PURETEQ GROUP A/S Sverigesvej 13, DK-5700 Svendborg +45 62 21 27 87 info@pureteq.com | info@estech.dk MANAGEMENT’S REVIEW 2022 PURETEQ A/S & ESTECH A/S PART OF PURETEQ GROUP - A GREENTECH COORPORATION www.pureteq.com | www.estech.dk

2 Copyright © PureteQ Group A/S 2022 Exerpts, including figures and charts, are allowed with clear source references. Made by the Executive Team of PureteQ A/S & ESTECH A/S

3 TABLE OF CONTENTS COMPANY INFORMATION Adress: Sverigesvej 13, DK-5700 Svendborg, Denmark Phone: +45 62 21 27 87 Email: info@pureteq.com | info@estech.dk Website: www.pureteq.com | www.estech.dk YEAR-IN-REVIEW 2022 GROUP STRUCTURE UPSCALING PROCESS AT VANDCENTER SYD COMBINED CO2 CAPTURE AND GREEN HYDROGEN PRODUCTION PROJECT SALES OTHER BRAND SCRUBBER SERVICE GROWTH ESG - ENVIRONMENT, SOCIAL AND GOVERNANCE REPORTING FINANCIAL REVIEW VISIONS FOR THE FUTURE 18 20 14 13 12 10 8 6 5

PURETEQ GROUP A/S MANAGEMENT’S REVEIW 2022

To help combat climate change PureteQ Group is committed to continuously optimize existing technologies and to invest in research and development of new technologies within the fields of Carbon Capture and Power-to-X.

4

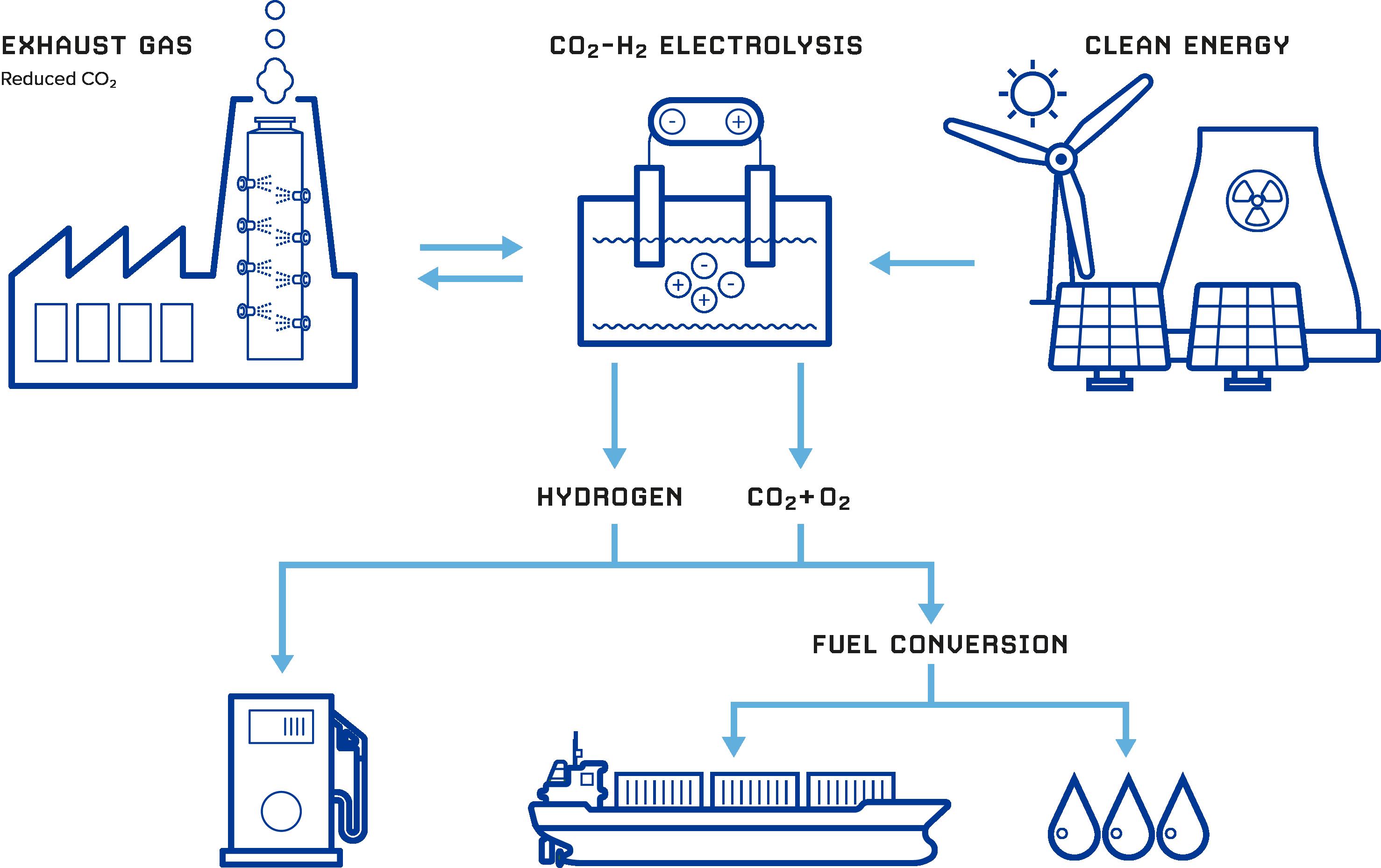

Hydrogen and CO2 are significant building blocks for the production of green energy

YEAR-IN-REVIEW 2022

ESTECH A/S and PureteQ A/S, that form part of the holding company PureteQ Group, are two Greentech companies that develop sustainable technologies to minimize human-induced climate changes and production of green fuel

