“The

“The

By Lori Tobias CEG CORRESPONDENT

Train passengers in the Pacific Northwest can look forward to an upgraded ride next year in the new Amtrak Airo, and with it comes a new $300 million facility in Seattle now under construction specifically for its care.

The contract was awarded to PCL Construction Services in 2024. Pre-construction work began shortly after, which largely included relocating operations such as the weld shop and “wheel gardens.”

“The new upgraded King Street Yard will enable modern, more efficient maintenance practices, and support the introduction of new Amtrak Airo trains set to enter service first on the Amtrak Cascades route in 2026, along with maintenance for trains on the Long Distance routes that operate out of this yard,” according to the Amtrak press release. “When the project is completed in 2027, the modernized rail yard will feature a new two-bay Maintenance and Inspection facility and a new Service and Cleaning bay that provide the foundations for a world-class maintenance yard.”

PCL Construction had a lot of coordination required to start work.

together beforehand because, obviously, in building a new building you'll be affecting operations that are currently there,” said Kevin George, Seattle project director. “So, upon us actually starting the construction was the relocation of all of those operations that were there, but nothing that was concrete of the facility. It worked out well in the sense that we geometry so that the facility is actually conducive to where we built it.”

One of the biggest challenges is the location of the new 100,000-sq.-ft. facility, which will be 600 ft. long, George said.

see TRAINS page 2

“It really comes down to such a shallow water table. We're at about 5 to 6 feet on the part of the property that the water table is at,” he said. “So, we've dug down as far as we can without hitting the water table. Now we're at that point that, for us to start doing the foundations, we really need to dewater the site, and so we’ve just been working through the city and state to get permits.”

Amtrak said about 500,000 gal. of water — enough to fill 15 residential swimming pools — need to be removed from the site daily. The “dewatering” is needed to lower the groundwater table and build on the historic tidal bed.

Amtrak expects to finish pile driving and mass excavation of the site by 2025 and begin erecting the preengineered metal building in early 2026.

About 17 mi. of piles will be driven 140 ft. into the ground, according to Amtrak.

As with most projects in this part of Seattle, the piles are needed for building stability. Not only does the former tidal bed sit on 30 ft. of miscellaneous materials (landfill) discarded by the city’s earliest settlers, but is also an active seismic zone.

The King Street Yard site is unique in that there is a roadway that runs across the yard. Along with the water table, that adds a challenge to the project.

“Just the speed and requirements of how fast you have to get this work done, it's always a challenge with any project,” George said. “But it just compounds it with being such a small site and having a roadway in

the middle of it doesn't exactly help. But it is a challenge that we have been addressing.”

Just eight of the new Amtrak Airo trains will replace the entire fleet of Amtrak Cascades trains that are operating today,” said W. Kyle Anderson, senior public relations manager of Amtrak. “The Airos are modern, state-of-the-art trains currently under construction by Siemens in Sacramento.”

The new trains are one full “trainset” or all six cars plus the engine combined in one train and maintained as one “set,” Anderson said. This allows for more efficient maintenance practices.

“Think about a six-car train where we pull it apart and bring one car into the shop for work at a time,” he said. “With this new facility being built, the full trainset will be maintained at once, which is quicker and more efficient for our crews.”

The project is funded through the Infrastructure Investment and Jobs Act signed into law by President Joe Biden in 2021.

“It basically gave the most money for passenger rail in America's history,” Anderson said. “It’s definitely in line with the state of Washington and Oregon DOTs’ plans to increase frequency, to add more trains and improve reliability for customers. This new facility is designed for our new trains. The trains being replaced across the country are, on average, about 40 years old. So, it's all part of our focus on building a new era of rail in America.” CEG

(All photos courtesy of Amtrak.)

bridge over northbound I-5 during demolition in 2023 for the SR 509 Completion Project.

The Washington State Department of Transportation opened the first section of the new State Route 509 Expressway in the Puget Sound area on June 28, 2025, providing travelers with another commuting option in south King County.

The first mile of the SR 509 Completion Project stretches between Interstate 5 and 24th Avenue South in SeaTac.

Atkinson Construction was awarded a $263.9 million contract in 2020 to build the first mile and other improvements.

The new highway is being built in stages. The first mile features two lanes in each direction between I-5 and 24th Avenue South. Northbound I-5 drivers will exit to a large fly-over ramp that connects to the expressway. Until the next section of the expressway opens, drivers will exit at 24th Avenue South. Travelers can also enter the expressway from 24th Avenue South and travel southeast to merge onto southbound I-5.

