By Lori Tobias CEG CORRESPONDENT

Construction crews on the $93 million Nolensville Pike project in Nashville, Tenn., are approximately midway through the projected four-year job, but progress hinges on two very important components.

“It’s very dependent on getting some of the utilities moved, which they’re making a really big push on now,” said Greg Woerdeman, team lead, District 37 Construction of the Tennessee Department of Transportation (TDOT). “A big challenge of this project is some of the environmental commitments that are on it due to the Nashville Crayfish. There’s only a certain time where they can work in the streams, and if they can get a lot of that work done during when we’re allowed to for those permits, that will really help our project. If not, they’re going to have to work elsewhere.”

The contract was awarded to Civil Constructors in November 2023 with work getting under way in December of the same year. The 4.4-mi. project, Phase 1, includes reconstruction and widening and is designed to reduce congestion, improve safety and

By Lucy Perry CEG CORRESPONDENT

This summer, OSHA proposed revising or removing existing safety standards that have a direct impact on transportation construction contractors.

Three such rules affecting road and bridge construction are among several the agency is presenting in efforts to either revise obsolete measures or scale back or withdraw certain long-standing obligations for businesses.

Offered the opportunity the construction industry responded with a resounding “don’t fix it.”

In fact, on July 1, OSHA published 25 proposed rules in the Federal Register, reported the Institute of WorkComp Professionals (IWCP). A general duty clause, construction

Site work is progressing in a rural corner of northeast Louisiana, Meta, the parent company of Facebook and Instagram, to build one of the world’s largest AI data centers, a massive $10 billion complex roughly the size of 70 football fields.

Although North Carolina’s Thorpe Landscapes has served the region for the past 15 years, it remains a youthful, yet experienced company made up of a team of talented individuals. Dan Thorpe opened the landscaping firm in 2011.

Ring Power hosted a customer appreciation open house event Nov. 7, 2025, at its new Leesburg, Fla., branch facility. Equipment and service displays were abundant inside and out and vendors turned out to lend their support.

Boeing broke ground in North Charleston, S.C., to mark the start of its Boeing South Carolina site expansion. Home of the company’s 787 Dreamliner program, BSC is set to increase production to a rate of 10 airplanes per month in 2026.

Skanska announced a leadership transition in its United States building operations. Leo Sinicin, chief financial officer (CFO) of both Skanska USA Building and Skanska USA Inc., will retire effective Dec. 31, 2025.

The Nashville-based distributor began marketing, selling and renting the Japanese manufacturer’s line of equipment in the spring 2019, just after Parman first opened its doors.

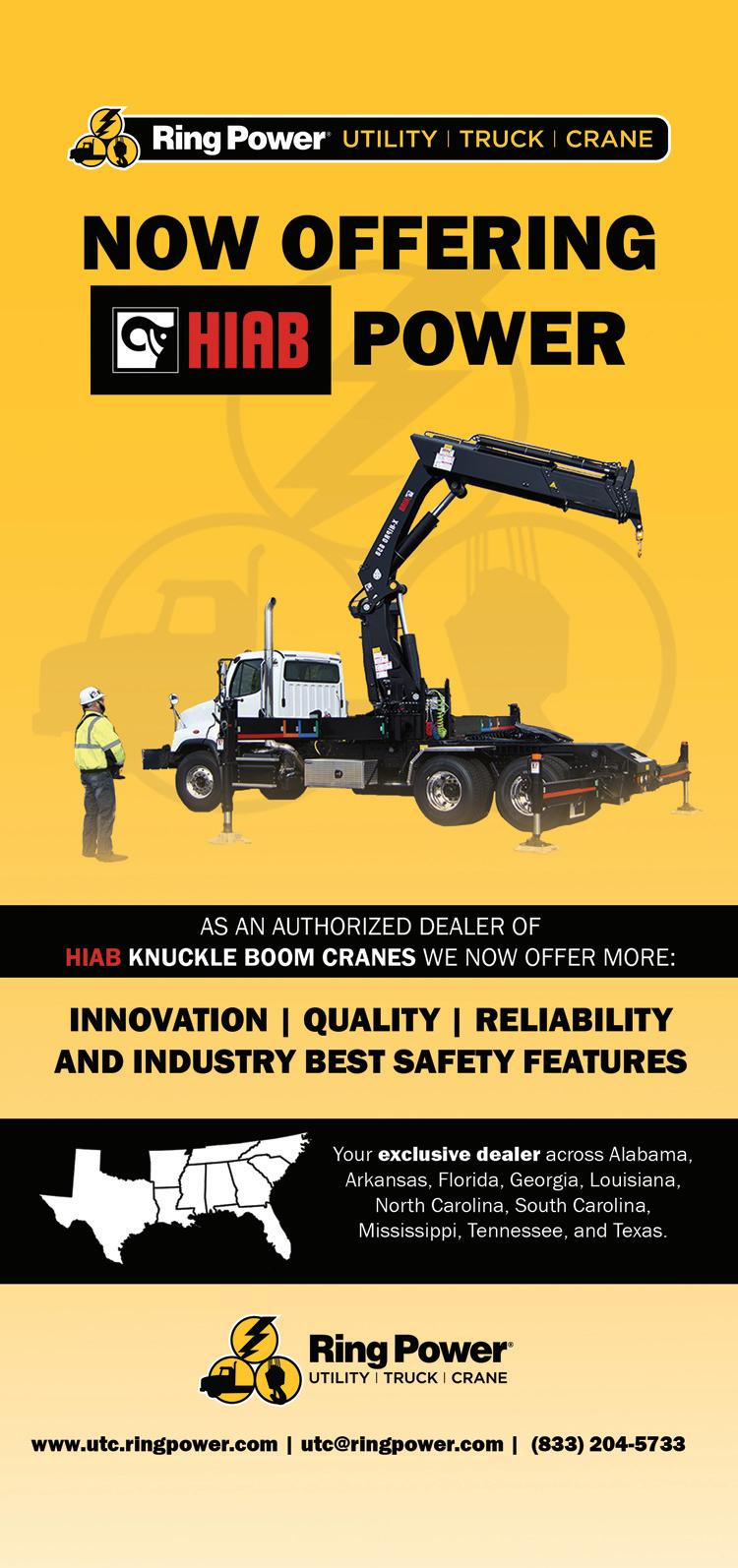

Ring Power Utility | Truck | Crane has expanded its upfit capabilities in Jacksonville, Fla., following the company’s exclusive distributorship agreement with Hiab earlier this year.

AEDF and ASE announced a new partnership designed to expand access to industry-recognized credentials and strengthen the connection between high school tech programs and careers in the equipment distribution industry.

Caterpillar Inc. announced that Indiana will be among the first states to receive funding from its five-year, $100 million workforce pledge, and has committed up to $5 million to training and upskilling efforts across the state.

36

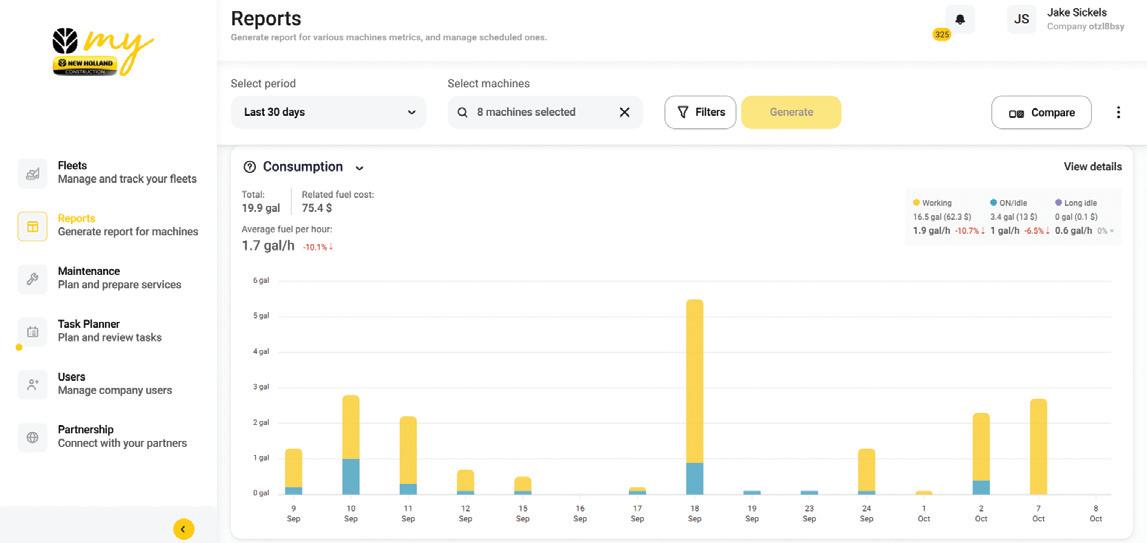

New Holland Construction is taking a bold step into the future of connected job sites with the launch of its new digital platform, myNewHollandConstruction — a next-generation fleet management and telematics system.

40

Trimble gave attendees of its annual user conference, Trimble Dimensions, a firsthand look at artificial intelligence innovation and the company’s vision for accelerating the development and expansion of agentic AI.

In order not to disrupt visitor operations at Neuschwanstein Castle, work could only be carried out at night. The contractor therefore opted for the Vögele Paver Super 1800-5 X with the integrated light package plus.

52

FROM SOYBEAN-BASED ASPHALT

Verde Resources Inc., a St. Louis-based construction and building materials company, tapped into the underused biochar industry, which produces a charcoal-like material made from organic matter such as soybeans.

