Mould Couplings

Quick connect couplings for tempering and cooling.

Quick connect couplings for tempering and cooling.

Wearepleasedtoofferyouacompleterangeofquickconnect couplingsystemsforthefeldoftemperingandcooling,under theParkerumbrella.Withthisextensiverange,weareableto offeryouthebroadestrangeonthemarketandwearetheonly supplierofallthreeprincipalEuropeanprofles–International,EuropeanandFrench.Oursystemsareavailablebothas individualproductsandascomplete,ready-madeunitswithany desiredhoselengthsandqualities.Naturally,ourspecialistadvisersarealsoavailableatanytimetoprovidepersonaladvice andassistanceifeveryoucannotimmediatelyfndwhatyouare lookingfororifyouhaveaparticularlyspecialproblemtosolve.

Important Notes:

● Pleasenotethatthetechnicaldata,specifcations anddrawingsinthecataloguearenotbinding.This informationissubjecttochangewithoutnoticeinthe interestofimprovement.

● Wereservetherighttomaketechnicalmodifcations forthepurposesofimprovement.

● February2018:Withtheactualcataloguetheolder versionsarenolongervalid.

● Theinterchangeabilityisguaranteedundertheassumptionthatthemanufactureroftherelevantproducthas notchangedanyfunctionalpartinthemeantime.

● Youwillfndimportantsafetyinstructionsonpages 8and9.

INTERNATIONAL

InternationalProgram: Series86/87/88

EUROPEAN

EuropeanProgram: Series10/11/12 Series10/11withsafetylock

FRENCH

FrenchProgram: Series608/612

FRENCHMATIC I

FrenchmaticProgram: Series6006/6009/6012/6016

FRENCHMATIC II

FrenchmaticProgram: SeriesNSI/NSP

MULTI-MATIC

from page 10

from page 18

from page 30

from page 34

from page 38

from page 42

Accessories

from page 46

Hoses

from page 50

Theproductsmarkedwiththissystemare fttedwiththeSafe-Locktechnology developedbyourdesigners.

Usingaspecialmechanism,theSafe-Lock technologyreliablypreventsaccidentaluncouplingofthesystemsunderpressure.As thenormallycontiguoustemperaturesofthe mediausedarebetween90°Cand170°C, accidentsofthisnaturecanresultinserious burns.TheonlyalternativestotheSafe-Lock systemsaredoubleshut-offcouplings, withwhich,however,thecomplexvalve technologyhasastrongnegativeimpact onthefowvalues.

Safe-LockCouplingSystems

>3bar Internationalranges systemsandarethereforealsoeasyto retroftatalaterdate

2006/42/EG

INTERNATIONAL

Profleprovenfordecadesinthefeldofplastic injectiontechnologyfortwo-handedcoupling systemswithgreatmarketpenetration.

DevelopmentoftheInternationalprofle.The couplingsystemswiththeEuropeanprofle standoutfortheircomfortablesingle-handed operationandareliableO-ringseal.

Availableonlyasastraight-throughcoupling withoutvalve.O-ringsareveryeasytoreplace. Moreover,simplecolourcodingispossiblehere, bymeansofColourClip.

Thisrangeofcouplingswasconstructedwith valvesasanalternativetotheFrenchprofles. AllfournominaldiametersinourFrenchmaticI rangeareavailablewithsingleanddoubleshut-off.

WesupplyourFrenchmaticIIcouplingsystemas adry-breakversion.Therangestandsoutforits single-handedoperationandminimumleakage whendisconnecting.

Withimmediateeffect,ourcoreseriesare availablewithanewsafetylock. Thesafetylockoffersprotectionfromaccidentaluncouplingandthusensuresmaximum occupationalsafety,notonlyinthehightemperaturerange.

Thisvariantisclearlydistinguishedfromour patentedSafe-locksystem,asthereisnoneed todepressurisethesystemforuncoupling. Endusershavethechoiceofwhichsafety principleisbestsuitedtotheirapplication.

Advantagesofthesafetylock:

doubleshut-offversion

ratureO-ringsuptoconstanttemperatureof 200°C

Withournewgenerationofhigh-temperature couplings,wetakeadifferentapproachfrom thecommonsolutionsonthemarketanduse

Theadvantageofthishigh-qualitycompound liesinthetemperatureresistanceupto200°C forcoolingmediasuchaswater/glycolaswell asheattransferoil.