Besides the first mile, this stage of the SR 509 Completion Project features many other improvements:

• extension of Veterans Drive, linking to a new tunnel under I-5;

• a wider South 216th Street bridge over I-5;

• A realigned southbound I-5 exit to SR 516;

• an improved eastbound SR 516 on-ramp to northbound I-5; and

• new sidewalks and multimodal connections

Since work began in 2021, construction crews have:

• excavated 750,000 cu. yds. of soil;

• placed more than 136,000 tons of asphalt;

• installed more than 1.8 million lbs. of rebar in new bridges;

• poured more than 10,700 cu. yds. of concrete;

• planted nearly 20,000 trees and shrubs throughout the project area; and

• laid down more than 10 mi. of drainage pipe

Atkinson Construction also will build the remaining 2 mi. of the expressway between 24th Avenue South and South 188th Street in SeaTac.

In all, the SR 509 Completion Project builds 3 miles of new tolled highway between I-5 and South 188th Street near the south end of SeattleTacoma International Airport. It includes improvements on I-5 between South 212th Street in SeaTac and South 272nd Street in Federal Way. The final stage of the project to build the remaining 2 miles of expressway is under construction and scheduled for completion in 2029.

The new expressway will be tolled beginning in the fall. Tolling based on time of day will be used to help manage congestion on the new corridor. Toll funding also will help pay for construction and ongoing maintenance.

“Opening a new highway is an exciting moment for us,” said John White, Puget Sound Gateway Program administrator. “Completing this section is a critical step toward delivering the entire SR 509 Completion Project to help reduce congestion and finish a vital freight link between the Port of Seattle and industrial areas in south King County.”

“Approximately 40 percent of jobs in Washington are tied to trade, and our economy depends on reliable, efficient connections between farms, ports, manufacturers and markets,” said Rep. Jake Fey, chair of the House Transportation Committee. “The SR 509 Expressway is more than just a new road — it’s a critical freight and commuter link that will ease congestion, improve safety and support good-paying jobs across the region.”

(All photos courtesy of the Washington State Department of Transportation.)

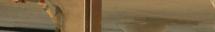

Lippmann named PacWest Machinery as its newest authorized dealer, expanding Lippmann’s presence and service capabilities in the Pacific Northwest.

PacWest will provide sales, rental and aftermarket support for Lippmann’s full line of crushing and screening equipment, bringing a wealth of experience and resources to aggregate producers in the region.

With six full-service branches in Seattle, Spokane, Mount Vernon and Pasco, Wash., and Portland and Eugene, Ore., PacWest Machinery offers comprehensive coverage throughout the Pacific Northwest. An exten-

sive mobile service fleet and remote service technicians ensure customers receive responsive, onsite support to keep operations running smoothly.

PacWest Machinery has long been a trusted provider of equipment and aftermarket support, representing manufacturers such as Volvo Construction Equipment, Metso Minerals and GOMACO. Its focus on customer success and operational efficiency makes it a valuable addition to Lippmann’s growing dealer network.

“We’re thrilled to welcome PacWest Machinery to the Lippmann family. Their strong reputation for customer service,

deep industry knowledge and expansive regional presence makes them an ideal partner as we continue to grow in the Pacific Northwest,” said Dillon Borchardt, Lippmann territory sales manager. “With PacWest’s commitment to excellence and our premium crushing and screening equipment, we’re confident this partnership will deliver unmatched value and support to aggregate producers throughout the region.”

With this partnership, customers in the Pacific Northwest will benefit from easy access to Lippmann’s equipment, along with PacWest’s comprehensive support network and industry

expertise. Whether through its full-service facilities or mobile service units, PacWest is committed to delivering exceptional serv-

ice and support to help customers maximize their productivity. For details, visit pacwestmachinery.com.

Seattle Public Schools began the process of replacing the 78-year-old Memorial Stadium at Seattle Center with a July 3, 2025, groundbreaking ceremony, according to queenannenews.com.

The start of construction on a new 6,500seat stadium comes after the city of Seattle and Seattle Public Schools jointly issued a Request for Proposal in March 2023 that sought a private partner to fund, redevelop, operate and maintain the project along with the two entities.

Sellen Construction, a Seattle-based builder, will lead construction, according to seattlecenter.com. The new stadium is being designed by Generator Studio.

Stadum completion is set for September 2027, according to queenannenews.com.

