NEW TECHNOLOGY PLUS MICKEY IN THE MANGROVES WHY DISNEY IS COMING TO ABU DHABI

LIUGONG AND GARGASH TALK CLEANER POWER WITH NO COMPROMISES ON SITE

NEW TECHNOLOGY PLUS MICKEY IN THE MANGROVES WHY DISNEY IS COMING TO ABU DHABI

LIUGONG AND GARGASH TALK CLEANER POWER WITH NO COMPROMISES ON SITE

12_EXCLUSIVE INTERVIEW: AYMAN AHMED

Bukhatir Industrial Investments’ CEO on why German Gulf Enterprises continues to thrive across the construction and industrial sectors.

16_DISNEY PARKS UP IN ABU DHABI

Why the House of Mouse is coming to the UAE capital.

22_COVER STORY

Gargash General Trading explains how LiuGong’s range of electric wheel loaders are just as capable as their diesel peers.

26_PARTS AND RE-CREATION

Blumaq takes CMME through its parts offering.

The

The

Bobcat unveils its

In an office of film geeks, Disney has had its fair share of slating at CMME HQ over the last few years. And, actually, if you look at the company’s desperation to bring back Bob Iger to the helm (in an attempt to stop hemorrhaging Disney dollars as audiences stayed away from its constant slew of princesses and super-geeks) we have not been its only critics.

The opening of the Disneyland castle gates in Abu Dhabi is a major boon for the GCC’s construction and machinery sectors — and potentially a turning point for the house of mouse. With 500 million potential park guests living just a flight away, this should also be exactly what Disney needs to reinvigorate its global appeal and reconnect with diverse international audiences.

The magic kingdom sprinkles fairy dust on an impressive portfolio of global-scale projects within the region, including Expo 2020 in Dubai and the highly anticipated FIFA World Cup in Saudi Arabia. Collectively, these mega-events underline not only the substantial opportunities available within the GCC’s construction market but also reflect its resilience and adaptability amid fluctuating global economic conditions.

The arrival of Disneyland is more than a tourism landmark; it should lead to continued investment in infrastructure, transportation, hospitality, entertainment venues, and residential developments around the UAE capital. Construction machinery suppliers, contractors, and equipment rental companies will see increased demand as new theme parks, hotels, roads, transportation links, and associated infrastructure projects are

launched. These opportunities extend well beyond the initial construction phase, encompassing ongoing maintenance and expansion, thereby ensuring continued business for equipment providers and service companies. From Expo 2020 to Expo 2030, The FIFA World Cup 2022 to 2034, and Disneyland Abu Dhabi (*circa 2031), there have been and willl be massive investments in state-of-the-art stadiums, transport infrastructure, accommodation facilities, and urban development initiatives. Machinery companies can seize this opportunities by showcasing their capabilities, investing in advanced training for local workforces, and aligning themselves with the highest global standards of safety, sustainability, and productivity.

Like the home of Disney a century ago, the GCC is entering a Hollywood-like golden era of development and expansion. For the construction machinery sector, the challenge — and significant opportunity — lies in making the most of this momentum to drive long-term sustainable growth and further establish the region as a global benchmark for construction excellence and innovation. It is critical to be doing it all at the highest safety levels possible. The world is watching, and Disney will be nervous.

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM

raz.islam@cpitrademedia.com

+971 4 375 5471

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM

shiyas.kareem@cpitrademedia.com

+971 4 375 5474

PUBLISHING DIRECTOR

ANDY PITOIS

andy.pitois@cpitrademedia.com

+971 4 375 5473

EDITORIAL

HEAD OF CONTENT

STEPHEN WHITE

stephen.white@cpitrademedia.com

+971 58 584 5818

ASSOCIATE EDITOR

PRIYANKA RAINA priyanka.raina@cpitrademedia.com

ADVERTISING

SALES MANAGER

BRIAN FERNANDES

brian.fernandes@cpitrademedia.com

+971 4 375 5479

STUDIO

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

MARKETING & EVENTS EXECUTIVE

LAKSHMY MANOJ lakshmy.manoj@cpitrademedia.com

SOCIAL MEDIA EXECUTIVE FRANZIL DIAS franzil.dias@cpitrademedia.com

CIRCULATION & PRODUCTION

DIRECTOR OF MARKETING & MEDIA OPERATIONS

PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

PRODUCTION & IT SPECIALIST

JARRIS PEDROSO jarris.pedroso@cpitrademedia.com

DIGITAL

SENIOR DIGITAL MANAGER

ABDUL BAEIS abdul.baeis@cpitrademedia.com

WEB DEVELOPER UMAIR KHAN umair.khan@cpitrademedia.com

FOUNDER

DOMINIC DE SOUSA (1959-2015)

PUBLISHED BY

PROPERTY

Sobha Realty launches new mixed-use development

INDUSTRY

ACCIONA Living & Culture completes the design and execution of Pathway to Peace exhibition

CONSTRUCTION

UAQ FTZ and Dubai Land Department sign Landmark Agreement

PROPERTY

Modon launches first townhouses on Hudayriyat Island at Nawayef Village

INFRASTRUCTURE

Saudi’s Roads General Authority unveils updated design guidelines for safer roundabout design

OPINION: Why is Disney building its first park in 15 years in Abu Dhabi?

EXPERTS: Public transport links and the rise of sustainable tourism

EXPERTS: Adaptive architecture is driving a new era of urban luxury living

PROPERTY

Luxe Developers sees increased demand for premium residences with co-working spaces

Research has shown a surge in demand for co-working spaces across the UAE, the market is projected to grow by 43% by 2029

INFRASTRUCTURE

AECOM extends collaboration with Saudi Arabia’s Ministry of Sports

AECOM Hunt will serve as a key consulting partner in the stadium’s transformation and brings extensive expertise managing the construction of sports and entertainment venues

TECHNOLOGY

IMKAN partners with Saal.ai to revolutionise UAE real estate

The collaboration will deliver smarter, faster, and more sustainable living experiences by empowering developers to design intelligently, streamline operations, and make evidence-based decisions

CONSTRUCTION

The Misk Heritage Museum announces start of construction

Upon opening, the museum will showcase a conservation laboratory dedicated to restoring and preserving heritage artifacts and artworks

SUATAINABILITY

Mace survey shows global climate response is largely theoretical

The survey spanning 14 sectors such as architecture and engineering, residential real estate and infrastructure, aimed to gain insights into how asset managers are addressing the global climate challenge

FINANCIAL DHAM

CONSULTANT

GENIE SURE THAT TREX.PARTS CAN DELIVER Genie has appointed TREX. PARTS as its new Genie Authorised Parts Provider in Germany. TREX. PARTS offers a cross-brand, user-friendly online platform destined to supply independent workshops and service technicians with parts for maintenance, service and repair.

HEAVY TRUCKS

UNITED DIESEL AND DAEWOO TRUCKS UNVEIL NEXT GEN TRUCKS

United Diesel has unveiled Daewoo Trucks’ next-generation commercial vehicles at a high-profile event held at Expo City Dubai. The launch introduced the all-new Maximus and Dexen trucks, setting a new benchmark for performance, comfort, and reliability in the UAE’s heavy and medium-duty transport segments.

Hosted at the Connect Conference Center, the event attracted key figures from the construction, logistics, and fleet sectors, alongside regional dignitaries and international executives. Among the VIP attendees were Lee Beom Chan, Consul General of the Republic of Korea in Dubai, Kim Bang-shin, CEO of Daewoo Trucks, Mazen Dalati, CEO of Al Rostamani Group, and David Sawiras, General Manager of United Diesel.

Johnson Arabia has strengthened its fleet with the acquisition of three additional Maeda MC405 spider cranes. Building on an already diverse lineup of spider cranes with varying lifting capacities, this expansion solidifies the leading crane and access equipment rental company’s commitment to delivering unmatched, high-performance lifting solutions across the GCC region, said Johnson Arabia.

The Maeda MC405C-5 spider crane is engineered for high-performance lifting in space-constrained environments. It delivers a maximum lifting capacity of 3.83 tonnes and a maximum working radius of 16.8 meters, which can be extended to 20.7 meters with an optional fly jib. Designed for maximum efficiency in confined spaces where conventional cranes cannot operate, the MC405 also features a pick-and-carry capability

of up to 500 kg. Equipped with advanced safety systems such as a programmable moment limiter and integrated tilt alarm, it provides reliable and precise lifting solutions for urban construction, oil and gas applications, and restricted-access indoor operations.

“This investment in the Spider cranes reinforces our drive to innovate and lead with new solutions,” said Martin Kirby, Managing Director of Johnson Arabia.

He added: “As we continue to expand and adapt in this region, we are committed to collaborating with our partners in UAE and Saudi Arabia to deliver the industry’s most complete and reliable lifting solutions.”

The decision to expand the fleet is driven by the rising demand for compact, high-precision lifting equipment, especially in sectors where space constraints and accuracy are critical.

With its new distributor agreement with Genie, TREX.PARTS is well positioned to provide easy access to Genie parts to a new, expanded customer group, send the access specialist.

Genie parts customers can quickly search and find parts, select the quality they require ; and benefit from high availability of fast-moving parts.

Speaking at the event, Mazen Dalati reaffirmed Al Rostamani Group’s long-standing partnership with Daewoo Trucks and its importance to the UAE’s infrastructure and transportation sectors: “This launch goes beyond the introduction of new models,” Dalati said.

“It reflects our shared commitment with Daewoo Trucks and United Diesel to deliver innovation, reliability, and long-term value to our customers. Together, we are helping shape the future of mobility in the UAE.”

Kim Bang-shin, CEO of Daewoo Trucks, highlighted the brand’s 20-year legacy in the region and its ambition to support evolving transport needs: “With Maximus and Dexen, we’re introducing smarter, safer, and more efficient solutions engineered to perform across the toughest terrain.”

