We hear a lot about the economy and the ups and downs in the construction industry. I have had the opportunity to listen to construction leaders and construction economists over the last few weeks and wanted to share that Crowder’s markets are strong. People are excited about construction in the Southeast especially in the states where Crowder works.

We are very optimistic about Crowder’s markets for the coming year. North and South Carolina, Georgia and Virginia, our primary work states, are continuing to grow which keeps our infrastructure markets, including water, wastewater, bridges, dams, and power/energy, strong. The Southeast, especially North and South Carolina, continues to attract new residents and companies because there are many attractive cities to live in, the weather is good and cost of living, although going up, is still somewhat lower compared to our neighbors to the North.

Both NC and SC DOT’s are spending significant amounts on our road systems now and have fairly robust plans for the coming years. With aging infrastructure and new regulations, power and water/ wastewater facilities continue to be upgraded or replaced. We see federal funding available in our markets and expect this to continue for the next several years.

Specifically for Crowder, we have a solid backlog for 2024. We see lots of opportunities in our work sectors. Crowder is positioned to take advantage of opportunities in all of our markets because of our past performance of building quality projects for our clients.

Thank you for the last year of quality performance which is key to our continued success!

Lynn Hansen,

We are dedicated to superior performance and committed to making a positive difference for our clients, our communities and in the lives of our employees.

SUPERIOR PERFORMANCE

Safety Updates on pages 3, 8, 15, & 19

OUR CLIENTS

All pages with job news

OUR EMPLOYEES

pages 20-22

If something is bothering you, if you have a question, if you feel you or another employee are being harassed, or if you believe that you have not been treated fairly, WE WANT TO KNOW ABOUT IT. Please go to your bulletin board and use our Employee Concern and Complaint Procedure (or call 1-800-849-2966 and ask for Employee Services) to get your question answered, your concern addressed, or your problem resolved.

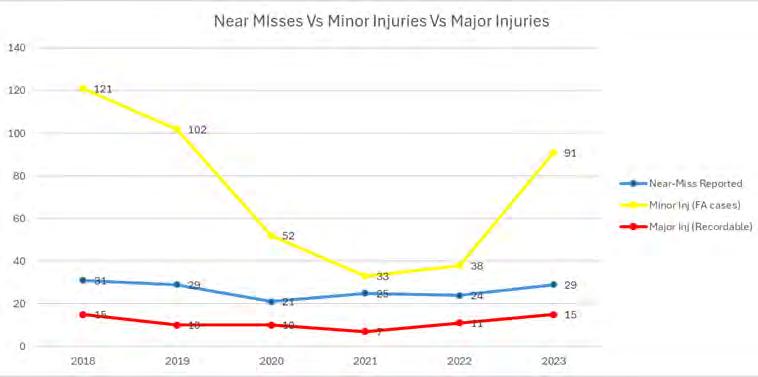

As with most reputable companies, we try and learn from our adversities to ensure that we avoid the same potential issues in the future. Whether the issue is associated with quality, schedule, budget, or safety, we MUST recognize what led to the issue and self-correct. Regarding safety, we do a phenomenal job of reporting and sharing the lessons learned from our incidents. However, I have recently pondered if our safety culture is representative of NOT wanting to know about any incident that did not cause property damage or injure one of our teammates? Just by evaluating our incident numbers (see Figure 2 – Incident Trend by Year), it is likely that we are missing opportunities to improve our safety performance and strengthen our safety culture by simply reporting all Near-Miss incidents.

To help ensure that our thought process is aligned with respect to the definition of a Near-Miss, below is a definition provided by the Occupational Safety and Health Administration (OSHA):

NEAR-MISS: An incident in which no property damage and no personal injury was sustained, but where given a slight shift in time or position, damage or injury could have occurred.

In simple terms, a Near-Miss is a “close call.” The lessons from a Near-Miss are just as important as the lessons learned from an incident that resulted in an injury or property damage.

