The pan-European magazine for the professional cleaning sector

OCTOBER 2025

Read

The pan-European magazine for the professional cleaning sector

OCTOBER 2025

Read

34 Brussels tackles red tape

Hartley Milner on how Brussels is rowing back on sustainability reporting for businesses

The people pleasers

People are one of the three pillars of sustainability - are they often forgotten?

Toilet challenges

Hygiene in public washrooms still comes with challenges.

Are no-touch dispensers in the washroom now becoming the norm?

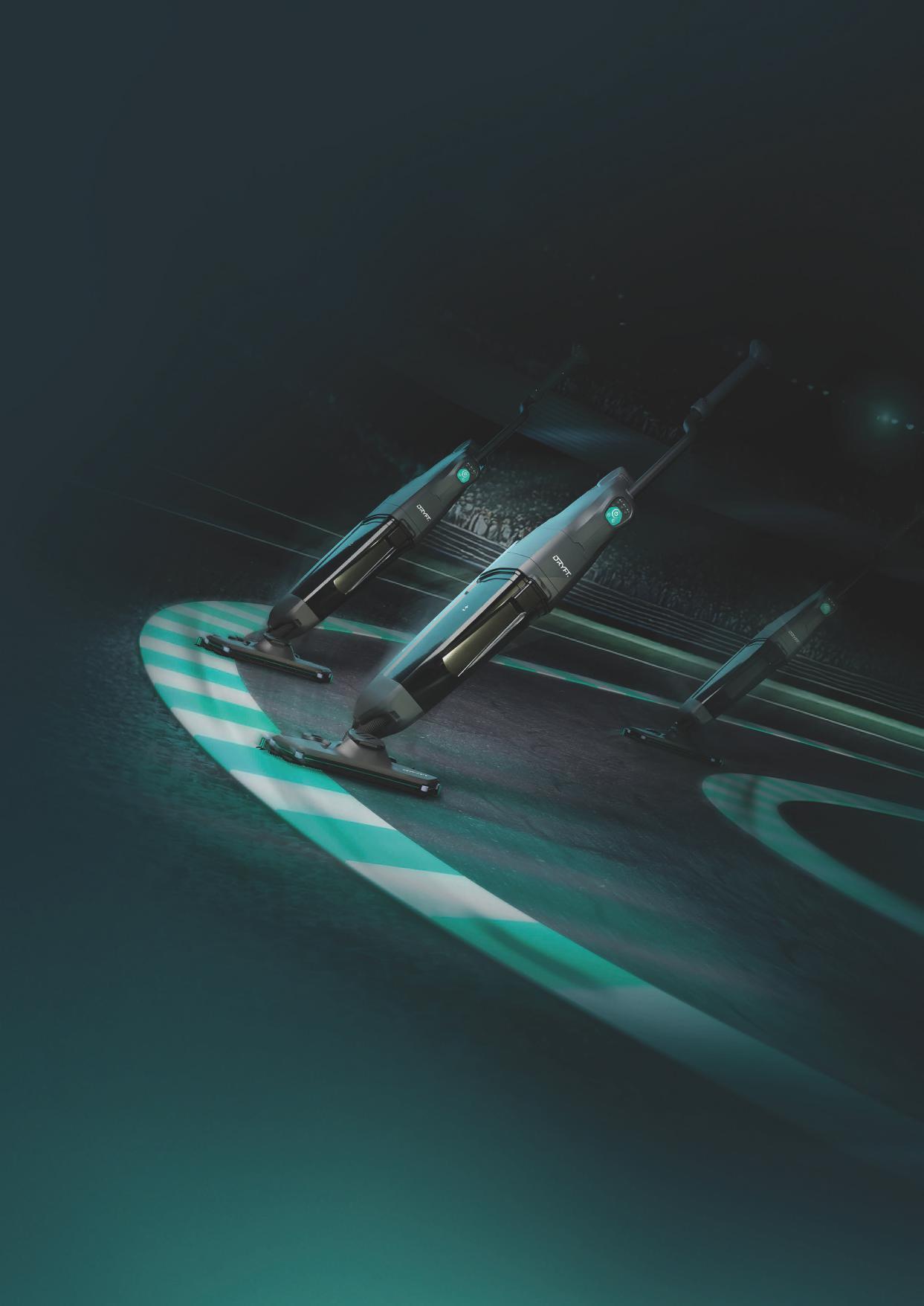

Do we need a human?

In the age of the robot, where do human operatives fit in to floor care?

From oversight to insight

How smart auditing tech is evolving into a real-time performance enabler.

Battery choices

What are the various battery types that can be used in a cleaning machine?

Criterion Publishing Ltd

Castle House, 89 High Street

Berkhamsted HP4 2DF, UK

T +44 (0)1494 791222

F +44 (0)1494 792223

info@europeancleaningjournal.com www. europeancleaningjournal.com

Subscriptions

UK - £60 / Continental Europe - £70 / International - £80

Editor Michelle Marshall

Features Writer Ann Laffeaty

Advertisement director

Chris Godman

Advertisement sales executive

Laura Bell

Circulation Marie Payne

Italy, Spain & Switzerland Fabio Potesta Mediapoint & Communications

Corte Lambruschini, Corso Buenos Aires, 8 V0 Piano, Interno 7 16129 Genova, Italy

T +39 010 570 4948

F +39 010 553 0088 info@mediapointsrl.it www. mediapointsrl.it

Interclean is blooming early in 2026! Join the community, expand your network and close deals at Interclean Amsterdam from 14-17 April 2026, your most efficient and enjoyable business trip every two years.

14 – 17 April 2026

RAI Amsterdam, Netherlands

Tork, an Essity brand and specialist in professional hygiene systems, has published the findings of a global Insight Survey of end users and cleaning staff that explored attitudes toward hygiene in washrooms.

Significant societal shifts have taken place with regards to awareness and accommodation of individual physical circumstances and conditions in washrooms in public spaces and the workplace. Changing places are more commonly seen in shopping centres and disabled toilet cubicles are incorporated into the design of public washrooms, signposted by the wheelchair sign. However, globally 95 per cent of people who report physical or cognitive conditions are not in a wheelchair.

The global Tork Insight Survey reveals many needs remain unrecognised in washroom design and maintenance. In fact globally, one in two people are likely to face barriers to hygiene in washrooms meaning there is a disconnect between their capabilities or needs and the washroom environment.

33 per cent of those who report a physical or cognitive condition have skin sensitivity, 29 per cent have anxiety and 22 per cent have rheumatism. Such sensory sensitivities, cognitive conditions or paruresis (shy bladder) can result in people refraining from using washrooms or being able to fully meet their needs in the washroom.

In the UK, 17 per cent of those who report a physical condition suffer from a skin sensitivity such as eczema, which can be aggravated by harsh soaps, and 12 per cent are challenged by arthritis or suffer from chronic pain, which can make using toilet paper and accessing soap from dispensers difficult. Drawing similarities with the global view that one in five washrooms do not meet hygiene cleanliness expectations, 24 per cent of people surveyed in

the UK cite ‘unhygienic’ as a reason for never using or having avoided a washroom, and 50 per cent say they have not used a washroom at a venue even though they needed to. Overall, in line with disappointing global survey stats, 83 per cent of end users surveyed in the UK are concerned about hygiene in public washrooms.

“Eight out of 10 people globally have concerns about washroom rooms - a figure that’s even higher for those with certain physical or cognitive conditions,” said Olivia Slater, commercial director at Essity Professional Hygiene. Impact on business

“When a washroom fails to meet these diverse needs, it directly impacts a business’s reputation and revenue. This is one reason why ‘hygiene for all’ is a core pillar of our sustainability strategy. By focusing on inclusive hygiene, we help organisations create better experiences that serve as many people as possible, including the cleaning staff who maintain these vital spaces.”

The research, which surveyed 11,500 people across 11 countries, shows there are high expectations for hygiene and cleanliness in the washroom.

Seventy-four per cent expect moderate or high levels of hygiene. Yet only 20 per cent of washrooms deliver on those expectations. Forty per cent of the general population is “very concerned” with hygiene and cleanliness of public spaces and that number jumps to 60 per cent for people with conditions like germaphobia.

What does this mean for venues and the workplace?

