Mowilex) has been awarded its sixth consecutive CarbonNeutral® certification from Climate Impact Partners. The company worked with ACT Commodities, a CDP goldaccredited organisation that helps companies navigate scope 1, 2 and 3 decarbonisation, to obtain related Renewable Energy Certificates. To complete the latest certification, Mowilex reduced its carbon footprint and offset emissions across production and distribution. Solar panels were installed at the Cikande plant will reduce the company’s dependence on nonrenewable electricity sourced from the grid.

Italian Fastener manufacturer Fontana Gruppo has acquired a majority stake in Indian manufacturer Right Tight Fasteners Pvt. Ltd. Specialising in the production of highstrength special nuts and bolts. The firm is adding five manufacturing plants in India to Fontana Gruppo’s portfolio, serving clients in the automotive, agricultural, industrial and construction sectors.

Jayne Sheppard, Purchase Office Manager at Harrison & Clough, has worked in the UK fastener industry for over 20 years. Speaking with Torque Magazine, Sheppard discusses the community feel of the industry and raising awareness of the opportunities the market holds for those considering joining the sector…

// It’s not just about nuts and bolts – there’s a wide range of roles where women can excel. Raising awareness of these opportunities would make a big difference //

How did you get into the industry?

Harrison & Clough has a strong local reputation for looking after its staff, which initially drew me to the company rather than the industry itself. When I joined 22 years ago, I didn't realise how vast the fastener industry was until I became a part of it. Over time, I’ve gained extensive knowledge and experience, but it all started with the appeal of working for a wellregarded company.

What does your day-to-day job involve?

I’ve worked in several areas within the company. I started in sales, then moved to product development, and eventually into purchasing, which I’ve been doing for the longest time. My role primarily involves buying imported and domestic fasteners. We source from the Far East, Europe and the UK. I also handle freight logistics, oversee container deliveries, assess product ranges and identify areas for development. We continuously monitor industry trends and innovations to ensure we stay competitive. It’s a varied and interesting role, especially when working with international suppliers.

Can you tell us a bit about your department?

Our department is relatively small, with three people—two women and one man. We each handle different responsibilities. Amie Cummins (Import Buyer at Harrison & Clough) manages all imports from the Far East, while Tyler Moyles (Assistant Buyer at Harrison & Clough) and I oversee domestic purchasing. I also handle freight logistics, container imports and deliveries. Despite being a small team, we cover a lot of ground and ensure everything runs smoothly. Currently, there are 36 people in the company,

What are the biggest changes you’ve seen in the industry and company since you started?

The biggest change has been technological advancements. When I first started, a lot of communication was done via fax and phone, whereas now most processes are automated and orders can be directly input into the system. The industry has become much more advanced. Another significant shift is the growing presence of women. When I started, it was quite unusual to see women in the industry, but now it’s becoming more common and accepted.

What do you enjoy most about working in the fastener industry?

The industry is incredibly friendly. Whether you’re meeting customers, suppliers or attending trade shows, there’s a real sense of community – everyone knows each other. I think this is something that needs to be highlighted more, especially to women who might assume it’s a maledominated sector. In reality, it’s an open and welcoming industry with plenty of opportunities.

Can you share some career highlights and milestones?

I didn’t initially join with any particular career ambitions, but I’ve been fortunate to work across different departments and develop my skills in various areas. Successfully navigating and excelling in what was once a maledominated industry has been particularly rewarding. Being recognised for my contributions and progressing through different roles has been a significant achievement.

The core of the Harrison and Clough business is the MATE brand of fasteners, fixings and screws

What needs to be done to encourage more women to join the fastener industry?

Women need to know that this isn’t just a maledominated industry. There are many different aspects, from global trade to research and development, legislation changes and product innovation. It’s not just about nuts and bolts – there’s a wide range of roles where women can excel. Raising awareness of these opportunities would make a big difference.

In your experience, which areas of the industry are more open to hiring women?

Buying and sales are two areas where we’re seeing more women. Years ago, seeing a female sales representative was rare, but now it’s much more common. If a woman is knowledgeable and confident, she can do just as well as anyone else. When I first started, I remember a customer once told me: “You can’t possibly sell fasteners because you’re a woman.”

This kind of thinking has thankfully changed over the years. Today, women receive the same training and background knowledge as men and there’s no reason they can’t thrive in this industry.

Based in Yorkshire, Harrison and Clough distributes quality fasteners and fixings

What advice would you give your younger self when starting in the fastener industry?

Take advantage of all the different opportunities available. Don’t limit yourself to just one department – explore different areas and learn as much as possible. I’ve been fortunate that Harrison & Clough supported my development across multiple roles. If I had known early on how much there was to explore, I would have been even more proactive in seeking out new opportunities.

Any final thoughts?

The fastener and fixing industry is constantly evolving. There’s always something new happening, whether it’s innovation, regulation changes or market shifts. It’s a dynamic and interesting sector to be in and definitely worth considering as a career.

www.harclo.com

pgb-Europe’s Melle, Belgium HQ (flanked by the A10) is currently undergoing a series of extensive investments