Previoussolutionsareoftenonlyacompromise,astheydisplaydifferenttemperature resistancesdependingonthecoolingmedium used.

AllseriesavailablearemarkedwiththeHTlogoin thecatalogue.

Advantagesofthehightemperatureseal:

perature200°Cforwater/glycolandheattransfer oil

tinction

DANGER: failureorimproperselectionorimproperuseofquick connectcouplingsorrelatedaccessoriescancausedeath,personal injuryandpropertydamage.Possibleconsequencesoffailureor

improperselectionorimproperuseofquickconnectcouplings orrelatedaccessoriesincludebutarenotlimitedto:

toxic,orotherwiseinjurious liquidspraying thefollowinginstructions.

tobeheldinpositionormovedbytheconveyedfuid

1.1 Scope: this catalogue provides instructions for selecting and using (including installing connecting, disconnecting, and maintaining) quick connect couplings and related accessories (including caps, plugs, hoses, blow guns). This safety instruction is a supplement to and is to be used with the specific Parker publications for the specific quick connect couplings and related accessories that are being considered for use.

1.2 Fail-Safe: quick connect couplings or the hose they are attached to can fail without warning for many reasons. Design all systems and equipment in a fail-safe mode, so that failure of the quick connect coupling or hose will not endanger persons or property.

1.3 Distribution: provide a copy of this safety guide to each person who is responsible for selecting or using quick connect coupling products. Do not select or use quick connect couplings without thoroughly reading and understanding this safety guide as well as the specific Parker publications for the products considered or selected.

1.4 User responsibility: due to the wide variety of operating conditions and uses for quick connect couplings, Parker RectusTema and its distributors do not represent or warrant that any particular coupling system is suitable for any specific end use system. This safety instructions do not analyse all technical parameters that must be considered in selecting a product. The user, through its own analysis and testing, is solely responsible for:

1.5 Additional questions: call the appropriate Parker customer service department if you have any questions or require any additional information. For the telephone numbers of the appropriate customer service department, see the Parker publication for the product being considered or used.

2.1 Pressure: quick connect couplings selection must be made so that the published rated pressure of the coupling is equal to or greater than the Do not confuse burst pressure or other pressure values with rated pressure and do not use burst pressure or other pressure values for this purpose.

2.2 Fluid compatibility: quick connect couplings selection must assure compatibility of the body and seal materials with the fluid media used. See the fluid compatibility chart.

2.3 Temperature: be certain that fluid and ambient temperatures, both steady and transient, do not exceed the limitations of the quick connect couplings. Use caution and hand protection when connecting or disconnecting quick connect couplings that are heated or cooled by the media they are conducting or by their environment.

2.4 Size:

other components of the system must be adequate to keep pressure losses to a minimum and avoid damage due to heat generation or excessive fluid velocity.

2.5 Pressurised connection or disconnection: if connecting or disconnecting under pressure is a requirement, use only quick connect couplings designed for that purpose. The rated operating pressure of a quick connect coupling may not be the pressure at which it may be safely connected or disconnected.

2.6 Environment: care must be taken to ensure that quick connect couplings are either compatible with or protected from the environment (that is, salt water, chemicals, and air pollutants can cause degradation and premature failure.

2.7 Locking means: ball locking quick connect couplings can unintentionally disconnect if they are dragged over obstructions on the end of a hose or if the sleeve is bumped or moved enough to cause disconnection. Sleeves designed with flanges to provide better gripping for oily or gloved hands are especially susceptible to accidental disconnection and should not be used where these conditions exist. Sleeve lock or union (threaded) sleeve designs should be considered where there is a potential for accidental uncoupling.

2.8 Mechanical loads: sidered include excessive tensile or side loads and vibration. Unusual applications may require special testing prior to quick connect couplings selection.

2.9 Specifications and standards: when selecting quick connect couplings, government, industry and Parker specifications must be reviewed and followed as applicable.

2.10 Vacuum: not all quick connect couplings are suitable or recommended for vacuum service. Quick connect couplings used for vacuum applications must be selected to ensure that the quick connect couplings will withstand the vacuum and pressure of the system.

2.11 Fire resistant fluids: some fire resistant fluids require seals other than the standard NBR (nitrile) used in many coupling systems.