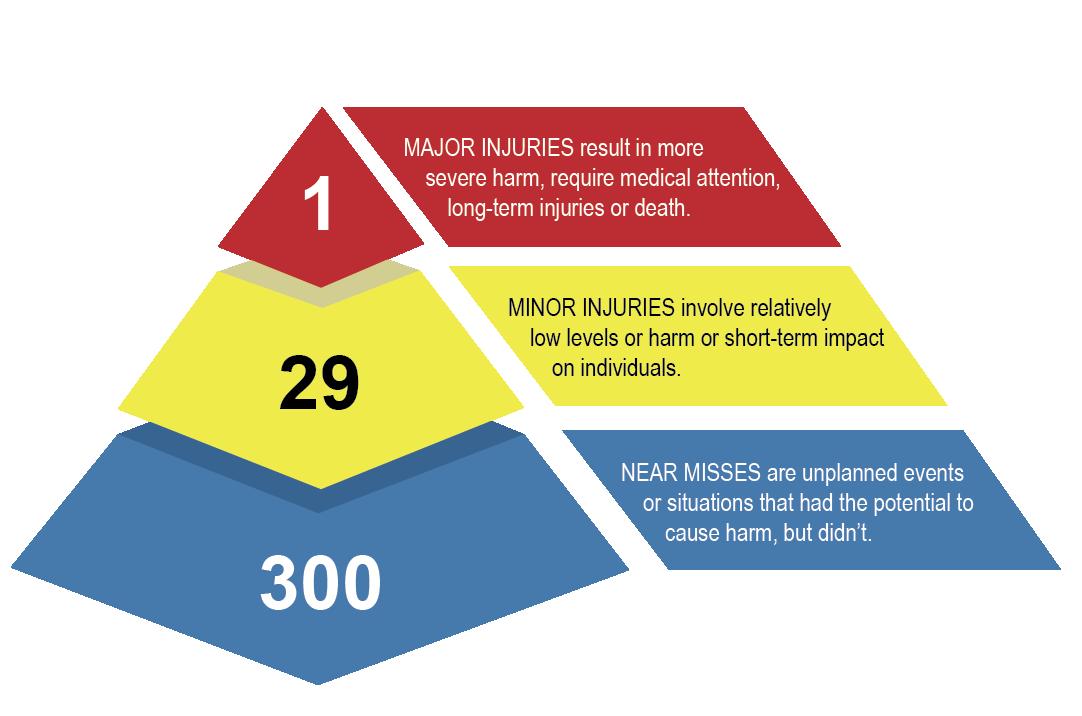

Strictly referring to incidents that resulted in an injury, the “safety world” often references Heinrich’s Injury Pyramid. The theory is simple:

• For every 300 Near-Miss incidents, there will be 29 minor injuries that require First Aid.

• For every 29 First Aid injuries, there will be one classified as serious (OSHA Recordable).

So, with our efforts geared towards decreasing and eliminating injuries and properly damage incidents, we MUST deliberately focus on Near-Miss incidents.

If Near-Miss incidents are not reported, opportunities to prevent injuries are drastically reduced. The rporting of Near-Miss incidents is a focus for all our divisions this year, so we need your help! Please do your part and report Near-Misses to your supervisor.

For Calendar Year 2024, additional Near-Miss reporting initiatives will be distributed to our project teams in the near-future.

Winding Pine has been extremely busy over the last few months. The pump station concrete has been completed and the masonry and roofing structure is installed. All process equipment is mechanically installed, including the grinder, screen, and conveyor system. The electrical building and chemical building have been architecturally completed as well, with electrical work well underway. The next steps are to complete the electrical work at Winding Pine and startup all facilities. The remaining 220 LF of 42-inch GS and 20-inch FM need to be completed as well and tied-in prior to performance testing.

Graham has been very productive the last few months. BNR (Biological Nutrient Removal) 1 & 2 concrete walls and decks have been poured, BNR electrical building has been built and dried in, mechanical work in BNR 1 & 2 has started with handrails, air pipe, diffuser piping, and mixers and digester walls are continuing. Chemical trenches are being installed and the maintenance building steel has been erected allowing masonry to start. The next steps are to finish mechanical and electrical work at BNR 1&2, electrical building and distribution box to get ready for startup. This includes setting the blowers, mixers, finishing air and diffuser piping, pulling wire and coatings. The digester walls will be complete in the next month and will be ready for grinding and patching. We are also working to complete chemical trenches, install chemical pumps and piping in the chemical facility.

of the

MGD was completed in November 2023, and construction of Phase 2 is underway. Majority of the underground piping has been completed, and we are currently focused on concrete for the new effluent pump station and digester. Excavation for the new headworks structure has been completed, and we are beginning concrete for this structure as well. Majority of the long-lead process equipment has been received onsite and will be installed following completion of concrete.

