FEATURE

FEATURE

JLG ON HOW INNOVATION IS KEEPING THE ACCESS GIANT AHEAD OF THE REST

12_ELECTRIFYING THE ACCESS MARKET

Mohamad Lakis of JLG, talks to CMME about the EC450AJ Compact.

14_THE HEIGHT OF LUXURY

Kanoo Cranes mobilises two Wolffkran 355B luffing tower cranes on a luxury resort on the Palm Jumeirah.

18_MOBILISING IN DUBAI

Mobility Equipment Rental’s new wave of high-reach Dingli kit.

22_TELEHANDLERS

JCB 540-170s arrive at Johnson Arabia.

30_NEW RELEASES

The latest releases from the world of construction machinery.

32_TOP TEN TIPS: SAFETY KIT

Protect your teams on-site with this technology.

36_OFF-ROADING ON RECORD

Talking all things off-highway with ZF.

38_HANGING TOUGH

The forklifts from Hangcha that are rising in the market.

10 SPOTTED! MC 96 Bauer’s duty cycle crane goes deep at the Cairo Metro’s newest station.

Walk onto any major jobsite in the Gulf today, and you’ll still find the familiar sights — steel rising against the desert sky, teams coordinating over radios, and a steady rhythm of progress that feels reassuringly human. Yet beneath that surface, something extraordinary is beginning to take shape. Above the contractor level, artificial intelligence is no longer a buzzword; it’s beginning to redefine how this region builds, manages, and even imagines its cities.

At last month’s Digital Construction Summit, one message came through loud and clear: the question is no longer if AI will transform the industry, but how quickly we’ll let it. From predictive analytics to generative design, from robotic tilers in Abu Dhabi to AI-driven safety cameras in Riyadh, we’re witnessing an inflection point that could change construction as profoundly as the shift from paper to CAD did decades ago.

The potential is immense. AI can automate design compliance checks in seconds, optimise schedules, reduce material waste, and even forecast risks before they happen. On a macro level, it can connect the fragmented ecosystem of developers, contractors, and suppliers into a single digital workflow. For a region like the Middle East — where gigaprojects and accelerated urban expansion are the norm — AI isn’t just a convenience; it’s a necessity.

But as several panellists reminded us, transformation is not about code, it’s about culture. The path to AI adoption runs through trust, standardisation, and collaboration. Developers must be willing to simplify and align their specifications; contractors need to share data; and technology providers must communicate in

ways that resonate beyond the boardroom. Without that cultural shift, AI risks becoming yet another shiny promise left on the shelf.

The encouraging news is that the Middle East is uniquely positioned to lead this change.

For machinery contractors and equipment rental houses, the implications are particularly exciting. AI-powered diagnostics, predictive maintenance, and fleet management tools are already extending machine lifecycles, reducing downtime, and optimising asset utilisation. Smart jobsite analytics can tell you which equipment is underperforming, which operator needs retraining, and where a rental machine could be redeployed for maximum return. As automation increases, so too does the need for smarter service, skilled technicians, and data-driven decision-making.

The takeaway is clear: AI is not coming to take the tools away from contractors — it’s coming to sharpen them. Firms that learn to harness it early will not only build more efficiently, but rent, service, and manage their fleets with unprecedented precision. The future of construction machinery in the Middle East won’t just be about horsepower — it will be about brainpower. We’re standing on the edge of something remarkable. It’s time to build smarter, not just faster.

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM

raz.islam@cpitrademedia.com

+971 4 375 5471

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM shiyas.kareem@cpitrademedia.com

+971 4 375 5474

EDITORIAL

HEAD OF CONTENT

STEPHEN WHITE

stephen.white@cpitrademedia.com

+971 58 584 5818

ADVERTISING

SALES MANAGER

BRIAN FERNANDES brian.fernandes@cpitrademedia.com +971 4 375 5479

STUDIO

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

MARKETING & EVENTS EXECUTIVE

LAKSHMY MANOJ lakshmy.manoj@cpitrademedia.com

SOCIAL MEDIA EXECUTIVE

FRANZIL DIAS franzil.dias@cpitrademedia.com

CIRCULATION & PRODUCTION

DIRECTOR OF MARKETING & MEDIA OPERATIONS

PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

PRODUCTION & IT SPECIALIST

JARRIS PEDROSO jarris.pedroso@cpitrademedia.com

DIGITAL

SENIOR DIGITAL MANAGER

ABDUL BAEIS abdul.baeis@cpitrademedia.com

WEB DEVELOPER

UMAIR KHAN umair.khan@cpitrademedia.com

FOUNDER

DOMINIC DE SOUSA (1959-2015)

PUBLISHED BY

Kanoo Cranes offers engineered solutions for any lifting requirements with knowledgeable experts engaged in the field of lifting. With a combined experience of more than 50 years with Mobile cranes, Crawler cranes, Tower cranes and passenger hoists we offer top quality products from: Our Focus is to provide engineered crane solutions to the Construction, Oil and Gas and Industrial markets.

King Abdullah Financial District announces opening of The Executive Centre in Saudi Arabia

Tissoli appoints Pininfarina to design $327mn Palazzo Tissoli on Al Marjan Island

REPORT

Rental increases frozen in Riyadh for five years

The total rental value of properties –whether in existing or new contracts – cannot be increased for five years within Riyadh’s urban boundary

PROPERTY

Arada launches newest phase of its forest community, Masaar 3

Arada has launched Masaar 3, the latest and largest master plan of its forest community. With a total expected sales value of US $3.4bn, Masaar 3 will be delivered in eight phases and spread across a 21m sqft plot

INDUSTRY

MERED expands UAE operations on Al Reem Island

The capital’s real estate market is experiencing growth, with transactions surpassing US $6.8bn in the first quarter of this year, a substantial increase from $5.17bn during the same period in 2023

Red Sea Global’s (RSG) CEO, John Pagano, has said that the regenerative and sustainable developer is currently considering a range of alternative financing options

OCTOBER

Access+Handling ConfeX 30 October 2025

Lapita, Dubai, United Arab Emirates

NOVEMBER

World Cup Build Summit KSA 18 November 2025

Holiday Inn Riyadh - Al Qasr, Riyadh, Saudi Arabia

DECEMBER

ME Consultant Awards 9 December 2025

Ritz Carlton JBR, Dubai, United Arab Emirates

JANUARY

Construction Golf Day Dubai 21 January 2026

JA The Resort Golf Course, United Arab Emirates

PROPERTY

BEEAH announces the launch of Phase One of Khalid Bin Sultan City

BEEAH has announced Phase One of Khalid Bin Sultan City, which is billed as an innovative new community in Sharjah. The city aims to redefine the future of urban living

FEBRUARY

Truck&Fleet Awards 12 February 2026

Dubai, United Arab Emirates

Topcon Positioning Systems has created a new organisation to focus on delivering high-precision technology, software, and services for geomatics.

Ex-ALEC CEO Kez Taylor has been appointed to the board of rival engineering firm AESG as a Non-Executive Director.

AESG has also added Roger Nickells, the Head of Design and Construction at Neom and former CEO of Buro Happold as Non-Executive Directors to the business with both appointments described an important milestone aligned with the company’s accelerating international growth strategy, said AESG in a statement.

Al Laith, a leading provider of demountable infrastructure and site services, has celebrated its 30th anniversary in Dubai. Founded in 1995 as a scaffolding company, the business has grown into a trusted partner for construction, events, film, oil & gas, and national programmes across the GCC and beyond.

With a portfolio spanning more than 20 service lines, Al Laith positions itself as a one-stop partner for complex projects – from cabins, logistics and access solutions to mega-structures and full site overlay. Today, the company operates under the umbrella of CG Tech, combining regional agility with international governance and a “people-first” culture. Over the past three decades, Al Laith has delivered more than 35,000 projects, supporting everything from

Formula 1 grandstands and international music festivals to scaffolding for some of the tallest buildings in the world. Its 1,000-strong workforce is active across the UAE, Saudi Arabia, Oman, Bahrain, and Qatar, with recent expansion into Uzbekistan.

Jason English, Group CEO of CG Tech and CEO of Al Laith, said the anniversary reflects the company’s enduring role in helping the Gulf deliver its most iconic projects: “For three decades Al Laith has helped the region build, stage and tell its stories. Our 30th anniversary is a celebration of the people, projects and partnerships that have made us a trusted partner for the Gulf’s most ambitious moments.”

Looking ahead, Al Laith says it will continue to build on its reputation for reliability, safety, and innovation, backed by CG Tech’s global network.

Topcon’s portfolio of surveying, geospatial, and GIS solutions has been consolidated to open new pathways into emerging markets. According to the technology firm, the specialised division is an addition to the company structure, which includes established divisions dedicated to construction and agriculture.

“Geomatics is entering a new era,” said Ivan Di Federico, CEO, Topcon Positioning Systems.

“The establishment of the board marks a pivotal step in AESG’s global expansion, coinciding with the opening of its new office in Cape Town, following the recent launch of operations in Cairo and Melbourne earlier this year,” it added.

AESG’s Board of Directors now comprises a ‘dream team’ of talent including Saeed Al Abbar (CEO of AESG), Scott Coombes (Managing Partner of AESG), Adam Muggleton (CTO of AESG), Kez Taylor and Roger Nickells.

