By Chuck MacDonald CEG CORRESPONDENT

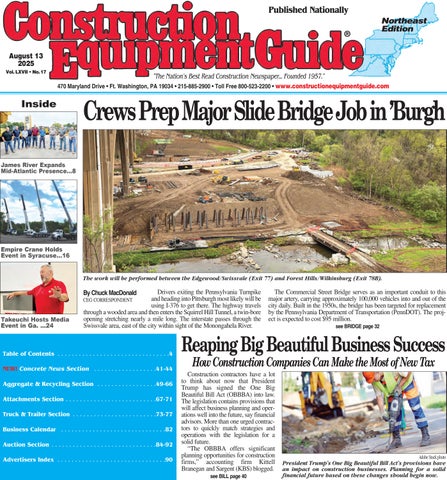

Drivers exiting the Pennsylvania Turnpike and heading into Pittsburgh most likely will be using I-376 to get there. The highway travels through a wooded area and then enters the Squirrel Hill Tunnel, a twin-bore opening stretching nearly a mile long. The interstate passes through the Swissvale area, east of the city within sight of the Monongahela River.

The Commercial Street Bridge serves as an important conduit to this major artery, carrying approximately 100,000 vehicles into and out of the city daily. Built in the 1950s, the bridge has been targeted for replacement by the Pennsylvania Department of Transportation (PennDOT). The project is expected to cost $95 million.

see BRIDGE page 32

Construction contractors have a lot to think about now that President Trump has signed the One Big Beautiful Bill Act (OBBBA) into law. The legislation contains provisions that will affect business planning and operations well into the future, say financial advisors. More than one urged contractors to quickly match strategies and operations with the legislation for a solid future.

“The OBBBA offers significant

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a problem.

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

8 JRE ACQUIRES FOUR MID-ATLANTIC JESCO EQUIPMENT LOCATIONS

Effective Aug. 1, 2025, James River Equipment expanded its footprint and services in the Mid-Atlantic region as it finalized the acquisition of four JESCO Equipment locations in Baltimore, Delmar, Frederick and Waldorf, Md.

S&B USA was named a Greatest Place to Intern in Pa. by the Pa. Chamber of Business and Industry. The award celebrates Pennsylvania employers who create dynamic, engaging and educational experiences for their interns.

The event welcomed crane enthusiasts, operators, industry professionals and curious community members from across the region to explore the latest equipment, meet with manufacturer reps and enjoy food and refreshments.

Mark Urso, Bear Contracting LLC, Bridgeport, W.Va., has been elected president of the Contractors Association of West Virginia (CAWV). He replaces James W. “Tripp” Dailey III, W. Harley Miller Contractors Inc.

Takeuchi hosted construction equipment journalists and dealer representatives to its United States headquarters in Pendergrass, Ga., July 21-22. The focus of the event was to introduce the new Takeuchi TL11R3 compact track loader.

25 TAKEUCHI INTRODUCES NEW TL11R3 COMPACT TRACK LOADER

Takeuchi introduced the sixth model in its compact track loader product line — the TL11R3. This new machine features new electric-over-hydraulic (EH) controls for greater precision in loader arm, bucket and travel speed operation.

28

The largest single investment in the tournament’s 145-year-history, the renovation project is set to be completed in time for the beginning of the competition in August 2027.

The AED Foundation (AEDF) announced that Warrick Pathways and Career Center in Booneville, Ind., has become the 115th Recognized High School Program under its national workforce development initiative.

In Basking Ridge, N.J., Konkus Corporation is breathing new life into aging infrastructure by replacing a deteriorating bridge deck with a robust new concrete surface.

73

Felling Trailers Inc. announced Ivy’s Legacy Foundation as the beneficiary of the 13th annual 2025 Trailer for a Cause auction. This tradition involves auctioning a custom FT-3 utility trailer online.

74 LEER GROUP STARTS PRODUCING ITS SNUGTOP PRODUCTS IN U.S.

The celebration at LEER’s Elkhart facility marks the full return of United States-based production for SNUGTOP, which manufactures more than 400 high-quality truck cap products for a growing number of automotive brands.

76 BELL TRUCKS NAMES RIDGELINE EQUIPMENT AS NORTHEAST DEALER

Bell Trucks America (BTA) announced the appointment of Ridgeline Equipment Sales & Rentals as an authorized Bell articulated dump truck (ADT) dealer serving the Northeast United States, including West Virginia regions.

PROTECTING YOUR EQUIPMENT: ACTIONS YOU CAN TAKE

Equipment

in North America alone.

S&B USA was named a Greatest Place to Intern in Pa. by the Pennsylvania Chamber of Business and Industry.

The award celebrates Pennsylvania employers who create dynamic, engaging and educational experiences for their interns. S&B USA and other recognized businesses will gather on July 31 at the State Capitol in Harrisburg to formally receive the award.

Awarded by the Pennsylvania Chamber Foundation, which supports the PA Chamber’s mission, the inaugural “Greatest Places to Intern in Pa.” awards honor organizations across industries and sizes that provide exceptional internship experiences to students throughout Pennsylvania. See the Foundation’s press release for additional details.

S&B USA’s 2025 internship program provided paid summer employment to 29 college students — the company’s largest-ever intern class — from colleges and universities including Gannon University, Mercyhurst University, Ohio University, Slippery Rock University, Pennsylvania State University, Pennsylvania College of Technology and the University of Pittsburgh.

“With the committed engagement of our leadership, our expanding partnerships with several key universities in the Mid-Atlantic region and collaboration with our clients and industry groups, we’re growing our internship program to shape the next generation of construction industry professionals,” said Laurie Roy, executive vice president and chief

human resources officer of S&B USA.

Angelina Sweeney, a senior civil engineering major at the University of Pittsburgh’s Swanson School of Engineering who is now in her second summer internship with S&B USA, said: “During my two internships at S&B USA, I gained valuable experience in the field of civil engineering both technically and professionally. I learned how to manage and develop schedules for large- scale construction projects, as well as collaborate on ideas with a team. This hands-on experience not only sharpened my knowledge of the construction side of civil engineering but also gave me confidence in my ability to contribute meaningfully to my field. S&B USA encourages learning and values everyone’s contributions to make the company a place where both people and projects can grow.”

S&B USA selects summer interns through a competitive application and interview process.

Internships are available in a variety of functions including concessions, construction, estimating and scheduling and

safety as well as in finance, human resources and marketing. The company will post its summer 2026 internship positions in the fourth quarter of 2025 at www.shikunusa.com/careeropportunities and www.linkedin.com/company/shikunusa/.

S&B USA interns earn competitive pay, and non-local students also receive a one-time housing stipend. All interns, regardless of department and role, visit at least one of the company’s construction sites during their internship, which typically lasts 10 weeks. Interns assigned to a specific construction site also have the opportunity to tour a different project site to broaden their experience.

In addition, several of S&B USA’s technical/engineering interns are selected to participate in the Transportation Quality Initiative Shared Interns Program sponsored by the Pennsylvania Department of Transportation, Pennsylvania Turnpike Commission, Associated Pennsylvania Contractors and American Council of Engineering Companies Pa. This experience provides additional exposure to four major career paths in transportation — agency/owner, consultants, contractors, academia — and hands-on activities alongside interns from the agencies and construction and engineering firms.

Throughout the summer, S&B USA’s interns enjoy social activities that range from attending Pittsburgh Pirates games and performing a community volunteerism activity, to joining company events. At the end of the summer, each intern prepares and delivers a presentation to S&B USA’s senior leadership team about what they learned during their internship.

