By Chuck MacDonald CEG CORRESPONDENT

with three other general contractors and a multitude of subcontractors on an 80-acre renovation of a 220-acre medical and scientific campus.

By Lucy Perry CEG CORRESPONDENT

No project can really start until the machinery arrives and is fired up. That’s why load securement is step number one in transporting heavy construction machinery. Assets can be damaged or destroyed, employees can be injured or worse during either loading or unloading, so hauling contractors cannot risk taking safety precautions lightly.

There are endless sources for solid information on proper load mobilization, starting with the USDOT. That’s why there’s no excuse for cutting corners during such a critical phase of the construction project.

8 OFFICIALS BREAK GROUND ON MIDWAY’S LARGEST PROJECT OF

Mayor Brandon Johnson on June 5 joined Michael J. McMurray, aviation commissioner, Southwest Airlines and local construction and union partners to break ground on the rehabilitation of Runway 13C/31C.

8

NORTH

WOOHYUN KIM AS ITS NEW

Woohyun Kim has been appointed CEO of DEVELON North America (HD Hyundai Infracore North America) and the DEVELON brand of heavy and compact construction equipment.

In addition to a special open house day only 10 percent off Bobcat parts, guests were treated to lunch which included Dairy Land sloppy Joes, chips and sundaes.

14 HD HYUNDAI ANNOUNCES MERGER OF EQUIPMENT DIVISIONS

HD Hyundai, headquartered in Seoul, South Korea, will merge its construction equipment divisions to create a new company, tentatively named HD Construction Equipment, effective Jan. 1, 2026.

16 BARRICK, KOMATSU REACH AGREEMENT ON $440M CONTRACT

Barrick Mining Corporation (Barrick) and Komatsu have finalized an agreement for the delivery of primary mining equipment to Barrick’s Reko Diq copper-gold project in Pakistan starting in 2026.

20 EXACT CRANE WELCOMES ROBERSON AS MICHIGAN SALES REP

Exact Crane & Equipment Corp. welcomed its new crane salesman, Kenny Roberson. Roberson will be serving customers throughout Michigan. He will be offering the broad range of new and used cranes, parts and attachments.

22 CASE DISCUSSES EV EVOLUTION IN MODERN EQUIPMENT

The construction industry is in the midst of a new kind of change — a wave of electrification in construction equipment with the potential to change the way we work on the job site.

On June 26 Fabick Cat hosted more than 300 guests at its Wausau, Wis., facility. The event featured the Cat Global Operator Challenge, as heavy equipment operators competed for a spot in the regional finals.

28

Wastebox, which serves the Chicagoland area with roll-off dumpster rentals for residential, commercial and construction needs, has had an open account with McCann Industries since 2017.

34

Craig Stephens celebrated 40 years with Roland Machinery Co. in 2024, but technically, he’s been around longer than that. He worked his way into a technician after being hired as a steamer to clean and prep rental equipment.

36

Altorfer Cat and Plote Construction teamed up on July 9, 2025, to celebrate 100 years of Caterpillar at Plote headquarters. The event featured an equipment showcase, which included a new D5 dozer and a rebuilt 980H wheel loader.

40 MINNESOTA UTILITY CONTRACTORS ASSOC. REBRANDS AS DIGIN MIDWEST

The Minnesota Utility Contractors Association was founded in the 1970s to better represent utility workers in the larger construction industry. Goals included representation and promotion of utility workers.

69 FELLING NAMES IVY’S LEGACY AS ITS ‘TRAILER FOR A CAUSE’ BENEFICIARY

Felling Trailers Inc. announced Ivy’s Legacy Foundation as the beneficiary of the 13th annual 2025 Trailer for a Cause auction. This tradition involves auctioning a custom FT-3 utility trailer online.

70 ROLLIE’S SALES & SERVICE ADDS THUNDER CREEK TO LINEUP

Rollie’s Sales & Service has added the Thunder Creek lineup of field fueling and service trailers to its offering of fuel storage and custom transport solutions for the construction and agricultural industries.

47 EXCAVATION SYSTEM CRUSHES AGGREGATE MARKET DEMAND

50 TOMRA LAUNCHES X-TRACT FOR X-RAY SORTING OF WASTE WOOD

52 FINLAY J-1280 AVAILABLE IN THREE FEED-IN CONFIGURATIONS

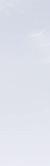

56 METSO ENHANCES PERFORMANCE WITH SIXTH IN HPE CRUSHER SERIES

58 FAE UNVEILS FIXED-TOOTH MULCHER WITH BITE LIMITER TECH

METSO COMPLETES ACQUISITION OF SWISS TOWER MILLS MINERALS

Cape Girardeau, MO

STK# KM2022307, 4628 HRS, Bridgeton,

2021 Case TV450B, S/N JAFTV450KLM487291, 541 Hrs, CAB/AIR/HEAT, 2 SPEED, HYDRAULIC COUPLER, 84" GP BUCKET, HIGH FLOW PERFROMACE PACKAGE, SERVICED AND READY TO GO, UNIT WILL HAVE A NEW DOOR

$69,900

2022 Case SV280B, 171 Hours, S/N JAFSV280HMM403668, CAB/AIR/HEAT, HYDRAULIC COUPLER, 72" GP BUCKET, 2 SPEED, RADIO, EXCELLENT CONDITION

Garrard • (630) 492-9115 Bolingbrook, IL

our complete Used & “Like New” inventory at

2018 Case 521G, S/N NHF240998, 813 Hrs, Cab/Air/Heat, JRB Coupler 3 Yard GP Bucket Third Valve Ride Control Limited Slip Diff

