Costello Dismantles

By Irwin Rapoport CEG CORRESPONDENT

Between March and April 2021 and an additional phase in 2022, the Costello Dismantling Company Inc. completed the demolition of the 400,000-sq.-ft. former Anaconda American Brass Company manufacturing plant in the city of

Waterbury, Conn. The contractor also removed asbestos and contaminated soil and materials.

The plant — 12 interconnected structures, primarily manufacturing facilities, which closed many years ago — is owned by the city and overseen by the Waterbury Development Corporation. The majority of the buildings

CTDOT Begins Study On How to Improve I-95 Between Branford, Rhode Island Border

Interstate 95 near the Raymond E. Baldwin Bridge, a link between the Connecticut towns of Old Saybrook and Old Lyme, carried an average of 40,000 vehicles a day in the late 1950’s.

By 2016, that number more than doubled to 97,000 vehicles daily, and is projected to increase to 126,000 vehicles in 2045.

The Day, New London’s daily news source, reported those increases are among the challenges facing state

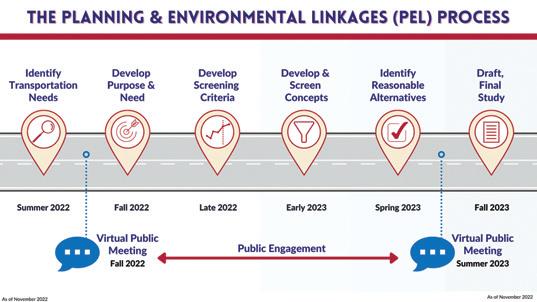

Department of Transportation (CTDOT) officials, who recently began a new study of I-95 from Branford east to the border with Rhode Island designed to find both the shortand long-term solutions needed to address traffic demands on the freeway.

CTDOT and CDM Smith, a global engineering and construction firm, with an office in East Hartford, gave two virtual presentations in November on the I-95 Eastern

12 Interconnected Brass Plant Structures

Waterbury THE NEW ENGLAND EDITION A Supplement to: Your New England States Connection • Kent Hogeboom 315-866-1423 ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” December 21 2022 Vol. LX • No. 26

in

secured the $2,704,253 demolition and abatement contract in

see STUDY page 12 see DEMOLITION page 16 CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service! CALL YOUR ONE-STOP HAMMER SHOP™ TODAY!!! CALL 888-81-GORILLA(46745) • Largest hammer repair facility in North America • Demolition tools and parts for ALL makes and models • Hammer-equipped excavator rentals • Backed by a 75 year family owned business Specializing in: Demolition, Portable Crushing, Material Sales, C & D Recycling, Land Clearing, Heavy Hauling & Trucking Call for Pricing 2208 Plainfield Pike • Johnston, RI 02919 401-943-7100 • Fax: 401-647-5041 www.jrvinagrocorp.com info@jrvinagrocorp.com LEED Accredited in Waste Management 508-484-5567 (BROCKTON, MA) 978-454-3320 (Dracut, MA) 603-410-5540 (Bow, NH) Authorized Doosan Dealer Visit Equipment East for a demo. www.foleyengines.com • Exhaust Scrubbers • Perkins Engines • Deutz Engines • Twin Disc/Rockford Clutches This space available for annual contract. For pricing contact Kent Hogeboom (315) 866-1423 ‘05 Caterpillar 928G $36,800 Phil (413) 427-7171 Tibbits Equipment Services, Inc. www.tibbitseq.com 802-479-9696 Specialty Construction Equipment SALES • RENTALS • HAMMERS Since 1989 KWIK KLEET® Traction Cleats

Costello Dismantling

early 2021.

Page 2 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide See Our Complete Inventory at www.wiclark.com stk# 26327, 653 Hrs, ROPS, Deutz diesel, single drum vibratory, good rubber, like new condition..............................................$69,500 2018 HAMM H7I 2014 DEERE 60G stk# 27845, 1400 hrs, hyd thumb, 24" bucket.. ............................................................$66,500 2018 DEERE 50G Cat power, 6'5" 15mm drum, rigid conveyor, 60% bottoms, good belting with grade, stk# 26377................................................$125.000 2010 WIRTGEN 2100 2019 JOHN DEERE 333G stk# 27812, 3300 hrs, skid steer cplr, coupler, 1yd bucket............................................$63,500 2015 DEERE 204K C/air, 120" 6 way blade, Topcon ready, new bottom with 22" pads, recent service.. Very good condition, 4986 hrs, stk# 27607 $125,000 2016 JOHN DEERE 700K 2018 GENESIS GSD170 stk# 27786, mount plate and stiff arm. Minimal usage on grapple. Fits Deere/ Hitachi 850 class excavators..................................$35,000 C/air, angle blade, hyd thumb, 24" bucket, new tracks, Stk#27764................................$67,500 Call Mark Doty @ 203-823-2316 stk# 24340, 1493 hours, 78” drums, dealer maintained since new, very good condition...... $84,500 2014 HAMM HD+120IVVH stk# 27123, c/air, hi flow hyds, 2 speed, forestry package, new tracks, 84” bucket........ $69,500

