CMME AWARDS 2025

CMME AWARDS 2025

AN ARRAY OF TALENT CELEBRATES AT THIS YEAR’S

MACHINERY MIDDLE EAST AWARDS

Make connections, expand your network and relationships, generate leads, elevate sales, grow your footprint with endless opportunities.

z Reach your target audience, engage with industry professionals, influencers, decision makers and highlight your products and services

The

This year’s Construction Machinery Middle East Awards 2025 honoured the trailblazers shaping the future of the regional heavy equipment industry.

QPMC

32_NEW

The

The

As the dust settles on another unforgettable evening at the Ritz-Carlton JBR, we’re proud to bring you full coverage of the Construction Machinery Middle East Awards 2025 — now in their fourth year and bigger than ever.

This year’s event was a genuine celebration of the people, projects, and businesses driving the heavy machinery and equipment sector forward in the Middle East. With more than 140 nominations across 30 categories, we saw record-breaking participation and, more importantly, an extraordinary showcase of innovation, resilience, and performance.

From ground-breaking rental partnerships and next-generation product launches to exemplary aftersales support and leadership, the quality and breadth of entries we received was truly inspiring. What stood out across the board was a heightened sense of ambition — a clear signal that this industry is not just growing, but evolving.

Our judging panel, made up of experts from across the region, faced the tough task of selecting winners from an incredibly competitive field. That in itself is a testament to how far the sector has come. It’s not just about having the right machines anymore — it’s about sustainability, smart services, digital transformation, and above all, delivering value to customers under constantly changing conditions.

This special issue offers a deep dive into the night’s top winners and shortlisted

nominees, providing insights into the strategies, innovations, and achievements that earned them a place on stage.

Whether you’re an OEM, a dealer, a rental player, or a contractor, there’s something here to learn from and be inspired by.

On a personal note, it was a pleasure to welcome so many of you in person to the ceremony. These awards are not just about recognising excellence — they are about reinforcing the strength of our community and highlighting the shared challenges and opportunities we all face. For me, the best thing about the evening was being able to catch-up with some old friends...well, at least when I wasn’t dealing with some technical hitches!

So, thank you to our sponsors, our judges, and every company that submitted a nomination. Most importantly, thank you to the people — the engineers, operators, service teams, and managers — who make this industry what it is. Here’s to another year of building boldly.

Stephen White Head of Content, CMME stephen.white@cpitrademedia.com

GROUP

MANAGING DIRECTOR

RAZ ISLAM

raz.islam@cpitrademedia.com

+971 4 375 5471

DIRECTOR OF FINANCE & BUSINESS OPERATIONS

SHIYAS KAREEM

shiyas.kareem@cpitrademedia.com

+971 4 375 5474

PUBLISHING DIRECTOR

ANDY PITOIS

andy.pitois@cpitrademedia.com +971 4 375 5473

EDITORIAL

HEAD OF CONTENT

STEPHEN WHITE stephen.white@cpitrademedia.com

+971 58 584 5818

ADVERTISING

SALES MANAGER

BRIAN FERNANDES brian.fernandes@cpitrademedia.com +971 4 375 5479

STUDIO

ART DIRECTOR SIMON COBON simon.cobon@cpitrademedia.com

DESIGNER PERCIVAL MANALAYSAY percival.manalaysay@cpitrademedia.com

MARKETING

MARKETING & EVENTS EXECUTIVE

LAKSHMY MANOJ lakshmy.manoj@cpitrademedia.com

SOCIAL MEDIA EXECUTIVE FRANZIL DIAS franzil.dias@cpitrademedia.com

CIRCULATION & PRODUCTION

DIRECTOR OF MARKETING & MEDIA OPERATIONS

PHINSON MATHEW GEORGE phinson.george@cpitrademedia.com

PRODUCTION & IT SPECIALIST

JARRIS PEDROSO jarris.pedroso@cpitrademedia.com

DIGITAL

SENIOR DIGITAL MANAGER

ABDUL BAEIS abdul.baeis@cpitrademedia.com

WEB DEVELOPER

UMAIR KHAN umair.khan@cpitrademedia.com

FOUNDER

PUBLISHED BY

Kanoo Cranes offers engineered solutions for any lifting requirements with knowledgeable experts engaged in the field of lifting. With a combined experience of more than 50 years with Mobile cranes, Crawler cranes, Tower cranes and passenger hoists we offer top quality products from:

Focus is to provide engineered crane solutions to the Construction, Oil and Gas and Industrial markets.

PROPERTY

Taraf appoints Pinnacle International as contractor for KARL LAGERFELD villas

INDUSTRY

Oia Properties expands presence with new Office in Abu Dhabi

INDUSTRY

CVC and Tabreed acquire PAL Cooling Holding from Multiply Group

CONSTRUCTION

Palma Development appoints APCC for shoring and piling works at West Residence

PROPERTY

Meraas unveils next chapter of City Walk Crestlane

EXPERTS: Public transport links and the rise of sustainable tourism

EXPERTS: The influence of invisible design

OPINION: Why is Disney building its first park in 15 years in Abu Dhabi?

INDUSTRY

PIF launches Expo 2030 Riyadh Company

The company will develop Expo as a model for sustainable tourism, and preserve the event’s legacy and is projected to contribute $70 billion to Saudi’s GDP

PROPERTY

Bvlgari Hotels & Resorts signs long-term agreement with Eagle Hills

INFRASTRUCTURE

Dutco and Sweid & Sweid launch Terralogix logistics park

The project will serve as a pivotal node in Dubai’s comprehensive supply chain infrastructure

INFRASTRUCTURE

Saudi Global Ports wins contract to operate Eastern Coast terminals

INFRASTRUCTURE

BEEAH expands into real estate development

BEEAH’s expansion into real estate development positions the organisation as a comprehensive innovator, aligning with national efforts towards a smart, sustainable, and diversified economy

PROPERTY

OMNIYAT acquires Marasi Bay Island in the Burj Khalifa District

The developer’s vision for an ultraluxury waterfront destination blends high-end living, premium workspaces, five-star hospitality, leisure, and wellness experiences

TECHNOLOGY

Emaar Properties launches digital resale platform for Emaar Homes VYOM was created to safeguard both investors and sellers and empowers homeowners to directly list properties and connect with prospective buyers, eliminating the need for intermediaries

CONSULTANT

SSH appointed Lead Design Consultant for new Radisson RED Hotel in RAK

CONSTRUCTION

Shamal awards main works contract for Dubai Harbour Residences

PROPERTY

Madar Developments unveils tenth edition of Tulip Oasis collection in Majan

Following the regional launch of its latest excavator line-up for the Middle East and Africa, Volvo CE claims its line-up has gains in productivity, fuel efficiency, and operator safety over rival machines.

The evaluation, held at a Gulf jobsite, pitted Volvo’s new EC210, EC220, and EC360 excavators against similarly classed machines from leading global OEMs. Each excavator was subjected to identical truck loading cycles, with data collected on core performance metrics such as dig speed, fuel economy, durability, and ease of service. To ensure consistency, the machines were operated by a trio of experienced professionals: a Volvo CE R&D specialist with 15 years of operating experience, alongside two local operators with a combined 22 years in the field. Performance results were averaged to reflect real-world usage and mitigate operator bias.

The EC210 excelled in its class, registering up to 7% greater productivity and 14% improved fuel efficiency compared to its closest rivals — even when running at lower RPMs.

“For contractors in the Middle East and Africa juggling performance expectations with fuel economy and uptime, the EC210’s results suggest it’s more than capable of punching above its weight –particularly in applications such as road construction, site prep, and utilities,” said Olle Watz, Excavator Product Manager at Volvo CE Region International.

In a direct comparison with the EC210, the EC220 recorded 32% higher productivity while maintaining similar fuel efficiency, claimed Volvo CE. The result positions it as an ideal solution for high-volume tasks such as material handling and bulk excavation, where both speed and control are essential.

KOBELCO APPOINTS

AL MARWAN MACHINERY AS ITS KSA DEALER

ALEC: OUR RESULTS PROVE SUSTAINABILITY PAYS OFF

ALEC Holdings, owner of AJI Rentals, has released its 2024 Environmental, Social and Governance (ESG) and Sustainability report, showcasing a year of measurable progress in ethical business practices, workforce development, and environmental impact reduction across its UAE and Saudi operations.