$107,500

2022 Case 321F, S/N NNHP04331, 241 Hours, CAB/AIR/HEAT, HIGH SPEED TRANSMISSION, SKID STEER STYLE COUPLER, 1.7 cu yd BUCKET, LIMITED SLIP DIFFERENTIAL, THIRD VALVE HYDRAULICS TIRES LIKE NEW, PREMIUM CAB

2023 Case TV370, S/N 2023 Case TR370B, 176 Hrs, CAB/AIR/HEAT, HYDRAULIC COUPLER, 84" GP BUCKET, DELUXE CAB, PREMIUM DISPLAY PANEL, GOOD TRACKS

$82,500

$72,500

2019 Case Cx130D, S/N DAC130K7NKS7D1558, 358 Hours, CAB/AIR/HEAT, HYDRAULIC COUPLER, 18" BUCKET, AUX HYDRAULICS

$109,900

2023 Case TR270B, S/N JAFTR270LNM421971, 281 Hours, CAB/AIR/HEAT, E-H CONTROLS, HYDRAULIC COUPLER, 78" GP BUCKET, RIDE CONTROL, SELF LEVEL, HIGH FLOW HYDRAULICS, REARVIEW CAMERA, PREMIUM DISPLAY MODULE, FULL MACHINE WARRANTY UNTIL 1-30-25, JUST SERVICED READY TO GO $54,900

2018 Case CX245DSR, S/N NJS7K1152, 1306 Hours, Cab/Air, Kent Coupler, Aux Hydraulics, No

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

Roadtec RX100e - ‘18, approx. 500 hrs. Includes grade controls $165,800 Sandvik CJ412 - ‘14, approx. 1400 hrs. Mobile jaw plant $540,800

Sakai R2H-4 - ’19, approx. 900 hrs. 83” triple drum static

$85,500

Double drum Oscillatory $148,400 Sakai SW300 - approx. 450 hrs, 39” drum, #C000211 $26,850.

ROADTEC RP195 PAVER - ’08, approx. 8890 hrs. Carlson EZIV 10 screed, Moba grade & slope controls ....................................$35,200

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd

ASTEC GT205MF, (’18), 3,296 Hrs, 5 x 20 top deck, 5x18 bottom deck, 8 cu. yd. hopper, 5' wide double deck multi-frequency screen w/hydraulic vibrators, #C005896 $229,900

HAUL TRUCKS

LIEBHERR TA230 LITRONIC, (‘23), 361 Hrs, #C005550 $CALL

Superior DT74J - ’19, approx. 1300 hrs. AC, Side shift, gutter brush, #C001774 $35,400

BOMAG BM600 - ‘16, 565 Hrs, 24” Drum, Load Out Conveyor

$152,800

Roadtec RX-300 - ’18, approx. 600 hrs. 4’ drum

$311,400

$P.O.R. Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd

$P.O.R.

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154

P.O.R. items may be on rent causing pricing and hours to vary. BROOMS MILLING MACHINES

$148,900

KPI FT2650 – ’19, approx. 1800 hrs. Tracked jaw crusher $546,950

Mauldin 1560 paver – ’22, approx. 600hrs. 8-14’, electric screed heat $99,600

HAZEMAG APPH1515QL, (’93), Primary Impactor Portable Plant, 400HP electric crusher drive, 15 cu. yd. hopper, #C005559

LIEBHERR TA230 LITRONIC, (‘23), 367 Hrs, #C005511 $CALL LOADERS AND EXCAVATORS:

$370,000

HAZEMAG APS1315, (’10), 7'x20' triple deck screen, #C005792

$362,500

SIMPLICITY 6203, (’96), Dual Portable Screening Plant, 6’ x 16’ Triple Deck Primary Screen, 6’ x 20’ Triple Deck Secondary Screen, #4873

LIEBHERR L550 XPOWER, (’17), 2,722 Hrs, innovative machine concept which combines performance, fuel efficiency, robustness and comfort. Power split driveline, #C003118 $125,747

$295,000

SUPERIOR BROOM SM80K, (‘17) 2,250 Hrs, Enclosed Rops, AC, #C006107

$26,500

SUPERIOR BROOM SM80K, (‘17) 2,090 Hrs, Enclosed Rops, AC, #C006106 $26,500

GROVE GHC85, (’23), 164 Hrs, #C005208 $CALL

LIEBHERR R924 LITRONIC, (‘23), 10 Hrs, The R 924 (Tier IV) crawler excavator replaces the predecessor R 924 (Gen 6) model. Its completely updated design is characteristic of the new range of "generation 8" machines, #C005679 $CALL LIEBHERR R934 LITRONIC, (‘23), 485 Hrs, The new R934 weighs approx. 35 tons, completely updated design is characteristic of the new range of "generation 8" machines, #C005399 $CALL

$1,099,000

GROVE GHC130, (’19), 932 Hrs, 130-ton lift capacity, #C004141

LIEBHERR R936 COMPACT LITRONIC, (‘18), 1,042 Hrs, Convenient and service-friendly, the R 936 Compact makes for safe working. With its tight slewing radius, this machine is especially well suited to urban applications, #C003377$CALL

$885,850

GROVE GRT880, (’22), 807 Hrs, 80-ton lift capacity, #C005002

GROVE GRT880, (’18), 2,476 Hrs, 80-ton lift capacity, #C004982

LIEBHERR R956 LITRONIC, (‘22), 1,800 Hrs, 35' boom and 21' stick, #C004867 $CALL

$628,750

SAKAI SV544TB, (‘23), 2 Hrs, #C005470 $CALL

Officials and local construction and union partners gathered to break ground on the rehabilitation of

Mayor Brandon Johnson on June 5, joined Michael J. McMurray, aviation commissioner, Southwest Airlines and local construction and union partners to break ground on the rehabilitation of Runway 13C/31C. The $47 million initiative will renew one of Midway’s primary runways and its intersecting taxiways, bolstering airfield safety at the “busiest square mile in aviation.”

