Vision of the future from China

At DAF, we’re dedicated to driving your business towards a more sustainable future. To support your journey, we’re offering a limited number of 100 zero-emission DAF XD Electric 350 FT 4x2 tractor units, designed to deliver a lower Total Cost of Ownership (TCO) over a five year period compared to diesel alternatives. It makes a compelling business case for making the move to zero emissions today. DAF – powering your success on the road to sustainable transport. WWW.DAF.CO.UK/ELECTRIC-OFFER

Being named editor-at-large of DNZ felt like being entrusted with curating the road transport industry—haulage and coach alike. A magazine is more than a set of articles; it is a tapestry of an industry’s aspirations, critiques, and shifting moods.

Founder Matt Eisenegger understood that true decarbonisation requires creating space for operators. As an entrepreneur, he also recognised that breaking new ground in publishing— especially when no one is asking for it—would be challenging. Yet his blank sheet of paper has grown into a publication with several thousand readers.

A trade magazine demands vision: a pulse on everything that moves (literally), and an ability to detect subtle societal shifts that others may miss. What issues are simmering beneath the surface? What bold paths are worth forging?

My work in publishing and finance has taught me that information drives action—and action, in turn, generates new information. It’s gratifying to see that cycle play out in the overlap between the magazines and PMD, who are now financing the decarbonisation of transport.

My involvement began on “my hill” (see photo). The Fool on the Hill, one

of The Beatles’ most enduring songs from the Magical Mystery Tour album, captures themes of introspection, observation, and outsider wisdom. McCartney wrote it after noticing how people respond to change—and how those on the fringes often see truths others overlook. The “fool” embodies both isolation and clarity, suggesting that outsiders can offer valuable insight.

Becoming editor-at-large requires enthusiasm for storytelling and listening. I’m doing both—and the page-turning adventure continues in 2026.

Ian Jones

INFORMATION

EDITORIAL

Publisher: Matthew Eisenegger

Editor at large: Ian Jones

Managing Editor: Richard Simpson

Designer: Harold Francis Callahan

Editorial Address: Commercial Vehicle

Media & Publishing Ltd, 4th Floor 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ

Telephone: 01257 231521

Email: matthew@cvdriver.com

ADVERTISING

Advertising Sales: David Johns

Telephone: 01388 517906

Mobile: 07590 547343

Email: sales@cvdriver.com

DESIGN

Art Editor: Harold Francis Callahan

Telephone: 01257 231521

Email: design@cvdriver.com

CONTRIBUTORS

Dean Barrett

Liam Campbell

Tim Harper

Anthony Humble-Smith

Grahame Neagus

PUBLISHED BY

Commercial Vehicle Media & Publishing Ltd, 4th Floor, 19 Capesthorne Drive, Eaves Green, Chorley, Lancashire. PR7 3QQ

Telephone: 01257 231521

NOTE

The publisher makes every effort to ensure the magazine’s contents are correct. All material published in Destination Net Zero magazine is copyright and unauthorised reproduction is forbidden. The Editors and Publisher of this magazine give no warranties, guarantees or assurances and make no representations regarding any goods or services advertised in this edition.

Destination Net Zero magazine is published under a licence from Commercial Vehicle Media & Publishing Ltd. All rights in the licensed material belong to Matthew Eisenegger or Commercial Vehicle Media and Publishing Ltd and may not be reproduced whether in whole or in part, without their prior written consent.

Destination Net Zero Magazine is a registered trademark. © 2025

If

Everything you need to know from the last two months

Zero-emissions vans of up to 4.25 tonnes maximum authorised mass will move to the Class 7 MoT testing system with a first test at three years, rather than the AFT stations which currently deliver the annual test to commercial vehicles of over 3.5 tonnes.

The decision to reduce cost and administrative burdens for ZE van operators follows a consultation earlier this year. Road safety impacts will be monitored in a postimplementation review.

The Department for Transport is also exploring options for the same vehicles to be moved from assimilated drivers’ hours (EU) rules into the scope of GB rules, to provide greater simplicity, flexibility and uniformity with equivalent internal combustion engine

(ICE) vehicles. Most 4.25-tonne zeroemissions vans are of similar size and payload to their 3.5-tonne diesel competitors.

Legislation will be required for the changes to come into effect, and the DfT expects this will occur in Spring or Summer 2026. DfT said there was a “clear view” that the existing roadworthiness testing burden for the affected vehicles was “likely to act as a barrier to their adoption.

“The benefits of moving these vehicles into the Class 7 MOT system were agreed on by many respondents: greater flexibility, reduced costs and reduced administrative burdens including for managers of mixed ICE and ZE van fleets in providing one consistent regime.”

The European Automobile Manufacturers’ Association (ACEA) is disappointed that the European Union’s revised Weights and Dimensions Directive falls short of what is needed to accelerate decarbonisation of the transport sector.

ACEA warns that the text adopted “Falls short of what is needed to accelerate the deployment of zero-emission trucks, buses and coaches. Europe has set the world’s most ambitious CO2-reduction targets for heavyduty vehicles. To meet them, zero-emission solutions must become the fully competitive go-to choice for transport operators in every segment and across all EU countries.

“To ensure that revised Weights and Dimensions rules really support this shift, several targeted improvements remain essential in the upcoming negotiations with the European Parliament. In particular, adequate weight allowances for the most common vehicle configurations, including 4×2 tractor-semitrailers and even a modest increase in axle weight limits are needed to enable payload and operational parity with conventional vehicles. At the same time, unnecessary complexity and cost, for example in relation to the On-Board Mass Monitoring (OBMM)

and Smart Tachograph requirements, are counterproductive and must be avoided.

“A swift transposition timeline of not more than 18 months will also be key so that operators can benefit from the updated rules without delay.

“Europe’s commercial vehicle industry remains fully committed to delivering climate-neutral road transport. We stand ready to work constructively with policymakers to ensure this Directive effectively supports Europe’s decarbonisation goals rather than slowing progress on the road to 2030,” ACEA concluded.

Moving to an integrated electric axle layout has enabled Renault Trucks to expand its heavy-duty electric tractor range. The E-Tech T 780 6x2 has a claimed 600 km range, while the E-Tech T585 has a 460 km range.

Both trucks feature an undriven tag/ steer axle to the rear, and can operate at 44-tonnes gvw. The new driveline layout, with motor and transmission integrated into the drive-axle, frees up space for batteries between the chassis’ side-members, with the 780 model having a 4100 mm wheelbase compared to the 585’s 3600 mm.

Two new Volvo FM Electric 4x2 tractor units have replaced a pair of diesel trucks at Fenn Logistics, as part of its strategy to offer environmentally friendly supply-chain solutions to its customers.

The zero tailpipe emission trucks are dedicated to a contract with one of the world’s largest food and beverage manufacturers.

Fenn Logistics worked with local Volvo Trucks dealer Hartshorne Group to calculate the exact routes that would best suit the electric trucks.

Managing Director Gary Major said:

“For the last 18 months, more than half of our fleet has migrated to HVO (hydrotreated vegetable oil) fuel and we are always looking at the latest

Iveco claims to have set a new benchmark in sustainable transport after its S-Way CNG truck traveled over 1,000 kilometres on a single refill of compressed natural gas.

Driven by French journalists Fabien Calvet (www.truckstop.fr) and Loïc Fieux (Les Routiers) on a route between the Belgian and Spanish borders, under real-world operating conditions, the tractor drew a loaded Krone curtain-sided semi-trailer at 30 tonnes GCW.

Iveco’s xCursor 13 engine by FPT Industrial, delivers 500 hp and 2,200 Nm of torque. This latest-generation gas engine is designed

Both models are compatible with charging stations equipped with the ultra-fast Megawatt Charging System (MCS), up to 720 kW. These stations can provide up to 350 km of range in a 45-minute driver’s rest break. They can also be charged at a depot using the standard CCS (up to 350 kW).

The 4x2 E-Tech T 540 tractor remains available for regional distribution roles and now has an extended range of up to 450 km.

technologies to deliver carbon savings for our customers. This first move to electric power is the next step of that process.

“It’s been a detailed project with Volvo to prove the concept. We looked at the data and modelling to make sure we found the optimal application. It’s been very pleasing to get these two new FM Electrics onto the road, immediately helping our customer make big strides towards its sustainability targets.”

The two trucks operate the same routes every day, transporting goods from the customer’s factory to its East Midlands Gateway distribution centre. They work double shifts, moving six loads across a 24-hour cycle with charging between runs.

for the upcoming Euro VII standards and delivers optimal performance between 1,000 and 1,500 rpm. Paired with the second-generation ZF TraXon 12-speed automated gearbox and a long rear axle ratio, the xCursor 13 maximises torque efficiency while keeping engine speeds low throughout the journey.