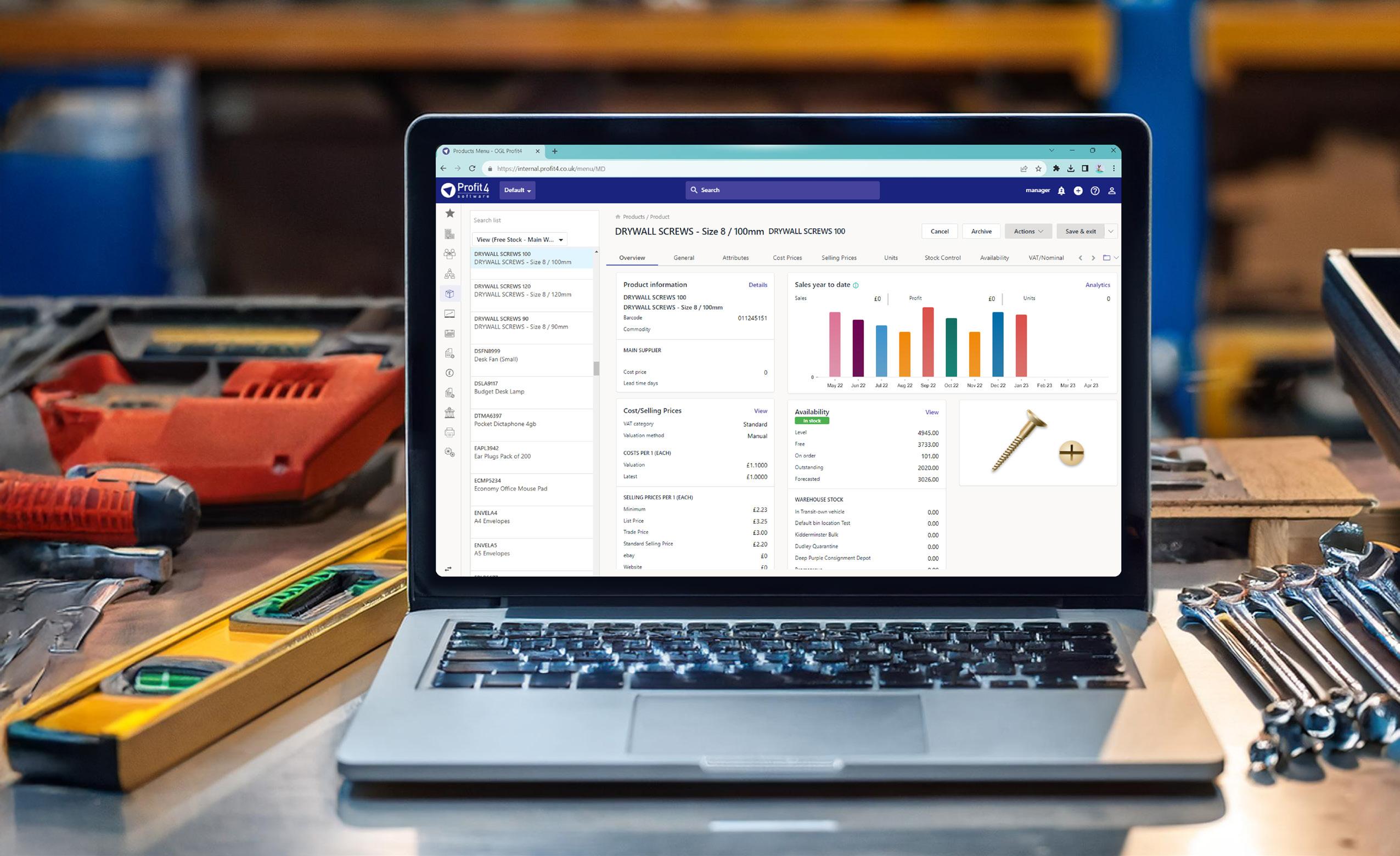

pgb-Europe is deep into an ambitious three-stage warehouse investment. Torque Magazine visits with the work underway to speak with COO Johannes Heye about the changes the latest investments will bring, future-proofing, digitalisation and the potentials of the market…

pgbEurope is an enormously familiar name to the fastener and fixing industry. The supplier and manufacturer has been in business since the 1950s and has a huge 80,000plus product database, including seven own brands and product families under the pgb umbrella.

The family business is also pretty familiar to the thousands who drive along Belgium’s A10 motorway near Ghent (part of the E40) where the pgbEurope branding is eyecatchingly emblazoned on the side of one of its large warehouses (which lights up at night).

Behind the vast wall and window of that warehouse, work is underway on some major internal projects which are set to drive the efficiency of the business still further to benefit its legions of customers, as well as broaden its scope.

Those big investments include a new automated picking

warehouse, which uses some of the existing warehouse space, the commission of a new exhibition zone and finally a further automated storage warehouse.

Work is set to complete on the first of those projects later this year, and Torque Magazine’s visit to pgb’s HQ in Q1 gave us a precompletion glimpse of what is to come, providing a heavy hint at the scale of what the business is doing, and the direction it is heading in. pgb clearly is investing for the future, even while the market is probably not at its most vibrant. As COO Johannes Heye says: “We will lack space if the current rate of growth continues for us.”

Evolution & investment

Always based in the vicinity of Belgium’s Ghent, pgbEurope moved into its current group headquarters in 1997. Things

have, as you might have guessed, moved forward considerably since those days, with numerous extensions, renovations and investments.

2007 saw the first major extension of pgbEurope’s warehouse facilities. Aesthetically, this warehouse is quite unusual with a huge window illuminating the vast space. The same year saw pgb install its first miniload warehouse system, with seven shuttles and cranes.

The next major change in the warehouse came in 2017, with a new automatic pallet warehouse. That was followed by a complete renovation of its office building over 2021/2022, with administration, sales, marketing and other functions now based over two floors. Now, in 2025, the firm is embarking on its third significant warehouse expansion.

Over the years, further investments have been slotted in between those larger projects, including the introduction of three Automated Guided Vehicles (AGVs) in the warehouse, and more of which are on the way, Heye tells Torque Magazine “They move goods with care and they do it exactly the same way each time.”

Moving and processing goods efficiently is what it’s all about. At pgb’s HQ, just under 1,000 containers arrive per year from Europe and the Far East.

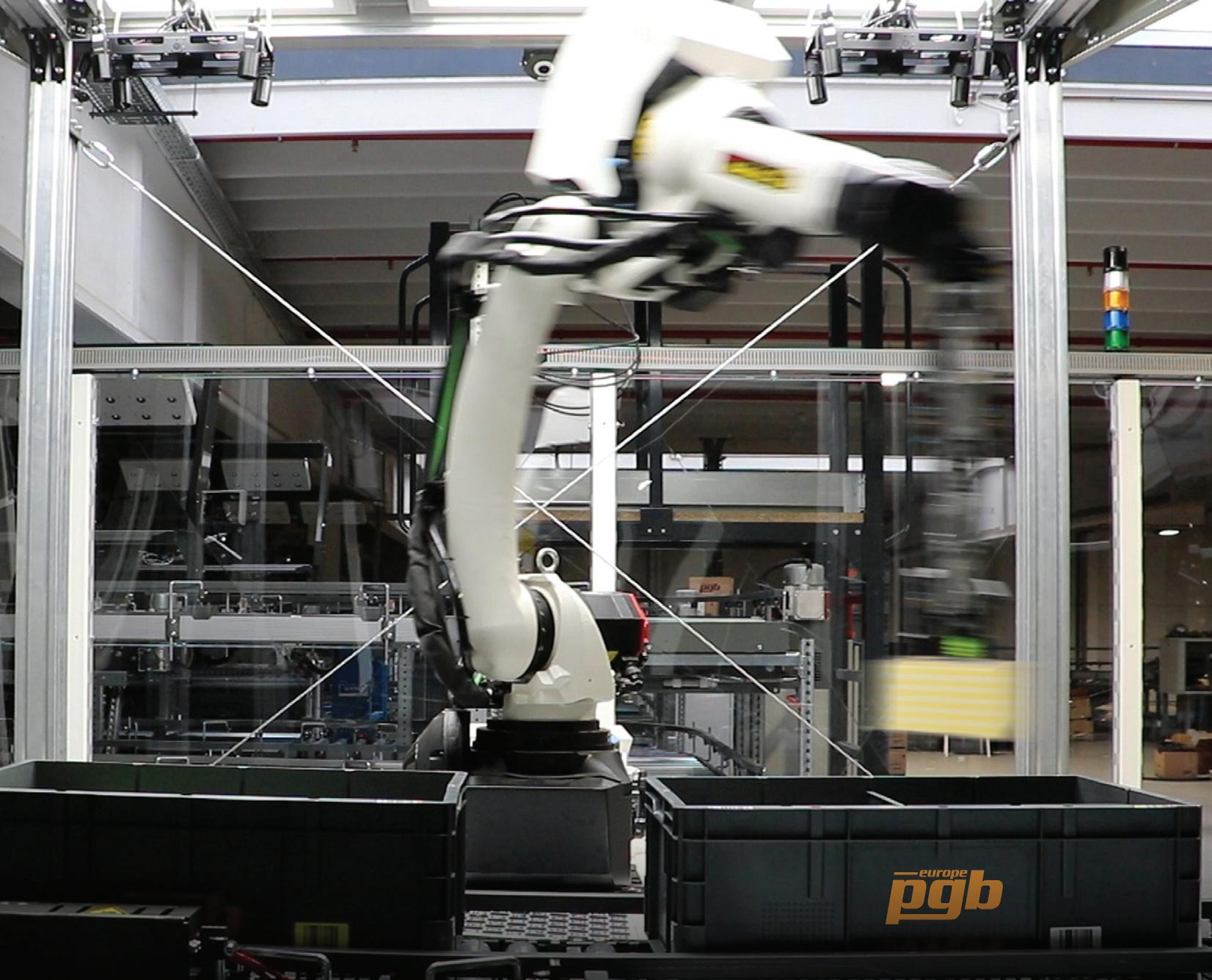

To help handle those, there is completely new technology being introduced in the new warehouse system. The new automatic OSR picking warehouse from KNAPP will include approximately 15,000 new pallet spaces, with around 40,000 places for cases in the automated bays, dealing with over 10,000 totes a day.

Carefully devised algorithms will guide robots along the most efficient picking routes and pack more economically and efficiently.

Among the myriad of moving parts that go into a project of this magnitude, pgbEurope is refining and standardising its packaging, so customers will receive samesized packages from the firm. The look of the packaging will be more unified too, while losing none of the brand focus: “It sounds simple, but it’s not so easy…” Standardised packaging also means further simplification of movement of goods in the warehouse too.