“Midway International Airport is one of the largest employers on the South Side, providing thousands of Chicagoans with quality jobs in a dynamic, ever-changing industry.

As we continue to Build Better Together across this city, this type of critical infrastructure investment is key to furthering economic growth and opportunity, while also providing for an even safer air travel experience for generations of Midway flyers to come,” said Johnson. “I thank Southwest Airlines and the Illinois Congressional delegation for their financial support of this project, and I look forward to continued partnership with all the airlines that call Chicago’s

neighborhood airport home: Allegiant Air, Delta Air Lines, Frontier Airlines, Porter Airlines, Southwest and Volaris Airlines.”

The rehabilitation of Runway 13C/31C includes repaving the main runway and its intersecting taxiways, as well as updating the airfield’s geometry to better align with federal aviation standards. The project also will enhance safety through the installation of new runway guard lights and the construction of a new roadway to support aircraft rescue and firefighting operations in the event of an aviation incident.

“Safety is the top priority of each of the more than 9,000 employees who work at Midway International Airport, and these investments will support that mission with the latest enhancements in airfield safety,” said McMurray. “Best of all: we expect to complete this tremendous airfield upgrade with absolutely no impact on passenger flight operations.”

Led by K-Five Construction Corporation, the $47 million project has been in various

safety at the “busiest square mile in aviation.”

stages of planning since 2022. The CDA is seeking more than $37 million in federal funding for the project through the 2021 Infrastructure Investment and Jobs Act and the Federal Aviation Administration’s Airport Improvement Grant program.

“We are appreciative of the partnership from the city of Chicago to launch this critical project that invests in the future of Chicago Midway,” said Steve Sisneros, vice president airport affairs of Southwest Airlines. “As Midway and Southwest both transform, we look forward to serving Chicagoans for years to come.”

As part of ongoing efforts to improve airfield operations at Midway, the existing Runway 13L/31R, which has been closed since 2023, was permanently decommissioned on June 12. On the same day, Runway 13C/31C — the runway undergoing rehabilitation as part of the project launched today by Mayor Johnson — was re-designated as Runway 13L/31R. Pilots and Midway-based personnel have been

Woohyun Kim has been appointed CEO of DEVELON North America (HD Hyundai Infracore North America) and the DEVELON brand of heavy and compact construction equipment.

Kim brings extensive experience in leadership, sales and finance to his new role.

“I look forward to building on our success in North America and growing the DEVELON brand,” Kim said. “We’ve made significant progress in recent years, changing the brand and expanding our construction equipment lineup. We will continue to grow with reliable and productive heavy and compact equipment, with the help of our more than 200 dealers in the United States and Canada.”

Most recently, Kim served as director of sales operation and programs for the DEVELON brand.

From January 2023 to December 2024, he was the director of

commercial planning and sales operations. In that capacity, he helped lead sales planning, product management, financial planning and remarketing. In addition, he was responsible for opening the new North American Customer Utilization Plant near Savannah, Ga.

Kim’s career with Doosan and then HD Hyundai Infracore spans 25 years in sales, business management and human resources. His roles included sales and leadership positions in Seoul, South Korea; Dubai, United Arab Emirates; and Atlanta, Ga. He began his career with Doosan in December 2001 as a human resources manager.

“Woohyun’s sales and leadership positions in the past two decades will culminate in his new strategic role in North America,” said Jaeyoung Moon, head of the construction machinery business division of HD Hyundai Infracore.

For more information, visit na.develon-ce.com/en.

notified of the upcoming change in accordance with federal requirements.

The airfield work builds upon terminal improvements made under the Midway Modernization Program, completed by the Johnson administration in fall 2023. The $400 million terminal investment revamped the airport’s concessions program, expanded the passenger screening area to accommodate twice the number of travelers per hour and upgraded the terminal’s main parking garage.

The rehabilitation of Runway 13C/31C is a critical aspect of Midway’s five-year capital plan, which invests in maintenance and upgrades to the existing airfield and terminal facilities to cultivate a culture of growth and safety at Midway.

Other upcoming improvements include lighting improvements in the economy parking garage; terminal restroom renovations; terminal roof replacement; and the rehabilitation of Runway 4L/22R, among other infrastructure projects.

715-752-8112

JD 50G, A/C, Hyd Thumb, 5’7” Long Arm, Blade, Aux, #292872 ......................................$45,000

JD 345G, A/C, CPLR, Hyd Thumb, 12’4 Arm, 32” Pads, #300530 ......................$279,000

JD 331G, A/C, Hi Flow Aux, 2 Speed, Ride Control, #262952 .. $65,000

JD 850K, A/C, Ripper, Semi U Blade, LGP, 36” Pads, Screen, #299904 $134,000

JD 130G, A/C, Hyd Thumb, Aux, 9’11” Stick, 24” Shoes, #261469 ....................................$119,000

Komatsu PC138LC-11, A/C, Long Arm, CPLR, Rubber Pads, #298908 ......................$165,000

JD 550K, A/C, XLT 18” Pads, 6 Way 105” Blade, 4th Function Aux, #262480 $105,000

JD 950K, A/C, LGP, 36” Pads, 184” Blade, Ripper, #301142 ...... $375,000

JD 135G, A/C, 9’11” Arm, 24” Shoes, Reduced Tail Swing, #249203 ........................$87,000

JD 180G, A/C, Hyd Thumb, Coupler, 24” Shoes, Rev Fan, #296325 ......................$125,000