Average fuel consumption was below 21 kg/100 km over more than 1,000 kilometres. The new 620-litre tank packs offer a total capacity of 1,240 litres (equivalent to at least 190 kg) of CNG – an 18% increase over the previous generation and a remarkable 72% improvement compared to the first Iveco CNG tractors introduced in 2011.

UK market leader DAF Trucks has pledged that the buyers of 100 of its XD Electric 350 FT 4x2 42-tonne tractor units will achieve total cost parity with comparable diesels over five years, thanks to a limitedtime contract-purchase offer.

The deal allows operators to reclaim all VAT upfront and claim100% First Year Capital Allowances, whilst retaining full flexibility at contract-end through a guaranteed future value provision.

This enables operators to either make a pre-stated balloon payment and take full ownership of the truck or hand back it back (subject to return conditions), owing nothing more.

The DAF XD Electric 350 FT 4x2 tractor features a 525kWh Lithium Ferro Phosphate (LFP) battery pack with 462kWh usable capacity, providing real-world range of up to 500 kilometres. The truck supports DC charging up to 325kW,

enabling rapid top-ups when required, while overnight charging provides a straightforward solution for singleshifted operations covering over 400km per day. An eight-year battery warranty demonstrates DAF’s confidence in the long-term reliability and residual values of its electric technology.

Louis Jones, EV & Connected Services

Director of DAF Trucks, said, “We’re not just trialling electric, we’re proving it works. This offer fundamentally changes the conversation around electric trucks. We’re not asking operators to pay a premium for environmental credentials – we’re demonstrating that electric operation, over time, can deliver a better TCO than diesel.

“The numbers speak for themselves: lower weekly costs, zero emissions and no compromise on performance or specification.”

• New DAF electrics driven: Page 22

ReFuels has arranged a £25 million debt facility with the Foresight Group for its partowned CNG Fuels subsidiary. Together with cash-flow from operations, the facility will fund the construction of three new high-capacity Bio-CNG refuelling stations as part of the company’s strategy to double UK-wide dispensing capacity by the end of 2028.

Philip Fjeld, CEO and co-founder of ReFuels, said: “We are progressing the next milestones in our growth plan backed by rapidly increasing operational cash flows and the new debt facility. This enables us to capitalise on the fast-growing demand for Bio-CNG driven by fleet owners transitioning to 100% renewable biomethane to meet decarbonisation targets while reducing fuel costs.”

The new stations include confirmed sites at Magor (South Wales) and Swindon (SouthWest England) and will increase the capacity of CNG Fuels’ network to more than 12,500 HGVs per day. They are further expected to unlock significant future orders from existing and new customers, including strong uptake of the new, larger 6x2 gaspowered trucks.

Construction has already started on the Magor site where the new station, owned and operated by CNG Fuels, is strategically located near the M4 motorway, providing direct access to key routes for efficient east–west freight between London, South Wales and the Midlands. The site is close to two international airports, the Port of Newport and home to distribution bases for major operators, including Tesco and AB InBev.

The Magor station will have the capacity to refuel 12 trucks simultaneously when at full utilisation. This enables refuelling of more than 800 trucks per day and the dispensing of more than 30 million kilograms (kg) of Bio-CNG annually.

In total, CNG Fuels (40% owned by ReFuels) plans to build out at least nine highcapacity stations over the next three years, complemented by a fleet of additional Mobile Refuelling Units (MRS), giving capability to fuel over 20,000 HGVs by 2028’s year end. The station roll-out towards the end of 2028 will be fully funded through cash flow from operations and the debt facility.

Paint manufacturer AkzoNobel has deployed its first two electric trucks to serve its urban trailer fleet together with switching its national fleet to hydrotreated vegetable oil (HVO). Working in partnership with its transport provider, XPO Logistics and the Government ZEHID programme, the initiative will cut the company’s transport emissions by over 50% and save approximately 3,000 tonnes of carbon emissions annually, directly supporting AkzoNobel’s SBTi to reduce Scope 1 emissions by 50% by 2030, against a 2018 baseline. Annual carbon savings of 3000 tonnes come in three key areas:

• Vehicle efficiency improvements: 300 tonnes CO2 reduction

• Euro 6 engines and electric vehicles: 700 tonnes CO2 reduction

• HVO fuel adoption: 2,000 tonnes CO2 reduction

These combined savings equate to removing more than 650 average passenger cars from UK roads.

Two Renault Trucks E-Tech T 4x2 electric tractor units will operate from AkzoNobel’s Slough site to serve London and the surrounding areas. These vehicles will deliver a 100% reduction in direct CO2 emissions while in operation and contribute to lower noise and air pollution. Complementing this, the HVO-powered fleet will operate nationwide, ensuring significant reductions in carbon footprint across both long and short-haul journeys.

Gridserve, the vehicle charging company, has started construction of two public truck charging hubs. These new locations form the foundation of the Electric Freightway giving operators access to high-powered, public charging designed specifically for electric heavy goods vehicles.

The first hubs are being installed at Extra Baldock (J10, A1(M)) and Moto Exeter (J30, M5).

Each site will include:

• four to eight ultra-rapid charging bays capable of delivering high power to vehicles with large batteries

• Drive-through design for articulated lorries and trailers, eliminating the need for reversing or awkward positioning

• Swept-path and manoeuvrability planning to ensure safe, efficient access for HGVs

• Wider bays, clear signage, and driver-height terminals to suit commercial vehicle layouts

• Secure facilities, including lighting, sensors, walkways, and CCTV

The Electric Freightway is part of the UK Government’s Zero Emission HGV and Infrastructure Demonstrator (ZEHID) programme. Supported by Innovate UK, the project combines Gridserve’s infrastructure expertise with national funding to accelerate the transition to zero-emission road freight.

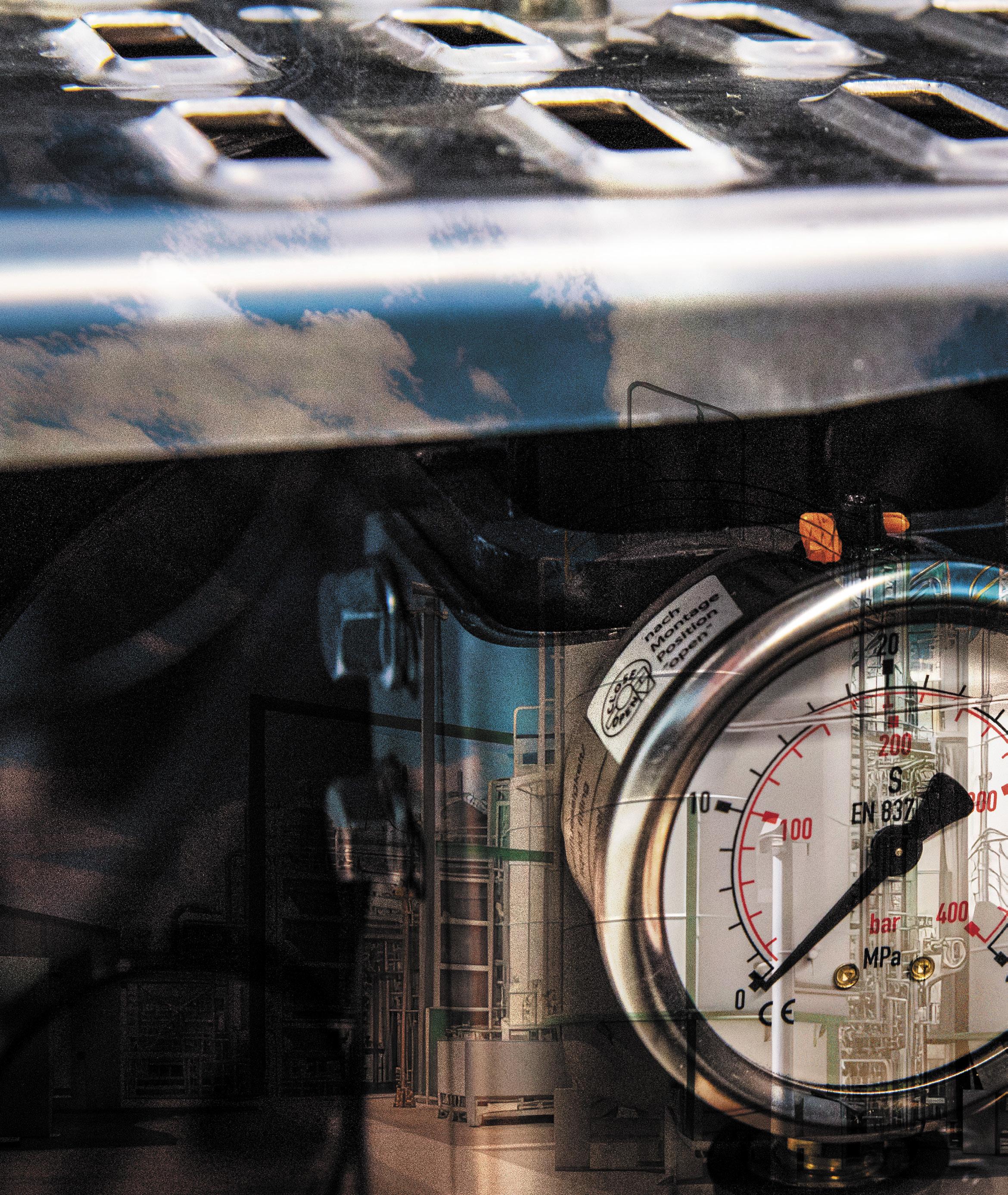

As fleets and operators pursue hybridisation and electrification, Fischer Panda UK | Power Solutions helps businesses integrate flexible, reliable onboard power systems. The company combines decades of expertise in diesel generators with the ability to design full-system solutions that integrate solar, fuel cells, wind, and diesel, supporting power-hungry equipment such as climate control, refrigeration, and specialist systems across marine, defence, specialist vehicle, and commercial applications.

