In memory of O.P. and Bill, Sr. In honor of Otis and Bill, Jr.

Our Company Mission

We are dedicated to superior performance, and committed to making a positive difference for our clients, our community and in the lives of our employees

Otis A. Crowder

Bill Crowder, Jr.

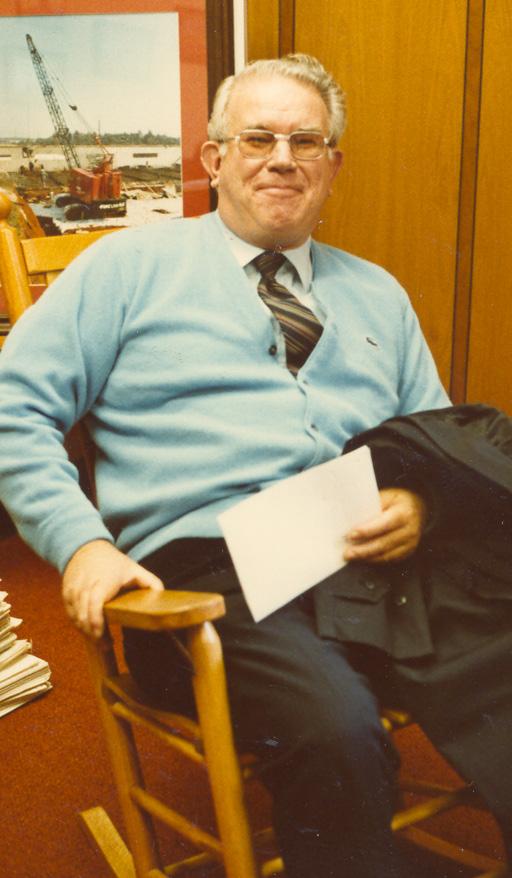

Otis P. (O.P.) Crowder Founder

W.T. (Bill, Sr.) Crowder Founder

Otis A. Crowder

Bill Crowder, Jr.

Otis P. (O.P.) Crowder Founder

W.T. (Bill, Sr.) Crowder Founder

CONTENTS It All Starts With Safety ............................................................................ Beginning the Legacy, The 1940s ........................................................... Laying the Foundation, The 1950s .......................................................... The Art of Expansion, The 1960s ........................................................... Building People, The 1970s ................................................................... Going in New Directions, The1980s ...................................................... Establishing a Broader Reach, The 1990s ............................................ Crossing a Millennium, The 2000s ........................................................ Constantly Advancing, The 2010s ......................................................... The Legacy Continues, The 2020s ........................................................ A Look at Crowder Today ...................................................................... Revenue History ................................................................................... Crowder’s Legacy Projects ................................................................... Living Our Mission ................................................................................ Ol’ Timers Group ................................................................................... Celebrating By Giving Back ................................................................... Recognizing Stellar Performance .......................................................... Building Our People .............................................................................. The Crowder Family .............................................................................. The CAGC Hall of Fame Awards ........................................................... Scholarships .......................................................................................... Shareholders ......................................................................................... Board of Directors ................................................................................. Building a Legacy 1947-2022 2nd Edition 2022 4 6 8 14 18 22 28 32 34 36 38 40 41 54 57 58 60 64 66 67 68 74 75 [2]

[3]

It All Starts With Safety

The safety and health of all employees is truly Crowder’s top priority. Crowder has not only the responsibility but a moral obligation to protect its employees, going above and beyond regulatory requirements. Crowder is committed to the responsibility of sending all employees home safe at the end of each day.

Crowder’s safety program has been nationally recognized for being one of the most effective programs in the country. The safety department is comprised of dedicated safety professionals at corporate, division and project levels, many of whom began their careers at the craft level and understand what it takes to be safe in the field. Crowder’s project teams start each day and any new tasks with Pre-Task Planning, hazard recognition and hazard mitigation. This focus on activities has resulted in Crowder being a safety leader in the construction industry. Crowder’s safety program and proactive efforts has resulted in partnerships with both Federal and State OSHA programs.

Training starts on the employees’ first day with a thorough safety orientation and is followed with many more hours of training based on specific trades and responsibilities. Whether the training is geared towards equipment qualification, a specialized certification (i.e., crane operator or advanced rigging) or any other of our current 80 safety-related topics, Crowder’s training is designed to ensure our employees work safely. Crowder’s Red Hat program provides structured training and informal guidance to all new craft employees during their first three months of employment when they are most likely to be involved in an incident.

With a mindset of continuous improvement, Crowder’s safety group worked with a local software developer to help streamline safety-related processes. What initially started as an avenue to electronically complete weekly project safety inspections and incident reports morphed into an all-encompassing Safety and Health platform. Having historical safety data and training records available is crucial to ensure that all employees are well-trained and are learning from the past to prevent future mistakes.

[4]

Crowder has learned over the years that the safety programs that involve all employees are most impactful and create a culture of ownership. Examples of the processes that have had a positive impact on Crowder’s safety are Behavior Based Observations, Dynamic Learning Activities, and Project Safety Committees.

Overall, Crowder’s safety success rests with every employee. There is an understanding of shared responsibility and accountability at all levels of the Company. Although project supervision and craft personnel carry the “safety torch” every day, they are supported and joined by all Crowder employees committed to staying focused to achieve safety excellence!

Safety Recognition

2020-2022: National AGC - Construction Safety Excellence Award

2017-2021: North Carolina Department of Labor - Safety Achievement (Gold)

2019-2020: South Carolina Department of LLR - Palmetto Shining Star

2020: ABC Diamond STEP (Safety Training Evaluation Process) Award

2019: Carolinas AGC - Merit Award (Outstanding Safety Performance)

2015-2019: ABC Gold STEP Award

2017: Carolinas AGC - Merit Award (Outstanding Safety Performance)

2018: Carolinas AGC - Achievement Award (Safety Excellence)

2010-2016: North Carolina Department of Labor - Safety Achievement (Silver)

2015: Carolinas AGC - Safety Achievement Award

2014: ABC Platinum STEP Award

2013: ABC Diamond STEP Award

Carolinas AGC Safety Achievement Award

ABC Georgia Chapter Award of Safety Excellence

2012: ABC Platinum STEP Award

U.S. Army Corps of Engineers Safety Certificate of Merit

2010: Carolinas AGC Safety Achievement Award

Duke Energy Contractor Health & Safety Award of Excellence

2002-2003: First Place Safety Excellence Award Heavy Division

2001: Seventh Consecutive Year for Outstanding Work in Accident Prevention

Active Participant: NC Department of Labor, Carolina Building Star Program

[5]

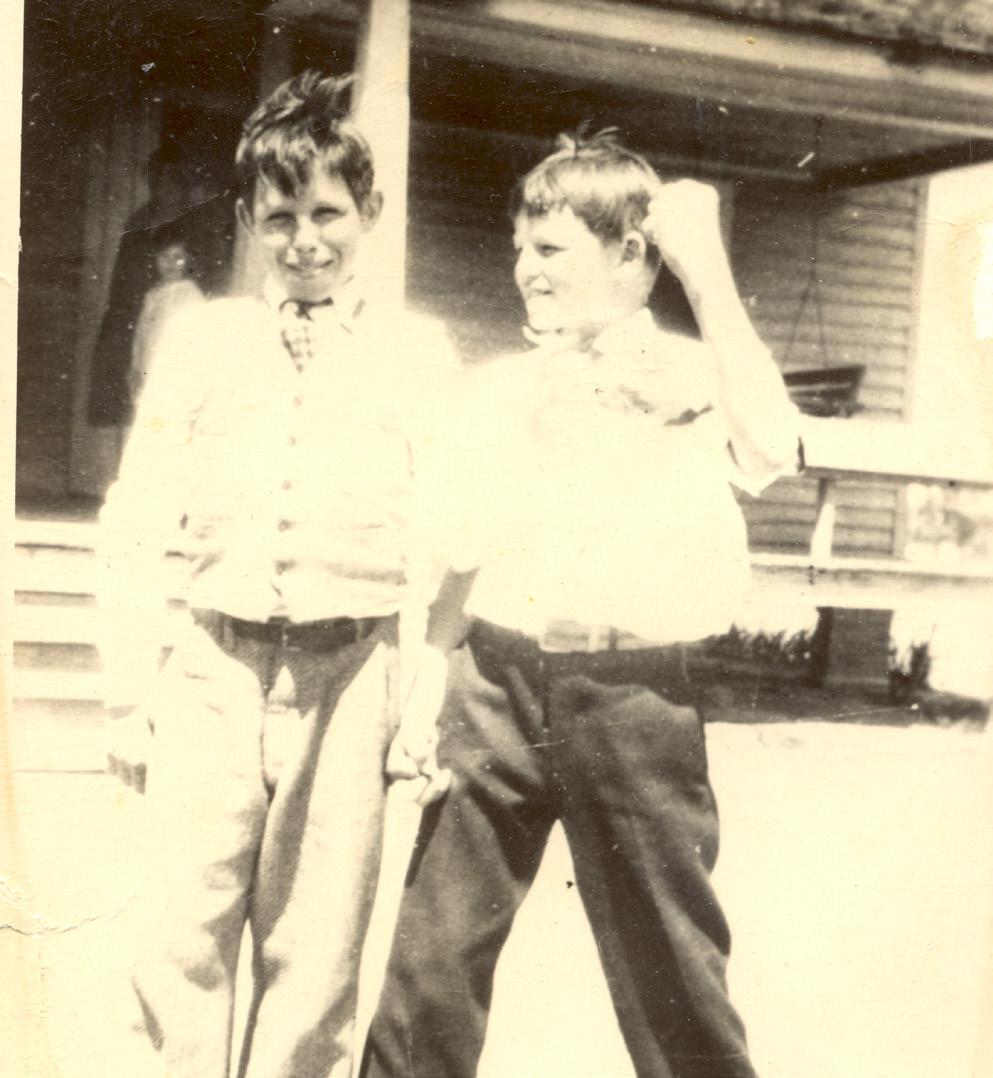

Beginning The Legacy, The 1940s

In 1947, brothers Otis P. (O.P.) Crowder and W.T. (Bill, Sr.) Crowder poured a sidewalk at Plaza Presbyterian Church for $125. This partnership between Bill, Sr. and O.P. began with the simple philosophy: “We will do a good job; we will give the customer their money’s worth; we will be honest; we will pay the bills and we will relate to the employees with respect.” This attitude formed the foundation for their soon-to-be burgeoning company. The first project began with a wheelbarrow, a level, two picks, three shovels and a pick-up truck with more than 100,000 miles on its odometer. They first did small jobs for homeowners in Charlotte, NC, pouring sidewalks and driveways. Over the next 75 years, Crowder would become a well-known, well-respected regional general contractor building bridges, treatment plants, hydroelectric dams and industrial facilities.

Bill, Sr. and O.P. had worked for Blythe Brothers Construction beginning in 1934. Bill White, a longtime friend from early childhood, also worked with them. He recalls that at the time they earned a mere 25 cents an hour digging ditches and laying pipe. At night, they would fill lamps with oil to keep jobsites along the roadways visible. Then came World War II, interrupting life for everyone. Bill, Sr. and O.P. each served in the military; O.P. in the Army and Bill, Sr. in the Marine Corps.

Following the war, both men returned to work for Blythe. O.P. began working for Concrete Supply (a division of Blythe), while Bill, Sr. worked on jobsites. O.P. and E.E. Smith formed a partnership in early 1947 that lasted for a short time. Then, Bill, Sr. and O.P. formed a partnership on July 1, 1947, a partnership that lasted the remainder of their lives and was the foundation for the Crowder legacy.

“We wanted to go somewhere where we could settle down, have a business, contribute something to the economy.”

- Bill, Sr.

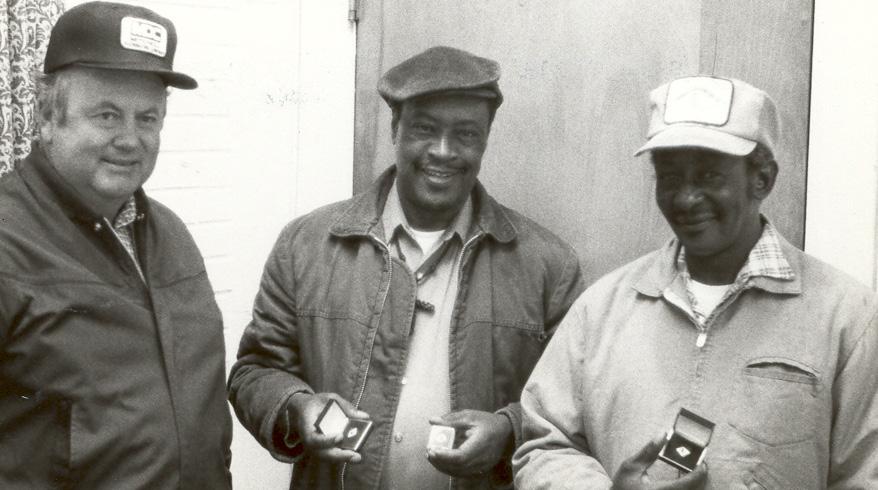

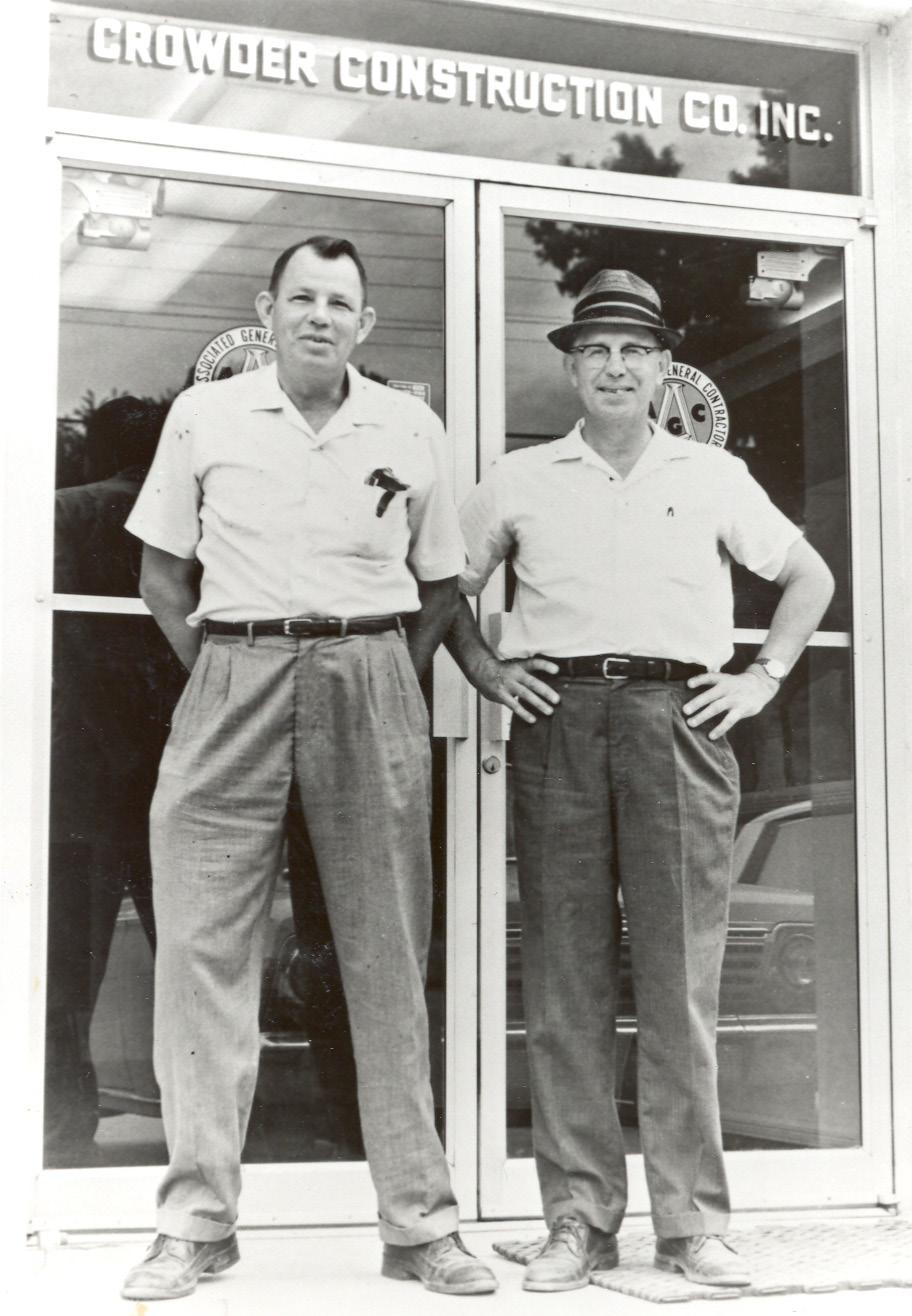

Crowder Construction’s founding fathers, O.P. and Bill, Sr.

[6]

O.P. and Bill, Sr. poured driveways and sidewalks after the day’s work with Blythe. Business picked up and Bill, Sr. began working full-time with the partnership. O.P. joined him full-time after a few months. There was a constant drive to be better. O.P. took correspondence courses to learn estimating and the two men tackled new projects whenever the opportunity arose. Jack Blythe gave them his blessing and even helped find work for the pair.

Sidney Crowder (O.P.’s wife) and Rita Crowder (Bill, Sr.’s wife) also helped get the business off and running. Sidney Crowder managed accounting and helped with estimating. Rita Crowder was a registered nurse. Both Rita and Sidney contributed greatly in the founding of Crowder. The women even signed for a mortgage used to purchase equipment.

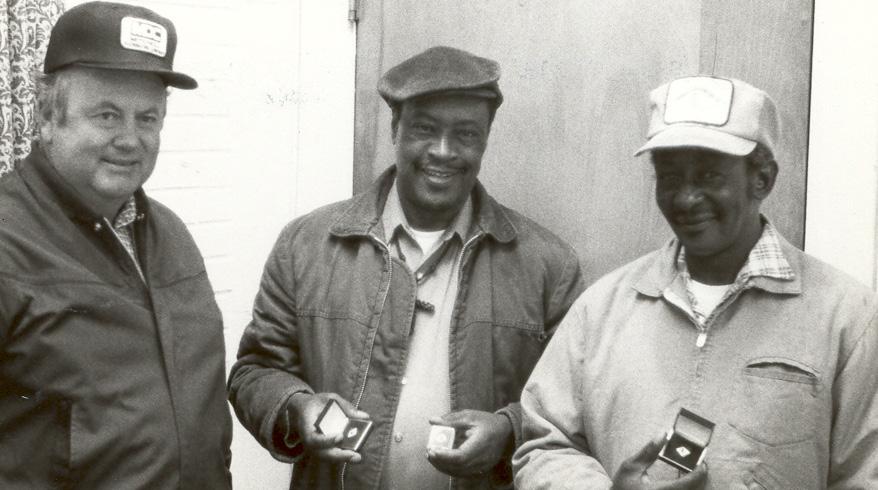

The Crowder Partnership changed its name to Crowder Construction Company in November 1949. Honesty and respect were expected — and practiced — daily among the workers and in dealings with all clients. The result? Jobs continued to come in steadily, and Crowder hired full-time and seasonal workers. In the early years, only five or six men were regular employees — Bill White, Edward Jennings (“Preacher”), Lee Walter, Buck Hampton, and J.R. Wilson. They helped start Crowder and spent the remainder of their careers as part of the Crowder family. As the work increased, the first employees brought friends and relatives to the company. The growth had only begun.