David Sawiras of United Diesel added that the new models are designed with the region’s unique operational requirements in mind.

Yanmar Compact Equipment has appointed Anna Christine Sgro as President of its North American operations, effective April 14, 2025. A seasoned executive with more than 25 years of experience across the construction, equipment, and financial services sectors, Sgro will spearhead efforts to elevate Yanmar CE’s market presence and performance across the region.

In her new role, Sgro will focus on advancing operational integration, strengthening financial outcomes and accelerating customer-centric product and service development. Her appointment signals a strategic move by Yanmar CE to bolster its North American leadership capabilities and drive long-term growth.

Sgro joins the global leadership team of Yanmar CE and will report directly to the company’s Global CEO, José Cuadrado. Her mandate includes reinforcing Yanmar’s reputation for compact equipment innovation while ensuring

continued success for customers and dealers across North America.

“I am honoured to join a company with Yanmar CE’s rich heritage and reputation,” said Sgro. “The values of product quality and innovation that have made Yanmar CE globally respected will remain central to our mission in North America. As always, we will focus on delivering value to our customers and dealers.”

Prior to joining Yanmar, Sgro served as President of Reesink

Walls Construction, a leading Irish builder, has deployed six Raimondi MRT573 flat-top tower cranes from Irish Cranes & Lifting for a landmark mixed-use development in Rathborne, Dublin. These cranes, representing the highest lifting capacities in Irish Cranes’ fleet, will remain onsite until project completion in approximately two years. Chosen specifically for their superior tip load performance and suitability for demanding precast projects, the MRT573-24t cranes have been instrumental in construction operations. Originally launched at Bauma 2019, the MRT573’s success paved the way for Raimondi’s latest model, the T577, introduced recently at The Big5 Construct Saudi Arabia in February 2025.

Canada Holdings, where she oversaw strategic growth initiatives in the agriculture, construction and complementary equipment sectors. Her earlier career includes leadership roles at major organisations such as Volvo Financial Services, Volvo Construction Equipment, Strongco Equipment, Ritchie Bros., and the Global Caterpillar Alliance. Cuadrado welcomed the appointment, noting, “North America is a vital driver of our global business, and I am confident that under Anna’s leadership, Yanmar CE will have a positive catalyst for change, supporting the interests of customers, dealers, suppliers, employees and the wider community.”

Sgro holds a degree in Economics with a minor in Political Science from York University, Toronto, and has completed post-graduate studies at the Kellogg School of Management, Northwestern University in the United States.

JLG Industries, Inc., one of the access industry’s leading global manufacturers of mobile elevating work platforms and telehandlers, says the appointment of a new parts and service manager in Middle East, Africa and India (MEAI) region strengthen its aftermarket leadership in the market.

The appointment of Ibraiz Ahmed has been appointed District Manager Parts & Service – MEAI, effective immediately, is described as a leadership appointment which enhances customer support and drives sustainable growth.

With over 13 years of experience at JLG, Ahmed has built a strong reputation in the region for his customer-first mindset and in-depth expertise in aftermarket operations. In his new role, he will lead the aftermarket strategy across MEAI with responsibility for driving parts and service performance.

Al-Bahar, the authorised Cat dealer in the UAE, Oman, Qatar, Kuwait, and Bahrain, has officially launched its local edition of the prestigious Global Operator Challenge, inviting some of the region’s most skilled heavy equipment operators to compete in a series of precision-based trials across three key locations.

As part of Caterpillar’s international competition, AlBahar’s Dealer level Challenge was hosted across its regional business centres in Abu Dhabi, Sharjah, and Muscat respectively. The event determines which top-performing operators will go on to represent the dealer in the

regional qualifiers later this year.

“Al-Bahar is committed to supporting our customers and recognizing their exceptional talent,” said Khaldoon Issa, Product

Rapid Access has officially inaugurated its new regional headquarters as part of a strategic move to reinforce its commitment to safety, innovation, customer service, and operational excellence.

The market leader in powered access solutions in the Middle East, Rapid Access is a subsidiary of Europe’s largest equipment rental provider, Loxam Group.

The new facility will enable it to play a key role in expanding the group’s footprint across the Middle East and serve as a central hub to support operations across multiple countries. With over 25 years in the business, Rapid Access leads the powered access rental market in the region while

offering a comprehensive fleet of boom lifts, scissor lifts, and specialty access equipment.

The new facility is intended to strengthen the company’s ability to serve core sectors such as construction, aviation, oil & gas, events, and infrastructure, while “supporting its forwardlooking approach to fleet management, technical support, and safety-focused training”.

It will also support the rental operation’s “forwardlooking approach to fleet management, technical support, and safety-focused training”.

“Loxam’s strong global foundation empowers us to grow with confidence in the Middle East.”

Manager, at Al-Bahar. “The Global Operator Challenge provides a platform for these operators to showcase their skills and demonstrate the critical role they

play in the industry. We are excited to witness their performance and celebrate their achievements.”

The competition tests participants on their ability to operate Cat machines such as wheel loaders, hydraulic excavators, and backhoe loaders.

Tasks are designed to evaluate speed, precision, and strict adherence to safety protocols.

Winners of the local challenges will progress to the next stage of the Caterpillar Global Operator Challenge, where regional champions will compete for a place in the global finals, bringing international recognition to their operating excellence.

Sinoboom Intelligent Equipment has launched a striking new global paint scheme, officially unveiled at the CICEE 2025 exhibition on 15 May in Changsha. Held at the company’s booth at 10:30 a.m., the unveiling was witnessed by industry leaders, experts, customers, and media, heralding what Sinoboom described as a symbolic new chapter in its commitment to innovation, safety, and customercentric manufacturing.

The refreshed global coating — dubbed “Red Flame Reborn” — blends bold aesthetics with technical excellence, with Sinoboom stating that the new colours encapsulate the spirit of its evolving brand.

The new paint scheme features two primary colours: “Star Flame Red” (RAL 2002) and “Star Shield Green” (RAL 6012). The vibrant red pays homage to the

brand’s origins, using an upgraded version of the company’s signature shade applied with automotivegrade coating technology for enhanced durability and gloss.

Meanwhile, the deep green offers a modern contrast, representing Sinoboom’s emphasis on industrial safety.

“This is not only a colour renewal, but also an embodiment of our brand values and a tangible presentation of the ‘customercentric’ concept,” explained Susan Xu, General Manager of Sinoboom.

“Red symbolises our original aspiration and heritage, while green defines innovation and the future.”

Reinforcing the piers that support a major UK rail viaduct spanning a river estuary is no easy task, which is exactly why the specialist marine subcontractor appointed to undertake this project approached Hoist & Winch Ltd for the optimal lifting solution. The brief provided to Hoist & Winch was for the supply of a turnkey lifting solution comprising two sets of four hoist units suitable for a marine environment. These hoists were to be suspended from temporary scaffold structures fixed to two separate motorised floating pontoons.

Hoist-mounted pontoons serve to locate special horseshoe-shaped reinforcing concrete collars either side of one of the bridge piers at high tide, prior to joining the collar halves together above the water with connection pins. Finally, the collar halves would require lowering to the river estuary bed for permanent fixing to the piers with concrete

at low tide, thus providing the necessary reinforcement.

To establish the optimal package of hire equipment, as well as site installation, load testing and additional technical support services, Hoist & Winch consulted extensively with both the motorised pontoon designers and installation personnel responsible for lowering the special concrete collars into position.

After reviewing all the information from project stakeholders, Hoist & Winch subsequently proposed eight JDN top-hook suspension air-powered hoist. Each of these Profi 3Ti 3t swl (safe working load) hoists featured its own heavy-duty steel lubricator coupled with appropriately sized air supply hoses. The two sets of four hoists units would be operated from their own individually connected, heavy-duty (brass) two-button pendant control.

In order to monitor the load applied to each hoist unit and assist with delivering a balanced collar

lowering procedure, Hoist & Winch also provided eight telemetry load cells of bow-shackle design. These load cells served to connect each hoist unit to its local scaffold anchor support position, transmitting individual hoist load data via radio signal to a central laptop display. Armed with this data, the appointed person directing lifting operations could instruct each hoist operator accordingly to ensure the load was evenly distributed between each set of four hoists and that each collar was lowered into position while remaining level.

Hoist & Winch carried out the installation of the eight air-powered hoist units. This work included pre-use inspection, static load/ deflection testing, and LOLER (Lifting Operations and Lifting Equipment Regulations) certification of the temporary scaffold structure and complete hoisting system.

Hoist & Winch also provided technical consultancy as part of the overall package, delivering

guidance on important project areas such as lifting equipment legislation, lifting operation planning and management, and specification and procurement of the portable diesel-powered air compressors to power the hoist units. In addition, the company delivered full handover training for operators. Both the specialist marine subcontractor and end client were extremely pleased with the final outcome, which saw the successful installation of two sets of trial pier-reinforcing concrete collars to the viaduct as part of a safe and controlled process.

“This specialist project demanded the application of our expertise and experience to ensure a successful conclusion in line with the appropriate safety standards and high performance levels demanded by our client,” says Andy Allen, Director of Hoist & Winch Ltd. “We worked closely with project stakeholders to ensure the delivery of a robustly engineered lifting solution with precision control.”

Kanoo Cranes lifting requirements with knowledgeable

Kanoo Cranes offers engineered solutions for any lifting requirements with knowledgeable experts engaged in the field of lifting. With a combined experience of more than 50 years with Mobile cranes, Crawler cranes, Tower cranes and passenger hoists we offer top quality products from:

combined experience of more than 50 years with Mobile cranes,Crawler cranes, Tower cranes and

Our Focus is to provide engineered crane solutions to the Construction, Oil and Gas and Industrial markets.