Effective Aug. 1, 2025, James River Equipment expanded its footprint and services in the Mid-Atlantic region as it finalized the acquisition of four JESCO Equipment locations in Baltimore, Delmar, Frederick and Waldorf, Md. The company said, with this move, James River

Equipment reinforces its commitment to delivering John Deere services to customers across the region, while further solidifying its position as a leading John Deere equipment dealer.

This acquisition enables James River Equipment to

expand its services into Maryland and Washington, D.C.

James River Equipment has a storied history with John Deere tracing back to 1926, while JESCO Equipment has been integral to the construction industry in the northeast and mid-atlantic regions since 1972. In addition, this acquisition is expected to fuel greater innovation and resourcefulness, enabling an even more comprehensive response to the evolving demands of the industry, the company said.

“This acquisition further strengthens James River Equipment and continues to allow our company to serve customers in the mid-atlantic region with quality machines, service, parts and support,” said Mark Romer, president and CEO of James River Equipment.

Terry Thomas, president of construction and forestry of James River Equipment, doubled down on a customercentric focus and mentioned employees have plenty to be excited about, as well.

“This acquisition not only drives customer care to new heights, but will also create a collaborative and valuable environment for customers and employees alike.” By completing this acquisition, James River Equipment will be able to provide enhanced support to customers. James River Equipment firmly believes that this transaction ushers the company into a new era, enabling it to provide enhanced customer support.

James River Equipment will continue to be headquartered in Ashland, Va., and looks forward to continuing to serve its customers with excellence.

more information, visit

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

New Rogers TAG25's, 24' or 26' deck. Wood or Ladderbar Style 6' Tail. Wood or Ladderbar Style 8' Air Ramps Full floor or Custom Bucket Pocket in the deck. Safety Lighting Package........ In Stock and In Production!

ASK

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint........IN STOCK

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

New Rogers 35 ton CR35GR Gentle Risers In Stock, No-Foot Neck w/ tool box, Gooseneck work lights, 24' deck, 16* slope, adj. width bi-fold ramps, side reinforcing full length, chain boxes, outriggers, 275's on alum. outers, Air Ride, Air Dump, Aux. Night Light Battery, Extra Markers & Turns, Rear Strobes. Side Strobes Viper Red and Black................In Stock!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

Empire Crane Company hosted a successful twoday open house event, Empire Crane Days, on July 17 and 18 at its Syracuse headquarters.

The event welcomed crane enthusiasts, operators, industry professionals and curious community members from across the region — and beyond — to explore the latest equipment, meet with manufacturer reps and enjoy free local food and refreshments.

On display and available for live demos were machines from Jekko, Manitex, Magni, Tadano and Broderson. Units such as all-terrain cranes, rough-terrain cranes, telescopic crawler cranes, mini cranes, boom truck cranes, rotating telehandlers and more were on hand. Manufacturer representatives also were on site throughout both days to speak directly with attendees, answer technical questions and showcase the features and capabilities of their respective units.

A highlight of the event was the wide selection of free food and refreshments provided by popular local vendors, including Via Napoli Wood Fired Food Truck & Catering, Habibi’s Halal Gyro Food Truck, CueDogs Hot Dog Trailer and Sara’s Lemonade, which featured fresh-squeezed flavored lemonades, freezedried candy and snow cones, offering a refreshing treat in the warm July weather.

“Empire Crane Days was all about bringing people together — whether you’re an experienced crane operator or someone just starting out in the industry,” said Luke Lonergan, owner of Empire Crane. “We wanted to create an environment where customers could not only see these incredible machines up close but also connect with the people behind the brands. The turnout and energy were amazing, and we’re already looking forward to the next one.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

see EMPIRE page 38

Mark Urso, Bear Contracting LLC, Bridgeport, W.Va., has been elected president of the Contractors Association of West Virginia (CAWV).

He replaces James W. “Tripp” Dailey III, W. Harley Miller Contractors Inc., Martinsburg, W.Va., who will serve on the board of directors as immediate past president.

Serving with Urso as officers for the coming year are:

• Shannon Hapuarachy, SMH Construction Company Inc., Beckley, senior vice president;

• Derick Foster, Paramount Builders LLC, St. Albans, vice president;

• James Scott Pierson, Remnant Contracting, Milton, treasurer; and

• Jason Kitzmiller, ALL Construction Inc., Petersburg, secretary.

Courtney Persinger, Persinger & Associates Inc., Charleston; Ryan Cocco,

Kokosing Construction Company Inc., Westerville, Ohio; and Brandon Duriez, Snyder Environmental Services, Kearneysville, were elected as members of the board of directors.

In addition, CAWV elected chairs of its four (4) divisions.

• Building Division Chairman: Matthew Bourne, March-Westin Company Inc., Morgantown;

• Highway and Heavy Division Chairman: Jason Workman, Mountaineer Contractors Inc., Kingwood;

• Municipal and Utility Division Chairman: Rob LaFon, Famco Inc., Huntington;

• Associate Division Chair: Marc Magro, Greer Industries Inc., Morgantown.

CAWV represents more than 500 businesses in the building, utility, and highway construction industries.

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER....................................................$32,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXT HOE, TOOL CARRIER, TURF TIRES, BHOT SET TO CAT....$29,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE............................................................................$99,995

CHIPPERS:

EXCAVATORS:

SKID STEER LOADERS:

$105,000

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD CPLR, 78” BKT, BACKUP CAMERA....SOLD

$149,995

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER..........................................................................

2019 KOBELCO SK140RLC, 2192 HRS, CAB, HVAC, HYD THUMB, FRONT BLADE, RUBBER TRACK PADS..................................SOLD

2023 KOBELCO SK140RLC-7, 288 HRS, CAB, HVAC, BLADE, THUMB, COUPLER SOLD

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS $45,000

TRACTORS:

2012 CASE MAX110, CAB, HVAC, 6380 HRS, 4WD, LOADER, 3PT HITCH, 3 SETS REAR REMOTS, AG TIRES........................$42,000

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..............

$169,995

MISCELLANEOUS:

$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH........................................

$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP........................................................................$64,995

SCREENERS:

2021 VIBROSCREEN SCM40

$79,995

2021 VIBROSCREEN SCM27 $62,995

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE................................................................$195,000

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........

$179,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED

$295,000

2003 TEREX HR16 MINI EXCAVATOR, CAB, HEAT, 3253 HRS, HYD

THUMB, RUBBER TRACKS, 4 TON........................................SOLD

2018 YANMAR VI080-1A, CAB, HVAC, 1351 HRS, THUMB, RUBBER TRACKS SOLD

WHEEL LOADERS:

2022 AVANT 528LX, 40 HRS, CAB W/HEAT, 51” BUCKET, 43” ROTARY BROOM, LIKE NEW CONDITION..........................$46,995

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER..................................................................................$39,995

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $17,995 HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT. HEAPED..................................................................................$3000

KUBOTA KX080 EXCAVATOR TO SKID STEER COUPLER ADAPTOR ..............................................................................................$3,199 48” REVERSE LUG GRADING BUCKET, FITS KUBOTA 57&55, NEW

WERKBRAU CEMETERY 36” BUCKET, FITS BACKHOE $2,200

CIT 84” ROTOTILLER FOR SKID STEER, DUAL MOTOR $3,995

2.8 YD BUCKET ISO STYLE MOUNT $7,500

HYD COUPLER, FITS HITACHI ZW140/ZW150-6 ISO

You call Milton CAT when you need to rent a generator:

• Availability. Even when everyone else needs a generator, you’ll get yours.