Each member of the board brings unprecedented expertise, offering deep industry insight, strategic leadership, and a proven track record in guiding high-growth, global businesses through complex market expansions, said AESG.

Saeed Al Abbar, CEO at AESG, said, “The appointment of the NonExecutive Directors reflects AESG’s commitment to excellence, integrity, and delivering meaningful impact as we grow our presence worldwide. The new members will provide independent oversight and strategic guidance, helping us navigate the complexities of rapid expansion while remaining true to our core purposedriven mission. For our clients, this enhanced oversight means they can have even greater confidence in AESG’s ability to deliver highquality, sustainable, and future-proof solutions. We believe in balancing bold ambitionwith a measured approach.”

COMPACT

The Permasteelisa Group, the UKheadquartered façade specialist, has reported a 33% year-onyear growth in its FaçadeCare business in the Middle East, driven by rising demand for specialist façade maintenance and aftercare services.

FaçadeCare is dedicated to extending the lifespan of building façades, helping owners preserve asset value, reduce long-term costs and improve environmental performance. The service portfolio includes inspections, planned and preventative maintenance, façade cleaning, glass replacement and rapid emergency callouts. Using advanced diagnostic techniques such as thermal imaging and water leakage testing, the FaçadeCare team can detect hidden problems early and provide targeted solutions before they escalate into major issues. With the Middle East’s challenging climate, services are tailored to address water tightness, structural integrity and areas prone to wind load and thermal stress.

“For decades, Permasteelisa Group has been trusted to preserve the façades we design and build. In response to growing demand for specialist aftercare, FaçadeCare allows us to offer our technical expertise, resources and experience to all building owners and managers in the Middle East,” said Alessio De Mitri, Executive General Manager. He added: “A façade represents up to 30% of a building’s total construction cost, so extending its lifespan is crucial. Without regular care, façades age rapidly, impacting energy efficiency, safety and aesthetics. In the Middle East, extreme heat, strong winds, sandstorms and temperature swings accelerate this degradation. FaçadeCare directly addresses these risks through preventative treatments and maintenance.”

By working with designers, engineers and suppliers, FaçadeCare aims to keep buildings safe, visually striking and environmentally sustainable.

All across Europe, new Bobcat machines and attachments are playing an important role in building the infrastructure for charging electric vehicles for use by the public and industry, which together with the construction of renewable energy systems such as solar and wind power, form the cornerstone for a sustainable future. In the UK, two companies at the forefront of these developments are PSR Turnkey Solutions and one of the country’s leading independent plant hire companies, H. E. Services (Plant Hire) Ltd. PSR Turnkey Solutions specialises in building the infrastructure for the growing renewables market, from preparing the foundations for concrete plinths for rechargers for EVs to building battery energy storage systems (BESS). MD Paul Strutt said: “We moved from another brand. We were impressed by the design and the performance.”

The construction industry has always been a reflection of the wider world. It rises and falls with global economic tides, adapts to policy shifts, and absorbs the shocks of geopolitical volatility. But according to Currie & Brown’s latest Construction Certainty Index 2025, the “new normal” is relentless uncertainty. Surveying more than 1,000 decision-makers worldwide – each managing construction pipelines averaging $12.9 billion – the consultancy finds that the sector is grappling with levels of unpredictability not seen in decades.

Dulsco People has launched a nextgeneration driver safety initiative that harnesses artificial intelligence (AI), psychometrics and the metaverse as a radical new way to conduct defensive driving training in the UAE.

The programme, introduced by Dulsco Group’s manpower operation in June 2025, is said to reflect the UAE Government’s commitment to improving road safety and is already setting new standards for fleet operations across the country. Delivered through DigiSkills’ immersive heads-updisplay (HUB), the system has been developed in partnership with Connected Safety Net (CSN) and integrates digital micro-learning, dynamic performance tracking, and personalised upskilling.

At its core, the initiative uses psychometric testing to create individual risk profiles, while AI monitors driving behaviour –

including acceleration, braking, lane handling and speed. Predictive analytics highlight potential risks before incidents occur, and a real-time feedback loop connects drivers, managers and trainers to encourage immediate corrective action and long-term improvement.

The programme also introduces a QR-enabled Driver Passport. Updated weekly through CSN

Aurigo Software, North America’s leading capital planning software provider, has announced a new integration between its capital planning platform and Autodesk Construction Cloud.

The collaboration enables facility owners and operators to connect long-range funding and strategy decisions directly with downstream project execution.

The integration allows project teams to synchronise Projects, Budgets, Commitments, Change Orders and Expenses between

Autodesk® Build Cost Management and Aurigo Primus Plan, giving stakeholders accurate planned-versus-actual performance updates. By extending Autodesk’s widely used PM capabilities upstream into planning, owner-operators can now identify risks earlier, forecast returns more accurately and maintain tighter control over large-scale capital programmes.

“With the integration, we are creating a single, connected loop for capital assets, starting in planning and moving to design, construction, and maintenance,” said Balaji Sreenivasan, CEO and founder of Aurigo Software. “By connecting every investment decision carries through to delivery, allowing owner-operators to make the right decisions faster.”

dashboards, it provides full visibility into each driver’s compliance status, training history and performance record.

The next development phase will see drivers enter a metaversepowered simulation environment, allowing them to practise and refine defensive driving skills in a risk-free yet realistic setting. Since its rollout, 251 drivers have been

trained, with plans to reach more than 600 by the end of 2025.

“Safety is a key priority for Dulsco People, and we are committed to protecting our drivers, passengers and the communities we serve,” said Antony Marke, CEO of Dulsco People. “Traditional training too often relies on one-off compliance sessions and fails to engage drivers meaningfully. Our approach changes the game by integrating AI analytics, continuous monitoring and personalised learning into one system.”

The AI and metaverse programme builds on a series of recent safety investments by Dulsco People, including the adoption of a comprehensive Safety Management System (SMS), the DriveSafe Telematics (GreenRoad) behavioural tool, and the Save Fast cloud platform to minimise workplace incidents.

German heavy lift and transport specialist Dornseiff Autokrane und Schwertransporte has added a new Tadano AC 3.045-1 City crane to its fleet, replacing an older AC 40 City model as part of Tadano’s trade-in programme. The new delivery marks the company’s fourth AC 3.045-1 City, underlining the popularity of the compact crane within Dornseiff’s operations. The handover took place in Lauf, with Tadano Sales Manager Helge Prüfer presenting the crane to site manager Anja Reger and crane operator Marco Wöltering.

The deal saw Tadano accept the outgoing AC 40 City as a trade-in unit, enabling Dornseiff to seamlessly upgrade while Tadano refurbishes the older model for resale.

“We’ve had three units of the AC 3.045-1 City in our fleet for quite a while now, and now we’ve traded

in our old AC 40 City for another new AC 3.045-1 City,” said Reger.

The new crane is configured to match the existing fleet, ensuring interchangeability and consistent availability. Equipment includes: a three-sheave 1.2m runner; a 15t boom head traverse with shackle and hook; a 25-tonne hook traverse and a 32-3/16/D hook block.

This alignment enables Dornseiff to deploy any of its AC 3.045-1 City cranes across identical projects without operational differences.

In one of the most complex underground construction projects currently underway in North Africa, BAUER EGYPT

S.A.E. is carrying out specialist foundation engineering works for the new Giza Station on Cairo Metro Line 4. Commissioned by Orascom, work began in November 2024, with completion targeted for December 2025. The station will eventually extend over an area of approximately 5,543m² and reach a depth of up to 81m, making it one of the deepest metro stations in the region. The foundation scope includes the construction of 209 diaphragm wall panels and 20 barrettes, with a total of approximately 49,000m² of diaphragm walls and 7,400m² of barrettes to be installed. Some of the diaphragm walls reach depths of up to 81 metres and thicknesses of 1.5 metres, while the barrettes – designed to bear loads of up to 3,600t – are being drilled to depths of 81 and 35m, depending on their position within the station structure.

Among the specialist equipment deployed is a BAUER MC 96 dutycycle crane, which is supporting the demanding excavation and construction processes. Work took place in double shifts, six days a week, to meet the tight timeline.

“At this size and depth, there’s zero tolerance for deviation – every centimetre counts,” explains Karim

Galal, Project Manager at Bauer Egypt. “The BAUER Construction Process provides us with a clear structure and guidance. It ensures that everyone involved in the project works to the same standards and helps us achieve our goals on time.”

In addition to the significant depth and complexity of the design, site logistics have added another layer of difficulty. Space is extremely limited, with parts of the site still being used by the contractor until November 2025 for backfilling an existing tunnel. This overlapping usage is necessary for the sequential excavation of diaphragm wall boxes three and four within the station.

“The logistics, the depth, and the constant coordination with other trades present daily challenges, but that’s exactly what makes this project so special,” Galal adds.

A further first for Egypt is the use of vertically stacked tunnel boring machines, which are operating one above the other – a novel approach in the region that has required new levels of planning and precision engineering. Despite the constraints, the project remains on track and represents a major milestone in Cairo’s push to modernise its public transportation network. The completion of the foundation engineering will pave the way for final structural works, ultimately connecting the station to one of the city’s busiest transport corridors.