A palletising robot is to be introduced in the summer to further aid that efficient movement of goods and save time on orders.

// Imports are becoming more expensive and difficult, but pgb-Europe can unburden other importers and serve them in that way //

“With the same people, we do more,” explains Heye. “We have good people and we believe we have a good balance.” Automation can also reduce the physical strains placed on warehouse staff. To that end, workstations in the new investment can have their height adjusted to suit whoever is working there.

Automation is used in the pallet storage warehouse too. This is a relatively slowpaced operation, making 100 moves in an hour at the most. But as it’s not picking, speed is not a major issue. This automated storage area has an approximate 15 metre usable height – there are limits to how high pgb can build new units, to adhere to local planning regulations. In fact, some of the newer buildings plotted have been cleverly designed to appear more residential to blend aesthetically into the surroundings, for the benefit of locals.

Ensuring quality of product on its journey through the pgbEurope system has also seen some recent investments in the firm’s QC facilities, including a Kistler torsion and torque tester was introduced for EN 14399 bolts in ’23.

pgb also offers jobsite tests as required. Torque quizzes the firm on QCrelated trends, not least in terms of newer materials – like Cross Laminated Timber (CLT) being used in construction and potentially needing different tests. That is an area of change, the firm says, but it also notes the impact of more powerful tools that QC departments have to account for. Heye explains: “Tools are placing more stress on bits and fasteners, such as from the likes of impact wrenches. We have to be aware of the differences in application and the working habits of the people that use fasteners.”

Johanne Heye has been with pgbEurope for almost two decades and now looks after the daily management of the business alongside Frederik Pennoit, who recently became the new CEO and Vincent Pennoit, CLO of pgbEurope.

Heye sees CBAM as one of the factors set to make a significant difference to many fastener businesses: “With CBAM there is difficulty but there is also opportunity. Imports will become more expensive and difficult, but pgbEurope has chance to unburden other importers and serve them in that way. We have the capacity.”

Related, pgbEurope has taken the step to establish a Sustainability Department within its HQ. Now in its formative months with 1.5 people working within it, the firm will monitor how it evolves and dedicate more resource there as is required: “It is a challenge for many companies, but we can handle it. It is something we can help our customers with.

“With CBAM and other cost pressures… while you can absorb some of the costs, finally you have to pass some of them on. That’s not a good thing for the growing economy when there are tensions. But we try and be positive and focus on what we can do, like with CBAM where we can unburden other importers.”

The automatic packing robot is one of the recent updates designed to boost efficiency and speed for the business and its customers

pgbEurope also sees growth in the private label market ahead, particularly at pgbPolska where there is considerable production and recent expansion in private label, not least in export. It’s a market that that pgb first starting serving around five years ago, but following some tentative steps, the business is looking to dive further into the private label arena, operating at two different levels, including both bigger projects but also a standardised offering for customers to get their own brand on a standard product.

Private label products can be harder work to handle, but Hey explains “it’s interesting to us and we see there is increasing demand to stock own brand products. And it can help with longer term relationships, sustainable growth and turnover.”

What about pgb’s own brands? There’s room for expansion there, Heye says, including with newer fasteners for steel construction sandwich panels, roof and façade items and highly corrosion resistant C4 coated products. pgb is also stocking additional black top coated product to keep up with market trends and methods. Meanwhile, Poland has a big focus on plastic fixings and insulation plugs with long expansion zone specially for renovation projects.

That territory is, of course, where pgbPolska is set. It’s part of an international footprint that also includes a base in Shanghai for procurement and, since 2017, a sales office in Northern France, which plays into pgb’s belief in the power of having local people supporting local markets. “Although France is nearby geographically, it is different to our market, so we stay local to be global. France has its own standards on certain washers, for example. We have those in stock so we are a complete supplier.”

Digitalisation is oft mentioned in the context of the fastener industry and pgb has an interesting perspective: “Our data team is the fastest growing team at pgbEurope! In the old days we used to have just one person. Now we have specialists covering different aspects, data analysis, customer service, product creation…

“We are experimenting with Artificial Intelligence (AI) to help make some processes more automated. We are examining the ways in which we can apply it.”

Looming regulation from the EU on Digital Product Passports is also being factored into pgb’s planning, with the firm

increasingly working with QR codes so that multilayers of information can be included with product packaging to adhere to upcoming regulation and also to make a wealth of information to customers easy to access.

Despite the wealth of digital information now available at the fingertips of distributors and their end user customers, the power of print persists, Heye says: “Maybe product catalogues are less popular than before, but they are still popular. Having the data in your hands is nice. Although it is arguable how much they are used when all that information is now available online and easy to find.”

Likewise at trade shows – and pgbEurope presence can be found at a great number of those – there will be product leaflets for stand attendees to walk away with.

pgbPolska hasn’t been left out of the current round of investments, Heye informs Torque Magazine. The business brought in a significant Weighpack packing machine one and a half years ago and is placing an order for a second later this year. Heye explains the reasoning: “Poland creates, for example, a great range of plastic fixings. While there might be a few more additions, it’s a very solid and complete range. Now we want to develop the packaging to take it to the next stage, to make it more robust and efficient and to take out the plastic windows from cardboard boxes, which are not so good for recycling. We’ve enhanced the labelling too, with a lot of information and specifications, and a QR code leads to all the documents.

“There’s a lot of product out there and to help ours stand out we try to be as good and helpful partner as possible, which helps build relationships.”

That philosophy of helping merchants and retailers to sell pgb products in their shop extends to a wealth of POS and merchandising options.

Clearly, pgb has a lot of areas and projects to focus on, not least its big warehouse investments. Two years in the making, the team is doubtless looking forward to completing the enhancements and maximising the benefits of the changes for itself and its customers. Torque Magazine will bring you further updates on those and more, so watch this space.

www.pgb-europe.com

Worldwide leading manufacturer of plastic standard elements Discover the variety. Straight away.

dk

BENEFIT FROM THE VERSATILITY OF PLASTIC STANDARD ELEMENTS.

Plastic injection moulded technical standard parts of the highest quality, made in Germany: that‘s PlacoTec®!