• Product quality. All EPA-certified, clean, well-serviced gensets.

• Complete range. From 20 to 2,000 kW; Diesel and gas; portable and Tier IV models.

• All the ancillaries.

• Expert support; 7/24 service.

• Priced to fit your budget.

Four locations serve Maryland, Delaware, Washington, D.C. and parts of Virginia, New Jersey, and Pennsylvania

Elliott & Frantz can show you the latest Gradall models, including Series IV excavators with highway speed travel capability. Featuring AutoDrive™, these models integrate a 6-speed automatic transmission and a new transfer case for efficient, simplified travel as well as convenient jobsite repositioning from the upper cab.

Gradall excavators also feature the job-proven telescoping, tilting boom that enables you to do more different jobs with just one machine – even under bridges and trees.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

Stephen Odum (R), Takeuchi national marketing manager, welcomes the newest Takeuchi Brand Ambassadors, Erika and Cody Archie of Bar 7 Ranch, Gatesville, Texas, to the event.

Many rooms of the 37,000-sq.-ft. training center house virtually every Takeuchi product for technical training for company and dealership salespeople, technicians and trainers.

The new TL11R3s are arriving daily and are merging in with the massive quantities of other Takeuchi machines in the warehousing area.

Guests were provided a complete tour of the facilities and an opportunity to interact with staffers in all departments.

Takeuchi hosted construction equipment journalists and dealer representatives to its United States headquarters in Pendergrass, Ga., July 21-22. The focus of the event was to introduce the new Takeuchi TL11R3 compact track loader and to showcase the entire Takeuchi line.

Takeuchi-US President Jeff Stewart spoke and was in attendance at all of the events. Stewart and the entire Takeuchi staff conducted an extremely enjoyable two-day event of learning and machine operation.

Press representatives and dealer representatives were given individualized and comprehensive machine introductions. Attendees operated the all-new TL11R3 and had the opportunity to operate other machines that were staged in the demo area situated directly behind the training center.

A complete tour of the corporate campus, walkarounds of all Takeuchi machines and attachments and an opportunity to interact with all departments and product mangers provided attendees a greater understanding and knowledge of Takeuchi. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Johnson (L), Takeuchi brand ambassador of Elite Earthworks, Joplin, Mo., and Dylan Freeman, Takeuchi product manager discuss the new TL11R3 compact track loaders at the demo area.

(L-R): Takeuchi’s Lee Padgett, David Pearson and Andrew Summerlin tell a tour group that Takeuchi is one of the only manufacturer’s that prep machines, including attachment installation prior to shipping to the dealers.

Takeuchi introduced the sixth model in its compact track loader product line — the TL11R3. This new machine features new electric-over-hydraulic (EH) controls for greater precision in loader arm, bucket and travel speed operation.

“The TL11R3 delivers impressive torque and horsepower along with leading bucket breakout and lift-arm forces for maximum performance,” said Dylan Freeman, product manager of Takeuchi-US. “And, with the addition of low-effort EH controls, this track loader helps even the most skilled operators work with more precision and control — elevating their craft while reducing fatigue.”

The TL11R3’s EH controls also enhance job site productivity by making several new features possible, according to Takeuchi. Operators can instantly switch between ISO and H patterns through the machine’s monitor to match their preferences. The TL11R3’s self-leveling up-and-down feature automatically keeps the bucket or attachment level while raising or lowering the loader arm for improved load handling.

A 14-pin detent provides continuous power to electrically operated attachments for uninterrupted operation. Operators also can adjust the track loader’s boom, bucket and travel sensitivity to match their needs for greater control during high-precision work. In low-clearance environments, the arm height limit feature prevents the TL11R3’s loader arm from exceeding a predetermined height, protecting attachments and surroundings from accidental damage, according to Takeuchi.

Available in both standard- and high-flow configurations, the TL11R3 allows operators to adjust flow rates and attachment presets from inside the cab. The high-flow configuration delivers up to 40 gal. per minute

of auxiliary flow for use with more powerful attachments like mulchers, cold planers and stump grinders. Both configurations come equipped with a 14-pin connector enhancing versatility and functionality for a wide range of attachments. Swapping attachments is simple with the mechanical universal quick attach on canopy models and the hydraulic universal quick attach on cab models. A 270-degree rearview camera comes standard on the high-flow configuration and is optional on the standard-flow configuration, according to Takeuchi.

The TL11R3 has an operating weight of 11,650 lbs. (canopy model), an ROC of 2,735 lbs. and a bucket breakout force of 7,958 lbs. Its radial-lift boom design is engineered to deliver superior breakout forces for exceptional lifting power with fewer moving parts, making it particularly well suited for grading and dirt work, according to Takeuchi. Rugged steel construction and a one-piece, purpose-built, fully welded frame offer greater strength and rigidity while protecting the engine and hydraulics.

With a 12.4-in. ground clearance, the TL11R3 provides excellent flotation, traction and stability for navigating on challenging terrain with ease, according to Takeuchi.

The machine’s undercarriage features heavy-duty sealed rollers with metal face seals to keep dirt and debris out, while double-reduction planetary drives and 18-in. tracks deliver powerful tractive effort.

Inside the TL11R3, operators will find a six-way, adjustable high-back suspension seat and an 8-in. touchscreen display for real-time machine vitals and visibility to the rearview camera, as well as access to the Bluetooth radio, HVAC controls and other machine functions. The track loader can operate whether its overhead roll-up door is open or closed, regardless of the loader arm position.

A lockable hood, steel rear door and integrated bumper protect vital engine components, with the rear door also providing access to a swing-out cooling module for easy cleaning and inspection. The TL11R3’s 107.3-hp engine meets Tier IV Final emis-

sions standards with a DOC, DPF and SCR after-treatment system.

Takeuchi’s Fleet Management (TFM) telematics system is standard on the TL11R3 for five years. TFM reduces downtime and controls costs by providing owner/operators with machine health and condition, run time (hours) and machine location, as well as remote diagnostics, scheduled maintenance reminders and customizable alert settings. TFM also gives owners the ability to geofence their machines, helping them protect and secure their investments, according to Takeuchi.

“We believe the TL11R3 offers the perfect blend of power, durability and operator comfort to tackle even the toughest projects,” said Freeman. “We listened to our customers and designed the TL11R3 with features that make it one of the most capable, durable track loaders available on the market today. It’s ready to work whenever you are.”

For more information, visit takeuchius.com.

1525 SE Cortina Dr. Ankeny, IA 50021 515-965-1000 2111 Grays Rd. Dundalk, MD 21222 443-399-7100

35170 Mark McCowan Drive Geismar, LA 70734 225-251-7500 1123

America’s biggest tennis stage will soon get a major makeover.

The United States Tennis Association (USTA) unveiled plans May 19, 2025, for an $800 million “reimagining” of the Billie Jean King National Tennis Center in Queens, N.Y., which will include a top-tobottom transformation of Arthur Ashe Stadium, the U.S Open’s iconic center court.

The largest single investment in the tournament’s 145-year-history, the renovation project is set to be completed in time for the beginning of the competition in August 2027. It will take place across three phases, without interrupting play or fan access for the next two tourneys.

The project is entirely self-funded by the USTA, with New York City continuing to benefit from more than $1.2 billion in annual economic impact due to the three-week-long U.S. Open.

Combined with the tournament’s most recent transformation project, completed in 2018, the USTA has invested nearly $2 billion into the U.S. Open and its home facility without using any public, taxpayer or government funding.