Central to this approach is a team of highly skilled electricians and engineers with over a century of collective experience in designing and managing complex power networks. Their expertise ensures every system is tailored to the unique requirements of each operator, enabling fleets to run efficiently, sustainably, and with confidence. Fischer Panda UK’s solutions are trusted by the UK Ministry of Defence, Formula 1 mobile units, Sky News, leading vehicle converters, refrigeration companies, and many more highlighting the company’s reputation for performance and reliability.

Operating from a purpose-built 9,000 sq. ft facility in Verwood, Dorset, and holding ISO UKAS 9000:2015 accreditation, Fischer Panda UK | Power Solutions combines engineering excellence with personalised, hands-on support. As a family-run business, it maintains a strong focus on customer service, building longterm relationships across sectors and delivering solutions that operators can depend on.

To provide the best outcomes, Fischer Panda UK | Power Solutions partners with premium global brands that share its values of quality, longevity, and reliability. This includes Fischer Panda diesel generators, All-In-One power systems from Clayton Power, EFOY fuel cells, and superwind turbines. The company is also the exclusive UK distributor for Mastervolt automotive power electronics and refrigeration and climate solutions from Autoclima as well as the Eberspächer Breezonic rooftop air-conditioning unit.

In recognition of its innovation, Fischer Panda UK | Power Solutions received the Motor Trader Vehicle Enhancement Innovation Award in

2025, celebrating their ability to combine traditional power expertise with emerging electrification technologies. By offering tailored guidance and fully integrated systems, the company supports businesses as they transition to hybrid and electric power, enabling fleets to meet operational demands while reducing environmental impact.

From its legacy of trusted diesel generators to advanced multi-source, hybrid power solutions, Fischer Panda UK | Power Solutions continues to empower operators to meet the challenges of modern, electrified mobility while maintaining the reliability, performance, and customerfocused approach that has defined the business for over 30 years.

“offering tailored guidance and fully integrated systems”

Salford City Council has added its first electric refuse collection vehicle, a 27-tonne Mercedes-Benz eEconic, to its 36-strong RCV fleet.

The eEconic combines zero emissions with a high payload capacity similar to the diesel Econic and a class-leading operational range of at least 150km in refuse operations, making it ideal for the stop-start demands of urban refuse collection.

It was selected after an extensive evaluation programme when it completed daily rounds on a single charge and returned to the depot with 40–60% spare battery capacity, outperforming all other models tested by Salford City Council.

At 27 tonnes fully-loaded the eEconic can collect over 1,200 bins per day.

Alan Fitzsimons, Transport Manager at Salford City Council, said: “The MercedesBenz eEconic is leaps and bounds above the rest. During our demonstration period, it completed every route with battery range to spare, while competitors struggled to finish on a single charge. It is 100% electric, and the range and regenerative braking are excellent. It has surpassed all our expectations and we’re proud to lead the way in sustainable waste collection for Salford residents.”

Agricultural services provider Agrii has taken delivery of its first all-electric heavy truck, Mercedes-Benz eActros 600 LS ProCabin Stream 4x2.

Supplied by Midlands Truck & Van, the new eActros 600 is one of the first of its kind to enter service in the UK.

The vehicle was selected after an extensive evaluation programme, including trials under full load on Agrii’s regular routes. With its class-leading 500 km+ range, the eActros 600 was the only electric HGV capable of completing Agrii’s demanding 460 km nightly round trip between its central distribution centre and network of depots on a single charge, with energy to spare.

Based on a typical annual mileage of 60,000 km, the eActros 600 is expected to reduce Agrii’s carbon emissions by around 59 tonnes each year.

Richard Pinnock, Agrii’s National Distribution Manager, said: “It’s almost unnatural to think a truck that size can be electric and achieve such a distance on one charge. Sustainability is an important issue for the agricultural sector, and adopting our first electric HGV is a crucial step in reducing our environmental impact.”

HVO trucks ‘most cost-effective’ RCVs

An early adopter of electric refuse collection vehicles has admitted that diesel vehicles running on HVO could be more cost-effective at environmentally-friendly refuse collection.

Nottingham City Council claimed a world first when it rolled out its first two Dennis Eagle battery-electric eRCVs in December 2020.

A further electric 18 trucks were subsequently added to the fleet, and a 2024 Freedom of Information request revealed that the vehicles had cost £8.7 million.

Problems with load capacity and range subsequently emerged when the trucks were used to collect heavy garden waste in leafy suburbs.

Council head of fleet, Ken France, pointed out that the electric RCVs had a gross weight of 26 tonnes, cost £560,000 and had a 12-tonne payload. The larger diesel RCVs had a 32-tonne gross weight, a 20-tonne payload and cost £265,000.

Switching these to HVO fuel “is the single most cost-effective approach to carbon reduction,” he told The Nottingham Post newspaper. “The cost of electricity is about the equivalent of diesel now”.

“So there are no savings with an electric vehicle. A diesel vehicle with HVO, gets the equivalent carbon reduction while saving the council a significant amount of capital.”

Lee Rowland, sales and marketing manager at Dennis Eagle, said: “Switching to electric isn’t purely a decision based on cost but also considers important factors such as air quality.”

The eActros 600 delivers the power and range needed for real commercial impact. At a 40-tonne gross combination weight (GCW), it can travel at least 500 km (310 miles) on a single charge.

Even with standard CCS charging at up to 400kW, the eActros can charge from 20–80% in under 60 minutes. When megawatt charging becomes widely available, that time drops to around 30 minutes - easily aligned with a driver’s statutory break. This means the truck could cover over 1,000 km (620 miles) per day with no added downtime.

UK fleets are already seeing the benefits. Mathias Krieger, Co-founder and CPO of HIVED, said: “With the eActros 600, HIVED continues to redefine what a modern delivery company looks like.”

Find out more: eActros | Mercedes-Benz Trucks UK

Infrastructure is key - and the UK government is helping accelerate the shift. Through its £30 million Depot Charging Scheme, part of a wider £63 million EV investment, more than 200 HGV chargepoints will be installed across the country.

Mercedes-Benz Trucks is also leading through investment, via Milence - a joint venture with Volvo Group and Traton Group - to build public charging networks across Europe. The first UK site in Immingham is already operational.

James Venables, Head of Future Sustainability, Daimler Truck UK, said: “We’re proud to support the infrastructure needed to make zeroemission transport a reality,”

Switching to electric is about more than just the truck. TruckCharge is a free consultancy service from Mercedes-Benz Trucks that helps businesses plan their entire electric transition.

Covering initial consultation, infrastructure, and operations, the in-house eConsultancy team works alongside the experienced dealer network to provide:

• Route and cost analysis

• Infrastructure and charging strategy

• Long-term decarbonisation planning

The goal? A seamless, informed path to zero emissions that supports both sustainability goals and operational efficiency.

Find out more: TruckCharge | Mercedes-Benz Trucks UK

The eActros 600 is making an impact in industries far beyond logistics.

• Formula One: The Mercedes-AMG PETRONAS F1 Team transported race cars from the UK to Zandvoort – proving a 673 km journey could be completed on a single charge.

• Live Music: Sam Fender completed the first all-electric UK & Ireland tour, showing electric trucks can deliver even in high-pressure, highperformance environments.

Sam Fender said: “Hopefully this will show what’s possible and others will jump onboard too,”

YOUR DESTINATION FOR ROAD FREIGHT TRANSPORT, DISTRIBUTION, AND LOGISTICS SOLUTIONS

CO-LOCATED WITH

THE PULSE OF PASSENGER TRANSPORT. POWERING PROGRESS, ONE JOURNEY AT A TIME.

A new variant of the all-electric MAN eTGL 12-tonne chassis, designed specifically for refrigerated box bodies, was launched at Solutrans 2025 in Lyon. Intended for the emission-free and very quiet local distribution of temperature-sensitive goods, such as foodstuffs, the truck features a high-voltage interface supplying the refrigeration unit directly from the vehicle’s electrics.