• SMIE-Anti collision

• JASO

• SPIERINGS

• MAEDA

Our Focus is to provide engineered c the Construction, Oil and Gas and

AN EXCLUSIVE INTERVIEW WITH AYMAN AHMED, CEO OF BUKHATIR

Established over half a century ago, German Gulf Enterprises (GGE) has etched a remarkable legacy in the UAE’s industrial landscape. Under the visionary leadership of CEO Ayman Ahmed, the company continues to thrive, redefining benchmarks across the construction and industrial sectors. We sat down with Ayman to discuss GGE’s journey, evolving strategies, and ambitious plans for the future.

Founded in 1974 by Mr. Abdelrahman Bukhatir, GGE began by representing renowned brands

such as Putzmeister and Liebherr. Today, the company represents over 100 global brands across construction equipment, industrial supplies, welding solutions, and hydraulics, with a solid presence through strategically placed branches in Sharjah, Dubai Industrial Park (DIP), Sajaa, and Abu Dhabi.

Over the decades, German Gulf Enterprises (GGE) has consistently demonstrated agility in aligning its strategies with shifting market demands.

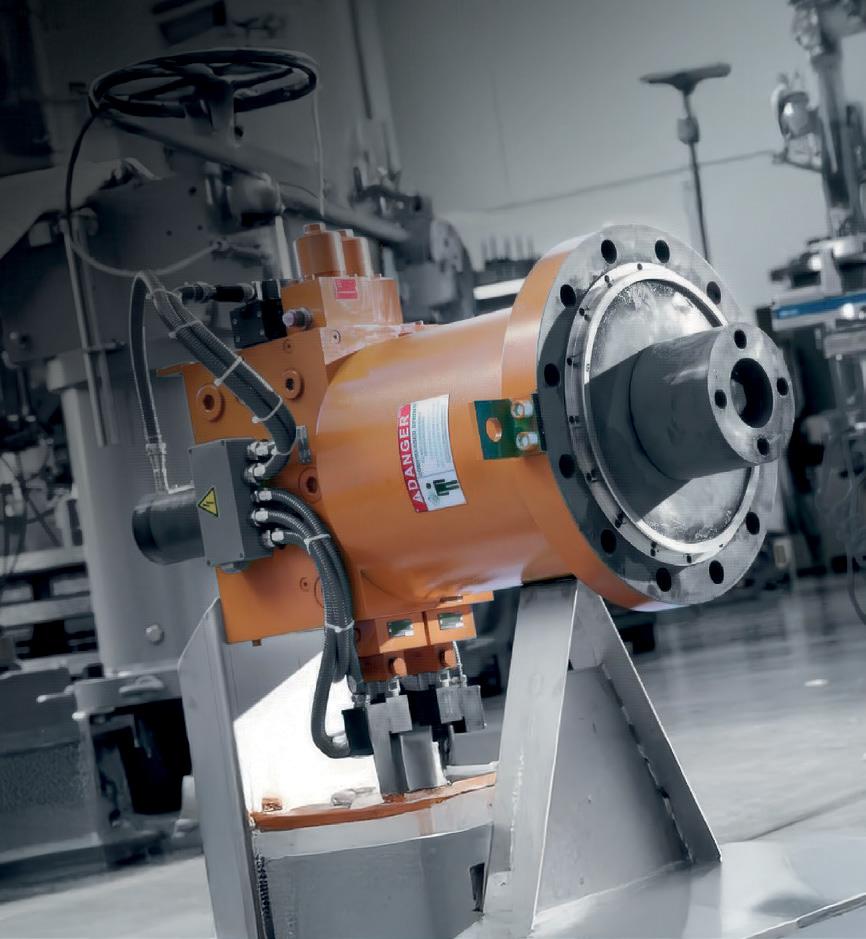

“As the authorised distributor for premier hydraulic brands including Bosch Rexroth, Danfoss, and Hydac, we leverage cutting-edge technologies to meet evolving industry needs.”

“Our commitment to portfolio expansion

ensures we stay ahead of market demands. In 2020, we added DEVELON – a game-changing partnership that drove remarkable growth, with our machines population expanding rapidly within just four years. Building on this momentum, 2023 saw the introduction of GEHL telehandlers, backhoe loaders, and skid steer loaders, along with EP Equipment for warehouse and material handling solutions.

“By continuously strengthening our brand partnerships and adapting to industry needs, German Gulf Enterprises maintains its leadership position, delivering unmatched value to clients and reinforcing our reputation for excellence,” notes Ayman.

GGE has also earned a reputation for resilience which is evident through a series of strategic shifts such as those prompted by the COVID-19 pandemic, which required rapid realignment within its Hydraulics division. As a consequence, the firm has learned the value of pivoting its focus towards high-growth sectors like oil and gas, marine, and energy. GGE’s ability to form strong and lasting collaborations across the industry have facilitated a smooth transition, Ayman tells CMME

“Over the decades, German Gulf Enterprises (GGE) has consistently demonstrated agility in aligning its strategies with shifting market demands,” he explains.

“One of the most significant recent milestones was our response to the COVID-19 pandemic, which prompted a strategic realignment within our Hydraulics division. Recognising changing dynamics, we shifted focus from construction to highgrowth sectors like oil and gas, marine, and energy. Supported by our partnerships with these industry-leading brands, this transition not only ensured business continuity but also reinforced GGE’s commitment to innovation and resilience in a rapidly changing economic landscape.”

For Ayman, maintaining longterm customer relationships remains paramount. GGE achieves this by continually aligning its product and service offerings with evolving client needs.

“We always nurture long-term relationships with our valued customers. Our approach centers on continuously enhancing these partnerships by attentively addressing their evolving needs. We achieve this through strategic expansion of our portfolio, incorporating only the highest quality products and services,” he says. “By maintaining this customer-centric focus, we have consistently strengthened trust and loyalty while positioning ourselves as a reliable industry partner dedicated to mutual growth and success.”

The company continues to expand its portfolio, and the recent addition of brands like DEVELON and GEHL are significantly broadening its capabilities and impact in the market: “Our recent partnership with GEHL, has already made a significant impact on our Construction Equipment Division’s capabilities. This collaboration has enabled us to rapidly expand our product portfolio to include backhoe loaders, telehandlers, skid steers, and track loaders - moving us closer to our goal of

becoming a complete one-stop solution for construction equipment needs.”

With the addition of GEHL’s extensive legacy and diverse range, GGE’ has been able to rapidly bolstered its offering with the company now positioned as a comprehensive one-stop solution for our customers’ varied needs.

“While relatively new in this market, GEHL’s 166-year legacy in the industry brings immediate credibility to our offerings and enhances our ability to serve diverse customer requirements. We view this as a

strategic, forward-looking partnership that complements our existing strengths and accelerates our growth in the sector.”

Also accelerating its growth is GGE’s recent ERP upgrades and the adoption of AI technologies which have are helping the company to reach new levels of enhanced operational efficiency.

“At German Gulf Enterprises, we are actively embracing digital transformation to drive operational excellence and business growth,” Ayman explains. “We have implemented cutting-edge ERP system upgrades and are strategically incorporating AI technologies across our operations. These technological advancements enhance our market intelligence, strengthen customer engagement through data-driven insights, and optimise operational costs. Our digital initiatives are carefully designed to improve decision-making, increase efficiency, and maintain our competitive edge in an evolving marketplace: “Integrating cuttingedge digital solutions enables informed decision-making and cost optimisation,” he says. “This ensures we remain competitive and future-ready.”

Ayman emphasises that GGE’s dedication to constant improvement extends beyond the sales experience through robust aftersales service structured around expert teams, mobile solutions, and competitive annual maintenance contracts.

“Ensuring operational continuity for our clients is non-negotiable,” Ahmed remarks. “We invest significantly in service excellence, thereby strengthening client trust.”

The company is also investing heavily into environmental responsibility, GGE powers its operations with solar energy, significantly reducing its carbon footprint. The strategic commitment to sustainability at GGE is aligning with broader national clean energy goals, Ayman explains. “It reflects our responsibility towards a greener future. We are committed to

environmentally responsible operations. A cornerstone of our sustainability strategy is the integration of renewable energy across our facilities. We are proud to power our operations with solar energy, significantly reducing our carbon footprint while maintaining operational efficiency. This initiative reflects our dedication to sustainable business practices and contributes to the UAE’s broader clean energy objectives.”

Ayman outlines a strategic vision focused on customer-centric growth,

geographical expansion into Saudi Arabia, and enhanced partnerships.

“Our strategy ensures sustained leadership and innovation,” Ayman asserts. “We are deeply committed to expanding our regional footprint and fortifying existing partnerships.”

Investing in People too Ahmed strongly believes in workforce development through continuous learning and recognition programs, such as the Bukhatir Group’s annual Taqdeer Awards.

“Our employees are our greatest asset,” Ayman emphasises. “We foster a learning culture and celebrate individual achievements, which fuels our collective success.”

Concluding the interview, Ayman emphasises GGE’s dedication to its stakeholders: “To our valued customers, your trust inspires our continuous improvement. To our team, your dedication drives our achievements. To our partners, we are committed to mutual growth and innovation. Together, we will build an even stronger future.”

Through strong leadership and with strategic innovation at its core, German Gulf Enterprises under CEO Ayman Ahmed continues to lead, inspire, and grow — setting industry standards for the market to follow.

Abu Dhabi is set to become the home of Disney’s seventh global theme park resort, following a landmark agreement between The Walt Disney Company and Miral, the UAE capital’s leading creator of immersive destinations and experiences.

The new waterfront resort, to be developed on Yas Island, will bring Disney’s iconic stories, characters, and attractions to one of the world’s fastest-growing cultural and leisure tourism hubs.