Tennis.com reported that fans can expect more elbow room in Arthur Ashe Stadium, which was built in 1997 and last renovated in 2016. The latest project will include new loge and promenade levels and an expansive promenade concourse with an oversized, publicly-accessible premium bar featuring views of the Fountain Plaza and the Unisphere.

Also in the works is a new Player Performance Center to support the nearly 2,800 players and teams that converge on the U.S. Open every summer.

The $250 million facility will feature a two-story player area designed with both indoor and outdoor performance and relaxation spaces, as well as expansive locker rooms and lounges and a two-level parking structure on what is currently Parking Lot A.

“This is an incredibly exciting moment for our sport and for the U.S. Open,” said Brian Vahaly, the USTA’s chair and president. “We’re proud to unveil the largest single investment in the history of this event, a multi-year transformation that will elevate the experience for every fan, player and partner who enters the grounds at the USTA Billie Jean King National Tennis Center.”

Lew Sherr, the USTA’s CEO and executive director, said the reimagination of Arthur Ashe Stadium and the nearby Player Performance Center will enhance the experience for everyone that comes to the tennis complex.

“There is something for everybody in this design,” he told Tennis.com. “We are enhancing and modernizing every aspect of

Arthur Ashe Stadium and the venue — from seating to concourses to restrooms to points of sale, including premium hospitality and courtside experiences.

“There’s also an extraordinary opportunity to support our athletes in a much better way [with] … a modernized and new facility with premium amenities and equipment to allow them to compete at their absolute best, and also to allow them to enjoy the threeweek experience with us in Queens like never before,” said Sherr.

Rossetti, an architectural firm based in Detroit, Mich., is behind the design of the reimagined Arthur Ashe Stadium, named for the only Black man ever to win the singles titles at Wimbledon, the U.S. Open and the Australian Open prior to his death in 1993.

In addition, Rossetti was the architect of the arena’s original construction, as well as the transformation project that was completed in 2018; and also is the lead architect of the newest renovations at the Billie Jean King Tennis Center.

The design studio, led by President and CEO Matt Rossetti, conceptualized and designed the Player Performance Center after having created similar facilities for the NBA’s Los Angeles Lakers and the NFL’s Green Bay Packers, Miami Dolphins and Jacksonville Jaguars.

To create the look of the new Grand Entrance of Arthur Ashe Stadium, Rossetti worked with Daniel Libeskind, the worldrenowned master planner and architect for the reconstructed World Trade Center in Manhattan. And, for the concepts and design of Ashe’s new club and restaurant spaces, Rossetti also collaborated with Garrett Singer, known for designing many of America’s trendiest restaurants and clubs.

The enhancements within Arthur Ashe

Stadium will include:

• a brand-new, visually striking Grand Entrance befitting the grandest stage in all of tennis;

• a 40 percent increase to the promenadelevel concourse, adding significantly more open space for fans at the promenade and loge levels;

• completely modernized concourses with newly designed retail experiences and food and beverage spaces;

• significantly increased access to restrooms on all concourses, and more escalators and elevators to all levels;

• an upward extension of the courtsidelevel bowl with 2,000 new seats, expanding the courtside experience from 3,000 to 5,000 seats;

• all-new club and restaurant areas with enhanced dining options and premium hospitality spaces; and

• two new dedicated luxury suite levels.

The ultramodern Player Performance Center will be built on the top two floors of a four-floor building on the west side of Arthur Ashe Stadium, adjacent to the practice courts. It will include:

• new and expanded indoor and outdoor fitness and warmup areas, featuring turf, track and U.S. Open court surfaces for training;

• redesigned and expansive locker rooms and lounges to provide players with a spalike experience;

• upsized indoor player dining and an allnew outdoor player courtyard, as well as a dedicated player-only cafe; and

• an entranceway specifically built for players.

The new Player Performance Center will be fully completed and accessible for players and teams by the 2027 U.S. Open, according

to the USTA, and the entire reimagination project will take place over three phases without interruption to scheduled play or fan access for the 2025 and 2026 tournaments.

For Phase one, in advance of this year’s U.S. Open, the timeline of construction at the tennis center is as follows:

• structural work reinforcing the column load for Arthur Ashe Stadium, enabling the in-stadium construction and overhaul to take place in future phases;

• erecting the first two stories of the fourstory Player Performance Center. The initial levels of the structure are designed to contain parking; and

• a great deal of behind-the-scenes work, with no major changes noticeable to fans attending the 2025 U.S. Open.

Phase two (in the year between the 2025 and 2026 U.S. Opens) will include:

• the removal of the existing courtside and suite levels in Arthur Ashe Stadium so as to replace them with a new, expanded courtside bowl and the pair of dedicated luxury suite levels; and

• the completion of the top two floors of the four-floor Player Performance Center. While both levels of this facility will be built during this portion of the work, it will not be finished and accessible to players until after Phase three as the interior will be completed during that time.

Phase three (between the 2026-27 U.S. Opens) will see the rest of the tennis complex’s renovations reach their end, including:

• Arthur Ashe Stadium’s visionary Grand Entrance, designed by Daniel Libeskind;

• its new loge and promenade levels, including the enlarged promenade concourse with its large, publicly accessible premium bar;

• full enhancements to all concourses, including retail and food and beverage spaces, as well as restrooms and other amenities;

• two new sets of escalators and elevator banks at the South entrance, improving fan traffic to all levels;

• the Garrett Singer-designed premium hospitality lounges in-stadium, enabling premium ticket holders to access unparalleled hospitality without having to leave the tennis arena; and

• the interior of the Player Performance Center.

“This project enables us to maintain the greatest stage in tennis … and modernize it in a way that will set it up for the next 25 years,” Sherr said. “It also provides us the opportunity to give the players that compete in [Arthur Ashe] stadium an unparalleled space that will enable them to perform at their best and enjoy a higher level of luxury and comfort while they are off the court.”

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

The undertaking began in the summer of 2024, and the construction team expects to finish by 2027.

The highlight of the project is the use of Accelerated Bridge Construction techniques to laterally slide the new bridge onto the existing alignment of I-376 (Parkway East). This effort would be one of the largest slide projects done in the state.

The prime contractor for the job is Joseph B. Fay with the bridge slide performed by Mammoet, a company that specializes in heavy lifts and moves. This gigantic undertaking will allow the new bridge to be constructed without interrupting traffic on the Commercial Street Bridge. The new bridge will be a steel delta frame structure and assembled on top of the temporary foundations and slider plates which will allow for the bridge to slide into place once it is completed.

The construction team has scheduled the slide to be ready in 2026. Once the new bridge is slid into place the old bridge will be crushed and reused for aggregate.

Last year, contractors accomplished numerous steps that will make the bridge slide possible, including reconstructing and lowering the westbound I-376 off-ramp to exit 78B. This will help to accommodate over-height trucks when this ramp is used for the I-376 detour.

This work will enable traffic to seamlessly connect when the new bridge is moved into place. The team also relocated sewer lines and portions of phased Intelligent Transportation Systems (ITS). The ITS is an electronic communication that helps traffic coordinators keep traffic flowing smoothly.

Workers have begun a busy schedule for 2025, which will include installing new signs, temporary and permanent piers, abutments and piles for temporary and permanent foundations and steel assembly. The construction team plans nine overnight full closures and detours of eastbound I-376, a full weekend closure and detour of I-376 in each direction. The team also plans 35 extended weeknight sin-

gle-lane restrictions on eastbound I-376.