OPRROOVVEN U

WITH UPTI

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

For more in

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to 2-6351 ) 29 (800 ongmead ast L E oa er R 1 Shak 25 yle t.ww our to commitment our

n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock w bout

C (800 Berli 1980 28 A 010 , M ow d om omers

and ready to built to match your m and 52-4473 ) 3 0 7 in, CT 0603 urnpike 0 Berlin T sennebogeen-na.com/beyond-the--machine

the best thing is in requipment.c cust

th s that

go,

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 3

BEYOND E H HE HIN D T MA virtual I ntime losellyt They are: • Easy to order and ea t d t stock asy to s l dow NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN y-t t act OGEN f tor ained technicians tr ned tec cians components and too • Ideal for stocking se and trucks Choose from the follo • Central lubrication • Preventive mainte • O-Ring kits • Electrical service k Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits rain e • T ervic ts • S Par e for (TCO) Ownership of thinki We’re equipment. par ing • Application Special customer very to machine” the “beyond ng NEBOGENNN BOGEN SEN ctor suppor xible Financing lists • Fle a uptime dependable deliver througho t ttachments • A Cost Total lower and its of life the out • Hydraulic service k And

stock

series. Count on in-house.

UPTIME Kits, scan

these kits,

are custommachine model SENNEBOGEN

PTIME IME KITS a more Learn

nformation on he QR code.

MassDOT Details Beginning of I-495/I-90 Interchange Work

The Massachusetts Department of Transportation (MassDOT) recently held a virtual meeting detailing the beginning of the construction phase of the remodeled interchange between Interstate 495 and Interstate 90, which straddles the towns of Hopkinton and Westborough southwest of Boston.

As part of the project, one of Hopkinton’s two Fruit Street bridges is undergoing reconstruction (the other currently is being redesigned). The result is that the area is closed to traffic and will remain so for a few more months, MassDOT told the Hopkinton Independent.

“The Fruit Street bridge will be replaced in two major stages,” explained Donald Cooke, the project’s design manager of Watertown-based engineering firm VHB.

He added the Hopkinton bridge construction will be performed with one alternating lane of traffic open during the building period. Roadway, utility work and landscaping are all included.

Nearby, the upper part of the structure of the Flanders Bridge in Westborough will be replaced as well, Cooke noted.

During the question-and-answer period, Barry Lorion, MassDOT’s District 3 highway director of central Massachusetts, clarified that there are two projects that involve Fruit Street. Separate from the first project is the ongoing reconstruction of the second Fruit Street bridge.

One commuter to Hopkinton, George Allegrezza, noted the current steep incline at the merge point to get onto I-495 south. He told MassDOT there is a “very tight radius”

to get into this incline and a narrow merge lane which is difficult for delivery trucks to navigate.

“Traffic following the trucks tends to pop out, move left one or two lanes, and accelerate quite rapidly up the hill,” he explained, while expressing his hope that the new configuration would address the issue.

In answering Allegrezza’s concern, Cooke explained that all the radii for the ramps were tight because people had to stop to pay their tolls manually.

“I could tell you with some confidence that every one of the ramps will have better radii more suited to the speed that people would like to drive — not high speed,” he said.

Because of the sheer traffic volume, Fruit Street project will not include accelerated bridge replacement strategies because the bridges need to remain open. In urban projects, Cooke noted that a bridge structure could be closed for a weekend for more rapid construction, but that is not feasible in this case.

Congestion, Poor Geometry Led to Interchange Rebuild

Interestingly, the I-495/I-90 Interchange Improvement project is the first complete interstate-to-interstate interchange effort that the transportation agency has undertaken in its history.

“This is one of the largest projects that MassDOT has ever advertised for construction since its inception in 2009,” Lorion said.

The project’s radius is three-quarters of a

mile from the interchange point, he noted.

More than 200,000 vehicles pass by or through the interchange on an average day, according to MassDOT, which includes 50 percent of the state’s commercial traffic. The need for a reconfiguration of the interchange arose after the removal of toll booths and the installation of the E-Z Pass electronic tolling system.

The goal of the nearly $300 million project is to alleviate what Lorion called “chronic congestion” and correct “substandard geometry” that currently contributes to crashes and rollovers on both roadways, the Hopkinton news source reported Nov. 30.

To improve those issues, the roadways’ on-ramps and off-ramps will be lengthened to provide smoother access for vehicles, and traffic no longer will have to weave through the old toll areas once the project is complete.

MassDOT terms the I-495/I-90 interchange upgrade as a design-build project because construction and design elements will happen simultaneously over the course of the next five years. Public meetings will be scheduled to explain the process throughout the build, the state agency’s team members said in November.

“We will completely replace the interchange, and it will be unrecognizable from what you see today,” Lorion noted.

Work to Begin Before New Year

Cooke said construction will begin before the end of the year on I-90’s on-ramps and off-ramps. Fiber optic cables will move from

the median of I-90 to outside its westbound shoulder, as well as from I-495’s median from the Massachusetts Pike/I-90 to outside of I-495 southbound.