With a usable battery capacity of 160 kWh, the range of the MAN eTGL is up to 310 kilometres without intermediate charging, depending on bodywork and use – more than sufficient for urban and regional distribution transport. Innovative fast-charging technology

recharges the two batteries from ten to 80 percent in around 35 minutes.

Friedrich Baumann, Director of Sales & Customer Solutions at MAN Truck & Bus, said: “With the new eTGL for refrigerated logistics, we are significantly expanding the range of applications of our lightweight eTruck. Together with eTGX and eTGS, we now have a highly efficient zero-emission portfolio for temperature-controlled logistics – from innercity distribution transport to long-distance transport.”

Like its big brothers eTGX and eTGS, the MAN eTGL benefits from current efficiency

improvements: more economical auxiliary systems, more consistent waste heat utilisation and improved driving functions increase the range by around ten per cent.

The MAN eTGL is based on the proven diesel 12-tonne model. With a payload of up to 6.6 tonnes, a wheelbase of 4,500 mm, body lengths of between 6,200 and 7,300 mm and cab access with only one step, the eTGL is ideal for urban distribution transport.

The fully digital 12.3-inch display provides information about the charge level, range and energy consumption.

Class-leading range of up to 180 miles, the Yutong TE7 7.5t electric truck is the perfect vehicle to begin electrifying your fleet

In short, asset finance is an alternative form of funding used by businesses to obtain the equipment they need to grow or access much-needed cash. Asset finance makes the otherwise unaffordable affordable because it gives businesses access to the equipment they need without incurring the cash flow disadvantage of an outright purchase.

Agreements can be customised to the business’s needs, with flexibility on both the term and repayment schedule.

• Hire Purchase (HP) allows you to buy the equipment on credit. The finance company purchases the asset on your behalf and owns the asset until the final instalment is paid, at which point you are given the option to buy it.

• Finance lease: The full value of the equipment is repaid to the finance company, plus interest, over the lease period. At the end of the term, you can choose to:

o continue to use the asset by entering a secondary rental period o sell the asset and keep a portion of the income from the sale o return it

• Operating lease: Similar to a Finance Lease, an Operating Lease allows you to rent the asset from the asset funder while you need it. The key difference between the two is that an Operating Lease is only for part of the asset’s useful life. This means you pay a reduced rental because the cost is based on the difference between the asset’s original purchase price and its residual value at the end of the agreement.

• Refinance: Refinancing or capital release, as it’s also known, is a proven way to make your assets work for you and release cash back into the business. It works by the finance company purchasing the asset and financing it back to you, with repayments calculated in line with the income the asset is expected to generate; at the end of the refinance term, you own the asset. This offers several benefits to a business that just needs a cash injection, whether it’s for investment in additional business-critical assets or to use in other areas of the business, including unexpected bills and invoices, salaries, VAT payments, diversification - the uses are almost endless. Funders can also look to take over a finance agreement with another provider and extend the term, ultimately reducing monthly payments and easing the pressure on cash flow.

Grahame Neagus, Head of LCV, Renault Trucks UK & Ireland

As we move into 2026, it’s clear that the commercial vehicle sector is operating within a period of significant change.

The increasing presence of Asian brands in the van and truck market, the direction of government policy highlighted in the recent Budget, advances in autonomous technology, new generational attitudes to mobility and buying decisions and a noticeable evolution in design thinking are all happening simultaneously. None of these trends sits in isolation; together, they’re reshaping the way the industry competes and how it plans ahead.

One thing that does remain fairly steady is the natural LCV demand base, at around 250,000 vehicles in the 2.8–4 tonne segment per annum. With that in mind, each new OEM market entrant simply increases competitive pressure on established players, even as vehicles become more efficient and sustainable. Maintaining market share becomes a tougher task for everyone.

That pressure is heightened by the growing stream of legislation around the decarbonisation of transport, with the Government’s November Budget giving a clear indication of where policy is heading. For the first time, we’re seeing moves to introduce additional tax burdens on those who have already gone electric in the car market. This naturally raises the question of how soon similar measures might reach the commercial vehicle sector.

It was encouraging, then, to see the Budget exclude vans and HGVs from the forthcoming Electric Vehicle Excise Duty in April 2028. It gives operators a clearer view of the investment landscape and acknowledges the tight margins the transport and logistics industry works within. The ten years of 100% business rates relief for eligible EV charge points and EV-only

forecourts reinforces the travel towards zero-emission transport. Alongside this, the additional £100 million for charging infrastructure - on top of the £400 million committed at the 2025 Spending Review - shows continued support for expanding national charging capacity. For operators weighing up the switch to electric vehicles, that level of commitment to charging infrastructure is essential.

The Budget also makes it clear that government thinking when it comes to vehicles now extends beyond emissions. There are strong indications that congestion is becoming part of the policy equation, with cost increasingly being used as a lever to influence mobility choices.

At Renault Trucks, our vision of The Good City aligns well with this direction of

travel. It’s our blueprint for how cities and larger towns could operate with all vehicles running at zero emissions, while ensuring logistics operators can still provide every service needed in a way that is calm, clean and efficient. Significantly, this isn’t a distant or idealistic concept. Around 90% of the vehicles required to bring The Good City to life exist today. The path ahead is about implementation rather than invention.

This thinking goes back to March 2021, when we revealed the HDD Express concept: an eco-friendly, quiet and emissions-free urban transport solution, ready for the future possibility of driverless or platooning applications. It demonstrated how design and technology can support the demands of tomorrow’s urban environment. Some aspects will work better in certain locations than others, but the future will always be a blend of what works today and what becomes possible tomorrow.

This period of change also raises a wider question around vehicle design direction. We are seeing more shared platforms across brands - sometimes three, four or even five models using the same core architecture, differentiated only by grille or trim. From a cost and lifecycle perspective, this is entirely logical and brings real benefits in development and parts supply. But it does risk turning vehicles into commodities, where individuality is pushed aside.

It may be that newer buyers place greater emphasis on efficiency and operating costs than on design cues. Even so, for many SMEs a van fleet isn’t just a tool - it’s a visible statement of the business. The look and feel of a vehicle matters because it represents the company out on the road, not just in terms of functionality but identity.

That’s why creativity remains important. Whether in today’s vehicles or future concepts like HDD Express, success will depend on

• Grahame Neagus

finding the right balance between capability, technical strength, suitability and desirability. With more global brands entering the European market, that balance becomes even more crucial. The response to the Renault Trucks Master Red Edition underlines this point. It has appealed to operators who might not previously have considered us, proving that practical strengths paired with genuine driver appeal still carry real weight.

Looking ahead, the direction is clear: greener, cleaner and quieter transport is becoming the norm, especially in Urban and Regional logistics sectors. As we move into 2026, there are real opportunities for the sector to benefit from today’s electric drivetrains. But from an OEM perspective, we must remember that a van is often an extension of a business’s values and aspirations. Individuality in design and presence still matters, and simply following the herd risks pushing us towards a commoditised world where creativity is lost.

In a sector where every mile and every minute matter, efficiency, reliability and innovation make all the difference. That’s why AS 24, a subsidiary of TotalEnergies, has been supporting transport professionals for over 36 years. With more than 1,800 service stations across 29 European countries, AS 24 operates one of the continent’s largest networks entirely dedicated to HGVs. Designed with drivers in mind, the stations feature wide lanes and 24/7 availability, making refuelling faster, safer and easier. Behind the wheel or behind the desk, AS 24 helps both drivers and fleet managers save time, stay in control, and keep moving.

Now, AS 24 is helping the road transport industry take the next big step: the energy transition.

AS 24 has expanded its fuel network across the UK and Ireland! You can now fill up with HVO100 at 24 stations in the UK and 2 in Ireland, supporting your shift towards lowcarbon fuels. Key locations include Dublin, Castleford (M62), Leeming Bar (A1), Liverpool, Bridgwater (M5) and West Thurrock (M25) — all strategically placed along major freight routes.

HVO100 (Hydrotreated Vegetable Oil) is a renewable, fuel made from residues, waste and plant materials. It’s chemically identical to diesel, delivering the same performance with a much smaller carbon footprint. And the best part? You can fill up 100%, alternate with diesel or mix both, with no vehicle modification required. It’s a plug-and-play solution that lets you go greener instantly.

Did you know? Using HVO100 from AS 24 can cut CO2 emissions by up

to 90% and reduce nitrogen oxides by almost 30% — all while offering excellent cold-weather performance.

So, choosing HVO100 also means aligning your transport activity with new sustainability goals across the industry. AS 24 supports this transition by providing a monthly report showing your CO2 savings, helping fleets demonstrate their environmental commitment.

Cleaner to handle, more stable in storage and better for engines, HVO100 keeps vehicles running smoothly mile after mile.

From its trusted European network to its constant drive for innovation, AS 24 delivers efficiency, control and peace of mind on every mile — now with 100% renewable energy at the pump. Find your nearest HVO100 station on the AS 24 Station Finder and start driving cleaner today.