2.12 Radiant heat: quick connect couplings can be heated to destruction or loss of sealing without contact by such nearby items as hot manifolds or molten metal. The same heat source may then initiate a fire. This can occur despite the presence of cool air around the quick connect couplings.

2.13 Welding and brazing: heating of plated parts, including quick connect couplings and port adapters, above 450 °F (232 °C) such as during

3.1 Pre-installation inspection: before installing a quick connect coupling, visually inspect it and check for correct style, body material, seal material, and catalogue number. Before final installation, coupling halves should be connected and disconnected with a sample of the mating half with which they will be used.

3.2 Quick connect coupling halves from other manufacturers: if a quick connect coupling assembly is made up of one Parker RectusTema half and one half from another manufacturer, the lowest pressure rating of the two halves should not be exceeded.

3.3 Fitting installation: use a thread sealant, when assembling taper pipe thread joints in quick connect couplings. Be sure the sealant is compatible with the system fluid or gas. To avoid system contamination, use a liquid or paste type sealant rather than a tape style. Use the flats provided to hold the quick connect coupling when installing fittings. Do not use pipe wrenches or a vice on other parts of the coupling to hold it when installing or a removing fittings as damage or loosening of threaded joints in the coupling assembly could result. Do not apply excessive torque to taper pipe threads because cracking or splitting of the female component can result.

3.4 Caps and plugs: use dust caps and plugs when quick connect couplings are not coupled to exclude dirt and contamination and to protect critical surfaces from damage.

3.5 Coupling location: locate quick connect couplings where they can be reached for connection or disconnection without exposing the operator to slipping, falling, getting sprayed or coming in contact with hot or moving parts.

3.6 Hose whips: use a hose whip (a short length of hose between the tool and the coupling half) instead of rigidly mounting a coupling half on hand tools or other devices. This reduces the potential for coupling damage if the tool is dropped and provides some isolation from mechanical vibration which could cause uncoupling.

4.1 Even with proper selection and installation, quick connect coupling life may be significantly reduced without a continuing maintenance program. Frequency should be determined by the severity of the application and risk potential. A maintenance program must be established and followed by the user and must include the following as a minimum:

4.2 Visual inspection of quick connect couplings: any of the following conditions require immediate shut down and replacement of the quick connect coupling:

4.3 Visual inspection all other:

4.4 Functional test: operate the system at maximum operating pressure and check for possible malfunctions and freedom from leaks.

4.5 Replacement intervals: specific replacement intervals must be considered based on previous service life, government or industry recommendations, or when failures could result in unacceptable downtime, damage or injury risk. See instruction 1.2 above.

Nominal Diameter 6/9/13

Technical Description

The 86, 87 and 88 Rectus Moldtite coupling series were especially developed for connecting coolant lines and injection moulds. Countersunk plugs can easily be connected and disconnected because of the extended sleeve. The angular connections prevent kinks from forming in the hose.

Advantages

Available in single shut-off, double shut-off, straightthrough couplings (with valve) are equipped with nickel plated sleeves for quick and accurate visual differentiation.

Working Temperature* -15°C up to +200°C (FKM) depending on the medium.

* For temperatures below -15°C and over +200°C and depending on the medium, other seal variants are available.

KF StraightThrough KA Single Shut-Off

Working Pressure**

15 bar

** maximum static working pressure with design factor 4 to 1.

Material

Coupling: Brass

Plug: Brass Seals: FKM

15 bar

KB Double Shut-Off

Coupling: Brass

Plug: Brass Seals: FKM

15 bar

Coupling: Brass Plug: Brass Seals: FKM

Flow diagrams

Pleaseconsideroursecurityadvicesonthepages8/9

Nominal Diameter 6/9/13

Technical Description

The 10, 11 and 12 Rectus Moldtite coupling series were especially developed for connecting coolant lines and injection moulds. These stand out for their convenient, single-handed operation and a reliable O-ring seal. Widely used in Europe.

Advantages

Available in single shut-off, double shut-off or straight-through versions also available with Safeequipped with nickel plated sleeves for quick and accurate visual differentiation. The angular connections prevent kinks from forming in the hose.

StraightThrough

Working Pressure**

15 bar

** maximum static working pressure with design factor 4 to 1.

Material

Coupling: Brass

Plug: Brass, Stainless Steel Seals: FKM

15 bar

Working Temperature* -15°C up to +200°C (FKM) depending on the medium.

