State Supplement sponsored by:

90 80 6 422

6 80 24

OHIO STATE EDITION

6

4

71

76

199

A Supplement to:

30 30 75

68

30 77

71 23 22 68

4

70 70

70

22 71

75

77

27 22 74

50

50 25

35

SHIP WITHIN 48 HOURS

52

SAME DAY PARTS AVAILABILITY

®

24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS

September 21 2019

Thousands in Service!

Vol. XIV • No. 19

“The Nation’s Best Read Construction Newspaper… Founded in 1957.”

Affordable Price. Premium Service.

CALL 800-367-4937

Your Ohio Connection: Ed Bryden, Strongsville, OH • 1-800-810-7640

*On approved credit • Financing Available

$830M Toledo HBI Plant Will Create Jobs, Boost Economy By Cindy Riley CEG CORRESPONDENT

tion, site work, conveyor installation and utility work on a massive scale.” In 2008, the former Chevron refinery brownfield site was acquired by the Port Authority, so the port area could be expanded, and direct access could be gained to a second Class I railroad. Improvements were made to the site, and in 2014, the facility officially opened as the Ironville Marine Terminal operated by Midwest Terminals. Infrastructure and transportation access were fully restored at the site that allowed the receipt and transfer of bulk, break bulk and liquid cargo between vessel, rail and truck. In 2017, Cleveland-Cliffs announced they would lease and use 100 acres of the facility to construct a hot briquetted iron production facility. “The HBI plant will process [more than] two million tons of iron ore and produce hot briquetWhen the new Cleveland-Cliffs hot briquetted iron (HBI) plant in Toledo, ted iron units that will be utilized by electric-arc Ohio, opens next year, the $830 million plant will have the nominal capacity Ironworkers Local 55 photo

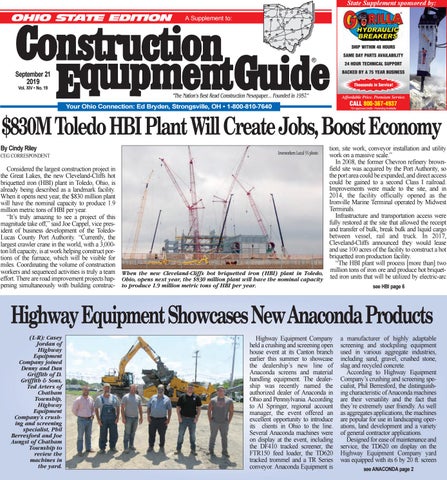

Considered the largest construction project in the Great Lakes, the new Cleveland-Cliffs hot briquetted iron (HBI) plant in Toledo, Ohio, is already being described as a landmark facility. When it opens next year, the $830 million plant will have the nominal capacity to produce 1.9 million metric tons of HBI per year. “It’s truly amazing to see a project of this magnitude take off,” said Joe Cappel, vice president of business development of the ToledoLucas County Port Authority. “Currently, the largest crawler crane in the world, with a 3,000ton lift capacity, is at work helping construct portions of the furnace, which will be visible for miles. Coordinating the volume of construction workers and sequenced activities is truly a team effort. There are road improvement projects happening simultaneously with building construc- to produce 1.9 million metric tons of HBI per year.

see HBI page 6

Highway Equipment Showcases New Anaconda Products (L-R): Casey Jordan of Highway Equipment Company joined Denny and Dan Griffith of D. Griffith & Sons, Ted Arters of Chatham Township, Highway Equipment Company’s crushing and screening specialist, Phil Berresford and Joe Aungst of Chatham Township to review the machines in the yard.

Highway Equipment Company held a crushing and screening open house event at its Canton branch earlier this summer to showcase the dealership’s new line of Anaconda screens and material handling equipment. The dealership was recently named the authorized dealer of Anaconda in Ohio and Pennsylvania. According to Al Springer, regional account manager, the event offered an excellent opportunity to introduce its clients in Ohio to the line. Several Anaconda machines were on display at the event, including the DF410 tracked screener, the FTR150 feed loader, the TD620 tracked trommel and a TR Series conveyor. Anaconda Equipment is

a manufacturer of highly adaptable screening and stockpiling equipment used in various aggregate industries, including sand, gravel, crushed stone, slag and recycled concrete. According to Highway Equipment Company’s crushing and screening specialist, Phil Berresford, the distinguishing characteristic of Anaconda machines are their versatility and the fact that they’re extremely user friendly. As well as aggregates applications, the machines are popular for use in landscaping operations, land development and a variety of general contractor applications. Designed for ease of maintenance and service, the TD620 on display on the Highway Equipment Company yard was equipped with its 6 by 20 ft. screen see ANACONDA page 2