Electric trucks are evolving fast: DAF’s latest offerings tick all the boxes from 12-tonne rigids to 4x2 tractors with long-haul cabs

DAF began its journey into electric transport back in 2018 when the first battery-electric versions of the LF and CF appeared on European roads. Since then, the manufacturer has steadily developed its BEVs to produce what a modern electric truck needs to deliver in real-world distribution.

Now, that early progress has culminated in a new generation of zero-emission products: the XB Electric, XD Electric and XF Electric. Together, they

give operators BEV options for everything from urban multi-drop to regional distribution and longdistance trunking.

The timing is important. Under current European legislation, CO2 emissions from trucks and buses must fall by 43% compared with 2019 levels by 2030. According to Raoul Wijnands, DAF’s senior product manager for testing, achieving this target will require around 400,000 electric trucks to be in operation across the continent. That’s a huge number, but DAF is positioning itself to

“CO2 emissions from trucks and buses must fall by 43% compared with 2019 levels by 2030”

ensure customers can begin their transition with confidence.

Of course, charging infrastructure across Europe and the UK will have to keep pace. But part of DAF’s approach has been to design electric trucks that can integrate easily into existing fleets where shorter routes, predictable duty cycles or returnto-base operations already make battery-electric transport a realistic and attractive option. By offering multiple battery capacities, motor outputs and body configurations, DAF is ensuring these vehicles can serve a broad range of applications from day one.

The smallest of the three new BEVs is the XB Electric: available as a 4x2 rigid at 12, 16 or 19 tonnes. Battery choices for the 12-tonner are 141kWh, 210kWh or 282kWh packs, with options for the two larger batteries only on the heavier trucks. Power comes from either the 120kW EX-M1 motor or the 190kW EX-M2 motor, depending on gross vehicle weight. Operators can choose between Day Cab and Extended Day Cab versions, and range is up to 350 km depending on specification and conditions.

DAF’s XD Electric offers the widest flexibility. It’s designed for regional, urban and national distribution and is available with Day Cab, Sleeper Cab or High Roof Sleeper. Configurations include 4x2, 6x2 and 6x2 rear-steer rigids, plus a 4x2 tractor. Power options span the EX-D1 and EX-D2 motors, giving outputs from 170kW to 350kW. Battery packs are available in 315kWh, 420kWh or 525kWh capacities. GVWs range from 20.5 to 29 tonnes, while GCWs reach up to 50 tonnes. Maximum range is over 500 km, though DAF suggests 350-420 km is a realistic working figure when running at full weight in hilly conditions.

The XF Electric is positioned for the top end of the market. It uses the same three battery capacities as the XD and exclusively features the EX-D2 motor, delivering 270, 310 or 350kW. Cab choices are Sleeper or High Roof Sleeper. GVW and GCW limits mirror those of the XD, and maximum range likewise matches its mid-range sibling.

A varied test route around Eindhoven showed how the new electric trucks perform in a variety of real-world scenarios. Our route included a long

motorway loop, tight village roads, A-roads, roundabouts, chicanes and slower sections with cyclists, pedestrians and changing traffic conditions.

The XF 350 FT Electric was the first truck of the day and it provided a superb introduction to DAF’s new generation of BEVs. Configured as a 4x2 tractor at 40 tonnes gross, it came paired with a two-axle trailer and a High Roof Sleeper Cab.

The specification was representative of a premium driver-oriented long-distance set-up: Xtra Leather Air driver’s seat, Xtra Comfort Mattress, fridge, cinema-style passenger seat and the familiar pull-out table that many DAF drivers swear by. The XF feels built for long stints of uninterrupted cruising. With the 350kW motor delivering instant, smooth torque, the truck gathers pace easily and maintains it with almost no effort.

What stands out most, however, is the level of quietness. Without engine noise, the cab becomes a calm, spacious workspace where conversations with co-drivers are refreshingly crystal clear. It’s an environment that encourages smooth driving and reduces fatigue.

Visibility is excellent thanks to DAF’s digital mirrors, excellent Corner View camera and Kerb View Window fitted low in the passenger door. Together they give an uninterrupted awareness of the truck’s surroundings. This test vehicle achieves a three-star London DVS rating.

Regenerative braking is managed via a threestage stalk, which becomes intuitive very quickly. The large power gauge on the driver’s

display makes it easy to see when the truck is drawing energy and when it is feeding power back into the batteries.

DAF was keen to demonstrate its ‘intelligent one-pedal driving’ set-up, which means the driver can for the most part adapt to using just the throttle to control acceleration, cruising and braking. It soon becomes the natural way to operate the truck, especially when planning smooth deceleration for roundabouts or tighter sections.

On the motorway, stage one or two felt ideal, though we stepped up to stage three when decelerating on a couple of shorter off-ramps. Of course, the service brakes are also on hand, but with enough foresight you may not need to use them too often. The route featured a broad mix of conditions: long motorway runs, flowing A-roads and a handful of tighter sections including narrow roundabouts and chicanes. These are the places where an electric powertrain’s smoothness truly shines. The XF handled it all with confidence, maintaining an even, predictable feel throughout. For operators who want a premium longdistance electric solution, the XF delivers a quiet, refined and highly capable driving experience.

After the XF we tried the smallest truck in the range: a 4x2, 14.5-tonne XB 190 FA Electric rigid with an Extended Day Cab. This part of the test route took us through a tight village, complete with narrow lanes, tree-lined verges, wide cycle lanes and a 30km/h limit. It was exactly the kind of environment where an electric distribution truck needs to excel – and the XB rose to the challenge.

The cab layout is practical and intuitive, ideal for fleets. Controls are straightforward, and everything a driver needs is close at hand. The XB on test used conventional mirrors and carries a three-star DVS rating. Despite the more compact footprint compared with the XD and XF, the driving position feels generous enough for a full working day.

A single-stage regenerative braking system is fitted to XB, controlled by a simple button on the steering wheel. While basic compared with the multistage systems in the larger models, it works cleanly and consistently. Drivers looking to maximise energy recovery simply need to choose their moments carefully – lifting early on approach to junctions or roundabouts and using smooth throttle control during slower sections. For typical distribution cycles involving shorter routes and regular returns to base, this is more than adequate.

The 190kW motor provides brisk acceleration around town and power delivery is reassuringly smooth. It feels nimble and easy to place on the road,

even when navigating the tight pinch points common in Dutch village streets.

Ride comfort is impressive for a smaller rigid. It maintains the same calm found in the XD and XF, contributing to a relaxed, unhurried driving style. For operators looking for a dependable, quiet and energy-efficient urban truck with DAF’s familiar ergonomics, the XB Electric fits the bill perfectly.

The final truck of the day was the 30-tonne XD 350 FT Electric, a 4x2 tractor with a Sleeper High Cab, and a two-axle trailer featuring a steered rear axle. With its combination of motorway, town and mixed rural sections, the XD had the most varied drive of the three –ideal for showcasing its versatility.

From the moment the combination was rolling, the XD felt reassuringly sure-footed. Visibility is excellent – this model achieves a four-star DVS rating – and the driver’s environment is roomy, uncluttered and well thought out.

As with the XF, the XD uses a three-stage regenerative braking system. One-pedal driving becomes second nature, especially once you’ve located the ‘sweet spot’ in the accelerator that allows the truck to maintain speed smoothly during cruise. Lifting the pedal lets regen step in, recovering energy and slowing the vehicle without fuss. Stage zero allows the truck to free-roll, which is helpful on long, gentle descents or when you want to maintain momentum.

Performance from the 350kW motor is strong even under load, and the combination felt agile throughout the route. Roundabouts, junctions and short bursts of acceleration were all handled confidently, while motorway sections highlighted the XD’s relaxed cruising style.

ergonomics. The regenerative braking systems, power delivery and display layout all contribute to a driving experience that’s easy to adapt to.

DAF’s approach demonstrates clear readiness for the industry’s transition toward zero-emission heavy vehicles. These trucks deliver quiet operation, strong performance and impressive smoothness – qualities that drivers will appreciate immediately.

Across the XB, XD and XF, DAF’s electric lineup leaves a consistently strong impression. Each model is thoughtfully engineered for its intended role, offering smooth performance, excellent refinement and the reassuring familiarity of DAF’s latest cab environment and end

“The 190kW motor provides brisk acceleration around town and power delivery is reassuringly smooth”

DAF’s New Generation XD and XF Electric trucks have been named International Truck of the Year 2026, marking a major milestone for the Dutch manufacturer and underscoring the rapid rise of zero-emission heavy vehicles across Europe.

The award—widely regarded as the most prestigious honour in the commercial vehicle sector—was presented to company president Harald Seidel during a ceremony at the Solutrans exhibition in Lyon, France. The win represents DAF’s third International Truck of the Year title in just five years, following victories for the New Generation XF/XG/XG+ in 2022 and the New Generation XD in 2023.

