PACIFIC NORTHWEST EDITION

A Supplement to:

®

October 2 2016 Vol. I • No. 20

“The Nation’s Best Read Construction Newspaper… Founded in 1957.” Your Pacific Northwest Connection – Patrick Kiel – 1-877-7CEGLTD – pkiel@cegltd.com

ODOT to Host Public Grand Opening for Highway 20 By Lori Tobias CEG CORRESPONDENT

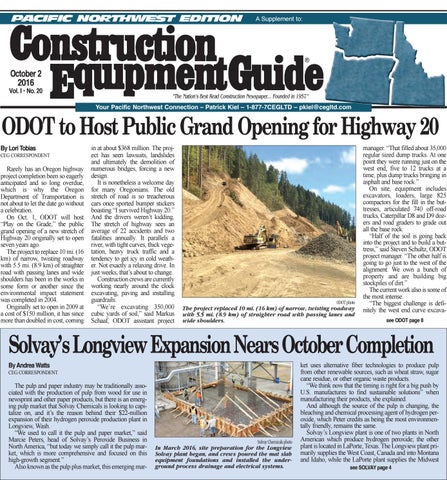

Rarely has an Oregon highway project completion been so eagerly anticipated and so long overdue, which is why the Oregon Department of Transportation is not about to let the date go without a celebration. On Oct. 1, ODOT will host “Play on the Grade,” the public grand opening of a new stretch of Highway 20 originally set to open seven years ago. The project to replace 10 mi. (16 km) of narrow, twisting roadway with 5.5 mi. (8.9 km) of straighter road with passing lanes and wide shoulders has been in the works in some form or another since the environmental impact statement was completed in 2004. Originally set to open in 2009 at a cost of $150 million, it has since more than doubled in cost, coming

in at about $368 million. The project has seen lawsuits, landslides and ultimately the demolition of numerous bridges, forcing a new design. It is nonetheless a welcome day for many Oregonians. The old stretch of road is so treacherous cars once sported bumper stickers boasting “I survived Highway 20.” And the drivers weren’t kidding. The stretch of highway sees an average of 22 accidents and two fatalities annually. It parallels a river, with tight curves, thick vegetation, heavy truck traffic and a tendency to get icy in cold weather. Not exactly a relaxing drive. In just weeks, that’s about to change. Construction crews are currently working nearly around the clock excavating, paving and installing guardrails. “We’re excavating 350,000 cubic yards of soil,” said Markus Schaaf, ODOT assistant project

ODOT photo

The project replaced 10 mi. (16 km) of narrow, twisting roadway with 5.5 mi. (8.9 km) of straighter road with passing lanes and wide shoulders.

manager. “That filled about 35,000 regular sized dump trucks. At one point they were running just on the west end, five to 12 trucks at a time, plus dump trucks bringing in asphalt and base rock.” On site, equipment includes excavators, loaders, large 825 compactors for the fill in the buttresses, articulated 740 off-road trucks, Caterpillar D8 and D9 dozers and road graders to grade out all the base rock. “Half of the soil is going back into the project and to build a buttress,” said Steven Schultz, ODOT project manager. “The other half is going to go just to the west of the alignment. We own a bunch of property and are building big stockpiles of dirt.” The current work also is some of the most intense. “The biggest challenge is definitely the west end curve excavasee ODOT page 8

Solvay’s Longview Expansion Nears October Completion By Andrea Watts CEG CORRESPONDENT

The pulp and paper industry may be traditionally associated with the production of pulp from wood for use in newsprint and other paper products, but there is an emerging pulp market that Solvay Chemicals is looking to capitalize on, and it’s the reason behind their $22-million expansion of their hydrogen peroxide production plant in Longview, Wash. “We used to call it the pulp and paper market,” said Marcie Peters, head of Solvay’s Peroxide Business in North America, “but today we simply call it the pulp market, which is more comprehensive and focused on this high-growth segment.” Also known as the pulp plus market, this emerging mar-

Solvay Chemicals photo

In March 2016, site preparation for the Longview Solvay plant began, and crews poured the mat slab equipment foundations and installed the underground process drainage and electrical systems.

ket uses alternative fiber technologies to produce pulp from other renewable sources, such as wheat straw, sugar cane residue, or other organic waste products. “We think now that the timing is right for a big push by U.S. manufactures to find sustainable solutions” when manufacturing their products, she explained. And although the source of the pulp is changing, the bleaching and chemical processing agent of hydrogen peroxide, which Peter credits as being the most environmentally friendly, remains the same. Solvay’s Longview plant is one of two plants in North American which produce hydrogen peroxide; the other plant is located in LaPorte, Texas. The Longview plant primarily supplies the West Coast, Canada and into Montana and Idaho, while the LaPorte plant supplies the Midwest see SOLVAY page 4