The current three-lane configuration for each direction of the two interstates will remain, he added. A temporary lane will be installed to help traffic flow during the construction period, the Hopkinton news source learned. Additionally, the number of lanes will not be increased by the project because of the proximity of sensitive environmental resource areas, including Whitehall Brook, and other wetlands and floodplains.

The bridges over Whitehall Brook in Hopkinton and the MBTA commuter rail station in Southborough are slated to be completely replaced, Cooke continued, adding there will be “minor horizontal and vertical changes” for the new single-lane ramps. Where the on-ramps and off-ramps converge, they will form double lanes.

New construction will take place on I-495 northbound within the existing median, Cooke made public, while the southbound side will stay as it is. This allows space for the staging of traffic throughout the construction period, he said. Crews will build an auxiliary lane northbound from the interchange to Massachusetts Route 9, and there will be a new direct lane from I-495 northbound to I-90 eastbound.

The freeway interchange upgrade also will include a new loop ramp from I-495 southbound to I-90 eastbound, part of a two-lane offramp that will enter I-90 as a single-lane onramp.

Page 4 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

A view of the proposed reconstructed interchange and ramps, looking east. Image courtesy of MassDOT

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 5 www.equipmenteast.com DRACUT 978-454-3320 61 Silva Lane Dracut, MA 01826 BROCKTON 508-484-5567 196 Manley St. Brockton, MA 02301 BOW 603-410-5540 1474 Rte 3A Bow, NH 03304 AUTHORIZED DOOSAN DEALER CHARGING FORWARD. POWERED BY INNOVATION. Visit Equipment East for a demo. The next generation of market-leading wheel loaders, redesigned Doosan® -7 Series models take productivity, durability and comfort to another level. ©2021 Hyundai Doosan Infracore. All rights reserved. Hyundai Doosan Infracore is an affiliate of Hyundai Heavy Industries Group. The Doosan trademark, , is used under license from Doosan Corporation.

Page 6 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide O Y NTHE R OUR O ELINE PUT E R VE EE NATIO Y Y IS YDA olu s S Sale engineered p y ee t k tha . T t t i e e g W d t ee u n o Yo eep s k Job Y unni d r n p a u u p yo ee t k ha s t tion P y entalit ” m one t d t i ge h a “ wit t n u g o ollin . R ward or g f ovin u m o h g t akin n m ee e b ’v y we h s w hat’ fi f e e or d m n r a aste e f on t d t i e o g eep s k imeline . T ougher g t tin get . ng. ter f Af rovidin achines w m e oves g m i e b ciently ter hor g s tin get g A tach u onstr C i h tac i H e y Becaus hi cm.us c n as c r me A y r ne h ac M on t c t e i v eser s d ustomer r c u d yo n . A t d i ne ar e e ou’v i Milford, NH 603.673.2640 Brentwood, NH 603.642.5666 Concord, NH 603.225.3361 chappelltractor.com Now Your Hitachi Dealer for Vermont, New Hampshire and Massachusetts

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 7 G - 0 0 8 .c aEquipNE lt A • 82) 5 62-2 4 - 0 0 (8 A -2-ALTTA Go LT com

New $25M Project Upgrading Bennington Hospital Begins

In mid-November, patients visiting the Southwestern Vermont Medical Center (SVMC) in Bennington who had previously used the connector between the hospital and its Medical Office Building were re-routed to a canopy for all the facility’s entrances and exits.

The detour is a necessary part of a significant $25 million renovation and expansion of SVMC’s main entrance and Emergency Department (ED). Hospital officials expect the connector to remain closed until May 2023.

“Very few patients who have two appointments — one each in the hospital and medical office building — sequentially on the same day, rely on this route,” said Pamela Duchene, chief nursing officer and vice president of Patient Care Services. “We are asking them to please use the canopy entrance for hospital appointments during the construction and appreciate their patience with this important project.”

The temporary canopy entrance can be accessed using the second right turn for folks entering the hospital campus from Dewey Street. It is the preferred entrance for people using not only the ED, but reaching various laboratories, and imaging, surgical, endoscopy and sleep studies facilities, as well as to visit inpatient rooms.

Upgrades Needed to Modernize Hospital

Operated by Southwestern Vermont Health Care, the Bennington hospital is modernizing its emergency department and hospital main entrance to address overcrowding,

operational flow and wayfinding on its campus. Besides expanding the SVMC complex, the effort will include parking and access road improvements.

SVMC’s Emergency Department Renovation and Expansion will nearly double the size of the current facility, originally designed to accommodate 14,000 patient visits a year. However, the medical center currently sees nearly 25,000 people annually, SVMC announced on its website.

The extended emergency department will have 18 treatment spaces, an increase of two from the current 16 rooms, and expanding SVMC’s mental health crisis care area will add five treatment spaces.

The expansion will further enhance patient safety, infection prevention and patient privacy. Vertical treatment areas

will allow for highly efficient treatment of lowacuity conditions. In addition, the construction includes increasing the size of SVMC’s Emergency Crisis Area for those experiencing mental health distress, and will boost telehealth connectivity with Dartmouth Hitchcock Medical Center in nearby Lebanon, N.H.