Work this year also will prepare for next year’s most innovative piece of the project: the bridge slide. Contractors will be constructing the new steel bridge on temporary foundations. When the new bridge is completed, the old Commercial Street Bridge will be removed, and the new bridge will slide into place. Before traffic can resume, safety features will be installed such as guard rails and medians. As those tasks are being completed, workers will connect auxiliary roads and new paving will connect the bridge so traffic can resume.

PennDOT performed a yearlong traffic study and found the month of July to be the lowest traffic volume with vacations and schools/colleges off for the summer.

The work team will prepare for the big slide by building foundations for the bridge. Much of the work will be done this year said John Myler, who is directing the overall project for PennDOT.

see BRIDGE page 86

The AED Foundation (AEDF) announced that Warrick Pathways and Career Center in Booneville, Ind., has become the 115th Recognized High School Program under its national workforce development initiative.

This significant achievement marks a new milestone in the foundation’s ongoing Vision campaign, launched in 2020 to address the skilled technician shortage facing the equipment industry.

“The future of our industry — and our country — depends on today’s youth,” said Bob Brucken, CEO of Diamond Equipment Inc. and AED member. “With AI rapidly evolving, we need bright, driven students to help build our industrial and commercial landscape — and that path doesn’t always require a college degree. Warrick Pathways and centers like it are shaping the future, and Diamond Equipment is proud to support their mission. Skilled trades offer rewarding careers, and we rely on that talent to drive our success. We encourage more schools to partner with the AED Foundation to grow the industry.”

The AED Foundation connects schools, educators and the equipment industry to strengthen the pipeline of future talent. Its success depends on the active support and participation of AED members. The Warrick Pathways and Career Center benefited from many contributors — but especially from the strong involvement of AED member Diamond Equipment, Inc.

In the fall of 2024, Diamond Equipment hosted students from Warrick Pathways and Career Center’s Civil Construction program at its facility, where they had the opportunity to operate a Case CX170E hydraulic excavator equipped with a Hemisphere 3D GPS machine guidance system. Very few of the students had ever been on a machine of that size — much less operated one. They were introduced to the technology used today to help operators dig efficiently and safely.

“The AED Foundation’s ability to connect industry with schools is one of the most powerful tools we have to solve the technician shortage,” said Brian P. McGuire, president of

the AED Foundation. “Our 115th recognized high school isn’t just another number — it represents a real, local partnership that prepares students for in-demand careers and strengthens the workforce pipeline for our industry.”

Since Vision’s inception, the AED Foundation has:

• delivered more than 5,600 technicians through accredited programs;

• certified nearly 5,000 more through industry-aligned testing;

• raised more than $8 million;

• expanded from 5 to 115 recognized high school programs — a more than 20-fold increase in less than five years; and

• added 52 new accredited post-secondary programs to the network Beyond education.

Vision is building a comprehensive support network that includes:

• nearly $10 million in public funding secured to expand Registered Apprenticeships;

• more than $500,000 returned to industry partners through grants;

• more than $200,000 invested in programs introducing youth to equipment industry careers; and

• innovative research such as the joint National Immigration Forum report exploring foreign-born talent solutions.

Since Vision, the AED Foundation has hosted over 75 workforce development events, with 60 more planned for 2025. For more information, visit aedfoundation.org.

In Basking Ridge, N.J., Konkus Corporation is breathing new life into aging infrastructure by replacing a deteriorating bridge deck with a robust new concrete surface.

Central to their success is the Atlas Copco XAS 188 portable air compressor, which delivers the power needed for demolition.

In road construction, time is always of the essence. Projects must be completed quickly and efficiently to minimize road closures, reduce detours and prevent traffic congestion.

Konkus Corporation, a seasoned construction firm based in New Jersey, specializes in bridge and highway projects. With decades of experience under its belt, the company mastered the art of planning and executing complex infrastructure works. Over the years, it has refined its processes and invested in equipment that supports its commitment to quality and efficiency.

In Basking Ridge, N.J., Atlas Copco equipment is used for a critical replacement of a highway bridge deck. It’s a complex operation that begins with the precise removal of deteriorated concrete. This initial phase requires a careful balance of power and control to avoid damaging the underlying structure while staying on schedule.

To meet these demands, Konkus Corporation selected Atlas Copco’s portable XAS 188 air compressor, paired with high-performance pneumatic breakers and saws. This combination delivers the reliable air power enabling the team to break out concrete with accuracy and minimal disruption. The mobility and consistent output of the portable XAS 188 air compressor make it ideal for time-sensitive infrastructure projects, ensuring that demolition is completed swiftly and safely, laying the groundwork for a smooth and timely reconstruction, according to Atlas Copco

“When you’re working on a critical structure like a highway bridge with a strict planning, there’s no room for error,” said Keith Konkus, owner of Konkus Corporation. “The portable XAS 188 air compressor is providing us consistent, reliable air and the breakers are tough and precise, which make us stay on schedule without compromising precision. Like that we can stay productive while keeping operating costs in check”

The mobility of the mobile XAS 188 air compressor proved to be a major asset on the Basking Ridge bridge deck renovation. Its compact footprint and easy towing and lifting capabilities allowed the Konkus Corporation team to reposition the unit quickly as work progressed across the span, minimizing setup time and keeping the workflow fluid. Coupled with an efficient supply of compressed air, the crew could stay agile and efficient, even under tight timelines, according to the company.

The bridge deck renovation progressed with effi-

ciency, driven by careful planning and the use of reliable, high-quality equipment. Konkus Corporation emphasizes the importance of a fast, responsive service team and streamlined coordination, both of which have played a key role in maintaining a smooth and productive workflow, according to the company.

“It’s reassuring to know that Atlas Copco support is just a call away,” said Konkus. “Their service network is well spread out and quick to respond, which makes a real difference when every hour counts.”

For more information, visit www.atlascopco.com/en-us

ROBERT H. FINKE AND SONS, INC.

Selkirk, NY 518-767-9331

Colchester, VT 802-316-3805

www.finkeequipment.com

East Syracuse, NY 315-437-1471

Kirkwood, NY 607-775-5010

Henrietta, NY 585-334-5120

Adams Center, NY 315-788-0200 Utica, NY 315-765-8746 • 800-872-2390 DuBois, PA 814-371-3600 Erie (McKean), PA 800-872-2390 COMING SOON! Pittsburgh (Zelienople), PA 800-872-2390

www.traceyroad.com

marshall-machinery.com

Clark Rigging purchased a new Jekko electric-powered SBX 5332 at the open house. (L-R) are Paul Lonergan, president of Empire Crane; Paul Goodman, general manager, Clark Rigging; Dave Clark, president of Clark Rigging; and Luke Lonergan, vice president, Empire Crane.

With its tilting cab and huge variety of attachments, the Magni Crane is opening up new markets for Empire Crane, especially in the forestry and arborist markets. (L-R) are Paul Lonergan, president of Empire Crane; Joe Leinwal of Magni; and Luke Lonergan, vice president of Empire Crane.