* For temperatures below -15°C and over +200°C and depending on the medium, other seal variants are available.

On request, series 10/11 are also available with a special FFKM high-temperature seal for applications up to constant temperature 200°C.

Single Shut-Off

Double Shut-Off

15 bar

Coupling: Brass Plug: Brass, Stainless Steel Seals: FKM

Coupling: Brass Plug: Brass Seals: FKM

Pleaseconsideroursecurityadvicesonthepages8/9

Pleaseconsideroursecurityadvicesonthepages8/9

Pleaseconsideroursecurityadvicesonthepages8/9

Nominal Diameter 6/9

Technical Description

The 10 and 11 Rectus Moldtite coupling series were especially developed for connecting coolant lines and injection moulds. These stand out for their convenient, single-handed operation and a reliable O-ring seal. Widely used in Europe.

Advantages

Coupling system with safety locking. Accidental uncoupling is prevented effectively and easily with the automatic safety lock. Available in single shut-off, double shut-off or straightthrough versions. The straight-through couplings are equipped with nickel plated sleeves for quick and accurate visual differentiation. The angular connections prevent kinks from forming in the hose.

StraightThrough

Working Pressure**

15 bar

** maximum static working pressure with design factor 4 to 1.

Material

Coupling: Brass

Plug: Brass, Stainless Steel Seals: FKM

15 bar

Working Temperature* -15°C up to +200°C (FKM) depending on the medium.

* For temperatures below -15°C and over +200°C and depending on the medium, other seal variants are available.

On request, series 10/11 with safety lock are also available with a special FFKM hightemperature seal for applications up to constant temperature 200°C.

Single Shut-Off

KB Double Shut-Off

Coupling: Brass

Plug: Brass, Stainless Steel Seals: FKM

15 bar

Coupling: Brass

Plug: Brass Seals: FKM

Therightplugcanbefoundunderseries10/11/12frompage24.

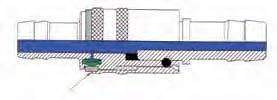

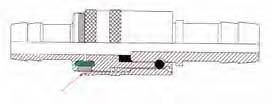

Nominal Diameter 8/12

Technical Description

The 608/612 series (French series) has been specially developed for cooling in the field of plastic injection machines / moulds. Using vertical plug inserts, the cooling connection can be installed directly in the mould / machine, so the external contour has no predruding extension components. This allows easy and safe handling during the work process and prevents damage to the coupling and the mould.

This system is supplied as a "straight-through coupling" with no valves. Coding of the in and outlets can be represented by simple fixing of the coloured clips / rings onto the coupling and plug.

KF

Working Pressure** 20 bar

** maximum static working pressure with design factor 4 to 1.

Material

Coupling: Brass nickel plated

Plug: Brass nickel plated Seals: FKM

Advantages

The use of the locking balls means that an optimum grip of the plug connection is guaranteed, even with forces that are applied laterally. The simple unlocking mechanism, which is optimised by knurling at the end of the sleeve, can be operated by pulling back once on the sleeve.

Working Temperature*

-15°C up to +200°C (FKM) depending on the medium.

* For temperatures below -15°C and over +200°C and depending on the medium, other seal variants are available.

Flow diagrams

Water

Pleaseconsideroursecurityadvicesonthepages8/9

Nominal Diameter

6/9/12/16

Technical Description

6006/6009/6012/6016

This range of couplings was constructed with valves as an alternative to the French profiles. All four nominal diameters in our Frenchmatic I range are available with single and double shut-off.

Advantages

The locking balls guarantee an optimum hold by the insert connection even with forces acting from the side. Optimum flow rate with absolute minimal flow resistance.

Working Temperature* -15°C up to +200°C (FKM) depending on the medium.

* For temperatures below -15°C and over +200°C and depending on the medium, other seal variants are available.

Single Shut-Off KB Double Shut-Off

Working Pressure**

20 bar

** maximum static working pressure with design factor 4 to 1.

Material

Coupling: Brass nickel plated

Plug: Brass nickel plated (6006Seals: FKM

15 bar

Coupling: Brass nickel plated

Plug: Brass nickel plated (6006Seals: FKM

Flow diagrams

Water

Pleaseconsideroursecurityadvicesonthepages8/9

FRENCHMATIC II

Nominal Diameter 3/6/9/12

Technical Description

The NSI are dry break couplings with flat face valves. The compact design make them suitable for reduced spaces. Coupling system with two-hand operation, i.e. both hands are required when connect/disconnect.