AT JLG, TALKS TO CMME ABOUT THE EC450AJ COMPACT, WINNER OF ACCESS MACHINERY OF THE YEAR AT THE 2025 CMME AWARDS, AND THE COMPANY’S VISION FOR ELECTRIFICATION IN

JLG has long been recognised as one of the world’s pioneers in access equipment, setting the standards for safety, reliability, and innovation. In the Middle East, the brand has established itself as a key player in shaping the access market, supplying machines that support the region’s most ambitious infrastructure projects and urban megadevelopments. The competition in the market may be increasing, but JLG is determined to remain one step ahead.

That legacy of innovation was celebrated at the 2025 CMME Awards, where JLG’s EC450AJ Compact was named Access Machinery of the Year. For Mohamad Lakis, Sales Director – MEA & Turkey, the recognition is not only a tribute to JLG’s product development but also a clear sign of how electrification is moving from niche to mainstream in the Gulf construction sector.

“JLG is delighted to win this award and for the EC450AJ Compact to be recognised by the industry,” he says. “It demonstrates how we’re constantly assessing and developing new products to match the needs of an evolving market. We have added value to this compact and lightweight model with rough-terrain capabilities and advanced technology, and created a valuable solution for zero-emission and noise-controlled job sites. At JLG we have a proud history of launching innovative products and the EC450AJ Compact is no exception.”

The EC450AJ Compact stood out to the judges and industry peers because it directly addresses the challenges of congested sites and sustainability requirements. “The EC450AJ Compact is a perfect fit for congested job sites,” explains Lakis. “It delivers a robust performance in confined spaces, and has a

lightweight and compact design that makes it easy to transport and manoeuvre. The lithium-ion batterypowered machine also meets today’s sustainability requirements for zero emissions and low noise levels, as well as offering reduced running costs.”

Manufactured at JLG’s facility in Italy, the machine has been designed in Europe with the same robust, ergonomic, and user-friendly controls as other JLG boom lifts. “Providing excellent traction on rough terrain, the new EC450AJ Compact has a 4WD AC electric drive system and oscillating axle. It also has two-wheel steering at the front axle and can operate on slopes up to 45% for site transportation and 5° when elevated, for greater access and maximum versatility,” he notes.

Other features include 355° turntable rotation, non-marking foam-filled tyres as standard, and a 250kg platform capacity. “It is one of the lightest models in its class, making it flexible and inexpensive

to transport on a standard truck bed – two units can fit onto a low-bed trailer,” says Lakis. The EC450AJ is also fitted with ClearSky Smart Fleet, the industry’s first platform for two-way fleet management and machine interactivity, which simplifies fleet management tasks and increases efficiency.

Electric power, lasting performance

At the heart of the machine’s appeal is its electric drive technology. “The EC450AJ Compact is equipped with 10kWh lithium ionphosphate (LFP) batteries as standard, with an option to extend to 20kWh for extended run time and peace of mind in challenging environments,” explains Lakis. “The batteries are tested to last the machine’s lifetime and have full warranty support, resulting in a reduced total cost of ownership.”

Recharging is straightforward: a standard 230VAC 1-phase onboard charger is included, with an optional 400VAC 3-phase charger available. “When both charger options are fitted, charging times are further reduced. The lithium batteries are also equipped with integrated heaters to enable charging and efficient operation in sub-zero temperatures,” Lakis adds.

Safety and sustainability to the fore “Safety is always paramount in access equipment,” stresses Lakis, pointing to JLG’s Skyline enhanced operator protection system, fitted as standard. “It features a slim wire rope design that is bolted to the left side of the platform with an opposing magnetic connection. If the operator contacts the cable, and the magnet detaches, the system stops all boom lift functions, then momentarily reverses or undoes most functions that were in use when the system was activated.”

For working in dimly lit environments, the EC450AJ also offers an optional lighting package to illuminate the floor around the machine and the platform control panel. “These features assist operators when loading, unloading and navigating obstacles in lowlight conditions,” says Lakis.

Electrification, meanwhile, is central to both JLG’s strategy and its customers’ sustainability goals. “The reduced machine weight, enhanced system efficiency and the use of lithium-ion batteries contributes to a lower carbon footprint,” Lakis points out. “The low weight and compact design also make it easy to transport – two machines can fit in a container or on a trailer, reducing transport costs and emissions.”

With major projects underway across the Gulf, demand for electric equipment is set to climb.

“Demand for electric equipment will increase in the Middle East, due to the major construction projects taking place there,” says Lakis.

He highlights how urban environments in particular will benefit.

“This lithium-ion battery-powered machine meets today’s sustainability requirements for zero emissions and low noise levels, as well as offering reduced running costs. The EC450AJ Compact is highly manoeuvrable. It is only 2m wide with true ZERO tail swing, providing excellent manoeuvrability on site and allowing operation in the most constrained spaces.”

The EC450AJ is part of a broader strategy by JLG to expand electrification across

its range. “Both JLG and Hinowa have for many years offered fully electric machines in other product categories and types. The Generation 2 EC Boom range (EC450AJ and EC520AJ) adds fully electric capability to the rough terrain category and at a height range which is the workhorse of the industry. The development of the EC450AJ Compact follows on from the development of the Generation 2 EC Boom range,” says Lakis. “The convergence of cost-effective technology and the rental market’s drive for sustainable zero emissions solutions led us to develop the EC Boom range. The general versatility of the 45ft articulated boom category gives a great opportunity for creating an even more flexible machine, allowing for both outdoor and indoor use with zero-emission operation.”

As regional regulations tighten and customers demand greener solutions, Lakis expects electrification to accelerate further. “We constantly seek input from our customers about future needs and this input is used in our product development strategy. Both JLG and Hinowa are very active in developing further models in the electrification ecosystem. Future new products will take a holistic approach to engaging with customers’ de-carbonisation journeys. Zero emissions is important in reducing carbon footprint, but customers are now asking for reduced embedded carbon solutions. Future new products will seek to address this.”

For rental companies and end-users, Lakis has a clear message: “Demand for electric products requires all stakeholders in the ecosystem to support the adoption in a positive way. Manufacturers such as JLG need to understand and develop the technical solution, it’s important that rental companies learn how to support and market this technology, considering where the technology works and, importantly, where it is still not a good solution. Construction companies need to adapt working practices to support their use, such as more charging infrastructure.”

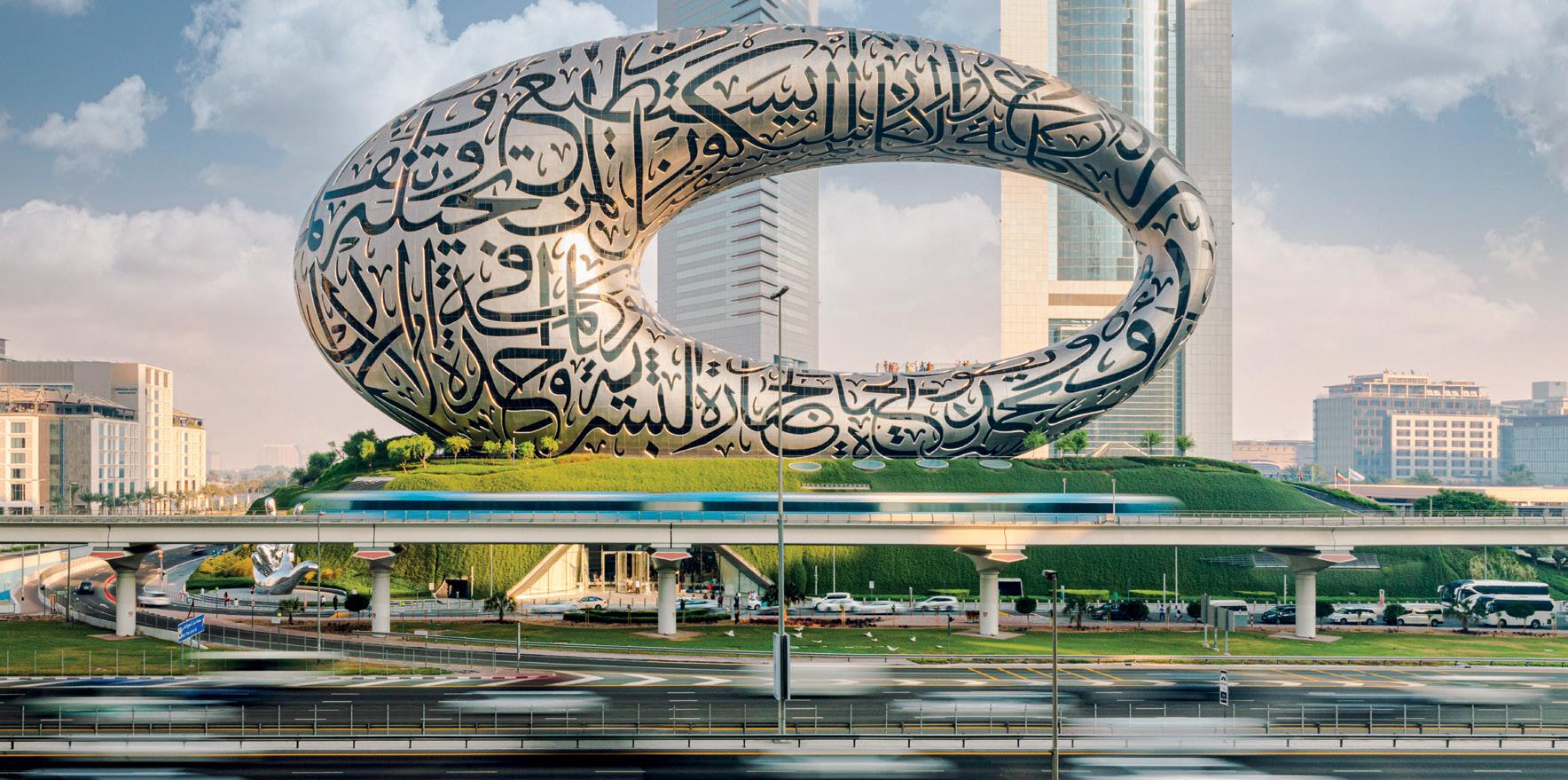

On the shimmering shoreline of Palm Jumeirah, a new residential icon is taking shape — a collection of ultra-luxury apartments and penthouses set among Dubai’s most exclusive hotels.