Outside the emergency department in Bennington, the project includes renovations of the main entrance to SVMC, as well as the outpatient registration area, the imaging department waiting area and upgrades to the phlebotomy and laboratory spaces.

Additionally, building a new connector will improve access to SVMC ExpressCare, the Respiratory Evaluation Center and the hospital’s Medical Office Building.

An alternate construction ramp will be available to staff, who also will be able to aid patients experiencing an emergency that requires more direct access to the ED.

The renovation and expansion project at SVMC is to be complete and have its grand opening in early 2024, officials said.

Southwestern Vermont Health Care (SVHC) provides care to the communities that make up Bennington and Windham counties of Vermont, as well as eastern Rensselaer and Washington counties in New York, and northern Berkshire County in Massachusetts. The

Page 8 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Bennington medical center is one of 25 primary and specialty care practices with the SVHC system. Operated by Southwestern Vermont Health Care, the Bennington hospital is modernizing its emergency department and hospital main entrance to address overcrowding, operational flow and wayfinding on its campus. Photo

of Southwestern Vermont Health Care The Nice Company, Inc Equipment Sales and Rentals 9 Rosenfeld Drive, Hopedale, MA Toll Free# 508-381-3939 • www.theniceco.com We sell NICE machines! 2021 Hamm H11i, 5 hours, Heat/AC/Radio, 84" Drum, Work Lights, 24K lbs., Immaculate Condition! $124,500 2018 CAT 336FL, 2500 hours, Single Grouser Pads, 54" bucket, QC, AC/Heat/Radio, Rear Camera, Long Undercarriage $259,000 2016 Hamm H7i, 850 hours, AC/Heat/Radio, 66" Drum, Work Lights, Kubota Engine $79,000 2003 CAT D8R, New Engine!, 375 hours, 80% UC, Recent Equalizer Bar, Work Ready! $159,000 2017 CAT 336FL, 7800 hours, AC/Heat, 21' Boom, 10'6" Stick, Aux. Hydraulics, Single Grouser Pads, 48" Digging Bucket w Hyd. Thumb, Long Under Carriage $134,500 2018 Deere 210G LC, 4000 hours, 36” bucket, QC, Hyd. Thumb, Aux hydraulics, Long undercarriage, Heat/AC, Clean Cab, Work ready $164,500 1998 Read RD90A, 500 Hours on Rebuilt Mitchell Motor, 4" Wire Top Screens, 3/4" Slotted Bottom, Runs Good! ..................$40,000

Cat 450F, Front Aux. Hydraulics, Heat/AC/ Stereo, Auto-Shift, Ride Control, Pilot Controls, X-Tend-A-Hoe, 36” Rear Bkt, 96” Cat 4-in-One Front Bkt, In Perfect Condition! $99,000

courtesy

2017

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 9

Page 10 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 11 Happy Holi Poughkeepsie, NY Bronx, NY 71 HlillNY6 liday’s from OPENN.COM OR SCAN HERE Y 845-452-1200 18-863-3800 631-758-7500 Y 845-733-6400 860-666-8401 FOR MORE INFO GO TO WWW.HO Holtsville, NY 6 Bloomingburg, NY Newington, CT East Longmeadow, MA 413-525-6351 Berlin, CT 860-356-0840 www.tylerequipment.com DAVIS Auctions, Inc. 210 Cheshire Road P.O. Box 7071 Prospect, CT 06712 203-758-4087 or 1-800-201-4368 www.davisauctionsinc.com MERRY CHRISTMAS In warm appreciation of our association during the past year, we extend our very best wishes for a happy holiday season. HAPPY HOLIDAYS from Chappell Tractor Sales Outfitters by Chappell B-B Chain Chappell Tractor East BRENTWOOD, NH 1.800.616.5666 MILFORD, NH 1.800.698.2640 CONCORD, NH 1.603-225-3361 Holiday Greetings www.equipmenteast.com HAPPY HOLIDAYS from 100 Quarry Drive, Milford, MA 01757 508-634-3400 North Reading, MA 978-276-2400 Warenham, MA 508-291-1200 Cranston, RI 401-946-6350 Richmond, VT 802-434-4228 Scarborough, ME 207-883-9586 Brewer, ME 207-989-1890 Clifton Park, NY 518-877-8000 Syracuse, NY 315-476-9981 Binghamton, NY 607-772-6500 Batavia, NY 585-815-6200 Tonawanda, NY 716-799-1320 Londonderry, NH 603-665-4500 Happy Holidays! 61 Silva Lane • Dracut, MA 01826 978-454-3320 Fax: 978-454-3325 196 Manley St, Brockton, MA 508-484-5567 1474 Route 3a, Bow, NH 603-410-5540 Happy Holidays from your friends at Christmas Spread.indd 111/21/2022 8:43:51 AMtaEquipNE.com A (800-462-2582) -ALTA BOSTON LOCATION 2 Rivergreen Drive, Everett, MA 02149 888.267.3857 • www.bostonftl.com BROCKTON LOCATION 2000 Main Street, Brockton, MA 02301 508.857.0280 • www.nereinc.com

Connecticut Looks to Improve Safety Along Stretch of I-95

project website.