Crowder crews are continuing exposed mechanical and process equipment installation at the (Nitrification Enhancement Facility ) NEF tanks, aeration basin, and blower building. Additionally, we are constructing the gravity thickeners and thickened solids pump station. Electrical crews are setting major gear and pulling/terminating wire. Process tie-ins and equipment start-ups for Phase 3 are slated to begin in the summer. The final GMP (guaranteed maximum price) for Phase 4 was approved by Water & Sewer Authority of Cabarrus County’s board in February. Work for Phase 4 will begin around April.

date we have placed over 16,000

linear feet buried yard pipe up to 42” diameter.

This spring, construction will begin on Stage #4, including the filter building and Stage #5 including the maintenance and administration/ operations buildings.

The JV supervision and management teams continues to work closely with CLT Water and other program contractors and consultants to coordinate hand-off points and to look ahead to plan an integrated commissioning effort.

If you have been employed in the construction industry for longer than a day, you have likely seen a worker dressed in fall protection equipment. This image of a worker equipped with a full-body harness, lanyard and attachment to an anchor point is the quintessential example of fall protection gear. Within the world of construction, “gravity” is a prevalent danger, and Crowder employees are prepared and equipped to effectively manage these hazards.

Falls continue to be a leading cause of death in the construction industry since the inception of the Occupational Safety and Health Administration’s (OSHA’s) “Focus Four” initiative in 1994. Crowder employees routinely perform work-atheight tasks across the company and complete these tasks efficiently and safely. Safe work at height can only be accomplished through commitment by both employees and project supervisors. The Quarles Creek Wastewater Treatment Plant (WWTP) project recently conducted two days of fall protection competent person training. This training involved twelve project supervisors/managers who were willing to be challenged, open to learning, and committed to providing knowledgeable oversight of work-at-height activities.

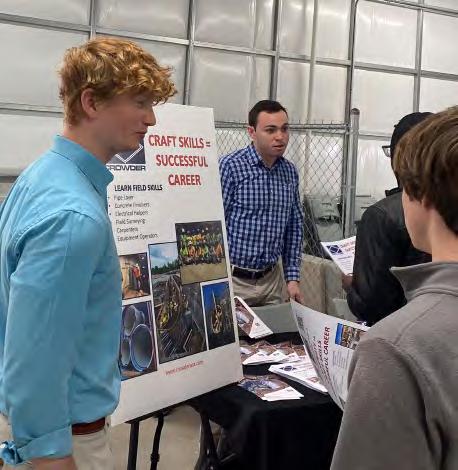

Lauren Kearney and her many volunteers have been busy meeting with prospective Co-Ops and Interns at Spring career fairs. Since January, Crowder has been present at 8+ career fairs in NC, SC, VA, GA, and OH! If you know of an Engineering student who is looking to gain first-hand experience with project management, field operations, and/or cost estimation, please visit our website here , so that students can learn more about our Co-Op Program!

Crowder continues with the timber pile driving operations at the north end of the project and is targeting late-March to be complete with the boardwalk foundations. Crews will follow behind with the precast superstructure and wooden handrails later in the Spring. In January, crews poured the bridge decks at bridges #1 & #2, set treads at boardwalk #2, set precast beams & treads at boardwalk #3, and completed the pile driving at boardwalk #4. In February, the team set the majority of precast at boardwalk #4, drove timber piles at boardwalk #8, and excavated and placed the precast footer foundations.

In January, we resumed work on the cable installation for the suspension bridge at the Crabtree Creek West greenway project. The goal is to complete the suspension bridge by the end of March. The pre-activity meeting for the cable installation was held the last week of January and cable installation began in early February. The cable and structural steel installation for the suspension bridge was completed at the end of February and the remaining suspension bridge deck and railing work will be completed in April 2024. We are on track to complete this project by July 4th, 2024!