Advantages

pressure drop. Specific design for cooling applications. Can be used either with water and heat transfer oils. Excellent resistance to vibrations and mechanical stresses.

Working Pressure** 60 bar

** maximum static working pressure.

Material

Coupling: Brass/Stainless Steel

Plug: Brass/Stainless Steel

Seals: FKM Flow

Water (3 and 6 mm)

Working Temperature* -20°C up to +200°C (FKM) depending on the medium.

* For temperatures below -20°C and over +200°C and depending on the medium, other seal variants are available.

Oil (3 and 6 mm)

1EndconnectionaccordingtoISO1179-2EDseal 2EndconnectionaccordingtoDIN235324°cone

Pleaseconsideroursecurityadvicesonthepages8/9

FRENCHMATIC II

Nominal Diameter 6/9/12

Technical Description

The NSP are dry break couplings with flat face valves. The compact design make them suitable for reduced spaces. Coupling system with single-hand operation.

Advantages

No spillage during connection/disconnection. Push to for cooling applications. Can be used either with water and heat transfer oils. Excellent resistance to vibrations and mechanical stresses.

Working Pressure** 60 bar

** maximum static working pressure.

Material

Coupling: Brass/Stainless Steel

Plug: Brass/Stainless Steel

Seals: FKM

Working Temperature* -20°C up to +200°C (FKM) depending on the medium.

* For temperatures below -20°C and over +200°C and depending on the medium, other seal variants are available.

Diameter 6 mm

Diameter 9 mm

Diameter 12 mm

Flow diagrams

Water (6 mm)

Water (9 und 12 mm)

Oil (6 mm)

Oil (9 und 12 mm)

1EndconnectionaccordingtoISO1179-2EDseal 2EndconnectionaccordingtoDIN235324°cone

Pleaseconsideroursecurityadvicesonthepages8/9

Nominal Diameter

8,1

MULTI-MATIC

Technical Description

Modular integrated coupling and plug for installation in multi-coupling systems (series 08). High resilience, low coupling forces and great resistance to liquid media due to the special coating of the coupling body.

Working Temperature* -15°C up to +100°C (FKM) depending on the medium.

* For temperatures below -15°C and over +100°C and depending on the medium, other seal variants are available.

Working Pressure**

15 bar

** maximum static working pressure with design factor 4 to 1.

Material

Coupling: Brass nickel plated, Steel PTFE coated

Plug: Brass nickel plated, Steel PTFE coated Seals: FKM

15 bar

Dry-Break

Coupling: Brass nickel plated, Steel PTFE coated

Plug: Brass nickel plated, Steel PTFE coated Seals: FKM

Pleaseconsideroursecurityadvicesonthepages8/9

At Parker, we’re guided by a relentless drive to help our customers become more productive and achieve higher levels of profitability by engineering the best systems for their requirements. It means looking at customer applications from many angles to find new ways to create value. Whatever the motion and control technology need, Parker has the experience, breadth of product and global reach to consistently deliver. No company knows more about motion and control technology than Parker. For further info call 00800 27 27 5374