Essity says a poor washroom experience can trigger powerful emotions amongst users, such as ‘disappointed’ (30 per cent), ‘disgusted’ (30 per cent) ,‘uncomfortable’ (27 per cent) and ‘frustrated’ (26 per cent) which have a negative impact on venue or workplace reputation.

• 30 per cent have spent less time at a venue because of the state of the washroom.

• 17 per cent have avoided

eating and drinking at a venue.

• 10 per cent have told their friends to avoid the location and seven per cent have left a poor online review.

• 18 per cent of people have made a complaint to staff or workplace management about poor washroom experiences.

• 15 per cent worked from home more than they otherwise would, because of poor

October 29-30

ISSA Cleaning & Hygiene Expo Sydney, Australia www.issa.com

November 4-6

Hygienalia Madrid, Spain www.hygienalia.com

November 10-13

ISSA North America Las Vegas, USA www.issa.com

February 18-19 2026

The Manchester Cleaning Show Manchester, UK cleaningshow.co.uk/manchester

April 14-17 2026

Interclean Amsterdam Amsterdam, Netherlands www.intercleanshow.com

October 8 2026

European Cleaning & Hygiene Awards www.echawards.com

washrooms at work, hindering return to office policies.

Tork Insight Survey 2025 was conducted in US, UK, Germany, France, Mexico, Canada, Australia, Spain, Sweden, Netherlands and Poland among 11,500 people from the general public and 1,000 cleaning staff.

To find out more: www. torkglobal.com/gb/en/about/ inclusive-hygiene

November 16-19 2026

ISSA North America Las Vegas, USA www.issa.com

March 16-18 2027

The Cleaning Show London, UK cleaningshow.co.uk/london

May 11-13 2027

ISSA Pulire Milan, Italy www.issapulire.com

November 8-11 2027

ISSA North America Las Vegas, USA www.issa.com

To have your event included in the Events section, contact ECJ via email at: michelle@europeancleaningjournal.com

The European Parliament has approved a non-binding owninitiative report on revising the EU public procurement directives, drafted by MEP Piotr Müller (ECR, Poland) - reports EFCI from Brussels.

The report outlines the EU Parliament’s priorities for the legislative overhaul of the public procurement rules, expected to start in the third quarter

of 2026. One of the report’s main messages is that instead of focusing on the cheapest price, public tenders should give more weight to non-price considerations and seek the best price/quality ratio.

The report also asks the Commission to assess ways to favour European companies, especially in strategic sectors, to stimulate demand for

European-made products and technologies and to anchor industrial capacity within the EU. This should, however, be done without resorting to outright protectionism, MEPs say.

MEPs want the Commission to promote small business participation in tender processes and to simplify both the 907 pages of law currently governing public tenders as well as the procurement procedures themselves.

Proposals from Socialists/ Greens to make social and green criteria mandatory failed.

The Parliament’s report has no legal standing but is intended to inform the Commission ahead of a proposal from the EU executive. Commissioner for industry Stéphane Séjourné will publish an impact assessment of the current framework, per his mandate from President von der Leyen.

TRU Global Solutions - the Belgian expert in cleanroom cleaning - has opened a new office in Switzerland. The new branch is based in Basel, a hub of the European pharmaceutical industry.

Founder and CEO Vanessa Morini explained: “Cleanroom cleaning is fundamentally different from conventional cleaning. It’s about more than just wiping down surfaces. Invisible contaminants can lead to costly product recalls, production delays and can pose serious health risks to patients. Our employees are highly-trained specialists who work according to the strictest GMP standards and international guidelines.”

Manuel Schütte, CEO of TRU Switzerland added: “Our clients can now focus fully on their core activities while we ensure a contamination-free production environment.”

In the UK, The Kingdom Group has completed the acquisition of Crystalcare Cleaning Services which is based in London and the south east of England.

The business will be rebranded as Kingdom Cleaning London and will be the specialist citybased division of Kingdom Cleaning. Kingdom operates throughout the UK across a diverse range of sectors, has a workforce of over 11,500 and a turnover of £300 million.

The operational management at Crystal will continue in their roles and the general managers will join the Kingdom Cleaning leadership team - reporting to Lucy Lloyd, chief services officer. Over 720 people from the Crystalcare workforce will be transferring.

Terry Barton, CEO of The Kingdom Group said: “Our existing cleaning business and south region is further

strengthened by the addition of Crystal. Together and united, we’re positioned to deliver even greater value and innovative cleaning solutions.”

“We have done this to further support our sustainable, innovative and ethical cleaning services,” added Toby Jerman, CEO of Crystal Cleaning. “With changing work practices, joining Kingdom will help us to further improve our sustainable approach, use of the latest technology and putting our community and teams at the forefront.”

US-based EMCOR Group has entered into a definitive agreement to sell EMCOR UK to international facilities services company OCS Group, based in the UK. EMCOR - a Fortune 500 business - is a leader in mechanical and electrical construction services, industrial and energy infrastructure and building services.

The deal is worth £190 million, equivalent to $255 million at current exchange rates.

”With the sale of EMCOR UK, we are accelerating our ‘local execution, national reach’ strategy to further focus our business across our large, diverse and attractive end markets in the United States, where we continue to see significant opportunity,” said Tony Guzzi, chairman, president and chief executive officer of EMCOR.

“We have a lot of momentum

in the business and intend to use the proceeds from this sale to expand our electrical and mechanical construction and mechanical services businesses, including through disciplined acquisitions, to provide customers with more comprehensive service offerings.”

Rob Legge, chief executive officer of OCS added: “EMCOR UK has built an impressive UK technical services business, with proven expertise in complex and critical environments. We see strong strategic and cultural alignment and look forward to working together through the transition to ensure a smooth and consistent experience for colleagues and customers.”

The transaction is expected to be completed by the end of 2025.

ONE HUNDRED restrooms, the Dutch company re-inventing the public washroom around Europe, has opened its first collab washroom concept with Fastned - a business that owns and operates fast-charging stations for electric cars. This first openings are the two motorway service areas at Gentbrugge North and South in Belgium.

The collab washroom concept is a new proposition developed by ONE HUNDRED restrooms for brands like Fastned that want to integrate the ONE HUNDRED high-end well-

being experience into their own branded environments. The codesigned washrooms enhance the customer experience and reinforce the visual identity of Fastned at the same time.

Go-to stop

“At Fastned, we build fast charging stations for people,” says Luuk Valk, head of retail development & retail operations at Fastned. “Because people on the road need more than just a charged battery: they want good food, drinks, clean restrooms, and a place to relax. Our goal is to become the go-to stop for

everyone travelling, whether you’re driving an EV or not.”

“That’s why we partnered with ONE HUNDRED restrooms. Their innovative and hygienic facilities perfectly align with our ambition to set a new benchmark along the road. Together, we offer a complete experience where quality, comfort and hospitality come first.”

In collaboration with design studio Desarc, ONE HUNDRED created a tailor-made concept that blends its distinctive wellbeing design with Fastned’s identity. Signature features

include fresh blue/wood colours, custom Fastned lighting and coat hooks shaped like the Fastned logo.

The new concept includes innovative modules such as a mini vending with fresh-up items for travellers, a digital face scan developed with Belgian health tech company IntelliProve2 offering insights into stress levels and overall well-being, ONE HUNDRED’s smart urinal that monitors hydration, as well as a shower, baby changing station and accessible toilet facilities.

Shared missions

On entering the restrooms through the turnstile, visitors receive a voucher worth €0.50 to use on their next food or beverage purchase in the Fastned shop.

“The collab concept represents a powerful blend of our shared missions: to enhance wellbeing and support a smooth, stress-free journey,” says Mariëlle Romeijn, co-founder and chief brand officer of ONE HUNDRED restrooms. “With the new Fastned restrooms, we are proving that a washroom stop can be a moment of care, innovation and new energy.”

Fastned has 24 more sites in Belgium under development. The partnership will also extend into charging stations in the Netherlands.

In the UK, the winners of the annual BICSc awards were announced during a gala dinner. Group managing director Neil Spencer-Cook said: “The BICSc Awards 2025 were an outstanding success. It was fantastic to be able to celebrate the very best in the cleaning industry and honour the incredible individuals and teams who make a real difference every day.

“These awards are about recognising excellence but more than that, they’re about celebrating the people who make our industry what it is, the

ones who go above and beyond, who innovate and who inspire.”

Spencer-Cook was himself the recipient of a trophy when he was announced as the winner of The David Bellamy Award for his decade of service.