ESTECH

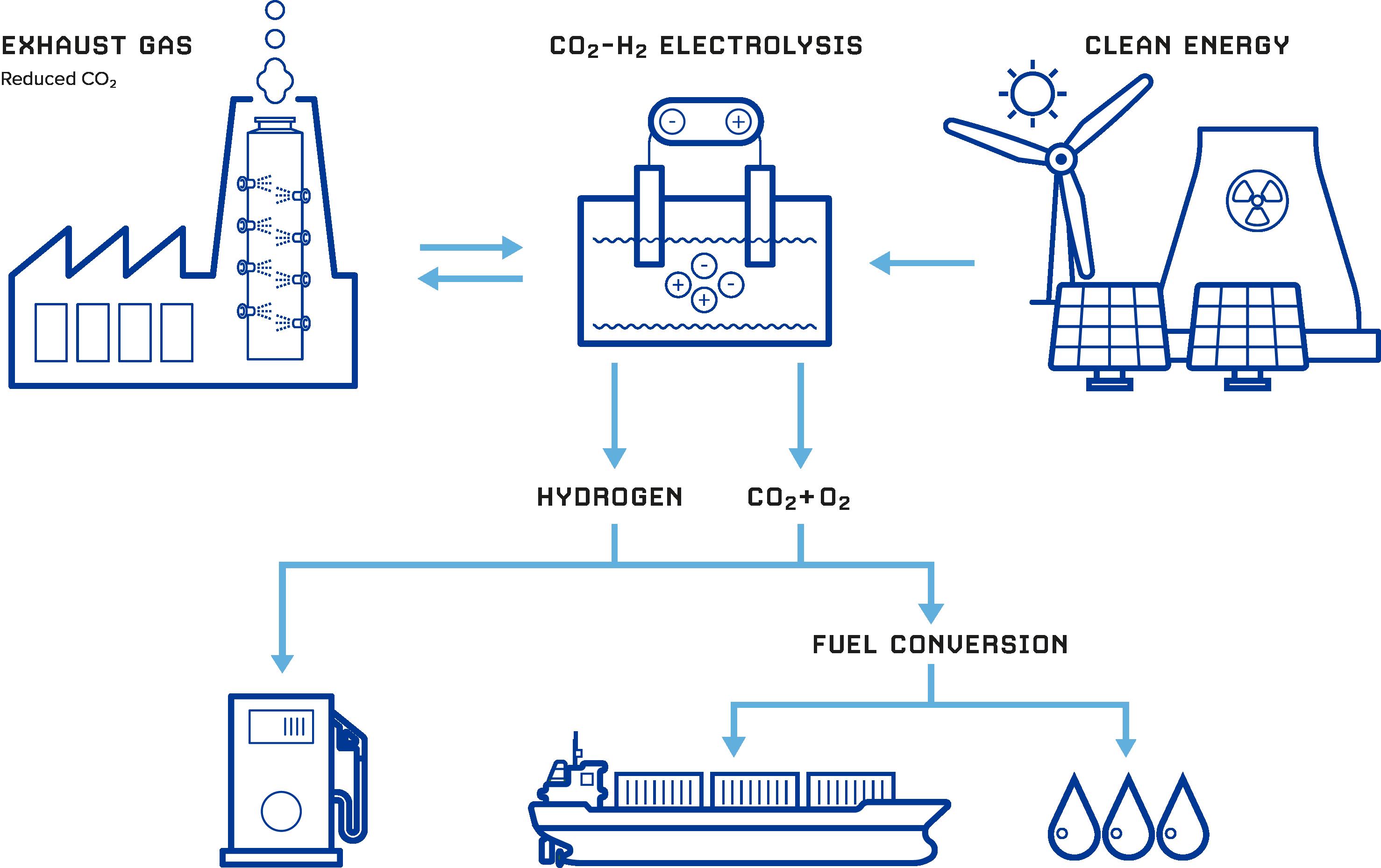

A/S has invented, developed, and patented a combined technology for carbon capture and production of green hydrogen in one and the same process (Power-to-X).

The technology is named CAPPOW (a contraction of Carbon Capture and Power). An application for trademark protection of the name was submitted to the Danish Patent and Trademark Office in 2022.

A patent on the basic technology has been taken out in USA and Europe and plan to expand to Asia.

In 2022 ESTECH received a grant from the Energy Technology Development and Demonstration Programme (EUDP) of approx. DKK 21 mill.

Along with additional independent funding these funds are earmarked for designing, developing, and constructing a larger plant to demonstrate the scalability of the technology.

With offices in Europe and Asia, and in-depth knowledge and expertise within exhaust gas cleaning, we are the largest service provider for all brands of scrubbers assisting shipowners and operators in safeguarding continuous operation, reliability, and MARPOL compliance of scrubbers.

The market for scrubbers has been surprisingly slow in 2022, despite the high price span between HFO and low sulfur fuel oil determining the potential low payback time.

Politicians and NGOs opose the use of scrubbers from a precautionary view, despite the fact that scientifc studies examining the effect of scrubber wash water on maritime organisms show no damage to the envrionment and that scrubbers have a lower carbon footprint than compliant fuel.

PureteQ

A/S supplies built-to-fit maritime scrubber systems to shipowners aiming to save money on fuel by continuing use of heavy fuel oil (HFO).

On these grounds, the primary operation in 2022 was based on PureteQ’s service and spare parts department ‘PureServ’ that today is regarded as the largest specialized scrubber service provider in the industry and is expected to grow even further.