The report highlights the integration of ESG into a core strategy, moving beyond compliance to a driver of resilience and regional growth. This effort has garnered external recognition, with ALEC earning the Dubai CoC ESG Label and the ‘Committed’ badge from ratings platform EcoVadis.

Al Marwan will represent Kobelco across Saudi Arabia, complementing its existing role as the authorised distributor for Kobelco crawler cranes

Al Marwan Machinery has been officially appointed as the authorised dealer for Kobelco excavators in Saudi Arabia, expanding the long-standing partnership between the two companies. It also expands Al Marwan’s Kobelco representation, which already includes the UAE, Oman, Jordan, Iraq, and Lebanon, explained the company in a statement.

According to the deal, Al Marwan will represent Kobelco across Saudi Arabia, complementing its existing role as the authorised distributor for Kobelco crawler cranes since early 2024.

“The move reflects Al Marwan’s broader regional growth strategy beyond the UAE, now bringing advanced Japanese excavation technology directly to the Kingdom’s growing infrastructure sector, and demonstrates its commitment to providing high-performance, tailor-made machinery solutions across the Gulf and the Middle East,” added Al Marwan.

Al Marwan’s entry into the excavator market in Saudi Arabia comes as part of its expansion into major hubs like Dammam and Riyadh, where demand for dependable heavy equipment continues to grow in line with Vision 2030 infrastructure goals.

KSA firms now have direct access to Kobelco’s full excavator range, supported by localised after-sales service, OEM spare parts, and flexible ownership options such as rentals and lease-to-own programmes. Al Marwan now offers the full spectrum of Kobelco excavators to serve projects of all scales and sectors.

MANUFACTURERS

Daikin UAE has announced a strategic partnership with Al Shola, a well-established provider of temporary cooling and equipment rental services, in a move aimed at transforming how the Gulf region accesses energyefficient rental cooling solutions. The collaboration unites Daikin’s century-long legacy in HVAC-R innovation with Al Shola’s deep-rooted operational presence and rental network across the UAE. Together, the companies will provide comprehensive, turnkey cooling

packages tailored to the needs of construction sites, infrastructure projects, events, and critical facilities operating in some of the world’s harshest climates.

The partnership comes at a time when the demand for flexible, high-performance cooling systems is rapidly growing in the Gulf, driven by a surge in mega-projects, expanding urban infrastructure, and the seasonal intensity of outdoor events. With environmental impact and cost-efficiency at the forefront

of regional priorities, the ability to deliver quick-deploy, energyconscious systems has become increasingly vital.

“This partnership brings together two industry leaders with complementary strengths,” said Mohanad Al Mashaikh, Head of Solutions at Daikin UAE. “Daikin’s commitment to sustainable innovation, paired with Al Shola’s local expertise and service reach, will enable us to deliver exceptional value to our customers.”

Under the agreement, Daikin will supply its advanced, energyefficient HVAC-R systems, while Al Shola will provide logistics, on-site installation, and ongoing technical support through its well-established rental service infrastructure. The end-to-end solution is designed to support both short-term project needs and longer-term operational requirements across key sectors including construction, healthcare, events, and energy.

SANY Heavy Industry has released its 2024 Environmental, Social, and Governance (ESG) Report, underscoring its firm commitment to green innovation, clean energy development, and sustainable manufacturing. The latest report reflects the company’s strategic efforts to lead the construction machinery sector in low-carbon transformation and responsible growth.

In 2024 alone, SANY invested 520 million yuan (USD72.12 million) in environmental protection initiatives, further embedding sustainability into the core of its operations. Chairman Xiang Wenbo says it is determined to scale its investment in clean technology R&D and facility upgrades, with a view to expanding clean energy product lines and enhancing energy efficiency: “We will support the green transformation with new quality productive forces,” said Xiang.

The brightest names in the construction equipment industry came together last month at the Ritz-Carlton JBR for the fourth annual Construction Machinery Middle East Awards, celebrating the standout achievements of the region’s leading manufacturers, rental companies, and innovators over the past year. The event welcomed over 200 senior figures from across the construction, infrastructure, and heavy machinery sectors. Read about the winners on page 12!

The Middle East Facility Management Association (MEFMA) has announced that three of its member organisations have received top honours at the Global FM Awards of Excellence 2025, underlining the region’s growing influence in the international facility management (FM) sector.

The prestigious awards, presented by the Global FM Association, recognise outstanding achievements, innovative practices, and leadership in FM across the world. This year’s winners from the Middle East include the Expenditure and Projects Efficiency Authority (EXPRO) from Saudi Arabia and Darwish Interserve Facility Management from Qatar, both of whom received the coveted Gold Award. Berkeley Services UAE LLC was also recognised, earning the Highly Commended Award.

The awards were announced as

part of the celebrations for World FM Day, an annual event that acknowledges the contributions of FM professionals globally and promotes awareness of the sector’s vital role in supporting quality of life and workplace performance.

Eng. Ali Alsuwaidi, Chairman of Global FM, praised the winners, stating: “The remarkable success of MEFMA members at the Global FM Awards highlights the region’s pioneering role in shaping the future of facility management. This achievement reflects not only their excellence and innovation but also an unwavering commitment to driving sustainability and operational excellence on a global scale.”

Jamal Lootah, MEFMA President, added: “At MEFMA, we believe that excellence is never a coincidence — it stems from true collaboration, strategic planning, and continuous support.

“Our members’ success in these global awards reflects our commitment to empowering talents and organisations in the region, enabling them to lead on the global stage.”

The National Fire Protection Association (NFPA) has entered into a strategic partnership with the Saudi Facility Management Association (SFMA) through the signing of a Memorandum of Understanding (MoU) aimed at raising fire and life safety standards across the Kingdom of Saudi Arabia. The agreement, signed in Riyadh by Olga Caledonia, Director of International Business Development at NFPA, and Aiyd A. Alqahtani, Board Chairman at SFMA, will focus on advancing the capabilities of the Kingdom’s facilities management workforce in line with international safety benchmarks.

The Raimondi LR213 is currently in operation at an impressive height of 322 metres, contributing to the build of a 75-storey premium residential tower in Dubai. Erected on a steel undercarriage and equipped with a 50-metre jib and a tip load of 3.30 tonnes, the LR213 was brought in to replace an earlier crane after the structure had already reached 100 metres in height. The change required meticulous planning and a series of bespoke engineering solutions, particularly because the project was within the constraints of a pre-existing foundation.

One of the most complex aspects of the deployment was the limitation imposed by the existing raft foundation, which had strict base load thresholds. Unlike typical setups where the crane foundation is designed based on manufacturer specifications, Raimondi engineers had to reverse-engineer the installation to ensure the crane’s base reactions did not exceed the allowable limits. To overcome this, the company utilised a 6x6 base and adopted a staged ballast removal strategy during the crane’s vertical progression. “At each climbing stage, we removed ballast blocks to maintain the base reactions within the studied load limits. This adjustment was critical for

maintaining stability while adhering to the site’s structural limitations,” Wael Hasan, General Manager, Raimondi Middle East, explained.

Further adaptations included a redesigned load curve engineered by Raimondi’s Applications Department. The new parameters were tailored to meet the tower’s final construction height and the unique lifting requirements at over 300m. The crane was structurally supported by GR5S mast elements – two 11.8m sections combined with over 100 smaller 2.95m elements – and braced with 12 structural collars. However, one of the most technically demanding tasks was the collar positioning. This required several rounds of redesign and recalibration to accommodate site-specific requirements, with extensive engineering calculations needed at each stage. With the main construction phase nearing completion, the LR213 will be jacked down to 50 m before being removed using a mobile crane, concluding one of the region’s most ambitious crane installations to date.

“The complexities of this deployment demanded an extraordinary level. From redesigning the base configuration to recalibrating the collars, every step of the process reflected Raimondi’s technical proficiency and commitment to excellence.”

Fixed Speed Rotary Screw Belt Compressors

Reliable & cost-effective with consistent air output for continuous industrial operations.

Fixed Speed Rotary Screw Belt Tank Mounted Compressors

Superior energy efficiency with enhanced compression for demanding applications.