The winners are:

• The David Bellamy AwardNeil Spencer-Cook

• The Chairman’s Award - Greig Cave

• The Eric Hill Award - Darrin

McCartney

• The BICSc International Award - Whitespot Facilities Management

• Innovation Award - Whitespot

Facilities Management

• Environmental (ESG) AwardJulius Rutherfoord & Co

• Corporate Member of the Year

- Deeland t/a Service Master

• Accredited Training Member of the Year - Clarion Housing

• Assessor of the Year - Steven Goldie - HMP Addiewell

• Accredited Trainer of the Year - Amaniampong Atakora, Goldsmiths University of London

• Cleaning Operative of the Year - Barrington Spencer, Bidvest Noonan

• Outstanding Candidate of the Year - Joshua Morel, Engie Solutions KSA

• Lifetime Achievement Award - Johanna Galindo, King’s College London

Three values ����a�� have ��e����e�� us ����r ���� ��ears a���� ��r��ve us ����

c����������ue crea������g pr����ess������al h��g��e��e s��lu��������s ����a�� ����sp��re

c��������e��ce a���� make a ����ffere��ce ���� ever�� space.

We wait for you at:

In the UK, the British Institute of Cleaning Science (BICSc) and the Cleaning & Support Services Association (CSSA) have together successfully completed a project exploring the future of cleaning. The aim was to offer insight through independent trials and scientific results.

The project aimed to:

• Determine the productivity of different types of current machine ranges.

• Provide clarity on the changes to productivity brought about by robotics.

• Evidence the effect on the standard of cleaning achieved from the usage of these machines and chemicals.

• Determine whether the use of this equipment or chemical range made changes to air quality and pathogen count.

Suppliers were approached to assist in trialling different types

Lithuania-based paper producer Grigeo Group is expanding into Western Europe with its acquisition of Huchtemeier Papier in Germany. The deal, it says, opens up the group’s largest European market and new expansion opportunities in Germany and the neighbouring countries. Based in Dortmund, Huchtemeier Papier is a family-owned business with over 125 years of tradition. Its products are used in the cleaning industry, hotel and catering, industry, retail and the medical sector. With sales offices in Germany, Austria, Poland, and Turkey, it employs 47 people.

Tomas Jozonis, CEO of Grigeo Group, commented: “By acquiring Huchtemeier Papier,

we are not only acquiring a company with deep traditions and a strong name in the German paper market, but also invaluable experience and partnerships built up over more than a century.

Strategic move

“This is a strategic move that opens up the largest European market for us - Germany, as well as Austria, where Huchtemeier Papier has a strong position. For our hygiene paper segment, this step will allow us to expand our logistics chain and ensure long-term partnerships with local customers.”

Huchtemeier Papier will continue to operate as an independent business unit, as well as retaining its name and management.

of equipment, chemicals and processes. Numatic, Birkin, Killis, Diversey, Kärcher and Orion Eco took part.

The trials took place at the University of Surrey, with each manufacturer given six weeks to establish their equipment and/ or chemicals. The BICSc Cleaning and Hygiene Audit App was used to assess changes in cleanliness.

Several challenges impacted the results, including

management changes, staff engagement and external consultant recommendations. The cleaning inspection results were mixed, with no clear correlation from the starting point to the completion results. However, valuable insights were gained say BICSc and CSSA, such as the importance of engaging operatives in the process and the need for effective change management.

“The trial has shown us that success lies not just in product performance but in the readiness of people and processes to adopt it,” said Paul Ashton, CSSA chairman.

“Management of change is key to the success of the process. Where staff are not engaged in the process, the installation of new equipment or processes is doomed to failure,” added Denise Hanson, commercial director at BICSc.

Neil Spencer-Cook, group MD at BICSc concluded: “How we manage change needs to be the biggest consideration, whether it is technological, chemical, machinery, or even providing training. Without clear guidance, leadership and ongoing support, change will not be effective.”

A retail worker was dismissed by a Dublin fashion retailer after complaining to the Health and Safety Authority about the lack of a washroom in the workplace.

The Yaya boutique has been ordered to pay €7,500 in compensation to Fiona Bird following a Workplace Relations Commission review.

When Bird started work at Yaya she said there were some inevitable start-up problems. But the biggest issue was the lack of a staff washroom, which also meant there was no onsite hand washing facility.

The employer made arrangements with the coffee shop next door to allow staff members to use their customers’ toilets. Bird said this was not always convenient.

When this situation went on

for several months, Bird reported the issue to the HSA. She later discovered the Authority had contacted her employer about the matter.

She was told to leave five months after starting work at the store. She claimed to be shocked at her dismissal since no probationary period had been mentioned and there had been no suggestion that her employers were unhappy with her work.

The employer said Bird was being dismissed for poor performance because her sales were not as good as those of her colleagues. But adjudicator Penelope McGrath ruled this out as a reason for Bird’s dismissal, while Bird herself said she believed she was being penalised for raising an issue with the HSA.

In

The winners of the European Cleaning & Hygiene Awards 2025 were revealed in early October during a glittering gala dinner at the National Museum of Scotland in Edinburgh.

Over 350 cleaning industry professionals from throughout Europe came together to celebrate its achievements, innovation and dedication over the past year.

With 61 finalists across 11 categories, this was another record-breaking year for entries.

The 2025 winners are:

• Digital TransformationVebego

• Investment in Training & People Development - NIC Services Group

• Excellence in Client-Contractor Partnerships - CleanEvent Services and Tottenham Hotspur FC

• Sustainability - Best Practice (Manufacturing) - Bona

• Sustainability - Best Practice (Service Provider) - Asito, CSU & GOM

• Commitment to Diversity in the Workforce - MTB Cleaning Service

• Best Initiative Raising the Profile of the Cleaning Sector - Breedweer

• Technological Innovation of the Year - Principle Cleaning Services and British Land Drone Window Cleaning

• Leader of the Year - Avril McCarthy, Derrycourt Cleaning Specialists

• Rising Star of the Year - Corey Watts, CleanEvent Services

• Best Company to Work ForJPC by Samsic

ECJ editor and founder of the awards Michelle Marshall

said: ”Each year, we are reminded just how dynamic and forward-thinking our industry has become - and 2025 has been no exception. The innovation, dedication, and commitment demonstrated in this year’s entries show that the professional cleaning and hygiene sector is not only keeping pace with change but leading it.

Celebration

“Bringing everyone together in Edinburgh to celebrate these achievements has been truly inspiring. From groundbreaking technologies to new approaches driving sustainability and raising standards, the progress on display was remarkable. Every finalist should feel proud of the impact they’re making, and we’re delighted to recognise our 11 outstanding winners who are shaping the future of our industry. Congratulations to them all.”

Judges include Michelle Marshall, Lynn Webster and Frank Veneman.

ISSA Pulire was the headline sponsor for the event. Other sponsors included BICSc; Ceris Burns International; Greenspeed; Interclean; i-team; Jangro; Kärcher; Nexaro; The Cleaning Show; Vectair; Tork, an Essity brand; Lucart Professional; CMS Berlin; Diversey, a Solenis company; and Grosvenor Services.

Media partners are GSA in Italy and Services in France.

The European Cleaning & Hygiene Awards 2026 will open for entries in January. Visit www.echawards.com for more information.

The host city for the 2026 European Cleaning & Hygiene Awards will be announced in November!

EFCI in Brussels is calling for the creation of a new central vetting system to make crossborder recruitment simpler and faster, while ensuring trust, safety and fairness. It says free movement is a cornerstone of the EU’s single market.

As the European Cleaning and Facility Services Industry (EFCI), the recognised employers’ organisation and Social Partner for the cleaning industry sector, we call for the creation of a Central EU Police Vetting System to simplify and accelerate cross-border recruitment while ensuring trust, safety, and fairness.

Labour mobility is a cornerstone of the EU’s single market, enabling workers to move freely across Member States and supporting economic integration. However, the practical implementation of the legal framework, including rules on the free movement of workers, the posting of workers and social security coordination, faces persistent challenges that undermine efficiency and legal certainty.

Key challenges of implementation

• Fragmented procedures across member states: national authorities maintain separate systems for background checks (eg, criminal records, police vetting), resulting in delays, varying quality standards, and limited interoperability.

• Administrative complexity

in cross-border recruitment: employers seeking to hire workers from other member states face lengthy and complex processes to verify records, particularly for sensitive professions such as security, childcare, and healthcare.