Announced in the presence of His Highness Sheikh Khaled bin Mohamed bin Zayed Al Nahyan, Crown Prince of Abu Dhabi and Chairman of the Abu Dhabi Executive Council, the project reflects the emirate’s strategic focus on building a diversified, creative economy. His Highness underscored that the Disney theme park aligns with national efforts to boost GDP growth through cultural and entertainment investments, in line with the UAE’s National Strategy for Cultural and Creative Industries.

The project will be fully funded and built by Miral, while Disney’s legendary Imagineers will lead the creative design and maintain operational oversight to ensure the delivery of an authentic Disney experience. Once completed, Miral will operate the resort, building on its proven track record of partnerships with global brands on Yas Island.

“This is an extraordinary opportunity for Disney to bring its renowned storytelling

to yet another region of the world with a completely new theme park experience that will be a cultural, entertainment, and technological marvel,” said Bob Iger, Chief Executive Officer, The Walt Disney Company. “Abu Dhabi’s position as an international crossroads, its embrace of global culture, and its ambitious vision for the future make it a perfect location for Disney to reach millions of new families and captivate guests for generations to come.”

With more than 120 million annual passengers transiting through Abu Dhabi and Dubai, and one-third of the world’s population living within a four-hour flight, the UAE represents a major gateway to global tourism. Yas Island, already home to Warner Bros. World Abu Dhabi, Ferrari World, SeaWorld Abu Dhabi, and other major attractions, is now poised to host what many see as its crown jewel.

“This is a thrilling moment for our company,” added Josh D’Amaro, Chairman of Disney Experiences. “The concept for this resort will push the boundaries of theme park design, showcasing groundbreaking technology and visionary architecture — including a modern castle unlike anything we’ve ever created. The location, anchored by a beautiful waterfront, will allow us to tell our stories in completely new ways and reach families in a part of the world where we’ve previously had only a limited presence.”

D’Amaro also noted that the Abu Dhabi resort will become the most advanced and interactive destination in Disney’s global portfolio. The park is expected to

No specific opening date has been confirmed, but with design work already underway and construction expected to follow soon, the resort is anticipated to open in the early 2030s.

“The concept for this resort will push the boundaries of theme park design, showcasing groundbreaking technology and visionary architecture — including a modern castle unlike anything we’ve ever created”

incorporate cutting-edge technologies and digital storytelling methods, in keeping with Disney’s evolving approach to immersive entertainment and guest engagement.

From Abu Dhabi’s side, the partnership is seen as a major endorsement of the emirate’s cultural and tourism ambitions. His Excellency Mohamed Khalifa Al Mubarak, Chairman of Miral and the Department of Culture and Tourism – Abu Dhabi, said: “Abu Dhabi stands as a unique model where authentic heritage meets a bold vision for the future, where we preserve our past while laying solid foundations for a promising tomorrow. The collaboration between Abu Dhabi and Disney demonstrates the remarkable results of combining visionary leadership and creative excellence.

“What we are creating with Disney in Abu Dhabi is a whole new world of imagination — an experience that will inspire generations across the region and the world, creating magical moments and memories that families will treasure forever. Through the development of unique attractions and experiences, Abu Dhabi continues to reinforce its position as a leading global

destination for cultural and family tourism.”

Mohamed Abdalla Al Zaabi, Group CEO of Miral, added: ““Bringing a Disney theme park resort to Yas Island marks a historic milestone in our journey to further advance the island’s position as a global destination for exceptional entertainment and leisure.

“Together, we are creating a place of boundless innovation, where the vision of our leadership continues to inspire the world.”

The development of unique experiences will support sustained economic growth in Abu Dhabi and beyond.

Upon completion, the resort will feature signature Disney entertainment, themed accommodation, retail and dining, and immersive storytelling experiences designed to reflect both Disney’s heritage and Abu Dhabi’s futuristic architectural and cultural identity.

No specific opening date has been confirmed, but with design work already underway and construction expected to follow soon, the resort is anticipated to open in the early 2030s.

In a move hailed as both strategic and symbolic, and the end to years of anticipation

for many fans of the house of mouse, The Walt Disney Company has announced plans to build a brand-new Disneyland theme park and resort in Abu Dhabi, marking the seventh global Disney destination — and the first new Disney park in over 15 years. With construction expected to begin within the next few years and an opening slated for the early 2030s, the project represents a bold new chapter for Disney and a defining moment in Abu Dhabi’s rise as a global cultural and tourism powerhouse.

Speaking to CNBC, Disney CEO Bob Iger and Josh D’Amaro, Chairman of Disney Experiences, outlined the rationale behind selecting the UAE capital. “This, in many respects, is the crossroads of the world,” said Iger. “About 500 million people who are income qualified to visit our parks live within a four-hour flight of Abu Dhabi.”

That staggering accessibility is supported by projections that 39 million tourists will visit Abu Dhabi by 2030 — many of them passing through its international airport alongside neighbouring Dubai.

Crucially, Abu Dhabi offers more than geography. According to Iger, “They’ve shown a great interest in the arts and creativity… and most importantly, they love Disney.”

The emirate’s cultural ambition is evident in developments like the Saadiyat Cultural District and the successful hosting of global events such as Formula One and the NBA.

Mohammed Al Mubarak, the chairman of Miral — the Abu Dhabi-based developer leading the project alongside Disney — has played a pivotal role in shaping the city’s cultural landscape.

“The earliest happy memory I have is visiting Disney World with my mother and siblings,” he told CNN’s Becky Anderson. “That memory didn’t just create a fan — it created an emotional connection with the brand.”

For Disney, the Abu Dhabi project is more than just an expansion; it’s a testbed for the future of themed entertainment. D’Amaro highlighted that Imagineers and R&D teams are already involved, working on advanced technologies that will “push the envelope on creativity.”

The project will fully integrate Disney’s latest strategies around gamification and immersive digital experiences. Guests may earn points or unlock rewards starting from their hotel booking, with these digital experiences continuing seamlessly into the park.

“We’re thinking about how games and interactivity can interplay with the actual park experience,” said D’Amaro, referencing Disney’s $1.5 billion investment in Epic Games and the potential of virtual environments like Fortnite. Visitors could, for instance, take part in a Disney multiverse adventure online and then see it brought to life inside the park.

“Gen Alpha is gathering in digital spaces to play, socialize, and explore,” D’Amaro explained. “We’re building from the ground up with that in mind — where digital and physical storytelling are deeply intertwined.”

This Disney park will be unlike most of its predecessors in terms of structure and

financing. Miral will fully fund the development and construction, while Disney will retain full control over creative and operational direction. The agreement is a variation of the successful Tokyo Disney model, where local partners own the property while Disney steers content and brand experience.

“It’s royalty-based,” D’Amaro confirmed.

“It gives us access to a new audience, allows us to expand without diverting capital from our $30 billion expansion plans in the US, and lets us maintain creative and operational oversight.”

Iger added that this structure aligns perfectly with Disney’s broader ambitions.

“We’ve only superficially reached this region before,” he said. “Now we’ll be putting a Disney park right in the backyard of a whole new consumer base.”

For Abu Dhabi, welcoming Disney is more than a commercial win — it’s a cultural milestone. As Al Mubarak explained, “Disney

is the crown jewel of what we are trying to create here at Yas Island.” Yet he was quick to note that it’s not the end of the journey: “We continuously innovate. We’re always going to find ways to bring more people to experience our collective.”

Abu Dhabi’s focus on long-term, sustainable tourism development plays a vital role in its appeal. The emirate offers a strategic geographic hub—within reach of Asia, Europe, and Africa—and an increasingly sophisticated infrastructure. “We’re four hours away from a third of the world’s population,” Al Mubarak emphasised.

What’s more, both Disney and Miral see a strong alignment between their visions of the future. “Abu Dhabi has a lean toward technology and a futuristic view of what society can look like,” said D’Amaro. “That matches Disney’s forward-thinking approach to immersive storytelling.”

The Abu Dhabi park is expected to serve as a cultural touchstone and economic engine. According to Iger, similar expansions in Tokyo, Shanghai, and Paris have significantly boosted the brand across entire regions. The Abu Dhabi project aims to replicate that success in a market previously underserved by Disney’s physical presence.

The resort is still in its design phase, and no final opening date has been confirmed. But D’Amaro assured that the ambition is high: “We’re going to build this big, and we’re going to build it right. We’re not pinning down a date yet. It typically takes us between 18 months and two years to design and fully develop and approximately five years to build.”

