Firm Overcomes Slew of Challenges to Thrive in Decorative Stone Biz

Christopher DeFeo started DeFeo Materials in 2016 with one tri-axle dump truck hauling bulk materials.

Prior to starting the company in Connecticut, DeFeo had worked in the agricultural industry in the Midwest, where he gained exposure to many different types of equipment and the harvesting process for many different commodities that were shipped in bulk. Once DeFeo moved back to Connecticut, he started working in the construction industry, which laid the foundation for what would become DeFeo Materials.

DeFeo Materials main focus is to produce and distribute decorative stone

New England Patriots Near Goal Line in Completing Gillette Stadium Upgrades

The National Football League’s New England Patriots have released new renderings of their $250 million stadium renovations and additions, scheduled to be completed in time for the team’s regular season opening in September.

Gillette Stadium was originally opened in Foxborough, Mass., in 2002, about 22 mi. southwest of Boston. The stadium cost $325 million when it was built, and it is the only NFL stadium that was fully-funded through private sources.

Since then, it has seen a series of renovations, with the most recent one focusing on an enormous screen, a new lighthouse (that oversees a parking lot rather than the ocean) and improved concourses.

THE NEW ENGLAND EDITION A Supplement to: Your New England States Connection • Kent Hogeboom 315-866-1423 ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” August 2 2023 Vol. LXI • No. 16

New England Patriots rendering The stadium’s renovations include a new, 22-story lighthouse with an observation deck giving fans a 360-degree view of the surrounding area that will operate year-round, not just on game day. see PATRIOTS page 16 see DEFEO page 4 CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service! CALL YOUR ONE-STOP HAMMER SHOP™ TODAY!!! CALL 888-81-GORILLA(46745) • Largest hammer repair facility in North America • Demolition tools and parts for ALL makes and models • Hammer-equipped excavator rentals • Backed by a 75 year family owned business LON. . ard g onw nw eq w..equipmenteast.com w www ealer uthorized D A ww EL D with DEV Developing el acut, MA Dr MA M 978-454-3320 508-484-5567 Brockton, M 603-410-5540 , NH w n, Bo D ©2023 HD Hyundai Infracore. All rights reserved. DEVELON is a brand of www.foleyengines.com • Exhaust Scrubbers • Perkins Engines • Deutz Engines • Twin Disc/Rockford Clutches 938G,H • 950G,H • 966G,H WANTED LOW HOUR CAT LOADERS Phil (413) 427-7171 Tibbits Equipment Services, Inc. www.tibbitseq.com 802-479-9696 Specialty Construction Equipment SALES • RENTALS • HAMMERS Since 1989 KWIK KLEET® Traction Cleats

Graham Wiley (L), sales representative of Powerscreen New England, and Christopher DeFeo, president of DeFeo Materials.

Page 2 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide See Our Complete Inventory at www.wiclark.com stk# 26327, 653 Hrs, ROPS, Deutz diesel, single drum vibratory, good rubber, like new condition................................................$64,500 2018 HAMM H7I 2014 DEERE 60G stk# 27845, 1400 hrs, hyd thumb, 24" bucket.. ..............................................................$64,500 2018 DEERE 50G 2017 JOHN DEERE 85G Stk# 27802, 6885 hrs............................$49,500 2005 JOHN DEERE 450J Stk#27764, C/air, angle blade, hyd thumb, 24" bucket, new tracks................................$67,500 Call Mark Doty @ 203-823-2316 stk# 27248, 1780 hours, c/air, push blade, hyd thumb, well maintained........................$89,500 2017 JOHN DEERE 75G stk# 27856, 4216 hours, c/air, mech coupler, gp bucket..............................................$74,500 stk# 26377, Cat power, 6'5" 15mm drum, rigid conveyor, 60% bottoms, good belting with grade....................................................$79,500 2010 WIRTGEN 2100 stk# 27812, 3300 hrs, skid steer cplr, coupler, 1yd bucket............................................$59,500 2015 DEERE 204K 2014 LEEBOY 8515C stk# 28172, 4,000 hrs, Kubota, 8-15' HD electric screed............................................$59,500

OPRROOVVEN U WITH UPTI

PTIME IME KITS

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock :kits

Easy e for (TCO) Ownership of thinki We’re equipment.