» DIN standard: screws // nuts // washers // wing knobs // knurling knobs

» Material: PA // PA GF // PP // PE // PVDF // PEEK // ABS

» Sizes: M2 to M24

» Colors: Natural and RAL codes

» Other materials, colors and dimensions upon request

» Large stock for immediate availability

» Customized retail packaging according to your specifications

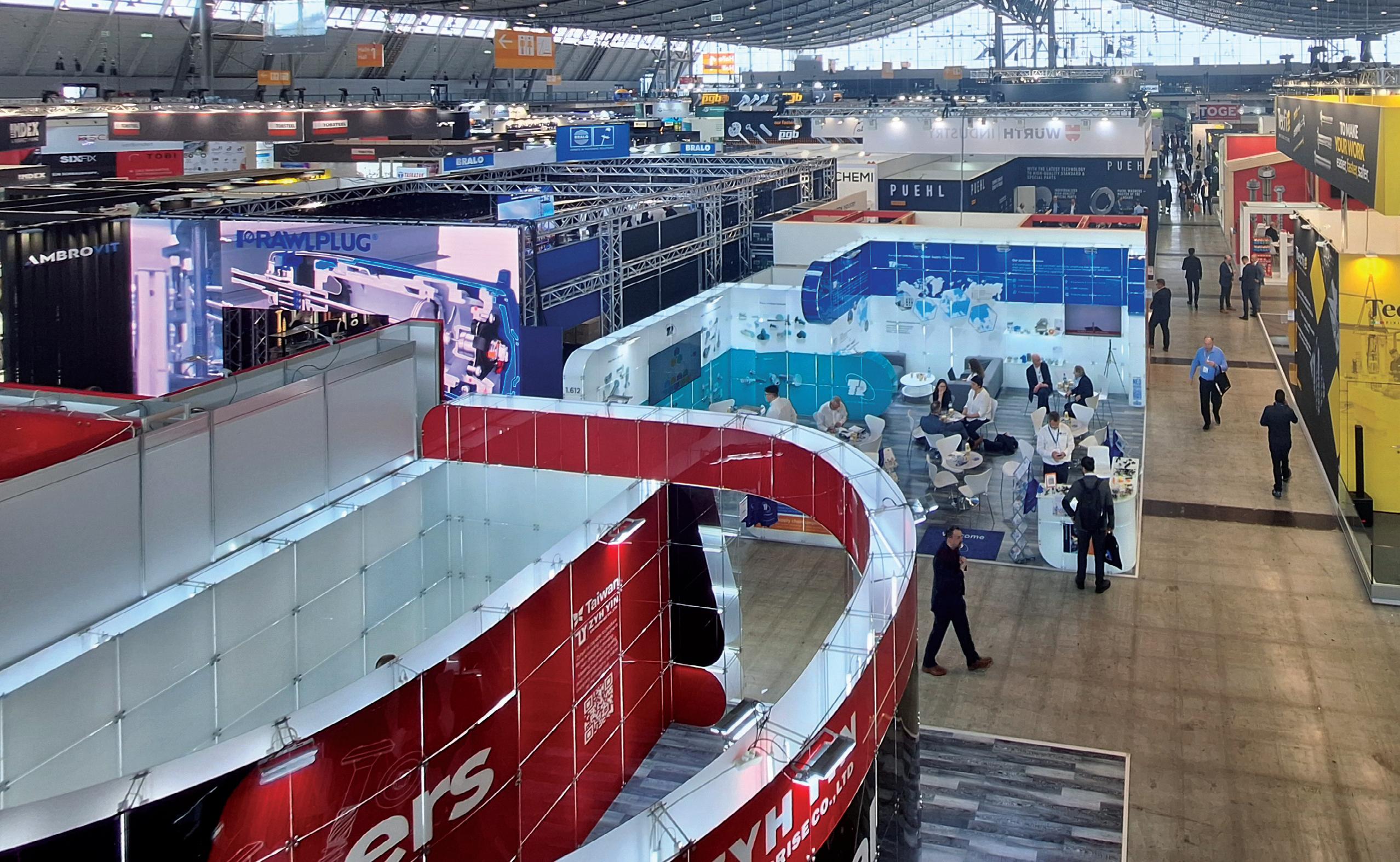

Despite the challenging economy, BAU 2025 was still fully booked with more than 180,000 visitors coming to the event, with the international share of exhibitors reaching a record high…

BAU 2025, running 1317 January 2025 welcomed more than 180,000 visitors at Trade Fair Centre Messe München. With 2,230 exhibitors from 58 countries, the event’s international participation was at an alltime high— 52% of exhibitors coming from outside Germany.

BAU 2025 focused on the key topics of “resilient, climatefriendly construction”, “transformations city/countryside/ urban district”, “resource efficiency”, “modular, serial, productive” and “costeffective construction”.

From modular and serial construction techniques to urban transformation strategies, the event provided a comprehensive look at the future of the built environment. The surge in international engagement was evident not only on the exhibitor side but also among visitors, with 44% coming from outside Germany. Key markets such as Austria, Italy, Turkey and China were particularly well represented, reflecting the trade fair’s expanding influence.

Exhibitors and attendees alike praised the event’s quality and scope, with a Gelszus market research survey revealing that 95% of exhibitors rated BAU 2025 as good to excellent. The internationality of visitors and the fair’s ability to foster highcalibre industry connections were also highlighted as key strengths. As the industry moves forward, the momentum generated at BAU 2025 will undoubtedly shape construction trends in the years to come.

The next edition of BAU is set to take place in Munich from 1115 January 2027, while digitalBAU, focusing on construction software solutions, will be held in Cologne over 2426 March 2026.

Torque Magazine spoke with several companies after the event to explore their upcoming plans and initiatives while assessing their outlook on the market. The featured companies are listed below in alphabetical order…

How was the show for you and your company?

We have gained new contacts who were interested in our products. We were pleasantly surprised by the international nature of the trade fair.

What products or services were you showcasing?

The focus of the products we presented was in the field of automation technology. It is mainly about processing screws semiautomatically or fully automatically.

What was the view on the market from the show? Were visitors buoyant about the market prospects in 2025?

The feedback from visitors about the current economic situation was varied, differing from country to country and across different industries. Overall, we would say that the outlook is slightly optimistic.

Any other thoughts to share?

This year, despite the significant costs for a small company, we are exhibiting at three trade fairs: BAU in Munich, Fastener Fair Global in Stuttgart and LIGNA in Hanover. We aim to introduce new automation technology systems for the fastener industry. Additionally, these events provide us with valuable opportunities to gauge the current market sentiment through numerous conversations and to swiftly respond to emerging trends.

www.adunox.com

How was the show for you and your company?

BAU 2025 in Munich was an outstanding platform for BECK to engage professionals in the construction industry, showcase our latest innovations and strengthen our position as a leading provider of fastening solutions. The energy at our stand was fantastic, and the FASCO® INMOTION Zone by BECK attracted significant attention, offering visitors the chance to experience the superior performance of our FASCO INMOTION handguided sled firsthand. The trade fair surpassed our expectations in terms of visitor engagement and meaningful discussions with partners and key players in the construction industry.

We also showcased a range of officially ETA codeapproved wall systems developed by our industry partners – enabled by our LIGNOLOC® wooden nail systems. After all, these innovative fasteners are the backbone of these solid wood wall constructions.

Our visitors were truly impressed with the extent to which LIGNOLOC® has already become an integral part of modern building practices. These wooden nails by BECK stand out in fully metal and gluefree wall and ceiling systems, making them ideal for multistorey and nonresidential buildings such as kindergartens, senior residences and more.

What products or services were you showcasing?

We showcased several innovations, including the FASCO INMOTION handguided sled, an entrylevel solution for series production. This versatile system, also available with a Pogo Stick in various lengths, provides ergonomic handling and excellent efficiency. It serves as the base for either LIGNOLOC® pneumatic wooden nailers or handheld tools for SCRAIL® nail screw fasteners by BECK, making it ideal for a wide range of applications. Visitors were also interested in testing our FASCO INMOTION system in combination with these specialised

fastening technologies. Moreover, we put a spotlight on our latest innovations: SCRAIL® CHIPBOARD nail screw fasteners, which can be flexibly readjusted to correct even warped wood. These are ideal for temporary applications, in particular for softwood and woodbased materials.

With our new LIGNOLOC® F33 system, equipped with our innovative wooden nail with stepped shaft, we offer a powerful duo ideal for delicate tasks in interior design, furniture and kitchen construction, as well as store fitting and stage construction. The perfect solution for joiners and carpenters seeking sustainability, precision and maximum efficiency.

Another highlight was our ET&F® line for lightweight metal construction which makes attaching metal as easy as wood, with highstrength steel nails featuring a ballistic tip that penetrate even the toughest surfaces.

Additionally, we presented various wall assembly elements, such as LCLT (LIGNOLOC® CrossLaminated Timber) and NLT (NailLaminated Timber), highlighting the ecofriendly advantages of our innovative wooden nail systems for a variety of timber construction projects.

What was the view on the market from the show? Were visitors buoyant about the market prospects in 2025?

The sentiment at the trade fair was positive, with visitors showing interest in the future development of the construction industry and the growing demand for sustainable and efficient building solutions. Many attendees were interested in technologies that contribute to ecofriendly construction, such as our LIGNOLOC® wooden nail system, which supports circular economy principles by helping reduce CO₂ emissions by 66% compared to traditional fastening methods.

www.beck-fastening.com

How was the show for you and your company?