Five Star Equipment, Inc. www.fivestarequipment.com

60 Paul Rd., Rochester, NY 585-235-3011

from page 16

1653 NY Route 11, Kirkwood, NY 607-775-2006

284 Ellicott Rd., Orchard Park, NY 716-662-2191

5835 East Taft Road, North Syracuse, NY 315-452-4560

1300 East Dunham Dr., Dunmore, PA 570-346-1701

46 Route 97, Waterford, PA 814-796-2663

2585 Lycoming Creek Rd, Williamsport, PA 570-494-4030

Groff Tractor & Equipment www.grofftractor.com

6779 Carlisle Pike, Mechanicsburg, PA 717-766-7671

2550 E. Cumberland St., Lebanon, PA 717-273-2616

800-225-4001

3215 State Rd., Sellersville, PA 215-258-5700

800-523-2209

400 Stoke Park Rd., Bethlehem, PA 610-867-4657

800-587-9790

640 Lowther Rd., Lewisberry, PA 717-938-6568

866-787-0001

179 Perry Hwy, Harmony, PA 724-776-3636

963 South Center Ave., New Stanton, PA 724-755-0124

Leslie Equipment

www.lec1.com

Beaver, WV

304-255-1525

Cowen, WV

304-226-3299

Cross Lanes, WV

304-204-1818

Pleasant Valley, WV

304-534-5454

Norton, WV

304-636-6421

Marietta, OH

740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

www.jesco.us

Middletown, DE

302-376-0784

South Plainfield, NJ

908-753-8080

800-241-7070

Fairfield, NJ

973-227-2221

800-321-8080

Lumberton, NJ

609-267-2020

888-217-0600

Beacon, NY

845-831-1800

800-724-0725

Deer Park, NY

844-482-0910

Clifton Park, NY 518-371-5111 Gouverneur, NY 315-287-0703

Hermon, ME 207-947-6786

Houlton, ME 207-532-6517

JohnDeere.com/Dozers

The legislation “creates avenues to reduce liability and boost profitability,” said the firm. Those opportunities fall under a wide range, from equipment purchasing and entity structuring to employee engagement and tax benefit education, it added.

Brian P. McGuire, president and CEO of the Associated Equipment Distributors' (AED), had high praise for the bill’s provisions.

“Certainty is paramount for all businesses, and this is exactly what OBBBA provides equipment dealers, manufacturers and our customers,” said McGuire.

Capital investment incentivizing will “help unleash the economy,” he said, by making these provisions permanent.

“AED members can worry less about an ever-changing tax code and focus on supplying and servicing the equipment needed to build, feed and fuel America.”

The law’s provisions “are poised to influence how construction firms plan, invest and operate for years to come,” said Carl Oliveri of Grassi Advisors.

The construction practice leader and a partner at Grassi, Oliveri analyzed the OBBBA and picked apart the provisions that most affect the construction industry.

The OBBBA permanently reinstates 100-percent bonus depreciation for qualifying property placed in service on or after Jan. 19, 2025.

Oliveri noted this includes construction equipment, vehicles and certain improvements to nonresidential real property. The provision applies to both new and used property and ends the phase-down schedule in place previously.

“For tax purposes, contractors can now fully expense the

cost of equipment, vehicles and qualifying property in the year placed in service,” said Oliveri.

Fully expensing those costs results in greater certainty in long-term planning and frees up cash flow for working capital purposes, he added.

“This may be especially valuable for contractors upgrading or expanding their fleets.”

However, equipment not manufactured or purchased domestically could face tariffs, which would be part of the cost to write off, noted Oliveri.

Effective for tax years beginning after Dec. 31, 2024, the maximum Section 179 deduction is increased to $2.5 million.

This, said Oliveri, is a phase-out threshold of $4 million, and both amounts are indexed for inflation. It is similar to the bonus depreciation rule.

Contractors can immediately expense the full cost of qualifying equipment, software and certain improvements to nonresidential property.

“The expanded limits provide construction firms with more flexibility to manage their taxable income,” said Oliveri. “Pairing Section 179 with bonus depreciation may offer a more strategic approach to maximizing large capital investments and managing state taxable income.”

The OBBBA introduces a new 100 percent deduction for Qualified Production Property (QPP): a category of newly constructed nonresidential real property primarily used for manufacturing, production or refining tangible personal

property.

To qualify, though, construction must begin after Jan. 19, 2025, and the property must be placed in service before Jan. 1, 2031.

According to the rule, the deduction applies to new buildings and improvements. However, it excludes property used for office, administrative, lodging, parking, sales, research, software development or engineering functions.

“This provision provides a powerful incentive for companies to invest in new production facilities,” said Oliveri.

Contractors fabricating their own materials for use on a job site may have a significant tax planning opportunity to reinvest in their business. These reinvestments can mean upgrading production facilities while utilizing the full tax benefit under the qualified production property (QPP).

The OBBBA preserves federal deductions for state and local taxes paid at the entity level under elective PassThrough Entity Tax (PTET) regimes.

PTET programs were designed to bypass the $10,000 state and local tax (SALT) cap applied at the individual level under the 2017 tax cuts and jobs act.

However, OBBBA increases the SALT cap to $40,000. That spells relief for business owners who face SALT above the expanded limit.

The PTET provisions will continue to provide relief for pass-through businesses in high-tax jurisdictions, such as New York and New Jersey.

Oliveri said for construction companies structured as partnerships or S corporations, this preserves a valuable federal deduction for state taxes.

see BILL page 72

(Editor’s note: This article and photos are courtesy of the University of Pennsylvania.)

From the mud, straw and gypsum mixtures of ancient Egypt’s monumental pyramids to the sophisticated underwater material employed by Roman engineers in iconic structures like the Pantheon, concrete has long symbolized civilization’s resilience and ingenuity.

Yet today, concrete finds itself in a paradoxical bind: The very material that allowed societies to flourish also is responsible for up to 9 percent of global greenhouse gas emissions. Climate change, itself deeply rooted in fossil fuel use, presents humanity with an existential challenge if people seek to sustainably build the structures that support modern life — namely, new homes, highways, bridges and more.

Now, designers, materials scientists, and engineers from the University of Pennsylvania have teamed up to create a biomineral-infused concrete by blending 3D printing with the fossil architecture of microscopic algae. This concrete is remarkably lightweight — yet structurally sound — and captures up to 142 percent more carbon dioxide than conventional mixes while using less cement and still meeting standard compressive-strength targets.

The key ingredient is diatomaceous earth (DE), a popular filler material made from fossilized microorganisms. The researchers found that the fine, porous and sponge-like texture of DE not only improves the stability of concrete as it’s pushed through a 3D printer nozzle but also provides abundant sites for trapping carbon dioxide. These findings, which are reported in Advanced Functional Materials, pave the way for building materials that both hold up bridges and skyscrapers and help restore marine ecosystems and capture carbon from the air.

Penn Today. photos Penn Engineering materials scientist Shu Yang and Weitzman School of Design architect Masoud Akbarzadeh teamed up to develop a 3D concrete printing system that captures carbon dioxide and boosts the structural performance of the building materials. The solution is based on diatomaceous earth and offers enhanced carbon capture and structural fortitude while using relatively fewer materials. At top, a 3D-printed model of a triply periodic minimal surface (TPMS) design.

“Usually, if you increase the surface area or porosity, you lose strength,” said co-senior author Shu Yang, the Joseph Bordogna professor of engineering and applied science and chair of the Department of Materials Science at the School of Engineering and Applied Science. “But here, it was the opposite; the structure became stronger over time.”

She noted that the team not only achieved “an additional 30 percent higher carbon dioxide conversion” when the geometry of the material was further optimized, but did so while maintaining a compressive strength comparable to ordinary concrete. “It was one of those rare moments where everything just worked better and looked nicer,” she said.

“But it wasn’t just about aesthetics or reducing mass,” added co-senior author Masoud Akbarzadeh, associate professor of architecture of the Weitzman School of Design. “It was about unlocking a new structural logic. We could reduce material by almost 60 percent, and still carry the load, showing it’s possible to do so much more with so much less.”

Yang saw potential in applying her materials science expertise toward imbuing the gravel, cement and water mixture of concrete with carbon-capture properties.