5

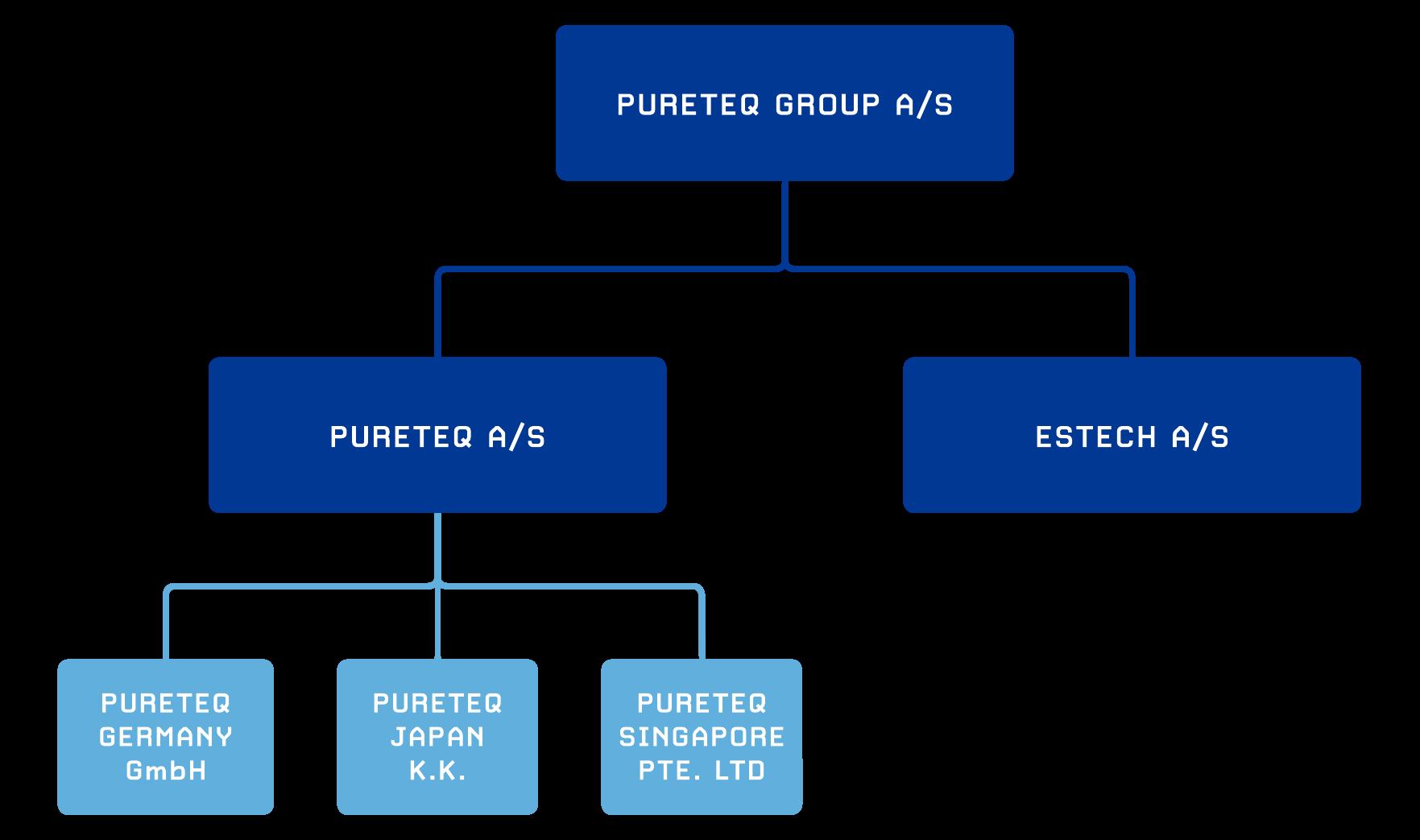

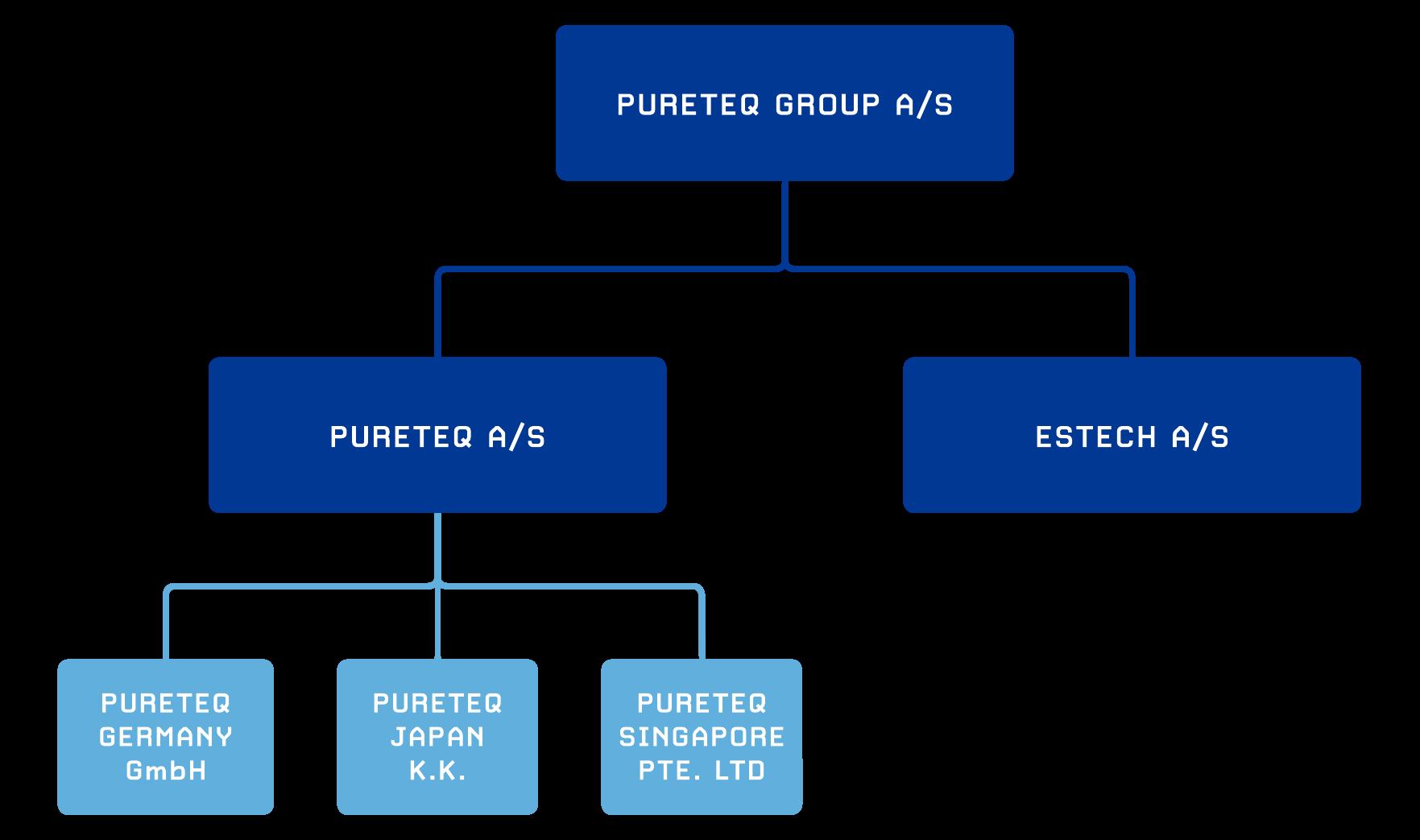

GROUP STRUCTURE

PureteQ Group A/S is a holding company represented by the two sister companies ESTECH A/S and PureteQ A/S, including the three foreign subsidiaries of PureteQ A/S as illustrated below.

The majority shareholder is Erik Skjærbæk, owner of PureteQ and ESTECH. Minority shares are owned by key employees.

The two greentech companies collaborate on developing Carbon Capture and Storage (CCS) and Power-to-X technologies. ESTECH has patented a combined technology for carbon

capture and production of green hydrogen (Power-to-X) in one and the same process and is based on PureteQ’s patented exhaust gas cleaning technology and digital platforms.

In 2022, PureteQ Group started to incorporate a more transparent marketing strategy for the up-coming commercialization and internationalization of the CCS and Power-to-X technologies to increase brandawareness and external investors’ engagement.