• Redundant vetting processes: mobile workers are often subject to repeated background checks when moving between employers (within the same country) and jurisdictions, creating unnecessary administrative burden for both workers and employers.

• Data protection and privacy concerns: divergent interpretations of EU data protection rules (eg GDPR) lead to uncertainty for authorities and

employers, particularly when exchanging personal information for vetting purposes.

EFCI’s proposal

These challenges risk slowing down labour mobility, creating barriers for employers in critical sectors, and eroding confidence in the fairness and consistency of the single market’s labour mobility framework. EFCI therefore calls for creation of a Central EU Police Vetting System, a single, EU-wide process that:

• Simplifies and accelerates hiring by replacing multiple national checks with one mutually recognised vetting procedure, accessible via a single online portal.

• Individual applications

to enable employees to vet themselves and provide their vetting number to employers. Registered employers could access the EU Policy Vetting Cert through the secure portal.

• Enhances trust and safety through accurate, secure, and fast verification, supporting both worker mobility and public protection.

By creating a single, digitally driven vetting process, the EU could reduce administrative burdens, improve hiring speed in critical sectors, strengthen cross-border trust, and protect both worker rights and public safety - fully realising the potential of the single market for labour mobility.

efci.eu

Lynn Webster in the UK says it’s time for those who work in the sector to take pride in what they do.

Cleaning operatives are so often thought of as the invisible labour force: unseen, overlooked and undervalued only until something negative occurs or it all goes wrong.

Cleaning teams can be considered expendable, purely a functional necessity without any thought for the people involved - leaving those who work in the cleaning industry feeling overlooked despite their essential worker status and importance.

The various cleaning industry associations are becoming more publicly aware of the need for RESPECT.

The narrative is clearly changing, recognising the and appreciating the members of our cleaning teams as no longer “just a cleaner” - a phrase that diminishes a person’s worth. We are now replacing that with our own positive messages and behaviours.

There is tremendous work being done.

For example the Clean Start initiative from the Cleaning and Support Services Association (CSSA). A finalist in the recent European Cleaning and Hygiene Awards, this is a campaign to change the way young people perceive cleaning and to encourage them to consider the cleaning industry as a worthwhile career move with the many facets and roles it has to offer.

Breaking the stereotypical vision of cleaning and promoting the opportunities available.

Challenging perceptions

Furthermore, there is the focus, the voice, from the British Cleaning Council on actively challenging the perception of cleaning as low skilled or in fact as not being skilled at all. It continues its work to gain official recognition from government and the public for the vital role cleaning plays in society.

Most recently there has been significant collaboration established between the Worshipful Company of Environmental Cleaners and the British Institute of Cleaning Science (BICSc). Both

organisations founded by Eric Hill are coming together in a new and exciting collaboration.

With the growing success of the Chartered Practitioner status provided through Royal charter status of the Livery, and with well over 50 people now on the register, BICSc is supporting those who are on their chartership journey. The opportunity to be recognised for your achievements is open to all those who meet the criteria of the five pillars: General Knowledge, Skills, Communication, Leadership and Professional Commitment.

Visit: wc-ec.com/charteredpractitioners to find out more.

Having considered these five pillars required for entry candidates are now able to fill gaps in their knowledge, hone their skills and further develop in their preparation for submission with training, mentoring and support in the process through defined links on the BICSc web page.

All these are great initiatives but the cleaning industry needs to take ownership of its future. There is certainly more to be done by the sector itself.

So perhaps a “call to arms” for the self-respect we should each demonstrate. Have respect for ourselves. Value ourselves. Take pride in our roles and in turn allow society to appreciate our industry. So, time to take those vital steps to recognise ourselves as a visible, professional and highly skilled industry we are proud to be a part of.

From Germany, Katja Scholz brings news of latest trends being discussed at the industry’s exhibition.

It was that time of year again: CMS, one of the most important German, European and indeed international trade fairs for cleaning and hygiene, took place at the end of September in Berlin. The Federal Association of Contract Cleaners (BIV), was again this year one of the sponsoring associations supporting the Berlin Messe as organiser and helping the event to get off the ground.

“If people say after the fair that they enjoyed it and have taken away from it some innovations, ideas and suggestions - then we’ve done our job”. With these words, federal guild master Thomas Dietrich summed up the significance of CMS Berlin in a nutshell. And this proved to be so: the fair did indeed show the direction in which the cleaning sector is moving - and which subjects are going to dominate the market in the coming years. The top trends are obvious: artificial intelligence, digitalisation and sustainability.

Complex challenges

The expert forums were particularly well attended, said Dietrich during the fair, and interest in new product innovations was high. We find ourselves in Germany and central Europe in a situation where new technologies, robotics and AI are ready to launch on the market while at the same time tough requirements are set for sustainability and efficiency and for environmental standards for packaging, cleaning agents, etc. This presents complex problems for manufacturers and service providers. It became very clear at the fair: sustainability is no longer an optional extra, it’s a must.

The high salary and associated costs in Germany make automation and digitalisation attractive but this is counteracted by the lack of qualified staff encountered every day which affects all levels. As so often happens, the solution lies somewhere in the middle, since qualified staff are needed both for and in spite of

high-tech.

Furthermore, the subject of efficiency is particularly controversial at the moment with rising energy prices, high operating costs and the necessary investment in new technologies. While large firms are able to invest in automation, this is more of a problem for smaller companies. They are battling with scarce capacity and are therefore often reluctant to make changes - whether for reasons of cost or lack of resources - factors which are not independent of political discussions and decisions.

Shake-up needed

In the special trade fair podcast from the new CMS Podcast Cube in Hall 5.2, Thomas Dietrich rates the new government’s first few months as disappointing from the contract cleaning sector’s point of view. “I hope there will be a shake-up and a move to actually tackle the necessary reforms free from any ideology and to act like a pragmatic alliance.”

The key requirement for the BIV is further bold reforms in the field of social insurance, such as pensions: “People are living longer and expect to draw their pensions for longer but they don’t want to pay more and don’t want to work any longer – this is the circle that has to be squared,” added Thomas Dietrich, wishing therefore the Federal government would “radiate confidence by action and not by arguing things away”.

A new record was set this year for the fair with the further expansion of exhibition space: more than 34,000 square metres of indoor and outdoor space were provided and over 440 exhibitors were represented from 29 countries, with growing international participation. Exhibitors from abroad came mainly from Europe and China, with new arrivals this year from the United Arab Emirates, North Macedonia, Hong Kong and Norway.

Christian Bouzols in France tells us about a community programme to combat litter.

In France, the equivalent of 200 million bin bags are still discarded in the environment every year.

Faced with this alarming reality, World Cleanup Day –France organised a major mobilisation bringing together citizens, businesses, associations, schools and local communities from during a week in September, as part of the world’s largest civic and environmental action. While this initiative transcends borders, it is worth noting that in 2024, more than 140,000 French people donned gloves and collected rubbish from public roads alongside 23 million volunteers in 190 countries and territories. This was an unprecedented mobilisation... but it is still not enough to curb the proliferation of litter.

A movement for everyone World Cleanup Day is not just for large organisations: it belongs to everyone, and thanks to local initiatives across the country, every citizen was able to join a clean-up near their home during the third week of September. Businesses, local communities and associations also mobilised their teams around the project. As for schools, many of them took advantage of this week to raise awareness among the younger generation, who are the real agents of change.

And there is much work to be done: every year, nearly one million tonnes of litter are abandoned in France. Plastics, cigarette butts, cans, tyres, bulky items... All these pollutants are left along public roads or in illegal dumps in rural areas. And while picking up litter is not a solution in itself – local authorities are increasingly

cracking down on offenders – it is the most active and probably the most effective way of raising awareness of the need to reduce our waste at source.

According to the initial figures available, 125,000 people took part in Operation 2025, which ended on September 21. Four thousand ‘clean-up events’ were recorded. However, the results are still provisional at this stage and will be finalised in the coming weeks.

Founded in Estonia in 2008, the Let’s Do It movement has set itself the mission of combating litter through citizen clean-up initiatives. Since 2018, participating countries have been coordinating their actions to take part in World Cleanup Day, the largest citizen mobilisation on a global scale. In 2022, World Cleanup Day attracted 15 million participants in 190 countries and territories.