10 - 13 November 2025 / Dhahran Expo, KSA

z Make connections, expand your network and relationships, generate leads, elevate sales, grow your footprint with endless opportunities.

z Reach your target audience, engage with industry professionals, influencers, decision makers and highlight your products and services Explore the industry of construction equipment and commercial vehicles building the kingdom

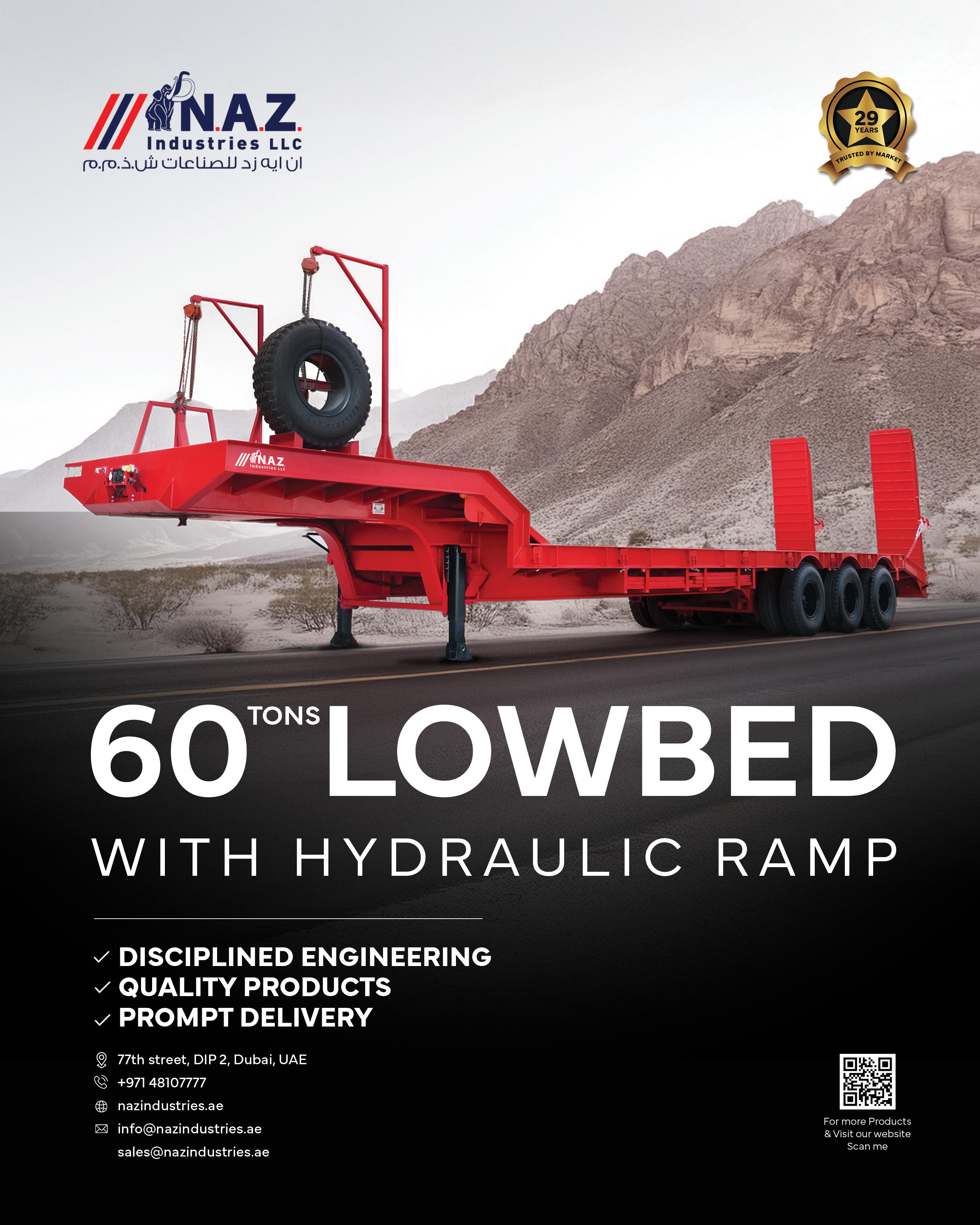

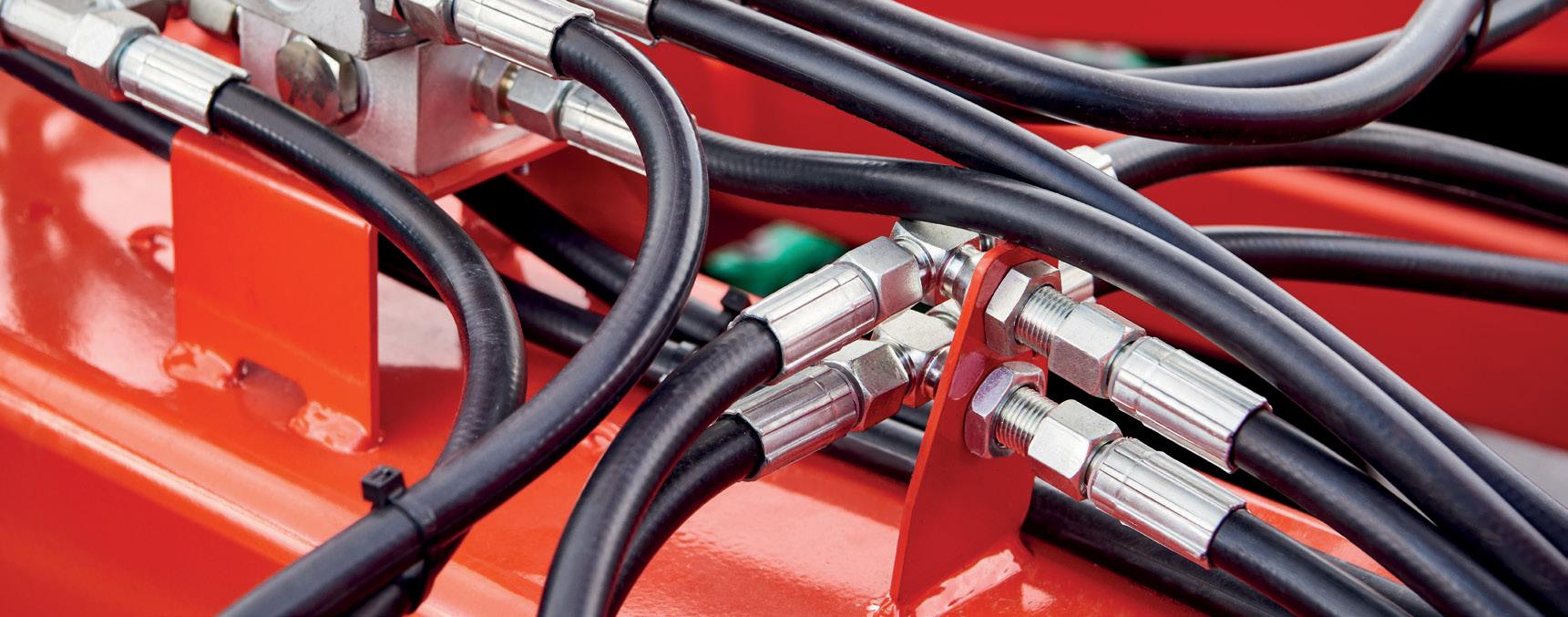

GARGASH GENERAL TRADING EXPLAINS HOW LIUGONG’S RANGE OF ELECTRIC WHEEL LOADERS ARE JUST AS CAPABLE AS THEIR DIESEL PEERS

As the global construction industry increasingly moves towards sustainability, electrification of machinery has emerged as a viable and necessary solution. Gargash General Trading, a prominent distributor for LiuGong machinery in the UAE, explains how LiuGong’s electric wheel loaders match and, in some cases, exceed their diesel counterparts in performance and productivity.

LiuGong, recognised worldwide for its innovation in electrifying heavy machinery, offers a broad electric portfolio including wheel loaders, excavators, dump trucks, skid steer loaders, and notably, the world’s first fully electric motor grader. Gargash General Trading highlights LiuGong’s electric wheel loaders as especially impactful in the Middle Eastern market.

The LiuGong electric wheel loader design stands apart by delivering superior efficiency, reduced cycle times, and significantly lower total ownership costs compared to diesel-powered loaders. According to Gargash, these electric wheel loaders are fully capable of handling the same demanding applications as conventional models. Particularly suited for stationary plant applications, where consistent grid power ensures maximum uptime, these machines thrive even in the region’s challenging extreme heat and dust.

Gargash outlines that the electric wheel loader comes with two Lithium-Ion battery options: a 350kWh battery designed for light to medium-duty tasks, and a more powerful 423kWh option tailored for heavierduty applications. A full charge enables operation that comfortably aligns with the region’s typical shift durations. To accommodate diverse operational demands, Gargash advises overnight charging using a 40kW DC charger, taking approximately 8-10 hours from a 20% state of charge. Alternatively, for demanding scenarios involving extended shifts, more powerful chargers (240-300 kWh) can replenish the battery fully within just 1.5-2 hours.

tailored smart energy solutions, including offgrid mobile chargers and battery storage systems combined with renewable sources such as solar power. These solutions help customers maximise uptime and confidently transition to electric machinery.

Looking forward, Gargash envisions government regulation as pivotal in driving the broader adoption of electric construction machinery, similar to existing electric vehicle policies. By mandating a portion of fleets to be electric, the UAE could accelerate the shift towards more sustainable construction practices, demonstrating clear operational benefits over diesel machinery.

The future is electric

Gargash General Trading views electric machinery not merely as a niche offering but as the future standard across construction equipment. As electrification rapidly becomes mainstream, Gargash’s early investment positions the company to lead market transformation.

240-300 kWh chargers can fully charge the battery within 2 hours

All LiuGong electric machinery features builtin telematics and connects seamlessly with the LiuGong iLink fleet management system, offered free of charge. This platform provides detailed insights into productivity, energy consumption, battery state of charge (SOC), and overall battery performance, enabling efficient fleet management and proactive maintenance strategies.

The demand for electric construction machinery is accelerating notably in sectors like readymix concrete, quarrying, mining, and oil & gas. These industries which typically run extended shifts and intensive usage patterns, are swiftly recognising the economic advantages of electric equipment through substantial fuel and maintenance savings.

Addressing common concerns such as range anxiety and power availability, Gargash provides

In anticipation of increased electric equipment usage, Gargash is adapting its aftersales service capabilities. Technicians receive specialised training and tools from LiuGong, ensuring dedicated and expert support for electric equipment. Spare parts commonality with diesel-powered counterparts simplifies inventory management, while dedicated electric vehicle service hubs and specialised mobile units further strengthen field support. Customers investing in LiuGong electric wheel loaders benefit from comprehensive warranty packages comparable to traditional models but enhanced with a standard 5-year battery warranty. Moreover, maintenance costs are projected to be approximately 40% lower than diesel-powered loaders, and Gargash provides extensive service packages, annual maintenance contracts (AMCs), extended warranty programs, and reliable spare parts supply to ensure maximum customer satisfaction and minimal downtime.