Aerospace

Key Markets

Aftermarket services

Commercial transports

Engines

General & business aviation

Helicopters

Launch vehicles

Military aircraft

Missiles

Power generation

Regional transports

Unmanned aerial vehicles

Key Products Control systems & actuation products

Engine systems & components

Fluid conveyance systems & components

Fluid metering, delivery & atomization devices

Fuel systems & components

Fuel tank inerting systems

Hydraulic systems & components

Thermal management

Wheels & brakes

Climate Control

Key Markets

Agriculture

Air conditioning

Construction Machinery

Food & beverage

Industrial machinery

Life sciences

Oil & gas

Precision cooling

Process

Refrigeration

Transportation

Key Products

Accumulators

Advanced actuators

CO2 controls

Electronic controllers

Filter driers

Hand shut-off valves

Heat exchangers

Hose & fittings

Pressure regulating valves

Refrigerant distributors

Safety relief valves

Smart pumps

Solenoid valves

Thermostatic expansion valves

Electromechanical

Key Markets

Aerospace

Factory automation

Life science & medical

Machine tools

Packaging machinery

Paper machinery

Plastics machinery & converting

Primary metals

Semiconductor & electronics

Textile Wire & cable

Key Products

AC/DC drives & systems

Electric actuators, gantry robots & slides

Electrohydrostatic actuation systems

Electromechanical actuation systems

Human machine interface

Linear motors

Stepper motors, servo motors, drives & controls

Structural extrusions

Filtration

Key Markets

Aerospace

Food & beverage

Industrial plant & equipment

Life sciences

Marine

Mobile equipment

Oil & gas

Power generation & renewable energy

Process

Transportation

Water Purification

Key Products

Analytical gas generators

Compressed air filters & dryers

Engine air, coolant, fuel & oil filtration systems

Fluid condition monitoring systems

Hydraulic & lubrication filters

Hydrogen, nitrogen & zero

Air generators

Instrumentation filters

Membrane & fiber filters

Microfiltration

Sterile air filtration

Water desalination & purification filters & systems

Fluid & Gas Handling

Key Markets

Aerial lift

Agriculture

Bulk chemical handling

Construction machinery

Food & beverage

Fuel & gas delivery

Industrial machinery

Life sciences

Marine

Mining

Mobile

Oil & gas

Renewable energy

Transportation

Key Products

Check valves

Connectors for low pressure

fluid conveyance

Deep sea umbilicals

Diagnostic equipment

Hose couplings

Industrial hose

Mooring systems & power cables

PTFE hose & tubing

Quick couplings

Rubber & thermoplastic hose

Tube fittings & adapters

Tubing & plastic fittings

Hydraulics

Key Markets

Aerial lift

Agriculture

Alternative energy

Construction machinery

Forestry

Industrial machinery

Machine tools

Marine

Material handling

Mining

Oil & gas

Power generation

Refuse vehicles

Renewable energy

Truck hydraulics

Turf equipment

Key Products

Accumulators

Cartridge valves

Electrohydraulic actuators

Human machine interfaces

Hybrid drives

Hydraulic cylinders

Hydraulic motors & pumps

Hydraulic systems

Hydraulic valves & controls

Hydrostatic steering

Integrated hydraulic circuits

Power take-offs

Power units

Rotary actuators

Sensors

Pneumatics

Key Markets

Aerospace

Conveyor & material handling

Factory automation

Life science & medical

Machine tools

Packaging machinery

Transportation & automotive

Key Products

Air preparation

Brass fittings & valves

Manifolds

Pneumatic accessories

Pneumatic actuators & grippers

Pneumatic valves & controls

Quick disconnects

Rotary actuators

Rubber & thermoplastic hose & couplings

Structural extrusions

Thermoplastic tubing & fittings

Vacuum generators, cups & sensors

Process Control

Key Markets

Alternative fuels

Biopharmaceuticals

Chemical & refining

Food & beverage

Marine & shipbuilding

Medical & dental

Microelectronics

Nuclear Power

Offshore oil exploration

Oil & gas

Pharmaceuticals

Power generation

Pulp & paper

Steel

Water/wastewater

Key Products

Analytical Instruments

Analytical sample conditioning products & systems

Chemical injection fittings & valves

Fluoropolymer chemical delivery fittings, valves & pumps