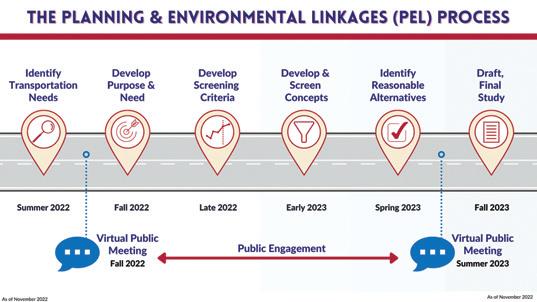

Connecticut Planning and Environmental Linkages Study, which started earlier this year.

The study came at a time when the corridor area was projected to see an 18 percent population growth and 26 percent employment growth between 2016 and 2050, a faster pace than Connecticut overall, Krista Goodin, project manager with CDM Smith, told The Day.

Goodin said the I-95 corridor from Branford to Rhode Island was examined in 2004, and again in 2018. Both studies identified the need for additional capacity to address increasing congestion, and improvements were recommended, including widening the highway in some areas and safety and design improvements at interchanges.

The state agency is intending the study to “consider environmental, community and economic goals early in the transportation planning process” and “use the information, analysis and products developed during planning to inform and streamline the transportation project development and environmental review process,” according to the

The examination also is “intended to provide the framework for the long-term implementation of transportation improvements as funding becomes available.”

Several NeededUpgrades to Make

I-95 Safer

The Day reported that Becca Hall, CDM Smith’s deputy project manager, outlined issues with the corridor, where many of the shoulders are too narrow, six bridges are in poor condition, and nearly half of the interchanges, including Exits 86 and 87 in Groton, are spaced together too closely.

The 59-mi.-long stretch of I-95 under review has five lefthand on- and off-ramps, which can lead to slower traffic in the left lane, Hall said. In addition, 70 percent of the off-ramps and 55 percent of the on-ramps are too short, which causes drivers to slow down on the highway. Another 40 off-ramps and 33 on-ramps have curves that are too

tight, and the highway itself has steep grades and seven curves that are too tight.

Citing the Connecticut Crash Data Repository, Hall noted there were 2,925 crashes in the study area from 2018-2020. About a quarter of the accidents resulted in an injury, with 19 proving fatal. During summer weekends, crashes were 67 percent higher than the state’s annual average.

CTDOT and CDM Smith said they have gathered and analyzed data on the corridor but stressed that there are no specific recommendations at this phase of the study.

In response to questions from residents and commuters about bottlenecks on I-95 in East Lyme, Scott Harley of CDM Smith said the team noted several highway issues in that area, including narrow shoulders, steep vertical grades, and tight spacing between all the ramps at Exits 74, 75 and 76. For example, the northbound Exit 76 off-ramp is on the left side, which is opposite of what drivers expect as most off-ramps in Connecticut are on the right side.

Harley noted that next spring, CTDOT plans to begin a project centered around the reconstruction of I-95’s Exit 74 interchange, including the replacement of the bridge carrying the freeway over Connecticut Route 161. At the same time, the design team will continue to investigate solutions to reduce congestion and improve safety along this section of I-95, he said.

Goodin announced that a final report on improving the I-95 corridor from Branford to Rhode Island is slated to be complete by the fall of 2023.

Old Bridge Connecting Two States to Close for Repairs

Upper Connecticut River Valley residents are facing an 18-month closure of the bridge that connects East Thetford, Vt., with Lyme, N.H., and many of them attending a Nov. 28 meeting hosted by the New Hampshire Department of Transportation (NHDOT) to address the project expressed their unhappiness about it.

New Hampshire already has the $11 million project, funded mostly with federal dollars, under contract with a Massachusettsbased construction company, reported the Valley News, a daily news source based in Lebanon, N.H.

Residents from both states packed into the auditorium at Thetford Academy in Thetford Center, Vt., to hear NHDOT officials walk through their decision-making process, as well as the timeframe for construction and traffic control plans at the crossing site.

The 85-year-old Lyme-East Thetford Bridge over the Connecticut River is expected to close in either April or May 2023 for refurbishment until the scheduled completion date in late October 2024.

The truss span, constructed in 1937 in what is still a rural part of both states, has the second highest priority in a lineup of almost 100 on New Hampshire’s “red list,” which catalogs the state’s bridges most in need of repair.

The rehabilitation project, which will be performed by New England Infrastructure Inc., of Hudson, Mass., will divert an estimated 2,200 cars a day during construction. Thetford Academy expects to be among the hardest-hit communities by the detours.

“Having to detour to Orford or Hanover will, at a minimum, add up to an hour to our students’ travel time, reducing their ability to meet their educational needs on campus,” Thetford Academy Board President Donna Steinberg wrote in a 2021 letter to Reczek.

Tara Pacht is an office manager at Long Wind Farm, a tomato farm that operates year-round in greenhouses, along with a tai chi business, and all but hugs the Thetford side of the bridge off U.S. Highway 5, west of the river. She told Valley News that the farm has been preparing for the bridge closing for years.

“We definitely agree collectively at Long Wind Farm that the bridge needs to be replaced,” Pacht said.