They are: rain e • T ervic ts • S Par

order and par ing • Application Special customer very to machine” the “beyond ng

stocking NEBOGENNN BOGEN SEN ctor suppor xible Financing lists • Fle

• Hydraulic service k

D T shops ols ervice owing kits system kits nance service kits its kits

trucks Choose a uptime dependable deliver througho t ttachments • A

Cost Total lower and its of life the out

And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th a more Learn

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 3

C BEYOND E H HE HIN

MA virtual I ntime losellyt

•

to

ea t d t stock asy to s l dow NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN y-t t act OGEN f tor ained technicians tr ned tec cians components and too • Ideal for

se and

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to from the follo • Central lubrication • Preventive mainte • O-Ring kits • Electrical service k Hydraulic service k

s that these kits, go, are custommachine model SENNEBOGEN 2-6351 ) 29 (800 ongmead ast L E oa er R 1 Shak 25 yle t.ww our to commitment our

nformation w bout

on he QR code. (800 Berli 1980 28 A 010 , M ow d om omers

requipment.c cust

52-4473 ) 3 0 7 in, CT 0603 urnpike 0 Berlin T sennebogeen-na.com/beyond-the--machine

Conn.’s DeFeo Materials Finds Transportation Solutions

products to wholesale landscape supply yards up and down the east coast — it supplies over 15 different products to approximately 200 different customers across the east coast.

“It’s common knowledge that the housing market has been very strong in the southeastern United States for a prolonged period of time,” said DeFeo. “Over the last decade, both builders and developers have become aware of the environmental benefits of using decorative stone in the landscape process versus other options such as mulches and pine straw. You are conserving water as well as not having to buy, reapply and pay to have the mulch or pine straw redone every year.

“And a big benefit is the stones keep their color yearround,” he added. “Once you put the stones down, they pay for themselves in two or three years and in the long term it is substantial savings, especially for commercial properties that spend a fortune on spreading mulch every year.”

This market opened up for DeFeo when a gravel pit in New Jersey fell behind on supplying product and could not supply a stone yard in western N.C. When DeFeo Materials delivered the product, they asked the customer “how much more of this would you like” and her answer was “Honey, you could never bring me enough.”

At that point, DeFeo knew it had tapped into a great market, and it has been exploding ever since. But to properly serve the market, some changes needed to be made in the mode of transportation.

“As we started to develop the market with more and more customers, we realized that this just wasn’t going to happen with truck delivery,” DeFeo said. “People don’t want to drive trucks over the road anymore, and there are not enough bulk commodity trailers. Frameless dump trailers are how the majority of bulk commodities are transported. There are just not enough trucks available to move our type of material in the volume that we need transported, and still be able to do it economically.

“There are not enough loads of other bulk commodities heading north to bring back the trailers, so you have no backload, which skyrockets your transportation costs. The other issue, and it is a constant problem with hauling over the road, is battling the strict rules and regulations with DOT, equipment breakdowns and the general cost of trucks and trailers, which are increasing at an unbelievable rate.”

DEFEO page 8

Page 4 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

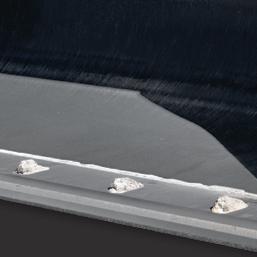

At its various facilities, DeFeo has invested more than $200,000 in concrete block and asphalt to ensure that its rinsed stone stays clean.

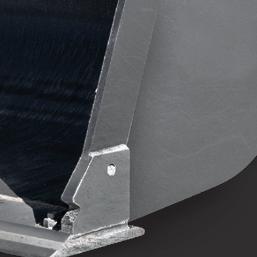

DeFeo Materials owns rail cars with different configurations. This car features bottom unloading hoppers for quick unload at rail stations that can accommodate this method.

DeFeo Materials’ EvoQuip Colt 600 screening plant has proven to be an absolute work horse.

see

DEFEO from page 1

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 5

Page 6 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide The Nice Company, Inc Equipment Sales and Rentals 9 Rosenfeld Drive, Hopedale, MA Toll Free# 508-381-3939 • www.theniceco.com We sell NICE machines! 2016 Hyundai HL980, 7000 Hours, 371HP Scania motor, 7.3 Yd Bucket, AC/Rear Camera, Load scale system, Powershift trans., 29.5 R25 tires 75% or better, Well maintained $139,000 2014 CAT 730 Truck, 9400 hours, 6x6, Tires 65% or Better, Rear Tailgate, Work Ready............ $189,000 2018 Hitachi ZX135USUS-6, 2500 hours, Trench bucket, Dozer blade, QC, Auxiliary hydraulics, Hydraulic thumb, Zero tail swing. Very good condition, Ready to work $89,000 2018 Deere 410L, 2600 Hrs, Ride Control, Backhoe Pilot Controls, Powershift Trans., 2017 US EPA Label, QC, Diesel Exhaust Fluid Req., Hyd. Cplr, 93" Loader Bkt, 24" Backhoe Digging Bkt, Rear Aux. Hyd REDUCED $99,000 $89,000 2007 Metso/Nordberg CV50, 832 hours, Duetz Motor, 3" Top Screens, 1" Bottom Screens, Newer rear tires, Pintle hook,