The show was a great success for us and our company. We were particularly pleased with the positive feedback we received from customers from many different countries, highlighting the international appeal and value of our products and services. Additionally, we had the opportunity to engage in numerous interesting discussions that provided us with fresh perspectives and valuable insights. The most exciting aspect, however, was the promising new contacts we established, which hold great potential for future partnerships and collaborations.

What products or services were you showcasing?

At the show, we showcased a wide range of our fixing solutions, highlighting their versatility and reliability. These included direct impact fixings, which provide secure and efficient installation, as well as specialised insulation fixings designed for thermal and acoustic applications. We also presented our innovative windows and frame fixings, which ensure stability and durability for vari

ous construction projects. Additionally, our range of concrete screws demonstrated exceptional strength and precision, catering to demanding applications in masonry and concrete environments. This comprehensive portfolio reflects our commitment to delivering highquality solutions for diverse customer needs.

What was the view on the market from the show? Were visitors buoyant about market prospects in 2025?

The market outlook presented during the show was cautiously optimistic. Despite the challenging economic situation in some major European countries, there was a consistent sense of resilience within the industry. Visitors expressed confidence in the steady emergence of new projects, which continue to drive activity and opportunities across various sectors. This positive sentiment suggests that, even in uncertain times, the market remains dynamic and adaptable, with promising prospects for 2025 and beyond.

www.celo.com

How was the show for you and your company?

BAU 2025 in Munich once again attracted many visitors and exhibitors to discuss current trends and futureoriented solutions. We used the show to showcase our range and new products.

In addition to focusing on our products, we also used the show to give our visitors a pleasant and varied time. We created an inviting atmosphere with small activities such as games, competitions and interactive test runs on our press. These activities not only provided entertainment but also allowed visitors to familiarise themselves with our products in a fun and practical way. In this way, we were not only able to communicate technical topics but also to deepen personal contacts and create positive experiences that will be remembered.

What products or services were you showcasing?

A highlight of the company’s stand was the display model of the Structus load transfer system, a new product developed specifically for the construction of multistorey CLT buildings. Manufactured from galvanised S355 structural steel, the Structus load transfer system provides a seamless connection of timber posts between slabs in multistorey CLT buildings. It offers an efficient solution for the construction of pointsupported slab systems, particularly in highrise and other largescale projects. A key feature of the Structus system is the design of the connectors, which interlock through the slab to provide a strong connection between the columns.

The post extension is versatile and supports both postandbeam and postandbeam constructions. The main function is

to provide a continuous vertical load path between successive timber columns to ensure that loads are efficiently transferred through the building structure. Structus meets EC5 standards and is designed for strength, precision and efficiency — paving the way for more sustainable and innovative timber construction. The post connector is available in a number of versions.

What was the view on the market from the show? Were visitors buoyant about the market prospects in 2025?

Visitors’ assessment of the current state of the construction industry was largely neutral to negative. The newbuild sector, in particular, came in for criticism, with many describing it as very problematic. Rising construction costs, high interest rates and uncertain economic conditions are weighing heavily on the sector. At the same time, many are hopeful that the elections in Germany could bring a positive turnaround.

Political measures are expected to strengthen the economy as a whole and revive the construction industry. Despite the challenges, the construction industry remains a key sector of the economy, with opportunities such as the focus on sustainable and climatefriendly construction. However, there are clear regional differences in construction activity, strongly influenced by the economic environment and local conditions. The mix of challenges and opportunities makes the future of the construction industry both exciting and critical.

www.eurotec.team

At BAU 2025, fischer not only exhibited its latest fastening solutions but also created an experience for visitors. Spanning 370 m², fischer’s stand became a hub of activity, drawing in professionals eager to explore the future of fastening technology.

Central to fischer’s presence was its interactive approach. A 45 m² show stage demonstrated the company’s innovations with live demonstrations, expert talks and competitions. The spotlight was on the BauBot, fischer’s autonomous construction robot, which encompasses precision drilling capabilities. Hosted by TV presenter Jens Pflüger and fischer Key Account Manager Uwe Moser, the BauBot demonstrations illustrated the potential of automation in streamlining construction workflows. Meanwhile, tradespeople took centre stage in fastening challenges, racing against the clock to complete tasks using fischer products—an energetic showcase of skill and innovation.

The company’s product testing zone also provided opportunities to visitors to explore the latest advancements in fixings and fastening solutions. Visitors tested highperformance anchors, screws and setting tools designed for a range of building materials, including concrete, steel and wood. It also showcased the gasactuated FGW 90F nailer, as well as the batterypowered FXC 85 and gasactuated FGC 100—both

designed to enhance efficiency in construction fastening. Additionally, the company introduced multiple solutions designed to extend the lifespan of reinforced concrete structures. Carbon fiberreinforced polymer (CFRP) laminates and fabrics were among the key innovations, offering a lightweight yet highly durable method for strengthening existing buildings and infrastructure.

Complementing these were new concrete repair mortars, concrete topping solutions for loadbearing reinforcement, and advanced injection systems for retrofitting structural connections. Notably, the FCCB bridge cap anchor—a fastening solution specifically developed for bridge renovation— drew significant interest from industry professionals.

Reflecting on fischer’s presence at BAU 2025, Michael Geiszbühl, Managing Director of fischer Deutschland Vertriebs GmbH, said: “The personal interactions, the exchange of ideas, and the opportunity to showcase our innovations in a dynamic way have been invaluable. We’re taking a wealth of insights with us as we continue working towards new solutions for the industry.”

www.fischer.group

How was the show for you and your company?

BAU 2025 was the most important event in our event calendar. In addition to the impressive size and visitor numbers, we particularly value the quality of the contacts and discussions with experts from the trades, planning and retail sectors. Our high expectations were exceeded again this year. We were not only able to present our product highlights but also take away valuable feedback and new ideas that we will evaluate and implement after the trade fair. Direct feedback from professionals within the industry helps us tailor our range even more precisely to the needs of our customers and find out where we can create additional benefits.

What products or services were you showcasing?

In our presentation, we focused on our range of products for structural timber construction. We showed the WS selfdrilling rod dowel together with the pneumatic setting tool. The interest in this solution, which is only available from HECO in combina

How was the show for you and your company?

The BAU show was a great success for MKT. The total number of visitors may have declined for the show, but not for us. We definitely had more visitors at our stand than last time in 2023. Nothing can replace the direct contact to the customer. They are curious about new products and solutions, and we want to learn about the latest developments in the application. Old business ties are renewed, and new ones knotted. We are looking forward to the next BAU in 2027 and hope that we can rent a bigger space then, as it was occasionally very crowded.

What products/services were you showcasing?

We showed our complete range of mechanical and chemical anchors, focusing on concrete applications. In addition, we highlighted some special applications, like installations in steel fibrereinforced concrete, waterproofed coatings and dynamic applications. Furthermore, we demonstrated our allnew MKT Anchor Design software, which attracted a lot of attention from professional visitors.

How was the show for you and your company?

It was very exciting for us to have a stand there for the first time—we usually exhibit at Fastener Fair Global in Stuttgart and the International Hardware Fair in Cologne. However, it was a great experience for us to be part of such a great show and to learn more about the next time we will be exhibiting there.

What products or services were you showcasing?

We were mostly exhibiting our mechanical anchors such as through bolt anchors, our new range of Option 1 concrete bolts that will come to the market this year, dropinanchors, our ceiling anchors, but also our gasnailer & nails for concrete and steel, our powder actuated tool LV500M & pins as well as some of our chemical resins and insulation anchors.

What was the view on the market from the show? Were visitors buoyant about the market prospects in 2025? Well, the view on the market and the market prospects depends on the country. Some people were talking about a decline in busi

tion with the setting tool, was outstanding. In addition, product highlights such as HECOTOPIXplus and MULTIMONTI were, of course, topics at the stand. For planners, we were able to show exciting offers with design manuals and design software.

What was the view on the market from the show? Were visitors buoyant about the market prospects in 2025?