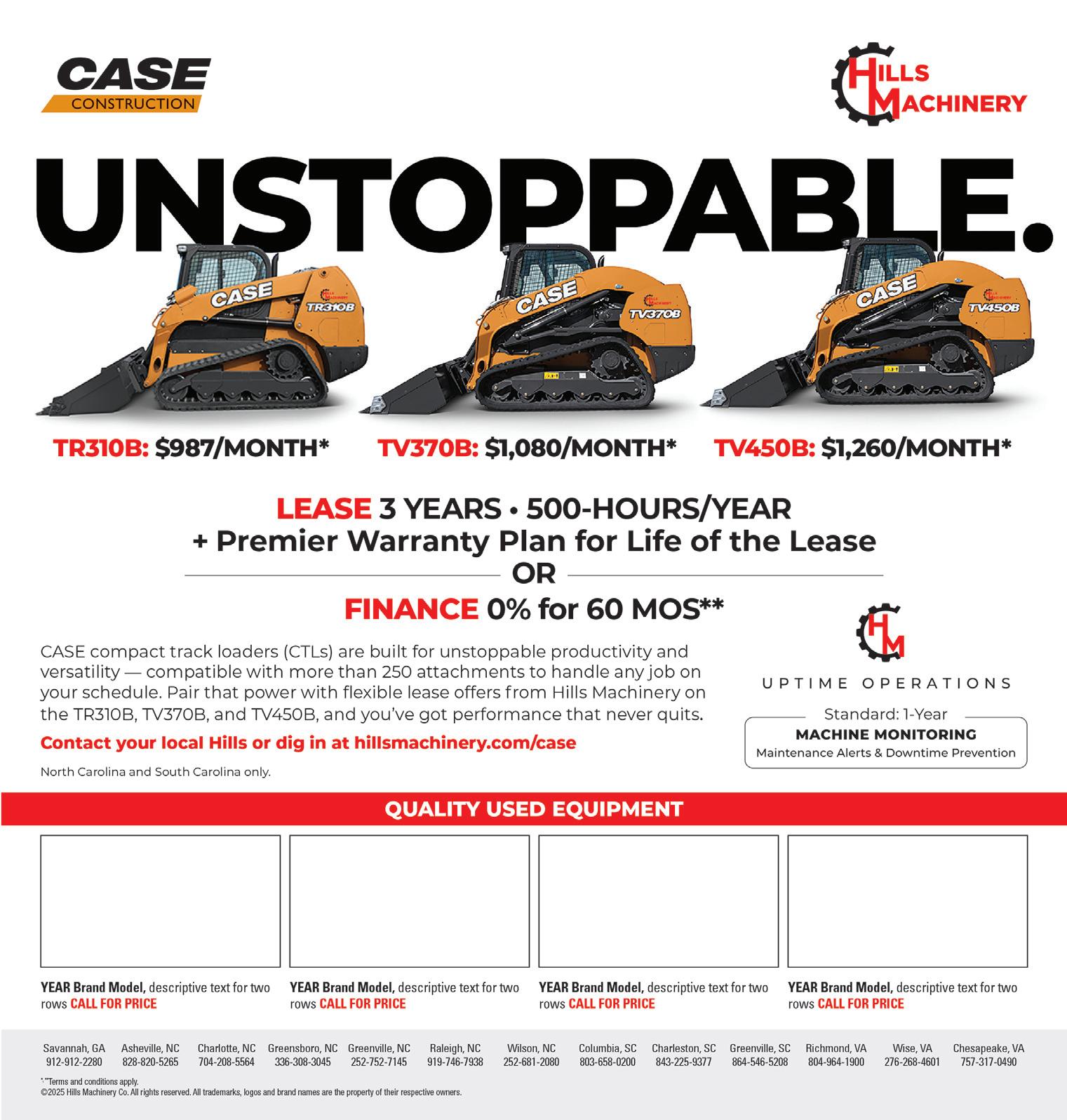

56 HILLS MACHINERY PARTNERS WITH AMMANN AMERICA

Hills Machinery announced that it has partnered with Ammann America to add new capabilities to the Hills Machinery Construction Equipment Division serving South Carolina and North Carolina.

68 FERROVIAL NAMES TIM CRESON U.S. CHIEF OPERATING OFFICER

Ferrovial announced Tim Creson has rejoined its construction division as United States chief operating officer, reporting to Pepe Baraja, United States and Canada CEO of Ferrovial Construction. 93

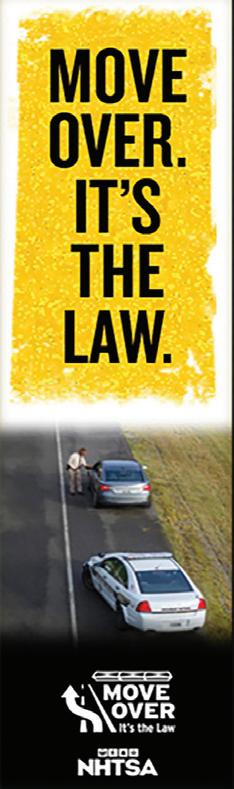

EXPANDS INDUSTRY’S EFFORT TO SAVE LIVES IN WORK ZONES

Adopted by the Oklahoma state legislature in 2023 as a component of driving certification, the Work Zone Safe program has since expanded into six more states, with a projected 250,000 teen drivers to be trained next year.

Site work is progressing in a rural corner of northeast Louisiana, Meta, the parent company of Facebook and Instagram, to build one of the world’s largest artificial intelligence (AI) data centers, a massive $10 billion complex roughly the size of 70 football fields.

Estimates are that when operational, the 4 million-sq.-ft. facility will consume more power in a day than the entire city of New Orleans on a hot summer day.

The expansive technology campus occupies the 2,250-acre former Franklin Farm mega site in Richland Parish, according to the Louisiana Economic Development (LED).

Meta projects the data center will support 500 or more new direct jobs locally, while LED estimates the project will result in the creation of more than 1,000 indirect jobs. The data company estimates 5,000 construction workers at the peak of construction, located between the small towns of Rayville and Delhi, approximately 30 miles east of Monroe.

Work kicked off on the Richland Parish Data Center in late 2024 with three major contracting firms set to build the gigantic complex. They include Minnesota-based Mortenson, Turner Construction Co. of New York, and DPR Construction, headquartered in Redwood City, Calif. All three companies maintain offices nationwide.

Mortensen has been on the site for several months using a full range of machines to move across the raw land in preparation for structural work. The contractor’s scope of work includes:

• site preparation and grading;

• underground utilities;

• medium voltage distribution and substations for onsite power;

• building an onsite water treatment facility;

• erecting an offsite wastewater treatment facility;

• constructing administration and intelligent building operating system (IBOS) structures, in addition to guard houses; and

• building telecommunications infrastructure for outside plant (OSP) fiber distribution.

Turner Construction’s work at the Meta project is limited to the four primary AI data center buildings on campus.

Construction on those structures recently got under way and its procurement activities will continue throughout the remainder of 2025, according to the contractor.

Meanwhile, DPR Construction’s duties on the project are to build approximately 2 million sq. ft. of data space, including one network data center building and four support data center structures, modular electrical rooms and modular central utility plant (MCUP) systems.

Meta expects construction on the new data center to continue through 2030. In addition, the company also has committed to investing more than $200 million in local infrastructure improvements, including roads and water systems.

Hyperscale data centers such as the one planned for Richland Parish are housed in huge physical structures designed to process the vast amounts of data required to support digital technologies, including AI workloads. The northeast Louisiana facility is the largest of more than 20 Meta data centers around the world.

To power the facility, which at its largest point extends more than a mile from front to back, Entergy will add clean, efficient power plants to its system to meet growing power demands, including from the data center. Meta has pledged to match its electricity use with 100 percent clean and renewable energy and is working with Entergy to bring at least 1,500 megawatts (MW) of new renewable energy to the grid through its Geaux Zero program.

“[We are] building the future of human connection and the technology that makes it possible. And this data center will be an important part of that mission,” said Kevin Janda, Meta’s director of data center strategy. “Richland Parish in Louisiana is an outstanding location for Meta to call home for a number of reasons: It provides great access to infrastructure, a reliable grid, a business-friendly climate and wonderful community partners that have helped us move this project forward. We’re thrilled to be a new member of the community and are committed to investing in its long-term vitality.”

project, one of the largest private capital investments in the state’s history, to spark new economic activity and investments throughout northeast Louisiana as multiple industries benefit from the billions of dollars invested.

LED noted in a news release that Meta “makes a concerted effort to source labor and materials locally, and partners with local schools and organizations to advance STEAM education and digital skills that can be used to compete in the digital workforce.”

In addition, the tech giant has committed to contribute up to $1 million a year to Entergy’s “The Power to Care” lowincome ratepayer support program, a figure that will be matched by Entergy Louisiana.

Meta has always prioritized water stewardship in its operations as well, including minimizing water use at its data centers. By establishing its presence in Richland Parish, the company is pledging to restore more water than it consumes at the data center by investing in water restoration projects in Louisiana.

To support both the construction and eventual operation of the data center, Louisiana Community and Technical College System (LCTCS) has committed $250,000 in Workforce Rapid Response funding to nearby Delta Community College to develop programs and expand capacity.

Delta plans to use those funds to scale up its construction trades programs to meet the data center’s initial construction needs, and partner with peer institutions experienced in developing and delivering curricula for Meta’s operations.

“This project will create a transformational change for the residents of the entire northeast Region,” said Rob Cleveland, president and CEO of Grow NELA, a private, nonprofit corporation and a regional economic development agency for northeast Louisiana. “Meta chose [this area of] Louisiana because of the availability of reliable, low-cost energy, access to flat and developable land and a business-friendly environment led by Governor Jeff Landry. This project opens the floodgates for data center development in Louisiana, and we are prepared for what’s ahead.”

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

By Eric Olson CEG CONTRIBUTING EDITOR

Although North Carolina’s Thorpe Landscapes has served the region for the past 15 years, it remains a youthful, yet experienced company made up of a team of talented individuals.

Dan Thorpe opened the landscaping firm in 2011 in Wilmington, located on the state’s southeastern coast. A native of Pennsylvania, he had earlier graduated from the University of North Carolina at Wilmington before serving a two-year commitment with AmeriCorps and the Philadelphia Teaching Fellows. While living in Philadelphia, Thorpe also earned his master’s degree in education from Chestnut Hill College.

As his company grew, Thorpe wanted to better understand business, which led him to earn his MBA from the KenanFlagler Business School at the University of North Carolina at Chapel Hill

“We started doing landscape maintenance in the summers when I was not teaching in Philadelphia,” he said recently at the site of a stream restoration project in the town of Wake Forest, just north of Raleigh. “We did some work for a great lady who managed an apartment complex, and she said, ‘You know, if you really start something significant, we’d let you bid on some of our projects.’ That led us to start an LLC and bid on some work. Pretty soon, we started getting a few.”