A public-private partnership between Seattle, Seattle Public Schools and the One Roof Partnership, which is a consortium of Seattle Kraken, Climate Pledge Arena and One Roof Foundation, will lead the project.

The $140 million funding for the project largely comes from the city and Seattle Public Schools, according to queenannenews.com.

Seattle set aside $40 million as part of its Capital Improvement Plan, while Seattle Public Schools allocated $66.5 million in voter-approved funds from its 2022

Buildings, Technology and Academics/ Athletics Capital Levy and capital funds.

The developers also raised $30 million in private funding for the stadium, according to queenannenews.com.

The Center Square previously reported on the One Roof Partnership ensuring that the total project is “derisked” for the public sector by having the developer take on all the construction risk.

The partnership will operate the facility as a not-for-profit. That means that revenue generated will go into a maintenance fund and projects that benefit community members, according to queenannenews.com.

The original stadium opened in 1947 and has hosted multiple notable events since then. Those include the opening ceremony of the 1962 World’s Fair, the region’s biggest high school football games and concerts by Bob Dylan, Pearl Jam and the Grateful Dead, according to king5.com.

Memorial Wall, which honors 762 local high school students and alumni who lost their lives in World War II, will be preserved and enhanced. Memorial Wall is a designated Seattle Landmark.

The project includes a new plaza in front of the memorial to make it more prominent, according to seattleschools.org.

Redmond Municipal Airport (RDM) launched its 80,000-sq-ft. terminal expansion project with a demolition event on June 18, 2025, symbolizing the major transformation ahead for Central Oregon’s gateway to the sky.

The symbolic demolition marked the start of RDM’s multiphase expansion project, which will significantly increase terminal capacity, enhance ADA accessibility and elevate the travel experience for the region’s growing number of passengers.

Skanska is serving as general contractor and is collaborating

with RS&H as the project architect and designer, Hennebery Eddy Architects as the architect of record, and Morrison-Maierle Engineering for structural engineering with a focus on mass timber design.

Once complete, the updated airport will feature additional gates and jet bridges to enhance boarding and deplanement efficiency, along with a redesign of the second floor and interior reconfigurations to minimize outdoor boarding and streamline passenger flow throughout the terminal. Skanska also will expand the baggage make

up to improve convenience and capacity, while upgrading amenities to offer a more comfortable and inclusive travel experience.

The new space will include seven new jet bridges, expanded waiting areas, more than 6,000 sq. ft. of new concessions and more than double the terminal passenger seating. Travelers also will benefit from enhanced accessibility, a companion care restroom, new restrooms, a post-security service animal relief area and an advanced public address system for clearer communication

Notable design elements

include enhanced ADA accessibility, increased energy efficiency and a mass timber roof structure that reflects the natural beauty of the surrounding region. Skanska is self-performing the timber installation.

The terminal expansion project is scheduled for phased construction through 2027, opening in early 2028, with early construction impacts beginning this summer.

The event included remarks and participation from Mayor Ed Fitch, Redmond City Council, members of the Airport Committee and Margaret Schinkel, the grand-

daughter of JR Roberts, for whom the airport is named. Roberts was a pioneering city leader and aviation advocate whose early contributions helped establish Redmond as a regional hub for air travel.

“With this expansion, we’re not just preparing for the future — we’re shaping it,” Fitch said. “Redmond Airport is a critical gateway for Central Oregon, and this project ensures we continue to meet the needs of our communities with vision, care and forwardthinking infrastructure.”

“This expansion is a critical investment in the future of Redmond and the broader Central Oregon region,” said Joe Schneider, senior vice president and account manager of Skanska USA Building in Oregon. “As travel to and from the region continues to grow, we’re proud to help deliver a modern, efficient, and sustainable airport that not only meets increased demand but also reflects the natural beauty and spirit of the community we serve.”

Wenatchee Valley College in Wenatchee, Wash., held a groundbreaking ceremony for its new $50 million Center for Technical Education and Innovation (CTEI) building on June 12, 2025, at the Van Tassell Center patio.

Fowler General Construction Inc. is the general contractor.

The Center for Technical Education and Innovation will serve as a hands-on learning facility for skilled trades programs, including agriculture, automotive technology, computer technology, electronics and aerospace electronics, environmental systems and refrigeration technology, industrial technology and more.

“This center will advance the college’s role in preparing students and professionals to make long-lasting contributions to the economic growth and vibrancy of our region in North Central Washington,” President Faimous Harrison said.