1-3 yd loader capacity $49,000

2013 Terex TA300, 6200 hours, 80% Front Tires, 40% Rear Tires, Runs Good, Work Ready! $99,000

2017 Doosan DX235 LCR-5, 2500 hours, Reduced tail swing, 36” bucket, Hydraulic thumb, Aux. hydraulics, Heat/AC, Work ready $114,500

CONNECTICUT 410 Burnham St., South Windsor, CT 06074 860-289-2020 MASSACHUSETTS 120 Interstate Dr, West Springfield, MA 01089 413-363-0780 WHY CHOOSE ABLE TOOL and EQUIPMENT... • Local Ownership with flexible approach • Trained staff for repairs and maintenance • Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff Sales • Service • Parts • Rentals abletool.net Coring Equipment, Bits and Vacuum Widest Range of Coring Equipment and Accessories Available! Weka DK12 Hand Held Drill Motor Assortment of Core Bits CC150XL-EE FIRST-CUT™ Saw M-1 Core Bore Rigs Proud to be your Full Service Dealer NEW Inventory In Stock! CORE VAC CVG1 Vacuum

2020 Hitachi ZX210 LC-6, 2400 hours, Aux. Hydraulics, QC, 36" Digging Bucket, Rear & Side Cameras, Ready to Work $139,000

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 7

DeFeo’s Stone Comes From Approximately Six Gravel Pits

DeFeo was determined to find a way to work around this transportation challenge.

“I have always loved working with big equipment and have been fascinated with the idea of producing products in large volume. I’m a numbers guy, so it was something that I could break the numbers down and analyze.

“The supply of natural minerals and stone in the northeast is abundant. As a teenager, I was in the landscaping business and really liked the way decorative stone looks when it is applied, particularly in commercial applications, around medians, apartment complexes and hotels. I think it’s a great touch to the property and doesn’t look old after only a couple months like mulch.”

“We were told by our customers that when other quarries run out of decorative stone, they throw up their hands and turn away customers rather than finding a solution to produce more product. I realized that if we could use technology, it would help improve efficiency and we could tap into a market with huge potential. But we first had to figure out the issue of transporting our product 800-plus miles.”

DeFeo then started hiring out trucks and building a network of trusted subcontractors, like Taylor Trucking, RLO Trucking and many more to be able to grow the volume of stone, without spending more capital on additional company owned trucks.

“They typically will each take about two loads a week and that represents a good amount of tonnage for us, but it still was not enough to satisfy what I was trying to build. The game changer was in 2020 when we started shipping by rail. We invested every last dollar, even sold a portion of the company to investors to build a loading area at our Utica, N.Y., rail yard. The first year we transported about 3,800 tons of our product by train and by the end of this year it will be around 75,000 tons.”

Once rail transportation and its benefits were implemented, it was a huge challenge, but a total game changer. DeFeo now has sites located with railway access along the east coast, where they stockpile product and use their fleet of equipment to load and unload their fleet of rail cars, where it is then shipped to various distribution yards and delivered in the southeast.

Even with the implementation of rail distribution, DeFeo still has challenges to overcome. Distribution from the rail depots to the end user and getting orders filled within its goal of a 10-day time limit is particularly challenging when you’re moving thousands of tons of stone thousands of miles. Quality control also is essential — the stones must be sorted correctly by size, and they must be clean.

DeFeo’s largest distribution point is in Utica, N.Y., from which it ships its most popular product, New England River Rock. It has other smaller loading facilities in New England from which it distributes some of its smaller volume prod-

ucts.

Utica has been an ideal location for DeFeo, even though the company is New England-based, as the northeast provides the ideal glacier created, multi-colored stones that its customers are looking for.

“The Mohawk and Northern Adirondack Railroad (the railroad in which DeFeo ships from) treat us very well. They appreciate our business and we have become one of their largest customers. Anything that we need they have been willing to work with us on.”

DEFEO from page 4 see DEFEO page 12

“In Utica, our current storage is about 12,000 tons. It could be more; but our production is limited by the weather. In this region you can only produce for about seven months out of the year, as the winters are harsh and the cold temperatures do not allow us to screen any product.”

A significant portion of its product is sent to DeFeo’s yards in North Carolina. DeFeo additionally works alongside Vulcan Materials, at their Mount Holly, SC rail yard, who handles the distribution of DeFeo’s product in the Charleston and Savannah regions. This allows customers in these areas to pick up their most popular product, New England River Rock.

When asked where their material comes from DeFeo said, “Our stone comes from about six different gravel pits that we work closely with. I like to describe these gravel pits as family-owned mom-and-pop type shops. They really are focused on just being able to get the sand out to sell to concrete plants.”

Page 8 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

The triple deck screen allows the production of at least three different size materials simultaneously.