A win rooted in e iciency

Each year, the jury of the International Truck of the Year organisation selects a model launched within the previous twelve months that delivers the greatest contribution to roadtransport e iciency. Evaluation covers technology, comfort, safety, drivability, environmental impact, energy e iciency and overall operating costs.

For 2026, the panel of 23 leading commercial-vehicle journalists from across Europe singled out the XD and XF Electric models for their standout energy e iciency, long driving ranges, and advanced electric architecture. Jurors praised the smooth, almost seamless driveline behavior and the trucks’ modular design, which allows operators to tailor battery capacity and axle configurations to di erent applications.

Florian Engel, chairman of the jury, noted that DAF’s decision to combine a central electric motor with a traditional rear axle delivered impressive results. He said the setup achieves energy e iciency on par with e-axle systems while o ering ideal weight distribution and broad operational flexibility.

Power, range, and real-world capability

The award-winning trucks are powered by PACCAR’s EX-D1 and EX-D2 electric motors, producing between 170 kW (230 hp) and 350 kW (480 hp). They can be equipped with battery packs ranging from 210 to 525 kWh, enabling more than 500 km of zero-emission range on a single charge. With optimised charging strategies, operators can achieve over 1,000 km per day—an important benchmark for both regional and longdistance use.

Designed for urban distribution and full-scale logistics operations alike, the XD and XF Electric models combine lowmounted cabs, excellent aerodynamics, and advanced digital camera systems to maximise visibility and safety.

momentum—for

Calling the award “a moment of pride,” president Harald Seidel said the recognition highlights the company’s commitment to shaping the future of zero-emission transport. He added that the accolade a irms the brand’s dedication to delivering e icient, comfortable, and safe vehicles to its customers.

With its latest win, DAF strengthens its position as a leading innovator in the transition to electric road transport—signaling that the race toward cleaner logistics is not only accelerating, but reaching new milestones faster than ever.

Liam Campbell reports from the show at Wuhan, China

Jaecoo, BYD, Omoda, Xpeng, and Ora are just some of the new Chinese brands introduced to the UK car market over the past couple of years but, in the commercial vehicle market Maxus – a brand introduced almost 10 years ago – remains the only mainstream competitor.

Is this all about to change?

China is exporting commercial vehicles in huge quantities. Of the 4.17 million vehicles exported from January to September 2025, 790,000 (15.9%) were commercial vehicles of which the vast majority were sent to developing markets in Africa, South America and Asian markets were legislation and homologation is less stringent than in the UK and EU.

However, in the UK and Europe, the primary focus has been passenger cars. This year, over 10% of new cars registered in the UK have been built in China, compared with around just 4% of LCVs and fewer still trucks.

There are signs that this is about to change. Farizon launched its SV van at the CV Show this year, and Yutong and JAC have plans to introduce their light trucks with collaborations with Pelican Engineering and Wrightbus respectively.

As with passenger cars, the Chinese manufacturers are using their technical advantages with EVs as their foot in the door for Europe and, at the CCVS, a range of potential new candidates were on show in full force.

Taking the largest stand at the CCVS was Dongfeng; a company whose global HQ is located just a couple of miles down the road from CCVS.

Dongfeng recently commenced trials of its new hydrogen truck in Wuhan, in conjunction with Honda. This combines Honda’s fuel cell stack and system architecture, developed through over three decades, and Dongfeng’s vehicle platform and manufacturing integration.

Other big news from Dongfeng is its successful partnership with Huawei to deploy megawatt chargers to fleet customers, with Dongfeng contributing to the world’s first 100MW charging station opened by Huawei in Sichuan Province.

One of the key’s to DongFeng’s success over recent years has been its joint ventures and some UK LCV buyers will know the DFSK (DongFeng SoKon Automotive) EC35 van imported to the UK by Innovation Automotive. Another JV with Nissan, DFAC (DongFeng Automobile Company) has produced this V8E van, launched in May with a 5 cubic metres loadspace and a 54kWh battery, priced at just £8,600!

“This year, over 10% of new cars registered in the UK have been built in China , compared with around just 4% of LCVs and fewer still trucks.”

Despite its huge stature in the car and bus markets, BYD is still a relatively small player on the CV scene with its eNV200-based T3 van being its most successful product globally so far. The recently-announced eVali van – earmarked for the UK – wasn’t on display at CCVS but there was a range of three trucks.

The T4 and T5 are rated at 3.5 and 4.5 tonnes, respectively, while the Q3 heavy truck is fitted with the BYD’s new-generation 452kWh battery pack, which is capable of charging at speeds of up to 350kW and can take a 60% charge takes just 50 minutes.

“Farizon launched its SV van at the CV Show this year”

JAC will be familiar with UK consumers thanks to its partnership with Wrightbus to launch the Rightech RT75 7.5t light truck in the UK. The Hefei-based company specialises in the light-end of the market (sub-12t), and was at CCVS to celebrate the launch of the new 4.5t ET9 light truck.

With its wedge-shape design, the ET9 has a drag coefficient of just 0.33 (33% lower than the segment average) to increase range by 15%, which stands at an impressive 510km from a 120kWh CATL battery.

Elsewhere on the JAC stand was a 3.5-tonne autonomous van (see cover), developed with Shine Auto. With approval granted in numerous municipalities across the country, autonomous delivery vans is a fast-growing sector in China thanks to their lower running costs and higher payloads and load volume.

Hybot’s striking H49 hydrogen truck won the 2026 Chinese Truck of the Year award at CCVS, and the relatively new startup was attracting plenty of attention. Earlier this year, Hybot secured £45m of Series A funding and plans to launch the truck early next year.

In addition to offering L4 autonomous driving, the H49’s main advantage is its efficiency. Its sleek, aerodynamic design affords a low consumption rate of just 7.1kg of hydrogen per 100km and a range of over 1000km.

A JAC salesperson explained that fleet operators don’t feel the need to fit autonomous vans with such powerful motors as conventional vehicles have, and this particular model is claimed to return around 300km from just a 50kWh battery.

Another new startup in the hydrogen truck market is Z-Trucks, a brand born out of a collaboration of Shanghai Wuliu Truck Company and Horizon Fuel Cells that manufactures a range of electric and hydrogen long-distance trucks.

Z-Truck’s latest offering is rated at 42 tonnes and combines Horizon’s proven VL-III Series fuel cell system with a locally sourced Type IV hydrogen storage system to offer an impressive range of 1,500km.

“Chinese manufacturers are using their technical advantages with EVs as their foot in the door for Europe”

Foton has recently announced an overhaul of its truck range with its latest ‘Daystar’ light trucks which feature new 800v battery architecture and full OTA servicing, and its nextgeneration ‘Galaxus’ heavy truck range with up to 97.5% efficiency and L4 autonomy.

Also on the Foton stand was its new light commercial vehicles, the ‘Wonder Plus’ light truck and ‘Cavan Lefu’ panel van and minibus. Based on an all-new skateboard chassis, the Cavan Lefu features its own self-developed 2.2C battery and returns 4.2 miles per kWh.

As its name suggests, First Auto Work’s (FAW) is China’s oldest truck manufacturer, dating back to 1953. Earlier this year it launched the ‘Track 1000’ which is China’s first independently developed 100kg-class onboard liquid hydrogen (LH2) system and FAW’s first 1,000km hydrogen system.

Consisting of a 300kW liquid hydrogen fuel cell paired with a 100kg LH2 storage tank, Track 1000 achieves its range thanks to a number of innovative features, including an aerospace-grade cryogenic insulation system (with a static evaporation rate of less than 3%), stable pressure management during operation and hydrogen storage density of 10%.