In 2023, participation reached record levels with 19.1 million participants worldwide. This year, World Cleanup Day was added to the UN calendar of international days and weeks.

World Cleanup Day in France

Created in 2017, the World Cleanup Day - France association is committed to ensuring that cleanup operations are a catalyst for behavioural change while raising awareness among individuals to adopt more responsible practices in terms of production, consumption and waste management. Driven by unifying, educational, inclusive and friendly values, the movement aims above all to raise collective awareness, beyond the million tonnes of waste collected each year.

As Anna Garbagna, ECJ’s correspondent in Italy explains, the new generation of cleaning machines combine efficiency, ergonomics and sustainability.

In Italy, as everywhere, the professional cleaning sector is undergoing a phase of significant technological renewal. Machinery manufacturers are investing in R&D to respond to new market demands: greater efficiency, reduced energy consumption, ergonomics for operators and attention to environmental impact. The result is a new generation of equipment that is changing the way professional cleaning is conceived.

Optimisation of working times and reduction of operating costs: these are the two key features. Thanks to more efficient motors and electronic control systems, energy and water consumption is reduced, ensuring a high standard of hygiene: modern floor scrubbers and sweepers adapt to different surfaces and dirt conditions, working faster and with fewer passes. Optimising consumption is not only an economic advantage for businesses, but also contributes to the sustainability objectives increasingly required by European regulations and end customers.

Manoeuvrable solutions

Another strong point is ergonomics: operators spend many hours using heavy or noisy equipment, with the risk of fatigue and musculoskeletal disorders.

The answer has been lighter, more manoeuvrable solutions with intuitive controls. Adjustable seats, digital control panels and driver assistance systems reduce physical effort and improve safety. Noise reduction is also key: quieter machines allow operation in sensitive environments such as hospitals, schools, hotels or offices without disturbing daily activities.

The new generation of machines is not only more efficient, but also smarter. The introduction of sensors and monitoring systems allows

real-time data to be collected on usage, consumption and maintenance conditions.

Some models offer IoT connectivity, allowing companies to plan interventions predictively and manage machinery remotely. This reduces machine downtime, improves operational continuity and ensures consistent cleaning standards.

Robotics is another rapidly growing frontier: autonomous robots for cleaning large surfaces are becoming increasingly common in logistics warehouses, shopping centres and airports.

ESG regulations

Finally, sustainability is now an essential element. New commercial cleaning machines use recyclable materials, systems that reduce the use of chemical detergents and technologies that minimise waste: an approach in line with ESG regulations and the growing awareness of businesses towards environmental impact.

For many companies, choosing suppliers who invest in green solutions represents a competitive advantage, as well as an ethical commitment: new-generation machines are not just an operational tool, but an integral part of corporate sustainability strategies.

The industrial cleaning market has always been moving towards innovation. The ‘new’ machines represent a strategic investment: they improve efficiency, protect the health of operators, reduce operating costs and contribute to concrete environmental objectives. For Italian companies, adopting these solutions means not only keeping up with the times, but also anticipating future market needs. In a competitive and regulated environment, technological evolution is not optional: it is the key to building a more modern, safer and more sustainable sector.

A municipal budget deal in Denmark favours cleaning at schools, nurseries and kindergartens. It pays according to American researcher. This from Lotte Printz in Denmark.

School washrooms have often been in the spotlight. But rarely for anything good. Usually, cleaning is not a priority for local government politicians when juggling the budgets. Therefore, this September’s budget deal for the Municipality of Copenhagen may come as a bit of a surprise. Allocating DKK 80 million (around €11 million) to school cleaning over a four-year period until 2030, this deal hopefully enables kids at schools, nurseries and kindergartens in the Danish capital city to enjoy cleaner washroom facilities. Although, the main amount is earmarked for refurbishments, DKK 7.3 million is allocated to educational initiatives, hygiene interventions and extra cleaning at the Copenhagen schools in 2026 as well as DKK 5 million annually in 2027-2029. Nurseries and kindergartens can look forward to DKK 4.5 million annually for these purposes. Good news for all

This is not only good news for the kids and from a cleaning and FM sector perspective, but can prove highly beneficial both health wise and in the monetary sense for these educational institutions where high-touch surfaces, shared equipment and washrooms serve as common culprits in the transmission of illness.

Recent studies in American elementary schools, reported by James Kim, PhD and senior vice president of American Cleaning Institute (ACI), on cleanlink. com, show that targeted surface disinfection protocols reduced

student absenteeism due to illness by 50 per cent. Cleaning also had a significant positive impact on staff absence, which may otherwise ‘require costly substitute coverage and disrupt continuity in instruction’ as Kim points out. On top of that, high hygiene standards improved staff morale.

Enhanced focus on evidencebased cleaning is key to Kim in this respect as it goes beyond routine schedules and visual inspection. It relies on measurable outcomes, data-backed procedures and validated products and technologies. ACI’s joint initiative with the Centers for Disease Control and Prevention, called ‘Healthy Schools, Healthy People’, offers practical, evidence-based resources as well as highlighting collective action. In his piece on cleanlink. com, Kim also addresses the cleaning and FM sector that is ‘in a unique position to drive transformation in school facilities’:

“By staying informed on research, embracing innovation and advocating for evidencebased standards, professional cleaning executives can shape healthier, safer learning environments (…) an evidence-based approach is not just best practice, it is a competitive advantage,” he says.

In conclusion, there’s no doubt that cleaning professionals can be essential partners in public health and keep the importance of spotless schools in the spotlight. However, municipal willingness and funding are prerequisites for succeeding.

John Griep at VSR in the Netherlands tells us about a system that standardises sector terminology.

Standardisation of terminology is a quietly powerful lever for improving safety, efficiency and commercial clarity in any technical service sector. In the cleaning industry the Standaard Informatie Systeem-Terminologie (SIS-T) performs that role: an alphabetical, maintained list of cleaningindustry terms with agreed descriptions so that stakeholders - clients, contractors, facility managers and auditors - use the same words to describe the same things.

A practical case

Before the 2025 refresh, Dutch terms like ‘dagelijks onderhoud (daily maintenance) and ‘dagelijks reinigen’ (daily cleaning) were often used interchangeably in tenders and work programmes, yet interpreted differently in scope and frequency. The SIS-T now explicitly equates these terms and anchors them to a measurable parameter; minimum once per week, which improves comparability across offers and contracts.

When linked to VSR-KMS inspections, the defined scope becomes auditable rather than a matter of interpretation. In regulated environments (eg, food production), pairing SIS-T terminology with VSR practice guidelines/food audits supports consistent verification against agreed methods and acceptance criteria. Embedding SIS-T references in tender texts and cleaning programmes therefore turns vague labels into enforceable, auditable specifications. From terminology to measurable practice

SIS-T provides the common vocabulary but its real value emerges only when those terms are linked to practical instruments. VSR practice guidelines require that terminology be translated into work instructions and quality criteria, while the VSR Quality Measurement System (VSR-KMS) offers standardised methods for audits. In addition, verification techniques such as ATP or UV testing are recommended to objectively assess cleaning outcomes. In this way, terminology becomes not just consistent but also verifiable in practice.

Recent update: SIS-T (2025)

SIS-T is actively maintained by sector organisations and saw its most recent update in 2025. The refreshes keep the vocabulary aligned with evolving practice and ensure procurement documents, operational work programmes and training materials rely on precise wording that prevents misinterpretation.

The renewed SIS-T list is publicly accessible via an alphabetical search function on the VSR website and is intended for everyone involved in the sector. Whether working in execution, planning, quality control or communications, professionals can use SIS-T as a single reference point: a reliable basis for consistent, professional language that supports clearer procurement, safer operations and verifiable audits. Adopted across documents and systems, SIS-T becomes less a glossary and more an enabling infrastructure for evidence-based, transparent cleaning practice.

• Stylish dispenser & hand wash refill with a wow factor

• Solid hand wash bar made from plant-based, natural ingredients

• Finely ground flakes provide an instant rich lather

• 12kg Co2 reduction per dispenser p.a. vs liquid soap

• Zero plastic packaging

• Zero plastic waste

• Up to 95% less water than liquid soaps

• Reduced waste

• Less storage needed

• Never-empty indicator

• Stackable refills

• Unique mechanism ensures every gram is used

Diversey are taking last year’s award-winning concept further with their latest release.