6

THE TWO GREENTECH COMPANIES

COLLABORATE ON DEVELOPING POWER-TO-X TECHNOLOGY FOR

BOTH THE MARITIME AND LANDBASED INDUSTRY

7

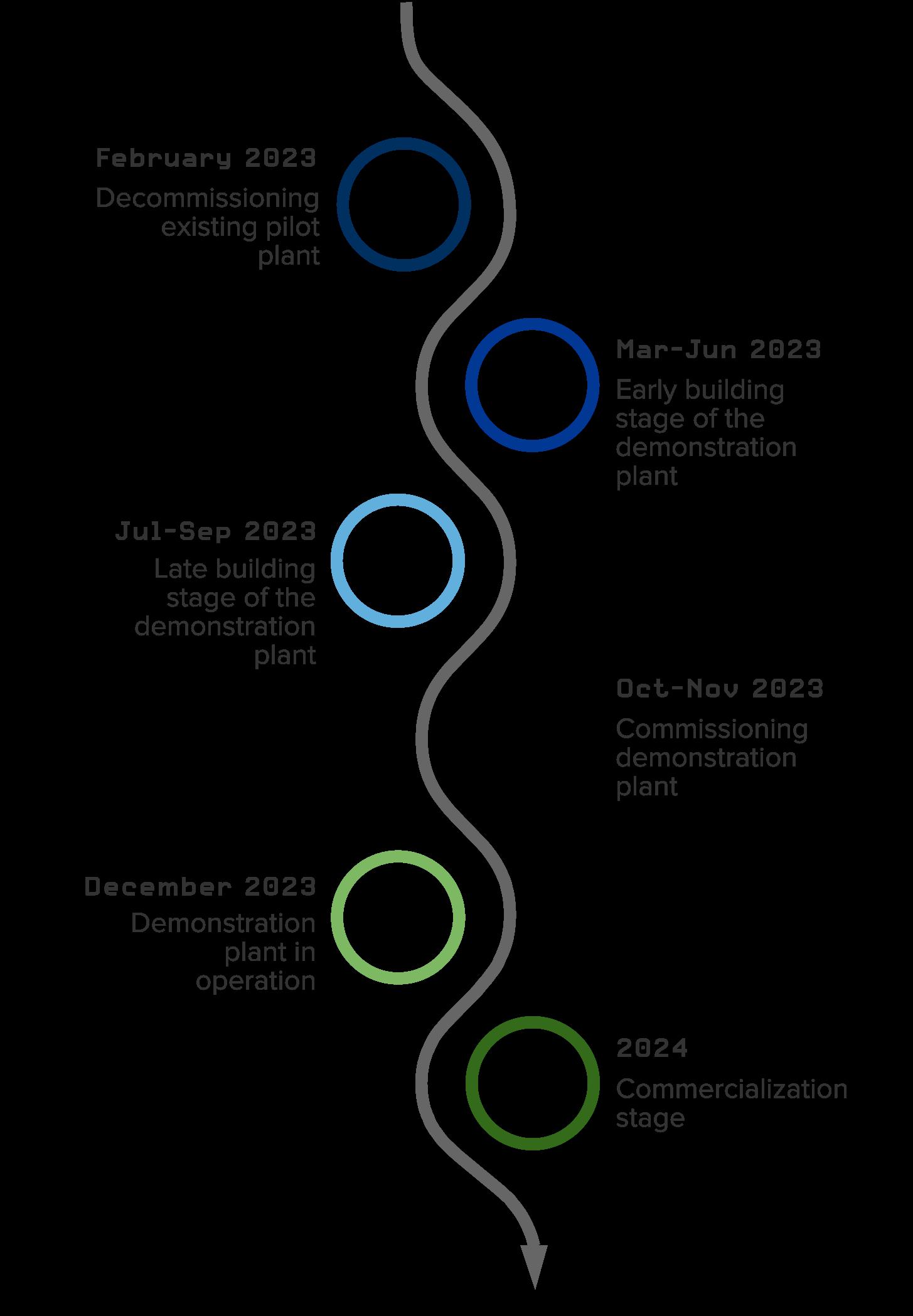

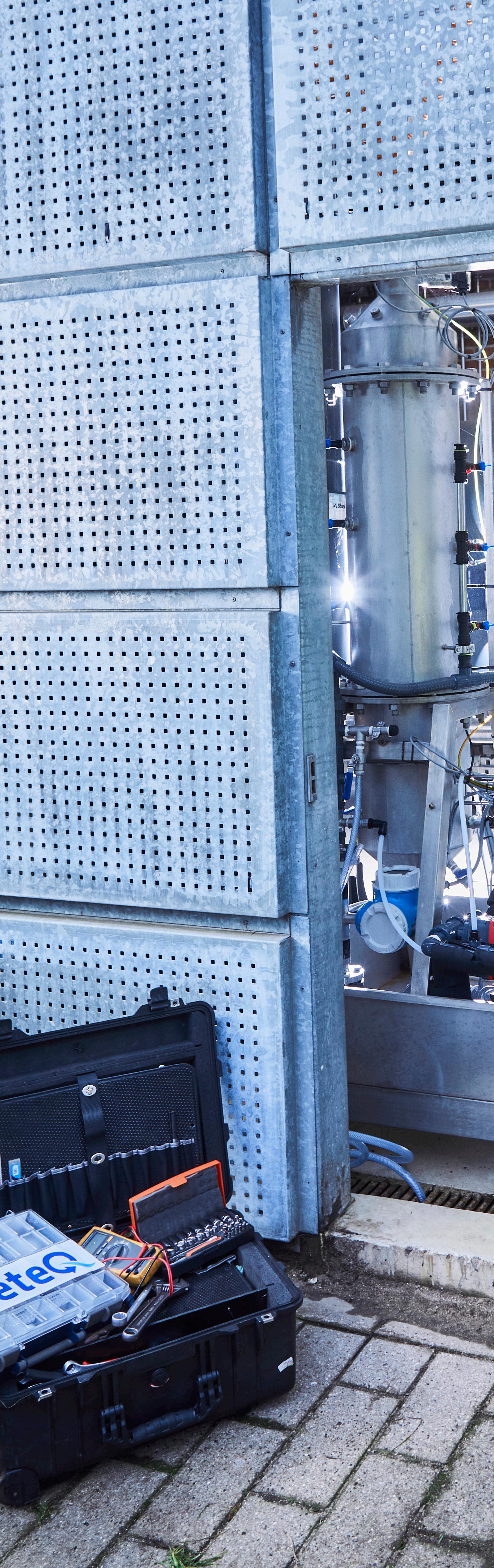

ESTECH’s Powerto-X pilot project at VandCenter Syd is performing better than anticipated and will form the basis of the further development of a demonstration plant and later upscaling for industrial use

UPSCALING PROCESS AT VANDCENTER SYD

For the past two years the pilot plant at VandCenter Syd has served as a test plant in preparation for the coming larger demonstration plant. Many interested scientists, NGOs, politicians, and even H. R. H. Crown Prince Frederik have paid a visit to the pilot plant.