Delivering this level of architectural ambition requires precision at every stage, and for the project’s heavy lifting and vertical logistics, Kanoo Cranes LLC was selected to supply, install, and operate a pair of Wolffkran 355B luffing tower cranes, renowned for their safety, reliability, and power.

“It’s a premium lifestyle project on the shores of the Arabian Gulf, with three- and four-bedroom apartments, duplexes and super-luxury penthouses,” said Ahmad Wraikat, General Manager, Kanoo Cranes LLC. “The development brings a new concept of lifestyle apartments to Palm Jumeirah, right in the middle of some of the city’s most prestigious hotels, such as the Marriott and Palm 5.”

The project’s complexity demanded equipment that could combine strength, reach, and flexibility. Kanoo Cranes supplied two Wolffkran 355B luffing tower cranes, each offering a 28-tonne lifting capacity, a 40-metre jib length, and a tip load of 11.3 tonnes at full working radius. With a maximum height of 135 metres, the cranes provided the stability and reach necessary to work in the dense and vertical confines of the Palm site, while maintaining safety and operational efficiency.

“These tower cranes were selected for their robust design and performance,” said Wraikat. “The 355B has a high-grade steel

structure across its tower elements, top parts, and machinery. The winch, collars, and ties all allow the crane to climb up to 460 metres with the same load capacity. All components are made in Germany, ensuring consistent quality and durability.”

The Wolffkran brand, with more than 170 years of crane engineering heritage, is known globally for its innovation and reliability. Ranked as the No. 1 tower crane in terms of quality and safety, the Wolffkran line forms a central part of Kanoo Cranes’ portfolio, enabling the company to deliver best-in-class solutions to the region’s most demanding developments.

Palm Jumeirah is unlike any other construction site. Its curved geometry, narrow access routes, and proximity to infrastructure — including the island’s elevated monorail — make heavy lifting operations particularly challenging. Space and timing are critical.

“The project site is very close to the monorail track, and road access was limited,” said Wraikat. “Our team managed to overcome every logistical challenge, ensuring that crane components and materials were delivered on schedule and in full compliance with Dubai’s stringent regulations.”

Because of the tight footprint, the decision to use luffing jib cranes proved essential. The 355B’s luffing mechanism allowed operators to minimise working radius and avoid conflicts with nearby structures or the monorail alignment. Deliveries of tower sections, counterweights, and machinery parts were coordinated with contractors and Dubai authorities to take place during permitted time windows, ensuring minimal disruption to surrounding residents and ongoing traffic on the Palm.

sector. As part of The Kanoo Group, one of the largest family-owned businesses in the GCC, it draws on more than 50 years of experience in crane operations and engineering.

Kanoo Cranes’ involvement extended to a complete lifting solution: “That included erection, maintenance, climbing, dismantling, and operation by licensed, professional crane operators. We also handled the anti-collision systems, foundation design, third-party supervision, and insurance. Everything was managed by our in-house technical and service teams.”

For the highest standards of safety and uptime, Kanoo Cranes ensured that all certifications, inspections, and insurance documents remained valid throughout the project. “Our operators and service teams work closely with the client and contractor to make sure everything is renewed on time,” Wraikat noted. “It’s part of our philosophy of proactive management — never waiting for an issue to arise before acting.”

Every component, from the crane’s hightensile steel structure to its control systems, was tailored to ensure seamless operation. The 355B’s modular design also allowed for efficient assembly and disassembly — vital for projects like this where time and access are restricted. During the climbing phase, precision and timing were critical to ensure the cranes were raised safely and without disrupting the workflow of other contractors on-site. The space constraints required not only careful logistics but also bespoke engineering and exceptional accuracy. “Given the site’s confined footprint, there was very limited space between the crane and the building,” said Wraikat. “Design teams at Kanoo Cranes and Wolffkran worked meticulously to create a precise design that could accommodate the tower crane loads without impacting the structure.”

For Wraikat, the Palm Jumeirah project was more than a technical success — it was a reaffirmation of Kanoo Cranes’ philosophy. “As a state-of-the-art company, we are committed to maintaining the highest levels of safety and quality,” he said. “Our cranes combine load capacity with performance to meet and go beyond client expectations. This project gave us valuable experience, especially during the climbing process, and we are proud that we met all the requirements without ever delaying the work progress.

Kanoo Cranes is preparing for the next wave of complex developments in Dubai by expanding its fleet and partnerships: “Alongside Wolffkran, we work with global partners such as Maeda for mini cranes and Spierings for mobile tower cranes. This range allows us to meet the needs of diverse projects — from tight urban sites to largescale infrastructure.”

“From compact indoor machines to high-reach units, we can now support a wider range of projects with confidence”

As demand for highperformance access equipment continues to rise across the UAE, Mobility Equipment Rental LLC has taken a significant step forward through a major partnership with Dingli Machinery. The collaboration represents both a milestone in the company’s growth and a reaffirmation of its long-standing commitment to innovation, safety, and customer service.

“Mobility Equipment Rental LLC was established in December 2014 with the vision of becoming a trusted partner in the access and material handling industry,” explains Nabil Al Tawil, Founder and Managing Director.

“Over the years, we have grown to become one of the leading rental companies in the UAE, specialising in aerial work platforms, lifting solutions, and specialised equipment.”

According to Nabil, the company’s rise has mirrored the UAE’s rapid development.

“The UAE has witnessed remarkable growth across construction, infrastructure, logistics, and events — all sectors where safe and efficient access solutions are vital. This growth has directly fuelled demand for high-quality equipment and reliable rental partners,” he says.

“We have responded to this demand by expanding our fleet, investing in the latest technologies, and ensuring our clients benefit from international standards in

safety and services. Today, our growth is not only measured in fleet size but also in the blend of special equipment we have and the long-term relationships we have built with leading contractors and organisations across the Emirates.”

While other GCC markets present potential opportunities, Nabil says Mobility Equipment Rental’s strategy is to strengthen its local leadership first.

“At Mobility Equipment Rental LLC, we are closely monitoring developments across the GCC, but we have no immediate plans to expand outside the UAE,” he explains. “For the foreseeable future, our focus is on strengthening our position locally — consolidating our success, ensuring excellence in service and operations, and planning regional expansion at the right time.”

He adds that diversification remains central to the company’s short-term goals.

“Currently, our business lines include Access Platforms, Spider Cranes, and Glass Lifting Solutions. We are also introducing a new line — Green Energy Solutions, specifically ‘Battery Boxes’ — to the UAE market. For now, our priority is to diversify and enhance our range of offerings rather than pursuing expansion into other GCC markets.”

The company’s recent agreement with Dingli Machinery marks one of its most substantial investments to date. “We recently signed a significant agreement with Dingli Machinery, which marks an important milestone for Mobility Equipment Rental LLC,” says Al Tawil.

“The deal includes a wide range of

machines, from compact models with an 8-metre working height up to large units reaching 44 metres. This variety allows us to serve projects of different scales, from indoor applications to major high-rise developments. While I cannot disclose specific quantities, I can confirm it is a sizable investment that reinforces our commitment to providing the latest and safest access solutions in the UAE.”

Nabil explains that the partnership developed organically from a mutual understanding of what the market needs. “Our discussions with Dingli began through a shared vision of bringing innovative and reliable access solutions to the UAE market,” he says.

“I was personally impressed by their track record in manufacturing high-quality, technologically advanced equipment, while they recognised our strong presence and reputation in the rental industry. What convinced both sides to move forward was the alignment of values — a commitment to safety, efficiency, and customer satisfaction. From my perspective as Managing Director, it was clear that this partnership would create a win–win opportunity, benefiting both companies and, most importantly, our clients.”

For Nabil Al Tawil, Dingli’s portfolio fills essential needs in Mobility Equipment Rental’s expanding fleet. “Dingli machines have allowed us to address several key gaps in our fleet,” he explains.

“As projects in the UAE grow in scale and complexity, there is an increasing demand for equipment that can reach higher working heights while remaining safe and easy to

As project complexity increases, the UAE market has begun to demand higher-reach, more specialised machines that are both powerful and safe.

operate. By adding machines ranging from 8 metres to 44 metres in working height, we can now serve a wider variety of projects — from smaller indoor tasks to large highrise developments. Personally, I saw this as a crucial step to ensure our clients always have access to the right equipment for their specific needs, while maintaining our commitment to safety, efficiency, and reliability.”

Adding Dingli machines, he says, was also about timing. “Adding Dingli machines to our portfolio at this time was a strategic decision.

The UAE market continues to see rapid

growth in construction, infrastructure, and industrial projects, with increasingly complex requirements for safe and efficient access solutions, he adds.