Direct Drive Rotary Screw Compressors

High efficiency & durability, ensuring long-lasting performance with reduced maintenance.

Oil-Free Compressors

100% pure, contaminant-free air for critical applications in pharmaceuticals, food, and electronics industries.

Portable Diesel Compressors

Robust & mobile, designed for heavy-duty applications in construction, mining, and drilling.

The construction equipment industry’s leading lights gathered at the Ritz-Carlton JBR last night for the fourth annual Construction Machinery Middle East Awards, as the sector’s top innovators, rental partners, and manufacturers were honoured for their achievements over the past 12 months.

Hosted by CMME magazine and CPI Trade Media, the sold-out gala brought together more than 200 senior professionals from across the region’s construction, infrastructure, and heavy machinery sectors. With over 140 nominations submitted across more than 30 categories, the 2025 edition marked the biggest and most competitive CMME Awards yet.

Speaking during the opening

address, Stephen White, Head of Content at CPI Trade Media, said the awards served as a critical platform for recognising the region’s ongoing transformation.

“This industry continues to prove it’s not just keeping pace — it’s setting the pace. Behind every innovation and successful project are the people, teams, and companies driving real progress in how the Middle East builds. Tonight is about them.”

Highlights from the evening included multiple wins for established industry names JLG Industries, Johnson Arabia, and Al Marwan Machinery, with joint awards issued in several categories to reflect the depth of competition. And there was also success for newer innovators in the market such as Sinoboom, winner of the Newcomer of the Year award, and SpiderPlus which was recognised

for its technological prowess.

In the Rental categories, Dayim Equipment Rental was named Access Rental Company of the Year, while Al Marwan Machinery took home the Heavy and Medium Rental Company of the Year award. Johnson Arabia, meanwhile, earned two major honours — Lifting Champion of the Year and Safety Champion of the Year — for its standout performance in high-stakes lift planning and safety culture. Dingli received the Innovation of the Year award for its AWP Innovation Programme, and Al Marwan Machinery and MYCRANE jointly recognised for Local Innovation of the Year. Judges praised the former’s amphibious excavators, engineered in the UAE, and the latter’s digital crane rental platform — both described as “regionally rooted and globally relevant.”

Volvo’s A40 Articulated Hauler and DEVELON’s DX1000LC-7 Crawler Excavator shared Earth Moving Machinery of the Year, while Komatsu’s D155-6R Bulldozer won Bulldozer of the Year. The title of Outstanding Manufacturer of the Year went to Bobcat, recognised for its commitment to electrification, local adaptation, and aftermarket support. The evening also saw a growing emphasis on sustainability and electric equipment. Dingli’s BA44ERT won Electric Access Machine of the Year as the tallest electric articulated boom lift in the world, while the Electric Machinery of the Year award was jointly given to Hangcha’s 48T Lithium Battery Forklift and SpiderPlus’ Multi-Loader platforms. Finally, Al Shirawi Enterprises Group received a final special award for its green transformation.

Dingli – S1612AC+ Scissor Lift

Bomag – BW211D-5 SL roller

CASE Construction – 1110 EX Compacto compactor

Volvo – G9220F Motor Grader NOMINEES

WINNER

Dynapac – SD2500C Paver

With road construction accelerating across the GCC, paving equipment must deliver both endurance and precision. Dynapac’s SD2500C Paver stood out this year for its ability to consistently produce high-quality surfaces under the harshest regional conditions. Lauded for its intuitive controls, rapid warm-up time, and outstanding finish, the paver has proven indispensable across major infrastructure projects in both the UAE and KSA. Its blend of productivity and reliability made it a clear favourite among the judges.

Genie – Z-60 FE hybrid articulated boom lift

JLG Industries – Power Tower CS NOMINEES

Sinoboom – AB46RJ articulated boom lift

WINNER

JLG Industries – EC450AJ Compact electric articulated boom lift

At just 2 metres wide and featuring zero tail swing, JLG’s EC450AJ is a top choice for tight urban spaces. The boom lift’s lithium iron phosphate battery system enables fast charging and dependable performance even in extreme temperatures. With intelligent drive systems, enhanced safety features, and transport-friendly dimensions, this machine epitomises how access equipment is becoming greener, smarter, and more efficient.

NOMINEE

Tadano – AC 5.250L-2

Terex – AC700

WINNER

Grove – GMK6450-1

A dominant force on demanding construction sites, Grove’s GMK6450-1 combines impressive lifting power with unmatched adaptability. The crane’s advanced design allows it to thrive across a variety of terrains, making it an essential asset for contractors working on diverse projects. With robust engineering and smart controls, it represents the latest evolution in heavy lifting solutions.

NOMINEE

Sinoboom

Spiderplus Construction Equipment Trading LLC

WINNER

Johnson Arabia

From strategy to execution, Johnson Arabia’s precision lift at Dubai’s Jaddaf Metro expansion demonstrated textbook lifting excellence. Using a Terex Demag AC700 crane to install a 65-tonne bridge section near underground services — with only overnight windows to operate — the team executed a complex operation with meticulous planning and high safety standards. Judges highlighted the flawless coordination, execution under pressure, and specialist rigging that made this one of the region’s most outstanding lifting projects of the year.

NOMINEE

Jaso – J638PA Tower Crane

Potain – MCT2205 Tower Crane

WINNERS

Jaso – J638PA Tower Crane & Potain – MCT2205 Tower Crane (Joint Winners)

In an exceptional year for high-rise development, the judges couldn’t choose just one tower crane to honour. Jaso’s J638PA earned recognition for its compact footprint and adaptability on congested city builds. Potain’s MCT2205 impressed with its high capacity and freestanding reach — ideal for supertall construction and expansive industrial zones. Together, they reflect the dual demands of space-efficiency and high-performance in the region’s evolving skylines.

NOMINEES

Al Futtaim Motors Commercial Vehicles – I_Site Telematics Solutions

Al Shirawi Machinery LLC – Hyundai Service

Johnson Arabia LLC– Johnson Arabia 24/7 Hotline

Kanoo Machinery UAE – 100% Customer Service Excellence Initiative (Bobcat)

Manitowoc Crane Group Middle East – EnCORE

WINNER

German Gulf Enterprises – Technical Training Excellence Initiative

With rising demand for uptime and TCO transparency, GGE has pushed forward with a holistic aftersales strategy. Judges praised its strong investment in diagnostic tools and region-wide support capabilities, helping customers increase productivity and protect their asset value across the lifecycle.

NOMINEES

SpiderPlus

WINNER

Sinoboom

Sinoboom has cemented its reputation for safe, innovative MEWP design and launched new models across the region through strategic partnerships and local support. Together, these two brands are redefining what newcomers can achieve in the Middle East. The CMME Awards team elaborated on the judges’ decision, saying, “This award celebrates those who have launched with purpose and proven they’re here to stay. Sinoboom hit the ground running in the Middle East with over 100 machines deployed, a safety-first design philosophy, and a product range tailored to regional needs. Their bold arrival has truly earned them this title!”

WINNERS

MYCRANE and Al Marwan Machinery (Joint Winners)

Two distinctly different but equally impactful projects shared this year’s local innovation spotlight. MYCRANE’s digital crane rental platform has created a new benchmark in how regional lifting equipment is sourced, compared, and mobilised — bringing efficiency and transparency to users. Founded in the UAE, MYCRANE is the world’s first digital platform for crane rental — connecting customers directly with equipment providers, streamlining quotation and procurement, and modernising a sector that’s long relied on paper and phone calls. Al Marwan Machinery’s amphibious excavators have enabled critical progress on sensitive water and coastal environments in the UAE. Both solutions address local needs with global thinking. Al Marwan’s amphibious and elevated excavators were engineered not in Europe or Japan — but right here in the UAE. These custom-built machines are transforming marine construction, dredging, and reclamation works across the Gulf.

NOMINEES

JLG Industries – Smart Fleet Telematics

PUTZMEISTER – INSTATIQ 3D technology

Spiderplus Construction Equipment Trading LLC – Multi-loader

Vita Inclinata Technologies – Vita Load Navigator 2.0

WINNER

Dingli – AWP Innovation Programme

Dingli took top honours for its strategic approach to innovation, rather than a single product. The brand’s AWP Innovation Programme has seen it consistently introduce electric, hybrid, and ultra-high-reach boom lifts that address jobsite emissions, range limitations, and urban space constraints. Its development of the world’s tallest electric boom lift — the BA44ERT — exemplifies the heights of its ambition, literally and figuratively.