“They (Blythe) helped us in many ways to get started, being good friends of ours … Mr. Jim Briggs (Blythe) would go out and get work and turn it over for us to do it, and do it right.”

- Bill, Sr.

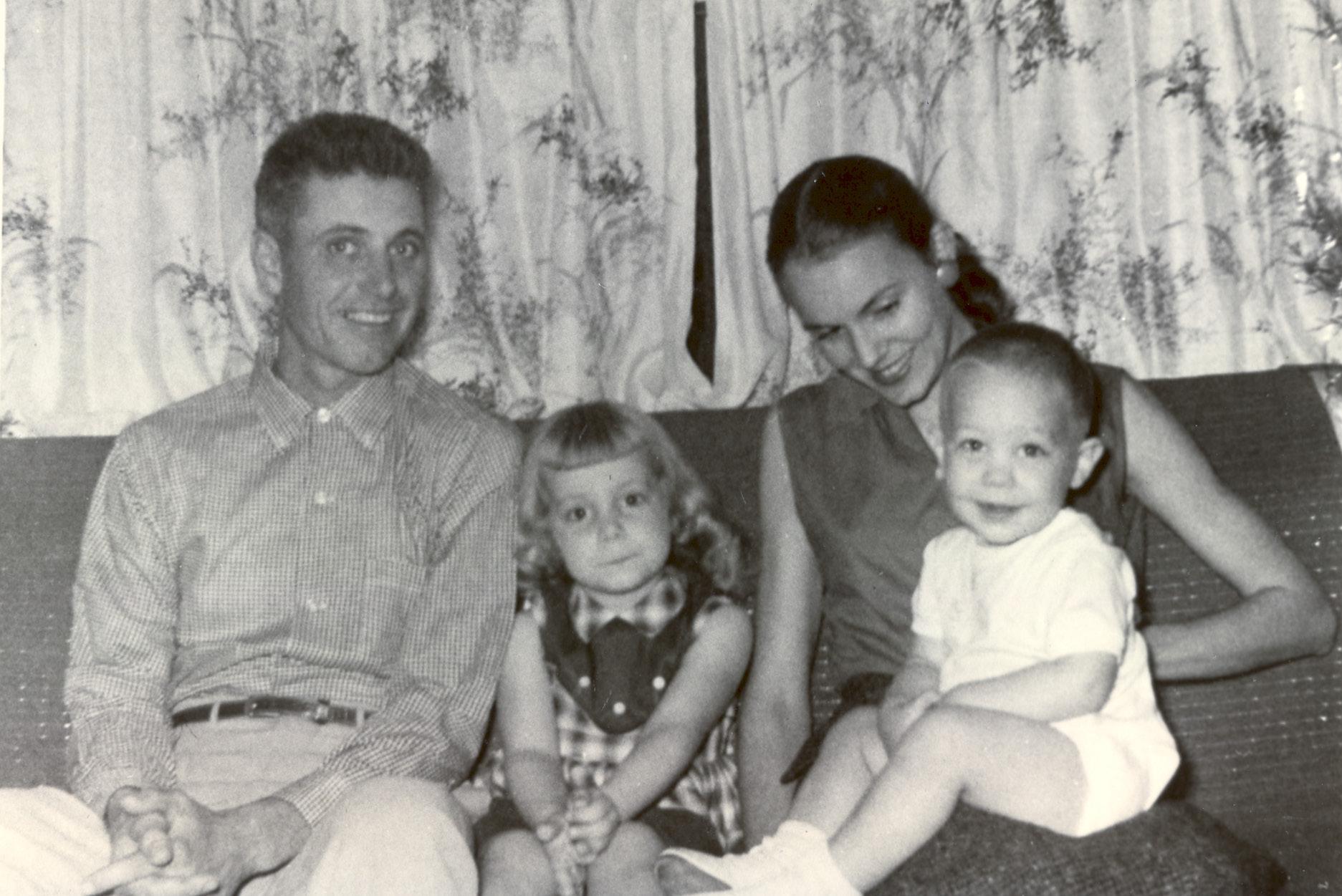

Bill, Sr. and Rita Crowder

O.P. and Sidney Crowder

[7]

Laying the Foundation, The 1950s

“Can you imagine your hip pocket?” This was O.P.’s description of the original office. The first location was at 1317 E. 4th St. in Charlotte. The building was owned by E.P. Nesbit, and was rented to the American Heart Association. Crowder sublet a small room for an office, and had a small garage for storage in the back.

As the 1950s began, Crowder was very busy. Jobs for housing projects and homeowners kept the company growing. Blythe subcontracted work, knowing that the jobs would be finished on time and would be done right. The workforce continued to grow. Mack Crowder, Robert Daniel Wilson, and Henry Walter joined the company. Al Lee (Sidney Crowder’s brother) began to manage the books in 1951.

Along with the work for Blythe, Crowder did a great deal of work for the D.L. Phillips Co. It was during these years that Crowder and the Phillips family began their long-lasting relationship based on mutual trust and respect. Crowder Construction became the preferred concrete subcontractor for both Blythe and the D.L. Phillips Co.

Crowder bid on a concrete job for the D.L. Phillips Co. When D.L. Phillips asked O.P. if he could lower the price some, O.P. said, “I cannot because this is already the best price.” Mr. Phillips promptly gave them the job and said, “You were too low anyways, and you’re the only person I’ve dealt with that wouldn’t cut his price.” The Crowder and Phillips families got along great. Blythe and the D.L. Phillips Co. subbed work to Crowder, helping it get established.

“A little hole in the wall office.”

- Al Lee (describing the 4th St. office)

[8]

Sidewalk and Bogue Court for Cherry Point, NC housing project in 1952

In 1951, D.L. Phillips subcontracted a $1.1 million housing project at Cherry Point, NC to Crowder. Concrete slabs, sidewalks, curbs and driveways were poured for military family housing units. Work on the Queen City Foundry in Charlotte also started that year, as well as a large housing project in Savannah, GA in 1952. These large projects enabled Crowder to buy heavier equipment, including a Bantam Crane and an International Tractor with a Bucyrus loader. These new pieces of equipment represented prized possessions and were put to good use.

Crowder Construction Company began to seriously organize itself for the future. The company was incorporated in North Carolina in May 1953, an important step as Crowder entered new areas of construction, such as highways and bridges. Marvin Ward, a graduate engineer from North Carolina State University, began his career with the company in 1952. He was the first of many excellent engineers who helped build Crowder. Crowder bid and built their first bridge in 1953. It also worked on the Kings Mountain bypass in that same year — its first project for the NC Department of Transportation.

Crowder always believed they could handle something new and challenging, and do a great job at it. In 1953, Crowder bid on two bridges for the NCDOT. They were the low bidder on both; however, they had a problem. The company only had one crane. The NCDOT agreed to award one of the bridge projects to the second lowest bidder at Crowder’s price. After successfully completing its first bridge project, a second crane was purchased in 1954. Building bridges has since been a very important part of the company’s legacy.

“We started our equipment on cold days by letting it go down the hill.”

- Marvin Ward

Foundations for housing project in Savannah, GA in 1953

[9]

Greer Dam, located on the S. Tyger River in South Carolina in 1954

In 1954, Crowder built an exciting and unique project in Greer, SC — a 426-foot dam on the South Tyger River. The construction of the Greer Dam demonstrated Crowder’s increased initiative as well as superb management. The confidence to move into new areas paid off. From housing projects along the coast to the Greer Dam, Crowder maintained a strong presence in South Carolina.

In 1957 C & W Construction Co. was formed to handle all of the work in South Carolina. The C was for Crowder, and the W was for the many employees who had “W” in their last names. People such as the Wilsons, the Walters, Ward and White were a part of the Crowder family. The number of employees increased, and they contributed greatly to the company’s success. During these years men like Carl Griffin, D.H. Epps, and Pete McCorkle began their lifelong careers with Crowder.

Crowder grew rapidly during the 1950s. The company needed more office space and a place for their equipment, so a house was purchased on the 1100 block of E. 10th St. in Charlotte. Even this office was soon too small. A land and house swap with their neighbors, the Allisons of Allison Fence Co., was arranged. That house was torn down and a building was constructed in 1959. A shop was built in the back to store and maintain the equipment.

Crowder built its first wastewater treatment plant (WWTP) at Pilot Mountain, NC in 1957. Bob Eller, a graduate engineer from North Carolina State University, began working with Crowder that year at Pilot Mountain, and the following year helped establish a Utilities Department.

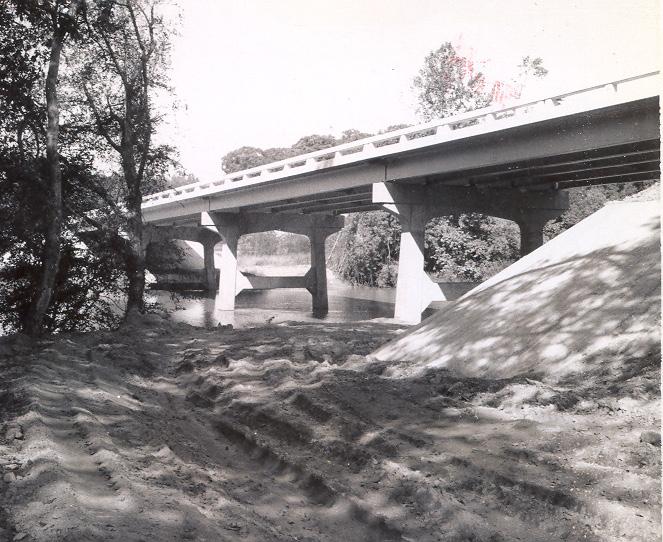

Greenville County Bridge, 1954

Gaston County Bridge, 1954

“The work we do will be the bestgood is not good enough”

[10]

- O.P.

In the 1950s, Crowder developed a strong, smart business relationship with Colonel W.K. Dickson (W.K. Dickson Co.) When Crowder ordered plans for the Wastewater Treatment Plant (WWTP) at Pilot Mountain from him, Dickson said that he already had enough experienced contractors for the job, but Crowder employees would not take “no” for an answer. They were certain they could do the project for a good price and deliver high quality work. When Crowder was the low bidder, Dixon acknowledged their abilities and awarded them the contract. Crowder proved itself with the job, and has been building water and wastewater treatment plants since.

There is no doubt that the booming 1950s laid a firm foundation for the future of Crowder. It expanded work on bridges and wastewater treatment plants. Pouring sidewalks, curbs, and driveways continued. Unique projects like the Greer Dam helped establish Crowder as a large-scale contractor. The decade came to an end similarly to how it began. In the 1950s Crowder worked on a large military housing project in Myrtle Beach, SC and then began working on construction of the Charlotte Merchandise Mart in 1959. These jobs had been subcontracted by D.L. Phillips.

Crowder’s new office at 1123 E. 10th St. under construction in 1959

Crowder’s new office at 1123 E. 10th St. under construction in 1959

“Working hard is good - working smart is better”

- Bill, Sr.

“When things go exactly as planned, then somebody is probably giving you bad information”

[11]

- O.P.

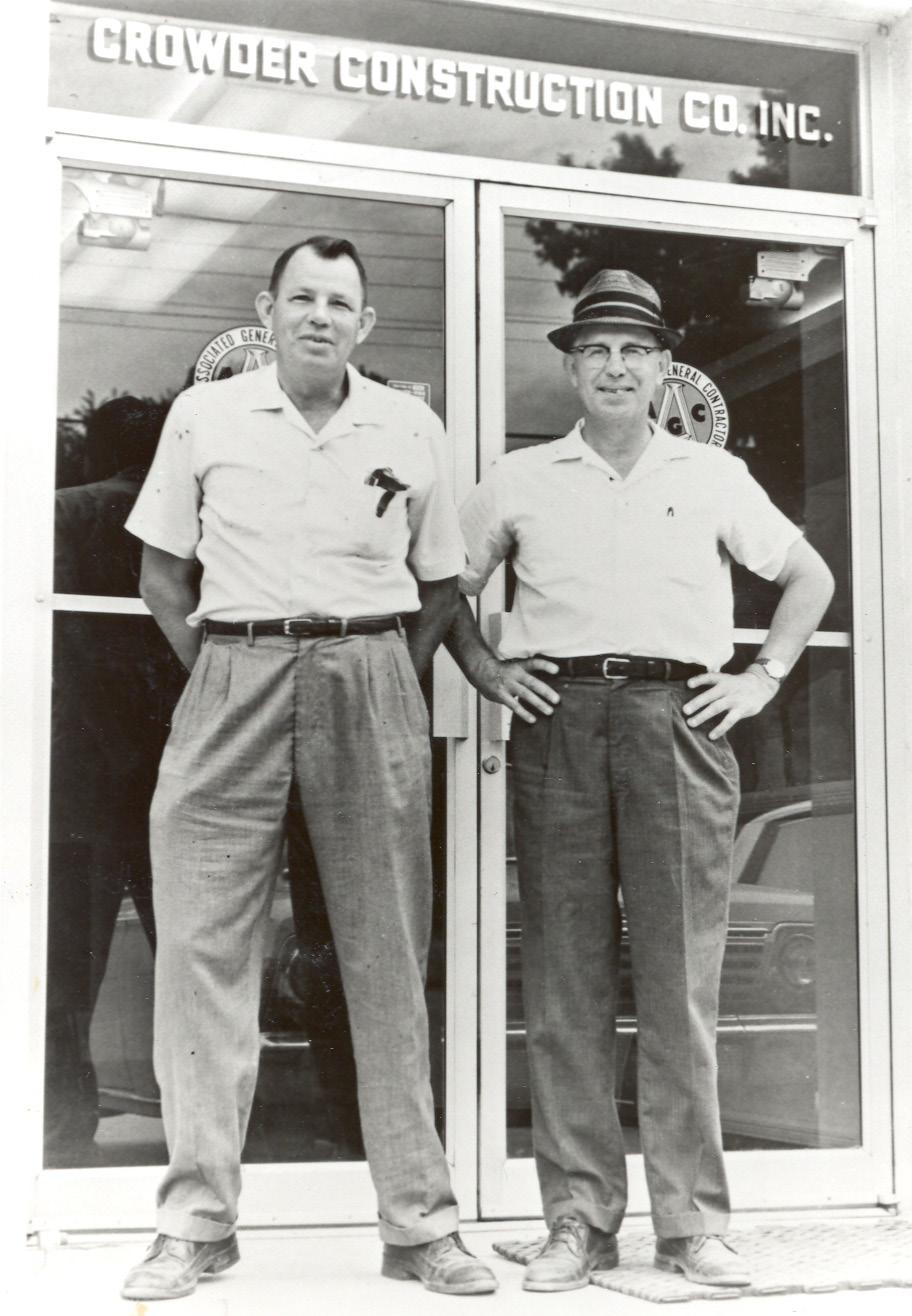

Bill, Sr. and O.P. Crowder at the 10th St. office, late 1950s

Surveying for housing project at the beach

Bill, Sr. and O.P. Crowder at the 10th St. office, late 1950s

Surveying for housing project at the beach

[12]

Bridge construction included projects in Kershaw County and Mecklenburg County in 1954, and Lincoln County in 1955