The closing will affect their business, she added, but that is something she and her husband, Jesse, have expected since attending the first public meeting about the project hosted by NHDOT in 2014.

“We went to those meetings, and we see the updates when they come through. It’s not a surprise for us,” Pacht explained. “It

will impact the tai chi business and our retail stand, but we’re hopeful that people will continue to still find us.”

Many Residents Had Issues With NHDOTÊs Plan

According to Valley News, an ad-hoc group has formed, and a letter is circulating between the two communities of East Thetford and Lyme calling for a halt to the bridge closure.

“There’s been a lot of information circulated about this project that’s not necessarily factual,” Jennifer Reczek, the NHDOT’s project manager, said at the meeting. “I look at [this meeting] as more of an educational opportunity. The project is in construction, [and] the contract has been awarded.”

While the project is already under contract, attendees at the Nov. 28 meeting came equipped with apprehensions, criticisms, and suggestions for how they thought the bridge rehab could be done better.

The NHDOT’s Reczek said she has been talking with town officials about the possibilities of adding some business signage “to help get the word out,” but “there’s not an ability to compensate [impacted businesses] directly.”

Due to financial constraints, as well as limitations put on the project by environmental and historical resources in the vicin-

ity of the project — the bridge was added to the National Register of Historic Places in 2020 — she noted that erecting a temporary bridge has been ruled out.

The bridge closing “is in keeping with our typical means of addressing traffic control on these Connecticut River crossings,” Reczek said. “Our plan is to close the bridge, get this rehab work done as quickly as we can, and get the bridge reopened.”

Others at the meeting were concerned about how the traffic diversion might add to already high-density commuter areas like Hanover, N.H., which has the nearest river crossing to the south and would add an almost 18-mi., round-trip detour.

“Unfortunately, there’s not a whole lot we can do, and the [NHDOT] just said, ‘We’re doing it,’” explained Peter Kulbacki, Hanover’s director of public works, in speaking to the Valley News. “Right now, we have to look at the morning commute — that’s about the time it will be the worst. But I don’t know that NHDOT ever really looked at that.”

New Hampshire transportation officials did not reach out to Hanover about the project, he said.

Beyond concerns about the impact on businesses, as well as school and work schedules, some people at the public

Page 12 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

BRIDGE page 18 STUDY from page 1

see

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 13 P • eatures: Outstanding F e THE MOST MOBILE OF A • T • errain Cr e No other All T A F ANY CRANE IN ITS CLASS! rane can make these claims ork o New Y Pennsylvani Massachuse mont Ver ALL TERR OUR #1 Y k 315-676-2008 a 717-795-0700 etts 508-499-1950 802-658-1700 ALS A RAIN RENT 1 SOURCE FOR BUY • LEASE • w.com www.woodscr .linkbelt com entucky | www Lexington, K RENT

Page 14 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide CONNECTICUT 410 Burnham St., South Windsor, CT 06074 860-289-2020 MASSACHUSETTS 120 Interstate Dr, W. Springfield, MA 01089 413-363-0780 Proud to be your Full Service Dealer NEW Inventory In Stock! WHY CHOOSE ABLE TOOL and EQUIPMENT... • Local Ownership with flexible approach • Trained staff for repairs and maintenance • Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff Sales • Service • Parts • Rentals abletool.net Made in the USA AW16-P Propane Powered Buggy AW-16-B Battery Powered Buggy Gas, Propane and Battery Powered Buggies Truck Haulers Also Available! Allen Engineering products are USA engineered & manufactured.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 15 THE MOST MATERIAL HANDLING MACHINES IN NEW ENGLAND SCREENING CRUSHING CONES IMPACTORS CONVEYORS TROMMELS WASHING RECYCLING USED AND NEW MACHINERY RENTALS AND FINANCING AVAILABLE CALL TODAY! 1-800-53-CRUSH Over 100 Machines in Stock Family Owned and Operated for over 20 years Call for Parts Today 140 Nutmeg Road South South Windsor, CT 06074 51 Veterans Drive Loudon, NH 03307 SCREENING CRUSHING CONVEYORS IMPACTORS TROMMELS 1-800-53 CRUSH WWW.POWERSCREEN-NE.COM LARGEST DEALER IN NEW ENGLAND ROCK SOLID SERVICE WE CRUSH YOUR ROCKS ROCK SOLID SERVICE WE CRUSH YOUR ROCKS

Crews Handle, Dispose More Than 10,000 Tons of Debris

work began.

were single-story high bay foundry buildings — 40-ft. tall in many areas — and also included a multi-story office space.

Due to widespread contamination and deterioration of the entire complex, more than 10,000 tons of debris was handled and disposed of as PCB and asbestos waste.

Waterbury was known as “The Brass City” because it was home to several brass manufacturing plants.

The plant was located at 130 Freight St. and 000 West Main St. After the company vacated the site, it was utilized as a Connecticut regulated waste treatment and soil remediation facility by Environmental Waste Resources, which ceased operations in 2011.

The 130 Freight St. parcel, 10.56 acres, had eight buildings. The demolition for this portion was covered by a $1.5 million Urban Act State of CT grant. The 000 West Main Street parcel is a 3.28 acres.