“From my perspective as managing director, it was essential to ensure that our fleet meets these evolving demands. Dingli’s technologically advanced machines allow us to offer a broader range of heights and capabilities, giving our clients the confidence that they have the right equipment for any project, while reinforcing our reputation as one of the leading providers of reliable and innovative solutions.”

“From our discussions with Dingli, it’s clear that this partnership is very significant for them in strengthening their presence in the Middle East rental market,” says Al Tawil.

“By collaborating with a well-established and trusted rental company like Mobility Equipment Rental LLC, they gain access to a strong network, deep local expertise, and insights into market needs. From my perspective as Managing Director, this partnership is mutually beneficial — it allows Dingli to grow their brand in the region, while enabling us to offer our clients the latest, high-quality access solutions.”

He believes the agreement directly enhances Mobility Equipment’s capacity to serve a broader client base. “This deal significantly enhances our ability to serve a wider range of projects and customers,” Al Tawil says. “With Dingli machines ranging from 8 to 44 metres in working height, we can now cater to everything from smaller indoor tasks to large high-rise developments. Personally, I see this as a crucial step in ensuring our clients always have access to the right equipment for their specific needs, while reinforcing our commitment to safety, efficiency, and reliability across all projects.”

Through this agreement, Mobility Equipment Rental has added an entirely new range of specialised machines to its fleet. “Many of these are special machines — whether in terms of working height, dimensions, or weight — designed for very specific applications,” Al Tawil notes.

“These types of units are not commonly available in large numbers in the UAE market, which makes them particularly valuable to our clients. By adding them, we are not only complementing our existing fleet but also filling important gaps, ensuring that we can support even the most specialised project requirements.”

“What stood out to us about Dingli was a combination of factors,” says Al Tawil. “Safety is at the core of their designs, which

aligns with our own priorities. They are also highly innovative, introducing technologies that make machines more efficient and user-friendly. In addition, their strong availability of stock and reliable after-sales service give us the confidence that we can support our clients without delays. And above all, Dingli offers flexibility — in the way they work with us as a partner. For me as managing director, these points made Dingli the right choice at this time.”

He adds that Dingli’s equipment is already making a difference across key sectors.

“Dingli’s equipment helps us meet growing demand in construction, infrastructure, and industrial maintenance by offering safe, innovative, and flexible solutions. From compact indoor machines to high-reach units, we can now support a wider range of projects with confidence.”

According to Al Tawil, Dingli machines bring tangible advantages.

“They bring real added value through their performance, advanced safety features, and energy-efficient designs,” he says. “They are built for reliability and ease of use, while also supporting sustainability goals with ecofriendly power options. Compared to many brands in the market, Dingli stands out for combining innovation with flexibility, giving our clients safer and more efficient solutions tailored to their project needs.”

The deal is already opening new market opportunities.

“By adding Dingli’s specialised machines — with unique heights, dimensions, and capacities — we can now serve applications that were previously underserved in

“This partnership means greater equipment availability, faster service support, and more flexibility in meeting project requirements,” says Nabil

the market,” he continues. “This opens opportunities in new segments, from high-rise construction to specialised industrial projects, while strengthening our core offerings.”

“For end-users, this partnership means greater availability of advanced equipment, faster service support, and more flexibility in meeting project requirements,” Al Tawil explains. “With Dingli’s strong stock and after-sales commitment, combined with our local expertise, clients can count on reliable machines, reduced downtime, and solutions

tailored to their needs.”

A Partnership Built to Last

“Yes, we see this as the start of a long-term partnership with Dingli,” Al Tawil confirms.

“Our agreement goes beyond a single transaction — it is built on shared values of safety, innovation, and customer focus. From my perspective as Founder and Managing Director, this is a relationship we aim to strengthen over time, ensuring our clients continue to benefit from the best solutions in the market.”

He adds that follow-up initiatives are already being implemented. “Supporting our fleet goes beyond acquiring the machines,” he says. “We are working closely with Dingli on training programs for our team and local service initiatives to ensure clients receive the highest level of support. From my perspective, these initiatives are crucial to maintaining safety, efficiency, and reliability for every project we serve.”

“From our conversations with Dingli, it’s clear that they are committed to building on this momentum by strengthening their presence across the Middle East rental sector,” Al Tawil concludes.

“They aim to continue introducing innovative, high-quality machines, expanding availability, and providing strong after-sales support. From my perspective as the head of Mobility Equipment Rental, this partnership positions both companies to better serve clients, address market needs, and support growth in the region.”

Johnson Arabia has announced a major investment a new fleet of JCB 540-170 telehandlers, strengthening its fleet to meet the growing demand for versatile equipment in the region.

The JCB 540-170 is a powerful telescopic handler designed for high-reach material lift operations. With an impressive 4,000 kg (4-ton) lifting capacity and a maximum 17-meter boom height, this machine is engineered to handle demanding tasks across construction, logistics, and industrial projects. Powered by by JCB’s Dieselmax engine that sits on a chassis it is specially designed to provide the ultimate load-bearing and stability during a lift and also offering outstanding reliability and fuel economy. Its compatibility with a wide range of attachments including pallet forks for heavy loads and sand buckets for bulk handling makes it one of the most adaptable machines in the market.

Recognising the market’s need for multifunctional

equipment, Johnson Arabia has strategically invested in the popular JCB 540-170. This expansion ensures clients have access to high-performance material lift solutions that can tackle everything from lifting steel beams to transporting bulk material with ease.

Speaking about the investment, Johnson Arabia’s Executive Manager for AWP Joe Keely stated “This is a continuation of the investment journey we have been making into alternative products which are aligned to our industry-leading rental service. Many customers who rely on Johnson Arabia for safe and efficient working solutions have requested Telehandlers from us.

“With our experience managing and operating other large heavy plant, Telehandlers fit perfectly into our business to complement our offering. Partnering with JCB was an easy decision given their classleading technology and the immediate recognition of quality for their Telehandler products”

This strategic move underscores Johnson Arabia’s commitment to staying ahead of industry trends and providing clients with cutting-edge solutions.

The addition of the JCB 540-170 units will not only improve efficiency on job sites but also offer greater flexibility for contractors seeking a reliable material lift partner.

To ensure maximum performance and safety, Johnson Arabia’s operators have already undergone training on the use of these telehandlers, conducted directly by the JCB team. This guarantees that every unit is deployed with skilled support for their clients. Several of the newly acquired telehandlers are already contracted out on active projects across the UAE, with more units scheduled to go on site in the coming weeks. This shows both the strength of market demand and the trust contractors place in Johnson Arabia’s ability to deliver advanced lifting solutions for projects.

As the GCC construction sector continues to expand under large-scale infrastructure and development projects, Johnson Arabia’s investment ensures that its customers benefit from advanced, high reach lifting equipment designed to perform in the region’s most challenging environments.

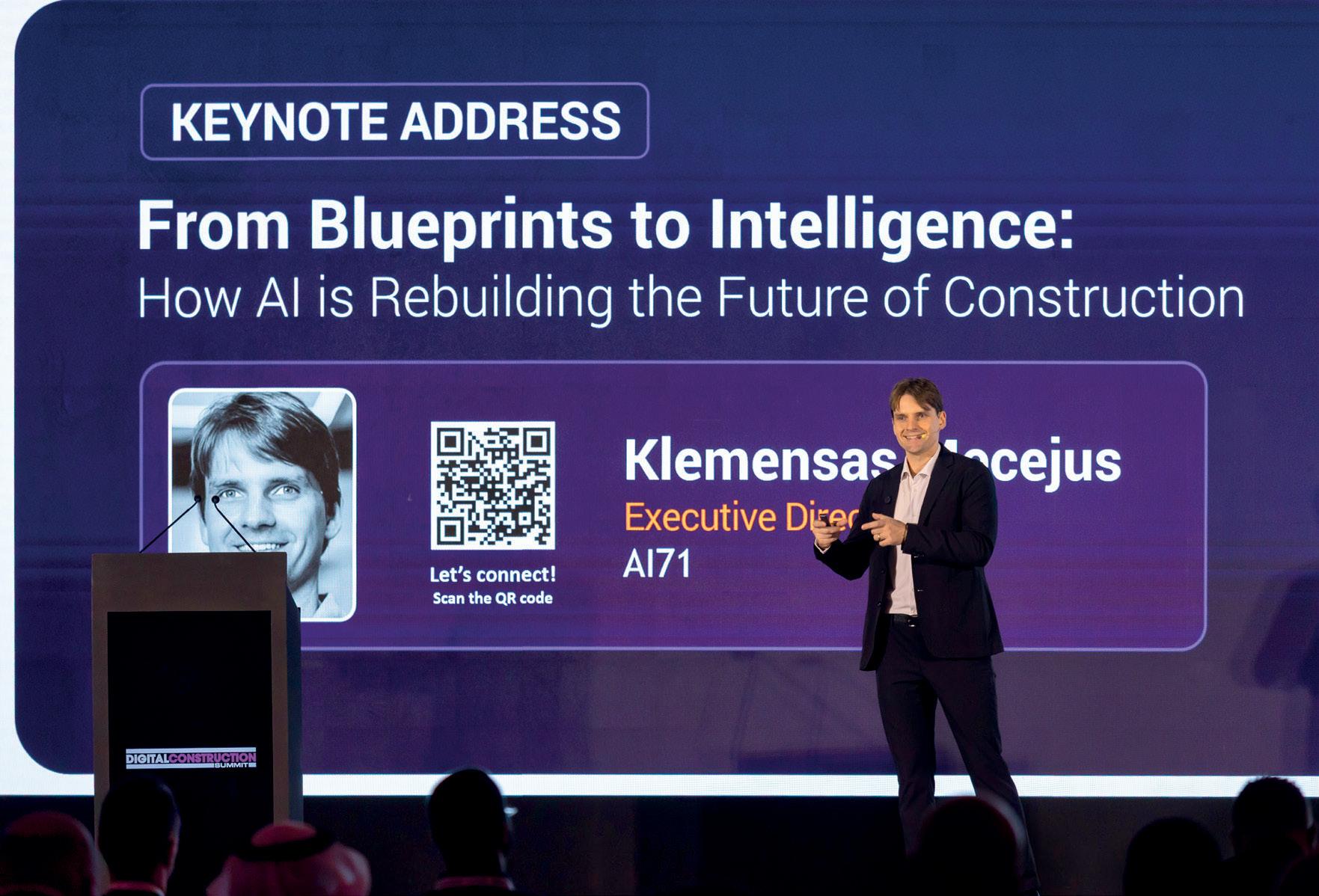

The construction industry has long been seen as conservative, asset-heavy, and slower to adopt digital transformation compared to other sectors.