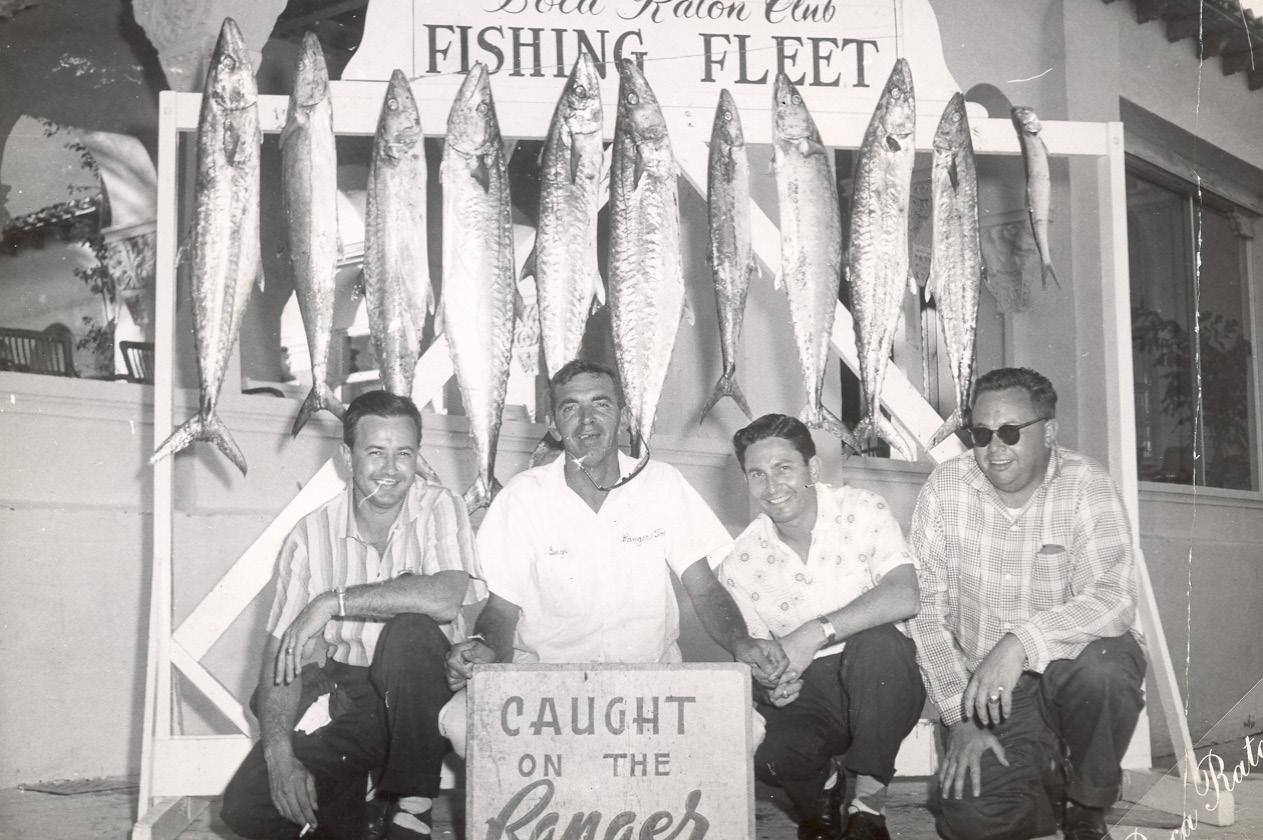

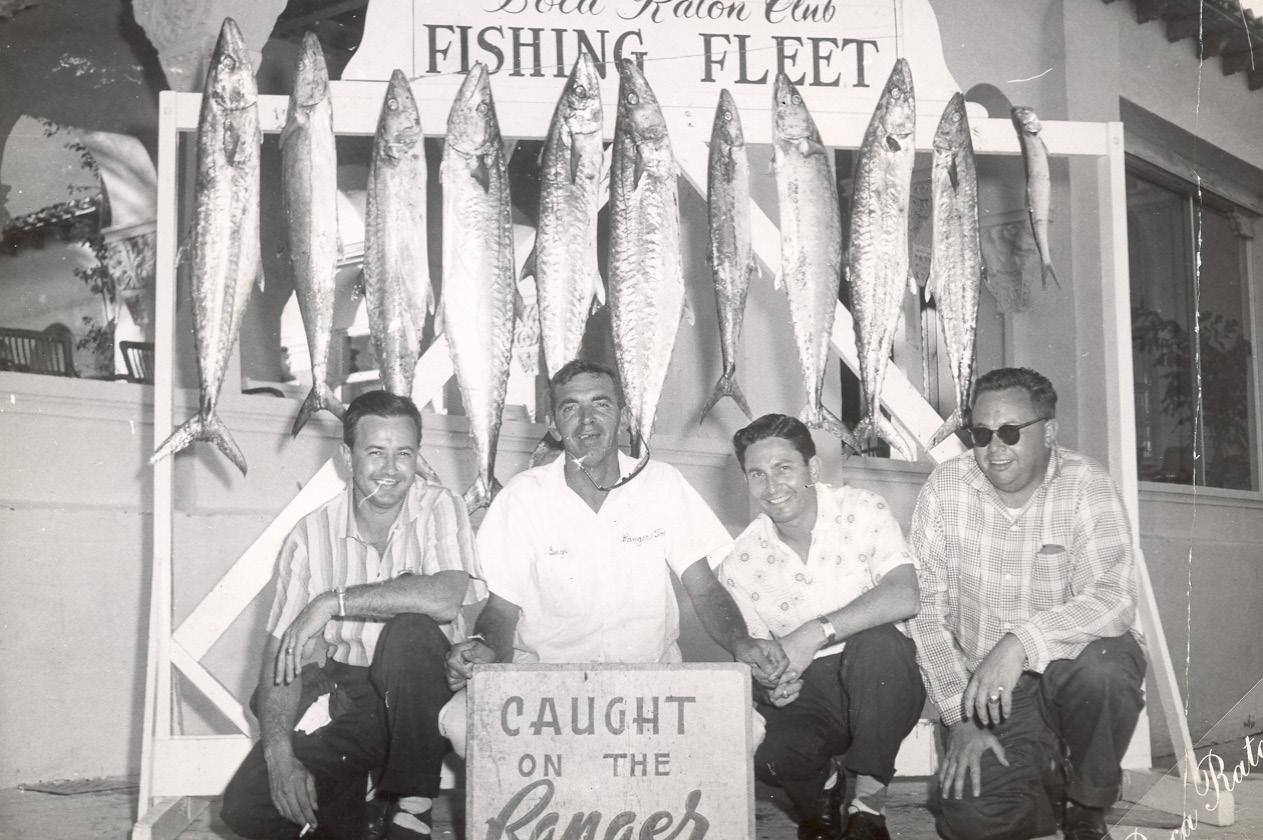

A fishing trip to Florida

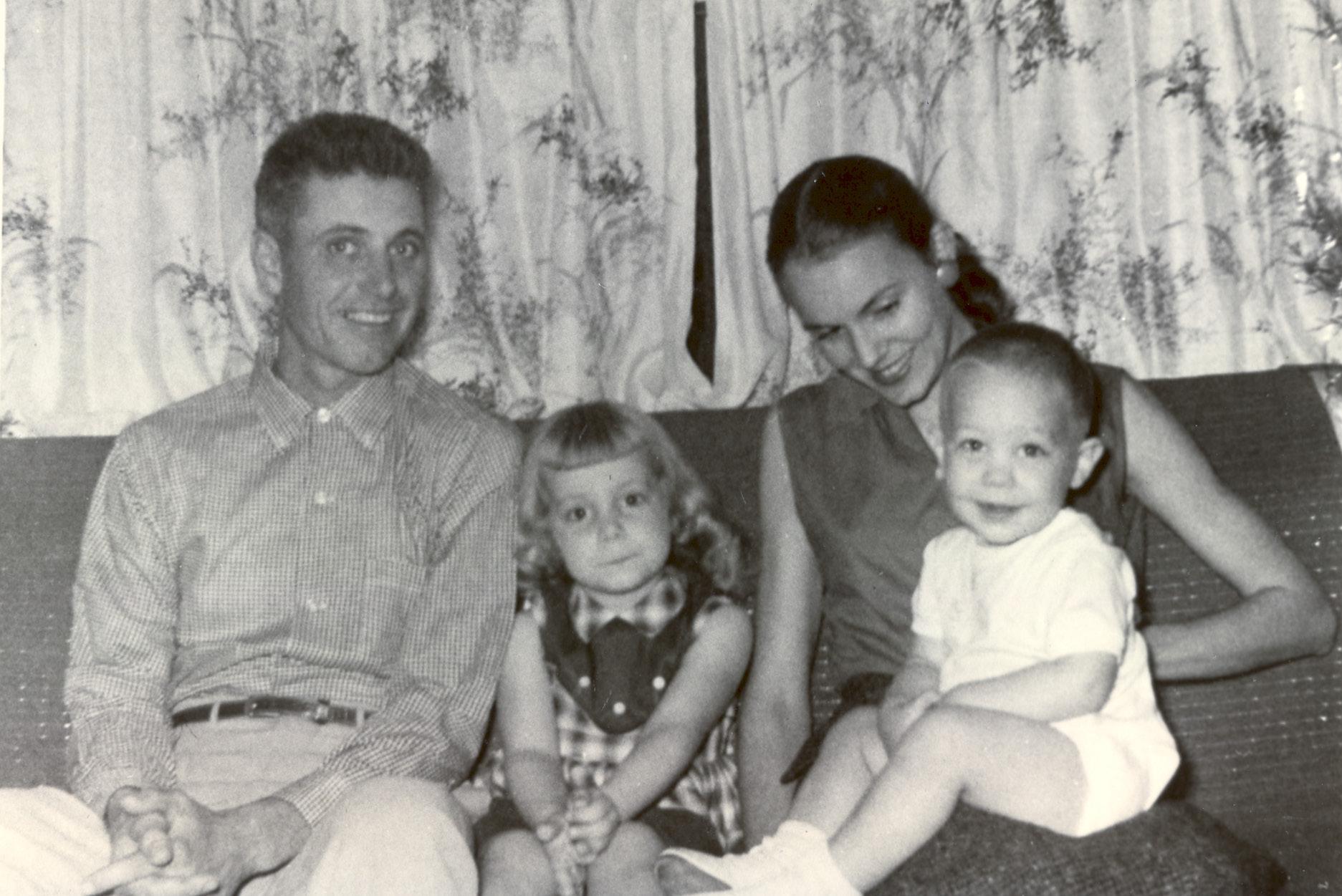

Carl Griffin with his family

D.H. Epps during the 1950s

A fishing trip to Florida

Carl Griffin with his family

D.H. Epps during the 1950s

[13]

Queen’s University Construction

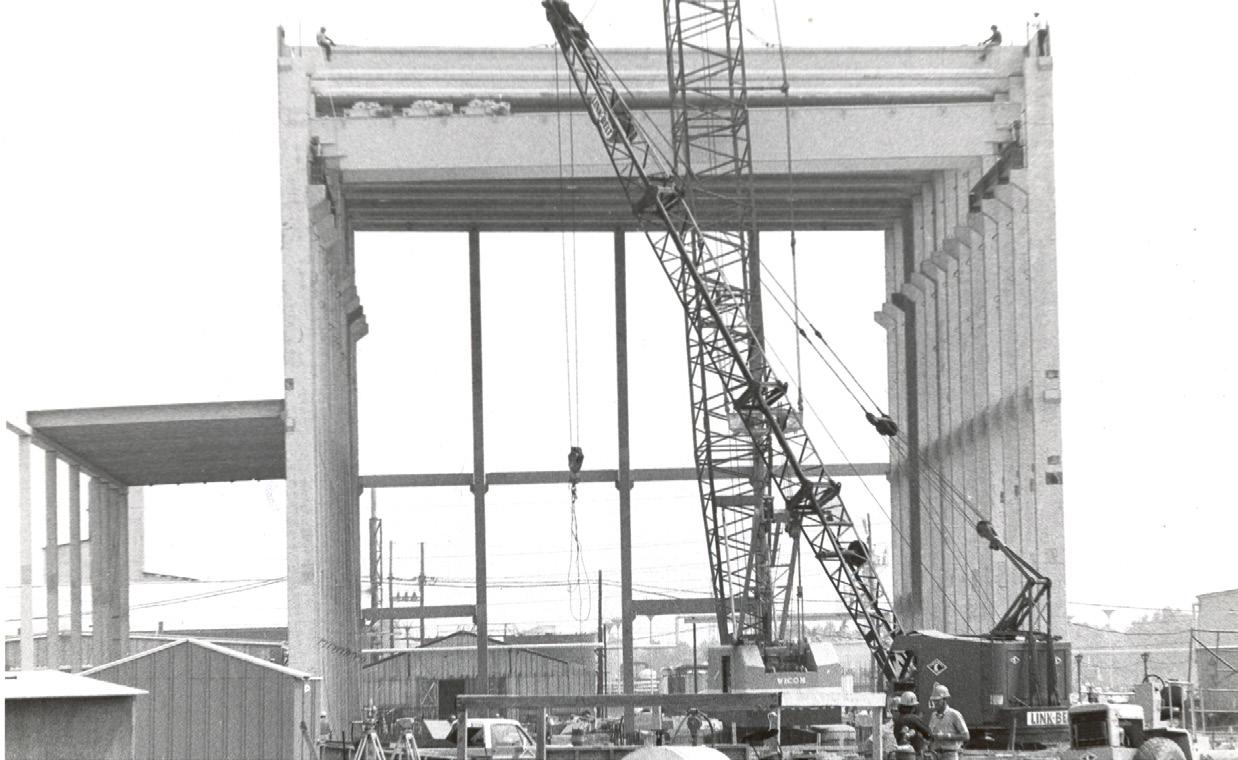

The Art of Expansion, The 1960s

Expansion for Crowder continued in the 1960s. Additions to the 10th St. office were made in 1962 and again in 1968.

Crowder continued to work for Blythe and the D.L. Phillips Co., and long-standing relationships with companies like Duke Power were forged in these years. Everything from roads to bridges to dams were built for Duke (now Duke Energy). A great relationship began with Russ Thompson of Refabco, Inc. Mr. Thompson supplied steel for Crowder projects. Bill, Sr., O.P., and Russ became good friends. Crowder excelled in heavy construction and concrete jobs. Men such as Bill Brant, T.A. Sherrill, Joe Ferebee, Fred Lancaster and Jimmy Harris helped grow Crowder. The company built the Tar River Dam in the 1960s, and began the first of many projects for Riegelwood Paper Mill in 1969.

Confident in its abilities, a Crowder Building Department was started in 1962. B.D. Rodgers was hired to oversee the commercial building. They built projects for many schools, including fraternity houses at NCSU in 1963. This business was not as profitable as Crowder had hoped — the department was closed in the mid-1960s, and the company returned to focus on building bridges, roads, treatment plants, foundations and heavy civil and industrial projects.

Crowder’s Foundations Department emerged from the Building Department, building heavy foundations for everything from water towers to office towers. Fred Lancaster ran this new department, and the challenging jobs it did helped establish the company’s later heavy industrial work. Crowder’s employees were gaining knowledge and experience in diverse areas of construction. The corporate family grew and gave birth to other companies.

Charlotte Merchandise Mart, 1961

Charlotte Merchandise Mart, 1961

[14]

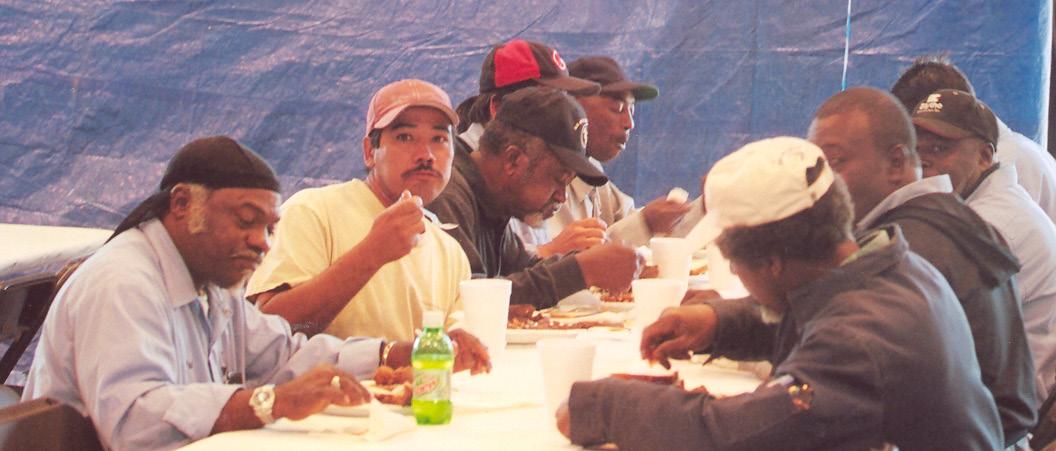

Daddy Bill’s Fish Fry

Some employees took what they learned and started their own companies, just as O.P. and Bill, Sr. had done many years earlier. B.D. Rodgers started his own commercial building company, B.D. Rodgers Builders, in the late 1960s, becoming a very large and successful contractor. Another employee, T.A. Sherrill, started a successful highway construction company in the Charlotte area during these years. Crowder Construction continued to work with them over the years.

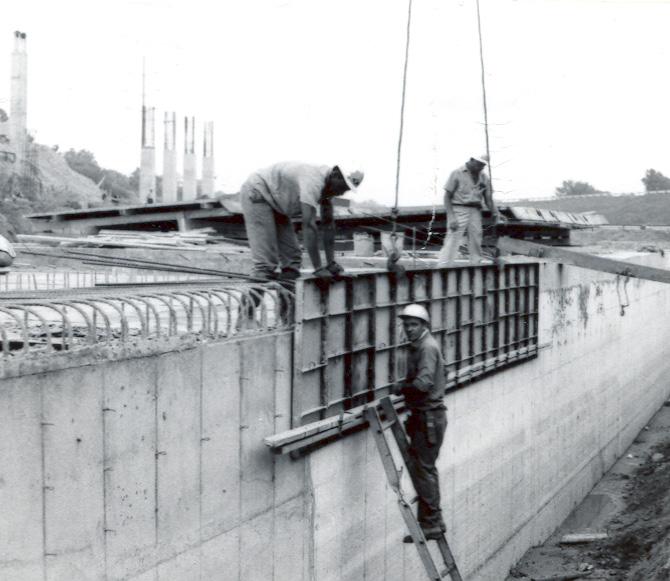

In 1962, Joe Ferebee began consolidating much of the work around the Charlotte-Mecklenburg region into the company’s Street Department, eventually becoming known as the City Division. Employees from the division did work for the city, county and state governments, as well as private clients. Sidewalks and curb projects expanded to include culvert and pipe work.

Crowder grew its water and wastewater treatment plant department and built bridges and highways across the Carolinas. The company had earned respect among its employees, clients, and vendors – and it was showing. Future company leaders were developing their skills and gaining knowledge during this decade: Bill Moore, Billy Sandifer, Fred Creech, Luther Wilson, and Mike Wilson, Sr. either began or continued their careers with the Crowder family during this decade.

During the 1950s and the 1960s there were very few women in the construction industry. Margaret Hough and Colleen Brumble worked with Crowder in the corporate office. Both women made an impact on the company, gaining an indispensable amount of knowledge that helped them manage office affairs efficiently. The pair became a part of many tasks, everything from estimating to ordering concrete. Margaret later formed her own company.

NCSU fraternity housing in 1963

[15]

Al Lee

“This year (1962) we had a proud moment. (We) got into commercial building. I said, ‘We had a happy day when we started this work’. We had another happy day when we got out of this business with our shirts.”

- Bill, Sr.

Work for City of Charlotte at Sharon Amity, 1966

- Bill, Sr.