The market outlook for 2025 varies depending on the market and trade. In addition to economic challenges, political uncertainties are also leading to rather subdued expectations among many market participants. Carpenters are positive about the outlook. Despite all the difficulties, the industry is starting the year with wellfilled order books. Overall, we hope that the noticeable trend towards timber construction throughout Europe will have a positive impact on HECO.

www.heco-schrauben.de

What was the view on the market from the show? Were visitors buoyant about the market prospects in 2025? The sentiment prevalent in the German construction industry is currently a bit overshadowed by the depression in residential construction. While MKT managed to compensate for the slowdown in this field by expanding into commercial and infrastructure construction, you could feel that the sluggish market in residential buildings is worrying many industry peers and customers. However, when you look at other international markets, the situation is much more positive.

Any other thoughts to share?

From an organisational perspective, many visitors complained that they spotted our stand only after some searching, as there were no detailed floor plans at hand, let alone a fair app. We expect an improvement from the organisers for the BAU 2027 and have already received some positive feedback.

www.mkt.de

ness in the construction industry as the construction of new buildings has declined mainly in countries like Austria, Germany and the Netherlands, but not in all areas of those countries. The companies mainly focus on renovating old buildings there. In some other regions, there is great hope for recovery in the construction industry, and more investments are being made again. All in all, the mood was very mixed, but there was hope and a great belief for improvements. People are curious and love learning about new technologies. Some people claim that the year 2025 will be very crucial in determining how the economy will develop in all countries.

Any other thoughts to share?

We’re really looking forward to being part of the BAU fair again in two years. Maybe we’ll have two stands then – one for our mechanical anchors, lightweight anchors, chemical anchors, insulation anchors and power tools, which will hopefully be ready by then.

www.trutekfasteners.eu

The recent iteration of the ever-reliable Fastener Fair Global nee Stuttgart closed. But what did we learn after expending all that shoe leather? Torque's Editor provides his take...

Brits, particularly those exhibiting at the show, may well have kept one eye on the unfolding chaos at Heathrow, where flights were cancelled five days before the show kicked off, and presumably even less days before setting up time.

At least one plucky UK exhibitor hired their own coach to drive the circa 800 miles from the UK’s West Midlands to Stuttgart to mitigate prolonged Heathrow difficulties, exhibiting some true ‘cando’ spirit.

The European Fastener Distributor Association (EFDA) met at the show to discuss the current state of Carbon Border Adjustment Mechanism (CBAM) legislation and the signs that the European Commission were moving (again) on the detail. But EFDA was not the only one discussing CBAM in Stuttgart, with the topic cropping up in pretty much every discussion Torque Magazine had, with the few exceptions being conversations with café staff. Although there’s a chance that even they were pretty well briefed on the topic by the time the show ended.

Also one to add to your trend chart was the growing phenomenon of fastener companies employing or recruiting

staff to deal primarily with sustainability related matters.

The lack of signs of growth in the general economy was another area under discussion, as it is no doubt in most other industries right now.

...green shoots from Germany?

But there were some cautious exciting signs on the horizon, not least from Germany’s government indicating the loosening of fiscal rules and the potential for more investment. There was considerable angst over what that investment will look like, but it was a positive talking point, nonetheless.

Tariffs

Trump’s latest round of tariffs affecting European businesses certainly sparked a few conversations – not least those announced during the show for Europeanmade automotives heading to America. All these weeks later and there’s still a lack of clarity on whether those tariffs will last. But Trump figured less highly than you might have expected. CBAM was a bigger talking point. And those that export or supply the USA were going to mitigate tariff issues in dealing with that nation in whatever way they could.

// While sustainability has been long on the agenda, we're just starting to see more major industry companies begin to recruit their own dedicated sustainability execs //

Innovation

The Route to Fastener Innovation collection was a tangible sign that the R&D departments of the fastener industry were continuing to toil away. And certainly there were also further new product launches that didn’t make their way into that neat showcase of new product.

Show business

And what about the show itself? Well, there was some anecdotal consensus that footfall might not have been quite as high level as in 2022 (though that was the first postlockdown show and therefore a unique outlier rather than indicative of a trend). But overall, from those we spoke to, exhibitors still seemed at least pretty happy with the show, the calibre of its visitors (yours truly excluded) and the allimportant decent leads that are hoped will turn into bona fide sales postshow.

The official stats revealed that around 11,000 trade visitors from 84 countries attended the show.

Trainers are in

Taking things on a more sartorial road than we usually cover in Torque Magazine , it seemed like good old fashioned common sense was prevailing when it comes to show footwear. While plenty were sticking with smart traditional and formal footwear, it seemed like there was a lot more trainers / sneakers even amongst the senior level execs. Maybe not quite the trend insight you were looking for, but one to bear in mind the next time you're heading for a show.

Before Fastener Fair Global kicked off, Optimas held its first awards ceremony in Stuttgart, celebrating the contribution of its valued supply partners…

Torque Magazine was kindly invited to attend Optimas OE Solutions inaugural Celebrating Excellence Awards, held for the first time at the stylish Movenpick Messe & Congress the evening before Fastener Fair Global – kickstarting the main event. With over 100 international attendees from 13 countries, this impressive networking evening was an opportunity for Optimas to show appreciation and thank their supply partners, whilst celebrating the outstanding contributions of those partners who have gone above and beyond.

The networking event featured an approachable and friendly team of Optimas representatives and senior leadership team members, with freeflowing drinks, food and a live singer performance.

Mike Tuffy, CEO of Optimas International, gave a speech to open the evening, welcoming attendees and highlighting how pleased and proud the Optimas International team was with high levels of service to customers, thanks to the help of all of its existing supply chain partners. Mike explained Optimas’ strategy plans up to 2028, focusing on how to move forward and look to grow business with its suppliers, whilst branching out into new territories and tapping into new opportunities.

// Our supply partners are at the heart of everything we do at Optimas, and this event was a fantastic opportunity to recognise their outstanding contributions. Their commitment to quality, innovation, and collaboration enables us to deliver exceptional service to our customers worldwide. As we look ahead at our growth strategy through to 2028 and beyond, we are excited to strengthen these partnerships, explore new opportunities, and continue driving mutual success //

Mike Tuffy, CEO Optimas International

Simon Wright, International Marketing Director, then proceeded to commence the awards with the outstanding contributions to supply chain partners. The first award to be announced was the ESG Champion Award – won by A Raymond who demonstrated leadership in sustainable practices, reducing environmental impact while enhancing efficiency.

This was followed on by Optimas’ Supply Partner Performance Award – with four winners recognised for their contributions – Net Civata, Fontana Gruppo, Ningbo Jinding Fastening Piece Co and Avdel Stanley Black & Decker. These recipients excelled in logistics, delivery performance, and costeffectiveness, enabling Optimas to provide outstanding service to their customers.

The Innovation Partner Award was then jointly won by both Boltun and Teconnex both of which demonstrated exceptional creativity and forwardthinking in their approach and introduced solutions that have significantly enhanced Optimas’ operations.

The Quality Excellence Award was also presented to two winners; AAM Neumayer and Vimi Fasteners Optimas’ customers depend on precision, reliability, and excellence in every component that is supplied. The Quality Excellence Award honoured these supply partners that consistently deliver outstanding product quality, meeting and exceeding industry standards.

Finally, the Supply Partner of the Year was crowned Ying Ming Industry. This accolade was reserved for a supply partner that consistently delivered superior products, outstanding service, and innovative solutions, making a significant impact on Optimas’ success.

This year’s winner demonstrated excellence in every aspect of their partnership with Optimas, setting new stan

dards in collaboration, efficiency, and innovation.

Simon thanked all suppliers for their dedication and expertise, while all attendees were also shown their appreciation by receiving their own individual ‘Valued Supply Partner’ awards to take away with them.