JD 650K, A/C, LGP, 28” Pads, 6 Way 128” Blade, Rev Fan, IGC, #262371 $114,000

JD 444K, A/C, JRB Coupler, Ride Control, #262773 ..$76,000

JD 210G, A/C, Hyd Thumb, Coupler, 9’7” Arm, Rev Fan, #261276 ......................$127,500

Volvo EC240BLR, A/C, 60’ Long Reach, 60” Ditch Bucket, #292240 ........................$84,000

JD 700K, A/C, LGP, 36” Pads, 6 Way 132” Blade, Rev Fan, #291338 $155,000

JD 544K-II, A/C, Rev Fan, 20.5 Tires, Air Seat, GP Bucket, #262551 $127,000

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ......................$198,000

JD 325G, A/C, Joysticks, 2 Speed, Aux Hyd, #293433 ......................................$52,000

JD 700L, A/C, LGP, 30” Pads, 6 Way 127” Blade, Drawbar, #298880 $158,000

JD 644P, A/C, Coupler, Ride Control, 3rd Spool, Camera, #262425 $279,000

Swanston Equipment hosted its customer appreciation open house at its Fergus Falls, Minn., location at 712 Frontier Dr.

In addition to a special open house day only 10 percent off Bobcat parts, guests were treated to lunch which included Dairy Land sloppy Joes, chips and sundaes. Those in attendance also had the opportunity to sign up for a chance to win a Bobcat ZT2000 mower.

Joe Keller, son of Louis Keller and nephew of Cyril Keller, inventors of the original Bobcat loader was on hand with two historic machines that helped launch a revolution in compact equipment:

• Keller Loader #7 — the machine featured at the 1958 Minnesota State Fair. This event marked the first major public debut of the Keller loader and the pivotal moment when the Keller brothers and the Melroe family connected — ultimately leading to a manufacturing agreement that shaped the future of Bobcat.

• Melroe M60 loader (serial #1001) — the first-ever Melroe loader, designed and built by Louis and Cyril Keller after joining Melroe Manufacturing. With the help of three dedicated teammates — Jim Toyne, Nels Nelson and Don Lloyd — they built the first six M60s by hand. Cyril hit the road with the very first unit, dedicating his career to sales, dealer support and operator training, while Louis stayed behind, continuously improving designs based on real-world feedback.

see SWANSTON page 64

photo

Nick Ott brought his 1960 Melroe M200, significant because it could be a 2-wheel drive with castor wheels or a 4-wheel drive by adding the rear axle and chains.

(L-R): Joe Keller, son of Louis Keller and nephew of Cyril Keller, co-inventors of the original Bobcat loader; Molly Swanston, owner of Swanston Equipment; and Darryl Schmidt, who restored a 1959 Melroe M200, pose for a photo before the event.

Guests were treated to lunch which included

Joes, chips and sundaes.

The first Bobcat was signed by Louis and Cyril Keller, inventors of this new machine.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

HD Hyundai, headquartered in Seoul, South Korea, will merge its construction equipment divisions to create a new company, tentatively named HD Construction Equipment, effective Jan. 1, 2026.

The merger will combine HD Hyundai Infracore and HD Hyundai Construction Equipment. The Hyundai and DEVELON brands will continue to coexist. The two companies operate independently in North America through distinct dealer networks. The independent brand and dealer network structure will remain in place.

Pending shareholder approval and regulatory review, the merger will create a stronger global construction equipment business while maintaining the success for the DEVELON and Hyundai brands in North America.

“While this merger creates a more powerful global entity, we are committed to ensuring stability and continuity for our dealers and customers in North America,” says WH Kim, CEO of DEVELON North America. “Our dealers will continue to work with the same staff they do today and the DEVELON and Hyundai brands will continue to be strong, independent forces in the market.”

The advantages of merging the two companies include the following:

● providing greater price competitiveness through increased scale;

● speeding up innovation in smart and electrified equipment;

● enhancing supply chain efficiency and product quality;

● expanding aftermarket support, including parts and service;

● growing the product lineup, ranging from compact to ultra-large machines; and

● building on the growth of engine sales and aftermarket services.

For more information, visit na.develonce.com/en.

Barrick Mining Corporation (Barrick) and Komatsu have finalized an agreement for the delivery of primary mining equipment to Barrick’s Reko Diq copper-gold project in Pakistan starting in 2026.

Valued at $440 million, the deal marks Komatsu’s first major mining equipment placement in its Middle East territory and underscores the strengthening partnership between the two companies.

As part of its commitment to supporting Reko Diq’s operations, Komatsu intends to establish Komatsu Pakistan Mining Limited, a new entity dedicated to providing service and technical expertise at Reko Diq.

Additional investments will also be made to Komatsu Middle East FZE, a regional headquarters in Dubai, UAE, to support an expanded equipment footprint in the region. These investments ensure Barrick will have the resources needed to efficiently operate at one of the world’s most significant greenfield mining developments.

“The Reko Diq project represents a long-term investment in our future and that of mining in Pakistan, and our partnership with Komatsu is an important part of that vision,” said Mark Bristow, Barrick president and CEO. “Komatsu equipment has proven its performance and reliability at our operations worldwide, and we are confident in their ability to support our goals at Reko Diq. We look forward to building on this strong relationship as we develop one of the world’s newest greenfield assets.”

The equipment package for Reko Diq includes:

• 980E-5 ultra-class haul trucks — manufactured and exported from Peoria, Ill., these trucks are designed for high efficiency and longevity in demanding conditions.

• P&H 4100XPC AC electric rope shovels — manufactured and exported from Milwaukee, Wis., P&H shovels provide electric powered material movement with high dig forces and payload capacity.