Smaller 2-3-in. freshly cleaned stone is stockpiled for rail transportation.

The Terex M 1700X with its 14-ft.-wide hopper easily handles a full load from a 12-ft. bucket.

DeFeo Materials is wellknown among landscape supply houses up and down the east coast for its river rock.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 9 .linkbelt.com entucky | www Lexington, K n t tur and righ Carrier Cameras • – winch operation and swing Upper Cameras • ’s cab with operator 20° tilting • and much more , www.woodscr ork 315 o New Y Pennsylvania Massachusetts mont 802- erVe w.com 5-676-2008 717-795-0700 s 508-499-1950 -658-1700 BUY • LEASE • RENT

Page 10 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 11 NH 03106 Hooksett, 1401 Hooksett Rd AmbroseEquipmen 603-644-8787 t.com and in 35 years of p ving Equ a Astec P New England’s PR wledge y kno dustr ving experience pa ipment with over EMIER dealer for

Terex ‘Rinse Plant’ Proves to Be Critical Purchase for DeFeo

DEFEO from page 8

“We are purchasing from them a byproduct of sand production, any gravel that is above half an inch. We can’t pull it all from just one location because number one, there’s just not enough material, and number two, we blend the gravel from the different locations, creating the multi- colored products offered”

DeFeo takes all of its mixed stone ranging in sizes from half-inch up to 12 in. and piles it in one large stockpile where it is screened and separated by size using an EvoQuip Colt 600 screening plant.

“The EvoQuip was our first screening plant, and it has been an amazing machine. It’s a compact plant that's relatively new to the market. We work it very hard, and it has been extremely durable, giving us little or no downtime. We had considered buying a simple box screen and I’m glad we did not do that. The productivity we get out of this machine far exceeds anything that would have happened with a simple box screen plant.”

“We purchased the machine from Powerscreen New England. As a dealership, they have been wonderful to work with, and their sales rep, Graham Wiley, has been invaluable as a resource.”

“What really makes Graham and the entire Powerscreen team fantastic to work with is their willingness to come out and work with you side by side in the field. They worked with us through the entire set-up process, showed us how to keep our repairs and maintenance costs down, and how to keep our production levels up without losing quality. If we experience issues that they were not familiar with, they are immediately reaching out and working with Terex in Ireland to get answers.”

“We get an added bonus with our sales rep Graham because he is a mechanical engineer, and he understands how the equipment actually works. We moved about 80,000 tons of product last year and our goal this year is 100,000 tons, so we are always expecting more from our equipment. What comes with that is expecting more from the vendors we work with.”

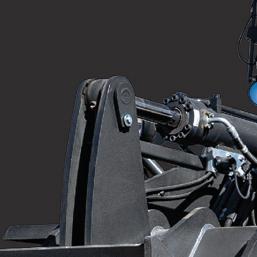

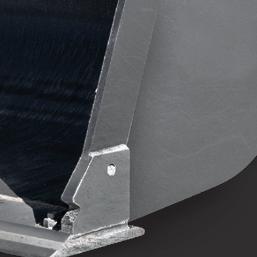

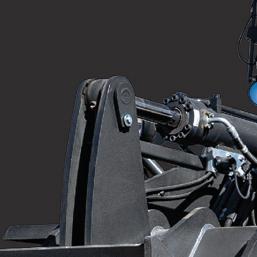

DeFeo separates the fines and oversized gravel with the EvoQuip, then they process the gravel further by their latest addition to DeFeo’s equipment fleet, a Terex M 1700X rinse plant.

“Terex refers to it as a wash plant, we call it a rinser, but by whatever name you want to call it we love it. It was the perfect option for us. We met with the owner, Seamus Sheelan of Powerscreen New England, and he and Graham Wiley felt strongly that this was the right machine that we were looking for to clean our stone.

“They took our needs very seriously and invited us to go to ConExpo to meet with some experts, which is where we made the final buying decision. We went with the Terex M 1700X for several reasons — most importantly is that it is

self-powered and self-contained. That allows the water to be directed back into our settling tanks.

Another feature that was important to DeFeo Materials was the large feed hopper, at 14-ft. in width.

“[This is] a big plus to us when other machines’ hoppers are only 12 feet wide, and our loader bucket is all of 12 feet wide. If you’re operating a loader of that size the extra two feet makes all the difference. It eliminates spillage and cleanup time.

“We measure our production from the onboard loader scale, so if we can’t get the entire bucket of material into the hopper, we can’t calculate our production. The hopper holds 10 yards, which allows us to put an entire bucket load from our Cat 980 in one pass, which is very efficient for us. It’s an impressive machine, allowing us to run hundreds of tons of material in an hour. Our total fuel consumption has dropped to just over 10 gallons per hour to wash a hundred tons, improving our carbon footprint by almost 40 percent.”