In January, crews at the airport taxiway project were working on completing final punch list items. These tasks included: final dress slopes and seed, installation of remaining trees, the subcontractor (TJC) touching up mechanically stabilized eart (MSE) walls and anti-graffiti work, and installing the fencing and finish any yard maintenance. This project was officially completed on Feb 2nd.

Installed

The Crowder project management team at our NCDOT I-40 Wade Ave to US1 project will monitor erosion control & maintenance of traffic (MOT) while project is idle from December 2023 through April 2024, due to ultra-thin paving temperature restrictions. All other work items are 100% complete except these remaining items: Eastbound I-40 ultra-thin paving and rumble strips, final thermo pavement markings & snow plowable markers, 2 added drainage structure repairs, and the final cleanup/demobilization. We are about 95% complete on this site and will be back in April.

This jobsite was flooded out for the majority of January, but we were still able to make some progress. Ductile iron pipe is 50% installed in the pump station. In January we were able to complete forming and placing the elevated slab and Mason (subcontractor) mobilized to begin Concrete Modular Unit (CMU) work. We removed the remainder of shoring and forms from pump station, and we are continuing to perform point and patch. We also worked to complete forming and placing concrete infills in bottom level of pump station, forming and tying the transformer pad and generator curb at the pump station, placing transformer pad and generator curb, and removing shoring and forms at intake after acceptable concrete breaks. In February, we worked on completing the infill placement, stripping the infills, and continuing CMU work. National (subcontractor) removed the remainder of formwork from intake and demobilized at the end of February. The next steps for our team will be to place bond beams every 4’ vertical, continue point and patch at the pump station and intake, assemble ductile iron pipe in pump room of pump station and to complete the intake handrails.

US178 Improvements

The majority of flatwork has been completed and backfilled, the guardhouse and columns are both nearing completion, and the concrete pours for the phase 1 tide gate walls are complete. The irrigation system is about 90% installed and the electrical sub has all the streetlights completed now. The next steps include completing the guardhouse, the fencing, and the irrigation. All that will remain is the landscaping and the work that that sub and electrical sub have left to do.

The Crowder team at the Old Dowd Rd project worked on erosion control, completing the installation of 36” waterline along Wilkinson Blvd, the Old Dowd Rd bore, and most tie-ins. The deck pours for span A, and the backfill for end bent 2 is also complete. There have been multiple deck pours throughout February, including spans C, D, and E. During the month of February, crews also worked towards the completion of the waterline tie-ins and get the chlorinate & pressure test system fully operational with the 24”/36” water system.

Crowder finished up the installing all the drainage in the overlook parking lot, including the underdrain, and graded up the aircraft display area in anticipation of the arrival and installation of a F4 Phantom in mid-February. The restroom is being finished up on the exterior block and we will move on to the interior and roof trusses. In February, subs started the installation of the mock runway, synthetic turf, the playground, and the memorial. More items we are hoping to work on through March include grading and adding stone to the parking lot, continuing work on restroom roof and installation, installing nitrification septic field, the DR-3 driveway, and conduits for lights, cameras, and irrigation.

Crowder has had multiple Subcontractors working on different scopes of work on this project. Crowder provided the barge access, which included 2 manlifts and a carry deck crane for the bridge repairs to take place. Crowder also repaired two of the bridge caps by forming and pouring new concrete and adding rebar around each cap. Once the caps were poured, Crowder hired Dan Kel to core drill holes for the post tension bars, which were installed and tensioned by Structural Technologies. The substructure concrete repairs, which included spall repairs and crack injection were completed by Dyckerhoff & Widmann AG (DYWIDAG). The jacking sub Applied Polymerics jacked up each bent of the bridge and replaced the bearing plates, elastomeric bearing pads and anchor bolts and are now 100% complete. Lee Construction is finishing up the full depth concrete repairs on the bridge deck, which are projected to finish up in June of 2024.

Overhead View of

All traffic was recently shifted to the southbound bridge and demolition of the northbound bridge began. The first section of the trestle has been installed and pile driving began at the end of February. We are currently working on completing the Pile Driving Analyzer (PDA) piles and installing the production piles at bent 8.