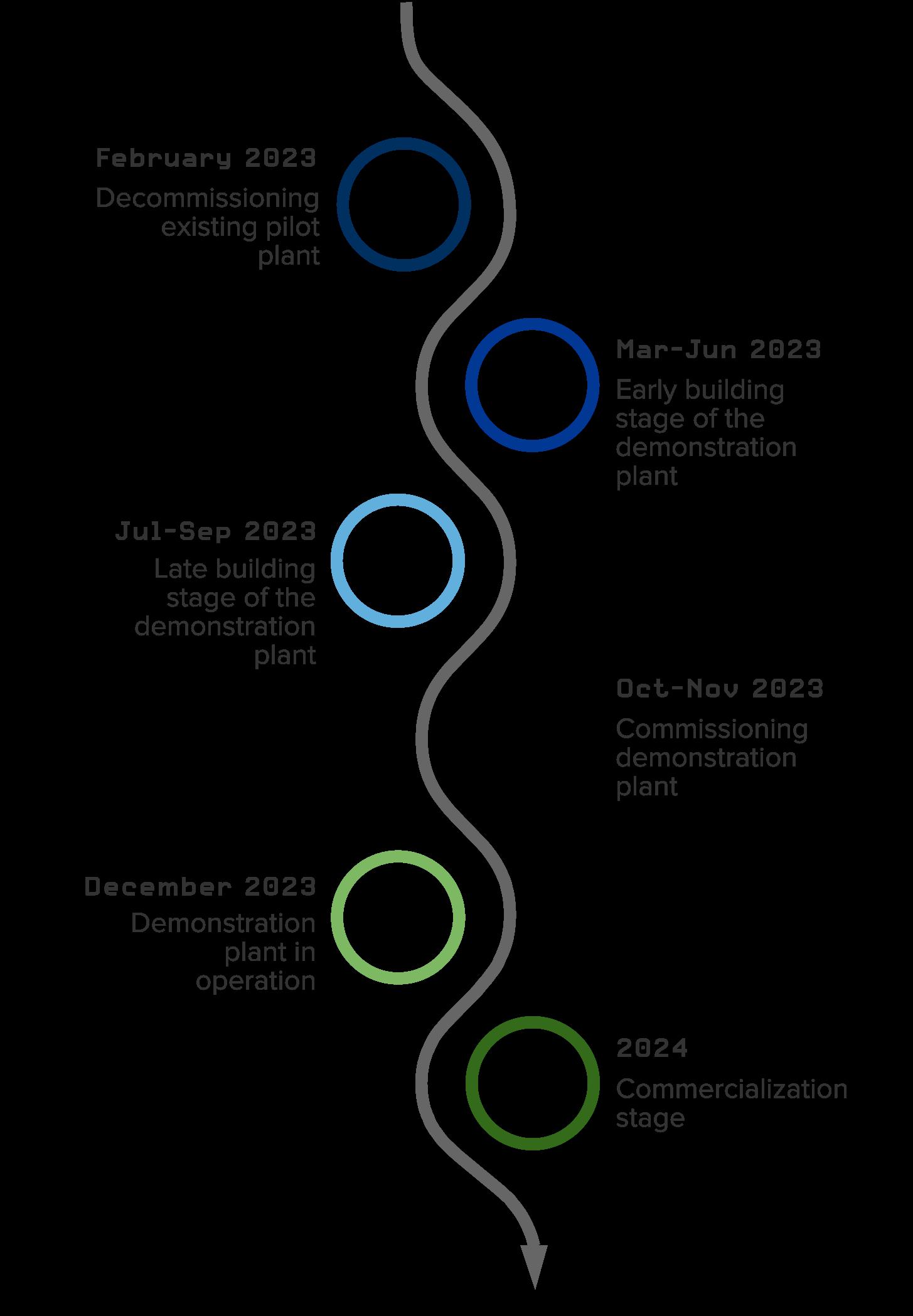

During 2022, the near-industrial size demonstration plant has been designed. The new plant will be constructed and commissioned during 2023 and will, when finalized, demonstrate the scalability of the technology. We expect the demonstration plant to attract many more visitors and potential buyers in the future to come.

The demonstration plant is built with industrial

components to ease the later upscaling to a fullsize industrial plant. The plant consists of:

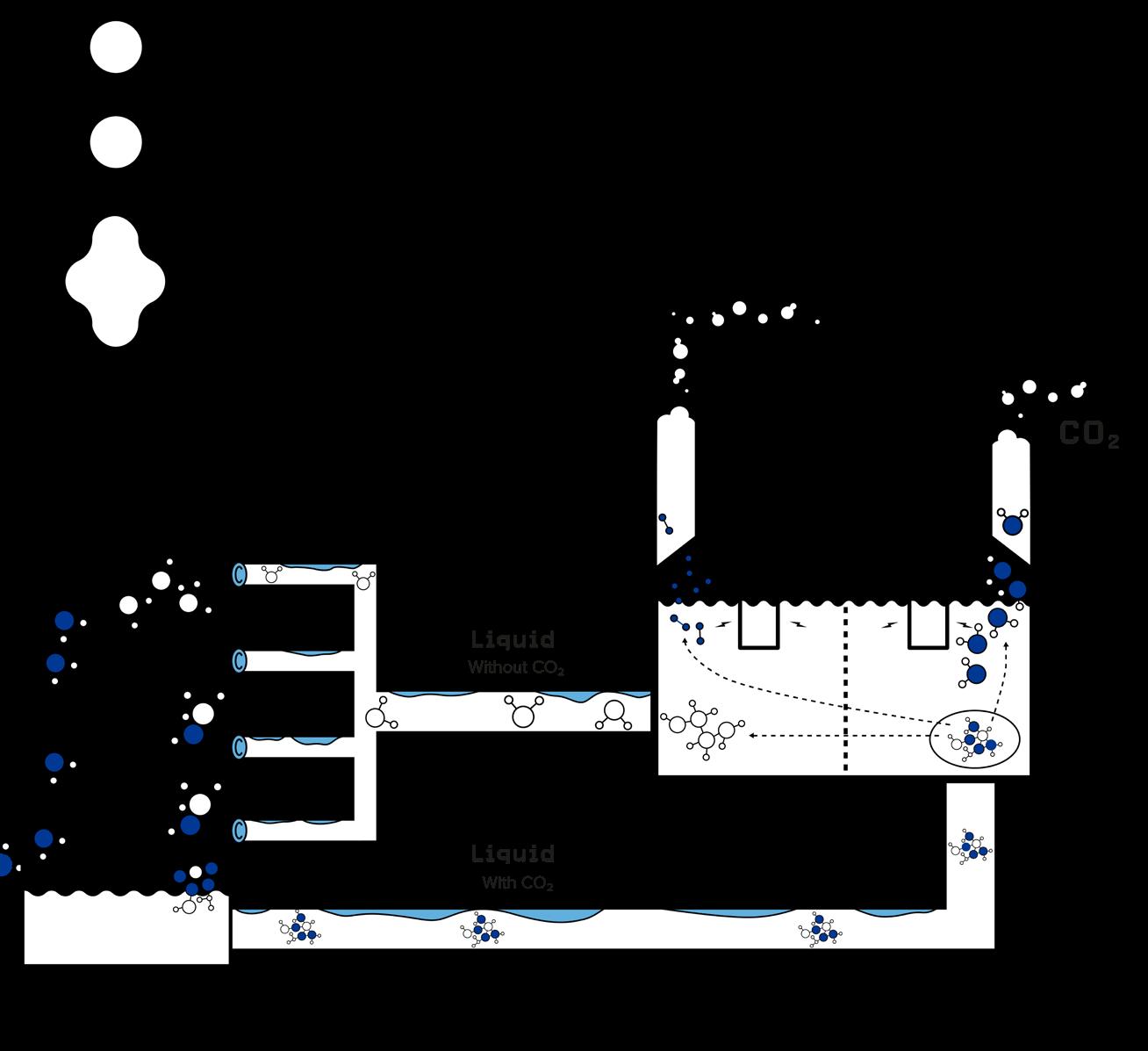

• An absorber: PureteQ scrubber technology for CO2 absorption (the three absorber towers on the technical drawing on p. 9)

• An electrolyzer: Electro-chemical cell for H2 desorption and related tanks, pump & control panel (left part of the technical drawing on p. 9)

We expect the first commercial plant to be designed in 2024, depending on the availability of clean electricity, which is the main barrier to all Power-to-X technologies.

8

9

OBJECTIVES FOR 2023/24

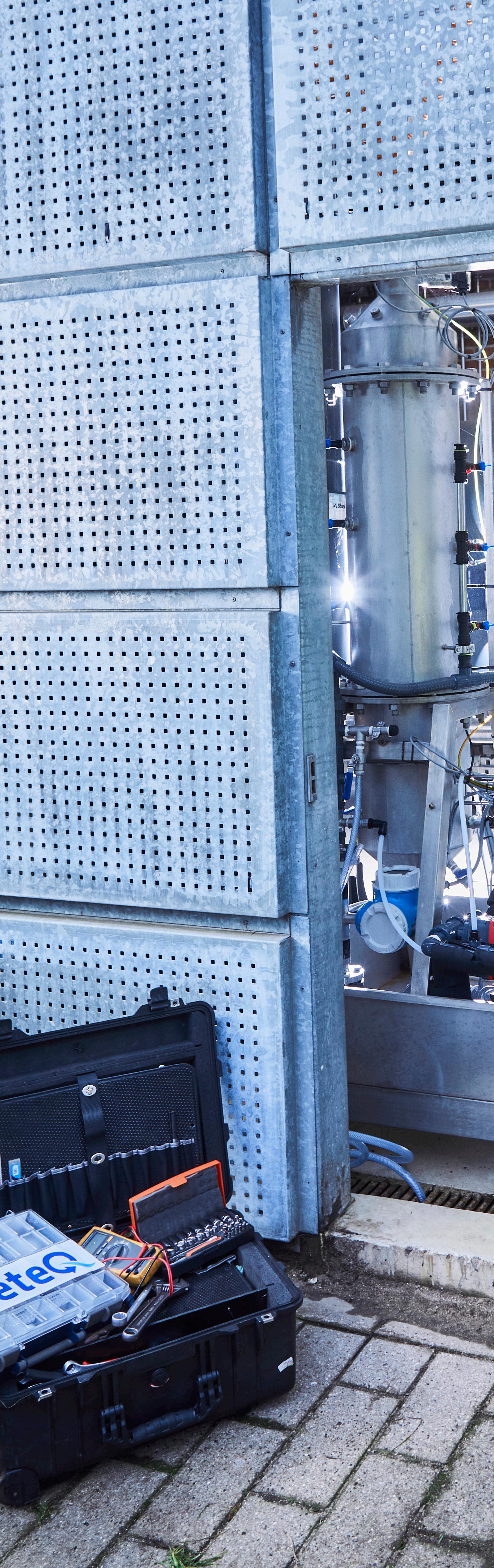

The test setup generating valuable data for construction of the demonstration plant

Technical drawing of demonstration plant to be built at VandCenter Syd in Odense

COMBINED CO2-CAPTURE & GREEN HYDROGEN PRODUCTION

ESTECH’s CAPPOW technology is unique as it enables carbon capture and production of green hydrogen in one and the same process, which reduces the energy consumption considerably as compared to two separate processes

The commercial focus for the ESTECH CAPPOW plant is, among others, small and medium-sized companies that have access to clean electricity but unable to electrify their production.

CAPPOW can be applied to combined heat and power plants, as well as waterworks, and any industrial production that emits CO2. The potential users include most companies within industries such as utility companies, privately owned companies, as well as the public sector e.g., hospitals.

In principle the plant will enable anyone with a gas boiler of a certain size to optimize the use

of traditional energy sources with exhaust gas cleaning and carbon capture combined with hydrogen production.

Today these segments are not offered similar cost-effective solutions, and individually their emissions are minor but combined they are emitting a large part of the total CO2 emissions.