Operating one of the largest and most diverse rental fleets in the GCC, Al Marwan Machinery continues to impress with its customer-centric approach, on-time delivery record, and fleet expansion efforts. From bulldozers and excavators to telehandlers and compactors, its inventory is matched by dedicated support teams, project-specific consulting, and strategic partnerships with OEMs.

Towering above its rivals — literally — Dingli’s BA44ERT was named the world’s tallest electric articulated boom lift and the region’s most promising access innovation. Designed to serve the upper reaches of construction without relying on diesel, the machine delivers both height and eco-performance. With a working height of 48.5 metres, four-wheel drive, and lithium battery packs, it’s tailor-made for giga-projects and enclosed environments that demand zero emissions and high manoeuvrability.

A long-time advocate of safe and efficient MEWP operation, Dayim Equipment Rental delivered a stellar year in 2025. The company expanded its powered access fleet with a $35 million investment while growing its footprint in Saudi Arabia and the wider GCC. Judges cited its consistent customer service, strong utilisation rates, and impressive track record of working on marquee sites like The Line and NEOM. Dayim’s ability to scale responsibly and retain operational excellence stood out in this competitive category.

JLG’s Power Tower CS stood out in the compact equipment field for bringing high levels of safety and productivity into a narrow, ultra-lightweight footprint. With a width of just 760mm, it easily navigates congested indoor worksites, including data centres, airports, and warehousing projects. Judges highlighted its smart battery management, zero-emission design, and ease of use — a powerful blend for fast-paced fit-out and maintenance work.

NOMINEES

Hangcha – 48T Lithium Battery Forklift

SpiderPlus Construction Equipment Trading LLC – Multi-Loader 3.0BL and 6.0BL

Toyota – TRAIGO 80-9FBH80T Electric Forklift

Volvo – L120 Electric Wheel Loader

WINNERS

SpiderPlus & Hangcha (Joint Winners)

This year, the electric equipment category had two clear winners. SpiderPlus’ Multi Loader series — tracked, low-ground-pressure carriers with lithiumion power — are already supporting landmark Saudi developments with smooth load handling on sensitive surfaces. Hangcha’s 48T Lithium Battery Forklift is equally groundbreaking, delivering massive industrial capability without tailpipe emissions.

NOMINEES

KCP – KCP 43 Concrete Pump

WINNER

Putzmeister – BSF 42 HLS Concrete Pump

A staple of high-rise and infrastructure projects, Putzmeister’s BSF 42 HLS pump delivers class-leading reach, volume output, and reliability. The machine’s hydraulic system and advanced controls allow for smooth, accurate concrete placement, even on complex jobsites. It was praised by judges for its smart system diagnostics and track record across mega-developments in the UAE and Saudi Arabia.

CASE Construction – SR150B Skid Steer Loader

WINNER

Skid steers are the unsung heroes of construction — from material handling to site prep, they are a core component of urban, industrial, and infrastructure projects across the region. The Bobcat S450 remains the compact machine of choice for contractors in the UAE and Saudi Arabia, particularly in tight job sites where space and manoeuvrability are critical. Its balance of power, comfort, and serviceability keeps it a market leader year after year.

NOMINEES

Putzmeister – P12 HR

WINNER

Liebherr – HTM 1304

Engineered for high-capacity concrete transport in the harshest climates, Liebherr’s HTM 1304 mixer has become a trusted solution on regional sites requiring both volume and durability. With a lightweight drum design and strong wear resistance, it maximises payload while reducing fuel consumption. The model is well-suited to long-haul site delivery and urban mobility, making it a favourite for major contractors across the Gulf.

NOMINEES

Bobcat – DV250S-7 Diesel Forklift

Hangcha – CPCD160 16T Diesel Forklift

Komatsu – FD 250-7 Forklift

Spiderplus Construction Equipment Trading LLC – Overhang Beams

Toyota – 8FD70N 7 Ton Forklift

WINNER

Manitou – MX50-4 4x4 Rough Terrain Forklift

Manitou’s MX50-4 offers a blend of off-road agility, load stability, and driver comfort. Its full-time four-wheel drive system, robust mast design, and ground clearance make it ideal for uneven sites and heavy pallet movement.

Spider Crane (URW095, URW295 & URW 376)

EK

Counterbalance beam designed for installations underneath overhangs or replacing loading bays for material placing

Ultra-compact and ideal for con ned spaces, with an extended reach for mid-range lifting tasks. (Libro 500, 800, 2500 & 3000)

( 3.0BL, 6.0BL & 3.0FX with dolly System ) Easily assembled/ dismantled and portable

Self-leveling tracked carriers for heavy material transport on uneven terrain or within buildings

A rolling conveyor system for safe and e cient material handling through windows and openings.

Work up to 100m below equipment setup.

A compact and versatile material lift designed for precise and e cient vertical lifting.

NOMINEES

CASE Construction – 570V Backhoe Loader

DEVELON – DX1000LC-7 Crawler Excavator

DEVELON – DX380DM-7 Demolition Excavator

Hyundai – HL775-9 Wheel Loader

Hyundai – R180W Excavator

LiuGong – 870H Wheel Loader

Volvo – A40 Articulated Hauler

WINNERS

DEVELON – DX1000LC-7 and Volvo CE – A40 (Joint Winners)

NOMINEES

Komatsu – FD-30 Forklift

Bobcat – NXE-Series Electric Forklifts

Linde – R14 1120 Reach Truck

STILL – VNA MX-X

WINNER

Toyota Material Handling – BT Vector 1.5t with Articulated Steering

Toyota’s BT Vector 1.5t forklift was this year’s standout for warehouse and cold store operations. Featuring advanced navigation, reduced aisle-width capability, and highly efficient power systems, the machine was recognised for enabling higher throughput in logistics environments.

NOMINEES

CASE Construction – CX220C LC HD Excavator

DEVELON – DX190WA Excavator

Gargash General Trading, LiuGong Machinery – 942E HD Excavator

Komatsu – PC 400-8R Excavator

Hyundai – R430 LC Excavator

Volvo Construction Equipment – EC210 Excavator

WINNERS

Volvo CE – EC480DL and CASE Construction – CX220C LC-HD (Joint Winners)

The excavator category winners are trusted across high-volume construction sites. Volvo’s EC480DL, known for its performance, durability, and l efficiency and CASE’s CX220C LC-HD for its high productivity in urban developments.

NOMINEES

DEVELON – DD130 Crawler Dozer

LiuGong – LD36D Bulldozer

WINNER

Komatsu – D155-6R Bulldozer

Komatsu’s D155-6R bulldozer continues to be the backbone of regional grading and land-clearing operations. With its hydrostatic steering, torque converter drive, and large blade capacity, it’s built for pushing performance and long duty cycles. Contractors value its reliability and comfort, while fleet owners note its strong lifecycle costs and serviceability — a true dozer built for the desert.

Bobcat – T40.180SLP Telehandler

GEHL – TX 4017 – Construction Telehandler

Manitou – MTX-1840 Telehandler NOMINEES

WINNER

JCB – JCB 540-170 Telehandler

JCB’s 540-170 telehandler won for its versatility, reach, and resale value. With a 17-metre lift height and 4,000kg capacity, it has become a musthave for mixed-use construction and industrial support. The judges noted its wide acceptance across GCC sites and praised its balance of modern operator features and robust mechanical simplicity. JCB continues to dominate this category by evolving a tried-and-tested design to meet today’s jobsite demands.

NOMINEES

Metso – C150 STD Jaw Crushers

Volvo – A40 Articulated Hauler

Volvo – L350H Wheel Loader

WINNER

HD Hyundai Construction Equipment – HX800UL Ultra Large Excavator

The HX800UL is a mining-class giant that brings precision and efficiency to large-scale excavation. Judges commended its durability, fuel-efficient engine, and excellent cab design, all of which are vital for long-shift mining operations. With regional interest in hard rock and infrastructure quarrying growing, the machine is proving indispensable on some of Saudi Arabia’s most ambitious development sites.