As is the case with many successful start-ups, Thorpe was able to grow his business from that one small kernel. In the beginning, the work consisted of simple yard mowing, edging, string trimming and leaf blowing.

“We also did some hardscape projects before getting into some larger land development with grading and excavation, and it kind of just went from there,” Thorpe said. “There were 15 years of growth in that 15-second answer. It was certainly a process.”

Thorpe Landscapes’s path to success also included working hard to become fully educated and certified to run a knowledgeable landscaping operation. Dan Thorpe obtained his licenses to become both a landscape contractor and a general contractor, the latter of which allows him to work on a variety of building jobs.

“Then we started taking stream restoration courses and got those certifications before moving on to secure the next set of certifications,” he said, “and as we did so, we got better at what we were doing.”

Eventually, all that effort paid off handsomely. Today, Thorpe Landscapes is recognized throughout the Tarheel State — as well as other neighboring areas of the South —

for its range of services, its expert team of professionals and environmentally friendly and sustainable designs.

Among the services it provides are residential and commercial maintenance, hardscapes, excavation and site work, drainage, and historical, hurricane,\ and stream restoration, in addition to several types of lawncare work.

The company flourished to the point that Thorpe later opened a second location in Asheville on the opposite end of the state. Although he primarily works from his base in Wilmington, Thorpe said he splits his time between the two offices and supervises jobs at various points in between.

The expertise includes the restoration work in Wake Forest, which he described more precisely as a stream bank stabilization.

“We’re restoring the stream to where it once was, so it doesn’t impact nearby commercial and residential developments,” Thorpe said. “We’re taking that stream back to a safe place so that it can handle significant storm events when they come through — like hurricanes.

“By stabilizing the bank, we’re making certain it doesn’t erode the back of these three houses,” he added while pointing to an adjacent development.

Thorpe noted that the creek’s reach is only approximately 300 ft.

“That is the length from where we’re starting to where we

end, but it’s a very technical 300 feet,” he said. “There are a lot of key measurements that need to happen and several important structures that need to go in to protect the backs of these three houses.”

Among them are the installation of three or four boulder sills in the waterway. Together, they form a boulder wall that allows the water to come over its top and down into a pool.

Once the water’s energy is dissipated in that pool, he said, it then flows down a riffle (created by the combination of rocks and shallow, rushing water) before going slightly uphill to another boulder sill. From there, the stream falls off to another pool — a process that continues to repeat itself.

“It is all designed as a way to slow down the energy of the water, so it doesn’t come rushing through and entrench the creek,” according to Thorpe.

He and his crew began the Wake Forest project in the third week of September, and he anticipates the work will last 90 to 120 days.

“We’ll finish somewhere in the middle of December, depending on the weather,” Thorpe said.

To get the machines it requires for its various projects, Thorpe Landscapes depends heavily on James River Equipment, specifically its dealerships in Asheville and Wilmington. The company has locations across North Carolina and Virginia that serve customers who need equipment for construction, forestry, turf and agricultural work. Thorpe has called on the equipment distributor to acquire several of its John Deere excavators, most of which are compact models.

“When we started out, our first machine was a John Deere 26G excavator, the smallest machine that John Deere made, before we began to move up in size,” he said. “Later, we got a model 35G — we now have two of them — then we went to the 50Gs. Eventually, we acquired the model 85Ps and 135Us, which is our largest. We just like to keep adding more tools to our toolbox.”

In addition, through 4 Rivers Equipment, a James River sister company located in the Rocky Mountain states, Thorpe Landscapes recently acquired a Topcon HiPer XR base and rover, a global navigation satellite system (GNSS) receiver engineered to work in survey applications, including property boundaries, engineering design, and cadastral projects.

Cat 352 - 2023, KXH Series, 2,500 Hours, Auxiliary Hydraulics, Hydraulic Coupler, 72" Bucket, Counterweight Removal System $479,500

Cat 265 - 2025, 17 Hours, GP Bucket, Warranty Remaining $Call

Cat 306 - 2023, 200 Hours, Auxiliary Hydraulics, Leveling Blade, Mulching Head

Cat 320 - 2019, 2,350 Hours, Trimble Earthworks, Auxiliary Hydraulics, Hydraulic Coupler, 36" Bucket

Cat D6T XW - 2018, VPAT Blade, Rear Ripper, Warranty Remaining

Cat 265 - 2025, 17 Hours, GP Bucket, Warranty Remaining

Cat 745 - 2019, 7,350 Hours, Tailgate, Warranty Remaining

Cat 745 - 2019, 7,550 Hours, 45 Ton Capacity

Cat 725 - 2021, 5,400 Hours, 25 Ton Capacity, 23.5R25 Tires

Cat 259D3 - 2022, CW9 Series, 1,500 Hours, Cab, New Tracks, G.P. Bucket

Cat 259D3 - 2021, CW9 Series, 700 Hours, Cab, G.P. Bucket

Dynapac CA30PD - 2023, 1,400 Hours, Cab, A/C, Heat, 84" Padfoot Drum

Hamm HC130i - 2023, 300 Hours, Cab, A/C, Heat, 84" Smooth Drum, Padfoot Shell Kit

Cat 306 - 2023, 200 Hours, Auxiliary Hydraulics, Leveling Blade, Mulching Head

Ring Power hosted a customer appreciation open house event Nov. 7, 2025, at its new Leesburg, Fla., branch facility.

Equipment and service displays were abundant inside and out and vendors turned out to lend their support. A catered lunch, raffle prizes and Caterpillar gear giveaways were available.

The entire local staff was in attendance to meet and greet their customers who turned out to learn more about maintenance and service offerings, tour the facility and look at static displays of new and rental machines, as well as everything offered at this new massive 77,000-sq.-ft. facility. CEG (All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

see FLORIDA page 60

Aerial rendering of the new Dreamliner factory.

Aircraft manufacturer Boeing broke ground on Nov. 7, 2025, in North Charleston, S.C., to mark the start of its Boeing South Carolina (BSC) site expansion.

Home of the company’s 787 Dreamliner program, BSC is set to increase production to a rate of 10 airplanes per month in 2026.

Late last year, Boeing announced plans to expand and upgrade the site near Charleston International Airport (CHS) and add a second campus.

Greenville Business Magazine reported Nov. 10 that Boeing is investing more than $1 billion in this infrastructure effort and plans to create more than 1,000 new jobs over the next five years.

When completed, the larger facility will include:

• A new final assembly building that is similar in size to the current final assembly structure, which encompasses roughly 1.2 million sq. ft., along with airplane production positions, production support and office space.

• A parts preparation facility, a vertical fin paint shop, Flight Line stalls and other production areas at the airport campus.

• Additions to the Boeing Interiors Responsibility Center, where many of the 787’s interior components are made.

So far, 90 customers from around the world have placed more than 2,250 orders for the Boeing 787 Dreamliner family, making it the best-selling widebody passenger airplane of all time.

After more than 1,200 deliveries, the 787 backlog stands at nearly 1,000 airplanes, including more than 300 orders added just this year.

In all, the commercial aviation industry is expected to need more than 7,800 new widebody airplanes over the next two decades, according to Boeing’s Commercial Market Outlook.

Skanska announced a leadership transition in its United States building operations.

Leo Sinicin, chief financial officer (CFO) of both Skanska USA Building and Skanska USA Inc., will retire effective Dec. 31, 2025.

Dan DeRooy will succeed Sinicin as CFO for both businesses, effective Jan. 1, 2026. DeRooy will join the Skanska USA Building senior leadership team and report directly to Clay Haden, president and CEO of Skanska USA Building.

Sinicin’s departure marks the close of a distinguished 30-year career with the company, including two decades as CFO of Skanska USA Building, 13 of which he also served as CFO of Skanska USA Inc.

“Leo has been a cornerstone of our financial leadership and a trusted adviser through every major strategic decision in the U.S. over the past several decades,” said Haden. “His contributions are far too many to mention, and his deep expertise, candor and insight have helped shape the business we are today. We are enormously grateful for his commitment and service to Skanska.”

A 20-year veteran of Skanska, DeRooy serves as vice president of finance, Skanska USA Building. Previously, he spent 12 years as corporate director of financial reporting and seven years as financial reporting manager. DeRooy joined Skanska in 2004 after five years as a financial and business analyst at MerckMedco.

“Dan brings a wealth of experience and a deep understanding of our business,” said Haden. “Leo set a high bar, and I’m confident Dan will build on that legacy with vision and integrity.”

For more information, visit

By Eric Olson CEG CONTRIBUTING EDITOR

Parman Tractor & Equipment hit a milestone earlier this fall when it sold its 1,000th Takeuchi-brand machine.

The Nashville-based distributor began marketing, selling and renting the Japanese manufacturer’s line of equipment in the spring 2019, just after Parman first opened its doors.

The maker of track loaders, excavators, wheel loader, crawler dumpers and attachments, Takeuchi’s products for the U.S. market are produced near Atlanta, the headquarters for Takeuchi U.S.

Its machines had been marketed in the Middle Tennessee region by Cumberland Tractor & Equipment and Nashville Ford Tractor, which was purchased by Parman Holdings Corp. in April 2019. Following the deal’s conclusion, the dealership assumed the Parman name.

With the 2024 addition of a second store in Columbia, Tenn., approximately an hour south of Nashville, the equipment distributor was able to broaden its customer reach to a new area of the state.

“Parman was a fuel lubricants company originally and when it acquired Cumberland, it entered into a whole new industry with construction equipment,” said Courtney Piercy, Parman’s rental manager of the Nashville location. “In doing so, they took on a team that, at the time, had more than 20 years of experience in sales and finance. I started with the company in June 2019 and grew with Parman.”

She added that Colin Hockenberger, now COO of Parman Tractor & Equipment, and Charley Crichton, the company’s president, “worked specifically with the existing team to learn everything they could about the construction industry. For instance, they saw to it that we became more involved with the Nashville construction scene through trade groups like the Tennessee Utilities and Construction Association (TUCA) and working with different municipalities.”

Due to Parman lacking experience in the construction industry, Piercy said it benefited the company tremendously

that Cumberland already marketed Takeuchi and Link-Belt, which gave the company a head start on accumulating more top OEMs.

