If you pull onto the scale at Benevento Companies in Wilmington, Mass., on any given weekday, there’s a decent chance the person you meet won’t be tucked away in some distant corner office. It might be Tim Allard, the general manager of the Sand and Stone Division, or it might be Johnny Benevento, the fourth generation of the family now helping run the business as chief operating officer.

For more than a century, the family has worked this same piece of ground, gradually turning a patch of land in Wilmington into one of New England’s best-known names in stone, hot mix and concrete. Today, that same family also is quietly building a strong relationship with Equipment East and a growing fleet of DEVELON machines.

The Benevento Company and Equipment East teams work closely together to ensure that the DEVELON equipment in their fleet is meeting all expectations. (L-R) are Tim Elliot, Equipment East; Johnny Benevento, Benevento Companies; Tim Allard, Benevento Companies; and Peter “PJ” Varone Jr., Equipment East.

According to family history, Michael Benevento came to the United States from Montemarano, Italy, in 1916. Like countless immigrants of that era, he came looking for opportunity.

The land that is now the Wilmington home base has been in the picture almost from the start. Early on, the family oper-

ated what was essentially a mushroom farm there. They lived on the property in a camp back in the woods, growing mushrooms, working the soil and selling their products through local farm stands and markets.

Following a surge of complaints about low water levels over the summer, engineers inspected the dam linking Pennesseewassee Lake and Pennesseewassee Stream in Norway, Maine, to determine whether water was leaking and contributing to the decline.

The Maine Monitor of Hallowell, Maine, reported Nov. 23, 2025, that engineers could find no significant water loss. Still, the unusually low water level revealed a faulty spillway and other serious structural vulnerabilities that could lead to a catastrophic dam failure during high-water events.

In an ironic twist, the damage might have gone undetected had water levels stayed high. Norway officials have moved

helping families and individuals throughout northern Maine.

On Nov. 13, United Ag & Turf hosted a food-packing event in partnership with End Hunger NE, uniting local farms and volunteers to help reduce food insecurity across Aroostook County.

This community event effort was inspired by the growing need in the region coupled with the Presque Isle team’s wish to honor the memory of Lionel Theriualt Jr.

Lionel Theriault Jr. was a respected business leader deeply connected to Maine’s agricultural community. He owned and operated Theriault Equipment in Maine and Harvest Equipment locations in Vermont before their sale to United Ag & Turf. His dedication to support farmers and his lifelong generosity continue to inspire those who knew him.

End Hunger NE is a non-profit organization that works across New England to bring people together, at meal packing events, helping to provide nutritious meals for those in need. During the event, the United Ag & Turf team along with local farms and volunteers packed 32,628 meals to be distributed through Catholic Charities, helping families and individuals throughout northern Maine.

“Our goal was to unite at least 25 local farms and raise $4,000 to pack and distribute meals,” said Brent Buck, the general manager of United Ag & Turf. “Our community’s generosity exceeded our expectations and we raised $13,050, which allowed us to pack so many more meals than we’d originally planned. This was an incredible opportunity to come together for something bigger than ourselves, supporting our neighbors and helping to reduce hunger in our own communities.”

“This is what community is all about. Working side by side to make sure no one goes hungry,” said Gary Nadeau of United Ag & Turf. “And doing it in Lionel’s memory makes it even more meaningful for our team.”

A ceremonial ribbon-cutting ceremony was held Oct. 17, 2025, in downtown Providence, R.I., to mark the completion of the 150 Richmond St. building, a 212,000-sq.-ft. life sciences development.

The seven-story structure is anchored by the new Rhode Island Department of Health State Laboratories and is the eighth building to be completed in the 195 District.

It was developed by Legal & General, designed by Kansas City, Mo.-based HOK, and built by Dimeo Construction, with offices in Boston and Johnston, R.I.

Rhode Island Gov. Dan McKee was joined at the event by representatives of the 195 District and numerous political dignitaries, including the Senators Jack Reed and Sheldon Whitehouse; U.S. Rep. Gabe Amo; state House Speaker Joseph Shekarchi; and state Senate President Valarie Lawson.

Other guests in attendance were Marc Crisafulli, chair of the I-195 Redevelopment District Commission; Stefan Pryor, Rhode Island’s Secretary of Commerce; Dr. Glen Gallagher, director of the State Health Lab; Mark Turco, president and CEO of RI Life Science Hub; and Caroline Skuncik, executive director of the 195 District.

“150 Richmond is our latest addition to a thriving 195 District that has put Rhode Island on the map for the life sciences industry,” McKee said during his remarks. “Not only do

the new State Health Laboratories provide the ideal environment for our researchers at the Rhode Island Department of Health, but the life science incubator and available business spaces in the building set the stage for exciting publicprivate collaborations in the future.”

Crisafulli noted that the state’s economic future depended heavily on a growing life sciences sector, something for which 150 Richmond was designed.

“[It] adds more than just square footage — it adds momentum. It adds jobs. It adds vitality. It continues to fill in the fabric of the 195 District, which is quickly becoming one of the most dynamic places to live, work and innovate in New England,” he said.