But according to Klemensas Mecejus, Executive Director of AI7, that perception is rapidly changing. In his keynote address at the Digital Construction Summit last month, he set out why the industry is on the cusp

of an AI-driven revolution — one that promises to transform design, planning, operations, and maintenance.

“Historically, the sector was very grounded,” Mecejus said, pointing to high capital expenditure, traditional engineering practices, and slow digital adoption. While industries such as finance and manufacturing raced ahead with IT and AI integration, construction lagged.

“Today, that’s no longer the case. We see advanced environments used in design and planning, IoT devices and wearables on sites, and

even satellite analytics driving reconstruction flows,” he explained.

From RFID-tagged equipment to connected sensors and drone imagery, data streams are being unified at scale — laying the groundwork for the next leap forward: autonomy and generative AI.

The autonomous future

Among the biggest opportunities Mecejus identified is autonomy. He painted a picture of AI-equipped inspection vehicles roaming sites day and night, automatically scanning for deviations between plans

and execution. “Imagine the overlay of what is being built versus what is supposed to be built, with instant signalling of risks and challenges — and at minimal cost,” he said.

Such applications, he stressed, would benefit regulators, municipalities, developers, and contractors alike, driving consistency and reducing risk across the entire construction value chain.

Generative AI and the design revolution

Another breakthrough lies in generative AI. In design and planning, where complex schedules, vast product databases, and multiple stakeholders once slowed progress to a crawl, AI is now able to simplify workflows.

“Previously, integrating all that into one system was almost impossible,” Mecejus admitted. “Now we can create unified data layers that power interactive AI.”

He cited permitting and compliance checks as an area already being transformed. AI can now interpret CAD files, identify walls, beams, and windows in natural language, apply regulatory maths, and cross-reference thousands of building codes — all in seconds. Even more striking is AI’s ability to then fix non-compliant designs automatically. “The user just reviews and approves. That’s it,” he said.

The gains, he claimed, are “thousands of percent” in efficiency, opening the door to faster creativity and safer, more compliant construction.

One particularly compelling use case lies in permitting. Mecejus described how AI systems can process both design drawings and regulatory codes simultaneously, marking compliant and non-compliant elements directly on the plans.

“This means municipalities and developers can move through approvals in hours instead of weeks,” he noted. “And every iteration of the design only takes minutes.” For the Gulf region, where rapid urban development often collides with lengthy approval processes, such solutions could prove game-changing.

Beyond design, AI is making inroads into site safety. Camera systems powered by AI can automatically check if workers are wearing protective equipment or whether site procedures are being followed.

“This is increasingly appearing on the dashboards of major developers,” Mecejus explained. “Safety and compliance are not just tick-boxes — they are areas where AI delivers measurable value.”

The pathway to widespread AI adoption requires cultural change, supply chain cooperation, and an industrywide willingness to standardise, simplify, and collaborate.

featured strongly in Mecejus’ vision. While historically used in isolated phases, he sees BIM as central to a “single source of truth” spanning the full lifecycle of a project — from masterplanning through permitting, construction, operations, and eventual maintenance.

By embedding BIM into digital twin models, companies can layer analytics on top, ensuring greater stability, predictability, and insight. “It’s not just about files anymore — it’s about creating a unified decision-

making brain for construction,” he argued. Once used primarily in design, BIM is evolving into a digital twin platform spanning a project’s full lifecycle.

“BIM offers a single source of truth — from pre-concept planning to construction and operations,” Mecejus said. “On top of that, you can build analytics and create what we call a unified decision-making brain.

That “brain” integrates satellite imagery, IoT sensors, contract details, and schedules to forecast risks such as project delays. For example, it can detect slowing progress in drone footage, cross-check contractor workloads, and flag where permitting issues could impact delivery.

Despite the enthusiasm, Mecejus was candid about the hurdles. Chief among them is proving return on investment. “It’s very difficult to link certain AI applications directly to bottom-line impact,” he warned.

High costs of compute power, data management, and agentic AI platforms demand significant upfront investment. Without clear evidence of scale, CFOs remain cautious. Yet, he believes technology maturity is improving rapidly, and those who lead early will reap the rewards.

His closing message to industry leaders was both practical and motivational. Adoption, he said, will not be linear. “Many things are new, untested, and risky. But leaders need to champion innovation, support their teams, and embrace risk appetite.”

He urged executives to “be bold, don’t be afraid, experiment, play, and be open to

failure. Fail fast, adapt, and move forward. That’s what will make you a true leader in this transformation.”

For Mecejus, what excites him most is how quickly the landscape is evolving. “All of this wasn’t possible two years ago,” he reminded the audience. Advances in algorithms, compute power, and data quality now make once-impossible workflows achievable at scale.

His optimism is contagious: an industry long defined by slow-moving processes and heavy equipment is suddenly finding itself at the cutting edge of applied AI.

“Tomorrow,” he said, “we will be able to do much more. And that’s what’s truly exciting.”

While AI is no longer a distant prospect for the construction industry the panellists of the W’AI Forward at the Digital Construction Summit highlighted the path forward is not without its challenges.

While AI can speed up repetitive or data-heavy tasks, the panel was clear that human oversight remains essential where safety and reliability are concerned. Paul Wallett, Regional Director at Trimble Solutions Middle East, pointed to tunnelling projects in the US where AI reduced analysis time from 30 minutes to just three. Yet he stressed that no contractor would — or should — let AI design or approve a structure without rigorous human verification: “If that structure collapses, it’s the contractor who is liable, not the algorithm.”

During the robotics and automation session, experts questioned whether robotics and automation are ready to play

a meaningful role in construction and manufacturing — or whether the sector still has fundamental barriers to overcome. Their observations revealed both the opportunities and limitations of applying robotics in an industry known for complexity, fragmented supply chains, and tight delivery schedules.

Douglas Zuzic, Chief Digital Officer at Innovo Group, argued that robotics should not be seen as a replacement for the workforce, but as a partner in

While AI can speed up repetitive or data-heavy tasks, the Digital Construction Summit panellists were clear that human oversight remains essential where safety is concerned.

delivering quality and safety. He cited a live project in Abu Dhabi where Innovo has been trialling a Chinese-made robot designed for floor tiling.

“We have a project in Abu Dhabi, Saadiyat Lagoons, where the robot doesn’t replace labour — it complements it,” Zuzic explained. “It can lay tiles at a pace and quality that helps us meet deadlines, while our workers focus on areas that require precision or adaptation. It’s not an either-or scenario. It’s about improving quality, timelines, and safety while still working with skilled trades.”

While early trials have shown promise, Zuzic stressed that automation will not solve every problem. Large open areas may benefit from robotics, but tight or intricate spaces still rely on human labour. “We are driven by time, cost, and quality. Technology is one way we can balance those pressures and keep our people safe on site,” he said.

Modular Construction as a Natural Fit

For Ihab Ramlawi, Managing Director and Co-Founder of DuPod, robotics finds its best use in controlled environments. Modular construction shifts activities from unpredictable job sites into factories where automation can be applied effectively.

“In modular, you can monitor efficiency like in a manufacturing plant,” Ramlawi said. “But before you invest in robotics, you need standardisation and simplicity. Our goal is to create design processes that machines can understand. Think of an IKEA manual—simple maps, standardised

components, and barcoded instructions for machines to read.”

Ramlawi warned, however, that the supply chain remains a sticking point. Developers often resist standardisation, demanding unique components and custom designs that undermine efficiency.

“Why do we need 50 different types of bathrooms in one tower?” he asked. “If we worked with clients earlier, we could standardise, optimise materials, and reduce costs. Without that mindset shift, robotics becomes harder to implement.”

Dr. Yasemin Nielsen of Heriot-Watt University Dubai added that embedding research directly into industry partnerships can accelerate adoption. Her team is working with companies that sponsor researchers to explore emerging automation and AI tools while tackling real-world projects.

“The challenge is not just in the technology,” she said. “It is in how we collect, process, and use the data that comes from construction sites. In manufacturing, data flows are consistent. In construction, the variability of projects creates barriers to adopting robotics at scale.”