NOMINEES

Grove – GRT 780 Rough Terrain Crane

WINNER

Tadano – GR-1000EX-4 Rough Terrain Crane

Tadano’s GR-1000EX-4 continues to set the standard for mobile lifting in the region. With a compact design and 100-tonne capacity, it is ideal for navigating confined jobsites without sacrificing power. Judges pointed to its Smart Counterweight system, improved fuel economy, and reliable safety systems — all factors that make it a go-to model for both urban and remote construction projects.

DISTRIBUTOR OF THE YEAR – UAE

NOMINEES

FAMCO

Galadari Trucks and Heavy Equipment

GB Equipment Solutions

GEHL – German Gulf Enterprises

Kanoo Machinery

WINNER

Al Shirawi Enterprises Group

Al Shirawi Enterprises earned this year’s UAE Distributor title through operational excellence and cultural transformation. Judges were impressed with its integration of sustainability and service delivery, setting an example for the broader industry.

NOMINEES

Bobcat Company

Linde Material Handling

LiuGong Machinery

Manitowoc Crane Group

WINNER

Bobcat Company

PUTZMEISTER

Toyota Material Handling

Volvo Construction Equipment

Wacker Neuson

With a strong regional presence and a reputation for building robust, high-performance compact equipment, Bobcat was once again crowned Outstanding Manufacturer of the Year. Its continued innovation in electric and compact machinery, reliable dealer support, and presence across multiple award-winning categories reinforced its status as a market leader in 2025.

Johnson Arabia raised the bar for operational safety with its work on Dubai Metro’s Jaddaf extension. The team overcame environmental and spatial constraints with rigorous lift planning, stakeholder coordination, and real-time risk monitoring. The judges applauded the firm’s culture of accountability and ongoing investment in safety training, which are central to its longstanding success in complex lift environments.

NOMINEE

Al Marwan Machinery

Kanoo Machinery

WINNER

FAMCO (Al-Futtaim Auto & Machinery Company)

With a strong OEM portfolio and regional coverage, FAMCO continues to lead as a trusted equipment partner across the Gulf. Its early investment in electric machinery, broad parts inventory, and customer-focused service network all contributed to this year’s win. The judges especially recognised its leadership in the early adoption of low-emission solutions.

NOMINEES

MYCRANE DMCC

WINNER

Al Shirawi Enterprises Group

The Special Contribution Award went to Al Shirawi Enterprises for its commitment to long-term sustainability through digital transformation. The company’s decision to overhaul traditional paper-based workflows has had an outsized impact — saving hundreds of thousands of pages annually and improving speed, transparency, and accuracy across departments. More than a green initiative, this was a strategic move that set new standards for operational change in the industry.

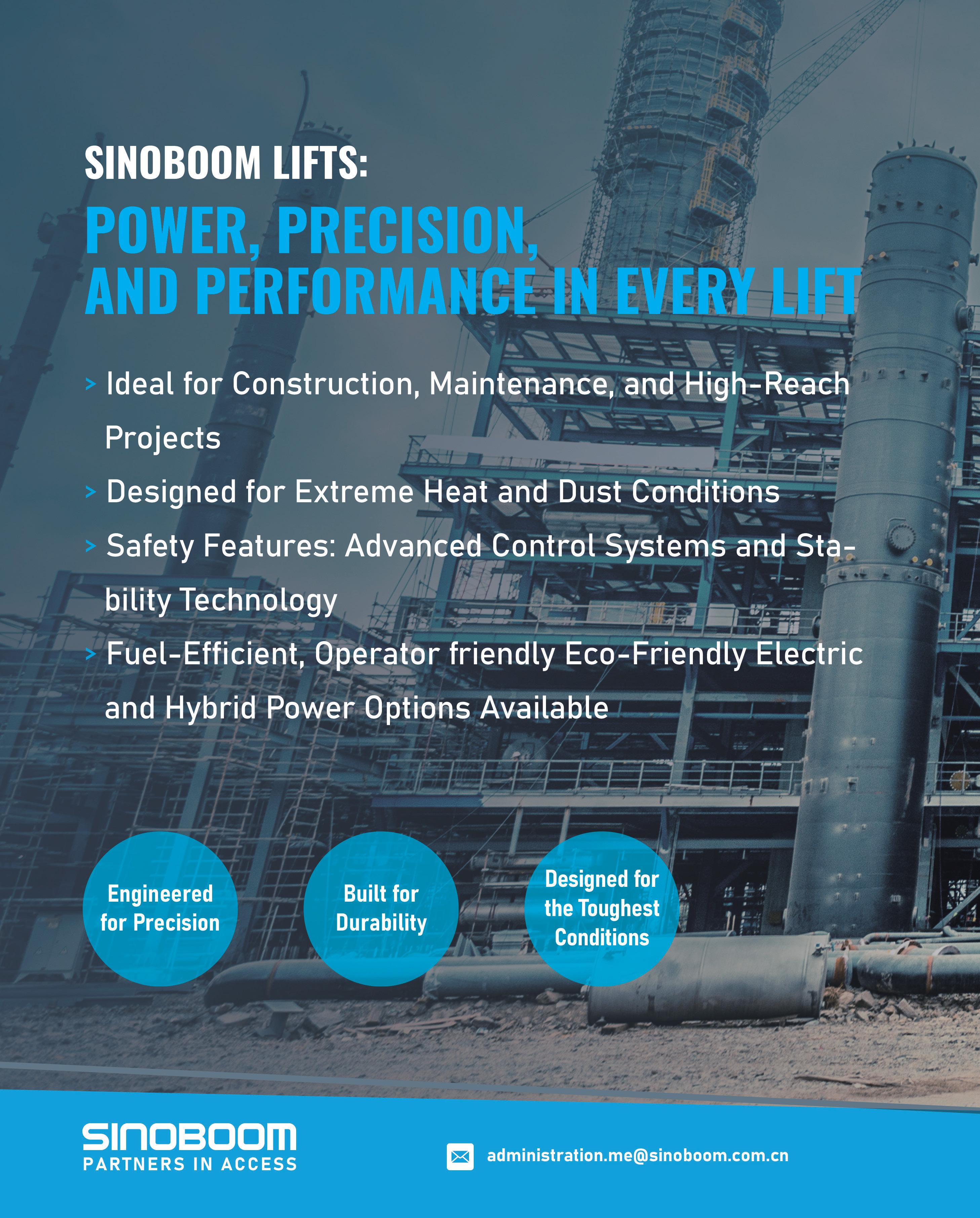

Almost 20 years ago, CDE, one of the leading suppliers of wet processing solutions for the natural minerals processing and waste recycling sectors, secured a landmark contract to design and engineer one of the world’s largest sand washing plants – a 1,200 tonnes per hour solution for Qatar Primary Materials Company (QPMC). Fast forward two decades and the original CAPEX investment by QPMC continues to lead the way for total capacity in the region with a remarkable 70 million tonnes of sand washed and fresh upgrades afoot to ensure the plant delivers maximum productivity for the business for years to come.

Comprising four lines of operation, each processing up to 300 tonnes per hour each, the monu-mental plant utilises an elevated platform that enables a continuous flow of in-bound trucks to feed the hopper directly.

Running in unison, each line consists of a series of 7x2m coarse rinsing screens, CDE’s patent-ed EvoWash sand washing system, a network of stockpile conveyors, and industry-leading wa-ter management systems, including CDE’s AquaCycle thickener and a high-capacity filter press. Together they process up to 12,000 tonnes per hour, and up produce up to 24,000 tonnes of washed and graded sand

per day, presenting a unique challenge for the aftersales team, said Sena Biswas, CDE’s CustomCare manager.

“A plant of this sheer scale requires an always-on approach to maintenance. It’s a bit like the analogy of painting the Golden Gate Bridge. It’s a continuous process. QPMC is also one of the three biggest local suppliers of construction materials in what is a fast-developing region, so proactive, preventative, and responsive on-the-ground support is paramount.”

Once a project is commissioned, every CDE customer is introduced to its CustomCare team, which offers 24/7 service and aftersales support.

“Every customer of ours is a customer for life. That’s our philosophy and its deeply embedded in everything we do. Our strong commitment to aftersales means we’re fully invested in our customer’s success and ensuring they maximise their return on investment,” Biswas said.