Construction of the new state health laboratories in Providence was financed by an $81.7 million Epidemiology and Laboratory Capacity Grant from the federal Centers for Disease Control and Prevention (CDC).

Serving as an anchor tenant, the new state laboratory structure provides a larger, more modern and technologically advanced workspace than the former lab building, according to a news release from McKee’s office.

“Rhode Island sorely needed a new state health lab, and I am delighted that we were able to leverage our investment to bolster our bur-

geoning life sciences industry,” said Shekarchi. “By bringing together world-class public health infrastructure, cutting-edge research space and private innovation, we are creating a powerful engine for economic growth, scientific discovery and community wellbeing.”

The updated space will provide the state health labs with the flexibility needed to quickly respond to emerging threats and apply new technologies, such as the expanding field of genome sequencing.

From testing for infectious diseases to working with law enforcement, and monitoring the safety of the state’s air, food, water and beaches, the new lab facilities will provide critical services to keep Rhode Islanders healthy and safe.

Like the former location, the new building also includes a highly secure Biosafety Level 2 and 3 facility equipped to safely perform environmental, forensic, chemical and biological testing.

In addition to the state health laboratories, the building will house Ocean State Labs, Rhode Island’s first life science incubator.

Powered by Portal Innovations, with financial support from the RI Life Science Hub, the 195 District and Brown University, Ocean State Labs recently announced the first five start-up companies that will be housed in the incubator when it opens in early 2026.

Plans call for three floors of the new struc-

ture to be set aside for private companies, McKee’s office said.

Several state partners collaborated to bring the 150 Richmond project to fruition, including the 195 District, and the Rhode Island Commerce Corporation, Department of Administration, Executive Office of Health and Human Services and Department of Health.

“The staff at the State Health Laboratories work every day to keep Rhode Islanders and their communities healthy and safe,” said Dr. Jerry Larkin, director of the state’s health agency. “This much-needed modern facility will help us better serve Rhode Islanders, perform cutting-edge laboratory science and quickly respond to emergencies and other public health events.

“We are incredibly grateful to the CDC, our congressional delegation and all our laboratory staff for helping turn our vision for state-of-theart labs into a reality and solidify Rhode Island’s position as a leader in public health and scientific innovation,” he said.

State Commerce Secretary Pryor noted, “By co-locating our state health laboratory with a private sector lab and incubation space, we are leveraging a key state asset in order to drive innovation and economic activity. This space exemplifies how strategic investment and partnership can position Rhode Island to compete nationally in the life sciences space.”

The town of Lancaster, N.H., has become the first in the region to operate its municipal transfer station entirely off grid, powered by solar energy and electric equipment.

This milestone was achieved through the leadership of Transfer Station Manager Rusty Scott and assistant Manager Rob Blanchette, with support from Chadwick-BaRoss and Volvo Construction Equipment.

The town of Lancaster’s municipal transfer station had an ambitious sustainability goal to be 100 percent carbon net zero and Chadwick-BaRoss helped it there with the Volvo L20 electric compact wheel loader.

Several years ago, Lancaster secured a federal grant to install solar panels, and today that system generates enough energy to power the facility’s balers, compactors and heavy equipment. The transition has significantly reduced electricity costs, diesel fuel usage and emissions.

“Our municipal transfer station had an ambitious sustainability goal to be 100 percent carbon net zero and Chadwick-BaRoss helped us get there with the Volvo L20 electric compact wheel loader,” said Rusty Scott, transfer station manager of the town of Lancaster. “Together, we were able to meet

with the product engineers at Volvo to get our questions answered, operate a machine in our facility and prepare for a town meeting that was critical to having our request approved by the municipality.

“The electric loader charges every three days from our solar system,” he added. “It runs quietly, requires little maintenance and saves the town about $3,500 annually in fuel costs. More importantly, it makes our site safer and more efficient.”

Recognizing that upfront costs can be a

The electric loader charges every three days from the town of Lancaster’s solar system and runs quietly and requires little maintenance and saves the town about $3,500 annually in fuel costs.

barrier for small municipalities, Mike Ouellet, Chadwick-BaRoss territory manager and N.H. state representative, worked closely with the town to help secure federal and state grants that covered 45 percent of the loader’s cost

“Many municipalities aren’t aware of the available grants or find the paperwork challenging,” said Ouellet. “Working closely with Lancaster, we were able to help them navigate the system, coordinate with government departments and secure the funding

that made this purchase possible.

“At Chadwick-BaRoss, our goal is to give communities the tools and support they need to be unstoppable,” he added. “Lancaster is a great example of how the right partnerships can make ambitious projects a reality.”

“What makes Lancaster’s achievement so powerful is the teamwork,” said Lars Arnold, North American product manager for electromobility of Volvo Construction Equipment.

“Chadwick-BaRoss guided the process locally, the town embraced the vision and together we’ve shown how renewable energy and electric equipment can transform municipal operations.”