Through innovative design, strategic infrastructure, and strong aftersales support, LiuGong’s electric wheel loaders delivered by Gargash General Trading represent a practical and economically advantageous solution, paving the way toward a sustainable construction future in the UAE and beyond.

As Gargash General Trading tells CMME: “The whole world is moving in a very fast pace towards electrification, and what we looked at as niche a couple of years ago is now part of our daily life, and we expect an increase in demand in the next few years from the market for electric machines. Being an early comer in the market with such solutions would help us setup the base foundation and ensures that we shall be the preferred supplier for these products.”

In the heart of Saudi Arabia’s sweeping transformation lies a singular ambition: to honor the Kingdom’s deep-rooted heritage while building a future shaped by innovation, culture, and sustainability. As part of the Vision 2030 framework, the Diriyah Gate Development represents one of the nation’s most ambitious and culturally significant projects.

Set against the historical backdrop of At-Turaif, the birthplace of the Saudi state, Diriyah is being revitalized not just as a symbol of national pride, but as a thriving cultural and lifestyle destination of global standing.

At the core of this development is Diriyah Gate Phase II (DGII), a key component of the broader Diriyah Gate initiative. Encompassing expansive

infrastructure upgrades, heritage preservation, and vibrant mixed-use developments, DGII is an architectural and cultural statement that blends tradition with modernity. As the groundwork for this monumental phase progresses, precision, safety, and innovation are essential. This is where Tesmec Saudi plays a critical role.

Through their advanced subsurface surveying capabilities, the company is ensuring that the foundations of Diriyah Gate are mapped with unparalleled accuracy—laying the path for a safer, smarter, and more sustainable development.

The Diriyah Gate project

Diriyah Gate Phase II (DGII) is a central component of Saudi Arabia’s Vision 2030, aiming to transform Diriyah—birthplace of the Saudi state and home to

the UNESCO-listed At-Turaif district—into a global cultural and lifestyle destination. Located just northwest of Riyadh, the project blends heritage preservation with modern urban development, restoring historic Najdi architecture while introducing luxury, education, and infrastructure enhancements.

The development features Diriyah Square, a mixed-use urban hub with over 400 commercial brands, more than 40 hotels, and 300 branded residences. It also includes major cultural and educational institutions like King Salman University and the House of Saud Museum, emphasizing heritage and future learning.

Sustainability is a core priority, with climateresilient infrastructure, green spaces, and energyefficient systems integrated into the design. The DGII project is backed by the Public Investment

Fund and managed by the Diriyah Gate Development Authority (DGDA).

Once completed, DGII is expected to host over 50 million visitors annually, accommodate 100,000 residents, and generate approximately 178,000 direct jobs. It represents a significant step in diversifying the Kingdom’s economy and positioning Diriyah as a world-class tourism and cultural hub.

Tesmec Saudi’s solution

Within this remarkable transformation, the company brings its unique expertise to the forefront. Specializing in technical services for infrastructure and environmental engineering, the company offers advanced surveying solutions that are crucial during the planning and construction phases of major developments. In October 2024, Tesmec Saudi entered into a strategic partnership with AICC to deliver comprehensive utility identification surveys for DGII. The objective of this partnership is to map and reconstruct the underground utility network of the DGII Infrapackage01, 02, 03 and KSU covering a total area of over 6.2 million square meters.

This task requires more than traditional surveying methods. Tesmec Saudi utilizes cutting-edge ground-penetrating radar (GPR) technology to detect and document subsurface utilities with precision. Their advanced system, the Georadar Explorer 3.0, represents a new era in non-invasive surveying. This system allows to identify underground utilities accurately, reducing the risk of accidental damage during excavation and infrastructure installation. By providing highly accurate underground mapping, Tesmec Saudi is supporting the integrity and efficiency of the entire development process. Their work ensures that the construction of roads, buildings, utilities, and green spaces can proceed safely and on schedule, without unforeseen interruptions caused by uncharted subsurface conditions. This level of foresight is particularly crucial in a project of DGII’s scale and cultural sensitivity.

Tesmec Explorer 3.0

The Explorer 3.0 represents the company’s most advanced Ground Penetrating Radar (GPR) system to date. Designed for both preconstruction surveying and real-time utility detection, this system is a cornerstone of modern infrastructure safety and precision. Engineered for operational flexibility, the Explorer 3.0 supports both vehicle-pulled and hand-pushed configurations, making it adaptable to varying environments and

project needs. With all electronics housed within the antenna box and stabilized via secure bracket locks, the system is highly durable and user-friendly in the field.

The Explorer 3.0 helps mitigate the risk of striking unknown underground assets, which not only ensures the safety of construction workers but also prevents costly project delays and service disruptions. This technology offers significant financial and environmental advantages by minimizing the need for invasive exploration digging. The result is a reduced environmental footprint, fewer traffic disruptions, and a smoother development process overall. Moreover, with digital interfaces, survey data can be visualized and analyzed in real time, enabling faster decision-making and

Tesmec Saudi was tasked with mapping and reconstructing the underground utility network of the DGII Infrapackage - 01, 02, 03 and KSU covering a total area of over 6.2mn sqm.

coordination among project stakeholders. By reducing the risk of costly mistakes and facilitating efficient planning, Tesmec Saudi’s GPR solution supports the larger goal of developing intelligent, connected cities. This is especially vital for developments like Diriyah Gate, where preserving heritage, minimizing disruptions, and meeting ambitious construction timelines are all imperative. Explorer 3.0 is not just a tool — it’s a technological partner in nation-building, and a key enabler of the sustainable infrastructure that Saudi Arabia envisions for its future.

Tesmec Saudi contributes to Saudi Arabia Vision 2023

The work being done at Diriyah Gate Phase II is emblematic of Saudi Arabia’s future: bold, rooted in identity, and powered by innovation. As the Kingdom transforms its historic landscape into a dynamic urban marvel, Tesmec Saudi plays a vital role in making that vision a reality. Their efforts beneath the surface ensure that what rises above will stand strong, safe, and enduring. From the ancient walls of At-Turaif to the smart infrastructure of tomorrow, Tesmec Saudi is laying the invisible yet indispensable groundwork of progress. As the Kingdom forges ahead on its journey of cultural and economic transformation, partnerships like these exemplify the power of collaboration between visionary governance and specialized private sector expertise. Tesmec Saudi is honored to be part of this national endeavor, contributing to a project that not only honors Saudi Arabia’s past but also shapes its future.

With more than 30 years in the business, Blumaq has quietly established itself as a global leader in spare parts for construction, mining, and earthmoving equipment. Known for pairing quality and speed with deep technical expertise, the Spain-based company is increasingly active in high-demand regions like the Middle East.

In this interview with Construction Machinery Middle East, Juan Manuel Buils, Marketing Manager at Blumaq, explains how the company is adapting to the evolving needs of fleet operators— and why the future of the aftermarket has never looked more essential.

For readers unfamiliar with Blumaq, could you provide a brief overview of the company’s history and its core business in the heavy machinery aftermarket?

Blumaq was founded in 1992 with a clear vision: to provide a reliable, high-quality alternative for spare parts and maintenance products in the heavy machinery aftermarket. Over three decades, we have grown from a local supplier to a global leader, offering more than 100,000 part numbers for construction, mining, and earthmoving equipment. Our core business revolves around delivering high-quality, fully compatible spare parts and components, coupled with exceptional service. Blumaq has become synonymous with efficiency, reliability, and a deep understanding of the operational demands our clients face.

Blumaq has a strong international presence. What does your current footprint look like

in the Middle East and how important is this region to your global operations?

The Middle East is a strategic region for Blumaq, not only due to its robust mining and construction sectors but also because of the unique challenges operators face there, such as extreme temperatures and demanding work cycles. We maintain an active presence through regional distribution partners and direct client relationships, ensuring fast delivery and localised technical support. The Middle East continues to be a growth market for us, aligning with our global strategy to provide comprehensive aftermarket solutions wherever heavy equipment operates.

What distinguishes Blumaq from other spare parts suppliers in the heavy equipment sector— particularly in terms of quality, speed, or service? What truly sets Blumaq apart is our unwavering commitment to quality, speed, and customercentric service. We combine OEM-level quality with competitive pricing, offering a vast inventory ready for immediate dispatch. Our logistics network ensures rapid delivery worldwide, minimising downtime for our clients. Moreover, our technical expertise and personalised customer service provide solutions that go beyond parts supply—we help our clients maintain productivity and extend the life of their equipment.

What types of machinery or OEM brands does Blumaq primarily support with its spare parts inventory?

Blumaq supports a wide range of leading OEM brands, including Caterpillar, Komatsu, Volvo, Cummins, John Deere, and more. Our inventory covers parts for construction equipment, mining machinery, earthmoving vehicles, and power systems. Whether customers require engine components, undercarriage parts, hydraulics, filters, or electronic systems, Blumaq provides

Blumaq supports a wide range of leading OEM brands, including Caterpillar, Komatsu, Volvo, Cummins, John Deere, and more. Our inventory covers parts for construction equipment, mining machinery, earthmoving vehicles, and power systems.

“The Middle East continues to be a growth market for us, aligning with our global strategy to provide comprehensive aftermarket solutions wherever heavy equipment operates”

comprehensive solutions that meet or exceed industry standards.

Does Blumaq focus on any particular sectors within construction or mining— for example, earthmoving, roadbuilding, or quarrying equipment?

Yes, Blumaq specialises in supplying parts for sectors that heavily rely on durability and performance, such as earthmoving, mining, quarrying, and roadbuilding. Our product range and technical support are tailored to meet the specific needs of these industries, where operational efficiency and minimising equipment downtime are critical.

How does Blumaq ensure the reliability and compatibility of its parts, especially

for operators in extreme climates like the Middle East?