“I didn’t know much when we first started,” she said, “but I understood that rheology — how particles flow and interact — was crucial to how concrete behaves during mixing and printing.”

To translate that understanding into a viable 3D-printing formulation, she leaned on the experience of her former postdoctoral researcher and first author of the paper, KunHao Yu, who had previously worked with concrete in civil engineering and additive manufacturing contexts.

“Concrete isn’t like conventional printing materials,” Yu said. “It has to flow smoothly under pressure, stabilize quickly after extrusion and then continuously strengthen as it cures.”

That complexity, he said, made it an ideal challenge to apply a mix of chemistry, physics and design thinking.

At the same time, Yang had been revisiting diatomaceous earth, which she had previously encountered in studies of natural photonic crystals and carbon sinks in the southern ocean, where diatoms help reduce greenhouse gases by ferrying carbon dioxide to the sea floor when they die. Diatoms — a kind of ancient microscopic algae — construct intricate, porous silica shells that, over millions of years, have accumulated into the DE now used in everything from pool filters to soil additives.

“I was intrigued by how this natural material could absorb carnon dioxide,” Yang said. “And I started wondering: What

Heidelberg Materials North America announced that it has acquired certain assets of Concrete Crushers Inc. (CCI), the largest concrete recycler in Calgary, Alberta.

The transaction includes a recycled aggregates yard in southeast Calgary and a contract crushing business with four mobile plants.

“The acquisition of the CCI assets further strengthens our existing footprint in the Calgary market and accelerates our focus on recycled concrete aggregates and circular solutions,” said Oliver Patsch, president of the northwest region of Heidelberg Materials North America.

This recent acquisition is aligned with the company’s strategic focus on optimizing its portfolio in core markets and strengthening its existing businesses through bolt-on acquisitions while advancing its focus on sustainable and circular products.

“We are excited about increasing our recycled concrete offerings in this growing market and pleased to welcome the CCI employees to our team,” said Patsch.

“The acquisition of the CCI assets further strengthens our existing footprint in the Calgary market and accelerates our focus on

The National Steering Committee (NSC) for the Concrete Industry Management (CIM) program announced that Nicole Maher, the former chief operating officer at the National Ready Mixed Concrete Association (NRMCA), was appointed executive director on Jan. 22, 2025, succeeding Rex Cottle, who had led the NSC since July 2022.

Maher brings extensive experience and a proven record of leadership in the concrete industry. Since 2013, she also has served as secretary/treasurer for the NSC, demonstrating her long- standing commitment to the CIM program.

Her forward-thinking vision aligns seamlessly with CIM’s mission to strengthen the concrete industry through education, empowering the next generation of leaders to tackle 21st-century challenges with innovation and resilience.

“The Board of the CIM National Steering Committee is thrilled to have someone with Nicole’s leadership, organizational skills and deep industry relationships to steward the NSC for years to come,” said Karl Watson, Jr., chairman of the NSC. “Although this is a new position for Nicole, she has played a key role

in both the foundation and growth of CIM for more than 20 years. We’re grateful to have her in this role.”

“Being part of the CIM program for the past several decades has truly been a passion project,” said Maher. “Watching it grow and evolve to meet the needs of a dynamic concrete industry has been incredibly rewarding. I’m honored to fulfill this role and help drive the program forward, building on the strong foundation laid by those who came before me.”

Recognizing the need for people with enhanced technical, communication and management skills, the CIM program launched in 1996. The individuals graduating from this program will have the skill set necessary to meet the growing demands of the progressively changing concrete industry of the 21st century.

It is a business-intensive program, providing solid management skills that can be used in any industry, but has been developed specifically for the concrete industry.

The program gives students many advantages including entering the concrete workforce with exposure to the

industry early in their careers, unlike others coming in with generic business degrees.

The goal of the program is to produce broadly educated, articulate graduates grounded in basic business management, who are knowledgeable of concrete technology and techniques and are able to manage people and systems as well as promote products or services related to the concrete industry. It entails a broad range of courses, from English and history to science and mathematics.

A series of required business courses such as finance, marketing, management and business law also are taken throughout the length of the program.

The concrete-specific courses teach the fundamentals of concrete, properties and testing, concrete construction and more. All these courses use practical case studies and an internship to make sure the student obtains real-world experience essential to starting a successful career. Additional opportunities for growth include on-campus socials and other organized events providing industry networking and professional development.

For more information, visit concretedegree.com.

if we could integrate it directly into construction materials?”

The team discovered that DE’s internal pore network not only provided pathways for carbon dioxide to diffuse into the structure but also enabled calcium carbonate to form during curing, thereby improving both carbon dioxide uptake and mechanical strength.

Yu led the development of the printable concrete ink, calibrating variables for the 3D printer like water-to-binder ratios, nozzle size and extrusion speed.

“We ran a lot of trials,” he said. “What surprised us most was that despite the high porosity that normally acts an impediment to stress, the material actually got stronger as it absorbed carbon dioxide.”

While DE optimized the material itself, geometry played an equally transformative role. Akbarzadeh and his team turned to triply peri-

odic minimal surfaces (TPMS) — mathematically complex but naturally occurring structures found in bones, coral reefs and sea stars. These “continuous” forms, which are devoid of sharp edges or breaks, are prized for their ability to maximize surface area while minimizing mass.

“The shapes are complex, but naturally efficient in that they maximize surface area and geometric stiffness while minimizing material,” Akbarzadeh said. “In nature, form and function are inseparable, so we wanted to bring that principle into the arrangements of these materials.”

Using polyhedral graphic statics, a method that maps force distributions through geometry, his team designed a concrete structure that could support itself, even with steep overhangs, while remaining open and porous enough for maximum carbon dioxide exposure.

In graphic statics, Akbarzadeh explained, every line in the form

diagram represents the force flow, allowing the team to tune how compressive and tensile forces distribute through the structure. They then coupled that with post-tensioning cables to enhance the internal stability of the concrete.

Once modeled, the forms were digitally sliced into printable layers and optimized to extrude smoothly without collapsing, sagging or clogging the printer nozzle. The resulting printed components were tested under load and subjected to carbonated environments, which culminated in structures that used 68 percent less material than traditional concrete blocks while increasing their surface-area-tovolume ratio by over 500 percent. In addition, the TPMS cube retained 90 percent of the compressive strength of the solid version and achieved a 32 percent higher carbon dioxide uptake per unit of cement.

Looking ahead, the team is

advancing the work on multiple fronts including scaling up to fullsize structural elements such as floors, facades and load-bearing panels.

“We’re testing larger components with more complex reinforcement schemes,” said Akbarzadeh, referring to the embedded post-tensioning cables and force-balancing geometries that his lab specializes in. “We want these to be not just strong and efficient, but buildable at architectural scale.”

Another avenue focuses on marine infrastructure. Due to its porosity and ecological compatibility, the DE-TPMS concrete may be well-suited for structures like artificial reefs, oyster beds or coral platforms.

“We’re especially excited about deploying this in restoration contexts,” said Yang. “The high surface area helps marine organisms attach and grow, while the material passively absorbs carbon dioxide from the surrounding water.”

Yang’s team also is exploring how DE might work with other binder chemistries beyond industry-standard cements, such as magnesium-based or alkali-activated systems. “We want to push this idea further,” she said. “What if we could remove the cement altogether? Or use waste streams as the reactive component?”

“The moment we stopped thinking about concrete as static and started seeing it as dynamic — as something that reacts to its environment — we opened up a whole new world of possibilities,” she added.