Diversey, a Solenis Company, is on a mission to drive the real innovations need

One of their key areas of focus is sustainable hand hygiene. With an estimated 400,000 tons of liquid hand wash used every year in public washrooms, emitting approximately 1 85 tons of CO₂e per ton, it was clear a better solution was needed.

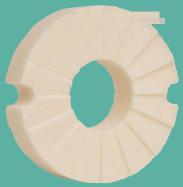

Last year, Solenis, in partnership with LESSEAU, launched the award-winning innovation: the LESSEAU® No-Touch Dispenser and solid wash bar, Mille Fleur, which claimed the Overall Winner of the Amsterdam Innovation Award 2024 and won the Sustainability & Environment category.

This year, LESSEAU® enters a new chapter in sustainable dispensing, building on the success of the no-touch system and expanding the range with the new LESSEAU® Manual Dispenser and two ECOCERT COSMOS Natural certified hand wash bars, a system that offers even greater sustainability credentials than its automated predecessor, highlighting Solenis’ commitment to transforming hygiene into a force for good.

With a sleek, push-activated design, the LESSEAU manual hand wash dispenser grinds solid hand wash bars into a fine powder that instantly transforms into a rich, creamy lather. The dispenser holds up to three bars at once, delivering 1,800 doses and featuring a “never-empty” refill indicator to ensure uninterrupted service Crafted from robust materials built for endurance, the dispenser is compact, lockable, and designed to fit seamlessly into even the smallest washrooms. It’s a solution that simplifies operations while helping businesses meet their Environmental, Social, and Governance (ESG) goals, cutting CO₂ emissions, transport costs, and product waste The hand wash range now offers three distinctive bars with PureSense and NaturFresh, joining the already popular Mille

Fleur.

• PureSense is a fragrance-free, dermatologically tested bar designed for sensitive skin. Certified by ECOCERT

COSMOS Natural, with Green Seal certification in progress, it’s the cleanest and most sustainable LESSEAU® bar yet, 100% vegan and microplastics-free.

• NaturFresh offers a soft fragrance derived from natural essential oils like linalool and vanillin. Approved by ECOCERT

COSMOS Natural, it combines indulgence with eco-conscious care, enriched with olive oil and shea butter.

• Mille Fleur, the original bar, remains a favourite for its vibrant floral scent and skin-loving ingredients. With notes of jasmine, lavender, basil, and geranium, it delivers a sensory experience that’s both luxurious and sustainable

Each bar is compatible with both LESSEAU® dispensers and delivers up to 600 activations The bars’ solid nature means they can be packaged for transit in cardboard, eliminating the plastic waste created by liquid solutions. And because the bars can be topped up, there is no longer a decision to make on when to change the bottle, which with liquid systems often leads to product being thrown away as sites try to avoid dispensers running empty between housekeeping shifts.

What is most impressive about the system, however, is just how great it is to use

Designed for Today’s Conscious Consumer

From boutique hotels and full-service restaurants to corporate offices and leisure facilities, LESSEAU® is redefining what hand hygiene can be. With 95% less water used in production and transport versus traditional liquid hand washes, and up to 12kg of CO₂ savings per dispenser annually, the impact is both measurable and meaningful

The LESSEAU® system doesn’t just tick boxes, it tells a story.

A story of innovation, care, and commitment to a better future.

It’s a hand hygiene experience your customers will remember, and your brand will be proud to share

Discover more at sales.solenis.com/lesseau

‘People’ - one of the three pillars of sustainability - are sometimes forgotten in the race to reach net zero. ECJ asks companies what they are doing to enhance the lives of people in the workplace, their community and in the cleaning sector.

MANY PEOPLE UNDERSTAND the word ‘sustainability’ to mean reducing waste, cutting emissions and minimising the use of water and energy.

But the three pillars of sustainability are generally defined as ‘Planet, People and Profit’. A company can only be sustainable if it profitable. And people are pivotal to its success whether they are customers, the workforce or the people using the products.

So, what are businesses in the cleaning industry doing to enhance the lives of people in their employ and in the wider community? And are people increasingly being left behind in today’s highly automated workplace?

The human dimension of sustainability is the beating heart of service provider’s La Lucente’s vision, says marketing and communications manager Gaia Lombardo Pijola. “It is the real engine that drives our commitment to the planet and our performance in the market,” she said. “In our philosophy People, Planet, and Profit are not competing elements - they form an inseparable equation of value because a prosperous and resilient organisation cannot exist without motivated and valued people.”

The company embraces a culture of well-being, she said. “We actively address issues such as stress management and work-life balance and we offer support to people returning from parental leave,” said Pijola. “We believe a happy employee is a more creative professional and a more

effective brand ambassador.”

She says La Lucente’s philosophy embraces three circles of ‘People’. “The first is our supply chain who we see as partners in our journey towards sustainability,” she said. “Customers make up the second circle and our mission includes ensuring their health and safety, using low-impact products for their environments and engaging in a transparent dialogue.”

The largest circle is that of the local community, according to Pijola. “Our goal is to actively engage local communities in sustainability dialogues because the prosperity of a company is inextricably linked to the health of the social and economic fabric in which it operates.”

The people who use the company’s services are the real protagonists, she adds. “We could design the most brilliant of strategies and select the most innovative of technologies, but it is the intelligence and professionalism of our operators who use them that transform that vision into a tangible result,” she said. “Our drive towards ecolabel solutions and low-emission products is not only a commitment to the environment, it is a pledge to care for and protect the health of our employees.”

La Lucente also offers training on risk perception plus the ability to deal with complex situations with third parties. “In this way we not only provide skills, we also build resilience, awareness and selfesteem,” she said.

Manufacturer Kärcher views the ‘People’ pillar of sustainability to be equally important as ‘Planet’ and ‘Profit’, according to corporate communications manager Linda Schrödter.

“True sustainability can only be achieved when all three dimensions are considered holistically,” she said. “Focusing on the well-being of our employees, customers and communities is fundamental to our long-term success and our responsibility as a global company.”

Kärcher’s interpretation of the ‘People’ pillar means fostering a safe, healthy and supportive working environment for staff

members, Schrödter adds. “It also involves promoting their development and ensuring fair labour practices. And it extends to positively impacting the communities in which we operate through social engagement and partnerships.”

Kärcher contributes to various causes overseas in regions where it can make a difference, she says. The end-user is also a key focus of the company’s sustainability policies.

“We are committed to designing and manufacturing equipment that is safe, ergonomic and user-friendly,” Schrödter said. “This includes intuitive operation, reduced physical strain and features that enhance the overall well-being and productivity of cleaners. Their safety and comfort are paramount in our product development process.”

According to Schrödter any focus on environmental goals such as net zero, waste reduction and energy usage should never overshadow the importance of people. “While these objectives are critical they must go hand in hand with social responsibility,” she said.

Kärcher offers its employees comprehensive training and development programmes, health and safety initiatives and diversity and inclusion benefits while also fostering a collaborative work culture. Outside the company it carries out various social projects, educational initiatives and partnerships both in local communities and globally.

2Pure Products - also a manufacturerdirector James Law also believes the ‘People’ the pillar should cover a company’s employees, the community and society in general. “For some organisations it applies globally, particularly where supply chains cross borders,” he says. “The most impactful strategies work on all three levels with a balance of internal responsibility and external contribution.”

He feels that employee safety and wellbeing are often overlooked in sustainability discussions. “Today’s focus on net

zero targets, reducing waste and conserving energy has led to people being moved down the priority list,” he says. “This has to change from the top down. It is essential that the individuals delivering frontline cleaning services don’t feel undervalued or left behind.”

Cleaning products need to be formulated with cleaners in mind, he believes, because these are the people who will be most exposed to them and who may need to work long shifts in environments where ventilation is limited.

“Traditional hazardous chemicals can pose significant risks from skin and eye irritation to long-term respiratory issues,” said Law. “Even enzyme-based products, while generally safe, can spark an allergic reaction if inhaled while probiotics pose a risk to immune-compromised individuals. These types of products also often incorporate traditional chemicals to enhance their capabilities.”

Wider community

2Pure Products manufactures non-hazardous formulations that carry non-toxic labels. The company’s patented multipurpose OdorBac Tec4 is designed to protect workers and building users. The company is also a Living Wage employer and staff members are free to take off as many days as they wish to volunteer for worthwhile causes.