“The portable aspect of the M1700X is a huge benefit, allowing us to transport the machine to other aggregate producers and make products at their sites. We need to know that we can produce anywhere at any time.”

“Terex worked closely with us to determine how much water capacity in our storage tanks we would need, what size pumps we would need, and what our water pressure requirements would be. All of this made us very comfortable that we were dealing with the right people.”

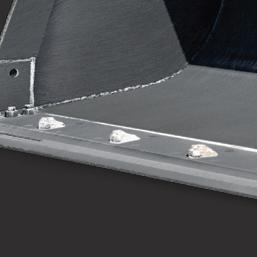

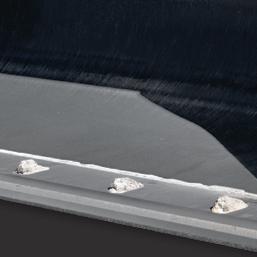

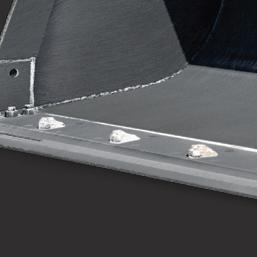

Another key feature to the plant is its triple deck screen.

“That feature alone saves us 30 to 40 hours a year because we do not continuously have to change out our screen sizes. Because the plant rinses while it screens, we are not limited to screening under only dry conditions. Utica can be noted for its cloudy, dreary days, which can limit your production opportunities. The Terex M 1700X eliminates that concern.

“We are experiencing a significant spike in demand and because of the Terex M 1700X we have been able to keep up with the orders.”

A big plus to the Terex M 1700X is it can be converted quickly and can be turned into a dry screening plant instead of a rinsing plant in less than one day, DeFeo said.

“There is an additional belt that goes on the bottom, and we can use this at different sites with different applications, where no water usage is permitted.”

The rinsing plant was a critical purchase for DeFeo, which needs to ship clean materials to its customers — the product does not sell well when it is dirty because customers can’t see the color and beauty of the rock. Without a wash plant, the best the company could do was run the stones through the screener multiple times, but it was not an adequate approach to cleaning the material. DeFeo had made a small, self-made contraption to wash the stones as they were being screened, but it just wasn’t doing the trick.

“What you or I may consider a clean stone is a completely different standard to the homeowner and the landscaper. They do not understand that it would be a simple process to just hose off the product after it’s put in place. They want it to look perfect when it’s laid down. So, for our stone to be delivered very clean is critical. Even after washing, the stone gets dirty again during transportation. That’s why we invested over $200,000 in the past year on asphalt and concrete floors where the stone is stockpiled. That way once we wash it, the stone stays clean. A lot of companies would think we’re crazy to do that, but we really care about the quality of the products that we sell to our customers. But just as important, one of the biggest keys to our success is our amazing employees that have worked as a team to help us grow.”

For more information, visit www.discountriverrock.com.

Page 12 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

photographs in this article

CEG (All

are Copyright 2023 Construction Equipment Guide. All Rights Reserved.)

DeFeo Materials’ Terex M 1700X purchased from Powerscreen New England has met and exceeded all of its production expectations.

The triple deck screen is the key element to meeting high production levels.

As stones pass through screening decks, they are rinsed clean by high pressure water jets.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 13 O Y NTHE R OUR O ELINE PUT E R VE EE NATIO Y Y IS YDA olu s S Sale engineered p y ee t k tha . T t t i e e g W d t ee u n o Yo eep s k Job Y unni d r n p a u u p yo ee t k ha s t tion P y entalit ” m one t d t i ge h a “ wit t n u g o ollin . R ward or g f ovin u m o h g t akin n m ee e b ’v y we h s w hat’ fi f e e or d m n r a aste e f on t d t i e o g eep s k imeline . T ougher g t tin get . ng. ter f Af rovidin achines w m e oves g m i e b ciently ter hor g s tin get g A tach u onstr C i h tac i H e y Becaus hi cm.us c n as c r me A y r ne h ac M on t c t e i v eser s d ustomer r c u d yo n . A t d i ne ar e e ou’v i Milford, NH 603.673.2640 Brentwood, NH 603.642.5666 Concord, NH 603.225.3361 chappelltractor.com Now Your Hitachi Dealer for Vermont, New Hampshire and Massachusetts

Work Progresses On New I-395 to Maine Route 9 Connector

The Interstate 395 extension that spans from Maine Route 1A in Brewer to Rt. 9 in Eddington is starting to take shape, officials with the state’s Department of Transportation (MaineDOT) said recently.

At a cost of $106 million, the I-395/Rt. 9 connector project has been under construction since early 2022 after years of planning. The prime contractor on the project is Sargent Corp. in Orono, Maine.