The project was completed between December 2024 and January 2025. Around the same time, Chadwick-BaRoss opened a new facility just two miles from the transfer station, ensuring ongoing support for the town’s electric fleet. CEG

(All photos courtesy of ChadwickBaRoss.)

from page 1

quickly to initiate repairs and reduce the risk of dam failure before the spring runoff next year.

Over a three-week period in October, Bancroft Construction Corp. of South Paris, Maine, repaired leaking timber boards, concrete beams and other structural elements of the dam, which was built in 1935 at an approximate cost of $91,000.

The final cost of the 2025 repairs to the dam has not been announced.

“The repairs will ensure that the gates will not fail during highwater,” interim Norway Town Manager Jeffery Campbell wrote in an email to Maine Monitor.

The bad news, however, is the fixes are not expected to significantly improve current conditions for residents and recreational boaters on Norway Lake, who endured extremely low water levels throughout last summer.

“The town was receiving a lot of calls from concerned citizens saying, ‘Oh, we see the water is really low, and we see leaking in the dam,’” Sarah Carter-Hill, vice chair of the Norway select board, told the independent and nonprofit news source.

She added that engineers who inspected the Pennesseewassee Lake’s dam determined that leakage was not the cause of the lake’s low water levels.

“There has always been flow-by of some water through the dam, even when it is completely closed,” Campbell noted in his email. “The significant reduction of the lake level was due to the extreme lack of rain this past summer.”

The low water levels allowed engineers to clearly identify the dam’s faulty spillway and made potential failure points easier to access and repair.

The repairs were completed in two phases with the boards visible above the waterline fixed first, followed by work on the underwater dam house boards, which were sealed using advanced techniques, according to minutes from the Norway Select Board’s Oct. 16 meeting Oct. 16.

Campbell said at least one of the dam’s boards was damaged to the point that it would likely not have withstood high water during the spring melt.

“This failure would have resulted in increased flow of water over the dam, but the main concrete structure of the dam is in good condition, and there was no risk of

flood or mass water loss of the lake,” he said.

Carter-Hill told Maine Monitor that an increase in calls from concerned residents about low water levels prompted a thorough inspection of the dam and revealed its failure points, which led to the recent repairs.

Norway officials were aware the dam needed repairs and had addressed its issues over the years, but Carter-Hill said she believes the complaints accelerated this particular project.

“It already had been in the works, and there was money being put into it,” she said, “because these were issues we knew we needed to fix anyway.”

Drought conditions and low water levels may have frustrated property owners around the lake, but Carter-Hill said they created ideal conditions for completing the repairs. Typically, construction crews must install a temporary cofferdam to hold back water during such work.

With already low water in the lake, little effort was needed to reduce its levels even

further to allow for crews to safely work at the site.

“It made for perfect timing to do the repairs,” she said. “These repairs are something we’ve definitely been talking about the last few years.”

In his email, Campbell wrote that the town also is taking other steps, such as using bark mulch, to reduce leakage during dry months.

The Pennesseewassee Lake’s water level is governed by a consent agreement between the Norway Lakes Association of Norway and the town.

Sal Girifalco, president of the Lakes Association of Norway, said maintaining target water levels is a tricky balancing act.

“It’s a very challenging operation to keep the water levels right,” he said. “If they guess wrong and there’s too much water, some areas flood. If they guess wrong and there’s not enough, and it doesn’t rain, then the lake stays low. So, it’s a real challenge to manage the lake levels appropriately.

“There’s always questions about the … water being too low in the summer,” he added. “So, it’s a perpetual topic. My strongest wish is that it is not a perpetual topic.”

BENEVENTO from page 1

Over time, they discovered that the sandy soils and underlying ledge had value of their own. Some relatives and acquaintances with masonry backgrounds recognized that the sand was well-suited to masonry work. The mushroom operation slowly gave way to retail sand sales and those simple sand piles gradually turned into a small-scale sand and stone business.

“They came over for the American Dream and started a mushroom farm,” Allard said. “From there they realized the soil and sand had value, then they hit ledge, and it just evolved into what we have today.”

The Wilmington property has been the anchor ever since. As the years went by, each generation put its own stamp on the business, but always on the same patch of land.

The second generation developed the sand and stone business. The third generation, led by Charles “Charlie” Benevento, moved the company firmly into the commercial materials space and began the transition from a local supplier into a larger, regional operation.

“Charlie’s vision has always been to mirror his father’s image,” Johnny Benevento said. “Hard work, loyalty, dedication to customers and employees and growth that still feels like a family business.”

Under Charlie’s leadership, Benevento expanded beyond Wilmington and into additional markets and product lines. The asphalt plant on the property, once owned by Heffron Materials, was acquired and folded into the operation. That was one of the company’s first major expansions beyond raw stone. From there, Benevento began adding facilities.

In Plaistow, N.H., Benevento acquired and now operates an asphalt plant. In Georgetown, Mass., they purchased a concrete plant that remains a ready-mix facility today. Those two moves extended the company’s reach on both the asphalt and concrete sides, tying nicely back to the Wilmington quarry and production operation.

At Wilmington today, the company runs two concrete plants, an asphalt plant, a quarry, and a large recycling operation for both concrete and asphalt. Trucks come in loaded with old concrete and reclaimed asphalt and leave with new hot mix or crushed aggregate.