The ‘People’ pillar is just as important as ‘Planet’ and ‘Profit’ to hygiene systems producer Essity, according to sustainability communications director Renee Remijnse. “For us it begins with creating a safe and inclusive workplace for our own people,“ she said. “However, the ‘People’ pillar goes far beyond internal culture. At Tork we see it as a commitment to improving lives through inclusive and sustainable hygiene.”

She says the company recently received the world’s first Design for All certification for the Tork dispenser development process. “Our Hygiene for All approach is about removing visible and invisible barriers to allow the majority of users to access hygiene comfortably,” she said. “This includes supporting those with physical limitations, neurodiversities, temporary injuries or stage of life challenges such as parenting.”

The people pillar also extends to the wider community and beyond, according to Remijnse. “We support local partnerships and global causes that promote wellbeing and dignity,” she said.

The cleaners who use the products are an integral part of the People pillar, she adds. “The 2025 Tork Insight Survey revealed that 80 per cent of cleaning staff reported mental health challenges linked

to their roles, with 46 per cent feeling stressed and 38 per cent having left positions due to burnout or lack of recognition,” she said. “These insights drive us to create products and services that support cleaner wellbeing and dignity as well as recognising their contribution and working to improve their experience.”

Essity’s Tork Vision Cleaning is claimed to support cleaners by making their working day more efficient and less stressful. It is said to provide real-time data on cleaning needs, helping staff to prioritise tasks and avoid unnecessary work.

Supporting individuals and communities is essential to Derrycourt Cleaning Specialist’s ethical integrity and long-term mutual success, says head of new business innovation and sustainability Bruce Hart.

“The ‘People’ pillar is every bit as vital as ‘Planet’ and ‘Profit’ because a sustainable future relies on people to deliver both environmental and economic strategies,” he said. The company invests heavily in training and skills development to offer growth opportunities and ensure human rights protections, he says. “Equal opportunity and fair wages are also paramount,” he adds. “People are at the centre of our operations and their health, wellbeing and safety remain our highest priority.”

The People Pillar begins with cultivating a supportive, inclusive workplace and extends to the communities and environments in which Derrycourt operates, according to Hart.

“We actively invest in local communities by employing local people, offering comprehensive education within the cleaning sector and by providing a wide range of personal and professional development opportunities including free English classes and internships.”

The cleaner’s health, safety, and comfort are central to the company’s

product decisions and sustainability strategy. “We provide extensive training on Derrycourt cleaning methods so that our whole team can have the tools they need to provide the best customer service possible,” added Hart.

“The training covers manual handling, chemical understanding, personal protective equipment, risk prevention and clear reporting lines with supervisors and managers. Cleaners are also supported to correctly manoeuvre equipment including height adjustments to avoid overreaching or bending.”

Derrycourt also offers flexible working arrangements and active commuting support through hybrid working, a Bike to Work Scheme and public transport tax-saver schemes. It offers training and progression planning and its new Lucky Strikes hazard identification initiative is designed to help raise staff awareness and to pre-empt incidents before they occur.

But as the use of automation increases in the cleaning industry, will the ‘People’ pillar of sustainability become less important in future? People will always be central to Derrycourt’s business, says Hart. “As a family-run company we know that relationships, empathy and expertise cannot be replaced by machines. Automation empowers our team but people will always remain at the heart of what we do.”

Automation will increasingly free people up from tedious and repetitive tasks, says La Lucente’s Gaia Lombardo “Machines in the future will take care of the ‘doing’ while people will take care of the thinking, feeling and deciding,” she said. “This is where their value will become exponentially higher.”

Essity’s Renee Remijnse says the ‘People’ pillar will become even more important in the future. “Automation will change how cleaning is done but it won’t replace the need for human insight, care and connection,” she said.

Kärcher’s Linda Schrödter agrees that the growth in automated systems will not diminish the relevance of people. “The human assets of empathy, problem-solving and adaptability will remain indispensable and our focus will be on integrating technology in a way that benefits both people and processes,” she concluded.

And 2Pure Products James Law concurs. “While automation and smart technologies are playing a greater role in facilities services, people will continue to be the most critical asset,” he said. “Automated systems cannot replace the judgement, adaptability and response that human operatives bring.”

Vibe Pro and V-Air Flow, two of the aircare solutions from Vectair, offer options for commercial spaces. Vibe Pro is intended for medium to large, high-traffic areas, providing controlled fragrance dispersal across open environments. Its patented dosing system delivers a measured dose each time and generates a fine mist that remains airborne for an extended period. The system

uses non-pressurised refills, avoiding propellants and aerosols, which simplifies transportation and storage.

V-Air Flow is designed for smaller spaces where limited airflow can reduce the effectiveness of passive scenting methods. It uses the Venturi effect to draw air over a 50 per cent plant-based refill and features an intelligent fan boost to circulate fragrance throughout a room. The dispenser is manufactured from 100 per cent post-consumer recycled plastic and incorporates an energyefficient fan that operates only when a building is occupied, reducing power consumption. www.vectairsystems.com

Kärcher has added the FloorPro Natural Industrial Cleaner RM 69N to its range of sustainable detergents. The product is formulated with over 99 per cent naturally derived ingredients and fully biodegradable surfactants, without the inclusion of mineral oils, colours or fragrances. The low-foam formulation allows

use in both scrubber dryers and manual floor cleaning applications, targeting light to moderate soiling.

The cleaner incorporates ingredients sourced from renewable materials, including coconut and maize, ensuring the surfactants are fully biodegradable. Its formulation places it in the lowest water hazard classification and it is not considered hazardous or a dangerous good under the CLP (Classification, Labelling and Packaging) chemicals ordinance. This classification simplifies handling and reduces associated costs for storage and transport.

The detergent is supplied in a canister containing 30 per cent recycled plastic. www.karcher.com

Filmop has developed OneFred, a modular washing system that can be configured with either two 15-litre or two 25-litre buckets, creating a 30- or 50-litre trolley according to operational requirements. Buckets with colour-coded handles help to separate cleaning solution from rinse water, supporting hygiene management. Compact and lightweight, OneFred includes an ergonomic handle for manoeuvrability and four integrated, impact-resistant bumpers to protect surfaces.

The system is available in several versions, including one equipped with the Peg Kit attachment system, which enables OneFred to connect with Filmop’s Alpha and Morgan trolleys. A version featuring the Uni-Connect fitting allows operators to attach and release mop holders or handles for window and surface cleaning tools, keeping essential equipment within reach while maintaining compact dimensions.

Sustainability is integral to the product design, the company

says. OneFred is manufactured partly from PSV-certified Plastic Second Life components, confirming the use of recycled materials. The absence of screws and metal elements allows complete recyclability at the end of the product’s life. www.filmop.com

Fimap has introduced a new generation of cleaning machines incorporating features designed to improve environmental performance and resource efficiency. Building on existing systems such as FSS - Fimap Solution Saver - which regulates water and detergent use, the machines now include the option to preprogramme cleaning zones. This helps to prevent waste and ensure consistent application. The FLR - Fimap Long Range - recycling system enables operators to clean larger areas using the same amount of water and detergent by reusing cleaning solution. And Fimap has also developed AQUÆ technology, which allows chemical-free cleaning by activating chlorine molecules naturally present in tap water.

Through the Fimap Fleet Management (FFM) monitoring system, users can track consumption, battery charging and CO2 emissions per working hour. The machines’ environmental performance is further supported by optional lithium batteries for energy efficiency, HEPA filters that retain particles down to 0.3 μm and tanks made from ReMade in Italy-certified recycled plastic. www.fimap.com

Greenspeed has introduced Trebio, its third-generation probiotic cleaning range developed to provide an alternative to traditional chemical cleaning.

At the centre of Trebio is the Trebio Consortium, a blend of three Bacillus strains selected for their complementary

enzymatic activity. These microorganisms break down organic residues such as fats, proteins and starches, helping to maintain a stable microbial balance on cleaned surfaces. This process continues after application, supporting ongoing surface hygiene and reducing the need for frequent intensive cleaning.

The formulation also manages odours, says Greenspeed. Instead of masking unpleasant smells, the probiotics act directly on the source, breaking down the organic materials.