Hockenberger added that Parman inherited a market share of Takeuchi and other products on its first day that was “in the single digits — low- to mid-single digits — and now we’re above 10 percent consistently, which is really good in a hot market like Middle Tennessee.”

The dealership’s best-selling Takeuchi machines are its compact track loaders and mini-excavators, with the loaders being at the top of the list. In fact, Piercy said Parman’s largest market demand in the region is for those Takeuchi workhorses.

“We sell a lot of track loaders that move not only dirt but serve as tool carriers that handle 20 different jobs on a work site,” Hockenberger said.

The dependability and versatility of Takeuchi’s products have endeared them to Parman customers, many of whom first used the machines after having rented the machines through Piercy’s department. That, combined with Parman opening its Columbia branch, brought more customers to the OEM’s brand and contributed mightily to the sale of the dealership’s 1,000th Takeuchi.

“Having that second location in Columbia has just expanded what we can get to the customer as far as rental, sales, parts and service,” Piercy said. “Without it over this past year, we would not have sold our 1,000th machine.” Hockenberger agreed and said, “That store has been a key to our success in an area where we're exceeding market share expectations.”

When asked which Takeuchi model reached the magic sales milestone, he was not certain, but speculated, “Most likely a Takeuchi track loader — a model TL8 or TL12; those are our most popular machines.”

Other factors also played a role in Parman being able to achieve the sales mark.

Not to be forgotten in helping to sell the 1,000th Takeuchi, according to Hockenberger and Piercy, was the salesmanship of Parman’s veteran associates.

“We have a tenured sales team — the best one in the Middle Tennessee area,” Hockenberger said. “I don’t think anybody thought we’d sell 1,000 machines when we originally purchased the business but through our motto, ‘Totally Outrageous Customer Service,’ and thanks to our salespeople and customers, we simply could not have done it.”

Parman also employs two sales associates, Dennis Stanley Jr. and Joe Williams, who were recognized this year with Takeuchi 360° awards. In addition, Scott Syler, who received the Takeuchi 360° Dealer Salesperson of the Year for 2024, helped Parman sell a large number of the machines, as did new sales reps that the dealership added to its team over the last several years, according to Piercy.

A a e n e ri I H R

Whether you’re la or grading Florida CASE delivers. E p g g o g s g u d,

Mini Excavators, Midi Ex &theMinotaur, 0% for 4 CTLs & Skid S teers, 0% months or 1.25% for 72

andscaping, building a’s toughest ground, xc a L th M d ee 0 f o s 1 % r

JOBS RUN T R c a e f fo 48 0 o hs a n ed c n a n m nt n u r

O R N S

Per fect fit for cons landscaping and s Backed by local de and suppor t. xcavators months. for 60 months.

N G R W TH C

WITH ASE t ti a s ev i op e struction, ite development. ealer ser vice E

A Hiab 082 knuckleboom crane is wheeled into the production facility and awaits installation.

The AED Foundation (AEDF) and the Automotive Service Excellence (ASE) Education Foundation have announced a new partnership designed to expand access to industry-recognized credentials and strengthen the connection between high school technical programs and careers in the equipment distribution industry.

Through this collaboration, AEDF recognized high school programs will now be able to use ASE entry-level assessments as an official industry-recognized credential for students. This integration provides a new pathway for students to demonstrate job readiness and earn meaningful credentials before graduation.

In addition, ASE will extend its school pricing for entrylevel assessments to all AEDF recognized programs, making certification opportunities more affordable and accessible. Schools also will be able to leverage student credentialing success to unlock incentive funding tied to measurable career outcomes.

“This partnership with the ASE Education Foundation represents another important step in aligning education with the real needs of our industry,” said Brian P. McGuire, president of AEDF. “By giving students access to ASE’s respected credentialing system, we’re not only validating their skills but also helping schools, employers and communities build a stronger, more sustainable pipeline of future technicians.”

ASE research underscores the importance of this alignment:

• 65.1 percent of American parents now recommend skilled trades to their children — up from 42.6 percent just two years ago.

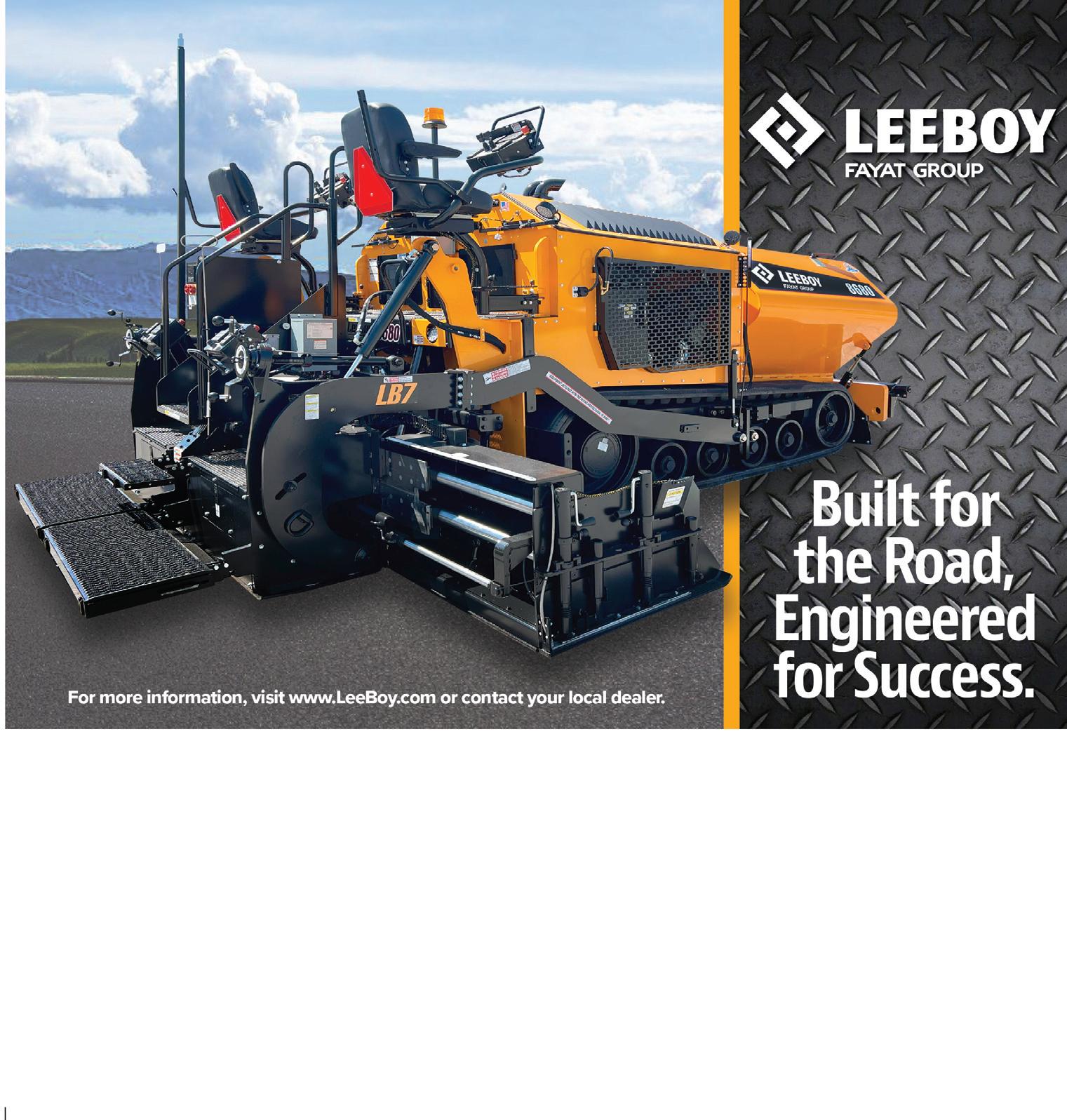

Ring Power Utility | Truck | Crane has expanded its upfit capabilities in Jacksonville, Fla., following the company’s exclusive distributorship agreement with Hiab earlier this year.

The Hiab 082 knuckleboom cranes are manufactured by Hiab, and Ring Power completes the integration, fabrication and finishing work required to deliver a fully engineered, work-ready knuckleboom flatbed truck.

The program is being executed at the company’s Jax U upfit and production facility, which has long specialized in building purpose-built utility, truck and crane equipment. The facility fabricates the flatbed in-house and integrates the 082 crane, hydraulics, controls, electrical systems, paint, decals and quality assurance under one roof.

“This marks a milestone step in our evolution as a supplier of premium equipment and integrated solutions,” said Jonathan Long, vice president of production. “It allows us to deliver complete, purpose-built units to the field, and opens doors into new markets where precision builds and reliability

matter.”

Long noted that building the flatbed in-house — rather than modifying an off-the-shelf bed — is essential to performance and turnaround time.

“Fabricating our own beds for this configuration reflects our investment in delivering the highest quality product possible,” he said. “It also lets us respond faster. We knew our quality standards and lead-time expectations could only be met internally.”

By fabricating the bed specifically around the 082 crane, the finished unit is cleaner, stronger and built for the application — without needing structural modifications after the fact. The result is a work-ready truck with reduced lead time and improved durability and appearance.

“This build proves our capabilities from engineering, to fabrication, to paint, to upfit, and all the way through QA,” Long said. It shows the process working the way it was designed — clean, efficient and purpose-built.

• In the 2024-2025 school year, more than 68,000 students took ASE entry-level tests, and more than 50,000 passed at least one.

• Technicians with ASE certifications demonstrate up to 40 percent higher productivity, 60 percent fewer comebacks and 20 percent higher earnings than their non-certified peers.

“We’re proud to partner with the AED Foundation to help more students earn credentials that truly make a difference in their careers,” said Dave Johnson, president and CEO of ASE. “Together, we’re helping schools deliver training that matches industry expectations and preparing students for rewarding jobs in the equipment sector.”

By combining resources, both foundations are committed to improving student outcomes, closing the technician skills gap and creating clearer school-to-career pathways in the heavy equipment industry.

This partnership is part of AEDF’s ongoing mission to develop a more robust and work-ready technical workforce through education, accreditation and industry collaboration. For more information, visit aednet.org/.