Since the beginning of the enterprise, Sargent and its subcontractors have been laying the groundwork for paving — expected to start this fall — and building five bridges for local traffic.

MaineDOT developed the roadway connector project to complete a “missing link” between I-395 and the state highway in north central Maine, just east of Bangor, with the goal of helping better connect communities and invigorate the local and state economies.

The agency noted on its website’s project page that the new 6-mi.-long road “will provide a regional solution to problems of transportation system connection, safety and mobility,” adding that the Bangor/Brewer area “is the economic and employment center” for that region of the state.

“Economically speaking, [companies] that do business in the greater Bangor region and serve markets east of here, all the way to, and including, Canada, will see the benefits of a more reliable, safer, [and] faster road,” Paul Merrill, director of communications for MaineDOT, told WFVX-TV in Bangor.

Construction Has Picked Up Since May

Just before the official 2023 Maine construction season opened, Sargent closed a portion of Eastern Avenue in Brewer for the installation of one of the new bridges that are being built for the connector road. Traffic was detoured from the intersection of Lambert Road to the intersection of Clewleyville Road.

For those folks who have been using the detour redirecting Clewleyville Road traffic in Eddington, though, an end is now in sight. Merrill said the road will reopen on Nov. 15, as will some other bridges involved in the project.

“This is one of five bridges involved in this project [and] the only one that has a road going under it,” he noted. “Right now, there’s a lot of bridge work, and earth work, going on along the 6-mile connector route.”

In its most recent update on the I-395/Rt. 9 connector project, looking at May and June, MaineDOT reported that excavation was removed from both Eastern Avenue and Clewleyville Road, and bridge abutment footers were started on both roadways.

By May, T Buck Construction Inc., located in Turner, Maine, was hard at work on the new Clewleyville Road Bridge to include placing concrete for both abutment footers, the abutment 1 breastwall and east wingwall section 2. The contractor also placed concrete for abutment 2 at the Eastern Avenue Bridge and started form work for abutment 1.

Additionally, Sargent began installing four box culverts between Levenseller Road and the Maine Rt. 9 end of the project, while Fremont, N.H.-based Heath Hathaway continued drilling and blasting in the project’s work zone.

In June, Sargent continued its box culvert backfilling at the site as well as prepping the area to install lightweight fill. The contractor also put in reinforced concrete pipes where needed and removed soil overburden on Ramp E and Ramp F to prepare for lightweight fill along a portion of the new connector road.

At the same time, T Buck’s crews have kept busy on the Clewleyville Road Bridge. They first completed the task of placing forms and rebar for the Abutment 2 east wingwall and west wingwall section 1, before pouring concrete in both areas. At the Eastern Avenue Bridge site, T Buck has also finished placing the forms and rebar for the Abutment 1 breastwall and set concrete.

In addition, Deerfield, N.H.’s East Coast Signals installed the ITS conduit, with digging and backfilling assistance from Sargent, and H.B. Fleming, from South Portland, completed driving piles at Eaton Brook East before moving to Eaton Brook West.

Merrill acknowledged that many drivers navigating the detours around the I-395/Rt. 9 Connector work zone project see it as a hassle now but will enjoy its benefits once it opens in the summer of 2025.

“If you’re going from I-395 to Route 9, 6 miles down the road, there’s a lot of turns and different speed limits, [and you will encounter a lot of] local traffic,” he said in speaking with WFVX-TV. “This will make it a smooth shot, especially for commercial vehicles.”

Page 14 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 15 THE MOST MATERIAL HANDLING MACHINES IN NEW ENGLAND SCREENING CRUSHING CONES IMPACTORS CONVEYORS TROMMELS WASHING RECYCLING USED AND NEW MACHINERY RENTALS AND FINANCING AVAILABLE CALL TODAY! 1-800-53-CRUSH Over 100 Machines in Stock Family Owned and Operated for over 20 years Call for Parts Today 140 Nutmeg Road South South Windsor, CT 06074 51 Veterans Drive Loudon, NH 03307 SCREENING CRUSHING CONVEYORS IMPACTORS TROMMELS 1-800-53 CRUSH WWW.POWERSCREEN-NE.COM LARGEST DEALER IN NEW ENGLAND ROCK SOLID SERVICE WE CRUSH YOUR ROCKS ROCK SOLID SERVICE WE CRUSH YOUR ROCKS

Suffolk Construction Leads Gillette Stadium Upgrades

PATRIOTS from page 1

The stadium also is the home field for Major League Soccer’s New England Revolution.

Work began in January 2022, led by Boston-based Suffolk Construction, and included the demolition of the stadium’s iconic lighthouse, built next to a bridge, a reference to the seacoast imagery of New England.

The stadium’s renovations include a new, 22-story lighthouse with an observation deck giving fans a 360-degree view of the surrounding area that will operate year-round, not just on game day.