The CTEI building is scheduled for completion by fall 2027. The 70,000-sq.-ft. $50 million facility will feature specialty labs and training centers.

WVC’s skilled trades programs prepare students to succeed in career paths that require skilled labor and specialized training. The new center will advance the college’s mission in delivering innovative educational opportunities to build a thriving community in North Central Washington.

Funding for the CTEI building is made possible by funds from the state of Washington 2023-‘25 capital budget allocation that are separate from the college’s operating budget.

Presenters included Harrison; Ruby Gaston, Central Washington representative of the office of Congresswoman

Kim Schrier; Francisco Sarmiento-Torres, agriculture faculty and co-director of WVC’s Hispanic Orchard Employee Education Program (HOEEP); and Ariel Torres, a student representative of WVC’s Environmental Systems and Refrigeration Technology (ESRT) program.

The Wenatchee Valley College district is the size of Massachusetts, covering more than 10,000 sq. mi. of Chelan,

Douglas and Okanogan counties. The Wenatchee campus is near the eastern slopes of the Cascade Mountains, midway between Seattle and Spokane. The WVC at Omak campus is near the Canadian border in Omak, about 100 mi. north of Wenatchee.

The architect is RGU Architecture and Planning, according to asumag.com.

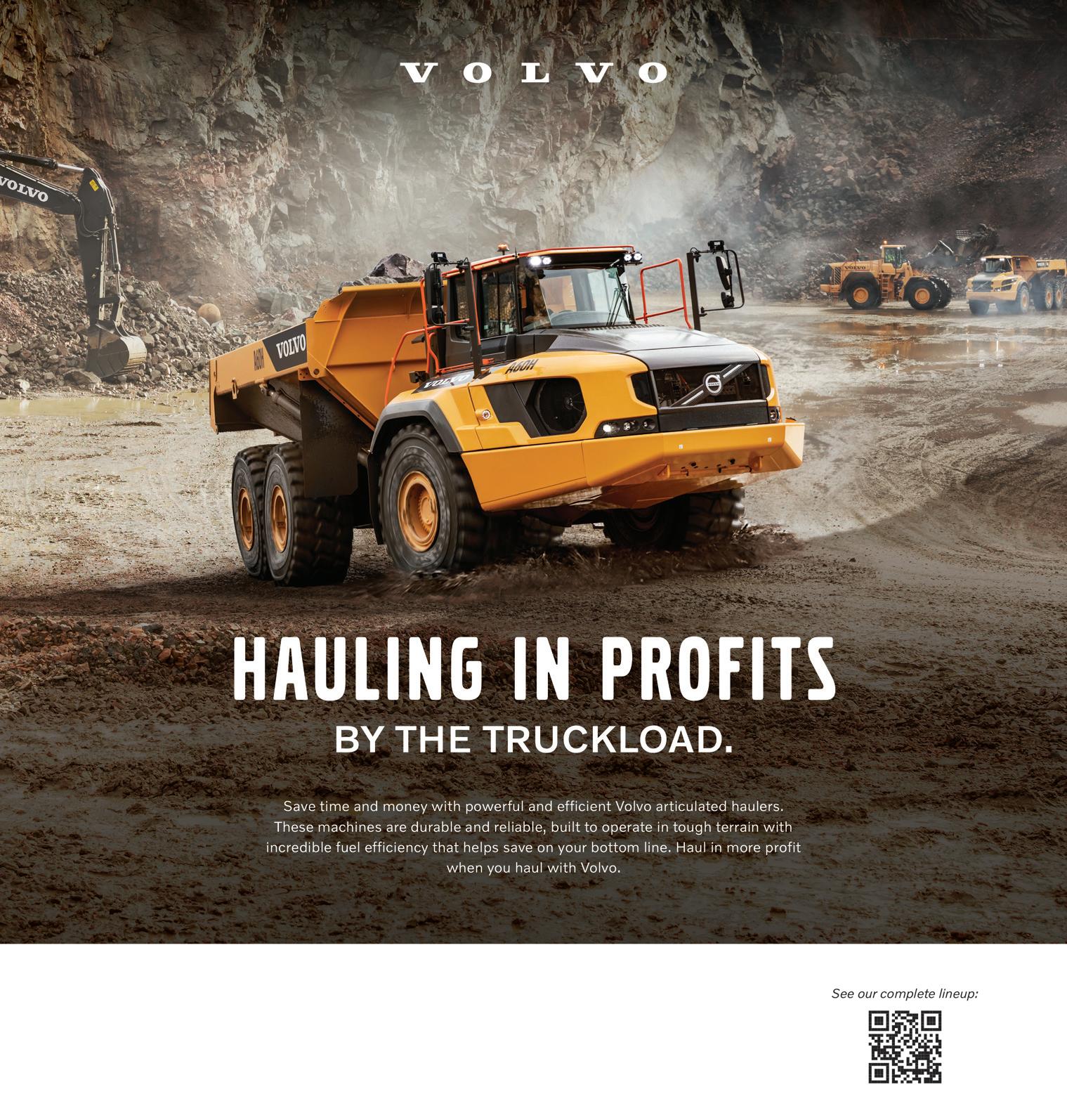

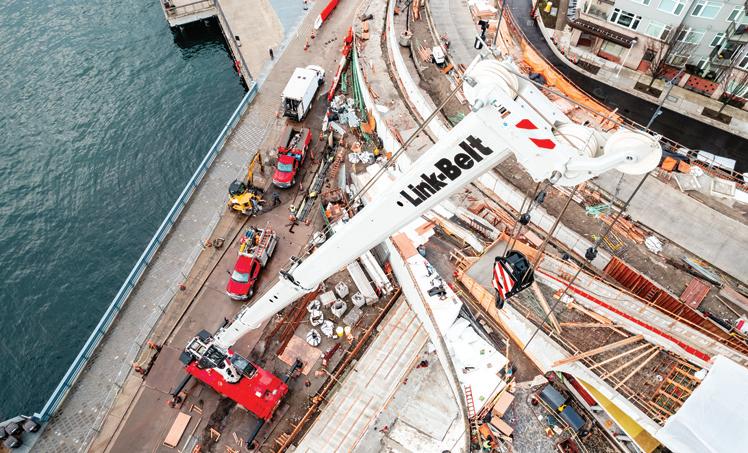

For eight months, the Link-Belt 85|RT 85ton rough-terrain crane took center stage in one of Seattle’s most ambitious urban renewal projects — the Overlook Walk.

The city’s waterfront required precision lifting in a dense high-traffic environment. For crane operator Nick Jaramillo of Seattlebased Garner Construction, the 85|RT proved to be the perfect crane for the job.

“Everything we needed to do with the 85|RT, we could do,” Jaramillo said.

The Overlook Walk, a decades-long initiative led by the Hoffman Construction Company of Portland, Ore., is a pedestrian pathway linking the bustling Pike Place Market to the city’s evolving waterfront. The development features vendor spaces, event areas and a pedestrian bridge connecting to the newly expanded Seattle Aquarium — all key elements in the city’s broader vision for urban renewal.