“We continue to see strong demand for the 787 Dreamliner family and its market-leading efficiency and versatility,” said Stephanie Pope, president and CEO of Boeing Commercial Airplanes. “We are making this significant investment today to ensure Boeing is ready to meet our customer’s needs in the years and decades ahead.

“This site expansion is a testament to the incredible work of our Boeing teammates and deepens our commitment to them, to South Carolina and to American manufacturing,” she added in a company news release.

For more than a decade, BSC in North Charleston has been the home of the full 787 Dreamliner production cycle. There, the Boeing factory’s teams fabricate, assemble and deliver the company’s three Dreamliner models — the 787-8, 787-9, and 787-10 — to customers around the world.

Boeing first established its Palmetto State operations in 2009 and today employs more than 8,200 people across its campuses in North Charleston and in Orangeburg, south of Columbia.

“We continue to see strong demand for the 787 Dreamliner...”

“Boeing’s continued investment in South Carolina is a tremendous vote of confidence in our state’s people and business climate,” South Carolina Gov. Henry McMaster noted in the news release. “This $1 billion expansion and the creation of 1,000 new jobs will strengthen our position as a global leader in aerospace and advanced manufacturing.”

In addition, McMaster said, “We are grateful for Boeing’s partnership and commitment to the Lowcountry, which will bring new opportunities and economic prosperity across our state.”

Boeing officials project that the building effort will employ more than 2,500 people working a total of more than 6.2 million construction hours through the joint venture of Charleston’s HITT Contracting and BE&K Building Group, based in Morrisville, N.C. in that state’s Research Triangle Park.

HITT Contracting is a top national commercial construction firm with offices in 14 U.S. markets; and BE&K Building Group is recognized as a leading national designbuild and construction management firm specializing in aviation and aerospace construction.

Officials with the airplane maker said they feel confident that the joint venture, along with that of BRPH, a Charleston architectural and engineering firm, will deliver the

ture

and

for the

budget.

787

Caterpillar Inc. announced that Indiana will be among the first states to receive funding from its five-year, $100 million workforce pledge, and has committed up to $5 million to training and upskilling efforts across the state.

The pledge, announced as part of the company’s centennial celebration, aims to grow interest in advanced manufacturing careers and prepare workers in the United States for the future, unlocking quality jobs and industry-wide innovation.

“The future workforce will need skills for what comes next,” said Christy Pambianchi, Caterpillar chief human resources officer. “We have our experts working on innovative training and resources to help skill and inform the next generation on how to navigate the work site of tomorrow, and we’re excited to be starting here in Indiana to enable U.S. workers to enter high-quality jobs in the American manufacturing industry.”

Caterpillar will announce future workforce pledges in other states soon.

“Indiana is proud to be among the first states selected for Caterpillar’s workforce investment, which is a testament to our progrowth policies, world-class workforce and reputation as one of the best states in America to start and grow a business,” said Gov. Mike Braun. “Caterpillar’s continued commitment to Indiana demonstrates the strength of our business climate and our shared vision for the future of American manufacturing. We look forward to working

together to prepare more Hoosiers for the high-quality careers of tomorrow.”

Caterpillar made the future workforce announcement at the company’s large engine facility in Lafayette, Ind., which recently announced a $725 million capital expansion — one of the largest single manufacturing investments in the company’s global history — to greatly increase engine production and help meet the nation’s growing power needs.

“The demand for energy is increasing like never before,” said Jason Kaiser, Caterpillar energy and transportation group president. “Many of the engines manufactured here in Lafayette will support power generation customers by providing reliable power — keeping operations running during outages and helping meet the growing energy needs driven by AI, data centers and other critical infrastructure across America and around the world.”

One of America’s oldest manufacturers, Caterpillar is a part of the country’s infrastructure, with more than 65 primary locations across 25 states and independent dealers from coast to coast. As a net exporter, Caterpillar workers in the United States build products that are shipped around the world, growing exports by 75 percent since 2016.

Caterpillar employs 51,000 people in the United States, including more than 4,100 workers at 12 facilities across Indiana.

For more information, visit caterpillar.com.

“Indiana is proud to be among the first states selected for Caterpillar’s workforce investment, which is a testament to our pro-growth policies, world-class workforce and reputation as one of the best states in America to start and grow a business.”

Serving Southwest Florida 11680 Metro Parkway Fort Myers, FL 33966

888-459-7147

www.allstareq.com

CCS Equipment Sales, LLC

Raleigh, Durham, Chapel Hill

5428 Highway 96 Youngsville, NC 27596 919-556-9110

Fuquay-Holly SpringsSanford-Fayetteville 836 North Broad Street Angier, NC 27501 919-935-0505

5886 Ernest Taylor Road Ayden, NC 28513 252-712-1033

www.ccsequipment.com

777 Laura Road Lakeland, FL 33815 863-937-6829

www.companywrench.com

By Katherine Petrik CEG EDITORIAL ASSISTANT

New Holland Construction is taking a bold step into the future of connected job sites with the launch of its new digital platform, myNewHollandConstruction — a next-generation fleet management and telematics system designed to make machine tracking, maintenance and performance monitoring easier than ever before.

Rolled out on Oct. 1, the new platform will fully replace the company’s legacy FleetForce system, which is scheduled to sunset on Dec. 19. But this isn’t just a software upgrade — it’s a complete rethinking of how operators, fleet managers and dealers interact with their machines.

“We didn’t just update the ecosystem — we rebuilt it from the ground up,” said Jake Sickles, product marketing manager of New Holland Construction North America. “The new interface is cleaner, smarter and more intuitive. It’s designed to meet the pace and expectations of today’s construction environment.”

From Fleet Force to Future myNewHollandConstruction offers a redesigned dashboard and a flexible user management system that tailors access based on job roles. Administrators, fleet managers, field technicians and operators can now be assigned specific permissions — ensuring that every user sees exactly what they need to see.

“For example, a field technician can receive push alerts just for fuelings, preventative maintenance or light service tasks,” said Sickles. “It keeps things simple and focused — no clutter, no confusion.”

This customization is coupled with advanced security features like geofencing and curfews. If a machine leaves its assigned area or moves outside approved hours, the system automatically sends an alert to the owner.

“It’s about peace of mind,” said Sickles. “You know where your machines are, who’s using them and how they’re performing — all in real time.”

Recognizing that job sites are moving faster than ever, New Holland made mobile accessibility a top priority. Alongside the desktop interface, the new platform includes iOS and Android apps, giving users instant access to vital data wherever they are.

“Owners and operators can check fuel levels, machine hours or engine load right from their phones,” said Sickles. “They don’t need to be tied to an office — they can make informed decisions from the field.”

The platform also integrates maintenance tracking and scheduling, with push alerts for upcoming service intervals. That means fewer surprises, less downtime and more

uptime for every piece of equipment.

All equipment previously connected to FleetForce has been migrated automatically to the new system. And moving forward, every New Holland Construction machine with a model year 2026 or newer will come standard with telematics connectivity — starting with units produced after Aug. 1, 2025.

It’s a sign of how deeply New Holland is committing to connected technology.

“Most manufacturers are adding telematics but we wanted to make it seamless — something that dealers and customers could actually use day to day,” said Sickles.

New Holland’s dealer network also will benefit from myNewHollandConstruction. The company has built online training programs into its dealer portal to ensure smooth adoption and support.

While dealers aren’t required to maintain centralized monitoring, many are finding success with it.

“When dealers use shared databases, they can see all customer fleets at a glance,” said Sickles. “That means they can dispatch service trucks proactively when they detect an error code.”

From there, the system’s predictive diagnostics can even flag potential failures before they happen.

“If a machine throws a code, we can often identify what’s about to fail — and send the technician with the right parts the first time,” said Sickles.

Of course, data privacy remains a key priority. Contractors must opt in to share their telematics data with dealers or CNH Industrial.

“There’s a user agreement in place,” said Sickles. “Customers always control who can see their machine information.”

For Sickles, myNewHollandConstruction isn’t just about software — it’s about redefining how contractors and dealers work together in an increasingly digital industry.

“The future of construction is connected,” he said. “We’ve listened to our dealers and customers, and built something that’s simple, powerful and built for the real world.”

With smarter tools, predictive diagnostics and seamless mobile access, myNewHollandConstruction is more than a new platform — it’s a cornerstone for how New Holland plans to help build the next generation of productivity on the job site.

Dothan, AL

334/794-8691

Troy, AL

334/566-4181

Riverview, FL (HQ)