(Other authors include So Hee Nah, Kun-Yu Wang, Yinding Chi and Peter Psarras of Penn Engineering and Teng Teng Hua Chai and Yefan Zhi, of the Weitzman School.

This work was supported by the Department of Energy (DE-FOA0002625) and the Vagelos Institute for Energy Science and Technology at the University of Pennsylvania.)

Bobcat Company was selected as one of America’s Greatest Workplaces for 2025 by Newsweek.

In the annual rankings, Bobcat was recognized in seven distinct award categories, reflecting its commitment to meaningful work, employee wellbeing and continuous career development for more than 5,000 employees in the United States.

Newsweek also featured Bobcat on its 2025 lists of America’s Greatest Workplaces for manufacturing, America’s Greatest Workplaces by State — North Dakota, America’s Greatest Workplaces for parents and families, America’s Greatest Workplaces for Gen Z, America’s Greatest Workplaces for mental well being and America’s Greatest Workplaces for inclusion and diversity.

“We are honored to be recognized among Newsweek’s list of America’s Greatest Workplaces 2025,” said Stacey Breuer, vice president of human resources of Doosan Bobcat North America Inc. “These awards are a reflection of the culture our employees help create every day — one where our employees are empowered to do great work and careers are built with intention.”

In facilities throughout the United States, Bobcat employs more than 5,000 people who are responsible for designing, building and supporting the industry with compact equipment and work site solutions. As a manufacturer, Bobcat’s roots began in America’s heartland and this legacy contin-

ues with Bobcat’s North American headquarters in West Fargo, N.D.

Bobcat continues to make investments in workplaces and programs that support and elevate the overall employee experience. This includes new onboarding, learning and mentorship initiatives; leadership and career development programs; resource groups; competitive benefit offerings; and more that support employee engagement, retention and development.

“At Bobcat, we are proud of our people and the positive impact they continue to have on our customers, communities and Bobcat’s success,” said Mike Ballweber, president of Doosan Bobcat North America Inc. “We will always strive to provide an innovative work environment for our employees and continue to invest in their future, so they have the opportunity to excel and succeed at Bobcat.”

Compiled in partnership with market data research firm Plant-A Insights, Newsweek identified America’s Greatest Workplaces by conducting a large-scale employer study based on more than 1.5 million comprehensive company reviews from approximately 250,000 United States’ employees across 78 different sectors, each of whom were surveyed on key factors in employee satisfaction, including compensation and benefits, training and career progression, work-life balance and company culture.

For more information, visit www.bobcat.com/careers.

www.tylerequipment.com

For almost three quarters of a century, the Duff family has produced and supplied crushed limestone, sand and gravel to all of west-central Ohio.

As the multi-generational family enterprise approaches its landmark 75th year in business, a new CDE wash plant, capable of processing up to 300 tons per hour (tph) of sand and aggregate, has been commissioned at the company’s Lewistown, Ohio, sand and gravel site.

“It’s an investment in the future of the business and in the future of the mineral production industry in the state,” said Ross Duff, president of Duff Sand and Gravel Inc. and vice president of Duff Quarry Inc. “It’s about honoring the history and heritage of our business and continuing that good work, ensuring we’re equipped and resourced to meet future challenges head on, and that we extract and utilize every valuable grain from our deposits. In short, it’s about longevity.”

In 2023, Ohio was ranked as one of the leading construction sand and gravel producing states, according to data from the U.S. Geological Survey (USGS). Of the 920 million tons of sand and gravel produced last year, the top 10 states by production volume accounted for more than 50 percent of the total combined output.

Similarly, USGS data shows Ohio as a top producer of crushed stone. Last year, an estimated 1.5 billion tons were produced. The 10 leading states, which included Ohio, accounted for more than half of the total output (54 percent).

An essential industry to support the continued economic development of the state, the Ohio Aggregates & Industrial Minerals Association (OAIMA), where Duff serves as an active board member, estimates raw mineral production in the state to be valued at more than $1 billion, employing more than 5,000 directly and up to 40,000 indirectly through associated construction activity, transportation and more.

Duff Quarry first discovered CDE at ConExpo-Con/AGG in 2020, where the

washing experts left a lasting impression on the family enterprise.

“We believed technology of this kind was beyond our reach,” Duff said. “It was everything we needed and more. When we left that show, we left with an impression of CDE and its equipment that would stay with us for the next few years. We knew it would be a major investment — one of the largest in the history of the company — but we knew just how impactful it could be.” It would be another three years before the two companies would meet again at ConExpo-Con/AGG in 2023.

“By then, we were ready to move forward with this project, and CDE was still the preferred supplier all those years later,” said Duff. “That second show just strengthened our resolve to bring this project to life with CDE by our side.”

TREES, BRANCHES, LIMBS, AND

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

Ronan Duffy, CDE business development manager, said the solution engineered for Duff Quarry is born from proven solutions and designed specifically for its Huntsville, Ohio, quarry.

“Material gradings can vary from one day to the next, so any solution needs to be approached with real understanding of the customer, their needs and the material to be processed,” said Duffy. “A full site audit, including material testing in our lab, helped inform and develop the best possible solution for Duff Quarry as they begin washing material for the very first time. Equipment specification, site layout — it’s all considered in order to create an optimized site workflow that can help accelerate return on investment.”

The final solution includes CDE’s AggMax scrubbing and classification system, which combines pre-screening, washing, scrubbing, lightweight and organics removal and sizing on a compact chassis to produce a range of washed and graded aggregates ready for market straight from the belt, according to the company.

Alongside this, CDE’s M4500 modular sand washing plant, which integrates feeding, screening, washing and stockpiling, features customizable cut point control and patented Infinity technology to deliver consistent in-spec sand products, according to CDE.

“Seeing the first containers arrive on site for the build, that was pretty neat,” Duff said.

Increased Production

Processing up to 300 tph, the new CDE plant is helping Duff Quarry produce more material per year to better meet the demands

of the local construction market through proven design, efficient processing and optimized operations, according to the company.

A major construction boom is under way in central Ohio where the now $28 billion development of two Intel semiconductor manufacturing plants — the single largest private sector investment in the history of the state — is continuing at pace. A further $90 million has been committed by the Ohio Department of Transportation to improve and enhance infrastructure around the facility.

This is in addition to continued work on the development of a new lithium-ion EV battery plant in Jeffersonville, Ohio, as part of a $3.5 billion joint venture between LG Energy Solutions and Honda.

“Within a matter of hours of booting up the plant, material testing showed concrete sand output to be perfectly in-spec,” Duffy said.

The plant is producing a range of construction materials, including C33 coarse concrete sand, fine sand and three different aggregate fractions: 1-2-in., #57 stone and pea gravel.

“I was amazed,” Duff said. “The result was immediate. Right from the starting block we were producing great looking stockpiles. The plant is making sure we have a constant supply of concrete sand for our six ready-mix plants.”

Since initial commissioning in June last year, the geology and material quality of the limestone deposit at the company’s operation in Huntsville has changed significantly, but Duff said the CDE plant has been able to adjust easily to the new conditions.

“We’ve been extracting here for almost 75 years now. It’s a large deposit about 400 feet

deep, and it spans an area of approximately 400 acres. Given its size and scale, we know that the make-up of the material is going to vary and, down through the years, we’ve invested in new equipment and adapted our operation in response to this,” he said.

The deposit continues to evolve even today.

“It’s a different deposit now to what it was at the outset of this very partnership — however now we’re equipped with a CDE plant,” said Duff. “We’re really impressed by the adaptability of the plant and just how little intervention is needed from our side to make the necessary adjustments in response to variations in the material we’re processing.