The Supply Partner Awards: Celebrating Excellence, are set to become an integral part of their event plans for Fastener Fair Global 2027. Planning has already started to elevate the event further and Optimas is excited to see how this grows.

optimas.com

// At Optimas, we believe that true success comes from strong, valued partnerships. Our supply partners play a crucial role in driving our growth, and this event was a testament to the trust, collaboration, and shared commitment that fuel our collective success. As we look to the future, we are excited to strengthen these partnerships, explore new opportunities, and grow together in an ever-evolving global market // Justin Parker,

VP Strategic Sourcing

Plastic fasteners offer multiple advantages including being lightweight and cost-effective in manufacturing. Volt Industrial Plastics rolls out new products to tap into opportunities in this sector…

USbased fastener manufacturer Volt Industrial Plastics has introduced more than 100 new products this year, further enhancing its offerings to customers.

The latest additions include hex jam nuts, machine hex, Phillips fillister, Phillips flat and pan, slotted fillister, slotted binding, slotted round and set, shoulder washers and special flat washers. These products are available on the Volt Industrial Plastics website.

Volt Industrial Plastics specialises in highquality plastic fasteners designed to outperform traditional metal alternatives. These fasteners help reduce weight and costs while improving durability and resistance.

According to the company, despite being lightweight, plastic fasteners are wellsuited to industries where reducing weight enhances performance, such as automotive and consumer electronics. While metal fasteners can add unnecessary bulk, plastic alternatives provide high tensile strength while remaining lightweight.

Moreover, plastic fasteners are corrosionresistant, offering a longlasting solution for outdoor applications, marine use and harsh industrial environments. In contrast, rust and corrosion are common issues with metal fasteners, particularly in humid or chemically aggressive conditions.

Plastic fasteners also provide a safe, nonconductive solution, making them ideal for applications where electrical conductivity is a concern. They are also nonmagnetic, making them suitable for sensitive electronic equipment and other environments where metal interference could be problematic.

Finally, plastic fasteners are more costeffective to produce and maintain than metal alternatives, Volt Industrial Plastics explains. They can also be customised in various colours to meet customer preferences, ensuring a perfect fit and aesthetic for any application.

www.voltplastics.com

// Volt Industrial Plastics specialises in high-quality plastic fasteners designed to outperform traditional metal alternatives //

NYLON + PLASTIC FIXINGS AND FASTENERS

BÄCKER has been a leading manufacturer of standardised plastic parts and operating elements for over 45 years. With a wide range of plastic screws, nuts, washers and other fasteners, the company supplies customers from a wide variety of sectors – from the mechanical engineering industry to electrical engineering and medical technology

BÄCKER consistently focuses on quality “Made in Germany” and combines decades of experience with stateoftheart production technology. The focus is on highprecision, durable and functional plastic parts made from highperformance polymers and engineering thermoplastics. The production of items with internal and external threads in particular requires absolute precision and expertise.

PLASTIC INSTEAD OF METAL –THE ADVANTAGES AT A GLANCE

Plastic fasteners are increasingly being used in many industries as an alternative to conventional metal screws. The reason for this lies in their numerous technical and economic advantages:

Corrosion resistance

Metal screws tend to corrode, particularly in damp or chemically aggressive environments. Plastic screws, on the other hand, are inherently rustproof and offer a durable fastening solution ideal for use in the chemical, food and medical technology industries.

Low weight

Plastic screws are up to 50% lighter than their metal coun

terparts. This is particularly advantageous in the aerospace, automotive and mechanical engineering industries, where weight reduction plays a crucial role.

Electrical insulation

While metal screws are conductive, plastic screws offer excel

lent electrical insulation. This makes them the perfect choice for applications in electrical engineering and electronics, where they prevent short circuits and electrical interference.

// The demand for innovative plastic solutions is constantly growing //

Many plastics are resistant to aggressive chemicals, oils and solvents, making them the ideal choice for industrial applications in the chemical industry and plant engineering.

Cost-effectiveness

Thanks to the lower material consumption and efficient manufacturing process, plastic fasteners are often more costeffective than comparable metal parts – without compromising on stability and functionality.

The demand for innovative plastic solutions is constantly growing as companies increasingly opt for lighter, more durable and more sustainable alternatives to metal. With its expertise, broad product range and customeroriented development, BÄCKER is ideally positioned to serve this market with highquality plastic standard parts and operating elements.

Whether for mechanical engineering, medical technology, the automotive industry or the electronics sector the plastic fasteners from BÄCKER offer a highperformance, economical and sustainable alternative to metal fasteners in numerous applications.

www.baecker.eu

Nyfast taps into opportunities in the nylon fastener sector as the industry lacks capacity to stock these products

In an industry where metal components dominate, Nyfast has established itself as the UK’s leading specialist in nylon fasteners. As demand for these components grows, the company continues to support both metal fastener distributors and end users, particularly in sectors such as electronics and lighting.

Many distributors focus primarily on metal fasteners, often lacking the capacity or expertise to stock nylon alternatives. Nyfast fills this gap, providing a comprehensive range of nylon fasteners that enable metal fastener suppliers to meet niche but essential industry needs.

“Many metal fastener distributors struggle to source nylon components at competitive prices because they are not their core focus,” said Jake Phillips, Sales Director at Nyfast.

“That’s where we come in. We maintain a wellstocked inventory, ensuring that our distributor partners can access what they need. By specialising in nylon fasteners, we can offer consistent quality and nextday service on 99% of our standard range,” he added.

Beyond distributors, Nyfast also works closely with end users, particularly in the electronics and lighting industries, where nylon fasteners are widely used.

“In electronics, nylon fasteners play a key role in assembling printed circuit boards (PCBs) by providing electrical insulation and reducing the risk of short circuits,” Phillips explained. “In lighting, they offer durability, heat resistance and insulation properties for securing fixtures.”

In electronics, nylon fasteners are found in control panel units, PCB box builds, and other applications where insulation and stability are essential. Common products include nylon spacers, nuts, screws, PCB supports and standoff spacers.

For lighting applications, nylon fasteners are valued for their heat resistance and UV stability, making them suitable for both indoor and outdoor use. Frequently used products include nylon spacers, snap rivets, washers, grub screws and standoff spacers.

Nyfast’s focus on market research and stock management has reinforced its position as a key supplier in this niche. As demand for specialised nylon fasteners continues to grow, the company remains committed to providing reliable solutions for distributors and end users alike.

www.nyfast.com

The Snap Rivets are designed for quick installation

// Nyfast offers a comprehensive range of fir tree clips, including removable, non-removable, standard and custom sizes //

Available in black PA66, the fir tree clips clips are designed for durability and secure panel fixing

Nyfast is the UK’s go-to supplier for Nylon Fasteners, offering unmatched support to both metal fastener distributors and end users. Specialising exclusively in nylon components, Nyfast fills the gaps in the supply chain by maintaining a healthy inventory to meet the growing demand for nylon fasteners—ensuring distributors can rely on them for those essential, smaller nylon requirements that complement their metal offerings.

Nyfast is also a key supplier for industries like electronics and lighting, where nylon fasteners are crucial for product safety and performance. Their range of products includes Nylon Spacers, Nylon Nuts, Nylon Screws, Snap Rivets,

Nylon Washers, Nylon Grub Screws, Nylon PCB Supports, and Nylon Stand-Off Spacers—each designed to meet the unique needs of these sectors. In electronics, nylon fasteners are essential for the assembly of PCBs, providing electrical insulation, while in the lighting industry, their durability and heat resistance make them perfect for securing fixtures.

Nyfast’s dedication to quality, service, and stock availability makes them a reliable partner for both distributors and end users, reinforcing their reputation as the UK’s leading Nylon Fastener specialist. Trust Nyfast for all your nylon fastener needs, and experience the difference of working with a true expert.

Fastener and fixing manufacturer CELO has launched a new insulation plug that can be fastened to mineral wool and Heraklith boards.

The new product, IPL 90, is designed for timesaving installation. Its sharp drilling tip eliminates the need for predrilling and reliably penetrates hard ETICS plaster up to 7 mm thick.