Work for City of Charlotte at Sharon Amity, 1966

[16]

Construction in downtown Charlotte, early 1960s

Lincoln County Bridge, 1966

Construction in downtown Charlotte, early 1960s

Lincoln County Bridge, 1966

[17]

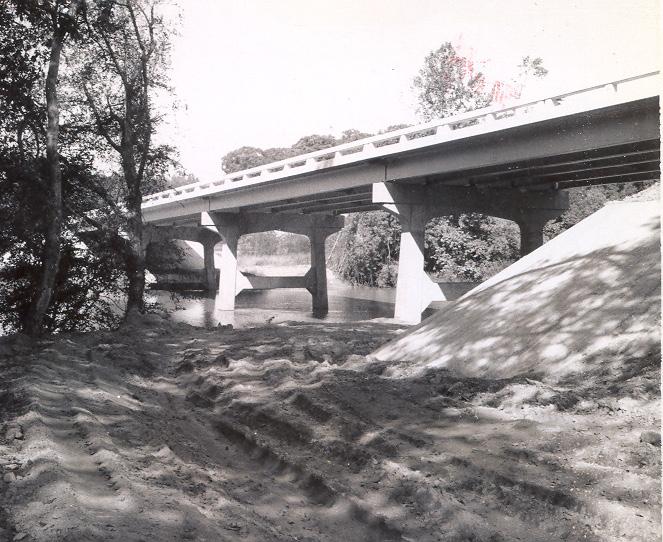

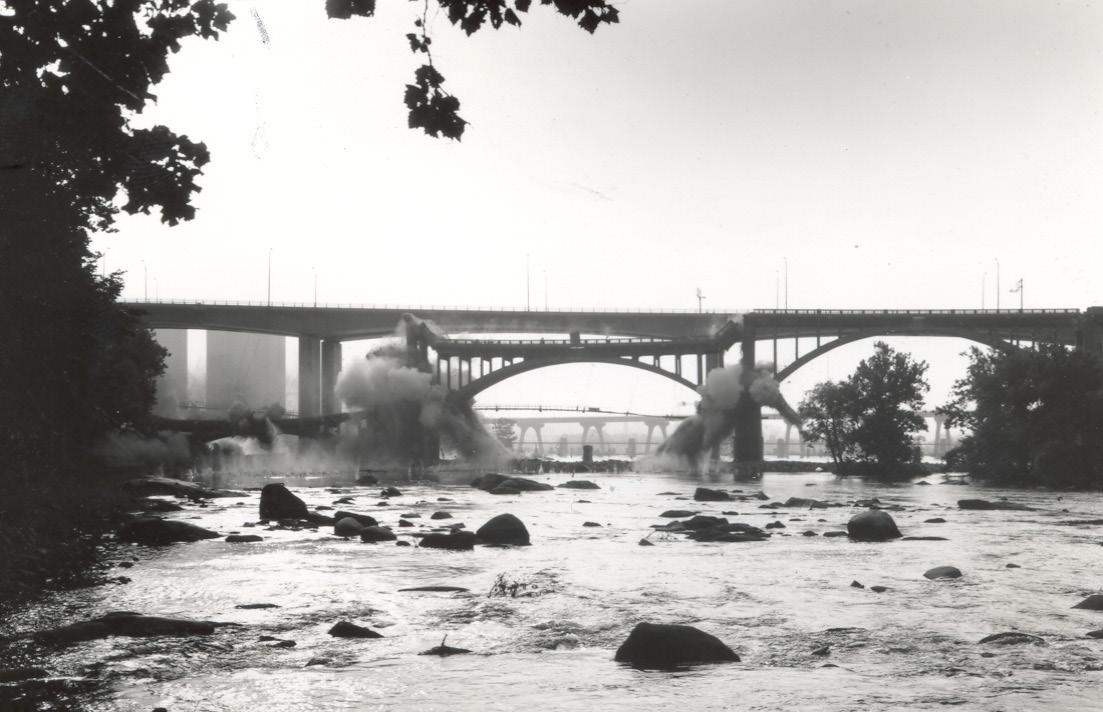

Sugar Creek Bridge, 1966

Building People, The 1970s

By the early 1970s Crowder was organized into four divisions, each able to efficiently manage the company’s numerous projects. As Crowder grew and diversified, the need for corporate controls increased. During this time, O.P. focused on business issues and Bill, Sr. oversaw the construction activities. The company’s business practices became more sophisticated and complicated — revenues and the accounting department had grown considerably. Mack Crowder, Al Lee, Colleen Brumble and others handled an ever-increasing payroll and accounts receivable and payable. The divisions were managed by:

• Foundations Division – Fred Lancaster

• Bridge Division – Bill Moore and Marvin Ward

• City Division – Joe Ferebee

• Utilities Division – Bob Eller, Jimmy Harris, Ed Tucker, and Otis Crowder

Marvin Ward oversaw estimating for all of the departments. Margaret Hough was the senior administrator for the project activities and worked closely with Ward.

Growth in the 1950s and 1960s had been extraordinary. Now there was no longer enough shop and yard space at the 10th St. office to accommodate all of Crowder’s massive equipment. To meet the current and future demands for storage and maintenance space, a 20-acre tract of land was purchased on Brookshire Boulevard (Highway 16). In 1971, twelve acres were cleared for use, and construction on a new shop and yard began. The shop building was finished and in use by the next year.

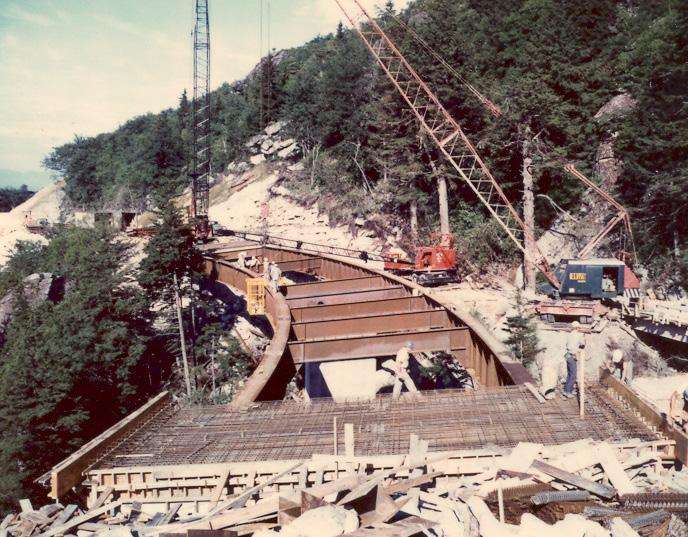

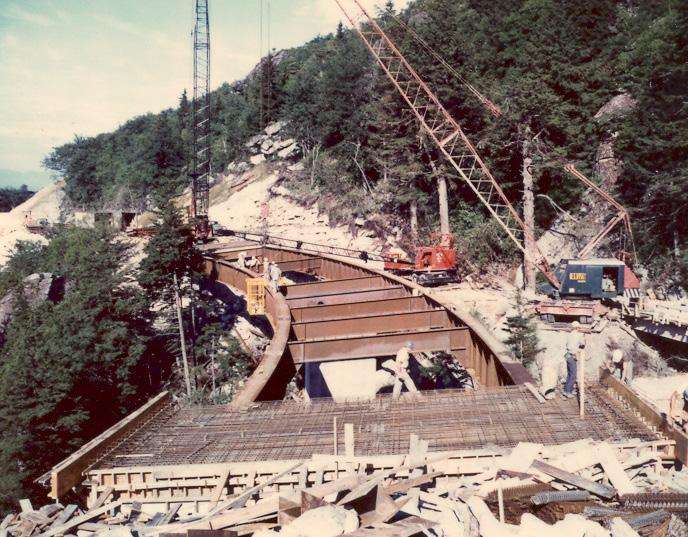

During the decade, the Bridge Division did very well, tackling very large and difficult bridge projects. The construction of the Blue Ridge Parkway bridges was one such job. Crowder worked on a section in Haywood County. The terrain was challenging, and Crowder’s

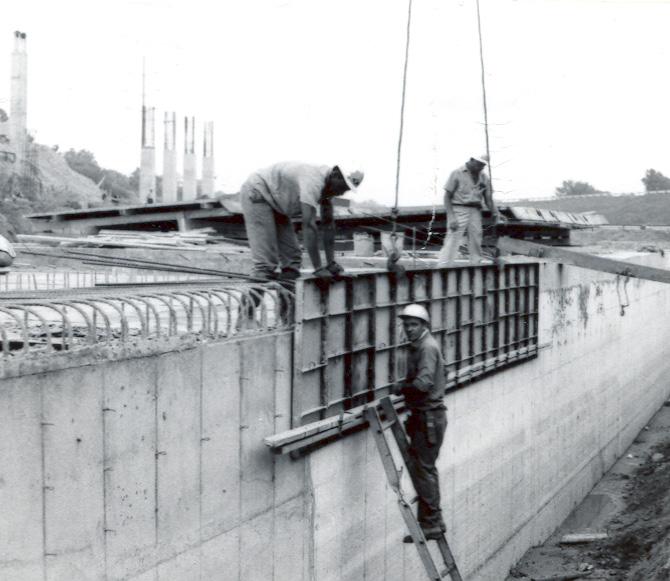

Pier construction in Haywood County

Pier construction in Haywood County

[18]

Blue Ridge Parkway

engineers, supervisors, and crews did exceptional work. In the mid-1970s the award-winning Maury River Twin Delta Bridges project was completed. Crowder was now building bridges in Virginia, North Carolina and South Carolina.

W.T. (Bill, Jr.) Crowder, Jr. and Otis A. Crowder began working full-time with Crowder during the 1970s. Both men had grown up around the company. When the two were kids they would visit jobsites and ride on the equipment with Bill White. During high school and college they did a variety of construction work with the company. Bill, Jr. received an associate’s degree in engineering from Wingate in 1967 and an engineering degree from UNC Charlotte in 1975. Otis graduated from North Carolina State University in 1970 with a degree in engineering.

The two would put their knowledge and skills to good use. Bill, Jr. worked in the Bridge Department, learning how to schedule people and equipment, buy material and handle the management side of projects. In 1976, he became the superintendent for the Bridge Department. Otis worked in estimating and project management for the Bridge Department and the Utilities Department, eventually transferring over to manage the company’s finances in 1979.

“We look for projects that are unusual or the time is tight. If you plan, you can build it. Or you can use different technology or find a better way of getting the owner what they want. In the end we can build projects faster and cheaper.”

- Otis

Pipe work on 4th St. in Charlotte, 1971

NW Expressway in Mecklenburg County, 1970

“Always work to earn and be worthy of others respect”

[19]

- Bill, Sr.

During this decade Crowder became known as a full-service general contractor doing turnkey projects throughout North Carolina, South Carolina and Virginia, managing the building of bridges and highways while subbing out the smaller parts of the projects. They also continued to grow the Utilities Department. Ed Tucker ran this department after Bob Eller and Jimmy Harris left. Eller and Harris had worked with Crowder and they had overseen the Utilities Department formation and growth. The two men each founded their own construction companies and have been successful in their own endeavors. As always, Crowder was proud when its employees took the knowledge that they gained in working with the company and applied it to start their own businesses. The skills needed to run a company were developed while working with Crowder.

In the mid-1970s Bill Crowder, Sr., O.P. Crowder, Marvin Ward, Joe Ferebee, T.A. Sherrill, Grady Thomas, Hank Grathwohl and several other Charlotte businessmen formed a private venture, Southern Asphalt and Construction Co. This company had a small batch production asphalt plant and did asphalt and concrete work. Southern Asphalt leased land for its asphalt production and its corporate office from Crowder Construction at the Hwy. 16 shop and yard. Hank Grathwohl was the company’s president and ran the daily operations. Crowder’s Asphalt Division was born here, and a decade later Southern Asphalt would be purchased by and merge with Crowder Construction.

Crowder first worked at Riegelwood Paper Mill in 1969 with Billy Sandifer as the superintendent. They began another project there in 1972. By the next year Fred Lancaster had negotiated a long-term project for the mill. Bill Brant began supervising the project and, along with Lancaster, founded a trusting relationship with Riegelwood that lasted 30 years.

Water and wastewater treament plant construction, 1970s

[20]

Crowder employees at Riegelwood

“Always remember that everyone has to take care of their family and we need to provide good pay and benefits.”

- O.P.

“Take time for others. Slow down and talk to people.”

- Bill, Sr.

Daddy Bill’s Fish Fry

[21]

Colleen Brumble and Her Husband

“(There are) no real hard, bold lines saying this is my territory, this is yours, don’t cross. We don’t do it that way. We are always meddling in other people’s business. It’s okay, that’s the way we do it.”

Going in New Directions, The 1980s

The economy and the construction industry grew rapidly during the 1980s. The company expanded into new areas of work and the next generation of leaders took the reigns of Crowder.

O.P. and W.T. Crowder, Sr. devoted their adult lives to turning Crowder Construction into a large, successful general contractor. Their personalities and their management style created a family atmosphere within the work environment. They built people as well as a company. Honesty, integrity, respect and pride in the working man and woman were cornerstones that Bill, Sr. and O.P. laid.

O.P. retired as President in 1981 and Bill, Sr. retired from day-to-day management in 1984. Following retirement, the two remained active in the company; both served on the board of directors – and they were always around the office and on jobsites, nurturing their creation. Otis A. Crowder and W.T. Crowder, Jr. stepped forward to run the company. As the 1980s began, Otis was handling the booming company’s finances and Bill, Jr. was working in the bridge department. In 1983, Otis became president and continued overseeing the company’s business side. Bill, Jr. had been managing the equipment along with construction work and in 1983 he became corporate general superintendent, overseeing all field work.

Bill, Jr. and Otis were — and remain — equal business partners. Their experience and talents complement each other. They did not begin their tenure running the company by themselves. Ed Tucker, Mike Wilson, Dane Horrell, and Kip Kiser took on greater management roles, and Crowder sought out new talent for the company. Steve Berry, Mack Mauldin, Charlie Hodgin, Karl Francis, and Bob Haltom began working with Crowder in the 1980s, contributing greatly to the company’s success.

[22]

- Bill, Jr.

In January 1980 the payroll was completed using a computer for the very first time. Crowder utilized a WANG system that managed the payroll and books, and could print a limited number of reports. Originally there were only three or four terminals, located in some of the administrators’ offices. As the decade passed, the computers became faster and were able to work with greater efficiency; drafting boards were replaced and bids were calculated faster.

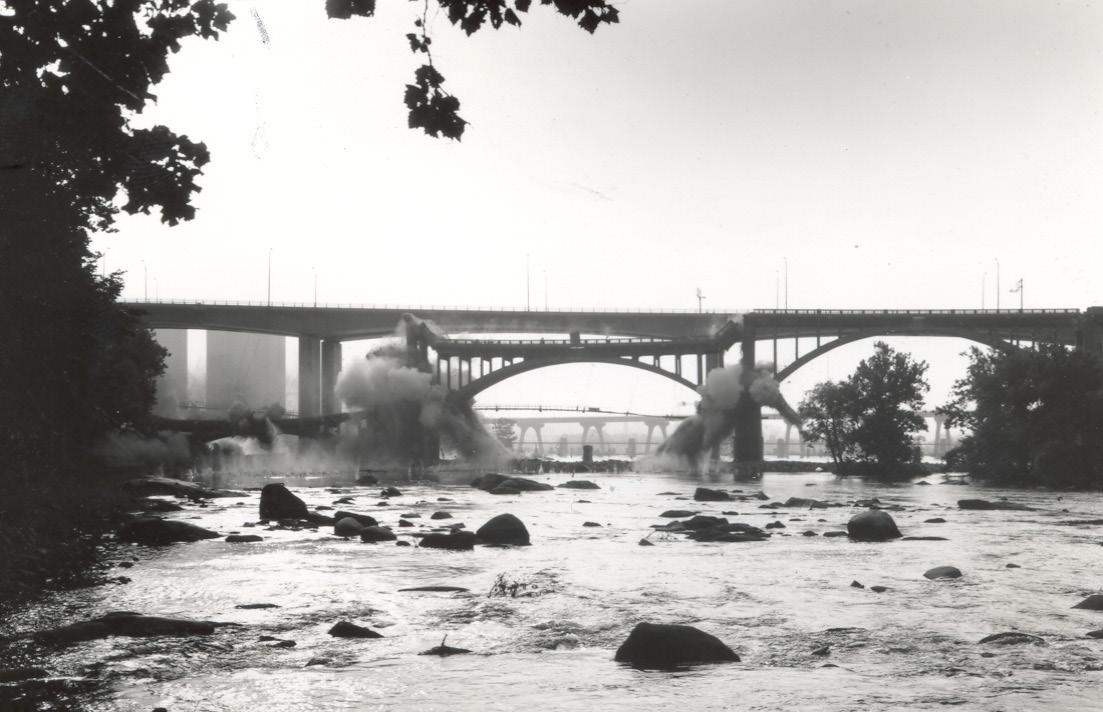

Crowder had a once-in-a-lifetime project present itself in 1981. The company entered into a joint venture with Republic Contracting, working on the Richard B. Russell Powerhouse. Ed Tucker supervised the building of the Powerhouse and Visitor’s Center on this massive project. This was another training ground for key employees.

Overall, bridge construction shrank in the 1980s; however, highway and bridge work still remained important. Crowder expanded into Georgia in 1983. In that year, Bill, Jr. and Mike Wilson managed a $20 million joint venture with Blythe Construction for the Georgia DOT. For more than two years the company worked on the turnkey job. Crowder had good growth financially after the Atlanta and Russell projects were completed.

Financial consolidation took place during these years. The parent corporation merged with the other companies it owned and operated on December 9, 1986. These corporations were: Crowder Corporation of Charlotte, Crowder Material Sales Company and C&W Construction Co., Inc.

American Express Building Construction

Cary Wastewater Treatment Plant

American Express Building Construction

Cary Wastewater Treatment Plant

[23]

“Relationships are based on trust and excellence” - O.P.

In 1986, Dane Horrell opened a Crowder office in Raleigh, NC to manage a new Raleigh Division. Originally, Raleigh did work along the lines of the City Division, creating sidewalks, roads, curbs and gutters. Horrell began converting the work in Raleigh into a very successful utilities division to service both private and public clients.

Crowder has often been recognized for its excellent work ethic, and in return seeks to recognize others. The Crowder Scholarship Fund was established in July 1986 by O.P. and Bill, Sr. to reward hard-working, dedicated high school and college students. The hope is to instill the importance of hard work, and that life rewards persistence and a willingness to learn.

Until 1970 our company used only the name “Crowder Construction Company” on equipment and letterhead. In the early 1970s Bill, Sr. and Margaret Hough designed a logo with the diamond shape that was used until the late 1980s when we decided to “update” our logo. There was a great deal of discussion, but it was decided to keep the diamond on the logo since it represents quality and value and that diamonds “last forever.”

[24]

[25]

“I would like to say that the construction industry has been my life since 1934; O.P. a year before me. We have both enjoyed our lives. It’s been my experience that there are a lot of good, hard-working people in this industry. The secret is finding those who say, ‘Yes I will’, then communicate, train and inspire. It’s a people industry. I believe that today we have the expertise to do any kind of project we start to do. I’m happy to see the young generation take over.”

-Bill, Sr.

“Surround yourself with the best people you can. Give them or get them whatever they need, then get out of their way.”

-Bill, Sr.

[26]

[27]

Establishing a Broader Reach, The 1990s

The 1990s ushered in an emotionally-charged era for Crowder Construction Company. Brothers Bill, Sr., Mack, and O.P. Crowder passed away within four years of each other. The three men were important for more than just Crowder — they had a huge impact on family, friends and the community.

Bill Crowder, Sr. passed away on December 14, 1995. Matthew (Mack) W. Crowder passed away shortly after that in January 1996. O.P. Crowder passed away on May 11, 1999. In addition to the Crowder legacy, they left behind a reputation of honesty, integrity, hard work, respect and goodwill. Both Bill, Sr. and O.P. stayed involved with the company and the community until their deaths.

Despite the passing of its founders, the company expanded and made large investments during the 1990s. The Asphalt Division expanded with the construction of a second asphalt production plant in 1991. The facility, located in Matthews, NC, enabled Crowder to sell and lay more asphalt. This also led to expansion, under Mike Leslie, in Crowder’s other highway-related construction activities, such as concrete, pipe laying and grading.

In 1991, Crowder then purchased RJR Mechanical located in Spartanburg, SC which has developed into Crowder’s current Industrial Division. Initially the division focused on mechanical and civil construction for private clients, but as it grew, it added electrical capability to its services. The division initially served customers such as Hoechst-Celanese, DuPont, SONOCO, Kohler and BASF, primarily as a specialty contractor. Over the years, the division gained a reputation for quality and safety. Currently, it has become a full-service industrial general contractor constructing turnkey, EPC and design-build projects.