• PC7000-11 mining excavators — manufactured and exported from Dusseldorf, Germany, these excavators deliver precision, productivity and advanced intelligent data solutions for optimized performance.

• WE2350-2 electric wheel loaders — manufactured and exported from Longview, Texas, the largest wheel loader in

the world is designed for high-volume material movement and fast cycle times.

Barrick and Komatsu have steadily expanded their collaboration in recent years across multiple projects, following successful fleet acquisitions at Barrick’s Lumwana copper mine in Zambia and the Nevada Gold Mines complex in the United States. In October 2023, the two companies formalized their commitment with a global framework agreement, laying the foundation for deeper cooperation across multiple projects.

“Barrick is an important global partner for Komatsu, and we are excited to expand our relationship to support the

development of Reko Diq,” said Peter Salditt, president, Komatsu mining business division. “The scale and complexity of this project demands proven, high-performance equipment, and we are confident our ultra-class haul trucks, electric rope shovels and other mining machines will meet the challenge. We look forward to continuing to work alongside Barrick to drive productivity and innovation in mining.”

Komatsu’s involvement in the project underscores its commitment to supporting customers with a comprehensive suite of mining equipment and solutions to optimize their operations.

For more information, visit www.komatsu.com.

Exact Crane & Equipment Corp. welcomed its new crane salesman, Kenny Roberson. Roberson will be serving customers throughout Michigan. He will be offering the broad range of new and used cranes, parts and attachments that Exact offers along with providing service and repairs.

Roberson brings a wealth of hands-on experience and technical expertise to the role, having worked as a field service engineer of Tadano America Corp. from 2019 to 2025. During his time with Tadano, he specialized in troubleshooting, repairs, programming and assembly support across Tadano, Demag and Mantis product lines.

“Kenny’s discipline, technical skills and dedication to customer support make him a tremendous asset to our team,” said Jeff Swan, vice president, Exact Crane.

Prior to Tadano, he worked for multiple crane rental yards and dealerships, gaining invaluable experience in the field. In addition, he has completed numerous advanced technical courses to sharpen his ability to diagnose and repair equipment.

“Roberson shows incredible disci-

pline, exemplified in his military service in the U.S. Army, where he completed six combat deployments and served as an Airborne Ranger,” said Swan. “He completed the Warrior leader course, the NCO Academy [placing in the top 10 percent] and an advanced combat medicine/trauma course.”

Exact Crane is confident that Roberson’s broad technical background and his customer-first mindset will provide unmatched value to crane owners and operators across the state.

Exact Crane & Equipment Corp. welcomed Kenny Roberson as its new crane salesman, dedicated to serving customers throughout Michigan.

Exact Crane & Equipment Corp. offers a full lineup of cranes including all-terrains, boom trucks, mini-cranes, roughterrains, telecrawlers and truck cranes, along with a wide inventory of parts and accessories such as blocks, balls, man baskets, ground protection mats, dump bins, lubricants and more.

To connect with Kenny Roberson, call 888/635-5636 or email Kenny@exactcrane.com.

For more information, visit exactcrane.com.

The National Ready Mixed Concrete Association named the Indiana Ready Mixed Concrete Association as the 2024 State Association of the Year.

The National Ready Mixed Concrete Association (NRMCA) named the Indiana Ready Mixed Concrete Association (IRMCA) as the 2024 State Association of the Year. This prestigious award highlights IRMCA’s leadership in promotion, education, advocacy and research within the ready mixed concrete industry.

“We are honored to receive this award from NRMCA,” said Chad Montgomery, IRMCA executive director. “It reflects the hard work and dedication of our members and staff. We remain committed to promot-

ing excellence in the ready mixed concrete industry and supporting our members in every possible way.”

The NRMCA evaluates associations based on achievements in key areas:

• Promotion: advancing the use and acceptance of ready mixed concrete in various applications.

• Education: providing valuable training and resources to members and industry stakeholders.

• Advocacy: engaging in legislative and regulatory initiatives that benefit the indus-

try.

IRMCA stood out for its commitment and accomplishments in these areas over the past year.

• Research: contributing to studies and innovations that enhance the quality and sustainability of ready mixed concrete.

IRMCA stood out for its commitment and accomplishments in these areas over the past year.

“IRMCA has demonstrated outstanding leadership and dedication to advancing our industry,” said Joe Roche, NRMCA CFO and interim president. “Their innovative promotion strategies, comprehensive educational programs, proactive advocacy efforts and

commitment to research set a high standard for state associations nationwide.”

NRMCA presented the award during its 2025 Annual Convention held in Tucson, Ariz.

The Indiana Ready Mixed Concrete Association serves the ready mixed concrete industry in Indiana through promotion, education and advocacy. IRMCA strives to enhance the quality and use of concrete, ensuring it remains the building material of choice for a sustainable and resilient future.