CDE CustomCare is delivered by an inhouse team of service engineers who are knowledgeable of the full CDE equipment range and familiar with the objectives and operation of the customer’s plant. This proactive and preventative approach guarantees customers get the maximum performance from their CDE equipment, ensuring the long-term value of their investment.

The service includes regular preventative maintenance inspections and site visits,

Soon-to-becommissioned upgrades to the plant, including new rinsing screens for two of the four lines, and updating the dewatering screen to the latest technology, are the first additions to the plant in over 15 years of operation.

“Every customer of ours is a customer for life. That’s our philosophy and its deeply embedded in everything we do”

management of wearable and consumable plant parts and components, including stocking replacement parts locally for rapid dispatch, and more. Soon-to-becommissioned upgrades to the plant, including new rinsing screens for two of the four lines, and updating the dewatering screen to the latest technology, are the first additions to the plant in over 15 years of operation, which has been described as ‘a real feat’ by Hamad Ali, sand operation manager at QPMC: “We shouldn’t underestimate the magnitude of the task at hand when it comes to servicing and maintaining a plant processing these volumes. It’s a critical part of the supply chain and ensures a wellmanaged supply of primary materials are readily available to help the nation achieve its construction goals. It’s a real feat what the CDE team has achieved in this time to maintain such a productive and highly optimised plant.”

QPMC plays a vital role in supporting Qatar’s construction sector by providing essential materials and logistics services. From Mesaieed Port (GBT), QPMC offers stevedoring facilities for both aggregate and non-aggregate importers, along with storage solutions. As a key supplier of primary construction materials, QPMC provides washed sand, dune sand, gabbro, and limestone to meet

the industry’s demands. In line with its commitment to sustain-ability, QPMC also processes construction, demolition, and excavation waste, producing high-quality recycled aggregates. These recycled materials serve as environmentally friendly alternatives to natural primary resources, contributing to environmental protection and sustainable development in Qatar’s construction sector. To ensure an uninterrupted supply of materials flow from the plant, CDE delivers a tailored service plan which includes bi-monthly preventative maintenance inspections, quarterly site visits by QPMC’s dedicated CustomCare manager, proactive management of equipment and stock to ensure parts are available in the local market before they’re needed, and even plant telematics to help boost efficiency, productivity, and enhance overall asset management.

Tonnes per hour per unit

“This ground support is directly linked to strengthening the quality of the product suite, which in turn is helping drive business growth for QPMC,” Biswas said.

Ali added that achieving strong return on investment shortly after commissioning was completed is in large part down to servicing and maintenance: “It’s one thing to commission a plant. The real job is keeping it up and running. The fast return on investment we saw speaks

CDE’s patented EvoWash sand washing system and CDE’s AquaCycle thickener and a high-capacity filter press process up to 12,000 tonnes per hour, and up produce up to 24,000 tonnes of washed and graded sand per day.

to both the efficiency and robustness of CDE’s equipment. It also demonstrates the dedication of its team to making sure the plant maintains its performance over the long-term, which it most definitely has.”

Bassem Idriss, Head of Operations, Middle East & Africa, said this is made possible by CDE’s commitment to investing in local support.

“We’re continuing strengthen our dedicated team in the region and recently made several strategic appointments, including a dedicated commissioning engineer and a regional service engineer, to ensure we maintain close proximity with our customers to help them really maximise the potential of their operations. Our relationship with QPMC has strengthened with two decades of collaboration and were excited to see where the future takes us to pioneer new projects in Qatar.”

By prioritizing long-term resource efficiency, QPMC contributes to both the industry’s growth and sustainable development in the country. Ali said the CDE plant is a key part of QPMC’s contribution to the Qatar National Vision 2030.

“The efficiency of the plant in terms of its energy saving capabilities and being able to maximise the availability of our natural reserves without waste is closely aligned with the environmental development goals of the national vision and has strengthened our own sustainability commitments.”

“A plant of this sheer scale requires an always-on approach to maintenance”

Cummins Engine

260 hp @ 2200 rpm

Operating Weight

23,000 kg

Moldboard Length/ Cutting Depth

4,320 mm / 838 mm

Drawbar Pull

112 kN

Cutting Pressure

10,120 kg

Ritchie Bros.

THE TB58RJ BOASTS AN IMPRESSIVE WORKING HEIGHT OF 59.90M, GIVING OPERATORS THE ABILITY TO ACCESS HIGH OR HARD-TOREACH AREAS WITH EASE

In today’s fast-paced construction, maintenance, and industrial environments, having the right equipment can mean the difference between a job done well and one delayed by inefficiencies. Enter the Sinoboom TB58RJ a telescopic boom lift that combines raw power with remarkable reach, agility, and safety. Engineered for performance and designed with operators in mind, the ideal solution for demanding tasks that require height, precision, and reliability. Safety is paramount in elevated work platforms, and Sinoboom integrates extensive safety features to protect workers and operators. These include anti-crush protection that alerts and halts operation upon detection, a platform load sensing system to prevent overloads and ensure optimal weight distribution, and an

emergency lowering system to bring the platform down safely in case of power failure. The lift also features non-skid platform flooring and toe boards, automatic braking and tilt alarms, as well as high-visibility warning labels and operational instructions.

Operator comfort is also a priority. The ergonomic control station within the platform includes intuitive joystick operation, proportional control, and emergency stop functions. Operators experience smooth, precise movements with minimal jostling, even at full extension. Sinoboom designs its machines to be both fuel-efficient and eco-conscious. Available in diesel, hybrid, and electric variants, Sinoboom boom lifts are suitable for indoor and outdoor projects alike. The TB58RJ boasts an impressive working height of 59.9m for easy access to high or hard-to-reach areas. Whether you’re performing facade maintenance on a skyscraper, installing large signage, or working on complex infrastructure projects, the TB58RJ gives you the reach to get it done. But height isn’t its only superpower. The articulating

jib provides a horizontal outreach of up to 24.4m, making it easy to manoeuvre around obstacles and access confined or awkward spaces. The extended reach allows workers to operate flexibly and efficiently, even on tight or congested worksites.

At the heart of the TB58RJ is a robust diesel-powered engine that ensures consistent performance across varied job site conditions. Its 4WD system and oscillating axle provide superior terrain adaptability, enabling the lift to tackle uneven ground, gravel, mud, and slopes without hesitation. Whether you’re on a construction site, in an industrial yard, or working across rough terrain, the TB58RJ delivers unwavering stability and traction.

SPECIFICATIONS

TB58RJ

Working Height: 59.9m

Horizontal Reach: 24.4m

Platform Capacity: 300/454kg

HOW IS IT SMART?

PEOPLE DETECTION HIGHLIGHTS INDIVIDUALS WITH RED BOUNDING BOXES ON THE IN-CAB MONITOR, ALLOWING THE OPERATOR TO ASSESS AND MITIGATE RISKS DYNAMICALLY.

Caterpillar has unveiled a suite of advanced technology options for its next-generation Cat® medium wheel loaders, aimed at enhancing safety, operational efficiency, and payload accuracy across a range of construction applications. Available on the Cat 950 through 982 models—including the XE variants—the upgrades include the newly introduced Collision Warning System with Motion Inhibit and the certified Cat Payload for Trade integration.

The standout addition is the optional Collision Warning System with Motion Inhibit, which enhances safety by combining Object Detection, People Detection, and automatic motion inhibition. The new system improves safety by alerting operators and inhibiting loader motion during transitions from inactive to active states.

SAFETY FIRST WHAT IS THE COLLISION WARNING SYSTEM?

This integrated package uses smart cameras and radar sensors to detect potential hazards behind the loader. It alerts the operator through audible and visual cues, and, critically, prevents the machine from moving in reverse if an object or person is detected within a predefined critical zone.

WHY GET IT?

NO EXTERNAL POWER IS REQUIRED; MAKING THE CDR A PERFECT MATCH FOR TEMPORARY JOB SITES

Atlas Copco has debuted six new models of its CDR and CDR+ portable dryer ranges. These deliver clean, dry air in any tough environment and enhance Atlas Copco’s total portable air solutions, says the Swedish firm.