Blumaq enforces stringent quality control processes that include rigorous testing for performance, durability, and compatibility. We work closely with trusted manufacturing partners who comply with international quality standards. For regions like the Middle East, where extreme heat and abrasive working conditions prevail, we select and engineer parts to withstand these environments, ensuring reliability and longevity in the field.

In terms of after-sales service, what kind of technical support or warranty structure does Blumaq provide to customers?

Blumaq provides robust after-sales service that includes expert technical

support, helping clients with installation, troubleshooting, and maintenance strategies. We back our parts with a solid warranty programme that reflects our confidence in their quality and performance. Our customer service teams and technical advisors are always available to assist clients globally.

How does Blumaq adapt its offering to meet the evolving maintenance strategies of modern fleet operators, especially with increased demand for predictive maintenance and telematics integration? We recognise the growing trend towards predictive maintenance and data-driven fleet management. Blumaq adapts by offering components designed to integrate seamlessly with telematics systems and

sensors. Furthermore, we collaborate with clients to provide solutions that support proactive maintenance, reducing unexpected failures and optimising operational efficiency.

The global spare parts supply chain has faced multiple disruptions in recent years. What lessons has Blumaq learned and how have you adapted your logistics and sourcing strategy?

The recent disruptions highlighted the importance of flexibility, local inventory management, and diversified sourcing. Blumaq responded by strengthening relationships with multiple manufacturing partners, increasing stock levels for highdemand parts, and enhancing our global logistics network. These measures have allowed us to maintain high service levels even during challenging periods.

Are you seeing any trends in demand from global customers—such as an increase in rebuilds over new equipment purchases—or shifts in inventory planning due to supply chain risks?

Absolutely. We are seeing a marked increase in demand for rebuilds and equipment life extension, driven by both economic factors and sustainability goals. Customers are also seeking to optimise their inventory planning, preferring suppliers like Blumaq who offer reliable availability and flexible stocking solutions. These trends align well with our value proposition.

What role do digital platforms and automation play in managing Blumaq’s logistics, stock control, and delivery efficiency across global markets?

Digitalisation and automation are integral to Blumaq’s operations. We leverage advanced ERP systems, like SAP, automated warehouse

For regions like the Middle East, where extreme heat and abrasive working conditions prevail, Blumaq select and engineer parts to withstand these environments, ensuring reliability and longevity in the field.

solutions, and e-commerce platforms to streamline order processing, inventory control, and delivery logistics. This enables us to provide fast, accurate, and transparent service to customers worldwide.

With growing pressure on sustainability, how is Blumaq addressing the environmental impact of parts manufacturing, logistics, and end-oflife components?

Sustainability is a core focus at Blumaq. We work with manufacturing partners who implement environmentally responsible practices, reduce waste, and minimise emissions. Additionally, by supporting equipment rebuilds and part refurbishments, we help customers extend machinery life and reduce the

environmental footprint associated with producing and transporting new equipment.

Looking ahead, what innovations or changes do you anticipate in the heavy machinery aftermarket, and how is Blumaq positioning itself to stay ahead of these shifts?

We foresee continued growth in predictive maintenance technologies, increased use of sustainable materials, and greater demand for fast, reliable parts supply solutions. Blumaq is investing in digital tools, expanding our global distribution capabilities, and collaborating with clients to support new maintenance paradigms. Our goal is to remain a proactive, innovative partner as the industry evolves.

32 NEW RELEASES

The latest releases from the world of construction machinery.

36 RECORD FOR RB

Ritchie Bros. enjoys a record start to its auctions in 2025.

38 TOP CATS

Tips to extending the lifespan of your equipment.

40 THE GIFT OF TESTING KIT

Why even the biggest truck s need test drives.

WHY GET IT?

THE MK35H HAS BEEN ENGINEERED FOR HIGH-EFFICIENCY SITES SEEKING RELIABLE, ALL-IN-ONE CONCRETE TRANSPORT AND PLACEMENT.

CIFA unveiled the all-new Magnum MK35H concrete mixer-pump at Bauma 2025, marking a major step forward in lightweight construction equipment technology. Making its world premiere at the international construction machinery trade fair in Munich, the MK35H features a 35-metre carbon fibre boom and a 9m³ drum, positioning it as the largest model of its kind on the market.

The new machine has been designed to combine high pumping performance with a compact, highly manoeuvrable layout. Mounted on an 8x4 Euro 6 chassis with a 4,850mm wheelbase, the MK35H offers a reduced footprint and

compliance with European emissions standards, while delivering up to 90m³/h of concrete pumping power.

“The Magnum MK35H introduces several innovations that make it a unique solution for jobsite productivity,” said a CIFA spokesperson. “By integrating a carbon boom and advanced control technologies, it offers unmatched efficiency, reliability and ease of use.”

A highlight of the new model is its foursection carbon boom, which improves durability while reducing the total machine weight to 14,230kg—enhancing transportability and overall fuel efficiency. The boom can be deployed at just 8 metres of height, offering improved flexibility in constrained jobsite environments.

CIFA has also equipped the MK35H with the new PB908 pumping group, utilising an in-line hydraulic system for improved performance and fewer interruptions.

Meanwhile, the Easytronic control system with remote functionality ensures intuitive and safe operations, lowering the training threshold for new operators.

The MK35H has been engineered for highefficiency sites seeking reliable, all-in-one concrete transport and placement. CIFA says it delivers long-term value through reduced maintenance costs, improved uptime, and better operator performance.

SPECIFICATIONS

MAGNUM MK35H

Max Reach: 35m

Unfolding Height: 8.3m

Pumping Unit: PB908

Max Output: 90 m³/hour

Mixer Capacity: 9 m³

Water Tank Capacity: 800l

STICK TO THE SERVICE SCHEDULE

Don’t skip a beat — follow your machine’s service intervals religiously to avoid costly breakdowns later.

RESPECT THE LOAD LIMIT

Overloading might save a trip, but it puts serious strain on engines, hydraulics, and frames—leading to expensive repairs.

It’s not just a branding thing— OEM parts are designed to last and keep your equipment performing at its best.

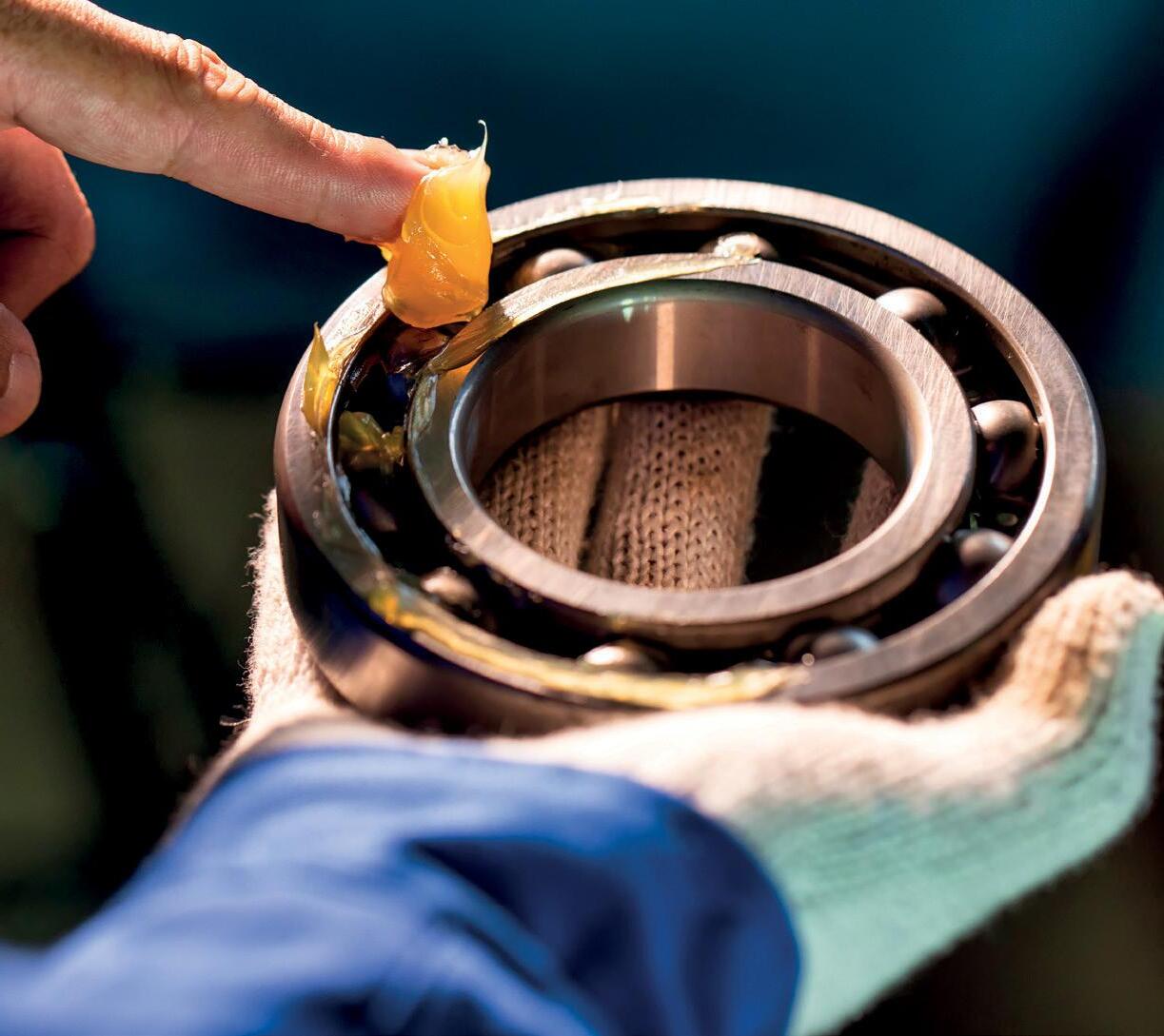

GREASE IS GOLD

Regular lubrication keeps moving parts smooth and protected from wear — don’t skimp on this simple step.