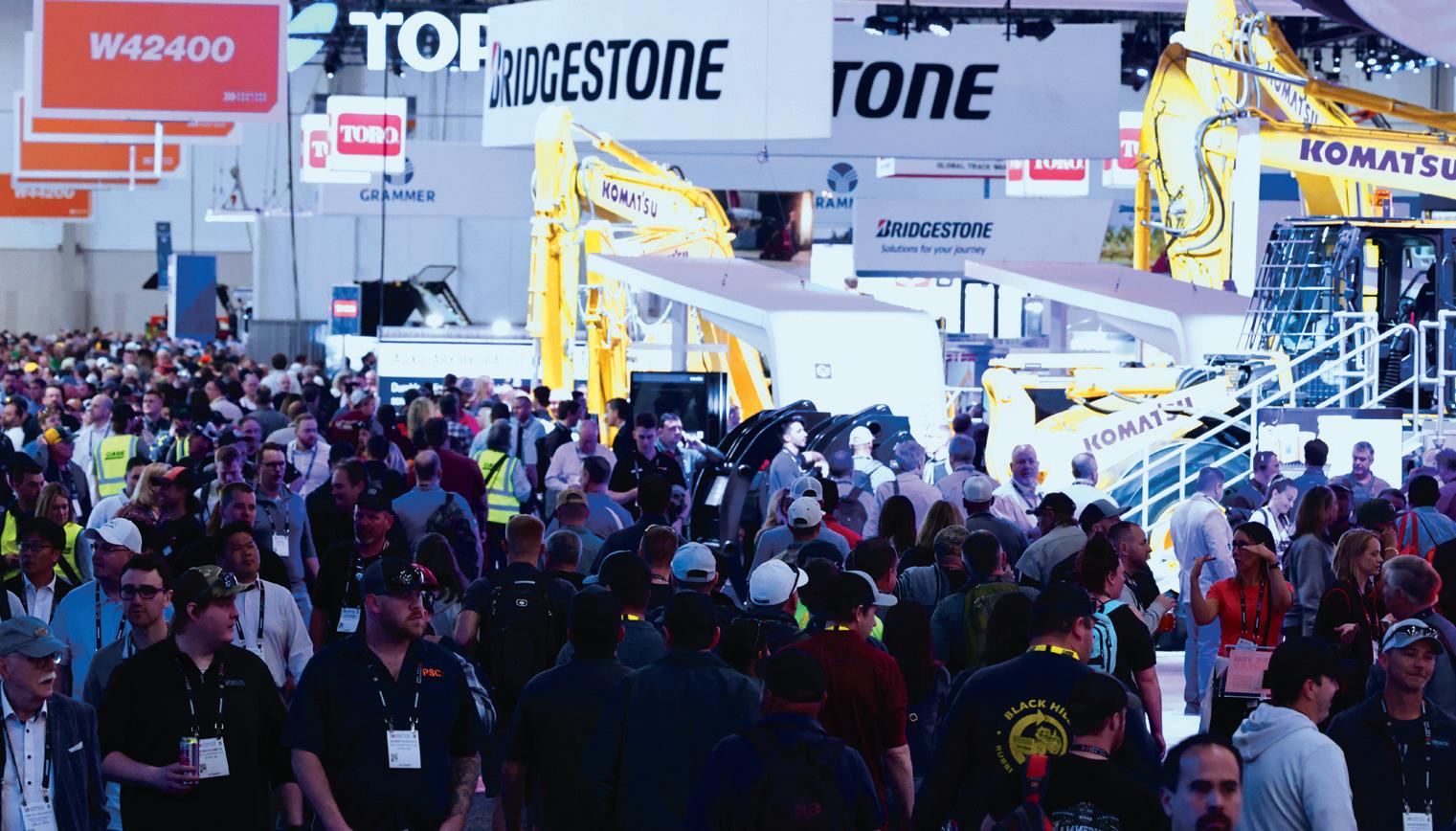

The construction industry is full of changemakers.

We shape the land to make it fit our needs, we build the infrastructure that transforms societies and we innovate to meet new challenges. The construction industry is in the midst of a new kind of change — a wave of electrification in construction equipment with the potential to change the way we work on the job site.

Adoption of this technology is moving faster in some places than others, as urban contractors, municipal crews, utility teams and others weigh the benefits of investing in EVs. Some are embracing the new technology and discovering the unique benefits of electrification, some are waiting for the technology to mature while others are skeptical EVs will benefit their business at all.

Not all projects are suited for an EV. And not all EV machines are created equal to meet the demands of the job. But, projects with special requirements better suited for EVs are on the rise and a wave of practical innovation is under way, resulting in smarter, more efficient machines.

EVs are all about unlocking more opportunities for customers, giving them new tools in their toolbox to meet unique challenges. The fact is, there are more opportunities than most people realize. Think about it: a powerful electric machine that produces zero emissions, minimal noise and requires no diesel fuel — it changes the game for where, when and how crews get work done.

More and more, we’re seeing projects with unique job site requirements. Whether it’s urban centers with rules for noise or emissions, confined or congested job sites, nighttime projects or work that requires indoor operation — EVs provide a clear advantage for these kinds of jobs. EVs also open doors to winning contracts on projects

that prioritize green credentials, which are becoming increasingly common.

These trends will only continue. 83 percent of the United States population lives in urban areas today, according to research from the University of Michigan, and that figure is expected to increase to nearly 90 percent before 2050, which will result in more confined and congested job sites.

Many municipal and state governments are introducing more rules and incentives to encourage construction crews to minimize disruptions and environmental impact. Some states like California are even offering heavy-duty voucher funds to incentivize the purchase of clean off-road equipment. And green construction projects are on the rise, with LEED-certified projects growing at an average rate of 20 percent every year between 2017 and 2022.

Beyond these application and business opportunities, EVs come with a range of benefits that can help crews boost their efficiency and profitability. EVs can deliver performance and power equal to their diesel counterparts, but require less maintenance, zero diesel costs and lower total cost of ownership. Does that mean every contractor should sell their diesel machines and switch to using EVs? Not exactly. There are still some jobs today that are better suited for diesel. But EVs can complement internal combustion engine machines for crews who want to diversify their fleets, offering a solution for projects where EVs may be the best tool for the job.

Remember that electrification in the construction industry is still in its infancy, and the technology is rapidly evolving. Consider how far EVs in the automotive industry have

come in the past decade, as the median driving range has more than doubled in just 10 years. EV construction equipment could see a similar pace of change, which is why continued investment in electrification R&D is worthwhile.