The SONOCO plant in Hartsville, SC

The SONOCO plant in Hartsville, SC

[28]

Neuse River Pump Station

Meanwhile, Crowder’s Raleigh Division continued to boom. With Dane Horrell and Carlos Norris at the helm, the division began to take on heavy civil projects such as the construction of WWTPs. It also developed the ability to self-perform electrical construction.

Crowder Construction opened an office in Bristol, TN, during the early 1990s. The division focused on building treatment plants in Tennessee, but was closed in the late 1990s. The Central Division was formed in the mid-1990s to handle construction work throughout western North Carolina. Rick Glassen managed this division until a restructuring occurred within the company. These divisions were later merged with the Raleigh Division, which became the Civil & Environmental Division.

As projects became more complicated, the company developed more sophisticated financial and scheduling techniques. Kerry Price and Karl Francis oversaw the company’s financial management. Offices in Charlotte, Raleigh and Spartanburg were linked with an IT network in the mid-1990s, technology that affected all aspects of the construction industry. Engineering plans were now drawn up digitally on CAD files. The speed of communication increased as cell phones and portable computers became standard tools of the industry. Crowder continued to work to make sure it used leading-edge technology to provide value to its clients.

As Crowder entered the new century, it was strong financially and ready to take advantage of the opportunities ahead. New talent was brought in to meet the growing demand for work. Lynn Hansen began as Vice President of Finance and Administration in 1999. Mark Lively joined the Bridge Division in 1998, followed by George Ellis in 2000. Steve Maness and Dirk Shelden both joined the Industrial Division in 1998.

[29]

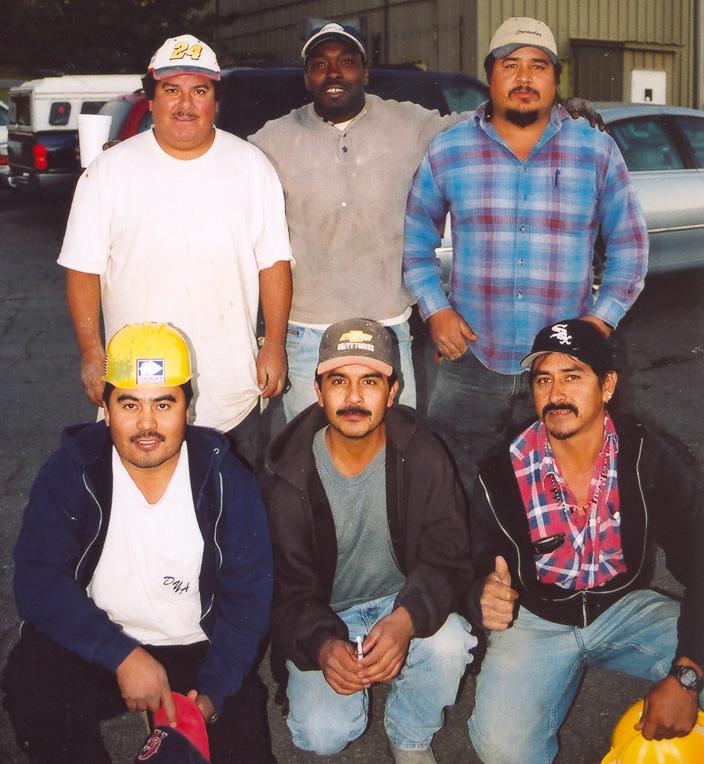

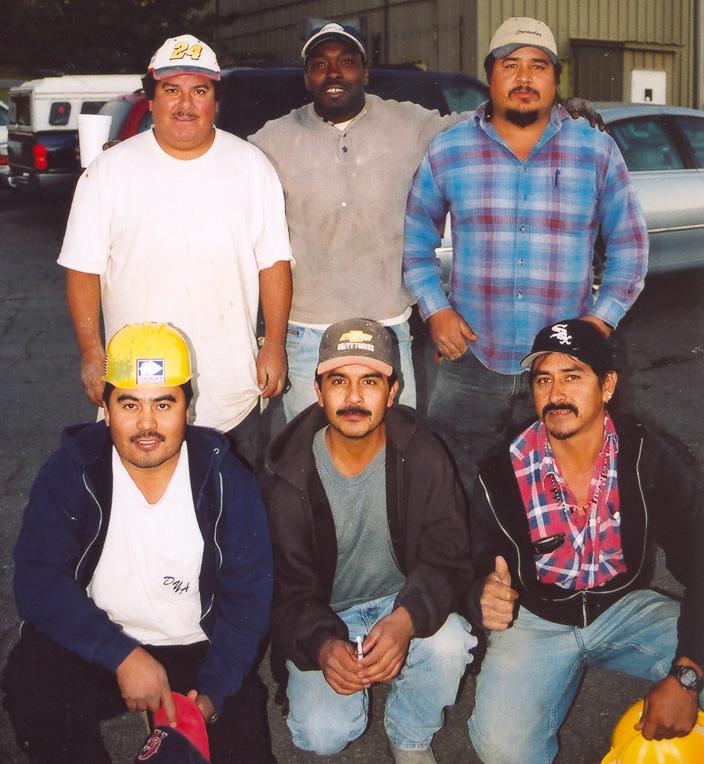

Crowder developed a diverse group of talented people throughout the decades. The company’s loyal, hard-working employees have been and always will be the backbone of the Crowder family and legacy.

[30]

[31]

Crossing a Millenium, The 2000s

In the years following 2000, Crowder focused on shifting the company to make it leaner while expanding its capabilities. The size and geographic area of both industrial and civil projects grew, increasing the size of the Spartanburg and Raleigh offices. In 2000, the Civil & Environmental division in Raleigh relocated to a new and much bigger office location in Apex. The highway and private site development increased, requiring more office space as well. In 2001, a new Corporate Office was constructed at 6425 Brookshire Boulevard in Charlotte — in front of the shop on Highway 16.This allowed room for growth for local Charlotte work.

In 2002, the company opened its first regional office in Conyers, Georgia, as a result of expanding to water and wastewater treatment plant projects in the Georgia region. This move was Crowder’s first effort to develop regional offices to expand geographically and, as importantly, allow employees to work as close as possible to the communities where they live.

The Asphalt Division was part of the Heavy Highway Group until August 2005. Crowder executives decided it was in the best interest of the company to sell this division. In August 2005, the Asphalt Division along with its laydown operations, two asphalt plants and the equipment were sold to Blythe Industries, Inc. All of the Asphalt Division employees transferred to Blythe. This sale returned the Heavy Highway Group’s focus to bridge building.

The Construction Solutions Division was formed to work on foundations and other unique heavy civil projects in 2006. Crowder developed a diverse team of men and women over the decades. Their knowledge, experience and skills enabled Crowder to build projects that many other companies are reluctant to undertake. After the sale of the Asphalt Division, the Bridge & Highway and the Solutions Divisions relocated to a new office next to the Corporate Office on Brookshire Boulevard. After working closely together, these divisions combined to become Heavy Civil, focusing on bridges, dams and other heavy civil projects.

[32]

In January of 2005, the Industrial Division moved its office into a new location in Spartanburg, SC. Along with office space, the facility has a 58,154 sq. ft. fabrication shop, increasing Industrial’s ability to support larger projects.

The 2000s were full of change and growth in many ways but were also a time of preparation for future growth and innovation. Crowder Construction Company had always operated as a single entity. In 2007 Crowder Constructors Inc. was formed as the parent of Crowder Construction Company, recognizing that corporate and personnel needs for Crowder’s diverse divisions may be different in the future.

Crowder’s Civil & Environmental division procured its first design-build project for Johnston County in 2003 on a 4 MGD water plant. Crowder was the design-builder and McKim & Creed was the engineer.

Claudia Dodgen joined Crowder in 2000 after working with Crowder as a Leadership Consultant.

Claudia’s first project was to develop Crowder YOUniversity, which included employee development along with the Legacy Training Program to accelerate the careers for young leaders throughout Crowder.

“One of our big advantages in the market … is that we can do four or five different things. So when part of the market is down, we can move people into another area. The other factor is that we like to do unusual projects that have a lot of different components that other people don’t feel comfortable doing — unusual projects and things that have electrical, civil and mechanical. We like projects that have a lot of different trades and require many diverse skills and ingenuity.”

-Otis

[33]

Constantly Advancing, The 2010s

To begin the 2010s Crowder was poised to take advantage of its reputation and relationships with clients and engineers to expand its alternate delivery markets. Crowder had developed teams with expertise to manage the complexity of design-build projects. As the decade progressed Crowder became known as a leading design-builder of water and wastewater plants in the Southeast. As state and local regulations changed, Crowder has been on the leading edge of innovative methods to provide projects to its clients. In 2016, Crowder was awarded its first Construction Manager at Risk with Charleston Water at its Plum Island Water Pollution and Control Plant in Charleston, SC.

In 2012, Crowder established Crowder Industrial Construction LLC and Crowder Energy Services LLC as sister companies to Crowder Construction Company. All operations of Crowder’s Industrial Division were moved to Crowder Industrial Construction. Under this entity, Industrial continued to grow and take on larger and more complex projects, focusing on energy projects primarily with Duke Energy, Dominion Energy and SCE&G. These first energy projects were primarily fossil fuel, but as the energy environment evolved so did Crowder, putting its focus and resources on hydro, gas turbines and other alternative energy projects.

Crowder Energy Services was formed in 2013 as an innovative and forward-looking marketing company to work with owners to develop alternative energy projects that Crowder’s operating divisions could participate in during construction. As a result, Crowder has helped develop and build utility scale solar fields, gas-to-energy projects, battery energy storage systems (BESS) and LNG plants.

Just as their fathers had done, long before Otis and Bill Crowder were ready to step back from day-to-day operations, they were planning for their succession. So as not to disrupt the operations of the company, between 2016 and 2020 they transitioned the leadership of Crowder to Lynn Hansen, CEO, Carlos Norris, COO and Karl Francis, CFO. Otis and Bill still maintain their leadership roles as Chair and Vice Chair of the Board of Directors of Crowder Constructors Inc.

[34]

[35]

The Legacy Continues, The 2020s

Although the 2020s are just getting started, what a start it has been. No one would have expected in March 2020 that a pandemic — Covid-19 — would have changed lives and businesses so much. Being an essential industry and service during the pandemic allowed Crowder employees to continue to work. As difficult as the last two years have been, Crowder’s over 900 employees have worked through difficult times and completed quality projects, safely and on time.

Many Crowder employees had to work remotely or differently by social distancing, a new concept. Crowder was prepared with technology infrastructure to allow for online meetings and total remote access. For the most part, paper went away and Crowder has become more efficient. But nothing can replace in-person interaction, mentoring and training, which makes employees feel a part of the Crowder family.

Learning from crisis has made Crowder stronger, and the foundation laid over the last 75 years has allowed Crowder to use its experience, relationships and talents to be successful.

Crowder has always been an innovator in its markets and has sought complex projects. Over the last 20 years, Crowder’s staff has developed expertise to deliver projects by whatever delivery method is best for the client. Whether Crowder is the builder, the design-builder, EPC, or the construction manager, Crowder brings the same high quality to all of its projects just as its founders did with their first project.

The Crowder legacy started in Charlotte 75 years ago with a few steps. Today we work or have worked in 12 states, mostly in the Southeast. Although it has a huge fleet of equipment, Crowder’s most precious assets are people.

[36]

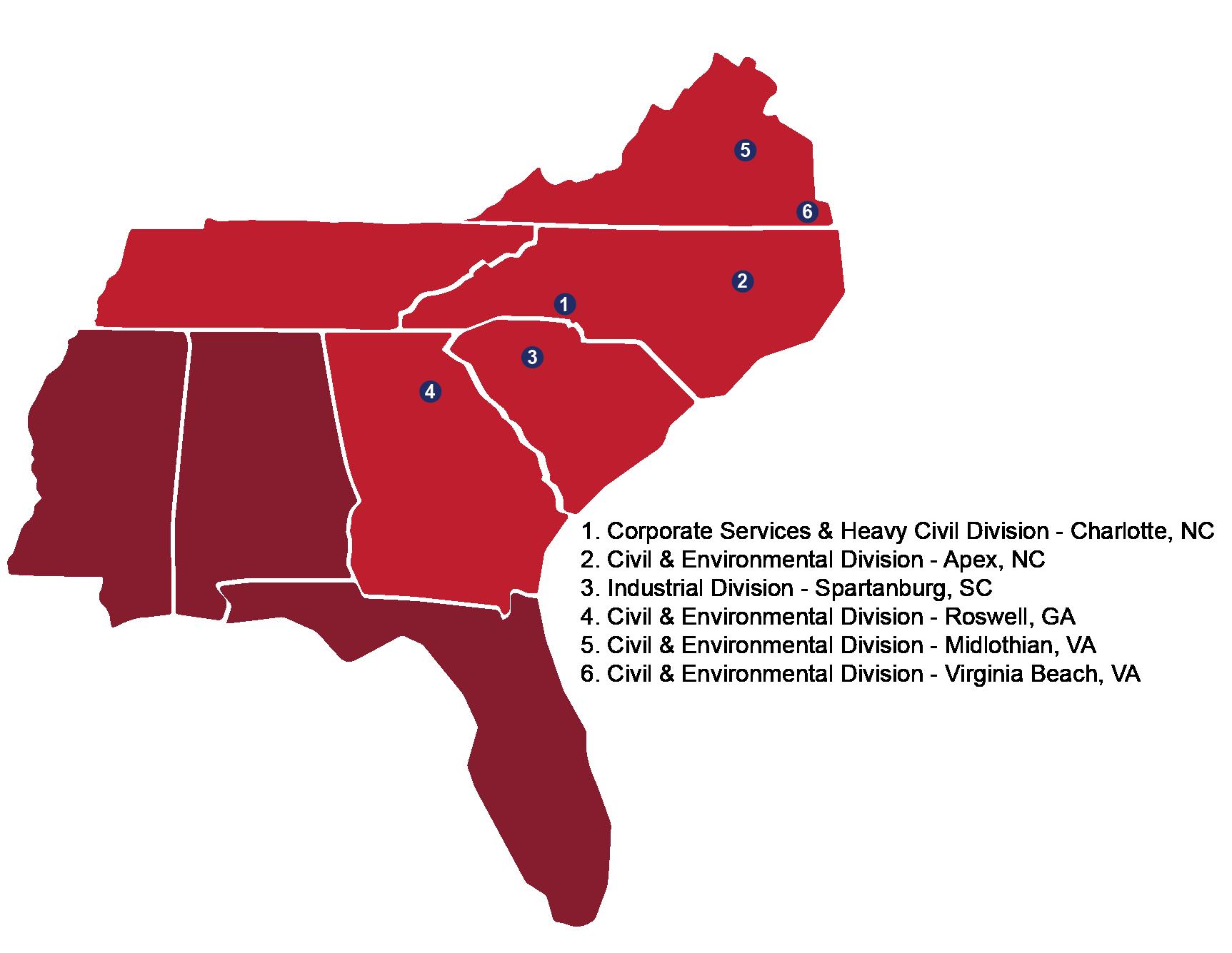

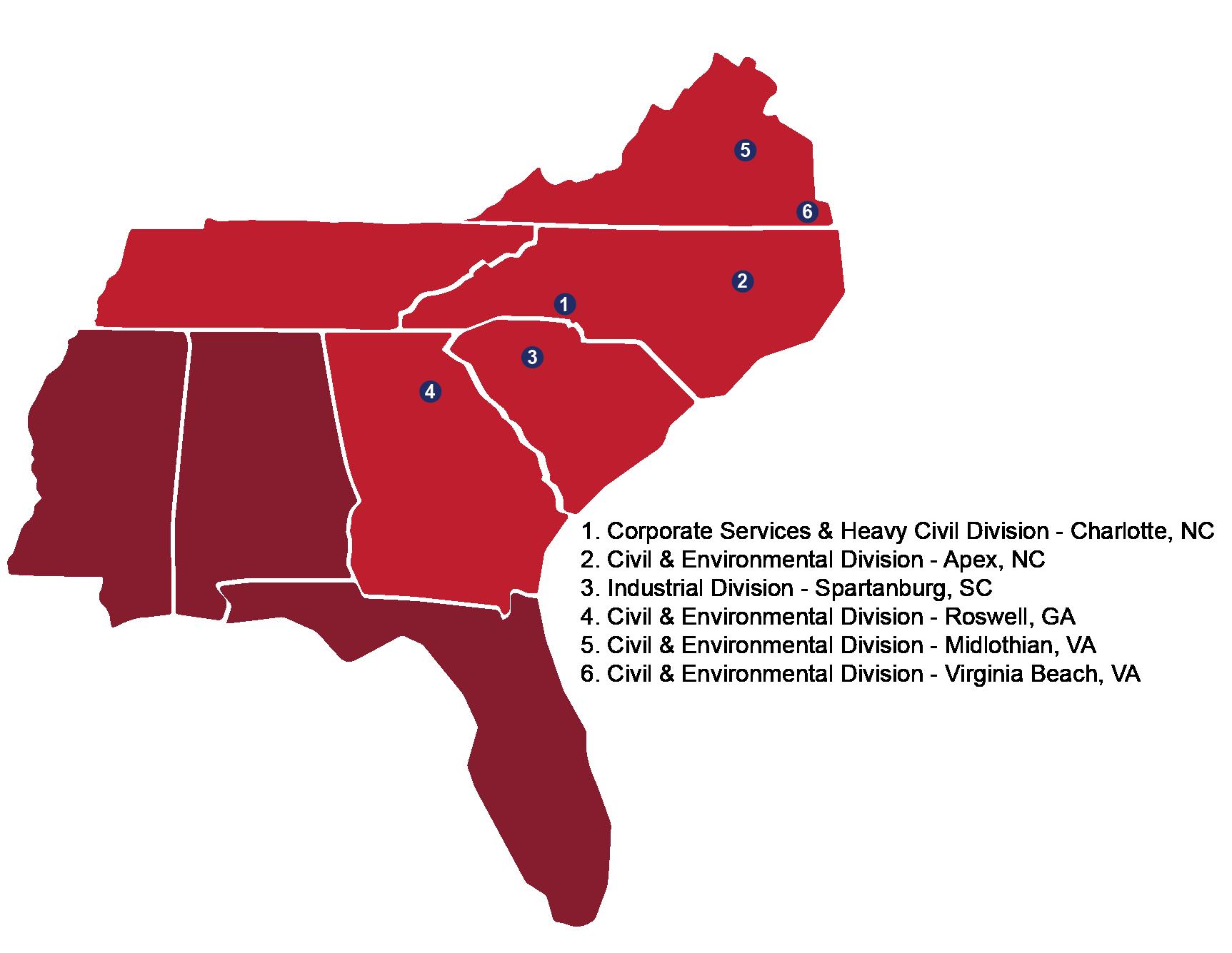

Crowder Offices

[37]

A Look at Crowder Today

Crowder Constructors Inc., headquartered in Charlotte, North Carolina, serves its markets through three subsidiaries. Crowder Construction Company, Crowder’s legacy company, houses Crowder’s Heavy Civil and Civil & Environmental Divisions. Crowder’s Industrial Division operates under Crowder Industrial Construction LLC. Crowder Constructors also has a subsidiary, Crowder Energy Services LLC, that markets and develops alternative energy-related projects.