Waterbury received $2.2 million — $2 million from the State of DECD and $200,000 from an NVCOG EPA RLF grant — to pay for the demolition, environmental assessment and remediation on both parcels, which are adjacent to each other.

“The two sites were tax delinquent and the city took them over in late 2020,” said Tommy Hyde, the WDC’s interim director. “The properties had been abandoned for quite some time and had become eyesores for the community. The sites were very contaminated and were subject to the Resource Conversation and Recovery Act. The remediation is still ongoing and it has to be cleaned up to EPA and Connecticut Department of Energy and Environmental Protection standards. The city just acquired an adjacent property at 170 Bridge St. and the plan is to convert both sites into a mixed-

use transit-oriented development.”

Costello Dismantling secured the $2,704,253 demolition and abatement contract in early 2021.

“The ravages of time, technology and the economy left the 400,000 sq.-ft. complex ‘worth more dead than alive,’” said Dan Costello, the company’s owner and president. “We developed a plan to decontaminate and abate asbestos and PCB waste, which then allowed demolition and recovery of the massive steel structures that comprised the brass mill. The recovered value of the salvaged steel greatly contributed to the economic efficiency of the project. In the end, a clean, level land parcel in the middle

of the city was returned to the development market for a new modern purpose.

“In the context of this project, creative traditional and non traditional asbestos abatement techniques were implemented to facilitate abatement and manage costs,” he added. “The familiarity with similar structures allowed us to select equipment to execute the demolition safely and efficiently to recover the substantial scrap steel component of the structures. The scrap credit greatly reduced the overall project costs.”

Costello noted that his firm had a month to prepare its bid for the project and a plan to go with it and after securing the contract, another month to tighten the plan before the

“Once we started, it was pretty straight forward,” he said. “We began at one end and worked systematically through the complex.”

Having been closed for many years, all the water, electricity and gas utilities had been shut off. Also, there were no functioning underground utilities spanning the approximately 14-acre site.

“We had plenty of space to set up our operations,” said Costello. “We had field offices via trailers, a site to wash the trucks and space to park our equipment.”

The debris from the demolition was removed from the site on a regular basis.

“Much of the site had deteriorated and the debris was cross-contaminated with asbestos, which is why we had to do a bulk loading scenario,” said Costello, who added that this was a day-shift operation that had approximately 15 employees on site — machinery operators, loader drivers and staff specializing in abatement operations.

To prevent asbestos and other contaminated materials from being blown by the wind, industrial misters were positioned around the work areas.

“There was always a shroud of water during the demolition process,” said Costello. “We used firehoses and point watering to minimize dust and we had air monitors at the perimeter to verify that no dust was leaving the site. We met all the environmental regulations of the state and municipality.”

Crew members also wore masks as part of site personal protective equipment requirements.

This was an equipment-driven project. A Volvo 750 high-reach excavator with a big shear brought down much of the structure.

Page 16 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

The plant — 12 interconnected structures, primarily manufacturing facilities, which closed many years ago — is owned by the city and overseen by the Waterbury Development Corporation.

The majority of the buildings were single-story high bay foundry buildings — 40-ft. tall in many areas.

from page 1 see DEMOLITION page 18

The plant was located at 130 Freight St. and 000 West Main St.

DEMOLITION

• www.constructionequipmentguide.com • December 21, 2022 • Page 17 THE DOER’S DREAM See the Hyundai difference yourself at your local dealer or hceamericas.com Loved for the features. Trusted for the performance. Hyundai wheel loaders have the power and performance — not to mention top-notch interiors, accurate onboard weighing system, unique bucket design for better load retention, clear sight lines, and handy tech — that make life on the jobsite easier. So you can do more without feeling like Chappell Tractor www.chappelltractor.com 251 NH-125 Brentwood, NH 03833 603/642-5666 454 RTE 13 Milford, NH 03055 603/673-2640 391 Loudon Rd. Concord, NH 03301 603/225-3361 Butler Equipment www.butlerequip.com 631 New Park Ave West Hartford, CT 06110 860-233-5439 Kahn Tractor & Equipment, Inc. www.kahntractor.com 520 Pond Road North Franklin, CT 06254 860/642-7596 Lorusso Heavy Equipment, LLC www.lhequip.com 160 Elm Street Walpole, MA 02801 508/660-7600 Quality Fleet Service, Inc. www.qualityfleetservice.com 548 New Ludlow Road South Hadley, MA 01075 413/213-0632 Whited Equipment Co. www.whitedhyundai.com 2160 Hotel Road Auburn, ME 04210 207/346-0279 17 Houlton Road Presque Isle, ME 04769 207/346-0279 837 Portland Road Saco, ME 04072 844/430-6810

Amid Many Challenges, Costello Completes Major Demo Project

from page 16

This was backed up by several Volvo 480 excavators with grapples and shears to process the downed materials. Debris loaded with two Volvo 180E loaders equipped with solid rubber tires for demolition work. Also on site were several Caterpillar 236 skid steers with solid tires and demolition grapple buckets.

“We were well equipped to handle any building structure we came across,” said Costello.

Greg Geyer served as the onsite project manager.