The key to making electrified construction equipment successful on the job is making sure they’re purpose-built for electrification, so they can deliver emissions-free performance in a way that makes sense in the field. Instead of simply retrofitting existing diesel machines, it’s critical to look at every aspect of the machine to see how systems can be optimized for electrification. By purpose-building new machines to be an EV from day one, we can create more energyefficient machines to boost performance in both the battery and the machine. Case considered this as it designed and developed its new electric backhoe loader, the 580EV. After debuting its first electric backhoe concept, named Project Zeus, at ConExpo in 2020, Case gathered a tremendous amount of customer feedback that influenced the final design, according to Case.

The result is a machine that can deliver the same breakout forces and dimensional digging specifications as its diesel counterpart, while also serving up all the benefits of electrification, according to Case.

It’s an exciting time for the industry, as advancements in electrification transform what we can achieve on the job. EVs provide new ways for construction contractors, utility teams and municipal crews to further improve their productivity, efficiency and profitability on projects that require innovative solutions.

Most exciting of all, the EV evolution has just begun. As the technology continues to evolve, we’re sure that crews all over will find new ways to use EV machinery to grow their business

(This article is courtesy of Case Construction.)

On June 26, 2025, Fabick Cat hosted an open house attended by more than 300 guests at its Wausau, Wis., facility at 9601 Christie Lane in Weston, Wis. The event featured the Cat Global Operator Challenge, as heavy equipment operators competed for a spot in the regional finals.

Also on display was a Cat 980G wheel loader rebuild. This machine arrived at Fabick’s Wausau shop in March and took three months for a full Cat Certified Powertrain Plus and Hydraulic Rebuild for customer County Materials.

Customers also had the chance to try out the Cat 249D3 compact track loader with Cat Command remote operation, as well as try other machines in the demo area.

“Any opportunity to celebrate our customers and show appreciation for their continued partnership is a great day,” said Kelli Fabick, vice president of Fabick Rents.

see FABICK page 44

are Ryan DeBroux of Fabick Rents; Joshua Krautkramer of Revi Designs; Colten Bloch of Revi Designs; and Tanner Shillinger of Fabick Rents.

(L-R) are Matt Hansen, sales manager, Fabick Cat; Brad Baumgart, product support sales representative, Fabick Cat; Kurt Behnke, County Materials; Mark Hanson, senior vice president of product support, Fabick Cat; Luke Peche, Tyler Larson and Nick Janak — the techs who did the rebuild on this Cat 980G wheel loader. The Cat Certified Powertrain Plus and Hydraulic Rebuild project took three months to complete.

An operator in a Cat 308 mini-excavator takes a turn at the “Mini-Masters” course in the Cat Global Operator Challenge.

This Cat AP1000 wheeled asphalt paver offers advanced technology, low fuel consumption and screed heat-up in as little as 15 minutes, according to Caterpillar.

(L-R): Mason Sasf, Mike Lewandowski and Mark Kizewski, all of Mark Kizewski Construction; Luyk, Ethan and Aidan Van Ornum, all of Rock Rose Company; and Douglas Johnson with a Cat 980G wheel loader, rebuilt by Fabick Cat.

When Kevin Loeffler, owner of Wastebox Inc. in Lemont, Ill., needed to expand his equipment fleet, he turned to the people he trusted.

Wastebox, which serves the Chicagoland area with rolloff dumpster rentals for residential, commercial and construction needs, has had an open account with McCann Industries since 2017. For years, the relationship focused on parts and service. But in 2024, Kevin made his first equipment purchase from McCann — a Case 621G wheel loader.

According to Pete Swanson, sales representative of McCann and who’s known Loeffler for more than two decades, that first machine sale was the result of long-standing trust and persistence.

“Kevin knew us for parts and service but had never bought a piece of equipment from us,” Swanson said. “I knew that once he gave us the chance, we could deliver.”

vocal about the level of support he’s received. He’s especially appreciative of Frank Cuevas, McCann’s field service technician, describing him as “respectful, reliable and a great representative of the company’s values.”

Loeffler also praised the broader McCann team — Melanie Evans, Nick Wilson, Ben Rivas and George Willer — for consistently supporting his business with urgency and professionalism.

To show appreciation, Swanson and Rivas hosted a cookout for the Wastebox team in the summer of 2025. After lunch, the McCann crew toured the Wastebox facility to get a closer look at how Kevin and his team operate.

The 621G did just that. Loeffler was impressed not only with the machine’s performance but with the support he received from McCann’s team. In February 2025, he came back for a second unit — a Case CX245D SR excavator.

For Loeffler, the decision to buy from McCann went beyond machines and price tags. As a fellow family-owned business, he appreciated McCann’s commitment to living its core values and delivering long-term support — not just a one-time transaction.

That shared philosophy is what has transformed McCann from a supplier into a trusted partner for Wastebox.

“This is exactly the kind of partnership we strive for,” said Pete Altenberger, vice president of sales and marketing of McCann Industries. “We’re not just selling equipment — we’re helping customers like Kevin grow their businesses with confidence, knowing they have a team behind them.”

Since then, Loeffler has expanded the amount of service work he does with McCann, and he’s been

“Kevin’s been great to work with,” Swanson said. “And we’re proud to be a small part of the great work his team is doing across Chicagoland.”

The HDX Series includes both root grapples and grapple buckets, engineered to make easy work of land clearing, landscaping, debris removal and storm cleanup projects.

Blue Diamond Attachments has announced the launch of its HDX Series Grapples, a new addition to the lineup between their current HD and Severe Duty Grapples.

The new units are specifically designed for midsized skid steer loaders, CTLs and tractors up to 75 hp. The HDX Series includes both root grapples and grapple buckets, engineered to make easy work of land clearing, landscaping, debris removal and storm cleanup projects. Blue Diamond’s HDX Series grapples deliver the performance and efficiency of a commercial grapple, all while saving you time and money, according to Blue Diamond.