813/620-1000

Miami, FL

305/592-5740

West Palm Beach, FL

561/848-6618

Orlando, FL

407/299-1212

Fort Myers, FL

239/334-3627

Lutz, FL

813/995-0841

Daytona, FL

407/299-1212

Riverview, FL

813/621-4902

Pompano Beach, FL

954/977-9541

Sarasota, FL

941/960-2004

Melbourne, FL 321-234-3344

Adairsville, GA

770/773-9857

Albany, GA

229/888-1212

Atlanta, GA

404/691-9445

Braselton, GA

770/965-1889

Brunswick, GA

912/264-6161

Columbus, GA

706/687-3344

Grovetown, GA

706/855-5440

Macon, GA

478/788-1586

Savannah, GA

912/964-7370

Valdosta, GA

229/474-6680 Andrews, SC

843/983-7337

Aynor, SC

843/358-5688

Ladson, SC 843/572-0400

Simpsonville, SC 864/963-5835

Walterboro, SC

843/539-1420

West Columbia, SC

803/794-9340

www.linder.com

Florida

Bradenton • 941/755-5722

Ft. Myers • 239/337-1313

Jacksonville • 904/786-6710

Ocala • 352/629-7585

Orlando • 407/849-6560

Pembroke Pines • 954/433-2800

Plant City • 813/754-2727

West Palm Beach • 561/863-0570

North Carolina

Asheville • 828/681-5172

Charlotte • 980/777-8345

Fayetteville • 910/483-3892

Greensboro • 363/792-3412

Greenville • 252/695-6200

Raleigh • 919/851-2030

Wilmington • 910/254-2031

South Carolina

Columbia • 803/794-6150

Greer • 864/877-8962

Myrtle Beach • 843/486-8090

North Charleston • 843/486-8080

Virginia

Bealeton • 540/439-0668

Chesapeake • 757/485-2100

Chester • 804/748-6411

Fishersville • 540/887-8291

Salem • 540/380-2090

POWER EQUIPMENT

www.powerequipco.com

Chattanooga, TN • 423/894-1870

Kingsport, TN • 423/349-6111

Knoxville, TN • 865/577-5563

LaVergne, TN • 615/213-0900

Memphis, TN • 901/346-9800

Saltillo, MS • 662/869-0283

Little Rock, AR

501/823-4400

Springdale, AR • 479/927-1672 TRACTOR

www.tec1943.com

Alabama

Alabaster • 205/621-2489

Anniston • 256/831-2440

Birmingham • 205/591-2131

Decatur • 256/355-0305

Dothan • 334/678-1832

Huntsville • 256/851-2222

Mobile • 251/457-8991

Montgomery • 334/288-6580

Tuscaloosa • 205/752-0621

Florida

Panama City • 850/763-4654

Pensacola • 850/505-0550

Georgia

Albany • 229/435-0982

Atlanta • 404-366-0693

Augusta • 706/798-7777

Calhoun • 706/879-6200

Columbus • 706/562-1801

Hoschton • 706/654-9850

Kennesaw • 678/354-5533

Macon • 478/745-6891

Savannah • 912/330-7500

www.wpi.com

Louisiana

Alexandria • 318/408-3099

Baton Rouge • 225/800-3711

Kenner • 504/467-5906

Broussard • 337/362-4331

Bossier City • 318/746-5272

Sulphur • 337/287-9455

CLM EQUIPMENT CO., INC. www.clmequipment.com

Lafayette, LA • 337-837-6693

Lake Charles, LA • 337-625-5942

Houston, TX • 281-598-2500

www.lylemachinery.com HILLS MACHINERY www.hillsmachinery.com

Charlotte, NC • 704-208-5564

Mills River, NC • 828-820-5265

Greensboro, NC • 336-308-3045

Raleigh, NC • 919-746-7938

Greenville, NC • 252-752-7145

Leland, NC • 910-800-2070

Columbia, SC • 803-658-0200

North Charleston, SC • 843-225-9377

Greenville, SC • 864-546-5208

Savannah, GA • 866-830-7577

Ashland, VA • 804-964-1900

Chesapeake, VA • 757-317-0494

Wise, VA • 276-268-4601

www.link-beltmidatlantic.com

Ashland, VA • 866-955-6071

Chesapeake, VA • 800-342-3248

Prattville (Montgomery), AL 334-717-2175

Because the versatile tool also is often used for construction site layout/stakeout, grade checking and material volume calculations, the HiPer XR unit has proved to be a perfect fit for Thorpe Landscapes.

“James River trained us on using the Topcon base and rover, but this model is specifically important for this stream bank stabilization project because of the tolerances for our elevation and our structures,” according to Thorpe.

“Everything must be within one-eighth of an inch. This base allows us to rove around the site and check our grades so we can put a tack on anything. It allows us to talk with the operator and cut here or fill here, and it’s just a great way to be able to grade the site in real time.”

If Thorpe Landscapes had not purchased the Topcon HiPer XR, he said, the same set of tasks at the Wake Forest site would take his crew 100 times longer to complete.

“That’s because we would have to hire surveyors to come out to shoot shots, determine where our grade is, see if we’re close or not and find out how much we need to fill and how much we need to cut. In the more than two months since we have been using it, the Topcon base and rover have simply been amazing.”

Thorpe said that almost all the company’s projects present their own specific problems and intricacies.

That includes its work at the Cape Hatteras Lighthouse on North Carolina’s Outer Banks, among Thorpe’s highestprofile projects. Until recently, the company had team mem-

bers at the remote National Park Service (NPS) site on Hatteras Island beginning in 2024 to perform a landscape restoration that also included installing new concrete sidewalks.

“Everyone has since demobilized for the rest of the year because they are trying to figure out some next steps for the lighthouse,” Thorpe said in September. “All of the contractors should be going back there to work next spring, though.”

Thorpe Landscapes serves as a subcontractor for a larger effort to completely restore the 155-year-old lighthouse, the tallest of its kind in the United States.

Twenty-six years ago, in a Herculean effort, the 210-ft.tall structure was moved back 2,900 ft. from the encroaching Atlantic Ocean when it had been just 15 ft. from the churning surf. Only recently, though, has the NPS contracted to have the grounds and the lighthouse itself restored.

“We just planted 12,000 native grasses around the grounds,” Thorpe said. “Now, the lighthouse, the principal keeper’s quarters and the museum all look like they had never been moved.”

He added that the new grass effectively prevents erosion from occurring, and by re-grading the entire site, Thorpe created dunes and several other natural features. In addition, the company put in all new concrete sidewalks.

To perform all the grading and earthwork, and install the hardscapes, pavers, concrete and walkways around the lighthouse site, Thorpe Landscapes has so far had to bring in 120 truckloads of native sand equaling 3,000 cu. yds.

Most of that material came from a local source that was

dredged from a site approximately 30 minutes north of the lighthouse.

“We used it to build up all the sand dunes five to six feet across the entire site,” he said. “The existing sidewalks were way too low and had flooded, so we raised up everything.”

Since the Outer Banks — and Hatteras Island, specifically — are in an isolated locale far from North Carolina’s mainland, Thorpe added that various factors out there can sometimes waylay the best-laid plans. That includes sourcing the materials needed for a construction site on the coastal lands.

One problem that repeatedly occurs is storm damage to N.C. Highway 12, the only major roadway on the thin strip of barrier islands. To reach the lighthouse means traversing the highway for more than 50 mi, from Nags Head south to Cape Hatteras.

However, most of Thorpe’s materials for the job must be trucked to Nags Head via U.S. 64 from sources on the mainland that are at least a few hours away from the beach community, he said.

“Our closest Vulcan quarry was four or five hours away, and our closest concrete plant was two hours away, so we are just at the limits of when we can get and use material,” Thorpe said. “The logistics are challenging, and it is so weather dependent. If we’re not working that day because a storm is coming in or a section of the highway is shut down, we’re just sitting there waiting for the weather to break.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Trimble gave attendees of its annual user conference, Trimble Dimensions, a firsthand look at artificial intelligence innovation and the company’s vision for accelerating the development and expansion of agentic AI in engineering and construction workflows.

At the core of recent initiatives is Trimble’s agentic AI platform, a collection of core services, security frameworks and tools used by Trimble to build and deploy safe, scalable and secure agentic AI systems. Trimble teams are leveraging the platform to create AI agents that deliver value and solve real-world problems for customers.

Trimble designed its agentic AI platform to be open and extensible. The company’s vision is to unlock industry-scale innovation by empowering partners and customers to create and deploy AI agents and multi-agent workflows across Trimble’s suite of construction solutions, supporting Trimble’s AI principles, according to the company. In service of this vision, Trimble announced that it is currently piloting the platform, Trimble Agent Studio, with select customers.

“As agentic AI use cases multiply, there is a growing need for common infrastructure that allows creators to rapidly and responsibly develop, deploy, monitor and maintain

high-value AI agents at scale,” said Mark Schwartz, senior vice president of AECO software of Trimble. “We see the platform as the engine that will help Trimble, its partners and its customers extract more value from both our solutions and their data.”

Today, the impact of Trimble’s agentic AI platform and other AI capabilities can be seen in solutions that are driving customer value through:

• Helping users learn and navigate Trimble software for faster onboarding and engagement.

• Eliminating the manual steps typically required to model from scratch, enabling users to generate 3D objects during design by describing what they want to model.

• Converting voice memos into documents in the field, capturing status updates from crews and helping teams avoid spending hours in front of computer screens back at the office.

• Accelerating access to data and streamlining asset maintenance and permitting workflows.

“Our connect and scale strategy has brought us to this point,” said Rob Painter,

Trimble CEO. “We are building an industry ecosystem aimed at breaking down data silos and empowering our customers to make smarter decisions, collaborate effectively and work faster. By embedding AI into our solutions and enabling improved data flow, we’re taking the next steps towards unlocking the power of connected data.”

Trimble is enabling customers to experience the impact of AI by integrating features into core solutions. Several of these capabilities are available through Trimble Labs, a pre-release, early engagement program that enables customers to test new features and provide user feedback:

• The Viewpoint Finance assistant and Accubid assistant are being demonstrated at Dimensions 2025. Both agents are expected

to be in Labs in early 2026.

• The Trimble ProjectSight Help Agent, Auto-Submittals and the AI Title Block Extraction capability are available now in North America and select regions. The ProjectSight Daily Reports agent is now available for select customers, as a Labs feature, in ProjectSight Mobile.

• The AI Render capability in Trimble SketchUp is now available. SketchUp assistant and Generate Object are expected to be available in Q4 2025.

• The Tekla Structures user assistant, developer assistant and AI Cloud Fabrication Drawings capability are now available. The Tekla Model assistant is expected to be available in Labs in Q4 2025.

• The Trimble Connect Help assistant is expected to be available in Labs in Q1 2026.

• Trimble Unity AI is now available as a Labs feature for all Trimble Unity Maintain and Permit customers.

• Trimble Agent Studio is coming soon to Labs for select customers.