For a more detailed account of the Power-to-X technology go to www.estech.dk

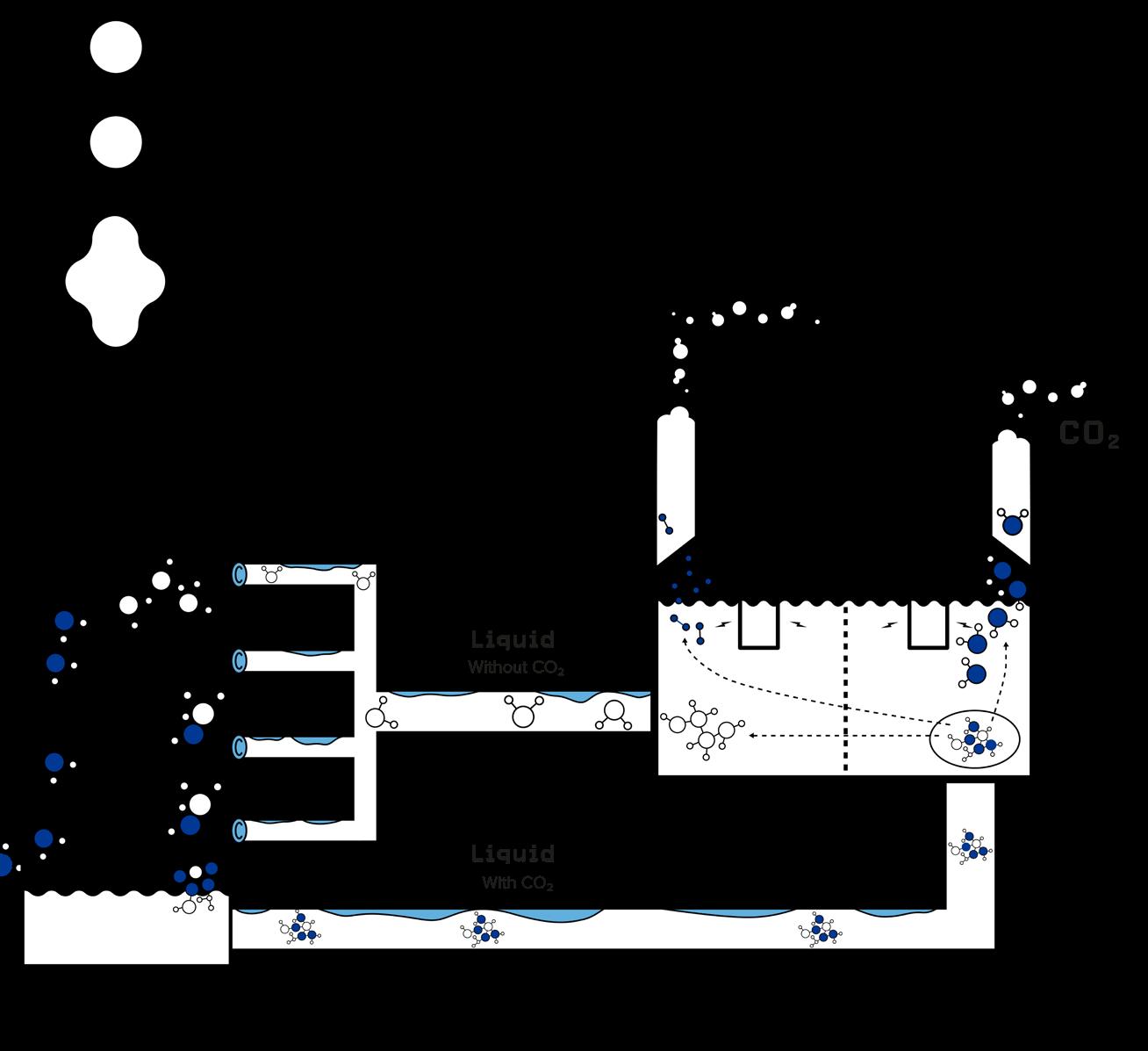

Detailed drawing of the technology showing the circular process where CO2 and hydrogen are released from the liquid. To avoid waste of chemicals the fluid is regenerated.

C A P P O W

CARBON CAPTURE & POWER GENERATION

DETAILS OF THE CAPPOW TECHNOLOGY

• First step is to remove CO2 from the exhaust gas in an absorber

• The absorbed CO2 is then placed in a fluid, and an electrolyzer splits the elements into hydrogen, oxygen and CO2

• All electricity is derived from green sources and is stored in the generation of hydrogen

• The hydrogen is industrial grade, and can be utilized to produce fuels and for other industrial purposes

• Most of the green energy used for carbon capture is stored in hydrogen

11

PureteQ invests in research and development of new technologies within the fields of CO2 capture and Power-to-X including Onboard CarbonCapture-Ready Scrubber Systems

PROJECT SALES

THE SCRUBBER MARKET

Most ships are built and retrofitted in China and Korea, the local governments of which prefer government owned scrubber suppliers. This makes it difficult to enter these markets unless new business alliances are made.

SERVICE PROJECTS

Service projects within e.g. replacement of other types of Water Monitoring Systems (WMS), Water Treatment Systems (WTS), and installation of our onboard Internet for Remote Assistance Services (IRAS) are increasing.

DEVELOPMENT, TECHNOLOGY & BUSINESS

A third generation PureteQ scrubber with lower cost and reduced installation time for shipyards has been designed.

On the smaller scale, a new version of the PureteQ WMS has been developed, tested, and released during 2022. PureteQ now has a fully type approved system being technically and commercially much more competitive than the previous version. We have received several purchase orders on these for delivery in 2023.

12

OTHER BRAND SCRUBBER (OBS) SERVICE GROWTH

OPERATION

PureteQ’s service and spare parts department

‘PureServ’ has shown significant growth the past year, both in terms of revenue and operational profitability, and will continue doing so over the coming years as no other companies offer equally attractive business propostions.

PureServ is a registered trademark and certified service organisation that provides service and support to all brands of scrubbers and sensors.

TRAINING

PureteQ has established a training academy often being included in the scrubber fitted ships’ on-boarding programs.

Most training is performed virtually. The number of training sessions are growing steadily, and we expect the International Maritime Organization (IMO) to put even more emphasis on crews’ familiarization of scrubber systems.

DIGITALIZATION

PureServ is and has always been at the forefront of digital development. An updated version of our web-based Scrubber Performance Optimization Tool (Pure-SPOT) was released by the end of 2022.

The software is valuable for environmental performance reporting and optimization of scrubbers across fleets and scrubber brands.

SERVICE CONTRACTS

In 2022 service visits and sale of spare parts have been equally shared among customers with and without a PureteQ service agreement. In 2023 we expect the share of service agreements to increase significantly due to economic benefits of having a service agreement and access to Pure-SPOT.

13

By 2030 world-wide emission of C02 must be reduced with

70%

Already in 2025 the world must reduce CO2-emissions with

50%

Focus is on the social and monetary challenges leading to climate changes and consequent global warming

Carbon capture and storage technologies are a prerequisite for becoming ‘carbon negative’

1.5°

The world must limit global warming to According to the UN Sustainable Development Goals, the world has to be carbon neutral before 2050

ESG ENVIRONMENT, SOCIAL AND GOVERNANCE REPORTING

For PureteQ Group, ESG is setting the framework for the way we act towards our employees, customers, suppliers, and other collaborators and stakeholders, and not least for our commitment to combating climate change

In our day-to-day operation, PureteQ Group focuses on being a socially responsible and sustainable workplace. To reduce our carbon footprint we are investing in energy efficiency in our buildings and facilities.