AI adoption also hinges on people. Mandatory training programmes are already common in tech-driven firms, teaching staff about cybersecurity, data protection, and the risks of uploading sensitive project information into open-source platforms.

Consultant Pratik Dalai of TBH stressed that piecemeal adoption will not deliver the full benefits. Instead, the industry must build an ecosystem where all stakeholders — from consultants and contractors to subcontractors and clients — engage early and consistently.

“We need to find balance between innovation and application,” Dalai said. “Pilot projects can prove feasibility, but wider adoption requires acceptance and collaboration. Innovation should not be about buzzwords; it must solve problems of time, cost, quality, and safety. That means involving subcontractors and manufacturers earlier, and building capacity across the whole supply chain.”

He also noted that contractors are increasingly leading discussions on design and optimisation — roles traditionally held by consultants and architects. “It’s a drastic shift, but a positive one,” Dalai observed. “Contractors are now shaping how projects are designed, which opens doors for automation and robotics to be considered much earlier in the cycle.”

The panellists agreed that early-stage engagement with technology providers is becoming critical, particularly as developers

in the UAE and Saudi Arabia show greater openness to modern methods. Ramlawi called it “an awakening” that has begun to reshape the market.

“If a project is badly designed, it’s almost impossible to add value later,” he said. “But when we are engaged from stage two instead of stage three, we can influence design, optimise costs, and integrate modern construction methods from the start. That is where robotics and automation can really add value.”

The debate underscored that robotics and automation are no longer futuristic ideas for construction—they are already being trialled in live projects. Yet the path to widespread adoption requires cultural change, supply chain cooperation, and an industry-wide willingness to standardise, simplify, and collaborate.

As Dalai concluded, “It’s about creating an ecosystem where innovation and application move in step. Without that balance, robotics will remain a buzzword. With it, the industry can finally start to deliver on the promise of smarter, safer, and faster construction.”

“Contractors are now shaping how projects are designed, which opens doors for automation and robotics to be considered much earlier in the cycle”

Join MEA‘s largest international trade show for the automotive aftermarket

30 NEW RELEASES

The latest releases from the world of construction machinery.

38 ZF GOES OFF-ROAD

FX Laubscher, ZF’s Head of Off-Highway, speaks to CMME

36 HANGING TIGHT

Top ten tech to protect workers on-site.

40 STRIKING DEVELOPMENT

The new tech that is making working with power safer

WITH THE OCTOPLUS 30 (OIL & STEEL SERIES), TADANO ONCE AGAIN DELIVERS AN AERIAL PLATFORM THAT COMBINES ITALIAN PRECISION WITH GLOBAL INNOVATION.

Tadano has unveiled the latest addition to its aerial work platform portfolio — the Octoplus 30 (Oil & Steel Series) — a new tracked platform that redefines standards for performance, compactness, and versatility. After its international preview at Bauma 2025, the Octoplus 30 will make its live demonstration debut at GIS 2025, offering operators a firsthand look at its industryleading reach and design innovations.

Engineered and manufactured in Italy, the Octoplus 30 delivers class-leading performance with a maximum working height of 29.6 metres, a horizontal outreach of 16 metres, and a maximum load capacity of 280 kilograms. These specifications place it firmly at the top of its segment, ensuring operators can reach even the most challenging elevated points — safely and efficiently.

WHY IT IS IMPORTANT?

WITH THE SMARTFLOW SYSTEM OPERATORS WILL GET SMOOTH MULTI-FUNCTION CONTROL, ALLOWING OPERATORS TO DRIVE, SLEW, AND LIFT SIMULTANEOUSLY — EVEN WHEN RUNNING HYDRAULIC ATTACHMENTS LIKE FLAIL MOWERS OR AUGERS AT FULL SPEED.

To mark the start of production for its next-generation R2-Series 1–2 tonne mini excavators, Bobcat has introduced a special limited-edition run of its top models. The Premiere Launch Edition will see just 50 machines produced across the Europe, Middle East and Africa (EMEA) markets, making them an exclusive collector’s item for operators and dealers alike.

The new R2-Series — first unveiled at Bauma 2025 — includes the E16, E17z, E19 and E20z models, designed to set new benchmarks for productivity, precision, and operator comfort in the compact excavator category.

The Premiere Launch Edition will be reserved for the range-topping E19 and E20z models, with only 25 units of each being produced. First deliveries of both the standard and limited-edition variants are expected to begin in September 2025.

Each machine is finished in a striking exclusive charcoal-grey colour scheme, immediately setting it apart from standard models. Inside the cab, operators are treated to a premium seat with red and black cloth or optional leather upholstery designed by MAD, a studio renowned for its work in the luxury, sports, and classic car industries.

Every Premiere Launch Edition also features an individually numbered plate on the cab, aluminium pedals, and a suite of factory-fitted high-value aftermarket kits supplied as standard. These include a Direct Return to Tank system, a Top Guard Cab, Travel Motor Hose Guards, and a Bucket Cylinder Cover — all designed to elevate durability, operator protection, and long-term performance.

Miroslav Konas, Product Line Manager for Doosan Bobcat EMEA, explained: “We are launching the Premiere Launch Edition to promote the new range and to emphasise our market presence at the time of the start of production for the new machines. The Premiere Launch Edition is a strong conversation starter and sales tool and gives dealers an opportunity to offer customers a truly unique, highspec machine that is both visually distinctive and technically enhanced.”

He added that the edition’s nonstandard colour and branding serve as a bold visual statement: “It helps increase awareness and generate buzz. It shows that the new generation mini excavators are not just an update — they are a bold step forward.”

CATERPILLAR’S NEXT-GEN ARTICULATED TRUCKS ARRIVE PROMISING ‘ENHANCED SAFETY, COMFORT AND EFFICIENCY’.

Caterpillar has introduced its next generation of Cat articulated trucks, unveiling a suite of upgrades designed to improve operator comfort, machine safety and overall performance. The new lineup covers the Cat 725, 730, 730 EJ and 735 models, all of which feature enhanced automation, safety systems and productivity technologies.

The redesigned interior puts control at the operator’s fingertips, with a touchscreen interface, keypad and jog dial navigation for easy operation. Push-to-start technology with operator ID accommodates up to 50 operators, improving site efficiency while reducing the risk of unauthorised use.

All models can be fitted with optional multiview cameras and object detection radar to enhance situational awareness.

The introduction of the Cat C13B engine on the 725 delivers up to 14% better fuel efficiency compared to its predecessor,

while a broader power range of 257 to 316 kW (345–424 hp) ensures compliance with global emission standards including U.S. EPA Tier 4 Final and EU Stage V.

The Cat 725, 730 and 735 feature redesigned dump bodies for easier loading, higher payload efficiency and reduced carryback, supported by integrated external payload indicator lights. The 730 EJ articulated truck adds versatility with an ejector body that disperses loads without raising the bed—ideal for sites with restricted overhead clearance or soft ground conditions.

A new Operator Coaching system provides real-time feedback on operator behaviour, offering up to 14 coaching tips with on-screen prompts and animated tutorials. Fleet managers can access GPS-linked performance data via VisionLink to monitor machine use and operator practices across the site.

Safety features include: the Dynamic Rollover Protection system which monitors lateral acceleration to warn of rollover risk and automatically applying corrective actions; Stability Assist

which prevents hoisting on uneven terrain; Auto Wait Brake (AWB) which automatically applying service brakes when stationary, reducing fuel consumption and operator fatigue; and a dump body height limiter that ensures compliance with site restrictions and preventing collisions with overhead structures.

Production of the new Cat articulated trucks will begin in January 2026, starting with the Cat 730 model. The update continues a four-decade legacy of innovation in articulated truck design since Caterpillar introduced the first model, the D400, in 1985.

SPECIFICATIONS

CAT 730 ARTICULATED TRUCK

Engine: Cat C13A / C13B

Net Power: 274 kW (367 hp)

Rated Payload: 28t

Heaped Capacity: 17 m³

Axles: 3

Drive Configuration: 6WD

SENSE AND SENSING ABILITIES

Proximity sensors warn operators of nearby obstacles and people.

FULL VISION 360-degree cameras improve visibility around large machinery.

WEAR IT WITH PRIDE

Wearable safety tech such as smart helmets and vests alert workers of dangers.

JOINING VR OPS

Virtual reality training can train operators safely in a simulated environment.