The Architect’s Newspaper reported July 12 that Patriots officials said visitors will be able to view both the Boston and Providence, R.I., skylines from the maritime-inspired structure.

Additionally, a revamped Enel Plaza, the stadium’s main entrance on its north end, will include an expanded grand staircase adjacent to the lighthouse.

Inside the revamped Gillette Stadium, work is well under way on the largest outdoor stadium video board in the country,

according to the team. Measuring 370 ft. wide by 60 ft. high, the curved screen is more than five times as large as its predecessor.

Other improvements include the full connection of all concourse levels around the stadium — some levels previously only wrapped around part of the venue.

A new fan space covering a 2,000-sq.-ft. patio and 4,000-sq.-ft. interior space, the Bud Light Celebration Beer Hall, is designed to give fans a field-level view of players as they walk from a tunnel into the stadium.

Changes to the north end will mitigate some wind from entering the stadium, but without a roof, fans will be far from weatherproofed.

However, hearty Patriots’ fans have come to rely on frigid, wintry weather to give the team an advantage over most of its opponents from warmer climes.

All improvements to Gillette Stadium are on-track to open for the Patriots’ first game of the 2023 NFL season against the Philadelphia Eagles on Sept. 10.

Page 16 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 17 THE DOER’S DREAM See the Hyundai difference yourself at your local dealer or hceamericas.com. Loved for the features. Trusted for the performance. Do more without feeling like it in Hyundai’s new HX mini excavator series. • Distinctive, award winning ‘Tiger Eye’ design • Load-sensing hydraulic system (HX40A, HX48A Z) • 5” color LCD monitor • Auto safety lock for unintended operation • Large, quiet, tilting cab delivers excellent service access • Free Hi MATE telematics access for 5 years • Bluetooth radio, now a standard option Chappell Tractor www.chappelltractor.com 251 NH-125 Brentwood, NH 03833 603/642-5666 454 RTE 13 Milford, NH 03055 603/673-2640 391 Loudon Rd. Concord, NH 03301 603/225-3361 Butler Equipment www.butlerequip.com 631 New Park Ave West Hartford, CT 06110 860-233-5439 Kahn Tractor & Equipment, Inc. www.kahntractor.com 520 Pond Road North Franklin, CT 06254 860/642-7596 Lorusso Heavy Equipment, LLC www.lhequip.com 160 Elm Street Walpole, MA 02801 508/660-7600 Quality Fleet Service, Inc. www.qualityfleetservice.com 548 New Ludlow Road South Hadley, MA 01075 413/213-0632 Whited Equipment Co. www.whitedhyundai.com 2160 Hotel Road Auburn, ME 04210 207/346-0279 17 Houlton Road Presque Isle, ME 04769 207/346-0279 837 Portland Road Saco, ME 04072 844/430-6810

New Manual Offers Guidance for Building Climate Resilient Roads

Ninety percent of the bridges and culverts on the roads in Maine that cross salt marshes and tidal waterways are not equipped to handle the ebb and flow of the tides.

That means higher road maintenance costs along the state’s scenic coast, along with a shortened lifespan for culverts and bridges, unplanned road closures that can put public well-being and safety at risk, and harm to commercial fisheries and important habitat.

As a result, the Department of Marine Resources’ (DMR) Maine Coastal Program, along with 30 other organizations, has published a 100-page manual offering technical guidance on how to increase the safety of road crossings over Maine’s coastal wetlands and waterways.

“The CoastWise Approach: Achieving Ecological Resilience and Climate-Ready Road Crossings in Tidal Environments” is designed to be a resource for municipal and private engineers, public works directors, land developers, landscape architects and habitat restoration practitioners, said Maine Coastal Program Director Kathleen Leyden.

The publication also may be of use to general audiences and those working to build community awareness, including local elected officials, neighborhood associations, conservation commissions, land trusts and the public, she added.

The manual provides information about tidal wetlands and the factors that are changing them.

“Safe, dependable roads are crucial for supporting Maine’s economy, access to critical services, and a way of life valued by citizens and visitors alike,” Leyden said. “The severity of today’s tidal restrictions is likely to worsen as sea levels rise and the volume of water flows increases over the coming decades.”

Among the other entities that worked to develop “The CoastWise Approach,” a free publication, were the Maine Department of Transportation, Maine Audubon, the University of Maine, The Nature Conservancy, the Federal Highway Administration and the U.S. Army Corp of Engineers.

Additionally, several Maine towns contributed by participating in community surveys: Arrowsic, Blue Hill, Bremen, Cape Elizabeth, Damariscotta, Kennebunkport, Surry, Yarmouth and York.