TRACK YOUR SERVICING AND REPAIRS

Modern machines can tell you when something’s wrong — use tracking and telematics to plan predictive maintenance before problems arise.

Dirty or contaminated fluids can wreak havoc on your engine and hydraulics. Keep

TRAIN YOUR OPERATORS WELL A well-trained operator won’t just boost efficiency — they’ll also prevent unnecessary wear and tear on your fleet.

Auctioneers are racking up record numbers as buyers tackle supply chain and pricing uncertainty globally, but it is still impressive that Ritchie Bros. has seen more people than ever bidding on its lots in 2025.

The 21% year-on-year surge in bidder activity that Ritchie Bros. saw during the early months of 2025, marks a significant rebound in used equipment demand across key global markets.

The results come as part of the company’s “Start 2025 Strong” campaign, which attracted more than 17,300 bidders and over 6,400 buyers for upwards of

20,000 assets — both setting five-year records across Europe, the Middle East, and Asia-Pacific.

The surge in activity reflects a tightening equipment supply environment as OEM prices rise and machinery availability becomes increasingly constrained. According to Duncan Ainscough, Head of International Sales at Ritchie Bros., this has led many asset owners to hold onto their fleets longer, further fuelling auction competition and supporting stronger returns for sellers.

“With OEM prices rising and supply constraints limiting availability, many owners are holding onto their assets longer, tightening the market and sustaining high price levels,” said Ainscough.

“This competitive bidding presents an opportunity for optimal returns for sellers, making this an ideal moment to sell.”

The standout results follow strategic investments by Ritchie Bros. in international marketing and platform expansion, drawing increased traffic to both its live auctions and online Marketplace-E platform.

RBA Dubai strong start to 2025

In the UAE, the company’s Dubai auction held on 2425 February, 2025 achieved notable success, selling more than 1,400 lots to buyers from 82 countries. The highest number of participants came from the UAE, USA, Canada, the UK, and the Netherlands — underlining Dubai’s continued importance as a regional sales hub for industrial equipment.

Showcasing strong international demand, the event featured an impressive selection of premium machinery. Among the standout sales were a

2024 Cat 980 wheel loader, which fetched $297,500; a 2020 Cat D9R bulldozer, sold for $265,000; and a 2021 Cat 740GC articulated dump truck, securing a bid of $162,500.

The continued strong interest in premium equipment highlights the increasing preference for digital transactions within the heavy equipment market.

Thanks to Ritchie Bros.’ timed online auction system, sellers accessed a wide international buyer base, achieving transparency and efficiency throughout the bidding process. The auction drew participants from 67 countries, notably Canada, the UK, and Saudi Arabia, reflecting a growing global confidence in online platforms for heavy equipment trading.

As the year progresses, Ritchie Bros. Middle East plans to continue offering sellers versatile solutions through its traditional auctions as well as Marketplace-E, its aroundthe-clock online equipment platform.

“As more sellers prepare to list their machinery, Ritchie Bros. Middle East continues to offer flexible selling options, including upcoming auctions and Marketplace-E, the 24/7 online equipment marketplace,” said the auctioneer.

David Fanning, Director of International Marketing at Ritchie Bros., attributed the momentum to the company’s scale and reliability. “We’re not just meeting demand—we’re leading the market with scale, transparency, global reach, reputation and results.”

That transparency remains a key draw for buyers, with every item sold to the highest bidder, and no hidden re-lists, seller buybacks or reserve pricing. These principles continue to set Ritchie Bros. apart as a trusted partner for both buyers and sellers of used machinery.

Huw Richards, General Manager at Walters Group UK, shared his company’s experience: “Ritchie Bros. presented a bespoke strategy that perfectly aligned with our needs. Their understanding of our requirements, combined with their successful track record, made them the ideal choice.”

Ritchie Bros. is now preparing for a packed Q2 auction calendar, with major events scheduled in the Netherlands, UK, Italy, Spain, Germany, and the UAE. The next Dubai auction is set for 17–18 June, while ongoing 24/7 opportunities continue via Marketplace-E.

As demand shows no sign of slowing and the spring selling season reaches its peak, Ritchie Bros. is positioning itself as the marketplace of choice for those looking to capitalise on high asset values and increased buyer competition.

FY2025 TO DATE

KEY STATS FROM THE “START 2025 STRONG” CAMPAIGN

• Assets Sold: Over 20,000, marking a 17% year-on-year increase

• Bidder Growth: 21% increase in participants vs. 2024

• Top Buyer Countries: Australia, Italy, Spain, Germany, France

• Most Popular Categories: Hydraulic Excavators, MFWD Tractors, Telescopic Forklifts, Wheel Loaders, Articulated Dump Trucks

• High-Value Lot Engagement: Participation in lots over £10,000 up 14%

• Average Bidders Per Item: Up by 5%

The Dubai auction held in February sold more than 1,400 lots to buyers from 82 countries

“This competitive bidding presents an opportunity for optimal returns for sellers, making this an ideal moment to sell”

At this year’s Bauma, Bobcat made a’ bold statement’ about the future of compact equipment, showcasing the next generation of its R2-Series mini excavators alongside an impressive lineup of electric and autonomous machinery.

With the unveiling of its new 1-2 tonne R2-Series mini excavators and upgrades to the flagship E88 model, Bobcat reinforced its reputation as a technology-driven innovator committed to both performance and sustainability.

One of the centrepieces of Bobcat’s stand was the debut of the new 1-2 tonne R2-Series mini excavators — the E16, E17z, E19 and E20z — which

replace the highly successful M-Series introduced in 2014. These models mark a new chapter for Bobcat, blending compact size with features traditionally reserved for much larger machines.

“The new 1-2 tonne mini excavator models build on the successes of the previous generation of machines with well over 34,000 units already retailed. After three years of development, the new models, featuring over 500 new components, will be available in the European, Middle Eastern and African (EMEA) markets later this year,” said Robert Husar, Husar, Product Line Director for Bobcat in Europe, the Middle East and Africa.

Designed for versatility and urban compatibility, the updated range includes standout enhancements like the SmartFlow hydraulic system, which combines a load-sensing pump and a flow-sharing main control valve for simultaneous multi-function operations.

This allows operators to maintain high-performance output — even when handling hydraulically demanding attachments like flail mowers — without compromising machine efficiency or smoothness.

In real-world terms, this means less fuel usage (down by up to 18%), quieter operations (up to 3 dBA lower than previous models), and reduced vibrations, all of which contribute to a more comfortable and productive workday.

“We reduced the operating noise by up to 3 dBA compared to the previous generation. This represents a significant decrease of 50% in sound energy, meaning a noticeably quieter machine on the job site. This not only enhances operator comfort but also reduces noise impact on surrounding environments, making the excavator better suited for urban and noise-sensitive areas,” said Robert Husar.

Each model in the new series has been engineered

with transportability and operator convenience in mind. The E16 is 100 kg lighter than its predecessor, enhancing ease of transport, while the E17z and E20z offer Zero House Swing (ZHS) capability — allowing nearly full rotation with minimal risk of collision in tight job sites. The E19 continues to offer best-in-class digging and lifting power while remaining under the crucial 2-tonne threshold.

All R2-Series models come standard with Bobcat’s Machine IQ telematics platform, enabling remote performance monitoring and proactive maintenance scheduling.

Bobcat also unveiled new attachments to enhance the utility of its machines, including a robust range of augers and trenchers. Five new auger drive models are matched with interchangeable bits for varied soil conditions, while a new series of trenchers will offer digging depths and durability for demanding applications. These attachments are expected to be commercially available in the second half of 2025 and compatible with Bobcat’s excavators and loaders.

In addition to the new compact units, Bobcat

showcased an upgraded version of its top-ofthe-range E88 mini excavator. This 9-tonne machine features a refined cab designed by Fritzmeier, which reduces noise and vibration and introduces operator-friendly features such as enhanced windscreen access, new radio connectivity, and an optional rear-view camera with a 7-inch display.

Powered by Bobcat’s D24 Stage V engine producing 48.5 kW (65 HP), the E88 continues to lead its class with strong breakout forces, excellent digging depth, and unbeatable stability — even when working over the side or with heavy attachments.

Bauma 2025 also offered Bobcat a global platform to demonstrate its forward-thinking approach to sustainable construction. On display was the TL25.60e electric telehandler concept, promising zero-emission operation without compromising performance. Also attracting attention was the groundbreaking RogueX, an all-electric, cabless, autonomous loader prototype. With no hydraulics and full electric actuation, it introduces a radical new direction for job site autonomy and machine control.

Rounding out the future-forward lineup was the T7X, the world’s first all-electric

compact track loader, which has already gained recognition in North America for its combination of raw power and zeroemissions operation. Its presence at Bauma signalled Bobcat’s intent to bring this technology to wider markets soon.

Throughout the Bobcat stand, a consistent theme emerged: taking innovation from the drawing board to the real world. The electric and autonomous machines on display — once the stuff of concept videos — are now working prototypes, and in some cases, commercially available products.

“Bauma 2025 has been the perfect stage to highlight how Bobcat is not just evolving — we’re reinventing the way work gets done,” added Husar. “Whether it’s through smarter hydraulics, cleaner energy, or more intelligent machines, our goal is simple: empower our customers to do more, with less.”

With an impressive portfolio of machines that span traditional performance, next-gen hydraulics, electrification, and autonomy, Bobcat’s presence at Bauma 2025 delivered a powerful message: the compact equipment revolution is well underway, and Bobcat is leading the charge.