Navigating the logistics of this high-profile project required strategic equipment selection. Hoffman purchased the 85|RT from Triad Machinery of Tacoma, Wash., for its simple transportability and compact footprint, recognizing its value for future projects.

In addition, its 142 ft. of greaseless boom offered impressive capacities at radius, lift-

ing a variety of materials such as 7,000-lb. boulders, precast benches, rebar bundles, and 9,600-lb. shoring tower flange beams from street level up a vertical incline to the elevated walkways. Paired with the crane’s Variable Confined Area Lifting Capacities feature (V-CALC) and multiple cameras, operating the 85|RT in confined spaces was seamless while completing lifts and traveling the crane down tight roadways.

“Its efficient, straightforward setup and breakdown allowed us to maintain a compact and well-organized job site,” said John Hamilton, Hoffman project manager.

Features such as its four-link rear suspension, all-wheel steer and LED lighting helped make navigating the congested job site simple. Inside the cab, thoughtful design features like cab tilt, ergonomically placed controls and automatic temperature control boosted both comfort and operational precision.

“You could sit in it all day,” Jaramillo said. Beyond comfort, the machine’s Link-Belt Pulse 2.0 rated capacity limiter system enabled Jaramillo to easily fine-tune swing, winch, and boom reaction speeds, ensuring smooth, consistent lifts. These features were critical for handling the diverse tasks required on-site.

“You can quickly set it to your liking, and it’s ready to work,” he said.

With previous experience operating a Link-Belt 100|RT, Jaramillo said the cranes’ shared design features made it seamless to switch between models. He highlighted the 85|RT as one of his favorites for its crucial role in elevating the Seattle waterfront to new heights, helping shape a vital public space for future generations.

“The more I operate Link-Belt RTs, the more I like them,” Jaramillo said.