Our employees are the company’s most important resource, which is why we highly value their well-being and job satisfaction, and do our utmost to foster a healthy and good working environment.

ENVIRONMENT, CLIMATE, SUSTAINABILITY

PureteQ Group is aware of the social and monetary challenges caused by human induced climate change and consequent global warming. It is part of our DNA to incorporate the lowest possible energy consumption into our designs and products.

We invest most of our earnings in the development of Power-to-X and carbon capture technologies.

Our objective is to provide sustainable technologies to reduce the emission of greenhouse gases. Our technologies are designed to

produce the main components for future green fuels such as hydrogen and CO2

CLIMATE CHANGE

According to the International Panel of Climate Change (IPCC) the world will not only need to reach net zero emmisions by 2050, but has to become ‘carbon negative’ i.e., remove CO2 from the atmosphere. Exhaust gas scrubber technologies are a prerequisite for succeeding with onboard carbon capture.

Even with a complete transition to renewable energy, we will continue to depend on steel, cement, medicine, paper and other welfare goods the production of which all rely on processes emitting a noticable amount of CO2

All in all, we must be energy efficient in every way possible, because energy is a scarce resource - the best ton of fuel is the ton not consumed.

REUTILIZATION OF CO

2

At PureteQ Group we believe in the reutilization of CO2 to minimize the consumption of fossil fuels.

With the UN Sustainable Development Goals as a starting point, PureteQ Group is committed to taking part in the green transition

15

Along with the ongoing expansion of green energy sources, such as windmills, solar power and nuclear energy, traditional sources of fossil fuels will still be in demand in combination with the abatement technologies.

A special focus on reducing CO2 emission from exhaust gas, as well as using Carbon Capture & Storage (CCS) technologies, is necessary.

CCS plays an important role in achieving climate

Experts claim that up to 17% of the captured CO2 may be reutilized in the production of new fuels and for other industrial purposes.

ESTECH’s CAPPOW technology that enables carbon capture and production of green hydrogen in one and the same process is unique in its approach as it reduces the total energy consumption considerably compared with two individual processes.

CAPPOW TECHNOLOGY WITH CARE

17

FINANCIAL REVIEW ESTECH

The development of a combined technology for carbon capture and production of hydrogen proceeds as planned, and the construction of a large-scale demonstration plant is initiated, thus activating the company’s research and development expenditures.

The new plant will be constructed and commissioned during 2023 and will, when finalized, demonstrate the scalability of the technology.

In 2022 the company realized a pre-tax deficit of DKK 6,2 mill. As of December 31, 2022, ESTECH’s equity totals DKK 35,9 mill.

Taking the activated research and development expenditures into account, the annual results and financial status are considered satisfactory.

The amounts are stated in TDKK

For further financial details see the official annual report at www.virk.dk

18 Financial and operating data ESTECH 2022 2021 2020 Gross profit 3.310 734 -846 EBITDA -4.393 -3.272 -3.971 Profit/loss before tax -6.249 -5.051 -5.104 Cash and bank 17.885 9.804 199 Assets 39.317 21.684 7.276 Equity 35.888 14.152 -8.094 Return on equity neg. neg. neg. Solvency ratio 91 % 65 % neg.

FINANCIAL REVIEW PURETEQ

PureteQ has gained a market share for service of other brand scrubber systems. After initial investments the service business has proven profitable, but in 2022 we did not manage to create a turnover compensating for the lack of new scrubber orders. We aim to grow this market share further in 2023.

Instrumental for this development is further development of our digital web-based platform “PureSPOT” for environmental performance reporting, as well as conceptual services such as onboard

internet for remote assistance services, training of crews, and water monitoring systems.

In 2022 the company realized a pre-tax profit of DKK 8 mill. As of December 31, 2022, PureteQ’s equity totals DKK 75,7 mill.

The overall results for 2022 are less satisfactory.

The amounts are stated in TDKK

For further financial details see the official annual report at www.virk.dk

19 Financial and operating data PureteQ 2022 2021 2020 Gross profit 38.723 50.288 66.353 EBITDA 9.448 24.935 34.703 Profit/loss before tax 7.678 21.662 31.506 Cash and bank 46.946 50.823 113.523 Assets 108.726 138.525 161.458 Equity 75.489 84.740 67.980 Return on equity 8 % 30 % 30 % Solvency ratio 70 % 61 % 42 %

VISIONS FOR THE FUTURE

Different opportunities will be explored both in ESTECH and PureteQ separately, and in collaboration

BIOGAS UPGRADE

The call for upgrading biogas can, in the short run, turn out to be applicable for the ESTECH CAPPOW technology.

In brief, biogas upgrade is a matter of omitting a great deal of the naturally occurring CO2, in biogas. This is a regulatory requirement before injecting biogas on the natural gas grid.

The CAPPOW technology can reduce both the amount of CO2 and produce the hydrogen necessary for further reduction of CO2 in biogas. In 2023 tests to demonstrate this will be completed and presented to interested biogas plants.

In Denmark alone, more than 120 biogas plants have the potential to use the technology for biogas upgrade. Abroad there are now thousands of plants producing biogas.

SOLEVENT BASED CARBON CAPTURE

Carbon capture and production of green hydrogen in one and the same process require access to green electricity in sufficient quantities. Green or clean electtricity may not be available for production of hydrogen for years to come, regardsless of political ambitions. On those grounds, we will explore the opportunities for employing the more common technology for carbon capture based on amines and

20

other solvents, parralel to the CAPPOW technology.

ONBOARD CARBON CAPTURE

The main barrier for Onboard Carbon Capture (OCC) is energy supply. In cooperation with ESTECH, a marine adaptable carbon capture technology is being developed. We believe that a combination of high temperature heat pumps combined with an activator in the solvent may be the answer to reducing the OCC conditioned energy. A feasibility study has been performed indicating that this OCC technology is competitive, especially regarding energy consumption.

Further, this could prove effective as to decreasing sensitivity of solvents towards particles, SOx and NOx.

A partner for the onboard testing of this OCC technology will be identified during 2023.

FUTURE SCRUBBER PROJECTS

PureteQ’s future project business will partly be based on sulfur (SOx) scrubber projects, but with focus on making our scrubbers future-proof with OCC ready installations, as well as adding PureteQ’s existing digital control system and other optimized equipment.

21

PURETEQ GROUP A/S Sverigesvej 13 DK-5700 Svendborg +45 62 21 27 87 info@pureteq.com | info@estech.dk www.pureteq.com | www.estech.dk