Trestle Installation in Progress

In February we completed the installation of the phase 1 tide gate slide gates and stop logs. We also completed retaining walls #6 & 7 and we continued to advance the bulkhead wall waler system this past month. We are coming up on a major project milestone with the completion of the phase 1 tide gate and start of the phase 2 tide gate later in March 2024. The overall project completion is still on schedule for the end of 2024.

The Cosgrove Avenue Extension Bridge project in North Charleston, SC consists of a 1,032 LF bridge over the Palmetto Railways and improvements to North Hobson Avenue. Cape Romain is the subcontractor responsible for the construction of the bridge and have almost completed their work and the drilled shafts and columns. Cape Romain has also completed the instalation of h-piles for both end bents and has completed the Pier 5 cap. Carolina Conduit Systems has installed the AT&T duct bank down McMillan Ave up to Noisette and begun installing both AT&T and Dominion duct banks towards N. Hobson. Keller has installed all earthquake drains for both end bents, and the MSE Walls at each end bent are under construction by CRG. Lowcountry Siteworks will continue to install storm drains down N. Hobson and begin the clearing and grading from end bent 1 to the Spruill intersection.

On December 19, 2023, Crowder was the low bid on an Emergency Design Build project for the SCDOT. This project is to replace and upgrade an existing road bridge over three CSX railroad tracks in Yemassee, SC. This is a very fast paced project that has a 246’ long bridge and almost 1/2 mile of roadway to upgrade. In February, crews re-signed the detour and road closure and mobilized to begin clearing & demolition in March.

When you hear the word “learning” what comes to mind? If you are like most people, probably a classroom setting with desk, a teacher and perhaps a whiteboard. While this is certainly one form of and setting for a learning environment, learning can take different forms including on-the-job learning with actual conditions of anticipated skill application. Crowder recognizes the need for and importance of learning and embraces the learning opportunities through weekly “Dynamic Learning Activities” or “DLAs.”

What is a “Dynamic Learning Activity” you ask? A “Dynamic Learning Activity” is an opportunity for workers to use their skills and knowledge while performing tasks in the work environment. Dynamic Learning Activities are designed to supplement safety topic information and provide a more interactive, hands-on experience to enhance worker engagement and facilitate learning transfer. DLAs are excellent opportunities to promote critical safety and health topics on-the-job by demonstrating ACTUAL skills needed to perform tasks safely.

Crowder Heavy Civil’s Greene Street Bridge over NS & CSX project was awarded a 2023 Pinnacle Award by the Carolinas AGC! This project consisted of constructing a new bridge with a complex stainless-steel mesh shade structure over the Norfolk Southern and CSX Transportation railroads to reconnect Greene Street. The team also converted Greene Street from a four-lane and two-lane roadway to a three-lane curb and gutter roadway with sidewalks and dedicated bike lanes from Huger Street to Gadsden Street. A stainless-steel mesh shade structure was built along the entire length of the 232-foot bridge and included protections for the railroad tracks below. To complicate the erection of the shade structure—which was meant to be functional and complement the University’s architecture—the bridge is in a vertical curve over the railroad tracks, making every support for the shade structure a slightly different angle and elevation from each other. This challenge was overcome by extensive planning and intense quality control while casting the columns and fabricating the stainless support structure and the mesh panels.

The stainless-steel mesh shade structure is also now a recognizable landmark for the city and provides connectivity, improved traffic flow and has helped spur economic development. By building a new bridge and closing Devine Street and Gadsden Street at the Norfolk Southern railroad crossing, this project also resulted in improved traffic flow and safety. And the USC students now have a more direct, convenient route to the university campus instead of traveling several blocks to get around rail-crossings. Due to strictly enforced safety standards and thorough pre-planning, the project had no incidents or accidents.

Congratulations to the Crowder team working on this project!