Crowder Construction Company

Heavy Civil manages and performs infrastructure and multi-craft work including bridges, tunnels, dams, intake structures, deep excavations, pile foundations, shoring and special utility work. Under the leadership of George Ellis, Division Manager, Heavy Civil is headquartered in Charlotte, North Carolina.

Civil & Environmental (C&E), under the leadership of B.J. Christman, Division Manager, constructs and manages water and wastewater treatment plants and specialty green energy projects in the Southeast. Crowder Civil & Environmental is headquartered in Apex, North Carolina, with operational offices in Roswell, Georgia; Midlothian, Virginia; and Virginia Beach, Virginia.

Crowder Industrial Construction LLC

Industrial performs heavy industrial construction including civil, mechanical, electrical and fabrication, primarily in the southeast. Under the leadership of Mike Reisinger, Industrial works on a wide range of industrial and energy-related projects. Industrial is headquartered in Spartanburg, South Carolina.

Crowder Energy Services LLC markets energy-related consulting services and construction services to be performed by Crowder Construction and Crowder Industrial Construction. Greg Cochran and Chad Link lead the effort to this endeavor.

[38]

Crowder Constructors Corporate Services in Charlotte provides safety, financial, risk management, equipment, and employee services support to all divisions. Claudia Dodgen, VP of Employee Services and People Development, Jody Barbee, VP of Risk Management, Matt Brooks, Equipment Manager, along with Lynn Hansen, Carlos Norris, and Karl Francis, provide oversight for the corporate functions as well as operational oversight and strategic direction of the company.

With over 900 employees working in 20 states the last year, Crowder has grown to a large regional infrastructure contractor with $400 million in annual revenue. Crowder builds the infrastructure that is essential for communities to live and work every day. Whether turning on your lights or a water faucet in the morning, or driving on a road or across a bridge to go to work or your home in the afternoon, you are probably intereacting with a project that Crowder was involved in.

Crowder is Building America and Proud of it!

[39]

[40]

Crowder’s Legacy Projects

Throughout the years, Crowder became well-known for a number of unusual, often award-winning projects. We have designated the following projects as Legacy Projects. One definition of “legacy” is “something transmitted by or received from an ancestor or predecessor or from the past,” but we recognize these jobs as completed projects that were significant in size or propelled the company into new and lasting directions. These projects will always be a part of Crowder’s great legacy and new projects will earn this title as Crowder continues to grow and advance in the industry.

[41]

Riegelwood Paper Mill

Crowder first worked on a project for Riegelwood Paper Mill in 1969. Billy Sandifer was the project’s superintendent. When Crowder returned to the mill in 1972 to build four digester foundations, Fred Lancaster and Bill Brant developed a strong, trusting relationship with the mill’s owners. The following year, an ongoing project involving three mill owners began that lasted nearly 30 years.

Bill Brant oversaw the heavy civil and industrial work at a paper mill where there was constant work to be done. Brant recalled, “We went around it a couple of times. What you do when you start a paper mill, you go around it, then you go around it again. Then you have to come back in and size it. Spend time in there rebuilding, one thing or another. They were always updating because of corrosion and the environment, metal, concrete and everything else just didn’t last but so long.”

Crowder worked in almost every area of the Riegelwood mill. Roads were built, piles were driven, rebar was tied, and concrete poured. There was also considerable construction on foundations, towers, storage facilities, clarifiers and water treatment systems. At times, Brant managed as few as 15 workers; at other times the workforce exceeded 150.

Some of Crowder ’s most experienced leaders came from the Riegelwood project. These include Dane Horrell, Ken Tysinger, Dean Evans, Johnny Hunt and Eugene Parker. Work for Federal Paper Co. was done at mills in Georgia, Michigan, and California. Bill Brant and Fred Lancaster forged and maintained an amazing spirit between Federal Paper and Crowder. After several years Crowder recently returned to the Riegelwood project to perform foundation concrete work.

“Quick response, on-site management and high quality performances have been the key to success at Federal Paper Co. in Riegelwood for over a quarter of a century.”

-Otis

[42]

Maury River Twin Delta Bridges

Crowder began construction on the Maury River Twin Delta Bridges on April 1, 1974. This award-winning project was in Rockbridge County, VA, and was part of I-64.

The bridges were designed for a specific place. The delta-shaped frame-welded steel bridges were built at a valley with two streams and a 150-foot drop-off, providing a spectacular view. The bridge’s unique design helped reduce cost. Prefabricated horizontal and inclined steel girders were hauled to the job site. The concrete piers were of moderate height and were shallower and less massive.

On October 4, 1976 the bridges opened to traffic. Crowder employees were proud to have worked on such a difficult project, dealing with tough terrain and many challenges. The hard work paid off. In 1978, Crowder was given the Award of Merit for medium span/high clearance bridges for the Maury River project.

Prefabricated steel pieces for the frame were used for this project. After the bridges were completed, a light gray paint was added to compliment the landscape surrounding the bridges.

[43]

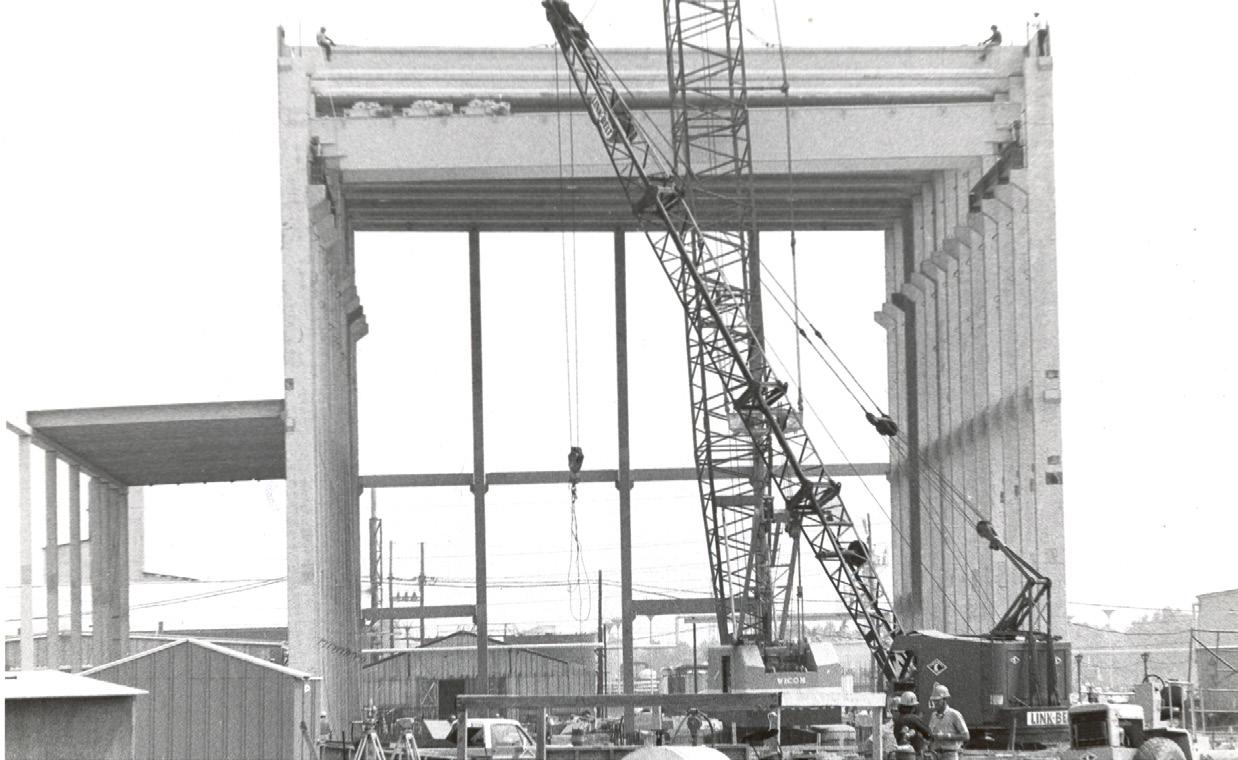

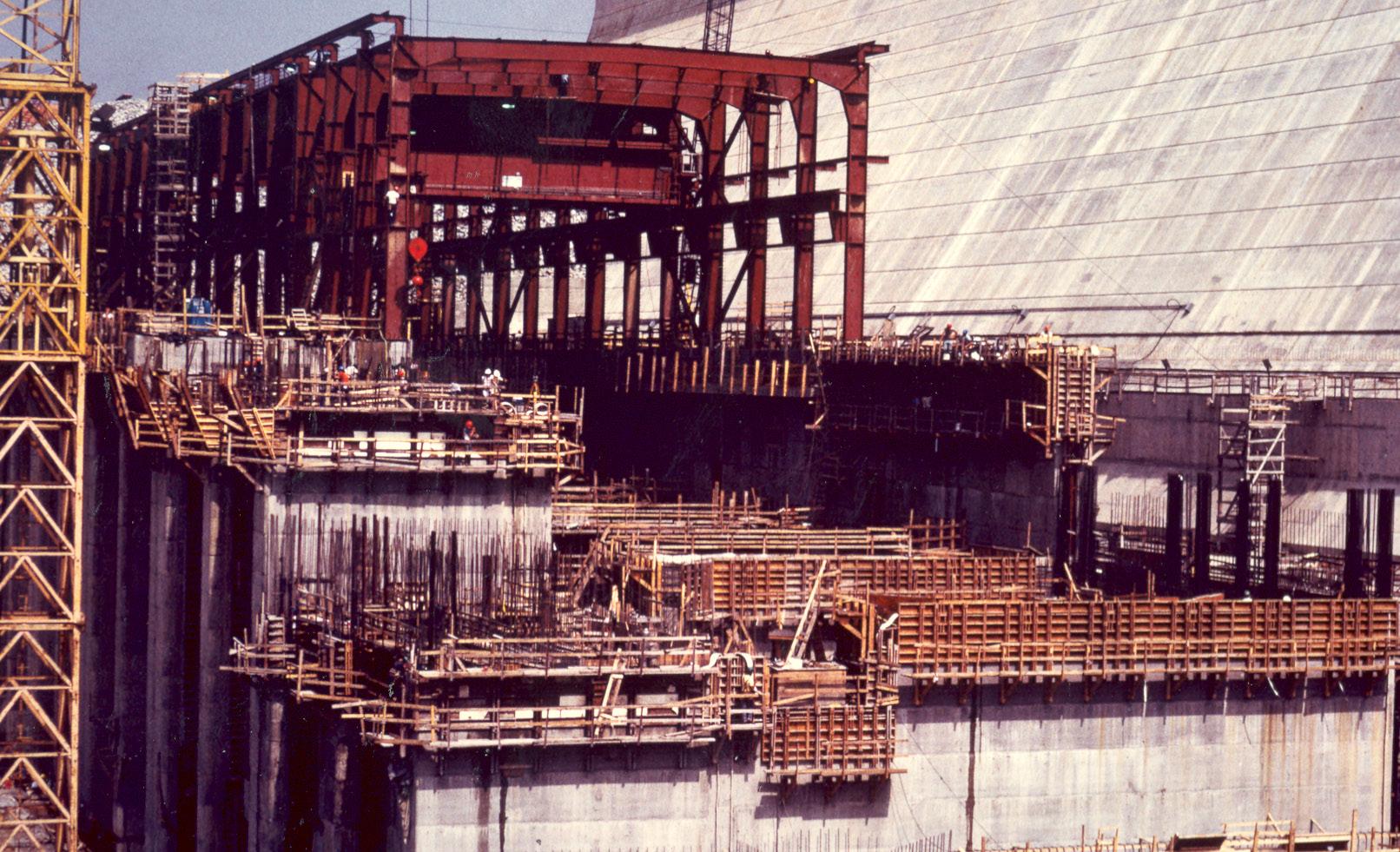

Richard B. Russell Powerhouse

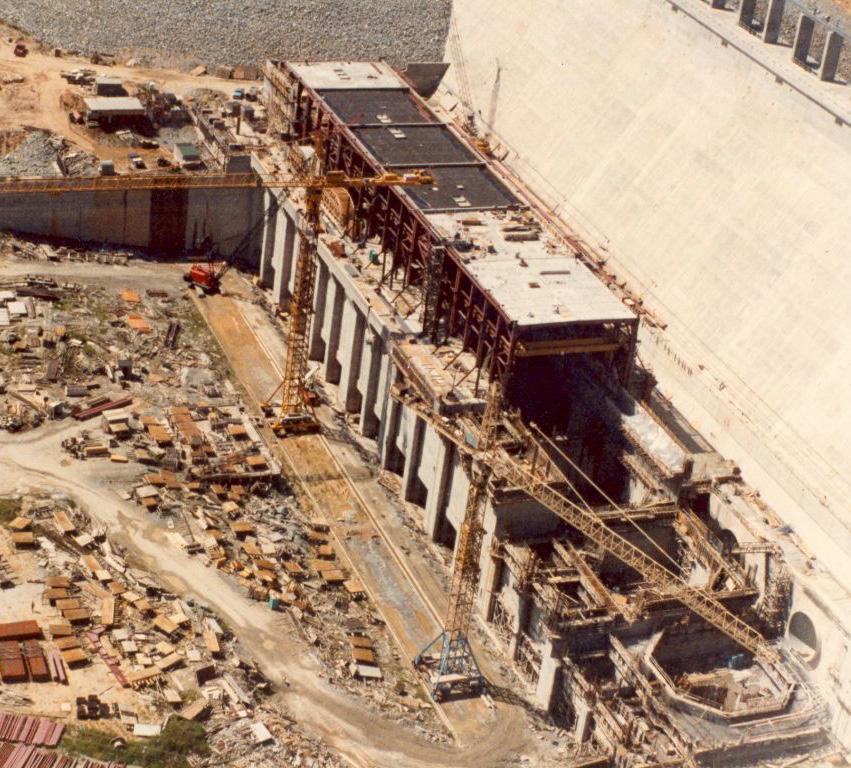

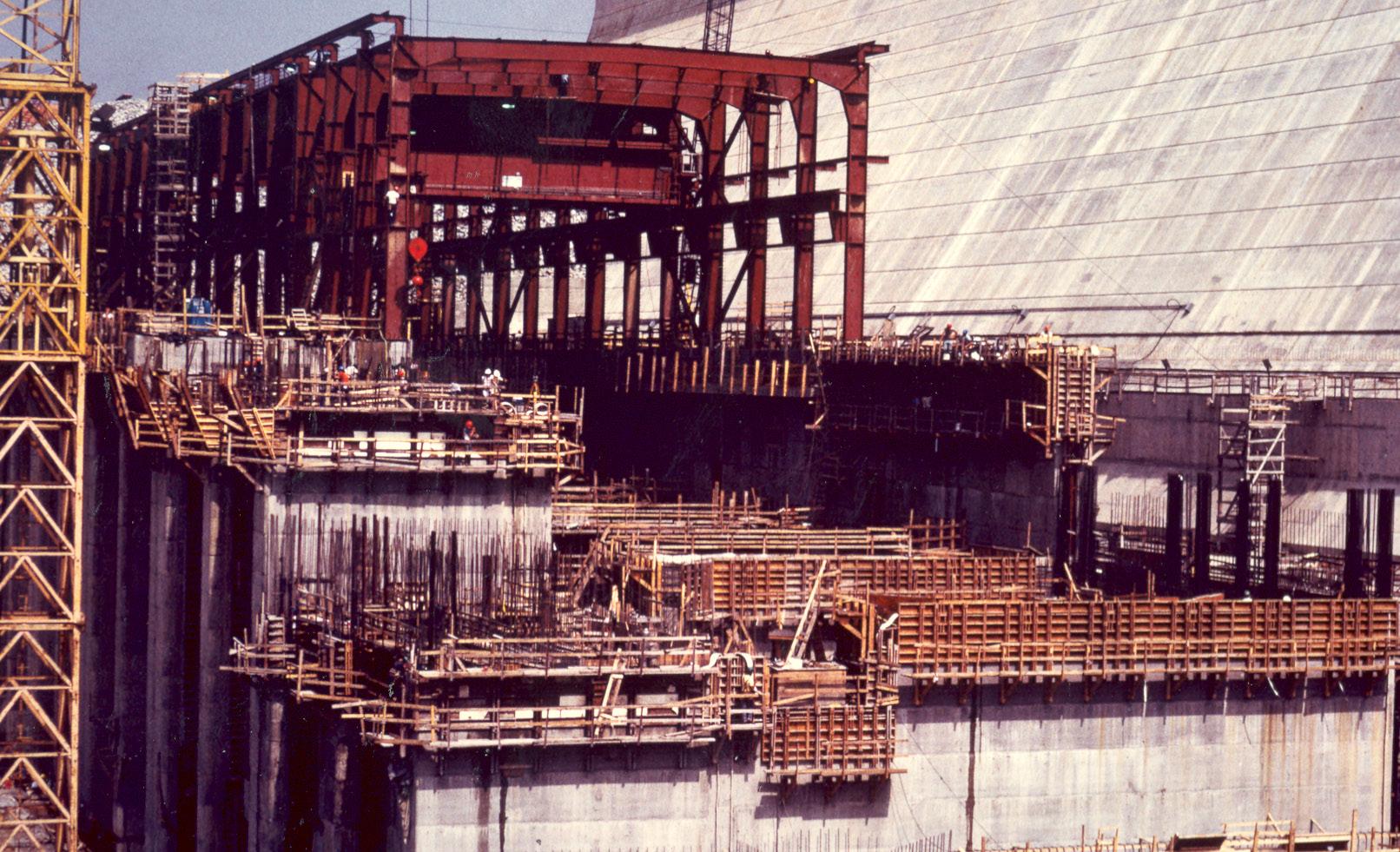

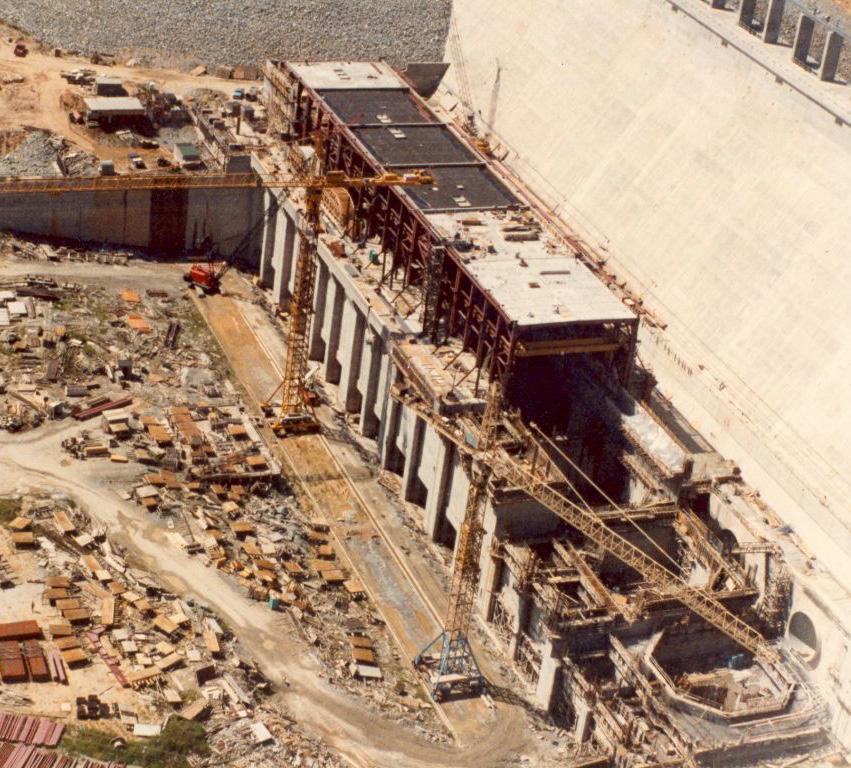

The Richard B. Russell Powerhouse was one of Crowder ’s largest projects. It proved to be a training ground for employees and the company’s future growth. Crowder and its project partner, Republic Contracting, entered a bid of nearly $63 million to build the powerhouse and the visitors’ center. The Republic-Crowder joint venture was the low bidder in July 1981. In August, they were awarded the contract. The massive government project’s cost would later climb to more than $67 million.