For more information about Trimble’s AI advancements, visit: trimble.com/ ai-at-trimble.

dynamicequipmentgroup.com

Daytona Beach, FL 386-274-1002

Fort Myers, FL 239-334-4987

Lakeland, FL 863-250-8762

Miami, FL 305-362-6632

Orlando, FL 407-273-7383

Sarasota, FL 941-248-3040

Stuart, FL 561-264-3287

Tampa, FL 813-626-3470

equipmentinc.com

Mobile, AL 251-443-5533

Hattiesburg, MS 601-296-2546

Richland, MS 601-948-3272

Alexandria, LA 318-491-8414

Shreveport, LA 318-674-8824

Texarkana, TX 903-838-4508

Serving Arkansas

MAKE YOUR MOVE

...to greater versatility, performance, comfort, and visibiliity

...to more standard features

...to easier service

...to excellence in compact equipment

...to HiMATE telematics, for greater operational intelligence

Apopka-Orlando, FL 407-401-8956

Ft. Pierce, FL 772-212-4043

Tampa, FL 813-940-4405

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com

Richmond Hill-Savannah, GA 912-756-7854

Dallas-Atlanta, GA 770-445-9019

Charlotte, NC 704-228-0455

Columbia, SC 888-865-1002

www.nedealers.com Bessemer, AL 205-428-7050 Huntsville, AL 256-384-3015

Douglas, GA 912-922-3232 Macon, GA 478-257-8300

Clayton-Raleigh, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Conway-Myrtle Beach, SC 800-968-0754

Piedmont-Greenville, SC 864-434-1154

Summerville-Charleston, SC 843-501-0566

www.taylorconstructionequipment.com

Louisville, MS 833-773-3421

Philadelphia, MS 833-773-3421

Montgomery, AL 334-279-6663

LaVergne, TN 615-392-4803

Maryville, TN 865-444-0883

125 Wilsons Mills Rd. Extension Wilson’s Mill, NC 27577

855-562-3526

141 Brickyard Rd Lexington, SC 29072

866-262-4181

803-520-0032

11301 Reames Rd. Charlotte, NC 28269 980-859-4680

www.companywrench.com

1609 Church Rd Chattanooga, TN 37421 423-899-1219 www.jcbofchattanooga.com

12450 NW South River Drive Medley (Miami), FL 33178 305-455-8305

www.goldcoastjcb.com

6851 Greenwood Road Shreveport, LA 71119 318-621-9000 340 Airport Road Jackson, MS 39208 601-939-9655

1150 LeBlanc Road Port Allen, LA 70767 225-383-6117

8489 West Oaklawn Road Biloxi, MS 39532 888-838-5485

www.deepsouthjcb.com

TriStar JCB

8215 Palm River Road Tampa, FL 33619 813-605-7800

3165 N. John Young Parkway Orlando, FL 32804 407-232-8820

2525 Phillips Highway Jacksonville, FL 32207 904-260-6105

5566 6th St W Lehigh Acres, FL 33971 239-458-5005

2755 Marshall Dr Tifton, GA 31793 229-388-8120

www.briggsjcb.com

1241 Salem Park Court Murfreesboro, TN 37129 615-809-3377

www.tristarjcb.com

WesPro JCB

1501 Atlanta Industrial Drive Atlanta, GA 30331 678-402-6867

www.wesprojcb.com

Heavy Machines Inc. www.heavymachinesinc.com

Murfreesboro, TN 629-335-3077

Piperton (Memphis), TN 901-260-2200 Birmingham, AL 205-323-6108 Mobile, AL 251-653-5955

Shreveport, LA 318-621-0854

Equipment Co. Inc. www.clmequipment.com

3135 US Hwy 90 East Broussard, LA 70518 337-837-6693

4851 E Napoleon Road Sulphur, LA 70663 337-625-5942

2815 N Sam Houston Pkwy E Houston, TX 77032 281-598-2500

JCB www.briggsjcb.com

8215 Palm River Road Tampa, FL 33619 813-605-7800

3165 N. John Young Parkway Orlando, FL 32804 407-232-8820

2525 Philips Highway Jacksonville, FL 32207 904-260-6105

5566 6th St W Lehigh Acres, FL 33971 239-458-5005

2755 Marshall Drive Tifton, GA 31793 299-388-8120

accommodate the growth expected in the coming years.

The existing road is primarily two lanes, Woerdeman said. The project will widen the road from two to five lanes which will include two 12-ft. travel lanes in each direction; a 12-ft. center turn lane; 10-ft. paved shoulders; bike lanes; curb and gutter; and 5ft. sidewalks on each side.

Due to the size of improvements on the roadway, SR 11, TDOT has split the project into two phases. This first phase covers the roadway from north of Mill Creek to near SR 254 in southern Davidson County.

“This area of Davidson County has experienced rapid growth in recent years, and the current facility does not adequately accommodate the existing volumes,” according to the TDOT website. “The route has a base year 2023 average daily traffic of 20,457 vehicles per day and a design year 2043 average daily traffic of 35,994 vehicles per day. The added capacity being provided by this improvement is necessary to maintain operations at an acceptable level of service.”

All the utilities — water, gas, sewer, power and communications — must be moved to make space for the additional lanes, Woerdeman said.

“Everything must be widened, so all the overhead utilities have to be moved to new poles. First, they must put in the new poles, then all the overhead lines must be transferred to the new poles. Some of it is going underground, as well and that is going well.”

The utility work started well ahead of the actual project when the utility companies came together for “deconfliction,” that is, the agreements determining where the utilities will be moved.

“We always have utility issues when it comes to urban projects,” Woerdeman said.

“One of the things we’ll do is we get all the utilities together and they’ll overlay all the plans and where everybody says they are, and then they go through each conflict point and find out a way to work with the other utilities to move their line over, to not affect others as well.”

On the ground level, it’s a race against time to get in-stream construction completed in the coming months.

“They can only perform in-stream construction between May 31 and October 1 due to the Nashville crayfish,” Woerdeman said.

The Nashville crayfish is a federally protected species.

“Additionally, they are required to sweep the stream prior to and after installing the instream diversions needed to build the structures. If the in-stream division is not completed within one hour, the contractor is required to perform an additional sweep. There also are restrictions on staging equipment near streams, wetlands, etc., but we see those on most projects with water features.”

Other challenges on the job include the limited right-of-way and traffic management, which is largely being handled by flaggers with some detours in place.

“There’s a significant amount of traffic that we have to work with,” Woerdeman said. “We have a new alignment. When you’re building a new road, and you don’t have to really worry about traffic. But on projects like this, we must maintain traffic throughout the corridor and impact motorists as little as possible. Obviously, there’s going to be an inconvenience, but we have to reduce that inconvenience as much as we can.”

Phase 1 is scheduled for July 2027 completion. Right-of-way appraisals and acquisitions for Phase 2 are under way. CEG

Construction crews on the $93 million Nolensville Pike project in

are approximately midway through the projected four-year job, but

hinges on two very important components.

The contract was awarded to Civil Constructors in November 2023 with work

ting under way in December of the same year.

The 4.4-mi. project, Phase 1, includes reconstruction and widening and is designed to reduce congestion, improve safety and accommodate the growth expected in the coming years.

Bobcat of Savannah Bloomingdale 912-236-5588 www.gatewaydealer.com

Emery Equipment Sales & Rentals, Inc. Baton Rouge 255-753-0541 www.emeryequipment.com

Bobcat of Jacksonville, LLC Jacksonville 904-288-9181 www.bobcatjax.com

Bobcat of Palm Beach West Palm Beach 561-689-9880 www.sbequipment.com

Bobcat of Broward Pompano Beach 954-763-9880 www.sbequipment.com

Bobcat of the Treasure Coast Fort Pierce 772-460-9998 www.sbequipment.com

Bobcat of the Space Coast Cocoa 321-633-6424 www.sbequipment.com

Dynamic Equipment Group

Bobcat of Orlando 407-273-7383

Bobcat of Tampa 813-626-3470

Bobcat of Miami 305-362-6632

Bobcat of Fort Myers 239-334-4987

Bobcat of Daytona 386-274-1002

Bobcat of Stuart 561-264-3287

Bobcat of Sarasota 941-248-3040

Bobcat of Lakeland

863-250-8762

www.dynamicequipmentgroup.com

Bobcat of Asheville Arden 828-684-4403 www.gatewaydealer.com

Bobcat of Asheboro Franklinville 336-737-4434 www.curtis-lane.com

Bobcat of Alamance Burlington 336-283-5600 www.curtis-lane.com

Bobcat of Charlotte Charlotte 704-343-9000 www.bobcatofcharlotte.com

Bobcat of Fayetteville Fayetteville 910-323-5300 www.curtis-lane.com

Bobcat of Johnston County Garner 919-661-1833 www.triangleequipmentgroup.com

Bobcat of Lenoir Lenoir 828-758-5506 www.curtis-lane.com

Bobcat of Lexington Lexington 336-704-8686 www.bobcatoflexington.com

Bobcat of Mount Airy Mount Airy 336-673-3557 www.curtis-lane.com

Bobcat of Monroe Monroe 704-289-2200 www.bobcatofmonroe.com

Bobcat of Wilmington Wilmington 910-395-2050 www.triangleequipmentgroup.com

Piedmont Bobcat Kernersville 336-993-5529 www.curtis-lane.com

R.S. Braswell Company Kannapolis 704-933-2269 www.rsbraswell.com

Triangle Equipment Company Morrisville 919-596-1995 www.triangleequipmentgroup.com

Bobcat of Wilson Wilson 252-206-0733 www.whitesequipmentco.com

Bobcat of New Bern New Bern 252-636-1837 www.whitesequipmentco.com

Bobcat of Winterville Winterville 252-756-4055 www.whitesequipmentco.com

Bobcat of Jacksonville Jacksonville 910-347-1646 www.whitesequipmentco.com

Bobcat of Lynchburg Concord 434-352-2401 www.curtis-lane.com

Bobcat of Roanoke Valley Roanoke 540-366-3469 www.curtis-lane.com

Bobcat of Columbia Columbia 803-933-9996

www.gatewaydealer.com

Bobcat of Charleston North Charleston 843-725-6330 www.gatewaydealer.com

Bobcat of Greenville Piedmont 864-269-3600 www.gatewaydealer.com

Bobcat of Spartanburg Spartanburg 864-342-9003 www.gatewaydealer.com

Bobcat of Rock Hill Rock Hill 803-670-2003

www.BobcatofRockHill.com

Bobcat of Myrtle Beach Myrtle Beach 843-236-4499 www.triangleequipmentgroup.com

Bobcat of Clarksville Clarksville 931-436-9555 www.gatewaydealer.com

Bobcat of Nashville La Vergne 615-941-4000 www.gatewaydealer.com

Bobcat of McMinnville McMinnville 931-488-4767 www.gatewaydealer.com

Bobcat of Maury County Columbia 931-981-9909 www.gatewaydealer.com

Dobbs Equipment

www.dobbsequipment.com

Dothan, AL

334/794-8691

Troy, AL

334/566-4181

Riverview, FL (HQ)

813/620-1000

Miami, FL

305/592-5740

West Palm Beach, FL

561/848-6618

Orlando, FL

407/299-1212

Fort Myers, FL

239/334-3627

Lutz, FL

813/995-0841

Daytona, FL

407/299-1212

Riverview, FL

813/621-4902

Pompano Beach, FL

954/977-9541

Sarasota, FL

941/960-2004

Melbourne, FL

321/234-3344

Adairsville, GA

770/773-9857

Albany, GA

229/888-1212

Atlanta, GA

404/691-9445

Braselton, GA

770/965-1889

Brunswick, GA

912/264-6161

Columbus, GA

706/687-3344

Grovetown, GA

706/855-5440

Macon, GA

478/788-1586

Savannah, GA

912/964-7370

Valdosta, GA

229/474-6680

Andrews, SC

843/221-4940

Aynor, SC

843/358-5688

Ladson, SC

843/572-0400

Simpsonville, SC

864/963-5835

Walterboro, SC

843/539-1420

West Columbia, SC

803/794-9340

In order not to disrupt visitor operations at Neuschwanstein Castle, work could only be carried out at night. The contractor therefore opted for the Vögele Paver Super 1800-5 X with the integrated light package plus.