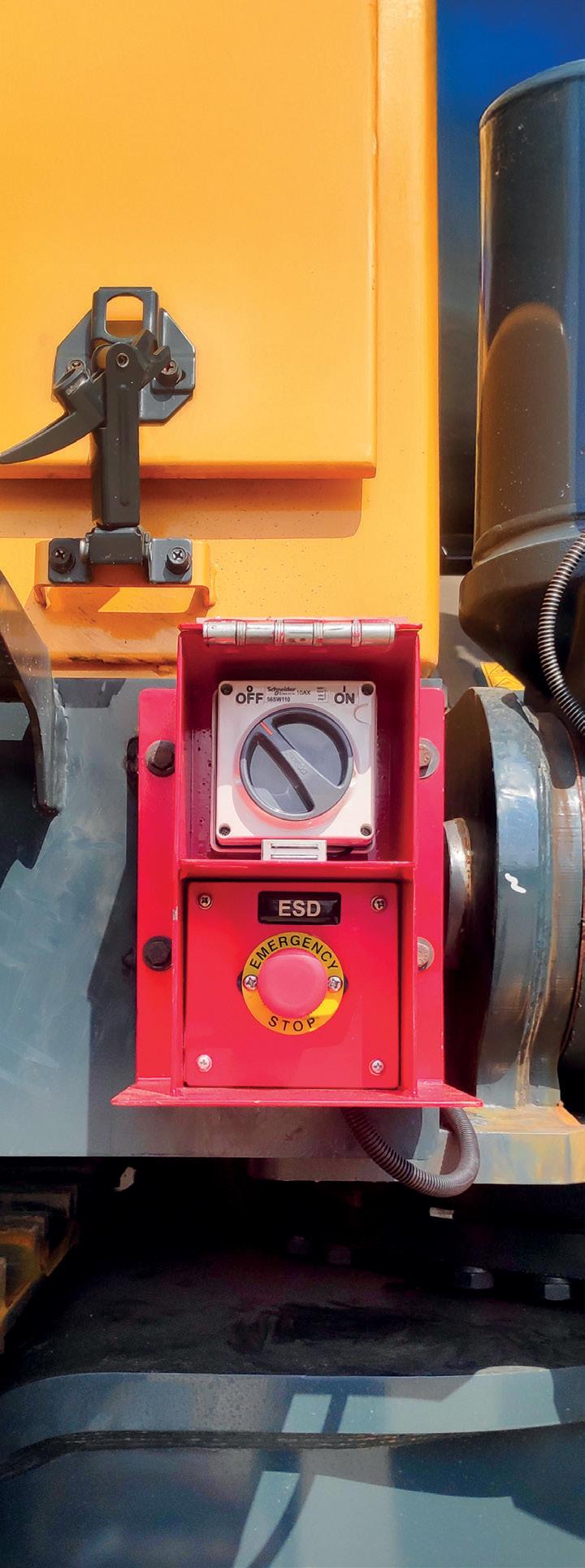

BRAKE IN CASE OF EMERGENCY

Emergency stop mechanisms ensure instant shutdown in case of system failure or danger.

KEEP CONTROL AT ALL TIMES

Remote-controls allow operators to control machines from a safe distance in hazardous zones.

Auto Engine Shutdown features stop the machine if the operator leaves the seat.

AVOIDING THE TIP RUNS

Load stability sensors prevent tipping by monitoring weight distribution.

Tesmec has been producing trenchers for 70 years, with three factories located in Italy, France and Texas. Over the last 20 years, Tesmec has focused on innovation and technology. Saudi Tesmec is our local branch, supporting the pipeline industry.

Tesmec 1875XL EVO Chainsaw only solution on the market trench widths up to 213 cm Featuring an impressive 950-hp is engineered to conquer challenges, making it ideal installations in hard and

Chainsaw Trencher stands as the market capable of achieving cm and depths up to 732 cm. 950-hp engine, this machine conquer the toughest excavation for large-diameter pipeline abrasive rock conditions.

Hangcha’s rise in the UAE has accelerated since its partnership with Select Auto, the automotive and machinery products and services subsidiary of Al-Futtaim Group, is already a globally recognised name in the material handling equipment (MHE) sector, Hangcha is now firmly embedded within the Al-Futtaim network — and that relationship is paying dividends across the region’s fast-growing industrial base.

“Hangcha’s presence within the UAE was already remarkable, and since Al-Futtaim Group took the dealership, its scale and visibility have reached new heights,” says the Select Auto team. “The brand now has credible backing and alignment with market

trends such as electrification, sustainability, and logistics expansion — all supported by Al-Futtaim’s robust infrastructure and customer service ethos.”

Al-Futtaim’s decision to bring Hangcha into its industrial and logistics equipment portfolio was a strategic one, aimed at expanding its reach across all segments of material handling — from warehouse automation to heavy-duty lifting for ports, oilfields, and construction sites. Hangcha’s range reflects that ambition, with electric and internal combustion forklifts, warehouse equipment, reach stackers, empty container handlers, side loaders, AGVs, aerial work platforms, tow trucks, and rough-terrain forklifts among its comprehensive line-up. “Hangcha allows us to cater to every industrial application,” says Select Auto. “From small-scale warehouse operations to the most demanding port or construction environments, the brand gives us a complete and competitive range.”

Hangcha’s versatility has proven to be one of its strongest assets in the UAE, where operators need equipment that performs across both climate extremes and varied applications. Its power pallet trucks, stackers, reach trucks, order pickers, and VNA (Very Narrow Aisle) machines are tailored for the region’s rapidly expanding logistics and warehousing networks. Meanwhile, Hangcha’s rough-terrain forklifts are engineered for off-road durability in construction and oilfield operations — available in both diesel and lithium-ion electric models to meet sustainability goals. “These are machines designed for harsh environments,” the team explains. “They’re rugged, efficient, and aligned with the UAE’s push for greener, electrified industrial operations.”

Hangcha’s innovation credentials were underscored by two nominations at this year’s CMME Awards — for the 48t Lithium Battery Forklift

and the 16t Diesel Forklift, both standout performers in their categories. The 48T model represents a major breakthrough in heavy-duty, electric-powered lifting, offering exceptional load capacity with a 48t lifting capability that allows it to handle the most demanding operations in construction, ports, and heavy industry. Its lithium-ion battery provides a long operational runtime and fast charging, with reinforced frames and an integrated Battery Management System (BMS) that monitors temperature, voltage, and charge status in real-time. The result is safety, battery longevity, and performance under heavy loads.

“The response to our electric forklifts has been overwhelming,” notes Select Auto. “Energy costs per hour are dramatically lower, and with the UAE’s national sustainability targets, Hangcha is perfectly placed to provide carbon-free, highperformance solutions.” The 48T forklift’s instant torque and steady power output across the entire discharge cycle give it a clear advantage over traditional internal combustion machines, while opportunity charging during breaks extends its daily runtime without the need for battery swaps. Alongside the 48T, the 16t diesel forklift remains a proven workhorse for construction and port operations. Equipped with premium European and US-manufactured engines, the model is built for continuous operation in demanding conditions. “It’s a reliable and powerful machine, and we offer options such as a fully air-conditioned cabin that enhances productivity, particularly during the summer when temperatures reach their peak,” says Select Auto.

Beyond raw performance, the machines integrate technologies that elevate operator safety and productivity. Ergonomic cabin layouts, improved visibility, advanced mast designs, and adaptive control systems all contribute to better handling and fatigue reduction. Telematics integration allows fleet managers to monitor performance and maintenance in real time, while features like climate control cabins and smart diagnostics support both comfort and uptime. “Every detail — from cabin layout to system diagnostics — is designed to help operators work more safely, more comfortably, and more efficiently,” the company explains.

Select Auto’s strength lies not just in equipment sales but in service continuity. Operating under Al-Futtaim’s trusted 3S model — Sales, Service, and Spare Parts — it ensures Hangcha customers receive the same level of attention and technical support that define the Group’s reputation. A dedicated team of highly trained technicians supports customers, while tailored on-site training programmes ensure operators understand their machines thoroughly before work begins.

Hangcha’s electric range also supports industry sustainability goals. Its lithiumion battery systems deliver zero-emission performance, cleaner air quality in urban and indoor environments, and lower total cost of ownership. The batteries’ long lifecycle also means fewer replacements, reducing waste and environmental impact. Hangcha is also positioning itself at the forefront of automation and smart logistics, integrating autonomous systems, real-time data analytics, and smart charging infrastructure into its future product roadmap.

“The shift toward automation and energyefficient equipment is transforming the MHE sector,” says the Select Auto team. “Hangcha is proud to be among the pioneers leading that change.” In 2025, Hangcha is rolling out its new XC and XE Series lithium-ion forklifts, designed to meet rising demand for smarter, cleaner, and more efficient MHE solutions across logistics, ports, and construction.

“Choosing Hangcha means choosing a partner committed to innovation, sustainability, and excellence — helping reduce TCO while driving a greener, more automated future for the UAE.”

HEAD

OFFHIGHWAY,

CMME

ZF is celebrating 110 years of innovation and its evolution into a global technology leader in sustainable mobility. Employing more than 160,000 people worldwide and operating 161 production sites in 30 countries, ZF supplies advanced products and systems across passenger cars, commercial vehicles, and industrial technology. For the industrial markets, ZF’s contribution has spanned more than 50 years. “Beyond the automotive sector, ZF has a strong presence in industries such as agriculture, construction, material handling, marine, wind power, and rail,” says FX Laubscher. “As the aftermarket division of ZF, we’ve been serving the industrial markets for more than 50 years, continuously refining components to meet

the increasing demands of heavy-duty machinery. This combination of heritage, global reach, and industrial know-how allows ZF to reliably partner with manufacturers and operators around the world.”

ZF’s Off-Highway business forms a key pillar of its Industrial Technology division, covering construction, agriculture, and material handling. These industries demand high-performance machinery that can withstand extreme conditions while delivering productivity and safety.

“The portfolio extends from drivelines, axles, and transmissions to electronic system solutions,” Laubscher explains. “ZF Aftermarket complements these products with spare parts, diagnostics, repairs, technical training, and remanufacturing services. We serve both OE and Aftermarket customers, enabling operators to maintain productivity across their equipment. In growth regions such as the MENA