With a 90 mm length, it provides secure anchoring in mineral wool boards, offering better hold than shorter plug variants. Its innovative thread geometry and slim core allow for easy insertion through prepunched holes in sheet metal profiles, ensuring a smooth and efficient installation process.

The fastener is also energyefficient, as it enables direct fastening in insulation without creating thermal bridges, helping to maintain insulation performance. Featuring a 25 mm head diameter and a TX40 drive, it is ideally suited for this type of application, ensuring a strong and stable hold.

Made from highquality nylon, the IPL 90 is resistant to

ageing and weather conditions, making it suitable for longterm outdoor use. Additionally, its semitransparent colour gives it a discreet appearance, and it can be painted to match the surrounding surface for a seamless finish.

Moreover, the IPL 90 is designed to easily handle two particularly challenging fastening applications.

Firstly, it is ideal for securing 10 mm or 12 mm thick Heraklith panels to ceiling panels made of mineral wool or EPS, providing a reliable and stable hold.

Secondly, it is wellsuited for attaching sheet metal profiles with 18 mm clearance holes to ceiling panels composed of mineral wool or expanded polystyrene (EPS), ensuring a secure and precise installation.

Lighting systems, motion sensors and detectors, letterboxes, clothes hooks and signs are ideal for IPL 90 applications.

www.celofixings.com

ad-tm-half-horizontal-spring-pins-vendor-of-choice-issue094-mar-apr2025-o indd 1

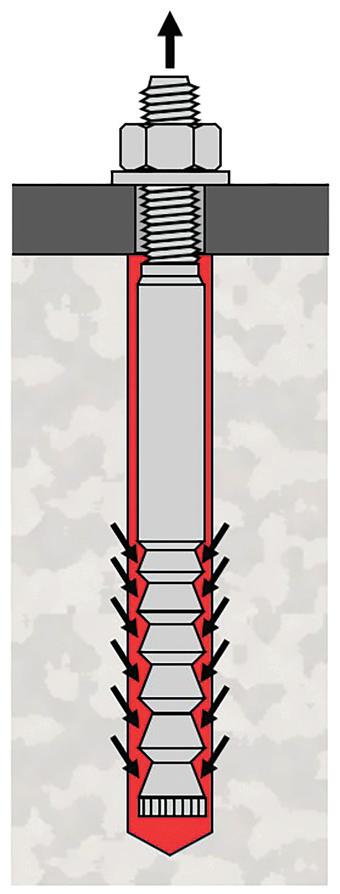

For critical concrete applications, bonded expansion anchors represent the pinnacle of anchor technology, offering a highend solution for demanding conditions. Marrying the strengths of mechanical and chemical anchors, these bonded expansion anchors deliver exceptional load transfer capabilities, even under extreme conditions such as seismic activity, dynamic loading, and structural fatigue. Their unrivalled performance makes them the goto choice for critical infrastructure projects, including nuclear power facilities, where uncompromising safety is nonnegotiable.

The MKT VMZ is a bonded expansion anchor that pushes the boundaries of performance and reliability. Assessed to EAD 330499 for both static and seismic loads—including C1 and C2 earthquake design categories (ETA04/0092)—the VMZ goes beyond the standard. It is also tested for dynamic applications under EAD 330250, meeting stringent fatigue design requirements (ETA17/0194). Additional test reports confirm its resistance to fire and impact loads, ensuring confidence in the most demanding environments.

While many anchors meet seismic C2 qualifications for cracked concrete up to 0.8mm, the MKT VMZ is one of the few approved for crack widths as large as 1.5mm (DIBt Z21.31965). This makes it particularly suited for installations in nuclear facilities, where anchor systems are designed for extreme structural damage from explosions or aircraft impact. Independent testing and evaluation of the adhesive proved also its resistance to radiation. The MKT VMZ is available in material grades zincplated steel, A4 stainless steel, and high corrosion resistant (HCR) steel.

Due to their complex manufacturing process, bonded expansion anchors are not as lowpriced as massproduced mechanical or chemical alternatives. However, their exceptional performance under extreme conditions enables anchor solutions otherwise impossible, making them the preferred choice for critical applications.

// The MKT VMZ is one of the few concrete anchors approved for crack widths as large as 1.5mm //

The 1990s marked a turning point in anchor technology, as the industry reached new levels of sophistication. It was during this period that bonded expansion anchors emerged, coinciding with the introduction of European Technical Assessments (ETAs)—then known as European Technical Approvals—at the end of the decade. Early qualification guidelines laid the foundation for today's European Assessment Documents (EADs), while advances in design methodology ultimately led to EN 19924, the European design standard within the Eurocode family.

While the market offers a range of mechanical anchors, including expansion anchors, and various chemical anchors, bonded expansion anchors are unique. They feature a conical anchor rod embedded within a hardened adhesive matrix, a design that optimises both load transfer and structural integrity.

The conical anchor rod is often imitated but its functionality is rarely understood. The adhesive must bond securely to the concrete surface, while the bond between the rod and adhesive deliberately breaks when the rod is torqued at the end of the installation process. This allows the cured adhesive to act similarly to the expansion elements of a mechanical anchor, enabling the bonded expansion anchor to respond to increasing load demands or opening cracks. This mechanism relies on both a smooth steel rod surface and a highperformance adhesive. Recognising its unique requirements, EAD 330499 includes a dedicated chapter distinguishing bonded expansion anchors from standard bonded anchors.

www.mkt.de

MKT is a manufacturer and one of the global market leaders for high quality anchors used in concrete structures. We offer the complete range of mechanical and chemical anchors for professional applications.

With decades of expertise in HT, Owlett-Jaton conducts rigorous testing to ensure the quality of its vast selection of products, now available packaged for the modern retail environment…

OwlettJaton is a leading force in the UK fastener and fixing industry, renowned for its extensive product range. The company is also a major distributor of hightensile (HT) DIN 931 bolts, DIN 933 setscrews and ISO 4017 assembled bolting.

With over 1,600 product lines manufactured to the relevant standards in grades 8.8, 10.9, and 12.9, OwlettJaton offers an impressive selection in a variety of finishes. The company imports and distributes approximately 4,500 tonnes of HT fasteners annually – equivalent to 375 tonnes per month –generating sales worth £6.8 million.

Beyond these figures, OwlettJaton supplies bolts and setscrews in A2 and A4 stainless steel, along with other HT products such as square square holding down bolts.

Quality is a top priority. The company follows a rigorous product testing process upon arrival, with its dedicated Quality Assurance department conducting routine dimensional checks against national and international standards. Around 60% of inbound fasteners are inspected—an impressive feat considering the company receives approximately 100 tonnes of stock every day.

OwlettJaton has been supplying HT fasteners since James and Tatton Ltd (Jaton) was established in 1951. The company remains a key player in the industry after 74 years of establishment. While HT products were once sold in plain brown boxes with basic labels, the market has evolved. Many merchants now favour a retailfriendly approach, and OwlettJaton has adapted by introducing colourcoded labels featuring line drawings and batch traceability, ensuring their products are ready for modern retail environments.

www.owlett-jaton.com

Owlett-Jaton inspects about 60% of inbound fasteners

The fischer Group of Companies once again launched the Expert Forum with multiple topics covered, including AI and digitalisation and timber system construction, to name a few

The fischer Group of Companies launched its 11th Expert Forum from 6 to 7 February at its headquarters in Waldachtal. Around 100 guests discussed key topics in fastening technology and the construction industry, focusing on digitalisation, automation, AI and Building Information Modelling (BIM).

AI expert Dr. Feiyu Xu outlined how AI can enhance products, processes and promotion in construction.

Following the keynote, Professor Reinhard Wimmer from Karlsruhe University discussed BIM's role in digitalising and optimising construction processes. This method was introduced in Germany in 2015 with the "digital planning and construction stepbystep plan" and is mandatory for infrastructure projects above a certain volume.