High purity gas delivery

fittings, valves, regulators & digital flow controllers

Industrial mass flow meters/ controllers

Permanent no-weld tube fittings

Precision industrial regulators & flow controllers

Process control double block & bleeds

Process control fittings, valves, regulators & manifold valves

Sealing & Shielding

Key Markets

Aerospace

Chemical processing

Consumer

Fluid power

General industrial

Information technology

Life sciences

Microelectronics

Military

Oil & gas

Power generation

Renewable energy

Telecommunications

Transportation

Key Products

Dynamic seals

Elastomeric o-rings

Electro-medical instrument design & assembly

EMI shielding

Extruded & precision-cut, fabricated elastomeric seals

High temperature metal seals

Homogeneous & inserted elastomeric shapes

Medical device fabrication & assembly

Metal & plastic retained composite seals

Shielded optical windows

Silicone tubing & extrusions

Thermal management

Vibration dampening

Europe, Middle East, Africa

AE – United Arab Emirates, Dubai

Tel:+97148127100 parker.me@parker.com

AT – Austria, WienerNeustadt

Tel:+43(0)262223501-0 parker.austria@parker.com

AT – Eastern Europe, Wiener Neustadt

Tel:+43(0)262223501900 parker.easteurope@parker.com

AZ – Azerbaijan, Baku

Tel:+994502233458 parker.azerbaijan@parker.com

BE/LU – Belgium, Nivelles Tel:+32(0)67280900 parker.belgium@parker.com

BG – Bulgaria,Sofa Tel:+35929801344 parker.bulgaria@parker.com

BY – Belarus, Minsk

Tel:+48(0)225732400 parker.poland@parker.com

CH – Switzerland, Etoy

Tel:+41(0)218218700 parker.switzerland@parker.com

CZ – Czech Republic, Klecany Tel:+420284083111 parker.czechrepublic@parker.com

DE – Germany, Kaarst Tel:+49(0)213140160 parker.germany@parker.com

DK – Denmark, Ballerup Tel:+4543560400 parker.denmark@parker.com

ES – Spain, Madrid Tel:+34902330001 parker.spain@parker.com

FI – Finland, Vantaa Tel:+358(0)207532500 parker.fnland@parker.com

FR – France, Contamines/Arve Tel:+33(0)450258025 parker.france@parker.com

GR – Greece, Athens

Tel:+302109336450 parker.greece@parker.com

HU – Hungary, Budaörs

Tel:+3623885470 parker.hungary@parker.com

IE – Ireland, Dublin Tel:+353(0)14666370 parker.ireland@parker.com

IL – Israel Tel:+3902451921 parker.israel@parker.com

IT – Italy, Corsico(MI) Tel:+3902451921 parker.italy@parker.com

KZ – Kazakhstan, Almaty Tel:+77273561000 parker.easteurope@parker.com

NL – The Netherlands, Oldenzaal Tel:+31(0)541585000 parker.nl@parker.com

NO – Norway, Asker Tel:+4766753400 parker.norway@parker.com

PL – Poland, Warsaw Tel:+48(0)225732400 parker.poland@parker.com

PT – Portugal Tel:+351229997360 parker.portugal@parker.com

RO – Romania, Bucharest Tel:+40212521382 parker.romania@parker.com

RU – Russia, Moscow Tel:+7495645-2156 parker.russia@parker.com

SE – Sweden, Spånga Tel:+46(0)859795000 parker.sweden@parker.com

SK – Slovakia, BanskáBystrica Tel:+421484162252 parker.slovakia@parker.com

SL – Slovenia, NovoMesto Tel:+38673376650 parker.slovenia@parker.com

TR – Turkey, Istanbul Tel:+902164997081 parker.turkey@parker.com

UA – Ukraine, Kiev Tel:+48(0)225732400 parker.poland@parker.com

UK – United Kingdom, Warwick Tel:+44(0)1926317878 parker.uk@parker.com

ZA – South Africa, KemptonPark Tel:+27(0)119610700 arker.southafrica@parker.com

North America

CA – Canada, Milton,Ontario

Tel:+19056933000

US – USA, Cleveland

Tel:+12168963000

Asia Pacific

AU – Australia, CastleHill

Tel:+61(0)2-96347777

CN – China, Shanghai

Tel:+862128995000

HK – Hong Kong

Tel:+85224288008

IN – India, Mumbai

Tel:+912265137081-85

JP – Japan, Tokyo

Tel:+81(0)364083901

KR – South Korea, Seoul

Tel:+8225590400

MY – Malaysia, ShahAlam

Tel:+60378490800

NZ – New Zealand, MtWellington

Tel:+6495741744

SG – Singapore

Tel:+6568876300

TH – Thailand, Bangkok

Tel:+6621867000

TW – Taiwan, Taipei

Tel:+886222988987

South America

AR – Argentina, BuenosAires Tel:+543327444129

BR – Brazil, SaoJosedosCampos

Tel:+558007275374

CL – Chile, Santiago Tel:+5626231216

MX – Mexico, Toluca Tel:+527222754200

European Product Information Centre Free phone: 00 800 27 27 5374

(from AT, BE, CH, CZ, DE, EE, ES, FI, FR, IE, IL, IS, IT, LU, MT, NL, NO, PT, SE, SK, UK)