The Richard B. Russell Powerhouse and Lake is located on the upper Savannah River, near the towns of Elberton, GA, and Calhoun Falls, SC. The project was designed with the primary purpose of serving as a source for hydropower. Other purposes included water supply, flood control and recreation.

Construction of the powerhouse was overseen by the Army Corps of Engineers from the Mobile, AL district. Crowder poured nearly 160,000 cubic yards of concrete and used approximately 58,000 tons of reinforcing steel in construction.

A massive amount of energy is generated by the powerhouse. Crowder installed four conventional 75-megawatt turbine-generators. These turbines produce more than 600 megawatts of electricity. The spillway has 10 tainter gates and 5 sluice gates. Energy produced by the Richard B. Russell Powerhouse is sent to more than 200 municipal and rural areas in South Carolina, Georgia, North Carolina, Mississippi and Alabama. As of 1986, it was the largest hydroelectric powerhouse in the Southeast.

[44]

Combustion Turbine Station

Originally Crowder competitively bid and was awarded the design and construction of Units #3 & #4 and GE Frame 7FA Gas Turbine Generators with appurtenances at one of Dominion’s combustion turbine stations. Based on an outstanding performance and prior to completion, Dominion Energy negotiated the design and installation of Unit #5. Dominion provided the gas turbines and associated equipment and Crowder provided final design, erection, and commissioning of the units.

Crowder provided the engineering, procurement, and construction of the balance of plant, including dual fuel systems. The dual fuel system allows the plant to use fuel oil as well as natural gas to operate the unit. The project was equipped with an inlet air fogging system to boost generation during the high temperature months and peak usage demands.

Crowder self-performed the majority of work, including underground piping and electrical work, foundations, equipment erection, mechanical, piping, controls, and electrical instrumentation. Crowder also utilized in-house fabrication capabilities to fabricate the main header, pipe spools, platforms and miscellaneous metal materials to proficiently expedite the construction process. This enabled successful completion of the project ahead of the original schedule and allowed Dominion to meet the community’s summer electrical peak generating demands.

[45]

OBG/Crowder Design-Build Team were recognized for their outstanding safety efforts when awarded the CONUS Large Category, Mobile District Annual Safety Award.

Anniston Army Depot WWTP

Crowder teamed with O’Brien & Gere (OBG) to form a joint venture (JV) for the Design-Build Anniston Army Depot Industrial Wastewater Treatment Plant. The original design-build proposal was for $34 million.

OBG/Crowder JV worked with the owner, U.S. Army Corp of Engineers (COE), to reduce the project scope in order to meet their budget. During the project and as funds were available, the owner added the deleted scope back into the project.

It was critical that the existing industrial wastewater treatment plant (WWTP) be kept online during construction. Clear and open communication was required to accomplish the phasing needs for the project. In an effort to minimize impacts to existing operations at this mission-critical facility, Crowder worked closely with Depot staff to coordinate all work. Heavy metals, TSS and grease were contaminant concerns for the project.

From beginning to end of this project, the U.S. Army Engineers, the Army Depot and the JV worked through difficult and complex issues, pledging to attack problems and not people, working collaboratively through proactive and frequent communication to pursue each other’s goals and common objectives. In 2012 the Anniston project and all its stakeholders received the AGC Marvin M. Black Excellence in Partnering Award.

“We, the partners of the Anniston WWTP project commit to function as one team, embracing the highest standards of trust, respect, transparency and open communication.” (from the Partnering Agreement with project stakeholders dated August 5, 2008)

[46]

SWIFT Demonstration Facility

Crowder was the Design-Builder, with its design consultant Hazen, for the SWIFT Demonstration Facility in Hampton Roads, Virginia. The Crowder and Hazen team provided Hampton Roads Sanitation District (HRSD) with design and construction services to receive wastewater from their Nansemond Plant in Suffolk, VA, to be treated to drinking water quality, then injected into the Potomac Aquifer without disturbing the natural environment. HRSD recognized that an innovative solution would be needed to manage regulatory requirements while simultaneously addressing regional water challenges and thus embarked on a multi-phase managed aquifer recharge program.

This initial project involved designing and building the first advanced water treatment and related research facility with the capacity to recharge the Potomac Aquifer with one million gallons a day of highly treated water. The primary objectives of the project were to demonstrate that advanced treatment will produce water that meets primary drinking water standards and is compatible with the existing groundwater chemistry and to monitor the aquifer’s hydraulic response. The facility also serves as a public education and outreach facility and provides a platform for operator training and process optimization.

Crowder ’s team utilized Building Information Modelling (BIM) to streamline the design process through collaboration with HRSD, their staff, and representatives. Working with BIM strengthened the ability to meet the compressed project schedule, provide an efficient design, effectively understand how each of the components should work together within the facility, and integrate within the site. The design-build process allowed for collaboration during every aspect of the project. Through close coordination and collaboration, the team was able to make changes valued by the owner while maintaining schedule and budget.

SWIFT is one of the world’s largest groundwater recharge programs, and when completed will return over 100 MGD to the Potomac Aquifer. In addition to mitigating land subsidence, SWIFT safeguards future drinking water supply, promotes Chesapeake Bay restoration, and supports economic development.

2018 U.S. Water Alliance, U.S. Water Prize

2018 ENR Mid-Atlantic Best Water/Environment Project

2018 ENR Mid-Atlantic Excellence in Safety Merit Award

2018 ABC-Carolinas Excellence in Construction Merit Award, Other/Specialty Category

2018 National ABC Excellence in Construction Eagle Award, Public Works/Environmental

2019 DBIA-SE Best Water Project

2019 AGC of America National Build America Award, Utility Infrastructure New Category

2019 DBIA National Award of Merit, Water/Wastewater

2019 DBIA National Best in Teaming Finalist

[47]

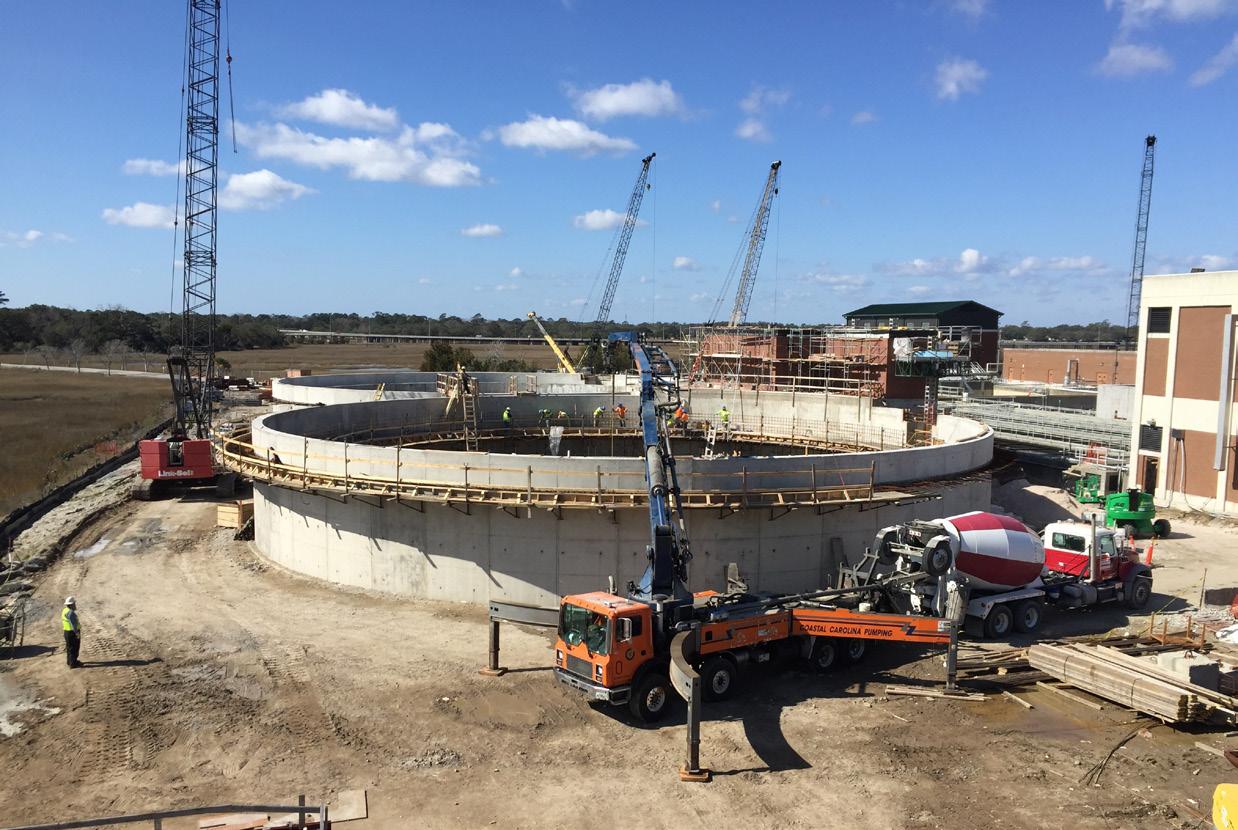

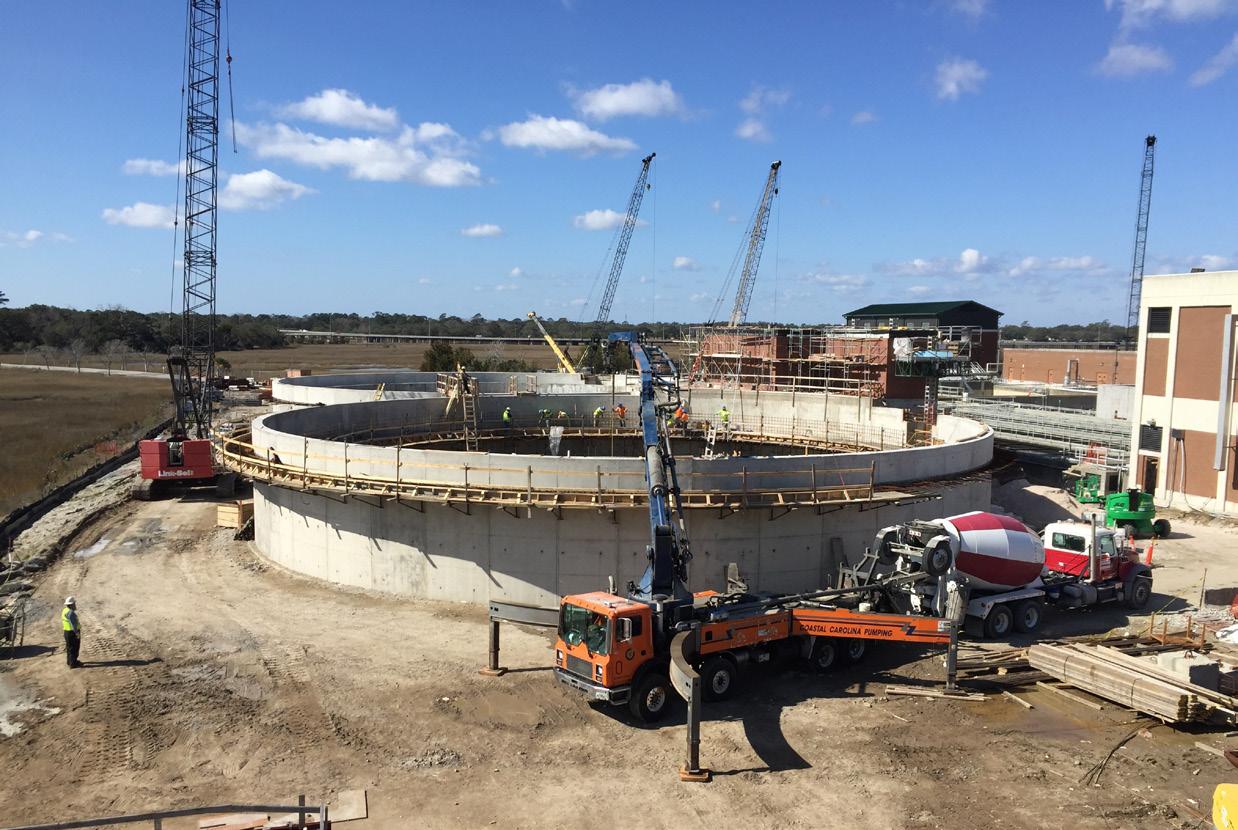

Plum Island Water Pollution Control Plant

In 2016 Crowder was selected as the Construction Manager at Risk (CMAR) by Charleston Water System to provide upgrades to its Plum Island Water Pollution Control Plant. The complex project consisted of major modifications to the existing 36 MGD plant in excess of $60 million. Although Crowder had completed several design-build projects, Plum Island was the first CMAR and largest alternate delivery project Crowder had undertaken.

Crowder worked with Hazen, the Owner ’s design consultant, to deliver a Guaranteed Maximum Price (GMP) at 60% design. Constructability reviews resulted in methods and sequencing that reduced Charleston Water’s risk and accommodated a very tight site with a critical schedule. Coordination and communication were important to keep the plant running, avoid disruption of daily plant activities, and accommodate other contractors working on the same site. Collaboration with Hazen resulted in value engineering ideas that reduced cost and improved plant performance.

The Plum Island project demonstrated not only Crowder ’s strengths and capabilities in the alternate delivery market, but more importantly, our dedication to being a partner to our clients during both the preconstruction and construction phases of their projects. Success on the Plum Island project also signaled the industry that Crowder was the premier choice for major project alternate delivery in the Carolinas and beyond.

2021 AGC of America National Build America Award, Construction Management Civil Category

[48]

2021 Carolinas AGC Construction Excellence Award

Charlotte Gateway Station

The Charlotte Gateway Station and related project was a multi-staged progressive project to move Charlotte’s intercity passenger rail station from its current location to Uptown Charlotte, closer to Charlotte’s employment center and within blocks of the City’s major sporting facilities. The project spanned three quarters of a mile ending behind the Carolina Panthers Stadium. The project included 1,100-foot Amtrak passenger concrete platform for the future Amtrak station along with a new railbed for the Amtrak track, which required demolishing and replacing eight bridges and site and utility work along the way with a new pedestrian underpass at the Panthers Stadium. With so many different aspects to this project, it required, at some point, most of the personnel of the Heavy Civil Division, serving as a training ground for future projects.

In the 1960s, Crowder worked in this same area to elevate four of the bridges above the roadways at railroad crossings. The Gateway project is much larger, over $55 million, but will have a similar positive impact on the City of Charlotte and its infrastructure. Over 50 years have passed, and Crowder continues to be a welcomed partner in the development and growth of Charlotte.

Uniquely, this project not only involved one long-standing working relationship but three; Crowder has performed many projects over the years with the NCDOT, the City of Charlotte and Norfolk Southern Railroad. Collaboration was key to ensure that all project stakeholders achieved their objectives. Due to significant delays in demolishing Charlotte’s old Greyhound station, Crowder had to resequence work to ensure that federal funding for the project would not be lost. Crowder met the owner’s needs by not only completing the project by federal deadlines, but also allowing the rail contractor to get an early start on trackwork. None of this would have been possible without the entire efforts of NCDOT, NSRR, and the City of Charlotte who worked through project obstacles as a cohesive team.

[49]

Duke Energy Ash Handling and Other Power Projects

After building smaller projects for Duke Energy at its fossil fuel plants, in 2004 Duke Power contracted with Crowder to build an ash-handling project for its Marshall Steam Station. The project included the building of concrete ash storage silos and the installation of new piping, turbine and electrical equipment. This was a fast-track project, which included managing a blackout to tie in the equipment. Crowder’s projects in Duke’s fossil fuel plants expanded quickly after the Marshall project as Crowder became a Duke Alliance partner.

Crowder ’s excellent work on this project and other coal plants led to more power projects across the Southeast. As fossil plant work decreased and fossil fuel concerns increased, Crowder expanded its capabilities to gas turbine projects and the refurbishment of hydro plants. Crowder has continued its long-standing partnership with Duke on these crucial energy projects and has also increased its working relationship and partnership with other southeastern utilities. Power projects continue to be a critical segment of Crowder’s project portfolio.

[50]

Renewable Energy

As the future of energy generation evolves, opportunities arise for those with the vision and resources to convert previously wasted energy sources into usable – and much-needed – renewable energy. Crowder Energy Services was established in the early 2010s to help energy companies, municipalities and other private owners develop and design innovative and modern energy facilities. Over the last decade Crowder has been responsible for the design and construction of alternative energy projects ranging from natural gas, cogeneration, solar, landfill gas, natural waste gas, and BESS projects

Expanding its capabilities with Crowder ’s water and wastewater customers, in 2009, Crowder was awarded the F. Wayne Hill Water Resources Center Gas-to-Energy project by Gwinnett County, Georgia. The project used ARRA funds to utilize digester gas to operate an engine generator set for generation power and recover the heat from the engine generator for heating the anaerobic digesters. Through value engineering efforts, a larger engine and generator set with natural gas/biogas blending system was provided for the same cost as a smaller, less efficient engine and generator.

In 2010 Crowder was selected to by a private developer to design and install a tri-generation plant that is housed within the Coke ASB facility in College Park, GA. At the same time, Crowder installed a landfill gas cleaning system at the Hickory Ridge Landfill site in Conley, GA, also for the same client. This began a long-lasting partnership with a trusted client, designing and constructing alternative energy projects in seven different states.