By reducing reliance on harsh chemicals and extending the cleaning effect, Trebio supports lower resource consumption and waste reduction. Its packaging is designed for reuse and produced entirely from recycled plastic. The refillable bottle format aims to promote long-term use.

www.greenspeed.eu

Microred from TTS is a new microfibre flat mop that has been awarded the EU Ecolabel and was also tested by an independent laboratory for microplastic release during machine washing. It was classified as a low microplastic release product. Laboratory testing also assessed the mop’s effectiveness in removing microorganisms without the use of chemical detergents. The tests demonstrated Microred can eliminate 99.99 per cent of Staphylococcus aureus, Enterococcus hirae, Pseudomonas aeruginosa, and Candida albicans. Other studies showed a single pass of the mop reduces Coronavirus 229E by 99.9 per cent.

The design promotes high collection efficiency, allowing cleaning with reduced water and chemical use. By combining mechanical action with sustainable materials, Microred provides a cleaning solution aimed at lowering chemical consumption, limiting impact and reducing the risk of developing disinfectant-resistant bacteria. www.ttsystem.com

THERE IS A LOT TO TELL about toilets and toilet habits. Apart from my own experiences, there is a great deal of information easily accessible online, and there are even a few books about toilets available. In terms of cleaning however, the smallest room in the building still has its issues.

Splashing the dirt

Men urinating while standing up causes urine contamination on the seat and the area around the toilet. A solution was found decades ago: the urinal, a special toilet version mounted higher on the wall and thus reducing the fall height of the urine.

However, there are also public washrooms without urinals. Or, if for whatever reason, the man wants to have more privacy and prefers to close himself off, he pees in a normal toilet anyway. Hopefully he sits down or at least puts up the lid, but unfortunately many don’t. Which is very unhygienic for the next visitor using the same toilet and needing to sit. Knowing this, the learning for cleaning is: always clean the area around the toilet thoroughly as well (floor, wall) and don’t forget the tools that are positioned next to the toilet (toilet brush holder, bins). They probably are sprayed over as well.

Disturbing stripes

Another issue is toilets featuring a shelf or inner walls where poop slides down before reaching the water, leaving visible streaks. To be removed with a toilet brush. A ‘dirty job’ which is often neglected. Not removing it immediately means it will dry and be harder to remove later. And don’t forget that a dirty toilet causes a negative perception for the next visitor. What about the brush or toilet bowl mop? Often very dirty, sitting in a holder filled with contaminated fluid. Unhygienic and in healthcare environments I guess it is a source of cross contamination. Room for improvement I would say. If product designers are able to solve these issues in an innovative way, it will be a major step forwards.

Tips: after cleaning the toilet, keep the

brush in the toilet bowl while flushing and move it up and down to rinse it. Use a piece of toilet tissue to absorb the fluid in the toilet brush holder.

Lid closed

Search the internet and you will find videos demonstrating droplets from the toilet flush water descending around the toilet. Including all the invisible dirt it contains. Lauren Aber, affiliated with Quinnipiac University (Hamden, Connecticut USA) discovered that the chance of poop particles ending up on your toothbrush displayed in the same room is no less than 60 per cent. She published her research in 2015.

During the continuous flow, very fine droplets are created that precipitate elsewhere while suspended in the air: aerosols. That’s why the toothbrush gets contaminated with dirt from the toilet. Not only Aber, but also other scientists discovered the Escherichia Coli, an intestinal bacterium, on toothbrushes that were displayed in bathrooms with a toilet. What we learn from this is that the lid on a toilet is there for a purpose. Closing the lid while flushing is hygienic and by the way, a closed lid looks better. So if you end up in a public toilet where the lid is missing: flush and run.

To sit, or not to sit

An interesting new idea to lower the incidence of urine-contaminated toilet seats, is to label washrooms differently. Not separating men from women, but separating by the need to sit from the option to stand. I recently spotted public washrooms with door signs that indicated ‘Sitting’ and ‘Standing’. A surprising, open minded, interesting, hygienic and effective solution.

And, by the way, gender neutral as well. Touchless

When I use a public toilet, I move the seat and lid with my foot, cover the seat with toilet paper, close the lid with my foot when I am done, push the flush button with my elbow, wash my hands, cover the

There is much to tell about toilets and toilet habits around the world. In terms of cleaning, the smallest room in the building still has its challenges. In this article industry expert Paul Harleman of Harlecom Products & Services addresses some of them and tackles a few other interesting topics.

tap with a paper hand towel before using, cover the lock handle with a paper towel when unlocking the door, open the door with my elbow and take care nobody sees what I am doing because, to be honest, I find it a little bit embarrassing.

However, an American survey executed by the Bradly Cooperation showed that I am not the only one. Seventy per cent of the respondents use toilet or towel paper as a barrier between themselves and the surface they have to touch or sit on. Forty-six per cent use their foot to press the flush button and 70 per cent of Americans said they have had an unpleasant experience in a washroom due to the poor condition of the facility. The learning we have here is the clear need for touchless operated toilets.

Design differs

There is a wide variety of toilet types around the world. User positioning can be sitting, squatting (hole in the floor) or standing (urinal). Modern toilets have flushing systems including gravity flush, dual flush, vacuum (aeroplane) but manually flushing still exists as well (bucket with water). And there are also toilets that don’t flush (compost toilets). To finalise ‘the bigger job’, toilet paper is often used,

Toilet challenges (continued from page 25)

but some cultures use toilets with a shower system - integrated in the toilet or in a separate device (bidet). Toilets are made of stainless steel, ceramic or synthetic materials and ‘output management’ varies from public sewer/water purifying systems to sceptic tanks to compost systems.

Last but not least, the design of a toilet varies from ultra-modern to very basic with the rough distinction of free hanging on the wall or standing on the floor. For those who want to have all the comfort they can get when disposing food and drinks leftovers, get yourself a Japanese designed Toto Neorest WX2 toilet which is equipped with the latest comfort technology.

What the future will bring

Toilets may seem mundane, but they reflect the values, resources and challenges of a society. While western nations focus on comfort and technology, many others prioritise simplicity and sustainability. Future toilets will blend technology, healthcare and environmental consciousness - aiming to solve global sanitation problems while offering more personalised, hygienic and sustainable experiences. Toilets are evolving to address hygiene, water conservation, climate change and access to sanitation.

Key trends include:

Waterless and minimal-water toilets

• Use vacuum or dry flush systems (inspired by aeroplane and space toilets)

• Crucial in water-scarce areas

Smart toilets

• Integrated health monitoring (urine/fae-

ces analysis for early disease detection)

• AI-based usage pattern learning (eg, for elderly care)

• Connectivity to health apps

Self-cleaning and disinfecting toilets

• UV disinfection

• Antimicrobial surfaces

• Automatic bowl and seat cleaner

Energy-producing toilets

• Convert waste to biogas, fertiliser, or even electricity

• Already in pilot programmes in India and Africa

Modular and portable designs

• Flat-pack or solar-powered mobile toilets for disaster zones and refugee camps

Redesigned urban toilets

• Modular, space-saving units for dense urban areas eg, retractable public toilets)

• Privacy features and genderneutral design

Circular sanitation systems

• Closed-loop systems that recycle water and nutrients locally

• Aim: zero-discharge toilets (no waste, no sewer)

Public street toilets, a speciality

In 2001, Hong Kong unveiled the world’s most expensive public toilet: a fully functional solid gold loo. While it dazzled tourists, it also reminded us how something as ordinary as a toilet can reflect pride, technology and even national identity. Back in everyday public washrooms, the reality is far less glamorous. For cleaning and IPC professionals, public toilets are high-risk zones for pathogen transmission, especially on handles, flush buttons

and taps. Odours often come not just from poor cleaning but from unseen biofilms in pipes and drains. And cleaning schedules rarely match the pace of foot traffic. But promising innovations pop up. Not only in the toilet-specialised Japan but also in the Netherlands. A company called Sanitronics designed an public toilet with an integrated, fully automatic toilet cleaning machine. Cleaning is crucial

Professional toilet and washroom cleaning is essential for hygiene and a positive reputation of a facility. Public washrooms can quickly become sources of infection if not cleaned properly - spreading bacteria, viruses and fungi. This is especially critical in healthcare, hospitality, education and food service, where poor hygiene can lead to health risks, complaints, or even legal consequences.

Many organisations can improve their approach by moving beyond fixed schedules and adopting cleaning routines based on actual usage. Areas like flush buttons, toilet seats and door handles need extra attention, as they are frequently touched. Well-trained staff, proper professional tools and clearly defined protocols are key to maintaining standards.