“We always try to be collaborative,” said Costello. “We have very experienced crews that have worked together for many years. Their concern for safety is paramount.”

In addition to having vehicles washed at the entrance and exit points, vehicles remaining on site were sprayed at a specially set up decontamination pad.

The contaminated material was shipped by truck to specialized landfills in Ohio and Pennsylvania. The steel was thoroughly washed to remove any residue from the

asbestos and other debris.

Costello Dismantling has recently purchased a fair amount of new equipment.

“I don’t recall any issues with the equipment on this project,” said Costello. “We have a fairly new fleet and we have a master mechanic with helpers and support services.”

Much of the equipment is still under warranty and when required, the dealerships send technicians to various work sites.

The project site was approximately 150 mi. from the company’s equipment yard.

The company purchases its Volvo equipment from Woodco Machinery in Woburn, Mass., and its Caterpillar equipment from Milton CAT in Milford, Mass.

The project had its challenges, but all went very well.

“You certainly learn something on every job to help you do the next one better,” said Costello. “We do a lot of this type of work, so we’re well equipped and well-trained to handle big industrial jobs and we do them well.” CEG

(All photos courtesy of Costello Dismantling Co. Inc.)

Residents Add Their Opinions About Plan to Refurbish Span

meeting were upset that the 471-ft.-long steel span was merely being refurbished, not renovated with new features, according to the Valley News.

“I’m really disappointed that in the vast bureaucratic approach to what bridge we would get, that it was all environmental and historical concerns [and] that the needs of the community were never addressed,” said Thetford Selectboard member Li Shen.

“You’re giving us a bridge that’s an antique from the past. We need bicycle and pedestrian access as we try to stop climate change. You seem to be telling us the door is shut, it’s all decided, you can’t go back on this. But is there any way we can put a halt on this and reevaluate?”

Delaying Project Would Harm Funding

Reczek acknowledged that “the strong need” for some other connection between the two states in that area of the valley is clear, and that NHDOT will work with

regional planning commissions on the issue going forward.

She closed the meeting by addressing calls that the project be punted down the road, emphasizing that the federal money that makes up the bulk of the budget must be spent by a certain date or risk losing it.

“We have spent millions of dollars that would need to be paid back to [the Federal Highway Administration],” Reczek explained. “So, what happens if we don’t do this project? The best case would be construction in 2033, and there’s a likely risk that this bridge could be closed for years before we’d be able to find the funding to do something different.”

Backing out of a contract with “no cause” would be “unprecedented,” Reczek noted, adding it would almost guarantee that the bridge stays closed for longer than currently planned.

“I know this isn’t the answer that people are going to want to hear, but we have to make difficult decisions with the transportation funding we have,” she said.

Page 18 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

BRIDGE from page 12 NEW ENGLAND SUPPLEMENT ADVERTISER INDEX The Advertisers Index is printed as a free editorial service to our advertisers and readership. Construction Equipment Guide is not responsible for errors or omissions. ABLE TOOL & EQUIPMENT..........................................14 ALTA EQUIPMENT COMPANY/NITCO LLC....................7 BARRY EQUIPMENT CO. INC.......................................20 BOSTON FREIGHTLINER/NEW ENGLAND....................9 CHAPPELL TRACTOR....................................................6 EQUIPMENT EAST........................................................1,5 FOLEY INC - WORCESTER............................................1 GORILLA HAMMERS........................................................1 HOLIDAY CENTER SPREAD....................................10,11 HYUNDAI CONSTRUCTION EQUIPMENT....................17 J R VINAGRO CORPORATION........................................1 M G EQUIPMENT............................................................1 POWERSCREEN NEW ENGLAND................................15 ROGERS BROTHERS CORPORATION........................19 SHAWMUT EQUIPMENT CO INC..................................14 T-QUIP SALES & RENTAL INC......................................14 THE N.I.C.E. COMPANY..................................................8 THE W. I. CLARK COMPANY..........................................2 TIBBITS EQUIPMENT SERVICES INC............................1 TYLER EQUIPMENT CORPORATION............................3 WOODS CRW CORP......................................................13

DEMOLITION

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • December 21, 2022 • Page 19 The Ultimate in Trailers® ROGERS BROTHERS CORPORATION ALBION, PA Over a CENTURY of building the very best heavy-duty trailers for your hauling needs! Contact your local dealer for a quote today. TRAILERS TO MEET EVERY HAULING CHALLENGE! Committed to building superior quality, reliability and durability into every trailer. Tyler Equipment www.cn-wood.com 200 Merrimac St. Woburn, MA 01801 (781) 935-1919 140 Wales Ave. Avon, MA 02322 (508) 584-8484 3 Rocky Hill Road Smithfield, RI 02917 (401) 942-9191 C.N. Wood Co., Inc. www.tylerequipment.com 251 Shaker Road East Longmeadow, MA 01028 (413) 525-6351 • (800) 292-6351 Parts: (877) 255-6351 1980 Berlin Turnpike Berlin, CT 06037 (860) 356-0840 • (800) 352-4473 Parts: (860) 356-0848

Page 20 • December 21, 2022 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide