LINE

Shop & Wellness Passport Reminder

Tillery Unit #1 Runner Replacement: New Head Cover and Runner

Seasonal Changes

At Crowder, we recognize that our people are our greatest strength. Your resilience, dedication, and teamwork have enabled us to grow and succeed, even in the face of uncertainty. As we enjoy the cooler weather of fall, we also have to juggle changing family schedules and shorter daylight hours to get everything done. It is common to experience increased stress as things change. Recognizing stress as a normal response to change is the first step towards managing it effectively

Crowder’s greatest asset is our people. This fall, let us look out for one another. If you notice a colleague struggling, offer a listening ear or a kind word. Sharing experiences of stressful events (and the strategies that help) can remind us that we’re in this together. Balancing work and personal life is not just a personal responsibility; it’s a collective commitment.

If you need to reach out for help (for you or someone else in your life), our Employee Assistance Program (EAP) can connect you to:

•Community resources for family support

•Guidance for managing work-life balance

•Confidential counseling services for stress, anxiety, depression, grief, or relationship issues

•Support for workplace conflict or burnout

•Help managing life transitions (e.g. divorce, loss, elder care, empty nest after your kids leave)

On page 21 you can read more about our EAP and how to get help, as well as how to access our Buildwell/YouTurn peer coaching benefit. In addition, our Employee Services team is always available to direct you to wellness initiatives and health benefits.

At Crowder, we strive for an environment where your well-being is valued. By prioritizing our health, supporting one another, and embracing the opportunities of the season, we can ensure that we all thrive—at work and at home. Thank you for your hard work, your resilience, and your commitment to one another.

We look forward to sharing a successful and healthy fall together.

SUPERIOR PERFORMANCE

Safety Updates on pages 3, 9, 16, & 19

OUR CLIENTS

All pages with job news

OUR EMPLOYEES pages 21-22

WE’RE LISTENING

If something is bothering you, if you have a question, if you feel you or another employee are being harassed, or if you believe that you have not been treated fairly, WE WANT TO KNOW ABOUT IT. Please go to your bulletin board and use our Employee Concern and Complaint Procedure (or call 1-800-849-2966 and ask for Employee Services) to get your question answered, your concern addressed, or your problem resolved.

Lynn Hansen,

I’m the Competent Person – Now What?

by Scott Allen, Corporate Safety Director

According to OSHA, a Competent Person is defined as someone who has both the knowledge to identify existing and predictable hazards in the workplace and the authority to take prompt corrective measures to eliminate them. This role goes beyond simply understanding safety requirements, it requires the ability to apply practical experience and training in real-world situations. Becoming a competent person typically involves a combination of formal training, hands-on experience, and demonstrated proficiency in recognizing hazards related to specific tasks such as excavation, scaffolding, or fall protection. Crowder is responsible for designating competent persons based on their skills, knowledge, and proven ability to ensure work is performed safely and in compliance with OSHA standards while adhering to our internal Construction Procedures.

The responsibilities of a competent person in our industry are critical to maintaining safe operations on the jobsite. They are expected to actively monitor work conditions, identify unsafe practices, and implement immediate corrective actions to protect workers from potential harm. This includes conducting inspections, verifying compliance with safety regulations, ensuring protective systems are in place, and stopping work when conditions present unacceptable risk. By serving as the on-site authority for safety in their area of expertise, a competent person plays a vital role in bridging the gap between regulatory requirements and safe work practices, ultimately helping to prevent incidents and promote a culture of safety across the project.

At Crowder, every employee is both empowered and expected to exercise Stop Work Authority in good faith if they encounter a situation that could result in injury or property damage. This responsibility is NOT limited to individuals designated as a competent person; any team member has the authority to intervene when safety is at risk.