The line-up includes six models –three twin tower models (CDR 850, CDR 1200, CDR 1700) and three units with Cerades technology (CDR+ 980, CDR+ 1350, CDR+ 1700) – each designed to provide a consistent flow of highquality, moisture-free compressed air in a wide range of mobile applications.

All models in the new range are housed in a robust, corrosion-resistant frame, designed to withstand extreme temperatures from -25°C to 50°C (-10°F to 122°F). The rugged build offers protection against dust, humidity, and mechanical shock; ensuring consistent uptime, even in the most challenging conditions.

“Customers working in harsh, outdoor environments need solutions

that are reliable, robust, and easy to use,” says Jan Nijs, Product Marketing Manager, Portable Air Division.

“With the new CDR and CDR+ dryers, we’ve delivered exactly that –a purpose-built air treatment range that completes the mobile air chain, offering clean and dry air on the go.” Designed with durability and simplicity in mind, the CDR and CDR+ dryers are ideal for all rental applications such as pipeline drying, offshore operations, exploration drilling, shipyard sandblasting, and construction sites. All models deliver a stable dew point of -40°C/40°F, ensuring optimal air quality that protects downstream equipment from corrosion, freezing and contamination.

The dryers operate within a pressure range of 7 to 16 bar (100 to 232 psi) and provide a free air delivery of 24–48 m³/min (850–1700 cfm).

The CDR range of portable desiccant dryers uses a traditional activated alumina desiccant, offering dependable moisture removal.

PREMIUM OPTION CDR+ SERIES

The CDR+ is equipped with Atlas Copco’s proprietary solid ceramic desiccant technology, Cerades. This is clamed to significantly reduce pressure drop, boost energy efficiency, and extend service intervals – resulting in lower operating costs over the dryer’s lifetime.

HYDRAULIC BREAKERS FOR DEMOLITION Smash through concrete, asphalt, and rock with ease.

TILTROTATORS FOR PRECISION

Full 360-degree rotation and tilting for ultimate control.

Dig deep, precise holes for fence posts or foundation work.

PLATE COMPACTORS FOR STABILITY

Improve ground stability after digging trenches or preparing foundations.

TRENCHERS FOR UTILITY WORK

Dig deep and narrow trenches for piping and cabling. 05

CLAMSHELL BUCKETS FOR MATERIAL HANDLING

Scoop, transport, and dump materials with precision.

Break up frozen or compacted soil with ease.

QUICK COUPLERS FOR EFFICIENCY Change attachments in seconds without leaving the cab.

RITCHIE

EVOLVING,

A

GOES

Ritchie Bros. may have built its global reputation on the power of the auctioneer’s gavel, but today, the company is operating far beyond the auction block. As the heavy equipment industry continues its digital evolution, Ritchie Bros. has repositioned itself as a full-service asset management partner — and in the Middle East, the transformation is being led by a regional team that combines global scale with local execution.

“Our model is no longer just about unreserved auctions,” says Shirin Bazargan, Regional Operations Manager at Ritchie Bros. “We now offer a fully integrated, data-driven, and omnichannel approach to asset disposition — particularly relevant in dynamic markets like the Middle East and Africa.”

As she explains, this evolution is being driven by a strategic expansion of the company’s digital platforms such as Marketplace-E, which allows for reserved-price sales alongside Ritchie Bros.’ signature timed online auctions hosted on IronPlanet. “At the same time,” Bazargan adds, “we’ve made strategic investments in local operational capacity in Dubai — from inspections and logistics to marketing and documentation — ensuring a seamless and tailored customer experience. By combining global buyer reach with on-the-ground service, we’re able to offer sellers maximum exposure and buyers a frictionless, digital-first process that adapts to the realities of each market.”

This hybrid global-local model is proving effective as markets across the GCC region and beyond shift in response to economic diversification and largescale infrastructure investment. In Bazargan’s view, the region’s appetite for equipment remains robust, though buyer behaviour is evolving quickly.

“In the UAE and across the Middle East, demand for heavy equipment remains strong but segmented, with key activity across the construction, mining, and logistics sectors,” she says. “Construction continues to lead the market, fuelled by ongoing megaprojects and infrastructure expansion. Meanwhile, the aggregates and mining segment is gaining momentum, and the logistics sector is experiencing a surge as the UAE strengthens its position as a regional freight and transport hub.”

This sectoral growth is matched by changes in how buyers approach equipment ownership. “Buyer behaviour is evolving accordingly, with a clear shift toward flexible ownership models — including rentals and certified used equipment acquired through trusted auction platforms such as Ritchie Bros. As a result, asset values have remained stable, particularly for machines with specifications that enhance efficiency and retain strong resale value. Across the board, purchasing decisions are

increasingly influenced by cost efficiency, sustainability targets, and a growing demand for technology-enabled machinery.”

A key part of this changing landscape has been the acceleration of online sales models. Though Ritchie Bros. has offered online bidding since 2002, the full transition to timed auctions — a shift prompted by the pandemic — has now become the foundation of its regional and global sales strategy.

“Since fully transitioning to timed online auctions in 2020 during the pandemic, we’ve seen notable increases in global participation and bidder convenience, driven by a transparent and user-friendly format,” says Bazargan. “Timed auctions offer buyers the flexibility to bid from anywhere, set priority bids, and benefit from a fair closing mechanism — the timer automatically extends by two minutes if a bid is placed near the deadline, giving everyone time to respond thoughtfully. Every bid is tracked and time-stamped, reinforcing trust and ensuring competitive outcomes.”

At Ritchie Bros.’ June auction, the results were clear: more than 1,000 active bidders participated from 73 countries, including the Middle East, UK, Australia, the US, and Canada. “This global reach and accessibility are key reasons our 100% digital auctions consistently attract diverse and highly engaged audiences — delivering unmatched scale, transparency, and efficiency,” Bazargan notes.

The evolution of the Ritchie Bros. business model is also visible in its service offering, which now goes far beyond sales alone. From equipment appraisal and pricing tools to logistics and documentation support, the company’s end-to-end asset management approach is rapidly gaining traction in the GCC.

“Offering a full-service approach is essential, particularly in regions like the GCC, where customers often seek comprehensive solutions that streamline asset sales and fleet management,” Bazargan explains. “In addition to auctions, we now provide equipment appraisals, pricing tools, and access to flexible selling formats like Marketplace-E, where sellers can control timing and price. We also offer logistics and documentation support to simplify cross-border transactions.”

This bundled model has proven particularly useful in high-velocity industries such as construction, logistics, and energy. Bazargan points to a recent project in the UAE as an example. “One client in the energy sector leveraged our end-to-end solution to liquidate assets across different countries, all within a short timeframe and with full compliance,” she recalls. “A consignor urgently needed to vacate a yard in the UAE and relocate 133 industrial items — including cranes, cabins,

and various smaller equipment — to another Emirate within a strict one-week deadline due to an expiring lease. All the items were successfully dismantled, transported, and delivered to the Ritchie Bros. yard in Dubai within the deadline, enabling the consignor to avoid penalties and move forward with the sale of their equipment in the next auction.”

For many fleet owners and asset managers in the region, this kind of responsive, tightly managed operation is essential — especially as sustainability becomes an increasingly important factor in equipment strategy. In

this regard, Ritchie Bros. is well-positioned to support circular economy principles.

“Sustainability and fleet optimisation are increasingly important priorities for companies, and Ritchie Bros. offers a comprehensive solution to support effective and responsible equipment management throughout the asset lifecycle,” Bazargan explains. “Through a combination of transactional platforms and complementary services, we help businesses address key challenges such as fleet utilisation, revenue optimisation, and operational cost reduction.”

From unreserved online auctions and Marketplace-E to services such as Mascus for listings, Rouse for valuation, and SmartEquip for maintenance and parts procurement, its platform helps owners make strategic decisions and extend the useful life of equipment: “These services support circular economy principles by extending the useful life of equipment through resale and redeployment. Thanks to our global buyer base, machines often find a second life in regions where they are still in high demand. Ultimately, Ritchie Bros. helps fleet owners reduce idle inventory, improve asset utilisation, and transition toward more sustainable fleet strategies over time.”

As Ritchie Bros. deepens its capabilities, its ability to offer end-to-end asset management is redefining what companies expect from auctions in the region. With transparency, reach, and flexibility as its hallmarks, Ritchie Bros.’ approach proves that asset disposition isn’t about liquidation — it’s about strategy.