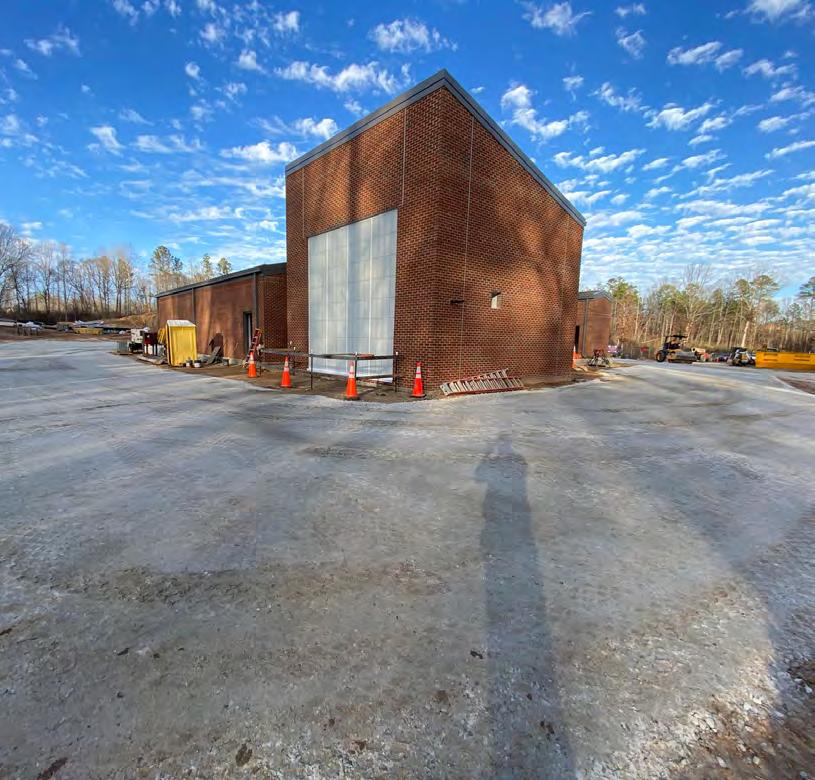

Construction will complete at this project later in March and we are in the commissioning and start-up phase. We began work on this paper and cardboard recycling facility in December 2022 and have been there since. Once operational, it will operate 24 hrs/day, 7 days/week and will process 300,000 lbs of recycled paper and Old Corrugated Containers (OCC)/container board material into clean reusable pulp material every year. This was a design build, EPC project. Crowder purchased all of the major process equipment from bulk handling systems. We partnered with Jedson Engineering on the design and engineering development. We were involved in all phases of contraction from the site work, utilities, foundations and piles to the structural steel erection, equipment setting, process pipe installation and electrical and controls portions of the project. The foundation and pile work began in December of 2022 and continued through the summer of 2023. Structural steel and equipment erection began in spring of 2023 and finished in the fall of 2023. Pipe and electrical installation began in the fall of 2023 and will complete this month. Peak manpower from November 2023 to January 2024 of approximately 100 Crowder employees.

Crowder Industrial has completed the first year of work on the Lake Michie/Little River Pump Station Improvements project for the City of Durham. Work has been focused on the first site, Lake Michie, with work to begin at the second site, Little River, during first quarter of 2024. Work activities began with several months of subcontracted lead paint abatement before proceeding with initial demolition work to remove old systems. Crowder’s primary diving subcontractor, Crofton, began work last summer on the dam side of the lake removing exiting gates and making repairs to the dam. Challenges have been many working in a 100-year-old facility and Crowder continues working with EOR, Hazen & Sawyer, and the City of Durham on solutions to unforeseen structural repairs and other remediations. Work is currently underway for installing a temporary bypass pumping system for allowing continued operation of the pump station to provide water to the City of Durham population.

The next steps will be to mobilize to the Little River site and begin installs for E&SC measures, electrical duct banks and new potable water service for the site.

On an already busy construction project which was partially completed by another company, something special is happening. 600+ Crowder employees from all over the world have joined forces to construct more than just a structural, mechanical, piping, and electrical system. They are creating a culture and, in some cases, a tight-knit community that’s all about keeping each other safe while performing their tasks.