Soon, we will be enhancing our competent person designation process and updating project-specific competent person listings to ensure clarity and consistency. If you are ever designated as a competent person based on your training, experience, or a combination of both, and you are not fully comfortable with the responsibilities of this role, please notify the Safety Department immediately so that appropriate support and adjustments can be made. While most of our employees may not hold a formal competent person designation, every team member shares responsibility for maintaining a safe work environment. Your continued commitment to identifying hazards, communicating concerns, and taking action to eliminate hazards or control risks is greatly valued. Let’s continue to look out for one another and remain Focused to Achieve Safety Excellence

Stowe

The Stowe WRRF project achieved Final Completion for the primary clarifier stage #1B and will reach substantial completion for the final clarifiers within Stage #1A within the coming month. Stage 2 structures saw significant progress, including leak testing, backfilling, roofing, painting, and electrical installations across multiple process structures. In Stage 3, masonry work continued at the aeration blower building, and concrete work advanced at chemical buildings #1 and #2. Stage 4 and 5 structures moved forward with the completion of the suspended slabs at both the filters and ulravoilet (UV) structures. The masonry veneer, drywall, ceiling grids, and electrical systems are advancing in multiple structures. Sitewide curb and gutter installation, site lighting, duct bank work, and the start of the motor vehicle (MV) bridge crossing continue.

By the end of 2025, Stage #2 structures will begin startup requiring the completion and checkout of the medium voltage work along with completion of the diffusers within the biological nutrient removal (BNR) basins and setting several pumps at each of the pump stations. Paving will continue with work on the administrative and maintenance building lots and grading for bridge electrical installations. Installation of HVAC, mechanical, and electrical systems will continue throughout all Stage 3 and 4 structures. Stage 5 structures will focus on final finishes and equipment installations, including handrails, gates, masonry veneer, and lighting. The final yard piping and duct banks should also be complete by the end of the year.

Neuse River Resource Recovery Facility Bioenergy Recovery Project

The bioenergy project is complete and punched out and Raleigh Water is now supplying clean RNG gas to the grid. The sidestream process has been commissioned and is currently 4 months into the 8-month long commissioning process. Our next and final step is to complete the sidestream commissioning process.

Rocky River Wastewater Treatment Plant (WWTP) Phase 3 Upgrades

The remaining phase 3 expansion items have been completed and commissioned at the Rocky River WWTP site. The team is currently working on finishing out additional scope around the plant and project closeout.

Rocky River WWTP Phase 4 Upgrades

Phase 4 construction at the Rocky River Wastewater Treatment Plant is well underway. The team recently commissioned the rehab of 5 of 8 total secondary clarifiers, commissioned 8 new return activated sludge (RAS) pump stations and completed the conversion of aeration basin 5 to diffused air. We recently began work on converting aeration basin 4 and preconstruction work is nearing the completion of prestressing equalization (EQ) tank #2. The team will continue with construction focusing on the critical path of the project through aeration basin #4 and begin work in the main pump station. We will also begin work at the existing screw pumps and new scum pump station. Then, we will finish construction of EQ tank #2, leak test, backfill and tie-in the structure.

Quarles Water Treatment Plant (WTP) 2 SCADA Replacement

The team has started conversion activities of the Q2 filter building from the existing iFix Supervisory Control and Data Acquisition (SCADA) system to ignition. Three filters have been converted over with the remaining scheduled to be completed in September. Next we will finish filter conversion and concurrently start the sedimentation basin conversion.

James River WWTP Automation Improvements

Crowder is continuing startup and commissioning activities on the James River WWTP project in Newport News, VA. This $12 million dollar automation project consists of new remote input/output (IO) cabinets, variable frequency drives, combination starters, actuators, instrumentation, and associated wiring for the Hampton Roads Sanitation District (HRSD). The project team consists of Jared Burton (Senior Project Manager), Roby Kilby (Project Engineer), Anthony Equipado (Electrical Superintendent), Roger Genzlinger (Electrical Superintendent), and Curtis Moore (Electrical Foreman). Crowder continues to work directly with the Engineering firm Hazen and Sawyer and HRSD staff to identify, troubleshoot, and resolve issues during the startup process. The James River Automation project commenced in September of 2023 and is currently scheduled to be completed by the end of October 2025.

EQ Tank #2

Aeration Basins Looking NE

New Turbidimeter and Particle Counter

Work on New Filter Control Panel

The A. Scott Emmons WRF Phase II-A Reclaimed Water System

Construction is almost complete of both the EQ and reclaimed storage tanks. Concrete was completed for the membrane building in July, and erection of the pre-engineered metal building is underway, with the bulk of the process equipment expected early 2026. Soon we will begin subgrade prep and concrete for break tank, lime storage and feed.