In the infancy of the solar market in the Southeast, Crowder completed a 38.6 MW solar project at the Simon Solar Farm in Georgia in 2013. The 170-acre site was, at the time, the largest single solar project in the Southeast. Crowder was proud to be at the apex of this market in the southeast as Georgia Power makes solar energy a strong part of its effort to offset its coal usage. Whatever the source –natural gas, LFG, biogas, battery, sun or something in between – innovation and engineering expertise has propelled Crowder to be a leading partner, not only in the construction but the development and design of renewable energy facilities.

[51]

2015 AGC of America National Alliant Build America Award, Utility Infrastructure Renovation Category

2015 DBIA-SE Honor Award, Industrial/Process Category

2015 DBIA National Award of Merit, Water/Wastewater Category

2015 ENR Southeast Merit Award, Water/Environment Category

2018 DBIA-SE Best Water/Wastewater Project

Charlotte Water Projects

Crowder has worked at Charlotte Water’s McAlpine Wastewater Management Facilities for over 50 years. In the 1970s Crowder rebuilt the existing pump station and worked on McAlpine’s major expansion. Thirty years later Crowder constructed a new pump station and performed further plant expansion.

In 2012, Crowder was awarded the McAlpine Creek Wastewater Management Facilities Effluent Filters Upgrades and Expansion project, the first major municipal design-build project awarded in North Carolina. This project increased the plant’s capacity to 80 million gallons a day, by far Charlotte Water’s largest plant. As this was a new process to Charlotte Water, Crowder and its design partner, HDR, worked closely with the city to ensure that this was a win-win project for all stakeholders.

Based on the trust and partnership developed with its previous projects, Crowder has performed numerous projects with Charlotte Water at most of its plants using a variety of delivery methods. Currently, Crowder is working with its joint venture partner, Garney, and design consultant Hazen, to design and build the Stowe Regional Water Resource Recovery Facility, a new state-of-the-art facility wastewater treatment plant that will have a positive impact on the Charlotte region for years to come.

[52]

[53]

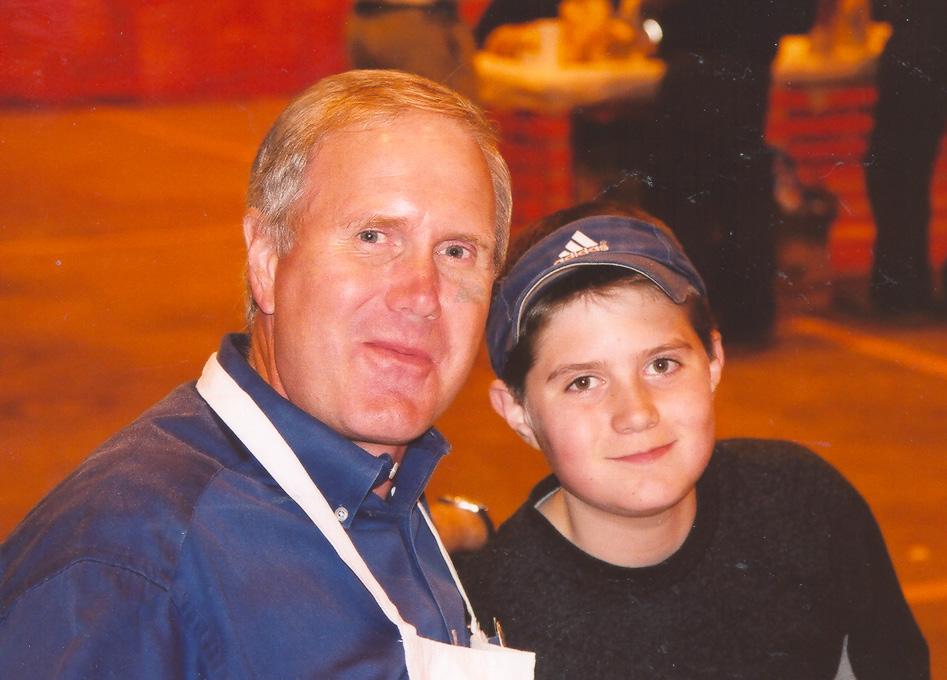

Living Our Mission

Otis and Bill Crowder learned from their fathers, O.P. and W.T. Crowder, that giving to others is the bedrock that the company should be built up from when growing a successful business. In fact, Otis and Bill were raised to believe that service to the community and helping those less fortunate are integral components of an individual’s character, and they have instilled that belief and practice into the collective fabric of the company culture.

Crowder ’s company mission statement is based on the strong foundation of serving clients, the community, and making a positive difference not just “for” employees, but in the lives of employees. Crowder views that positive difference as a “calling to serve” and it is demonstrated in how the company strengthens the communities that employees live in as well as the cities and towns where Crowder builds projects that serve the needs of the people.

Service to the community comes in many forms from leadership and Crowder employees, ranging from active participation in local churches, schools, civic organizations and charitable causes to supporting large non-profit institutions that are working to improve the health of employees like the Juvenile Diabetes Research Foundation (JDRF) and the American Heart Association. Employees raise money and “walk” for the good of others. Crowder as a company and employees as individuals have donated time, talents, energy and monetary support to move the needle on critical issues that help families to overcome obstacles to achieve and sustain success.

In the corporate and division offices as well as larger jobsites, Crowder often joins forces to deliver meals to the homebound, raise funds for local causes, tutor students, and collect food, clothing and gifts for children at Christmas time. When employees learn of someone who is going through a challenging time, the company works to make the positive difference that the employee and the family need.

[54]

As part of our 75th Anniversary, everyone is banding together once again to align the talents and time of Crowder employees to offer at least 75 acts of kindness across all of the communities that employees live and work in. For Crowder, it is not an event or a moment in time, it is just something employees do and will continue to do. It is part of why the company is as strong as it is and why it has come so far, and it will serve everyone well as Crowder and its employees continue work to support each other in the coming years.

[55]

“Our folks work to better the lives of other folks in the community.”

-Otis

“I think everybody is a child of God. I think that everybody, being a child of God…certainly deserves the opportunity to do something for other people.”

-Bill, Sr.

“We have access to equipment and expertise that, literally, money can’t buy for most organizations.”

-Bill, Jr.

“Everything that we earn — our success — comes from the communities …success would mean that we should give back to the communities in which we work.”

-Otis

“It was a chance to give them something that was invaluable.”

-Bill, Jr.

[56]

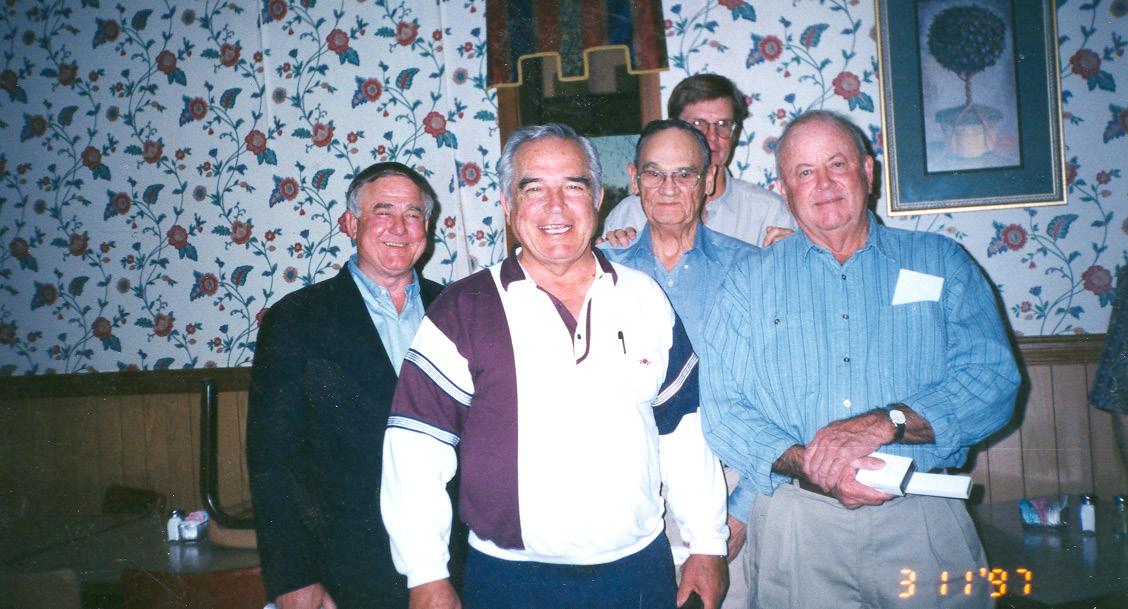

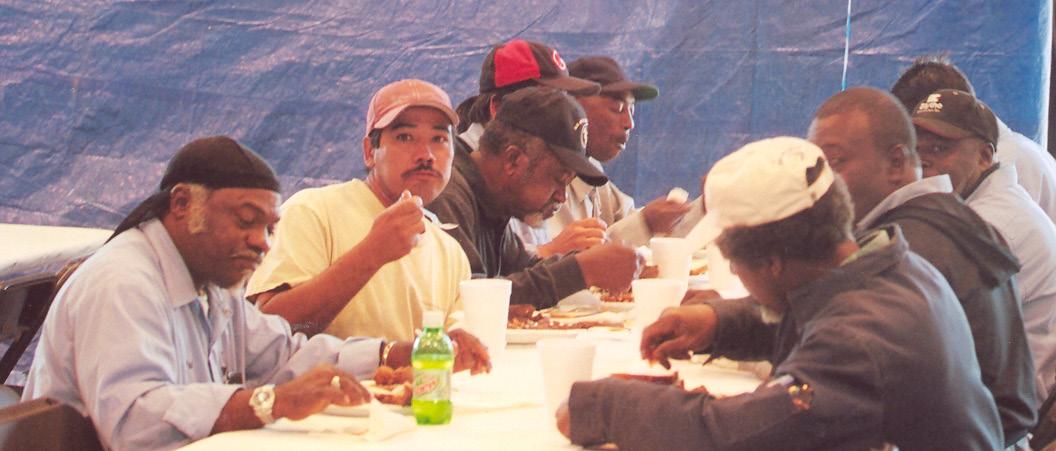

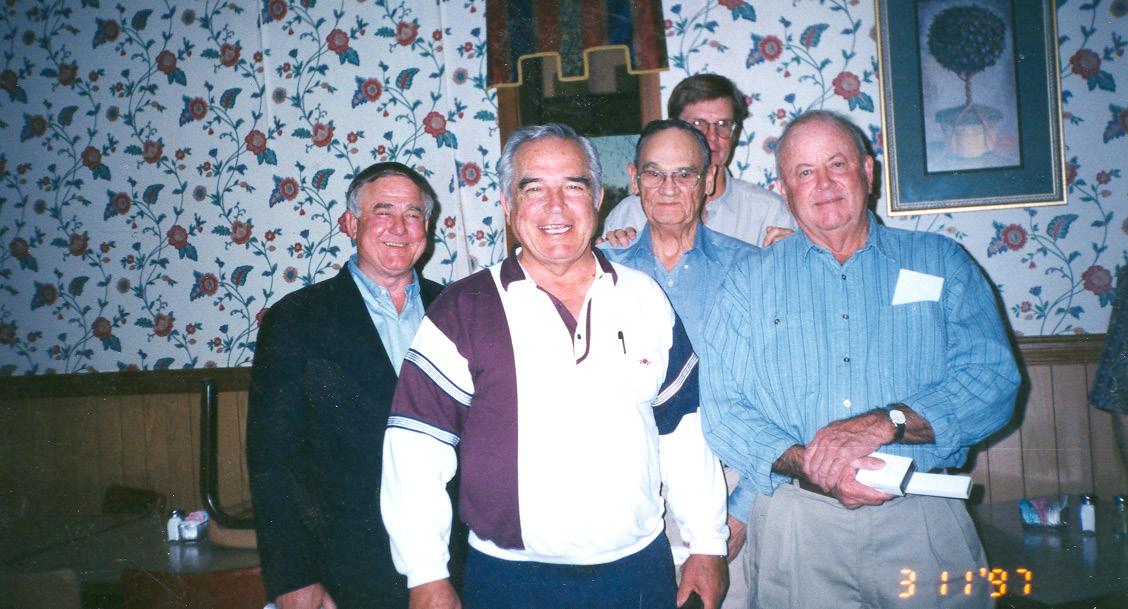

Ol’ Timers Group

There are numerous occasions for retired and current employees to get together and catch up on their lives. Luncheons, a famous annual fish fry and Crowder’s annual Christmas party give all a chance to have fellowship and remember that they are all still a part of the Crowder family.

[57]

Celebrating By Giving Back

50th Anniversary

Crowder Construction Company celebrated its 50th Anniversary on July 3, 1997 when all employees and resources of the company performed community service projects throughout the work areas. This was a way to “give away the company for a day” and was called “Interdependence Day.” Employees, their families and friends came together and accomplished service projects throughout North Carolina, South Carolina, Virginia, and Tennessee. Community service projects were done for schools, community centers, and towns. Work for Habitat and Adopt-A-House ranged from needed repairs to new home construction. Various ministries and non-profit organizations received a helping hand. The Shelter for Battered Women, The Havens, Rape Crisis Center, and the Children’s Shelter were just a few of these important charities.

60th Anniversary

In 2007, Crowder recognized its 60th Anniversary with a celebration of the Crowder Construction legacy. O.P. and Bill, Sr. believed in building up people. They always placed a great importance on education and training. During their lives, they supported numerous endeavors in higher education, from nursing school to a liberal arts degree. As part of the 60th Anniversary, Crowder donated $500,000 to Central Piedmont Community College in Charlotte, NC. The contribution will support scholarships, as well as program and equipment needs at the O.P. and W.T. Crowder Construction Institute at CPCC’s Harper Campus.

“Be a giver. This came from his (Bill, Sr.) life, from my earliest years of memory -time, talent, treature, kindness, and genuine care for others”

-Bill, Jr.

[58]

70th Anniversary

During the summer of 2017, Crowder celebrated its 70th Anniversary by giving back to the schools in the communities where our employees work and live. Crowder employees contacted elementary, middle, and high schools close to our offices and larger project sites in North Carolina, South Carolina, Georgia, and Virginia to see how Crowder could help their schools. As the summer progressed Crowder employees worked outside and inside six different schools. Employees pulled weeds, planted flowers, trimmed shrubs, poured a new sidewalk, repaired a water garden with new electrical and provided a new weather station for the students. One project included providing and installing soccer, volleyball and disc golf equipment for excited students. Painting both inside and out was a top priority at one school and Crowder employees topped it off by painting over 100 tables for classrooms.

75th Anniversary

What better way to celebrate Crowder ’s 75th anniversary than by performing 75 “Acts of Kindness” in the communities where Crowder works. Crowder is helping support what is important to Crowder employees. Whether supporting student scholarships, holding a fishing tournament for charity, writing cards to veterans, filling needs at a women’s shelter or collecting canned goods for the hungry, Crowder continues to live its mission of making a positive difference in its communities. Crowder is at work in our communities, building important infrastructure projects, but as or more importantly, helping build and support people.

“Remember, we must ‘build’ our people, not just build ‘things.’”

[59]

-O.P.

Recognizing Stellar Performance

The Crowder family has produced a workforce that has great character and is highly skilled. Employees take pride in their work and have made the company one of the best in the industry. Subsequently, Crowder –and its entire work family — has been recognized for their hard work, excellent management and quality craftsmanship.

Since 1950 Crowder has been an active member of the Carolinas branch of the Associated General Contractors of America (CAGC). The CAGC bestows awards annually, recognizing the cooperative process in construction as well as the scale and quality of projects.

Providing five-star quality on construction and engineering projects is our primary focus at Crowder. We believe this is not only necessary to satisfy our clients and meet their needs but to aptly serve our communities.

Many professional associations including the Associated General Contractors of America, the Design-Build Institute of America, Associated Builders and Contractors, and the Engineering News-Record have recognized this excellence and honored us with many and varied awards. We are proud to receive these honors and strive to always exceed expectations.

Crowder has received a number of awards in addition to those shown in the table on the following page. In 1978, Crowder received the Award of Merit / Medium Span, High Clearance for the Maury River Delta Twin Bridges project and Crowder was a 2002 Finalist in the Charlotte Ethics in Business Award Program by the Charlotte Chapter of the Society of Financial Service Professionals.

[60]

Crowder Honors and Awards

1994 Carolinas AGC Pinnacle Award General Contractor of the Year

1996 Marvin M. Black Excellence in Partnering Award

2001 Carolinas AGC Pinnacle Award: Best Partnering Project

2005 Carolinas AGC Pinnacle Award: Best Utility Project

Lincoln County Combustion Turbine

Cary/Apex WTP Expansion

Table Rock Lake Intake Structure

2005 Carolinas AGC Pinnacle Award General Contractor of the Year

2006 National AGC Marvin M. Black Excellence in Partnering Award

Table Rock Lake Intake Structure

2006 ENR Top 200 Environmental Firms #88

2008 Carolinas AGC Pinnacle Award: Best Highway-Heavy Project

2009 ABC-Carolinas Excellence in Construction Merit Award, Other/Specialty Over $50 Million

US76 over Chattanooga River Bridge

James A. Loughlin WWTP Expansion

2009 ABC-Carolinas Excellence in Construction Merit Award, Other/Specialty $10 - $25 Million Cherry Point BNR Repairs

2010 Carolinas AGC Pinnacle Award: Best Utility Project

2010 Continental U.S., Mobile District Annual Safety Award, Large Category

2010 ACEC Engineering Excellence Grand Award, Water and Wastewater

2010 ACEC Engineering Excellence Honors Award, Water and Wastewater

2010 ENR Top Sewerage/Solid Waste Disposal Contractor

2010 ENR Top Power Contractor

2010 ENR #42 Top Contractor

2010 National AGC Education Excellence Grand Award

2011 ABC-Carolinas Excellence in Construction Eagle Award: Other/Specialty Category

2011 EPA Landfill Methane Outreach Program-Project of the Year

2011 ASE Small Project of the Year Award

2012 U.S. Army Corps of Engineers Wilmington District Certificate of Merit, No Recordable Injury

2012 AGC of America National Marvin M. Black Excellence in Partnering Special Recognition

2012 ABC-Carolinas Excellence in Construction Merit Award, Electrical Category

2012 ABC-Carolinas Excellence in Construction Eagle Award, Renovation/Rehabilitation Category

James A. Loughlin WWTP Expansion

Anniston Army Depot D-B Industrial WWTP

Mainland WTP Reverse Osmosis Expansion

James A. Loughlin WWTP Expansion

Crowder YOUniversity Program

Sugar Creek Primary Clarifiers Improvements

Zemel Road Landfill Gas Energy Plant

RM Clayton WRC Design-Build Congregation