PRE-FABRICATION

PRE-PLUMBED MODULAR WALL SYSTEMS

WhenChaddCookejoinedScottDowsett'splumbing businessin2008toformCooke&Dowsett,theunion combined years of plumbing expertise and industry knowledge.Thecompanyhassteadilygrownallowing us to strengthen our offering under the umbrella of Cooke&DowsettPlumbingGroup(CDPG).

Our extensive experience on large projects span the accommodation, commercial, defence, education, health,infrastructure,retail,sportsandleisuresectors.

Ourcontinualexpansionislargelyduetoourstrategic vision and passion to be innovative, commercially aware of our surroundings and needs, encourage diversity within the group and ensure we are a companywhosevaluesgobeyondfinancialgains.

CELEBRATING 30 YEARS IN THE CONSTRUCTION INDUSTRY.

A founding partner and well respected leader withintheindustryboastingmorethan30years’ experience,Scottestablishedhisfirstplumbing business in 1992. In 2008 he merged with Chadd Cooke to form Cooke & Dowsett, which hasgrownintoanationallyacclaimedcompany.

Scott is Vice President of the Master Plumbers Associationandontheboardofnumerousnotfor-profit organisations with a focus on supporting Indigenous youth. His drive and passion for cutting edge technology and innovation is apparent, through the company andthroughouttheindustry.

Chaddcompletedhisapprenticeshipatatier one commercial plumbing company and boasts over 27 years of experience in the industry. Commencing his apprenticeship in 1989, he has worked his way through the business from site management, estimating, project and construction management. In 2008 Chadd joined forces with Scott Dowsett, together an enviable force that is highlyregardedwithintheindustry.

CHADDCOOKE SCOTTDOWSETTCooke&DowsettPlumbingGroupisapartnerof choice for everything PLUMBING, one of the only truly recognised Australian National Commercial Hydraulics Plumbing companies that provides an endtoendDesign&Constructsolution.