Byrd Park Reservoir Rehabilitation

The project team recently completed the retrofit of the 2nd outlet well for our west reservoir, following a complete Engineer redesign due to unforeseen conditions. The outlet well redesign included a new 48” ductile iron pipe (DIP) conduit and the placement of mass concrete. All underground electrical is complete and work is underway to finalize the interior electrical installation. The crews will be wrapping up the final concrete inside the tank (footers, walls, and sloped liner), installing the new 36” high-density polyethylene (HDPE) mixing system, and finalizing the roof installation. We’re targeting to have the west reservoir turned over to the City of Richmond in early 2026 and move right into demolition of the east reservoir roof.

1.5MG Reclaimed Storage Tank

South Outlet Well Before

South Outlet Well After

Membrane Building Erection

0.5MG Equalization Basin

Atlantic

Treatment Plant Reliability and Odor Control Improvements (ROCI)

Emergency odor control has ramped up construction over the past couple of months at this construction manager at risk (CMAR) project in Virginia Beach, VA. The team has worked hard to complete the main carbon polishing equipment slab including installation of under-slab drain piping, trench drains, in-slab conduits, and rebar, as well as self-performing the placing and finishing of (2) 350 CY concrete pours. The next steps will be the installation of the carbon polishing equipment including 54” – 96” fiber reinforced plastic (FRP) outside air (OA) piping and supports, mist eliminators, blower fans and carbon adsorber vessels and media.

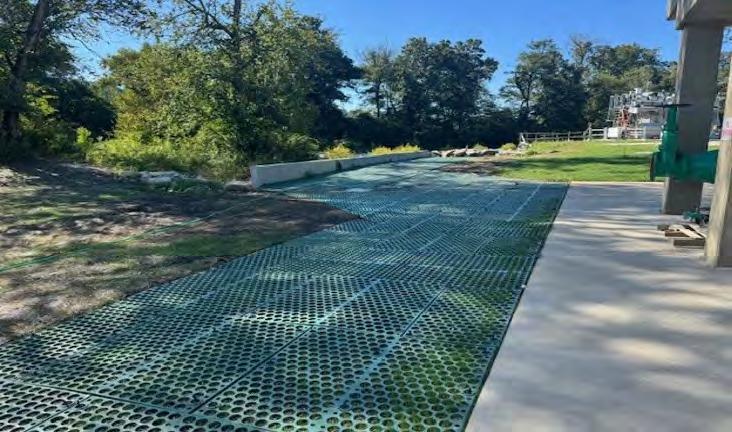

Spring Hollow WTP - Granular Activated Carbon (GAC) Project

The Spring Hollow WTP; GAC project is now substantially complete, and the Owner has assumed full operation of all (3) upgraded GAC contactors and their new backwash header. The punch list is near completion as the crews put the finishing touches on the project. Crowder was awarded a 2nd phase of work which includes the demolition and installation of a new decant recycling pump, pipeline, and variable frequency drive (VFD). We anticipate substantial completion for phase 2 in early 2026 while the preconstruction team continues design of the new clearwell and pump station (phases 3 & 4).

Construction phases 3 & 4 are targeting the 60% good manufacturing practice (GMP) milestone in mid-2026 and hope to add more scope onto an already successful project.

Place and Finish of Carbon Polishing Equipment Slab

Carbon Polishing Slab Trench Drain & Electrical Rough-in

Richmond WTF Valve & Actuator Replacements Project

Crowder has been actively replacing the valves and actuators at the Richmond Water Treatment Facility since January of this year. This emergency rehab Time and Material project consists of replacing existing actuators and valves for both plant 1 and plant 2’s gravity filter system. The team consists of Jake Neumann (Project Manager), Doug Baker (General Superintendent), David Estrada (Site Superintendent), Mike Stewart (Electrical Project Manager) and Jimmy O’Brian (Electrical Superintendent). Crowder progressively works to support the plant’s operational needs alongside the Owner’s representative AECOM and the design engineer WRA. The Richmond WTF project started in January of 2025 and is tracking to be complete by the end of 2025.