end

• Tim Harper

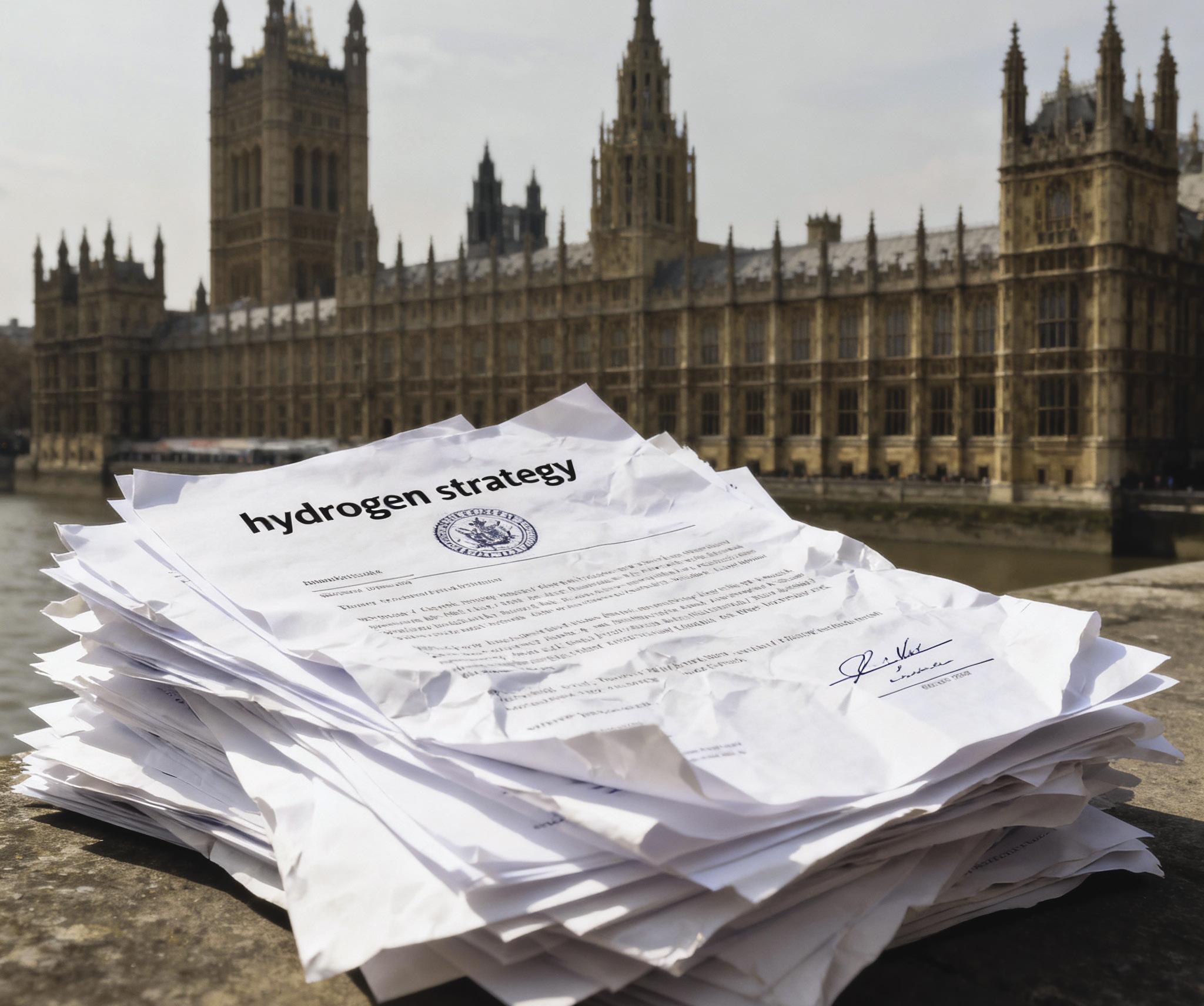

Tim Harper identifies three signs that hydrogen is going nowhere fast in Britain

Ask anyone actually working in the hydrogen economy what they think about UK policy and you’ll rarely hear a positive word. Speak to project developers, investors, or engineers, the people building real infrastructure, not just drafting policy, and the verdict is unanimous: we are falling further behind global leaders. Worse, there is precious little faith that our endless pilots and “consultations” will amount to anything more than political window-dressing.

And you have to ask: If the UK government is so reluctant to fund green hydrogen properly - or is simply opposed in principle - why bother at all? Poorly funded, small-scale projects aren’t going to lower costs or prove competitiveness. If all we’re after is a handful of pilots and ambitious targets, it would almost be more honest to spend nothing and focus national effort elsewhere.

But here’s what nearly everyone agrees on: The UK government really only has one job in this sector and that is to bring the cost of hydrogen down to an economically useful level. Once that happens, the private sector will do the rest. Investors want to build; companies want to scale. But nobody is going to pile in when green hydrogen costs three times as much as the fossil alternatives and government funding is a fraction

“risk-averse, underfunded, bogged down by process, and oddly resistant to learning from the rest of the world.”

of what Germany, the USA, and even parts of Asia are putting up. Until clean hydrogen is economically viable, in other words, until policy makes meaningful scale possible, the market won’t move.

Yet we find ourselves in a classic “emperor’s new clothes” situation. There are a number of companies - and the trade associations that represent them - that depend, at least in part, on government funding. With livelihoods and future projects on the line, nobody is willing to speak truth to power. The entire sector is going along with the charade, everyone recognising the problem privately, but few willing to say so in public.

There’s a peculiar British habit of trialling and piloting technologies that already work perfectly well elsewhere. Hydrogen buses?

They’re carrying passengers in Europe and China.

Hydrogen Bus Pilot

Green steel?

Commercial sites are already running in Sweden and Germany, providing real data on cost and performance.

Yet in the UK, millions are spent to see “if it works here.” It’s as if we need a national pilot project for iPhone functionality in London because it was designed in California. Rather than learning from successful reference projects abroad, we seem determined to duplicate the groundworkmistakes and all - even when others have already solved the challenges.

If you want to know if a hydrogen bus works? Take a short flight, ride one, talk to the operators, bring home the lessons. There’s no value to obsessively re-inventing the wheel.

Hydrogen heating

Nothing illustrates British hydrogen hand-wringing better than the recent trials of 100% hydrogen as a domestic

mains gas. For nearly a century, Britain’s own ‘town gas’ supplied by the gas grid was over 50% hydrogen. People cooked, heated water, and survived winters using it. We know that hydrogen works in a domestic setting because it always did.

So why the repeated urge to test hydrogen all over again, with more pilots and local demonstrations? Why spend millions

proving what history already settled?

Nobody is suggesting converting the entire gas network to 100% hydrogen. But blending modest percentages into the current gas grid could cut emissions right now: instead we’re caught in an expensive, time-consuming loop of reinventing what was routine two generations ago.

Make hydrogen economic

This isn’t just a hydrogen story, it’s a parable for the entire UK net zero approach: riskaverse, underfunded, bogged down by process, and oddly resistant to learning from the rest of the world.

But it all comes back to that one job for government: make hydrogen cheap enough for the private sector to take over. That doesn’t mean there’s one magic price point—cost reduction is a stepwise process, with new applications enabled at each stage as prices come down. The first to benefit will be sectors where hydrogen is already close to competitive, like replacing expensive fossil fuels such as diesel in heavy transport. As costs keep falling, hydrogen becomes viable for even tougher, hard-toabate sectors - eventually unlocking deep carbon abatement in steel, cement, and other heavy industries.

That requires proper funding and bold market mechanisms, not more halfmea sures and endless pilots. If the government isn’t willing to do what it takes to unlock real market-driven growth, maybe it’s time to stop pretending otherwise.

Because until hydrogen is truly economic, the UK will keep spending public money on nicesounding but ultimately pointless trials, while competitors build industry and jobs, and cut emissions at a global scale.

“...requires proper funding and bold market mechanisms, not more halfmeasures and endless pilots.”

Anthony Humble-Smith suggests practical strategies to save fuel, cut emissions and strengthen your business

The haulage industry stands at a pivotal moment. Rising diesel prices, stricter emissions regulations, customer demand for greener supply chains and reputational pressure are all converging.

For many hauliers, the question isn’t if to decarbonise, but how to do so in a way that supports business profitability, not undermines it.

The good news? You don’t have to wait for fleets of electric trucks or hydrogen infrastructure to make a meaningful difference. By focusing on smart, operational improvements, often with little or no large capital outlay, you can reduce fuel use, cut carbon emissions, improve efficiency and strengthen your bottom line. This article explores accessible, cost-effective strategies across multiple dimensions, and uses realworld case studies to show what’s already being achieved.

Drivers are the frontline of any haulage operation. How a vehicle is driven has a direct

impact on fuel consumption, vehicle wear and emissions, and therefore cost. Training drivers in efficient driving techniques is a highly leveraged step with relatively modest investment.

What good driver-training covers:

• Smooth acceleration and braking: avoiding sudden throttle or brake applications reduces wasted energy and improves fuel economy.

• Correct gear-selection and keeping in a high and appropriate gear: For manual transmissions especially, reducing unnecessary gear shifts (and revving) improves overall fuel efficiency. In one case 15 drivers improved average MPG by 7% after training and gear changes dropped by 42%.

• Reducing idling: engine idle time is fuel burned but no distance gained. One case cut idling time by 50% and saved £700 per week across the fleet.

• Anticipation and route-planning: Drivers trained to anticipate changes in traffic, hills and load conditions can maintain steadier pace, reducing fuel use.

John Mitchell (Grangemouth) Ltd (UK) trained all its 100+ drivers in a SAFED (Safe and Fuel Efficient Driving)-type programme and achieved:

• A 7% fuel improvement across the test group.

• Annual cost savings of ~£274,000 in fuel use.

“Collateral benefits included fewer accidents, reduced wear and improved driver behaviour”

Collateral benefits included fewer accidents, reduced wear and improved driver behaviour.

Branston Ltd, a UK potato haulier, undertook a driver-training course using telematics (Volvo Connect) and boosted driver efficiency by one MPG across 33 trucks, equating to £60,000+ per year savings.