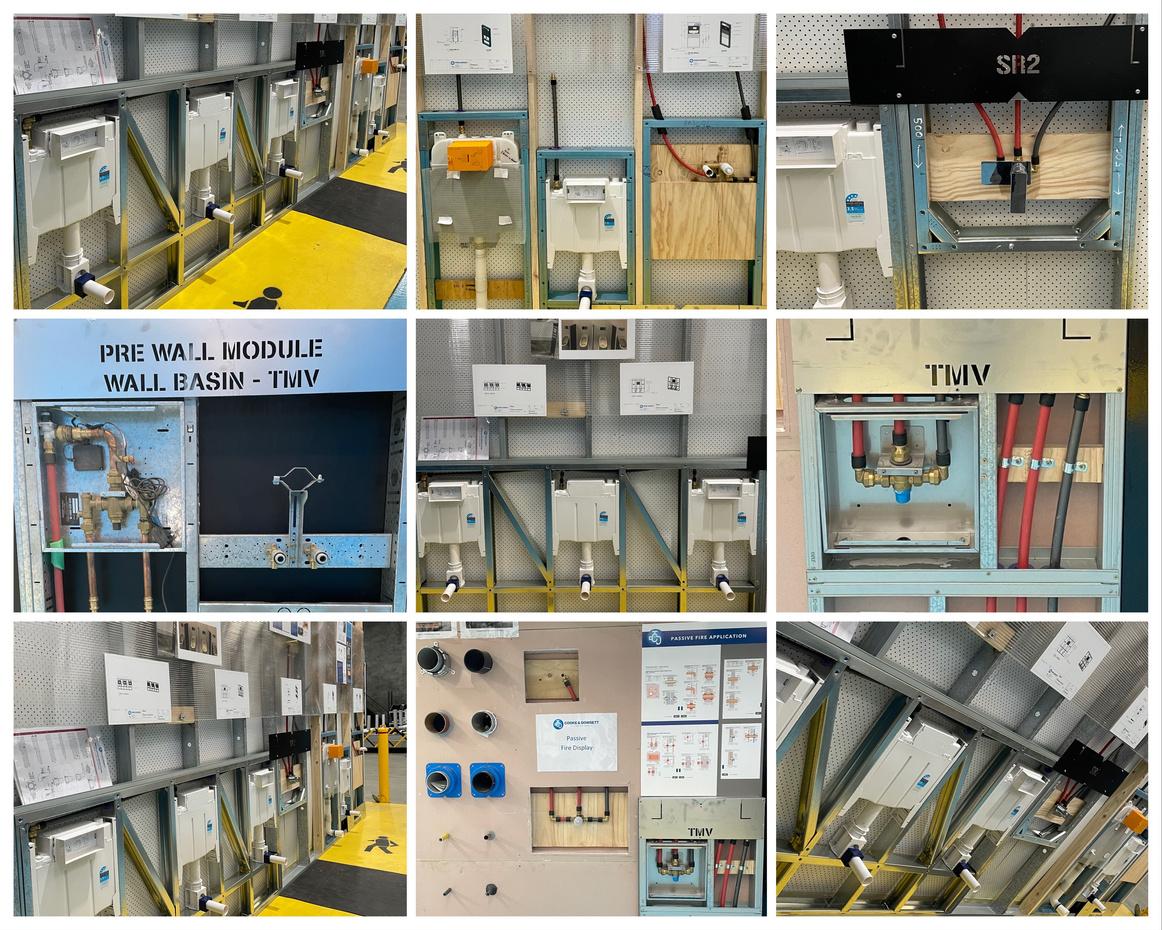

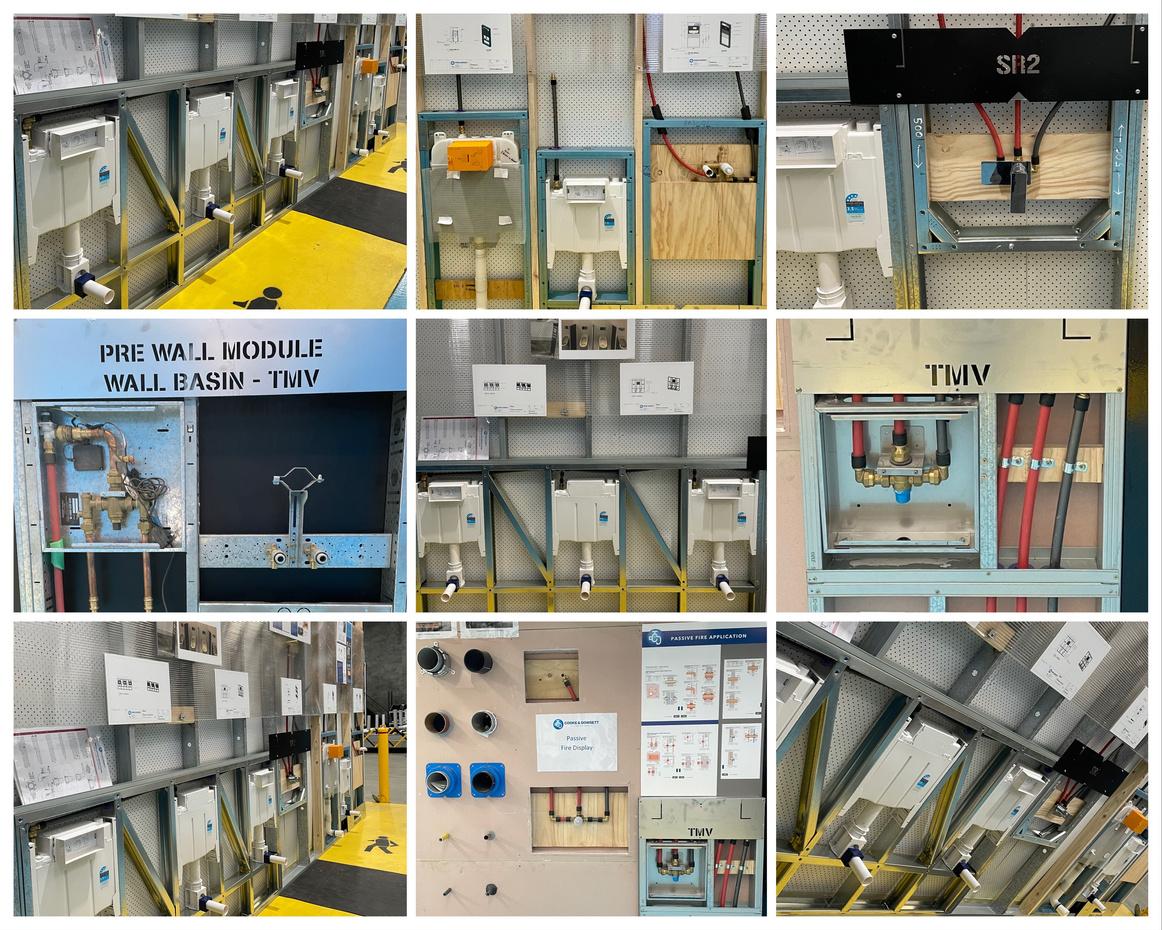

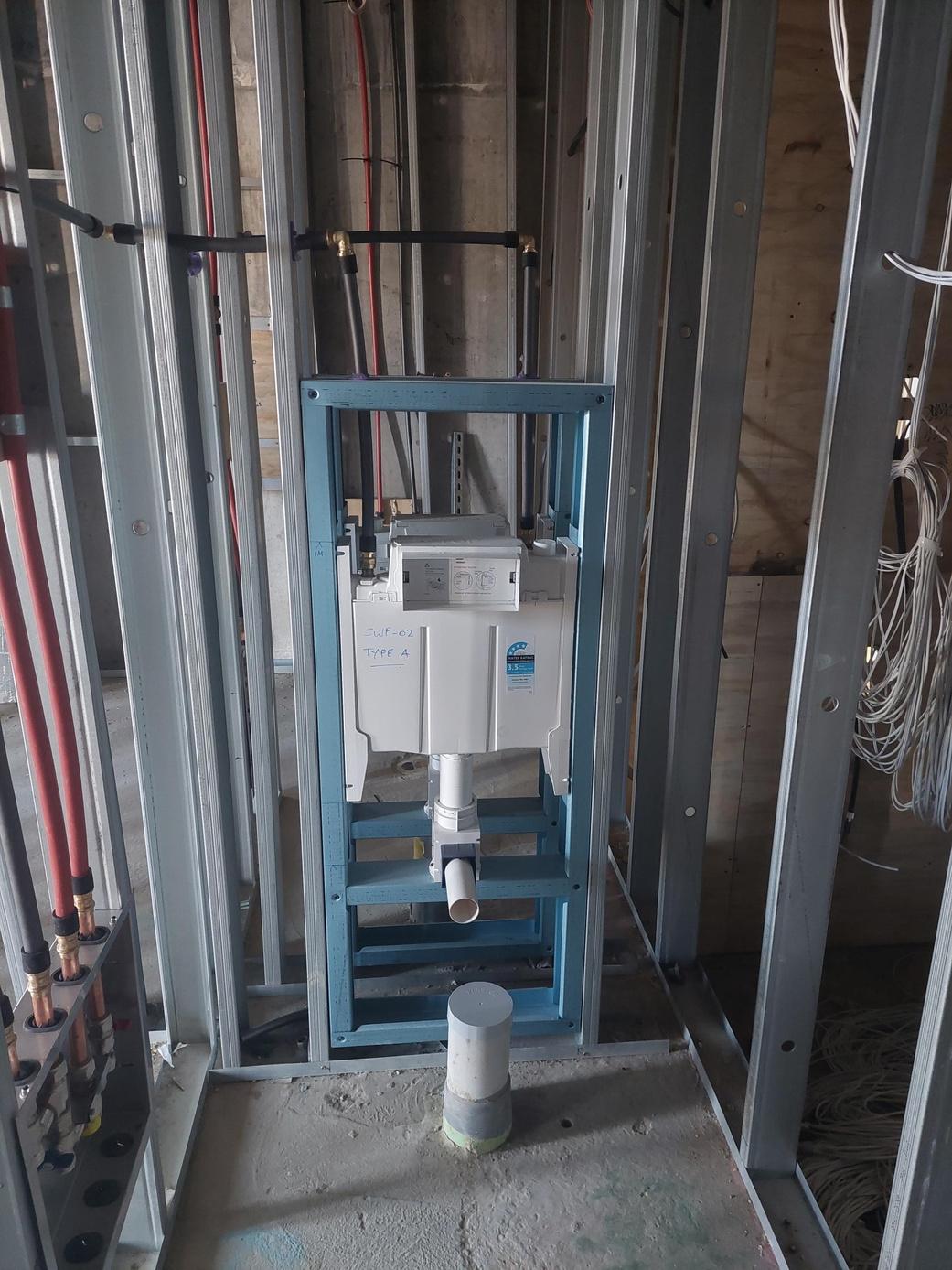

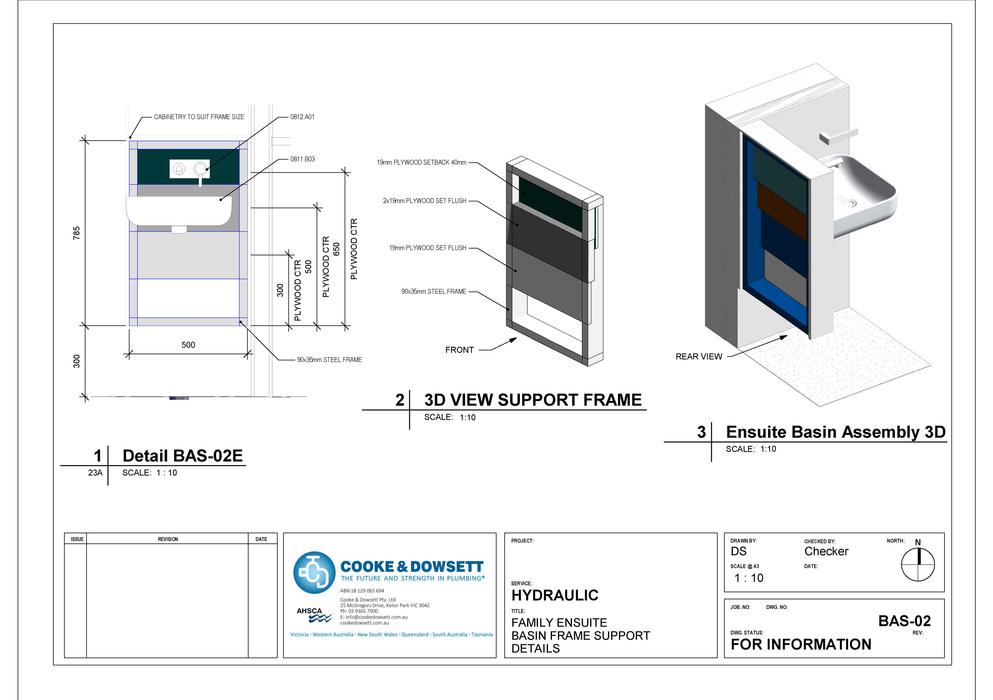

Our pre-fabrication is the practice of assembling plumbing systems in a centralised controlled environment, pre-packaged and completed for transportingtotheconstructionsite.

Off-site, pre-fabricated, pre-assembled, preplumbed modular wall systems, provides assurance of on-time delivery minimising current supply chain delays as well as allowing social procurement opportunities which are in line with oursocialvalues.

Our experienced designers work closely with all project partners and participants to ensure a seamless, co-ordinated, cost effective design whichisresponsivetoeverychallenge-ultimately providing a faster, safer, innovative and costeffectiveresult.

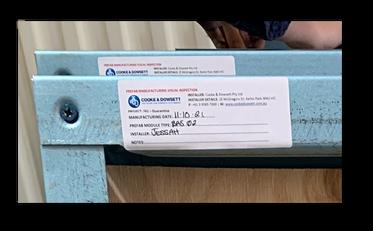

We are constantly improving our processes, minimisingourriskofinjury,reducingpackaging waste and operating costs by controlling our Quality Assurance and adopting fullycoordinated 3D BIM - REVIT Modelling design and shop drawings which can be easily customisedforyourprojectsrequirements.

INNOVATION IS ABOUT TURNING IDEAS INTO REALITY....

JUST IN TIME DELIVERIES TO AVOID STORAGE AND DOUBLE HANDLING

REDUCTION OF ONSITE WORKFORCE MINIMISES SAFETY RISKS

CONTROLLED WORK PLACE ENVIRONMENT MAXIMISES QUALITY ASSURANCE

WASTE MINIMISATION FOR SUSTAINABLE OUTCOMES

FROM DESIGN CONCEPT THROUGH TO THE FINISHED PRODUCT.

It’s a simple philosophy, in business, reputation matters. Byendeavouringtomeetandexceedclientexpectations, westandbyeveryprojectwedeliver.

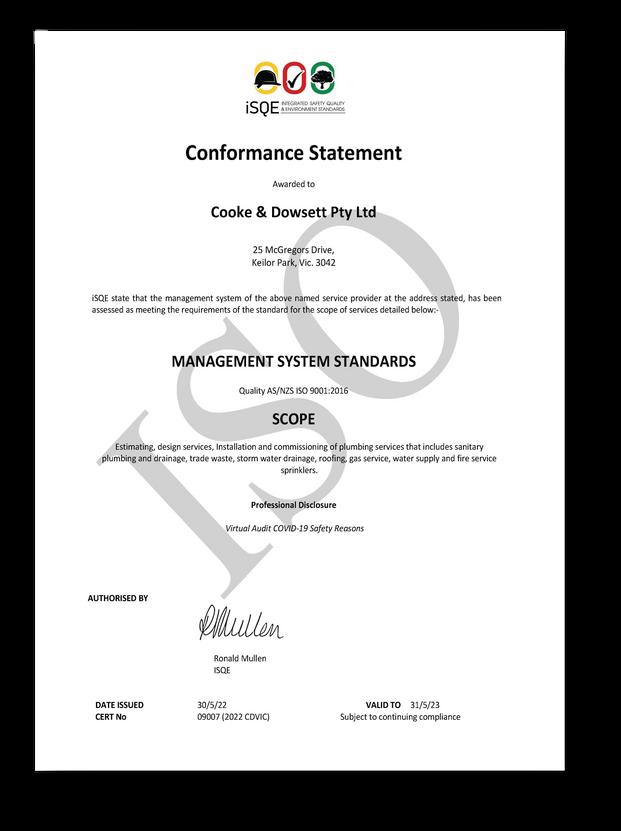

Cooke & Dowsett Plumbing Groups confidence in our ability to deliver industry-leading projects is founded on the design and implementation of our Quality Management System that details a clearly defined set of principles, processes and strategic goals that foster continuous improvement across all levels of the organisation.

Our Quality Management System is fully integrated into thebusinesswhichensuresthatallpersonnelinvolvedin project delivery, from project conception through to completion, understand the importance of producing qualityworkforourclients.Thiscommitmenttoqualityis strengthened by our qualified design and project management teams recognised through a range of industryexcellenceawards.

• ISO-accredited (AS/NZS ISO 9001:200 Quality Endorsed Company CR No 09007) and adhering to strict procedures and methodologies.

• All staff are trained in customer service to ensure customer satisfaction and sustainable supplier relationships.

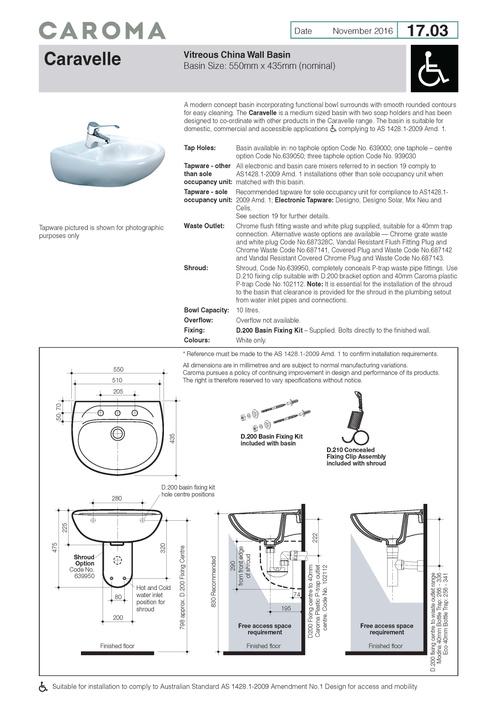

Shop drawings and schedules to meet individual fixture and tapware requirements

Limited only by imagination, our project teams are driven to evaluate all project pre-fabrication opportunities and to implement those that add value to any given project.

CDPG BIM technology addresses system coordination as well as pre-fabrication. Shop drawings are extracted from theprojectmodelsconsideringprojectlayoutsandlogistics, whichallowsforthenecessaryaccuracyrequiredtofacilitate systemfabricationwithinourstate-of-the-artfacility.

CDPG maintains a unique suite of Virtual /3D /BIM technologies that provide the highest value during all designandconstructionphases.

CDPG's extensive library and range of Modular Wall units can be project / client specific integrating documents held by the architects and included within the fixtures and tapware schedules.

CDPG continues to be a leader in pre-fabrication with the following systems:

Pre-Plumbed Modular Wall Systems

Shower Units

Invisi In-wall Cisterns (multiple options)

Wall Hung Basins & Wall Mixers

Wall Hung Urinals

Site Specific - Off Site Assembly

Pre-Plumbed Water Meter Assemblies

Manifolded Piped Services Risers;

-Stainless Steel

- Copper Pipe & Fittings

- PVC & Specialty Piping

Hangers and support systems

Engineered Seismic Solutions

Skid Mounted Hot Water Packages

Pre-Fab below ground drainage solutions

Pre-Plumbed mounted valve assemblies

CDPG Catalogue of Innovative options

Thermostatic mixing valves

Gas Check meters

Pre-cut pipe althread & piping clips

Pre-assembled solenoid valves

Multi Pipe Services Risers

Cold Water Pump Packages

Dual Hot Water Circulating Pumps

In-wall and in-slab rough-in units

Isolation valves

QUARANTINE FACILITIES

A purpose-built quarantine facility in WA was required during the COVID19 pandemic to accommodate those returning to WA and needing to quarantineforthemandatory14-days.

Thefacilityfor500bedsconsistedofa mix of modular units accommodating from 1- 4 people. Each unit needed to befullyself-sufficientandwitheasyto useappliances.

Constructedascompletemodular pre-fabricated units in VIC these were then transported to WA and installed. This pre-fabricated process enabled thefacilitytobeconstructedwithboth timings and number of people on-site tobecontrolled.

PRE-FABRICATED MODULARUNITS

TOILETS 185 SHOWERS 185 BASINS 200

At the heart of the Kardinia Park Stage Five project is the construction of a 14,000-capacity, two-tier Northern StandtoreplacetheageingFordStand and Ablett Terrace. This will increase the stadium’s capacity to more than 40,000people.

Stage Five of the Redevelopment includestheinstallationofour pre-fabricated modular wall frames in the Ground Floor and Level 2 cricket change room and event staff managementarea.

Work is expected to be completed by late2023.

Designed and manufactured offsite. The installation of the pre-fabricated duct risers sat between the levels throughout the building.

03 9365 7000

INFO@CDPG.NET.AU

CDPG.NET.AU

C D P G

CDPG COMPANIES;

CENTRAL PLUMBING & HARDWARE

HYDRAULIC PLUMBING SERVICES

DESIGN & CONSTRUCTION

FIRE SERVICES & SPRINKLER SYSTEMS

COMMERCIAL & INDUSTRIAL PLUMBING

DRAINAGE CONTRACTORS

GAS INSTALLATIONS

PROJECT MANAGEMENT & COST PLANNING

ROUTINE & PREVENTATIVE MAINTENANCE

PRE-FABRICATION

PATHWAY PLUMBING SERVICES

COOKE & DOWSETT ALBURY PROJECT PLUMBING & MAINTENANCE

COOKE & DOWSETT

NUDJ PLUMBING SERVICES

THE PLUMBING AND GAS GUYS L O C A T I O N S

COOKE & DOWSETT ROSETTA