& Upgrades

Piloting for the advanced treatment technology is complete, and the design-build team is working closely with Piedmont Triad Regional Water Authority (PTRWA) to make final process technology selections and move into the design. The expansion GMPs have been submitted to PTRWA, and the team is working to finalize negotiations and move forward. The next steps will be to continue the advanced treatment phase into design. The D-B team will begin procurement, finalize permitting and begin mobilizing crews and subcontractors to start work on-site.

John Franklin Kimes WTP Expansion

Plant 1 Pipe Filter Gallery

Replacing an 18” Air Scour Valve

New 16” Effluent Isolation Valve/Actuator

Original 16” Effluent Isolation Valve/Actuator

Outreach: Education for Crowder’s Tomorrow

by Denis Logie, Crowder Construction Company Safety Director

5,283 fatal, and 173,200 non-fatal work injuries were reported in the construction industry in 2023. There are approximately 1,850 OSHA safety and health inspectors responsible for nearly 130 million workers across the nation. This translates to about one compliance officer for approximately 70,000 workers. These staggering statistics demonstrate that construction workers are still losing their lives at an alarming rate and that the responsibility to ensure workplace safety and health MUST lie with employers nationwide.

Crowder Construction takes its responsibility to ensure safe and healthy projects for its employees very seriously. Our first step in meeting this responsibility is to provide education and training for our supervisors and managers. First line supervisors and managers are the most important roles within our safety program because they serve as the foundation and driving force directly controlling what gets accomplished on the project. Over the span of four days, we hosted OSHA 30-hour construction outreach training to select foremen, superintendents, and project managers. The purpose of this training was to increase awareness of jobsite hazards and how to identify, control, and manage these risks. The four days were filled with interactive training and expert safety and health instruction from our construction partners at Dillon Supply, United Rentals, Milwaukee Tool in addition to our internal, qualified OSHA Construction Outreach trainers and Safety and Health professionals. This OSHA 30-Hour session culminated with the issuance of class certificates including theFoundations of Safety Leadership module. Employees learned hazard identification, best practices, and safety leadership principles.

Fall Recruitment

This fall, Crowder is set to participate in 16 university recruitment events across the Southeast as part of its ongoing effort to develop the next generation of construction talent.

The visits will focus on meeting students interested in Co-Op assignments and entry-level Project Engineer roles and offering insight into how classroom learning translates to real-world construction experience. Through these positions, students gain hands-on exposure to estimating, scheduling, field operations, and quality control while working alongside experienced Crowder teams.

Crowder’s recruitment schedule reflects the company’s long-standing commitment to workforce development and its investment in helping young professionals build meaningful careers in the construction industry. We can’t wait to meet future Co-Ops and Project Enigneers!

City of Hendersonville French Broad River Intake and Pump Station

Crews have completed installation of the closed-circuit television (CCTV) system, giving the plant full visibility of the site. Coordination is underway with the generator supplier to schedule a hard startup once the VFDs are installed. The team is also checking out the remaining I/O and preparing for Fortech to begin their SCADA system review. In early September, the roofing supplier inspected the pump station roof and issued acceptance and warranty documentation. Electricians will return to finalize outstanding items, including installing a thermostat for the ventilation fans and mounting the surge tank digital readout on the second-floor fencing. Additionally, crews are cleaning out the pump coffins in preparation for pump startup, ensuring the site is ready for the next phase of commissioning. With key systems coming online and final details being addressed, the project is on track for successful completion.

Windsor Woods Tide Gate Project

A local system test was run for the city on 8/20/25 and all local programming and wiring were tested and completed ahead of touch screen monitor installation. The project is substantially complete and will reach final completion here in the next few weeks after the change orders for the touch screen monitors have been completed.

Local Programming and Wiring Testing

Pump Control CO Installed

Actuator Control Wiring CO

Windsor Woods Site

Erosion Control Installed

Erosion Control Installed

Cosgrove

The Cosgrove Avenue Extension Bridge and North Hobson Avenue Roadway Improvements project in North Charleston, SC continues to make excellent progress. This effort includes a 1,032-foot bridge spanning Palmetto Railways, along with roadway upgrades along North Hobson Avenue. Cape Romain, the bridge subcontractor, successfully completed construction, and the new bridge and roadway officially opened to traffic on September 4.