Neuschwanstein Castle is a UNESCO world heritage site and one of the most famous tourist attractions in Germany. A large proportion of approximately 1.4 million visitors each year make the ascent to the castle by horse-drawn carriage. This is because, apart from emergency and maintenance vehicles, only they are allowed to drive on the steep, winding road. However, the horses' iron-shod hooves place a heavy strain on the asphalt. The Bavarian Palace Administration therefore commissioned the renewal of the surface layer over a total length of 0.8 mi.

Steep inclines, hardly any room to maneuver, darkness: The conditions for rehabilitating the access road were difficult. That is why the construction company opted for the Super 1800-5 X paver. With its 129 kW power output, high traction, compact dimensions and integrated lighting, it was perfectly tailored to the requirements, according to Vögele.

First, the team milled approximately 70,000 sq. ft. of asphalt surface with a Wirtgen cold milling machine W 100 CFi. Subsequently, the Vögele universal class paver laid approximately 800 tons of surface course material in three nights, in varying widths of 16.4 to 19.7 ft., and a thickness of approximately 1.57 in.

Given the curves, the new steering via SmartWheel was very helpful: The rotary knob on the ErgoPlus 5 paver's console allows for particularly precise control. In combination with the SmartWheel on the screed control console, the paving team achieved a highquality and even paving result on curves.

Researchers at Iowa State University (ISU) in Ames think they may have found a solution to help soybean farmers desperate to find buyers for their crop.

American farmers are continuing to struggle as the U.S.China trade war wages on, which led to China not purchasing any United States-grown soybeans in September, NewsNation reported Oct. 24.

According to China’s General Administration of Customs, imports from the United States fell to zero, while their buying power in Brazil and Argentina increased.

It marks the first time since 2018 that this has occurred and represents a massive drop from the 1.7 million metric tons the Chinese bought in 2024. As a result, American farmers are left with unsold product.

However, ISU scientists have an innovative solution in mind. For several years, researchers at ISU have been working to turn soybeans into asphalt with tremendous success.

The discovery happened accidentally, the school said, when a first-year student added too much oxygen to a soybean oil mixture. He then noticed the chemicals begin to thicken and create a sticky substance similar to the composition used in traditional asphalt.

Eventually, the student, along with ISU professors and advisors, patented bioasphalt and began thinking of ways to use the innovative product to strengthen American roads.

Bioasphalt can be combined with other recycled gravel to create an asphalt substitute or used to add 20 to 30 more years to the life of a repaved road.

University scientists and partner companies are rigorously testing different blends to determine the durability and longevity of the bioasphalt under different conditions.

Already, the development and refinement of bioasphalt shows promise as a way to rejuvenate dying roads when sprayed on existing pavement. NewsNation noted that the mixture not only gives streets and highways a facelift and adds additional service life but saves on construction costs as well.

But with the United States crisscrossed by approximately 2.6 million mi. of streets and roadways, approximately 94 percent of which are paved with asphalt, the composite

material also packs a climate punch, releasing carbon dioxide emissions throughout its production and installation process.

“We have 80,000 miles of unpaved roads in Iowa alone. It’s pretty crazy,” noted ISU Professor Eric Cochran. “So, you see pavement everywhere, but the need for new pavement is just extreme and ongoing. And keeping existing pavement in good shape is also an ongoing headache for departments of transportation.”

Verde Resources Inc., a St. Louis-based construction and building materials company that focuses on net-zero products, tapped into the underused biochar industry, which produces a charcoal-like material made from organic matter such as soybeans.

Unlike traditional hot-mix asphalt, bioasphalt is a cold mix that can also be installed in cold temperatures, according to Civil Engineering Source, the news arm of the American Society of Civil Engineers (ASCE).

Using aggregate mixed with a proprietary chemical in Verde’s binder, the company created a cold-mix, odorless, reduced-emission asphalt that can be driven on immediately after installation. The asphalt incorporates biochar into the aggregate, which also sequesters carbon within the mix.

The bioasphalt was installed late last year at Auburn University’s National Center for Asphalt Technology Test Track (NCAT) in Alabama and is in the midst of a threeyear testing period, which has so far shown promising results.

Verde hopes its bioasphalt product will prove to be a costeffective, carbon-credit road material that can be installed during all seasons.

The happy accident at Iowa State that led to the discovery of bioasphalt occurred years ago and is now being brought to scale at manufacturing facilities all across the country. In fact, NCAT is currently in the process of getting the product greenlit by more than a dozen state transportation agencies.

www.richmondmachinery.com 2350 Greystone Ct. Rockville, VA 23146 (804) 359-4048

www.reynoldswarren.com

1945 Forest Parkway Lake City, GA 30260 (800) 875-5659 • (404) 361-1593

180 Thunderbird Drive Richmond Hill, GA 31324 (912) 445-2880

708 Gil Harbin Industrial Blvd. Valdosta, GA 31601 (229) 554-3660

(844) 4 MY DOBBS

www.dobbsequipment.com

2730 Falkenburg Road HQ Riverview, FL 33578 (813) 620-1000

4343 Northwest 77th Ave Miami, FL 33166 (305) 592-5740

3933 Martin Luther King, Jr. Blvd West Palm Beach, FL 33404 (561) 848-6618

4333 North John Young Pkwy Orlando, FL 32804 (407) 299-1212

3005 Hanson Street Fort Myers, FL 33916 (239) 334-3627

4618 Scarborough Drive Lutz, FL 33559 (813) 995-0841

1730 N. Nova Road Holly Hill, FL 32117 (407) 299-1212

1705 Columbia Lane Melbourne, FL 32904 (321) 234-3344

2710 Falkenburg Road Riverview, FL 33578 (813) 621-4902 - Parts

1751 Copans Road, Unit 8 Pompano Beach, FL 33064 (954) 977-9541 - Parts

6265 E Sawgrass Road Sarasota, FL 34240 (941) 960-2004 - Parts

150 Piper Lane Alabaster, AL 35007 (205) 621-2489

5336 Messer-Airport Hwy Birmingham, AL 35212 (205) 591-2131

800 Church St. N.E. Decatur, AL 35601 (256) 355-0305

4307 Reeves Street Highway 431 North Dothan, AL 36303 (334) 678-1832

www.tec1943.com

243 South Jackson St. Grove Hill, AL 36451 (251) 275-4158

108 Skylab Drive NW Huntsville, AL 35806 (256) 851-2222

2100 East I-65 Service Rd. North Mobile, AL 36617 (251) 457-8991

3285 Selma Highway Montgomery, AL 36108 (334) 288-6580

309 Hamric Drive West Oxford, AL 36203 (256) 831-2440

3820 Greensboro Ave. Tuscaloosa, AL 35405 (205) 752-0621

3305 Highway 77 Panama City, FL 32405 (850) 763-4654

9036 Pine Forest Rd. Pensacola, FL 32534 (850) 505-0550

www.powerequipco.com 3300 Dozer Lane Knoxville, TN 37920 (HQ) (865) 577-5563

4295 Bonny Oaks Drive Chattanooga, TN 37406 (423) 894-1870

1487 Rock Springs Road Kingsport, TN 37664 (423) 349-6111

320 Waldron Rd. LaVergne, TN 37086 (615) 213-0900

3050 Ferrell Park Cove Memphis, TN 38116-3502 (901) 346-9800

1545 Highway 45 Saltillo, MS 38866 (662) 869-0283

beardequipment.com 6870 Philips Highway Jacksonville, FL 32216 (904) 296-5000

2578 SE Baya Drive Lake City, FL 32025 (386) 752-9544

4539 NW 44th Avenue Ocala, FL 34482 (352) 732-4646

356 N. Hwy 17 Palatka, FL 32177 (386) 326-6268

3033 US Hwy 27 E. Perry, FL 32348 (850) 584-9200

7566 W. Tennessee St. Tallahassee, FL 32304 (850) 575-5600

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

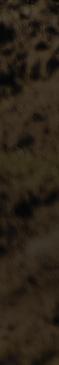

Hills Machinery announced that it has partnered with Ammann America to add new capabilities to the Hills Machinery Construction Equipment Division serving South Carolina and North Carolina.

Hills Machinery is now an authorized dealer of the company’s compaction equipment and will be supported by the Hills Machinery branches located throughout North and South Carolina.

Ammann America is a sixth generation, familyowned business that is a manufacturer of soil and asphalt compactors and asphalt pavers, as well as light equipment such as vibratory plates and walk-behind rollers.

our customers’ needs. We look forward to a long and prosperous relationship that will benefit our customers, the industry and our companies.”

“Ammann America shares our commitment to providing high-quality equipment and exceptional service and support,” said Jim Hills, president of Hills Machinery. “With this partnership, we can strengthen our offering of compaction solutions to meet

“Hills Machinery has built a strong reputation for customer service and industry expertise,” said Mike Conley, director of sales and distribution development of Ammann America. “Their deep regional presence and commitment to supporting contractors aligns perfectly with Ammann’s goal of delivering dependable, high-performance equipment and exceptional support across North and South Carolina.”

FLORIDA from page 16