One of the company’s biggest strategic moves came around 2015, when Benevento bought a sand and gravel operation in Pembroke, N.H.

“At that time, we were strictly ledge producers,” Allard said. “We realized that if you want to be serious in concrete, you have to control your sand. It’s a main ingredient. If you can control that, you can control pricing and be more competitive.”

The Pembroke site started modestly with a screening plant and a small crew. It didn’t stay small for long. Over the years, Benevento grew that foothold into a much larger New Hampshire presence.

The company now operates a large sand and gravel and quarry operation on approximately 1,100 acres in Loudon, N.H., and works under a mining rights agreement in Belmont. Two additional gravel pits in the Loudon area are in the process of being opened.

Pembroke was the company’s introduction to the New Hampshire sand and gravel market; Loudon is now the centerpiece. Material from Belmont is excavated and hauled back to Loudon for processing.

DEVELON

“It’s different from what we were used to,” Allard said. “But controlling your own sand makes you more self-sufficient and more competitive. It’s made us stronger overall.”

Because concrete and asphalt are perishable, Benevento views its realistic delivery radius at approximately 30 miles from each plant. Stone can travel farther, but for hot mix and ready-mix concrete the company focuses on serving jobs within that core radius, using its own trucks and a sizable pool of third-party haulers.

Benevento supplies a mix of municipal customers and private contractors, but it does not operate paving crews or sitework crews. “We’re strictly a supplier,” Allard said. “We don’t compete with our customers.”

The volumes are large enough that Benevento has been recognized among the top 50 aggregate producers in the United States. The company chooses not to publish tonnage, but the ranking speaks for itself in terms of the scale they’ve reached while still operating as a family-owned organization.

Talk to Benevento employees and two themes repeatedly come up: family and flexibility.

Allard has been with the company as an employee for approximately 18 years, with another decade before that as a contractor. He has watched three generations of the family steer the operation and has raised his own children while working there.

“One thing I was told from the very beginning was family comes first,” he said. “Don’t miss your kid’s play. Don’t miss the game. Don’t have regrets when they’re grown. If you need to leave at 10 a.m. to go see something at the school, you go. Then you come back and finish the work.”

That philosophy, he said, traces back to earlier generations and remains intact today. The expectation is that people work hard and take care of the business — but in a way that allows

them to take care of their families, too.

The company also has also made a point of keeping people year-round rather than running a large seasonal workforce. Over the past five years, approximately 90 percent of employees have been year-round, due in part to milder winters and a deliberate strategy of building inventory in the offseason. Running some plants and pits through the winter creates stockpiles so there is always material on hand when spring hits.

Inside the operation, there are no rigid walls between divisions. The leadership team — stone, asphalt, concrete — meets weekly, talks about what’s going right, what’s going wrong and figures it out as a group. When someone has a family issue or an unexpected problem, others step in. Johnny Benevento will get in a loader. Allard will jump in a loader. People get moved around to cover gaps.

“Charlie expects us to treat this like it’s ours,” Allard said. “And we do. That’s how we run it.”

Johnny Benevento added another key point: the family is present.

“My dad and I are here every day,” he said. “A truck driver can come in, get on the scale and talk to Tim [Allard]. Or he can walk into the office and have the same conversation with my dad or with me. People like knowing the owners are here and listening.”

On the fleet side, Benevento runs an impressive amount of iron and rubber. The company owns one of the largest fleets of triaxles, dump trailers and concrete mixers in the New England market. In addition, Benevento has a large network of third-party trucks it can call in when demand spikes.

Across all sites, the company has an impressive amount of equipment — loaders, excavators, haul trucks — and support machinery.

see BENEVENTO page 16

• Local Ownership with flexible approach

• Trained staff for repairs and maintenance

• Dedicated Parts personnel on site • Focused on the

Seventeen Connecticut cities and towns have collectively been awarded $12 million by the state to improve the safety and mobility of pedestrians, bicyclists and transit users in community centers.

The funding is part of the seventh round of awards for the Connecticut Department of Transportation’s (CTDOT) “Community Connectivity” program.

“Connecting residents with their communities through these projects is vital to boosting economic development, creating dynamic town centers and encouraging alternative modes of transportation like walking or biking,” Gov. Ned Lamont said in a recent press release. “Supporting this program improves the quality of life for towns and cities across the state.”

The municipalities receiving the grants are Ansonia, Berlin, Branford, Bristol, Brookfield, Chester, Manchester, Marlborough, New Haven, North Haven, Norwalk, Old Lyme, Plainfield, Salisbury, West Hartford, Wethersfield and Windsor Locks.

Applications from the New England state’s cities and towns were scored using a rubric to assess a proposed project’s “public benefit impact,” as well as considering its planned connectivity with transportation,

projected budgets and a town’s “readiness to proceed” being factored, noted the Daily Campus, a Storrs, Conn., news source, on Nov. 20, 2025.

Delegations from the selected communities have expressed their appreciation for the funding opportunity. One such town is Marlborough, which will be using its $348,224 grant to extend sidewalks in the town center’s green area near Connecticut Highway 66.