Lowcountry crews are wrapping up items from the original contract and preparing to begin work associated with recent change orders. Sanders Brothers has paved the base and binder on nearly all of North Hobson Avenue, along with the surface course on Cosgrove Avenue and Noisette Boulevard. Red Electrical Design has installed traffic signal mast arms at the Spruill and Bainbridge intersections and is completing conduit work for the project’s lighting system. Chandler Construction has finished the waterline relocation, while CCS has completed installation of the Dominion and AT&T duct banks.

With these milestones achieved and finishing touches underway, the project is well positioned to deliver lasting transportation improvements for the North Charleston community.

Black Creek Greenway Project

We completed the setting of the Cary Parkway Bridge this past month. We also completed the

list for

Phase 1 and opened up to the public on 8/28/25. We closed Phase 2 of the greenway on 9.2.25. We are scheduled to complete the Cary Parkway Bridge Project at the end of October 2025 and Phases 2 & 3 are scheduled to complete summer 2026.

punch

Black Creek Greenway

Parkway Bridge Aerial Set

Completed Paving

Bridge Officially Open

Completed Work from Spruill to N. Hobson

Completed Work from Spruill to N. Hobson

SCDOT Calhoun Lexington I-26 Corridor

As we begin to roll into Fall of 2025, the I-26 Crowder team has completed bridges 1 and 3 on the project. Work continues on bridges 2,4 and 5. Bent 2 work is in progress on both bridges 2 and 4 and both should be ready for girders in early October. Bridge 5 is in full swing with stay-in-place (SIP) pans in place and reinforcing steel not far behind. With good weather the deck should be poured in early October.

USC Campus Village Pedestrian Overpass

In July, the project team achieved a major milestone by wrapping up all remaining work on the USC Campus Pedestrian Overpass. Crews successfully completed the electrical systems, installed the new handrail, performed final site restoration, and began demobilizing equipment and materials from the site.

The overpass, which enhances pedestrian safety and accessibility across the busy corridor, is now fully complete and open for use. Its thoughtful design and durable finishes provide a welcoming connection between campus areas, improving walkability and supporting the university’s long-term infrastructure goals.

Bridge Open to Pedestrians

Bridge Aerial

Completed Bridge Bridge 5 Work

Bridge 1 Open to Traffic Bridge 3 Open to Traffic

VDOT Route 58 SPSA Flyover Interchange Improvements

Crowder is well under way with substructure for the bridge project at the Route 58 Southeast Public Service Authority (SPSA) Flyover Interchange project. Abutment A is poured up through the backwall and pier 1 is poured up through the cap, which was a mass concrete pour. Pier 2 is poured through the column and pier 3 is poured through the cap. All work on the abutment B pile driving is complete. A major milestone of the project is the completion of 60” reinforced concrete pipe (RCP) and the stabilization of the surrounding area.

Duke Mountain Island ESSI

The Crowder team made steady progress at the Duke Mountain Island Embankment Seismic Stability Improvements (ESSI) project site throughout the summer. Crews advanced installation of the dewatering wells and eductor system, excavated and placed leveling concrete for the gravity wall, and formed, tied, and placed wall #1 for the tailrace wall extension. Work also began on hammering and removing rock in zone 4 to prepare for upcoming structural activities. Rock excavation will continue in zones 4 and 4B, with material hauled off-site once sufficient volumes are stockpiled

Looking ahead, the team will complete the dewatering wells and eductor installation, connect the header pipe, and begin pumping water. Structural crews will move forward with forming, tying, and placing wall #2 on the tailrace wall extension and wall #8 on the tailrace

SCDOT Greenville I-85 at I-385 Wall Improvements

Crews completed hydro-demolition on Wall 10, and welders mobilized to install Nelson studs before beginning installation of welded wire fabric in preparation for shotcrete placement. Shotcrete crews are now on site and ready to begin as soon as reinforcement activities are finished.

Traffic operations also advanced, with temporary signal heads being replaced and striping applied to support detours and maintain safe traffic flow through the work zone. At Wall 38, the team installed new highway guardrail and began saw cutting in preparation for upcoming construction. Meanwhile, crews from AK Industrial Services mobilized at Wall 26 to prepare for the next sequence of work.

Wake Forest Dunn Creek Greenway Phases III

Progress continues as all bridges and boardwalks have now been completed, marking a major milestone for the trail. Grading operations are in full swing, and crews have begun paving portions of the greenway to bring the project closer to completion.