GM

CONMIX has opened a new ready mix concrete facility in Abu Dhabi, a development General Manager

Tim Senior describes as a “significant milestone” in the company’s nearly five-decade presence in the UAE. The new plant, while modest in scale, is part of a broader strategy to expand the company’s reach across the capital and its surrounding regions, and to support the country’s long-term vision for sustainable and diversified growth.

Speaking to CMME , Senior explained, “The opening of our new Ready Mix Concrete Facility in Abu Dhabi marks a significant milestone for CONMIX, a company that has been proudly serving

the UAE construction industry since 1975.”

He added that the expansion strengthens CONMIX’s presence in the capital, helping the company better support the pace of urban development and infrastructure growth taking place across Abu Dhabi and beyond.

“This facility ensures that CONMIX remains a reliable partner for our clients even during market fluctuations or unforeseen challenges,” he said.

“Ultimately, this expansion strengthens CONMIX’s national presence, commitment to quality, sustainability and innovation, while aligning with the UAE’s goals of economic diversification and long-term growth.”

The new facility comes as Abu Dhabi positions itself

as a global hub for sustainable development, and CONMIX has deliberately aligned this new operation with those ambitions. According to Senior, the plant has been developed with advanced infrastructure and sustainability principles in mind, allowing it to respond to the “accelerating infrastructure and construction demands of the UAE.”

“As Abu Dhabi continues to grow as a global hub for innovation and sustainable development, this facility ensures that CONMIX remains fully aligned with the master plan and vision of the UAE,” he said.

“This factory not only enhances our production capacity but also supports the UAE’s vision for a resilient economy. CONMIX is proud to contribute to the nation’s development goals, in full alignment with the visionary guidance and strategic leadership of the UAE Leadership.”

Like many companies in the materials sector, CONMIX is operating in an environment shaped by high demand, growing complexity, and logistical challenges. Timely delivery of raw materials is one of the biggest hurdles facing the industry today, said Senior.

“One of the key challenges faced in the industry is logistics,” he explained. “Due to the high volume of construction activities that are taking place nationwide, there is a significant demand for the timely and efficient delivery of materials.”

However, CONMIX is already benefiting from key infrastructure developments in the UAE, particularly the newly launched Etihad Rail network, which is easing pressure on supply chains.

“The newly opened Etihad Rail Line plays a crucial role in our supply chain by easing the transport of essential raw materials such as aggregates with greater efficiency and reliability,” he noted. “This not only reduces logistical pressure but also aligns with the UAE’s broader vision of adopting innovative and sustainable transport solutions.”

CONMIX, he added, continues to invest in optimising operational capabilities to “ensure uninterrupted supply, superior quality and high service delivery to meet the dynamic needs of our valued customers.”

As the UAE construction sector embraces sustainable building practices, CONMIX is actively pursuing ways to reduce the environmental impact of its production processes. The company’s research and development team is tasked with developing more environmentally conscious materials and methods.

“Sustainability is indeed a priority for CONMIX,” said Senior. “We are committed to integrating sustainable production processes and materials at every stage of our operations.”

He added that the company is “exploring alternative eco-friendly ingredients to reduce the environmental footprint of our concrete products” and that sustainability is being approached in a way that aligns with the UAE’s national goals for green development.

“At CONMIX, we take great pride in aligning our efforts with the nation’s vision for sustainable growth, ensuring that we contribute positively to a greener and more resilient built environment.”

While the new Abu Dhabi facility represents CONMIX’s immediate priority, the company’s growth ambitions stretch

further across the Emirates and potentially into wider GCC markets. Senior confirmed that the company is pursuing a carefully targeted expansion strategy, particularly in regions where infrastructure and industrial projects are on the rise.

“In Abu Dhabi, our immediate plans include anchoring our presence in the capital and potentially expanding to the western region, particularly to support oil and gas sector’s both onshore and offshore projects,” he revealed. “We are actively pursuing growth opportunities in each Emirate.”

This approach, he said, allows the company to customise its offering in line

Tim Senior describes the recently opened facility in Abu Dhabi as a “significant milestone” in the firm’s five decades in the market.

with local development plans: “Our plans in each region are thoughtfully aligned with each Emirate’s unique development vision and infrastructure projects.”

With the UAE continuing to push forward with major infrastructure and development initiatives, CONMIX sees strong growth potential on the horizon. Senior is optimistic about the company’s role in supporting this trajectory.

“Looking ahead to 2025 and beyond, the outlook for construction and infrastructure development in UAE and the broader Gulf regions remains highly promising,” he said. “We anticipate increased investments in various projects aligned with the UAE’s long-term strategic plans such as the UAE Vision 2030.”

“CONMIX remains committed in supporting the UAE’s ambition for a resilient, diverse and next-generation built environment and is very positive with regards to what the future holds in the UAE.”

As CONMIX celebrates this latest milestone, Senior used the occasion to highlight the company’s values and broader mission, drawing inspiration from its parent group, Bukhatir.

“As we celebrate this important milestone, we reaffirm our commitment to excellence, innovation and sustainable growth in line with the UAE’s visionary goals,” he said.

“At CONMIX, we believe that continuous learning and development are the cornerstone of lasting success. Inspired by the Bukhatir’s mission to cultivate lifelong learners and global citizens rooted in strong values, we strive to adapt an inclusive culture that embraces innovation, change and ethical practices.”

He concluded: “CONMIX believes in leading with a purpose, fueled by lifelong learning and a commitment to excellence.”

he Port of NEOM has marked a major milestone with the arrival of the first fully automated, remote-controlled Ship-ToShore (STS) and Electric Rubber-Tyred Gantry (eRTG) cranes in KSA—advancing its goal to become a global hub for smart, sustainable trade. Strategically located on the Red Sea, one of the world’s busiest maritime corridors, Port of NEOM is already serving as a critical gateway on the East–West trade route. The newly arrived state-of-the-art cranes will play a critical role in the port’s automation strategy, unlocking the potential for high-volume, highefficiency operations. Importantly, their remote-control capability allows for a future-ready workforce model, where operators can manage equipment from secure, ergonomic environments.

driving regional industrial growth, opening access to global markets, enhancing supply chain resilience and unlocking business opportunities.

Sean Kelly, Managing Director of Port of NEOM, said: “The arrival of our first automated cranes marks a tangible milestone as we lay the foundations for an advanced, future-ready port. We’re not only accelerating industrial growth in northwest Saudi Arabia, we’re setting a new benchmark for performance, efficiency, innovation and establishing a vital trade gateway for the Kingdom and the region beyond.”

Development of Port NEOM continues at pace ahead of the 2026 opening of Terminal 1 2026

Development of Port of NEOM continues at pace ahead of the 2026 opening of Terminal 1, a nextgeneration container terminal, with recent infrastructure milestones including the completion of a 900-meter quay wall and the deepening of the port channel to 18.5 meters—enabling the world’s largest vessels transiting the Suez Canal to call at Port of NEOM. Terminal 1 will also feature horizontal transport automation as part of the broader goal to achieve full automation. Once operational, these technologies will significantly expand the port’s logistics capacity,

Port of NEOM is also committed to developing local talent, including training Saudi women to take on high-tech roles. Central to this effort is a pioneering initiative to train the next generation of Production Specialists to gain the skills to become remote crane operators, thereby helping shape a more inclusive future for the logistics and industrial sectors. Ten participants from the Tabuk region are currently enrolled in an intensive two-year program that blends technical instruction and hands-on training with dedicated mentorship. Hajjer Alatawi, a trainee participating in the programme, said: “This experience has shown me that port logistics is far more complex than just moving cargo; it’s about teamwork, precision and responsibility. Seeing more Saudi women entering this space gives me hope.”

When it’s hard. When it’s painful. When it’s loud. The Tadano rough terrain crane GR series has it covered. Demonstrating impressive robustness and high performance, our line-up from 13t to 145t rough-terrain cranes feature state-of-the-art technology to handle even the most demanding requirements. With efficient motors, the longest boom in its class (GR-1000EX-4), compact design and smart assistant systems, everything is on board for maximum success. The GR series: maximum flexibility for your success.