When this project kicked off, the site team had to hire a lot of skilled craftsmen, supervisors, engineers, and managers in recorf time. They had to go from zero employees on site to almost 400 in a matter of weeks. They cast a wide net and brought in workers from all over the United States, US Territories, and other countries. It wasn’t easy getting everyone on the same page when it came to safety rules, but they are making it happen. Orientations and training sessions have turned into chances for everyone to learn from each other, sharing their safety know-how from their home locations and other companies they have worked with in the past. Ensuring that they are looking after the best interests of one another and being engaged and comfortable to challenge and coach someone if they are not meeting the Crowder safety expectations.

As the project moves forward, something interesting is starting to happen. People have gone from being strangers to buddies, even if they don’t speak the same language or have anything in common. There have been many friendships formed and they are looking out for each other on and off the project.

One big reason for this is that everyone feels valued from the first day of orientation all the way to the safety meeting each Tuesday morning. It doesn’t matter if an employee is emptying the garbage, pulling cable, flying iron or welding a pipe – every person’s role matters, and it is a constant talking point. This has made everyone feel like they are part of something bigger than just another job. They are part of a family.

At the time of this writing, not unlike many of our projects, the site team is right in the middle of some extremely critical points of the project: Electrical systems are being energized, piping systems are being tied-in, processes are being transitioned from Crowder-planned-and-driven to Client-owned-and-operated. All of this is taking place at the same time all other contractors on the project are constantly moving in and out of our work areas while trying get their own tasks completed.

The opportunity for an unwanted event to take place is typically highest during this time of a project. That said, the safety team there has placed themselves on high alert. With tasks, home and schedules constantly lingering in their minds, the entire team must truly come together as a family and set themselves to high alert to reach the goal of Zero Incidents. This isn’t just about the project being completed, the tasks our team has performed or the effort that went into each hour on the project. It’s about the bonds and friendships they’ve built and the safety culture they’ve learned and created from a “melting pot” of backgrounds. This shows that when people come together, no matter where they’re from or where they are going, they can do amazing things as a team focused on one true goal. And that’s something worth celebrating.

Kudos to any team that is experiencing something like what the team in Prattville, Alabama is currently living!

We are proud to receive the gold level distinction of the Cigna Healthy Workforce Designation for our wellness program! This designation from Cigna healthcare recognizes that a commitment to employee well-being and vitality can impact everything from employee health and satisfaction to company productivity and business performance.

At Crowder we are always looking for ways to make a positive impact in the lives of our employees, and we believe that providing tools to create a solid financial foundation for their families is one of the most important We have arranged for Creative Planning to offer our 401k Plan participants a wealth of FREE tools and resources to help manage debt, save for college or retirement, understand investing and stock market volatility, and many more relevant topics. Plus, they offer free one-on-one financial consulting to help employees meet their financial goals, as well as options for employee-paid wealth management services providing more direct plan guidance.

Just click on the featured articles and available podcasts below to learn more about what Creative Planning can do for you. All of the training or participation in meetings is at your discretion, and your information will remain confidential. If you want to better understand the benefit or schedule a one-on-one meeting with your dedicated financial wellness consultant, you can contact Kymona Thomas with Creative Planning directly at the email below or you can click on the schedule a meeting button to schedule a 30 minute meeting. Kymona.Thomas@CreativePlanning.com.

Don’t hesitate to reach out to anyone in Employee Services if you have any questions or concerns at: 1-800-849-2966 or employeeservices@crowderusa.com

The Civil & Environmental team at our Graham project enjoyed a Big 5 Team Walk together. A Big 5 walk shares personality traits with all involved to help understand how one another work and operate and identify any gaps to help strengthen the team. The team ended by brainstorming what core competencies are important to the team and the job to work together to end the job successfully!

If you would like to do a Big 5 walk and team building event, contact the Crowder YOUniversity team at CrowderYOU@crowderusa.com

One of the many benefits of being a Crowder employee is that your children have the opportunity to apply for a scholarship through the Carolinas AGC Scholarship Program if they attend an accredited school, college or university located in the Carolinas.

CAGC Scholarship Program

A total of seven (7) scholarships will be awarded from three (3) distinct scholarship categories as follows:

1. University/4 Year College Scholarship

2. Technical/Trade School Scholarship

3. Industry Certification/Advancement Scholarship

We invite your student to review the link below to determine which one best applies to them. The application and detailed eligibility requirements can be found on their website, along with contact information should you have any questions.