Asphalt has already been placed and seeding completed on roughly one-third of the trail. Next, State Contracting will remobilize to pave the stretch of -L3- from the 72-inch reinforced concrete pipe (RCP) crossing to the Juniper Avenue entrance, followed by seeding and mulching. In parallel, grading operations will continue with a focus on placing fill along the lower portion of -L3- and the second half of -L2- leading toward the Wildflower Ridge Road entrance.

Wake Forest Dunn Creek Greenway Phase IV

Crowder crews recently completed the bridge structure, paving the way for the Permatrak subcontractor to begin their work. Drainage installation is approximately 75% complete, with all drainage pipe, structures, and riprap outlets now in place.

Construction of the boardwalk is moving steadily forward and is anticipated to wrap up within the next few weeks. The remaining drainage tasks, completing the 42-inch RCP and 42-inch corrugated metal pipe (CMP), will close out that portion of the project. Meanwhile, grading operations remain a primary focus as crews prepare areas for the upcoming asphalt trail placement.

Wall 10

Walls 26 & 27

Oconee/Jasper Emergency DB Package 29

Oconee US-76 celebrated the opening of the new bridge with a SCDOT ribbon cutting ceremony on June 16th. All that is left is a change order for some extra asphalt shoulder. The project reached final completion at the end of August.

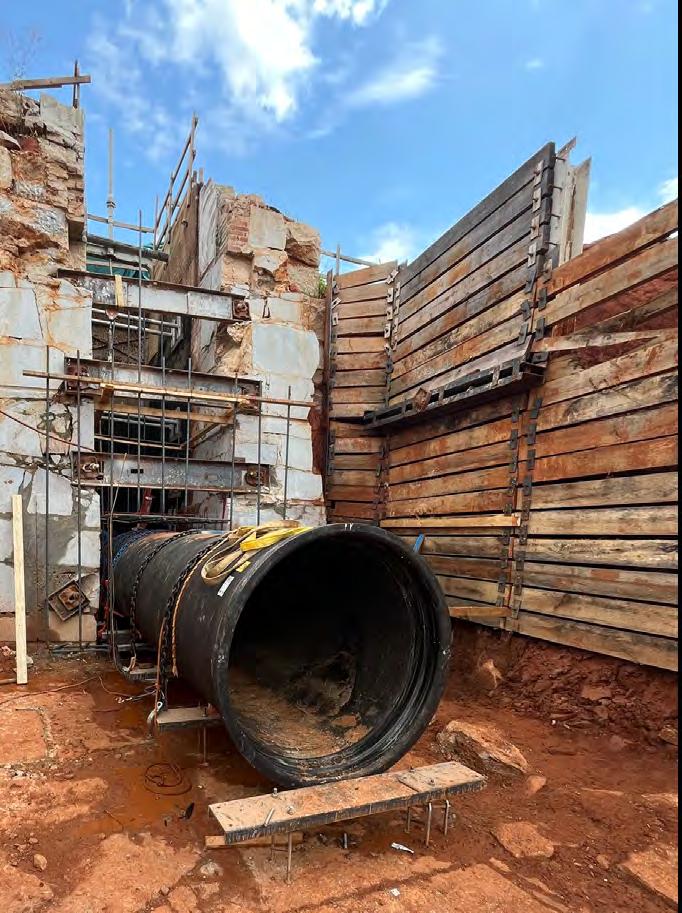

Garland WWTP Improvements

Work on the Garland WWTP started on August 11th, 2025 and is on schedule to be completed on February 27th, 2026. S&C mobilized onsite at the beginning of September and will install the sheet pile for our temporary shoring for the two concrete structures. When that is complete, Donley’s Concrete will mobilize to start working on the structure floor slabs. Crowder crews will install the utilities under the chlorine contact chamber after S&C performs their work.

Mechanical Bar Screen

Jasper US 278 Site

Ribbon Cutting June 16th, 2025

Aerial of US 76 Oconee

US-76 open to Traffic

Chlorine Contact Chamber

Construction began in June for the six bridges included in the Design Build Package 32 contract with the SCDOT. The project consists of six low volume bridges in Orangeburg, Calhoun and Bamburg Counties. The project was awarded in April and the Design of all six bridges has been completed. Traffic control for all six bridges has been completed and Crowder is currently working on the construction of three of the bridges. The superstructure for the first bridge is complete and is set to open in October and will have four completed and open to traffic by the end of this year. All six bridges will be completed by the end of March 2026.

Bridging Safety and Operations

by Denis Logie, Crowder Construction Company Safety Director

Note: The employees located in the areas of the downed guard rails are equipped with a Personal

A typical Crowder Construction project is complex regarding work scope, planning requirements, and implementing concept-to-field operation. These modern-day projects require highly skilled, experienced and adaptive professionals capable of making decisions in real time. Here at the SCDOT Calhoun-Lexington I-26 Corridor project, the project team demonstrates all these attributes during lifting operations while setting girders into place. The I-26 project team seamlessly integrated required safety controls to manage hazards associated with lifting operations, fall protection and work zone locations. This integration resulted in the successful setting of a 144 ft., 140,000-pound girder into place while controlling traffic using a 20-minute pacing operation. The I-26 project team exemplifies Crowder excellence and the importance of empowering people to get the job done safely.

Fall Arrest System (PFAS).

Bridge 1

Work

Tillery Unit #1 Runner Replacement

The final assembly at the Tillery project is in process, all new parts have been installed and adjustments are being made to some of the owner supplied equipment. The commissioning for Unit #1 was completed on September 25th, 2025. Soon we will finish modifications and installation of the owner supplied equipment, finish the final alignment of the shaft and rotor and begin commissioning.

New Head Cover and Runner

Turbine Runner

New Thrust Bearing Thrust Runner installation

New Wheel Pit Platform

Lake Michie and Little River Raw Water Pump Station Improvements

Crowder Industrial has continued mechanical and electrical installations of the permanent pumping system at the Lake Michie site while the plant operates under the temporary bypass system. Subcontracted work for lakeside diving scope, interior finishes and HVAC systems have also remained in progress. The project has faced many challenges while continuing to push forward on the schedule, including a storm of the century flood event during the 4th of July weekend. The permanent pump system at Lake Michie is scheduled to begin start-up in September which will be followed by a 30-day operational period for turnover to the City of Durham before moving back to the Little River site. The next steps here include completing the remaining lakeside work and interior finishes by subcontractors at Lake Michie. We will also relocate the temporary bypass pump system from Lake Michie to Little River in order to begin demolition/installations for the new permanent pumping system at that site.

Lake Michie Unit 1 and 2 Pump Install

Lake Michie Medium Voltage Switchgear and MCC Install

Dominion Gaston Shoals South Traveling Hoist Refurb

Work is moving forward on hoist #3 of 4 at the Roanoke Rapids and Gaston Shoals Project. Crews are currently focused on the installation and final alignment of the gearboxes and drive system, as well as electrical installation and roof hatch work. These efforts mark the last major steps before the hoist enters the commissioning phase.

In the weeks ahead, the project team will continue progressing with equipment and drive system installation, electrical connections, final alignment, and paint touch-ups. Commissioning activities will follow, ensuring all systems are operating safely and efficiently. Final completion of hoist #3 is scheduled for late November,

Before Disassembly of the Hoist

CIC Fabrication Shop: Over 2,600 Days of Safe Work and Still Going Strong

by Steve Fortson, CIC Division Safety Director

The Spartanburg fabrication shop has now passed an incredible milestone—more than 2,600 days without a significant safety event. That’s over seven years of working safely, thanks to the dedication, teamwork, and focus of every person in the shop. Safety isn’t just something the team talks about—it’s something they live every day. From the moment someone joins the shop, they receive necessary safety training and are partnered with a proven team member where they learn that safety is everyone’s responsibility. Team members are encouraged to speak up, ask questions, and stop work if something doesn’t feel right. That kind of trust and communication keeps everyone alert and protected.

Supervisors play a big role in keeping safety front and center, but the employees performing the tasks are also at the heart of the operation. They lead by example, make sure rules are followed, and help the team stay focused, even when the work gets fast-paced or challenging. Their support helps build a culture where safety isn’t just expected, it’s respected. The team also takes pride in reporting near-misses and sharing ideas to make tasks safer. This helps the shop improve its processes and prevent future incidents. Everyone understands that reporting isn’t about blame, it’s about learning and protecting each other. The open door to anyone at any time is proof of their transparency and pride in their safety effort.

This milestone is more than just a number. It shows how much the Crowder Industrial Fabrication Shop team cares about doing things the right way. And they’re not slowing down. With continued effort and teamwork, they’re proving that safety is not just a goal, it’s a way of life. It all comes down to a vision and true safety leadership which is evident in this team.

Hoist Delivery to the Paint Shop

Welcome Fall 2025 Co-Ops

Collins Wilson NC State University

Mark Grichenko Clemson University

Joseph Turner NC State University

Alana DeVilbiss Purdue

Alana DeVilbiss Purdue

Karson Faria University of Cincinnati

Jacob Sharpe Auburn University

Luke Shore NC State University

Brandon Keating University of Cincinnati

Angel Velazques-Galvez NC State University

Evan Olszewski Clemson University

Benefits Open Enrollment

It’s almost that time of the year – open enrollment is right around the corner! This is your annual opportunity to review and make changes to your benefit elections for the upcoming plan year. Open Enrollment will begin on Monday, November 3rd and end on Monday, November 17th for benefits coverage beginning on January 1, 2026. Mark your calendars and stay tuned for more details.

Things to keep in mind:

• If adding dependents for the first time, you will need to provide Employee Services with “proof of relationship” document(s) or your dependents may not be added to your plan in 2026.

• All employees enrolled in the medical plan for 2026 MUST complete the 2026 Medical Insurance Surcharge Affidavit. If you do not complete the Affidavit before the plan year begins, you will be charged an additional premium of $25 per week.

• You are required to re-enroll in your flexible spending accounts (Medical and Dependent Care FSAs).

For additional information contact Employee Services by phone at (800) 849-2966 or by email at EmployeeServices@crowderusa.com.

Helping Families at Crowder

Crowder’s Employee Assistance Program (EAP) is a FREE mental health benefit for you and any immediate family member living in your household. This benefit gives you and your family members FREE access to a counselor for up to 6 sessions (per issue) per calendar year.

The EAP can help with:

•Community resources for family support

•Guidance for managing work-life balance

•Confidential counseling services for stress, anxiety, depression, grief, or relationship issues

•Support for workplace conflict or burnout

•Help managing life transitions (e.g. divorce, loss, elder care, empty next after your kids leave)

You can call 24/7 to talk to a clinician at 800.633.3353. You can also click on the “Current Participants” tab at top of the page and then click “Access Online Services” on the right side of the MYgroup website (https://mygroup.com/portal-employee/) to read about the many ways you can get help for you and your family. To log in: Username: crowder Password: guest

Unlocking Potential: The Power of Training

In today’s fast-paced work environment, continuous learning isn’t just a perk—it’s a necessity. That’s where CrowderYOU steps in, offering employees the tools to grow, adapt and thrive in their current role while getting ready for the next role in their career path.

Why Training Matters

• Boosts Confidence & Competence When employees sharpen their skills, they feel more capable and empowered to take on new challenges.

• Fuels Career Growth Training opens doors to advancement by preparing team members for leadership roles and cross-functional opportunities.

• Strengthens Team Performance A well-trained team is a high-performing team. Shared knowledge leads to smoother collaboration and smarter problem-solving.

• Drives Innovation Learning sparks creativity. Training sessions often lead to fresh ideas and new approaches that benefit the entire organization.

• Building a Culture of Learning Investing in people sends a powerful message: growth is valued here. That mindset becomes contagious.

Real Impact, Real Results

Whether it’s an in-person training, lunch-and-learn, a hands-on workshop, or a digital course, training helps us stay sharp, agile, and ahead of the curve. It’s not just about checking a box—it’s about building a workplace where everyone has the chance to level up.

So next time a training opportunity pops up, take it. Your future self will thank you.

Crowder is an Equal Employment Opportunity Employer, and we are committed to providing a working environment for all employees that is free from discrimination and harassment based on race, color, religion, sex, marital status, age, genetic information, national origin, veteran status, mental or physical disability, sexual orientation and gender identity or any other characteristics protected by federal, state or local laws. Visit our website to view current open positions and to see other news!