Keeping Reliable Roads Across Wetlands Is Challenging

Maintaining well-built roadways has become a challenge for most communities in the state, especially in coastal areas experiencing rapid change due to accelerated sea level rise, Maine DMR noted.

Where roads cross tidal wetlands at more than 800 locations in Maine, those challenges are magnified considerably, according to the new manual.

Tidal wetlands are essential to the state due to their ability to provide coastal storm and flood damage protection, pollutant filtration and breakdown, habitat for fish and wildlife, and opportunities for robust commercial harvesting and recreational activity for humans.

Maine DMR said that some wetlands, like salt marshes, also store atmospheric carbon that would otherwise contribute to sea level rise and other climate shifts.

To deliver those benefits, tidal wetlands must remain healthy and resilient to sea level rise. That requires unimpaired tidal flow.

But about 90 percent of Maine’s tidal road crossings are tidal restrictions. Such crossings put the state’s tidal wetlands at risk, but are also more apt to experience flooding, incur higher maintenance costs, and interrupt access to emergency services.

Tidal Complexities Abound

Traditional practices for designing tidal road crossings do not adequately address the unique complexities, uncertainties, risks, or benefits associated with tidal environments, according to the state’s DMR.

In response, the Maine Coastal Program and the CoastWise Steering Committee convened experts in the field and marshaled the input of more than two dozen organizations to develop the new CoastWise manual, which discusses tidal wetlands as dynamic systems influenced by a wide range of interacting social and environmental factors requiring a design approach that addresses complexity and risk, both now and in the future.

The free publication offers best practices to help road owners, municipal staff, engineers and others in helping to replace tidal road culverts and bridges with safe, climate-resilient crossings, Leyden said.

Partners involved in the project are currently developing training modules, which are anticipated to be unveiled in 2024. To view the manual, visit www.maine.gov/dmr/programs/maine-coastal-program/coastal-community-support/the-coastwise-approach.

Page 18 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

NEW ENGLAND SUPPLEMENT ADVERTISER INDEX The Advertisers Index is printed as a free editorial service to our advertisers and readership. Construction Equipment Guide is not responsible for errors or omissions. ABLE TOOL & EQUIPMENT............................................6 ALTA EQUIPMENT COMPANY/NITCO LLC..........1,10,11 BARRY EQUIPMENT CO. INC.......................................20 CHAPPELL TRACTOR..................................................13 EQUIPMENT EAST........................................................1,5 FOLEY INC - WORCESTER............................................1 GORILLA HAMMERS........................................................1 HYUNDAI CONSTRUCTION EQUIPMENT....................17 J R VINAGRO CORPORATION........................................1 M G EQUIPMENT............................................................1 MILTON CAT..................................................................14 NEW ENGLAND ROAD EQUIPMENT..............................7 POWERSCREEN NEW ENGLAND................................15 ROGERS BROTHERS CORPORATION........................19 SHAWMUT EQUIPMENT CO INC..................................16 T-QUIP SALES & RENTAL INC......................................16 THE N.I.C.E. COMPANY..................................................6 THE W. I. CLARK COMPANY..........................................2 TIBBITS EQUIPMENT SERVICES INC............................1 TYLER EQUIPMENT CORPORATION............................3 WOODS CRW CORP........................................................9

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • August 2, 2023 • Page 19 The Ultimate in Trailers® ROGERS BROTHERS CORPORATION ALBION, PA Over a CENTURY of building the very best heavy-duty trailers for your hauling needs! Contact your local dealer for a quote today. TRAILERS TO MEET EVERY HAULING CHALLENGE! Committed to building superior quality, reliability and durability into every trailer. Tyler Equipment www.cn-wood.com 200 Merrimac St. Woburn, MA 01801 (781) 935-1919 140 Wales Ave. Avon, MA 02322 (508) 584-8484 3 Rocky Hill Road Smithfield, RI 02917 (401) 942-9191 C.N. Wood Co., Inc. www.tylerequipment.com 251 Shaker Road East Longmeadow, MA 01028 (413) 525-6351 • (800) 292-6351 Parts: (877) 255-6351 1980 Berlin Turnpike Berlin, CT 06037 (860) 356-0840 • (800) 352-4473 Parts: (860) 356-0848

Page 20 • August 2, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide with Deve DEVEVEL eloping elo ON. a g onw w rds r you demand for you able mac for the dur ount on your local C ork ur most challenging w ng ma chines and unmatched servi l team at Barry Equipment E ice ll ri acore. A ©2023 HD Hyundai Infr ealer uthorized D A and of ON is a br EL ed. DEV ights reserv Web 30 B 508 We igh Webster, s 7 Harry’ 508-949Webste , MA 01570 bster oad Birch Island R 8-949-0005 ebster , South Windsor 1608 John Fitch 4600288-860South Winds MA 01570 Way -0005 r 4 CT 0607 Blvd. sor 06