“Supporting this program improves the quality of life for towns and cities across the state.”

Ned Lamont

Connecticut Governor

work will be completed within three years, according to the CTDOT.

The agency also noted that municipalities would be responsible for any expenses that exceed the grant cap and costs outside of construction activities, such as property acquisition or public involvement activities.

“Marlborough consistently ranks as one of the best communities to live in around Greater Hartford, so I’m pleased that with these new, extended sidewalks, [people will] be able to see more connectivity in the center of town,” said State Sen. Cathy Osten, District 19, which includes Marlborough and eight other communities.

Some selected towns are using the funds to construct or improve bike lanes and trails.

For instance, Manchester’s $800,000 award will be put toward the city’s “Downtown Manchester Improvements Project” through the construction of a “cycle track” alongside Main Street.

“Cycle tracks are intended to be exclusively used for bicycles,” noted the city’s

project narrative. “On streets where on-street parking is allowed, cycle tracks are located to the curbside of the parking — in contrast to bike lanes which are typically between parking and the travel lane. While not the first cycle track in Connecticut, we believe this would be the first cycle track of its type in a downtown district.”

“This funding will enhance safety and accessibility for our community,” State Sen. MD Rahman explained on social media. “I look forward to working with our local leaders to make these improvements a reality for everyone.”

The Community Connectivity program funding can only be used for a town’s construction plans costing between $100,000 and $800,000, with an expectation that the

“We remain focused on increasing safety and enhancing connectivity across Connecticut … helping towns and cities deliver important projects,” Connecticut Transportation Commissioner Garrett Eucalitto said in the news release. “We’re grateful to Governor Lamont and the General Assembly for their continued support of these efforts.”

Previous rounds of the program have awarded 155 grants totaling approximately $74 million, according to the transportation department. CTDOT began the funding in 2023 and said at the time that a new solicitation process for the program would be announced every two years.

Previous projects funded by the agency’s grant initiatives include ADA upgrades, multi-use pathways, landscaping and weatherproofing of sidewalks and other public facilities in cities and towns statewide.

www.equipmenteast.com

61 Silva Lane

Dracut, MA 01826

978-454-3320

196 Manley Street Brockton, MA 02301

508-484-5567

1474 Route 3A Bow, NH 03304

603-410-5540

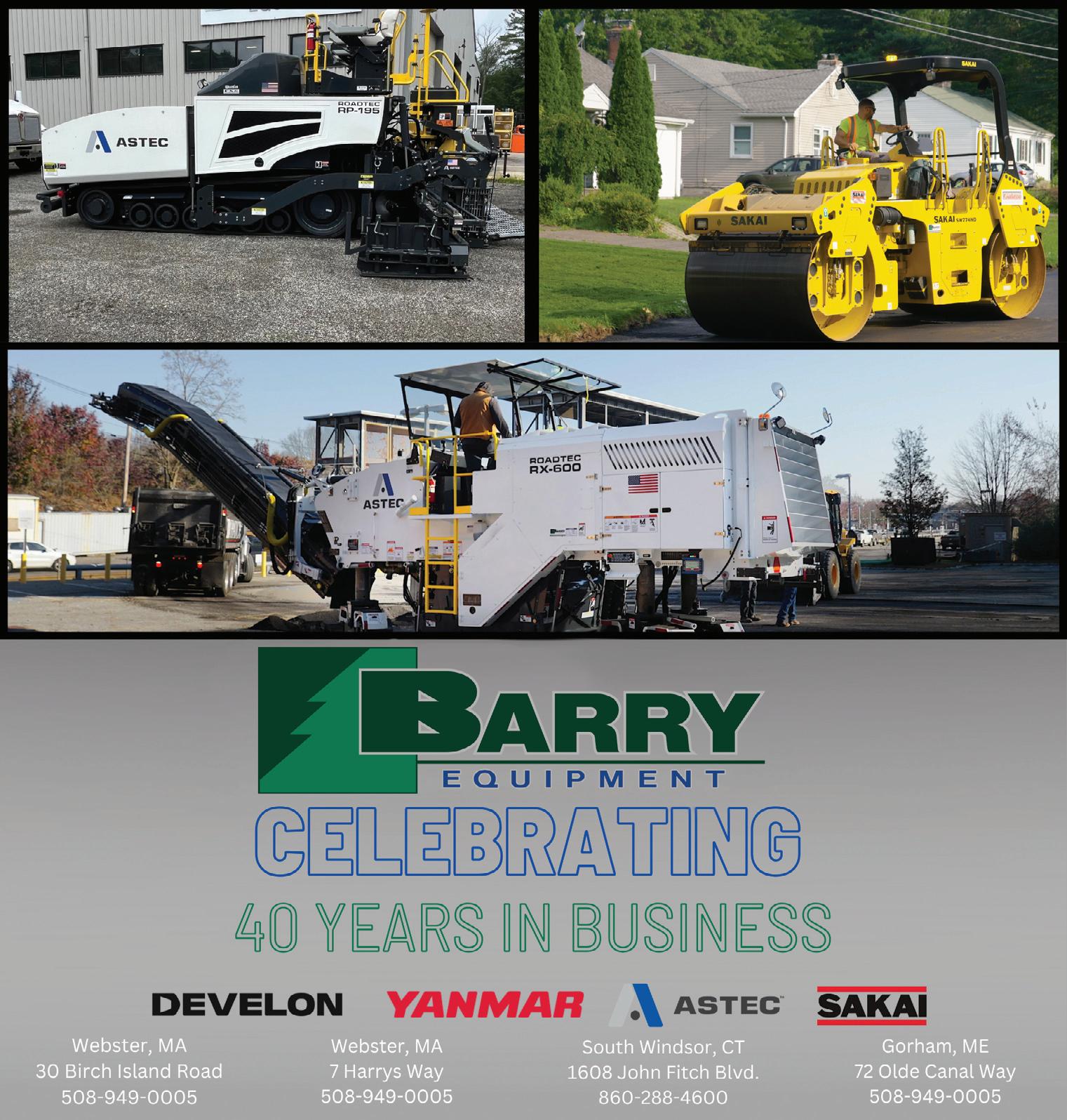

www.barryequipment.com

30 Birch Island Road Webster, MA 01570

508-949-0005

7 Harry’s Way Webster, MA 01570

508-949-0005

72 Olde Canal Way Gorham, ME 04038

508-949-0005 1608 John Fitch Blvd South Windsor, CT 06074

860-288-4600 Rhode Island

BENEVENTO from page 12

The company’s philosophy on equipment is straightforward: maintain it, train the operators and know when to rebuild versus replace. Preventive maintenance and operator training are stressed heavily.

Before DEVELON came into the picture, Benevento was not a single supplier, but it did lean heavily on a dealership relationship that went back to earlier generations. Over time, that relationship naturally changed as people retired or moved on.

At the same time, the Benevento family developed a longstanding personal relationship with Giovanni and Gilda Albanese of Equipment East. Long before entering the dealership business, they had done business together for many years.

There's nothing corporate about this story, according to Equipment East. It’s about real people standing by each other in their respective businesses through difficult business cycles and making the tough decisions that come when things do not go as planned.

Although the two businesses operate in different industries, they are aligned in their core values — family-run operations built with strong leadership teams, dedicated employees, good old fashioned hard work, trust and commitment that endures across generations. That kind of relationship carries weight in a family company.

When the time came to look at some alternatives for heavy equipment, that friendship opened the door to DEVELON (formerly Doosan).

“Let’s be honest,” Allard said. “DEVELON is not the first name people think of when they think heavy iron in New England. So, we had to be confident we weren’t stepping off a cliff.”

What gave them that confidence was, in their words, service and commitment. Equipment East made it clear it believed in the brand and would stand behind the full DEVELON line of wheel loaders, excavators, articulated dump trucks (ADT’s) and more. They agreed to meet with DEVELON factory representatives — including delegates from South Korea — who met the team and worked through details on financing, warranty and service support that made sense for the way Benevento runs its operations.

Price, they said, was a factor but not the deciding one.

“You can buy the most expensive brand in the world, and if it’s down or no one answers the phone when you call, what did you really buy?” Allard said.

The first DEVELON machine Benevento brought was a DL550-class wheel loader, approximately seven or eight years ago. At that time, the machine did not have every “bell and whistle” that some competitors were adding. For Benevento, that was more plus than minus.

“Technology is great,” Allard said. “But technology fails. One of the biggest problems we’ve seen across the industry over the past several years has been electrical and sensor issues. Codes, computers, parts you can’t get. Simple is sometimes better.”

The first experience with the loader went well enough that the company later traded it in and bought another. Today, Benevento runs approximately five DEVELON loaders, five articulated dump trucks and one 100,000-lb. excavator.

The articulated trucks started as 40-ton Doosan models and have since moved into the 45-ton DEVELON units. The feedback has been strongly positive.

“Reliability and durability,” Johnny Benevento said. “We had some equipment from other brands that started corrod-

ing and falling apart far earlier than they should have in the same environment. The DEVELON trucks have held up. We think they’ve built them with the idea of proving themselves in this kind of heavy work.”

On the loader side, operator buy-in came slowly and then all at once.

“I’ve had guys look at a new loader and say, ‘I’m not running that thing, I’m a diehard [other brand] guy,’” Allard said. “Two weeks later, you hear them say it’s the best loader they’ve ever run. For most of them, it comes down to power, comfort and simple controls. They don’t want three touchscreens between them and the bucket.”

The excavator — roughly a DX420-class, 100,000-lb. machine — may have been the biggest surprise. It went to a seasoned operator known for being fiercely loyal to another brand.

“He’s as old-school as they come,” Johnny Benevento said. “He came back and said it was the best excavator he’s ever run — power, ease of operation, comfort. That’s high praise from him.”

The machine is used for site development and sand and gravel pit development, not hammer work. But the early results, the company says, have been eye-opening,

What ties it together for Benevento is the level of support the company gets from Equipment East. Peter “PJ” Varone, sales representative, is the company’s day-to-day contact and is described as responsive without being pushy.

“He follows our growth and checks in,” Johnny Benevento said. “He knows sometimes a quote is just a quote and he doesn’t beat us up about it. But he’s always there when we need him. He answered his phone on vacation. That says something.”

If they can’t reach PJ, they know they can call the Equipment East team, whether it’s for parts, service, sales or rentals and get the same urgency and attention. They also

know their friends at Equipment East are just one phone call or text away, according to Benevento.

Equipment East also has invested heavily in infrastructure and facilities, with a “hell of a garage,” as Johnny Benevento put it, and additional locations that align well with Benevento’s push into New Hampshire. They even assigned a dedicated mechanic to Benevento’s account.

“He works on other stuff when we don’t need him,” Johnny Benevento said, “but if we call, he’s coming. Knowing that is invaluable. You’re not buying spare loaders to sit in the yard ‘just in case.’ You’re relying on your dealer to have your back.”

All equipment breaks down or has issues; it’s the commitment and response to those situations that makes the difference. That combination — an equipment line that has proven reliable and a dealer that answers the phone and shows up — is ultimately what has kept Benevento buying DEVELON.

From mushrooms in the woods to one of the top aggregate producers in the country; from sand and stone for local masons to quarries, asphalt plants, concrete plants and sand and gravel operations across Massachusetts and New Hampshire; from old cable machines to a fleet that now includes a growing lineup of DEVELON loaders, trucks and excavators — the Benevento story is, at its core, a straightforward one.

Show up. Work hard. Take care of your people. Be there for your customers. Partner with suppliers who share that mindset.

“We want to be the one call our customers make,” Johnny Benevento said. “For stone, hot mix, concrete — and for the service behind it. And we want to work with vendors like Equipment East and DEVELON who help us keep that promise.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

SATURDAY, December 13, 2025

LOCATION: 210 CHESHIRE ROAD, RT. 68, PROSPECT, CT 9:00 AM Davis Auctions, Inc. will be conducting our next auction of utility and construction equipment and related supplies on December 13, 2025. This auction will consist of excess equipment from the power companies, municipalities, and others to be sold in absolute.

Wheel Loader Backhoe: 2014 JOHN DEERE 310SK, 4x4; 2009 JOHN DEERE 310SJ; Excavator: 2005 LANDHERO LDH-ME18-ZW Mini; Skid Steer: (2) 2025 LANDHERO LDH-T460 Mini; (2) 2005 LANDHERO LDR-T460K1 Mini; Skid Steer Attachments: Brush Cutters; Tillers; Trenchers; Auger Drive & Bit; Grapple Bucket; Concrete Breakers; Land Leveler; Rippers; Sickle Bar Mower; Forks; Quick Hitches; 3 PtH; Quick Attach Mount Plates; Utility Hitch Adapter; Pallet Fork Frames; Dozer Blade; Snow Pusher; Pallet Fork Extensions; Bale Spears; Tree Puller; Big Arm Backhoe; Power Rake; Rock Buckets; No Till Seed Drill; Forklift: 2006 LULL 644E 42’; CLARK C500 S30; CLARK C500 25; CAT TC30; Misc.: ONAN 4R8/21540 Generator; RVI MD5000C Electric Pallet Jack; Electric Pallet Jack w/charger; Fertilizer Spreader; Quick Hitches for Tractors; 32” & 36” Hyd Backhoe Excavator Thumb; Mini Ripper; Hyd Winches; Hyd. Grab Bucket; Hyd. Forks & Frame

Bucket Trucks: 2018 INTERNATIONAL Durastar 4300 w/Altec AT41M Material Handler; Digger Derrick: (2) 2012 INTERNATIONAL Durastar 4000 Digger Derrick; Crane Trucks: 2006 INTERNATIONAL 4400; Dump Trucks: 2004 MACK 700CV13 Tri-Axle, diesel, electric tarp; Misc. Trucks: 2010 FORD F450 w/Reading Utility Body, 4x4; 2000 FORD F350 w/Western Plow Mount, no bed, Powerstroke diesel; Pickups: 2018 CHEV Colorado; (2) 2017 CHEV Colorado; (3) 2016 CHEV Colorado; (2) 2016 GMC Canyon Ext Cab, 4x4; 2015 CHEV Colorado; 2013 FORD F150; 2010 FORD F350 Crew Cab, 4x4; (4) 2010 FORD F350, 4x4; 2007 FORD F150; 2006 CHEV Silverado 1500 Ext Cab w/plow, 4x4; 2005 DODGE Ram 2500, w/plow, diesel, 4x4; 2000 FORD F350 Ext Cab, w/plow; Cars/SUV: 2019 CHEV Trax; 2014 JEEP Grand Cherokee; 1985 JAGUAR Sovereign 4 dr Sedan; Vans: 2014 FORD Transit Connect; (2) 2010 GMC Savana, AWD; 2009 GMC Savana, w/Kohler Generator; ATV/Motorcycle: 2006 YAMAHA Rhino; Trailer: 2008 TRANSCRAFT TL2000 Flatbed; 2006 TRANSCRAFT TL2000 Flatbed; 2004 DOOLI 1250 Landscape w/ramp; 2003 HOGG DAVIS T150 Reel; 2004 WABASH Van; 2003 WABASH Van; 2002 TRAILMOBILE Van; Tents/Storage: (2) 40’ High Cube Multi-Door Storage Container; (2) 11’x19’ Metal Garage Shed w/double Front Doors; (13) Misc Size Metal Sheds; (2) 20’ All Steel Car Port; (3) 19’ All Steel Car Port; Stone: Pallet- 24”x36”x1” Thermal Bluestone Pattern; Pallet- 24”x24”x1” Thermal Bluestone Pattern; (3) Pallet- 24”x36”x1.5” Thermal Bluestone Pattern; (3) Pallet- 24”x24”x1.5” Thermal Bluestone Pattern; Pallet- Thermal Standup Irregular Bluestone; Pallet- 12” Mixed 2” Thermal Bluestone Treads; Pallet- 12”x36”x2” Thermal Bluestone Treads; Pallets- 6”x12”x2” Tumbled Pavers; Pallets- 12”x12”x2” Tumbled Pavers; Pallets- 12”x18”x2” Tumbled Pavers; Pallet- 4”x4” Random Length Tumbled Belgium Blocks; Pallet- 1.5” Tumbled Garden Path; (8) Pallets- 1.5” Bluestone Patio Kits; (4) Pallets- 6” Steps, sawn top, natural face; Pallet- 16”x72”x6” Thermal Bluestone Steps; Thermal Bluestone Bench; Bluestone Bird Bath; Misc.: Concrete Cutter; Plasma Cutter; Plate Compactors; 40 Gallon 2 Stage Truck Mounted Air Compressor; Ladder Rack; Pallet- Misc. Tools; Metal Animal Figures; Tail Gates; Bumpers; Rigging Equipment; Leaf Blowers; Putty Ash Mixer; 60 Drum Pioneer Machine; Welding Machine; Hyd Winch; 10’ Cattle Squeeze Chute; Fuel Transfer Pump; Impact Wrenches; Hyd Shop Presses; Gantry Cranes; Tire Changer; Wheel Balancer; Racket Tie Downs; Anchor Shackles; Lifting Chain Slings; Webbing Slings; Racket Binders w/chain

Inspection: Friday, December 12 - 8:00 am to 5:00 pm

Online bidding will be available through Proxibid. Please register for online bidding minimum of 24 hours before sale.

Skanska announced the substantial completion of the new 40,300-sq.-ft. Belmont Skating Rink and Athletic Facility in Belmont, Mass.

Skanska announced the substantial completion of the new 40,300-sq.-ft. Belmont Skating Rink and Athletic Facility in Belmont, Mass. The new facility occupies the site of the former Viglirolo Skating Rink, which was demolished prior to construction.

“Skanska’s team provided construction expertise in a professional manner to navigate the twists and turns that come up during this type of project and were able align their trade partners to focus on the town’s vision and goals,” said Mark Haley, chair of the building committee.

“The Viglirolo Skating Rink had long been a focal point of the local Belmont hockey community, and we’re honored to have played a role in the revitalization of the space through the construction of the new Belmont Skip Viglirolo Rink,” said Bryan Northrop, executive vice president and general manager of Skanska USA Building’s New England region. “Skanska is proud to have delivered a modern, sustainable facility that will serve future generations of Belmont athletes and residents, serving as a testament to our team’s experience building state-of-the-art athletic facilities for the New England region.”

“The Galante Architecture Studio was super proud to design a state-of-the-art, fossil fuel free, CO2 driven ice plant, and covering most of the building with solar panels,” said Ted Galante, design principal of The Galante Architecture Studio. “Our goal is to deliver the most sustainable buildings for the long haul, and the town of Belmont has the depth of foresight to inspire this to

happen.”

The new facility designed by The Galante Architecture Studio provides the Belmont community with an energy-efficient, yearround venue for youth and high school hockey, figure skating and recreational programs, supporting the town’s long-term commitment to sustainability and public recreation.

The project scope included the construction of a new 40,300-sq.-ft. steel-framed, pre-engineered metal building, inclusive of the new rink complex with a conventional 200-ft. by 85-ft. ice sheet. The fossil-free facility also features four High School team locker rooms, four dressing rooms, public toilets, bleacher seating and a concession stand. Skanska also installed PV solar panels on the roof of the main building and a heat pump refrigeration system to ensure the ice surface remains sufficiently cool, in addition, through the use of energy recovery systems the spaces within the facility.

The Belmont Skating Rink expands upon Skanska’s breadth of experience building athletic facilities in the New England region, including projects such as Deerfield Academy’s athletic complex, Boston College’s Margot Connell Recreation Center and upgrades to the high-definition scoreboard, video board and sound system at Northeastern University’s Matthews Arena.

Skanska worked closely with the town of Belmont to deliver the project safely and on schedule during the 18-month construction period, which commenced in October 2023. For more information, visit skanska.com/.