Fuel is one of the largest controllable costs in haulage. Training that improves driving behaviour also improves fleet longevity, reduces maintenance and supports decarbonisation. It’s one of the highest-return, lowest-capital actions you can do.

Beyond how you drive, where and how far you drive has a huge impact. Optimising routes, reducing empty miles and maximising vehicle utilisation are steps that in many cases fund themselves.

Key tactics include using AI-enabled or algorithm-driven route-planning tools to analyse distance, stops, traffic congestion, driver hours, and load sequences. Optimised routes reduce extra mileage, downtime and idle time.

Combined deliveries/pick-ups ensure vehicles are fuller and avoid returning empty or near-empty. Monitor route adherence using telematics; identify deviations, excessive idle or detour mileage and address them. Leverage load-matching platforms to fill return legs, reducing empty running.

A UK logistics firm reported savings of up to 20% in fuel consumption by using route optimisation tools.

Use of clustering/platooning algorithms in European fleets reduced fuel by 10–20 % through smarter routing.

Digital freight-exchange platforms in the UK such as HaulageHub are enabling hauliers to

cut empty miles substantially. One platform helped reduce empty runs, which account for over 30% of HGV miles nationally, by better matching return-load opportunities and improving overall fleet utilisation.

Reducing empty or inefficient legs directly cuts diesel use, reduces wear, lowers labour and frees up capacity. The return on investment for route-optimisation software is often less than a year, especially given today’s fuel price environment.

At highway speeds, aerodynamic drag becomes a major contributor to fuel consumption. Many hauliers underestimate how much difference simple aerodynamic enhancements can make, while the cost/ time to implement is relatively modest. Roof deflectors/fairings and side-skirts on trailers: reduce turbulent airflow and help the vehicle “slice” through air. Cab fairings ‘bridge’ the gap between tractor and trailer and stop the formation of drag-inducing vorticies.

Under-tray panels and trailer tails (boat-tails) help manage airflow beneath and behind the vehicle. Even modest modifications can pay-back quickly: one study showed a retrofit roof fairing cost £300 and paid back in under six months.

John Mitchell (Grangemouth) Ltd invested in aerodynamic aids across the fleet: this alone delivered an estimated 9% improvement in MPG, saving ~£355,000 per year.

In research on trailer skirts, savings of 4-7% were reported depending on design.

Aerodynamic losses are largely ignored until fuel bills force attention to the topic. But small changes add up, especially given the high annual mileage of HGVs. The investment is often modest and the pay-back short.

Maintenance and Tyres

Even with optimised driving and routing, equipment inefficiencies can undo gains. Vehicles that are poorly maintained cost more fuel, emit more and require more repairs.

Maintenance best practices

Tyre pressure and condition: Under-inflated tyres increase rolling resistance and fuel use. Studies show ~2% fuel penalty for tyres a bar under-inflated.

Wheel alignment: Misaligned axles increase both rolling resistance and wear. One guide showed misalignment on trailers could increase fuel consumption by up to 15%.

Engine filters, clean injection systems, correct oil/lubricants: Ensuring combustion efficiency and reducing internal friction.

Tyre technology: Low rolling resistance (LRR) tyres represent a compelling upgrade. Research shows typical fuel savings of 4–6% from LRR tyres in heavy-vehicle service. For example The Continental “Conti Eco” heavyduty tyres claim up to 12% improvement in rolling resistance over predecessor models, plus up to 10% more mileage.

Maintenance isn’t just about reliability, it’s about fuel efficiency and carbon efficiency. Every litre saved is fewer emissions and fewer pounds spent. Over a large fleet, these efficiencies stack Also, digital freight-exchange platforms in the UK — such as HaulageHub — are enabling hauliers to cut empty miles substantially. One platform helped reduce empty runs, which account for over 30% of HGV miles nationally, by better matching return-load opportunities and improving overall fleet utilisation.

Beyond the truck itself and the driver, what truly affects profitability is how effectively each vehicle is used?

Are you carrying full loads?

Are you returning empty?

Are your assets working to their full potential every day?

For many hauliers, optimising utilisation is one of the quickest, lowest-cost ways to reduce emissions and boost income simultaneously.

Key tactics include load maximisation ensuring trailers are filled as close to capacity as possible and that loads are balanced to prevent “partial legs.”

Smart scheduling and digital load-planning tools help ensure no space or energy is wasted.

Back-hauling and return loads avoiding empty return journeys is one of the simplest ways to improve fuel efficiency and profitability. Coordinating collections for the return leg of a trip can turn what was once a cost into a source of revenue.

Collaboration and digital freight marketplaces: Platforms such as HaulageHub and the Transport Exchange Group are changing the way operators do business. By connecting hauliers in real time with available loads, these platforms dramatically cut empty running. They allow companies to share capacity, match journeys, and build flexible partnerships across the logistics sector.

For example, a recent UK initiative led by the Transport Exchange Group, in partnership with HaulageHub and the Road Haulage Association, offered hauliers free access

to digital freight-matching tools during a pilot programme. The results were striking: participating operators reported a marked reduction in empty miles and improved fleet utilisation. Across the wider network, hauliers were able to cut empty-running from roughly 30 percent of total mileage to significantly lower levels, while also improving delivery efficiency and driver productivity.

Every mile travelled without revenueproducing cargo is a direct hit to profitability. Fuel, driver hours, maintenance, and tyre wear all continue to accumulate even when a trailer is empty. Collaboration platforms like HaulageHub turn those empty miles into earning opportunities, helping fleets to reduce fuel consumption and emissions per tonne-kilometre, increase asset utilisation and revenue, and build stronger partnerships across the logistics ecosystem.

By embracing digital collaboration, hauliers can decarbonise operations and grow profitability at the same time proving that sustainability and efficiency are no longer competing goals, but two sides of the same smart strategy.

procurement

While we often focus on fleet renewal, there are other strategic steps hauliers can take now to reduce cost and carbon without buying new vehicles.

Review whether you operate too many or sub-optimally utilised vehicles. Matching fleet size and vehicle type to actual demand cuts fixed cost and fuel use.

Alternative fuel blends can offer rapid gains. While full electric/hydrogen may be long-term, bio-diesel, HVO or renewable diesel blends can reduce the carbon intensity of current fleet operations for a lower investment.

These strategies don’t require replacement vehicles, instead they optimize what you already have, your spend, your contracts, your asset base, your fuel procurement. They support a rational transition rather than a disruptive one.

A positive road Decarbonisation is often framed as a burden, but it doesn’t have to be. For haulage firms, it can be a source of competitive advantage,

leaner operations, better margins, stronger reputation, and future-proof operations.

By combining training for drivers, smart routing and technology, aerodynamic upgrades, disciplined maintenance, utilisation improvements, strategic procurement and load optimisation, fleets can reduce emissions by 20–30% or more without major capital investment. In many cases, the savings pay for themselves within months.

Moreover, the business benefits go beyond fuel. You’ll see:

• Lower maintenance and repair costs

• Longer vehicle life and fewer breakdowns

• Better driver retention and satisfaction

• Stronger positioning with customers who demand sustainable logistics

• Improved compliance and reputational resilience

If you’re a haulier reading this, you don’t need to wait for huge subsidies or electrified roads to act. The tools, tactics and frameworks are available today. The path forward is positive, and profitable.

GB Domestic Hours

Record your GB domestic hours fully digitally for the first time ever! Fleet portal Comprehensive management portal for all managers to have complete visibility of all checks instantly

Drivers

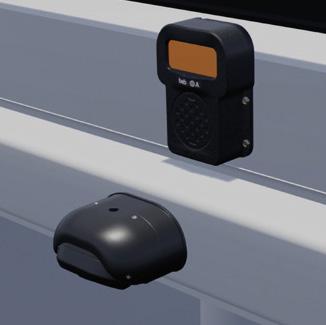

The bebo Human Detection System is an advanced vehicle safety solution designed with one primary goal: to reduce the risk of serious injuries and fatalities in daily operations.

How It Works:

By monitoring critical blind spots and high-risk zones, the system helps deter unsafe behaviour and reduce the likelihood of accidents. While no system can eliminate all risks, this solution includes a builtin failsafe that can stop vehicle functions if serious safety threats are detected — adding a crucial layer of protection.

Internal A-Pillar Monitor & Speaker – Real-time visual and audio feedback Key Components:

Hopper Camera – Monitors rear operations

Passenger-Side Blind Spot Camera – Covers areas drivers can’t see

Audible Sounders – Alert operators to potential hazards

Licence checks

Conduct licence checks remotely all using the CheckedSafe App

We’re proving electric trucks work in the real world. With millions of electric miles already covered, we have the proof to back our promises. Experience you can rely on. Expertise you can trust.

renault-trucks.co.uk

Scan the QR code to watch our Zeroing In electromobility series