A key advantage of Blue Diamond HDX Series grapples is the wide opening which allows the operator to grab bulkier items in one load. Uneven or awkward material are stable and secured by the independent acting top clamps that have commercial grade hydraulic cylinders for maximum clamping force, according ot Blue Diamond. The updated and heavier construction of the new series also means they can handle rugged use on midsized machines, making them a cost-effective long-term investment, according to Blue Diamond.

The HDX Series root grapples and grapple buckets feature enhanced design elements that take

the overall performance and versatility of the attachments to new levels. These include:

• stronger cylinder protection covers;

• a fully welded cylinder for increased clamping force;

• thicker ¼-in. tubing in the frame weldment;

• pivot point grease fittings;

• enhanced hose protection; and

• dual top clamps for load stability.

“We added the HDX Series grapples to our full lineup to fill a gap in the market for a site cleanup attachment that meets the needs of contractors and landowners looking to work in that 75 horsepower range,” said Drew Truan, CEO of Blue Diamond Attachments. “We listened to those customers and developed this new series, so they had what they need, when they need it. We believe the HDX Series will become the go-to grapples throughout North America.”

The new HDX Series open to 32 in., are 37 in. deep from front to back, and have 72 in. working width.

All Blue Diamond HDX Series grapples come with Blue Diamond’s satisfaction guarantee and are backed by a one year warranty.

For more information, visit bluediamondattachments.com.

Auger Technologies introduced its redesigned bullet tooth puller, a device to quickly and safely remove even the most stubborn conical auger bits from augers, cold planers, asphalt grinders and other equipment with conical bits in blind holes.

Powered with an impact wrench (not provided), the patented bullet tooth puller is heftier for more durability and cylindrical for better heat dispersion. It removes conical auger teeth in a fraction of the time normally required, saving time and money, and eliminating the knuckle-busting methods like fork wrenches, used previously, according to Auger Technologies.

Augers with worn teeth that are stuck fast are often relegated to the “bone yard,’ however, now the teeth can be efficiently removed in just minutes, new teeth can be added and an asset is placed back in production. It is ideal for any auger with standard conical teeth, or bits in blind holes like pavement grinders, cold planers and more.

Simply fit the split-ring bullet tooth puller collet over the conical auger bit, then slide the driver arm over the collet, locking it in place. Using an impact wrench, drive the extractor screw which in turn backs out the tooth. Once out, reverse the motion on the extractor screw to remove the tooth from the collet. Can be used with an impact wrench (recommended — not supplied) or manually with a wrench. Either method eliminates the knuckle-busting methods previously employed — much safer and faster than fork wrenches.

It is ideal for use with all standard conical teeth and augers. Part #9055, for .865 bit, is in stock for immediate shipment; extractors for larger bits (.990) also are available. Extractors also can be paired with an Auger Technologies driver for easy re-insertion of auger bits.

For more information and a video of the bullet tooth puller in action, visit augertech.net/tooth-extractor/.

Murphy Tractor & Equipment Co.

murphytractor.com

Park City, KS (316) 942-1457

Great Bend, KS (620) 792-2748

Humboldt, KS (620) 473-7020

Olathe, KS (913) 298-7373

Topeka, KS (785) 233-0556

Ulysses, KS (620) 356-1071

Dodge City, KS (620) 227-3139

Gering, NE (308) 436-2177

Omaha, NE (402) 894-1899

Lincoln, NE (402) 467-1300

Grand Island, NE (308) 381-0741

North Platte, NE (308) 534-7020

Kansas City, MO (816) 483-5000

Springfield, MO (417) 863-1000

Des Moines, IA (515) 263-0055

Fort Dodge, IA (515) 576-3184

Sioux City, IA (712) 252-2753

Waterloo, IA (319) 235-7085

Brunswick, OH (330) 220-4999

Cambridge, OH (740) 439-2747

Canton, OH (330) 477-9304

Cincinnati, OH (513) 772-3232

Columbus, OH (614) 876-1141

Jackson, OH (740) 688-4100

Lima, OH (419) 221-3666

Painesville, OH (440) 639-0700

Poland (Youngstown), OH (330) 629-6299

Rossford, OH (567) 352-7001

Vandalia (Dayton), OH (937) 898-4198

Craig Stephens officially celebrated 40 years with Roland Machinery Company in 2024, but technically you could say he’s been around longer than that.

“My dad worked for Roland as a mechanic for 30-some years, and I got to hang around with him a bit, so I feel like I’ve been a part of the family for as long as I can remember,” said Stephens, a field service technician based out of Roland Machinery’s Springfield, Ill., branch. “That, along with helping him out around the house and tinkering with things like minibikes and lawnmowers, got me interested in being a technician.”

Stephens worked his way into a technician role after being hired as a steamer to clean and prep rental equipment. Whenever possible, he helped in the shop, which led to him moving into a shop technician role and eventually field service.

“We were fortunate to have Craig’s dad, Short, with us for many years, and Craig continued that legacy after starting in our wash bay and working his way up to a lead technician,” said Chris Ingram, Roland’s Springfield division manager and vice president of the Road Material Solutions Group. “One thing that stands out to me is that Craig learned on the job. He never went to school to be a technician, and yet he was the top tech at a Komatsu competition. But he can also work on anything we carry: Komatsu, WIRTGEN and other brands. He’s phenomenal about passing his knowledge on to our younger technicians. He’s a great resource for them, and like his dad, Craig’s a tremendous asset to Roland. We appreciate everything he does for us.”

Craig Stephens, field service technician, Roland Machinery, marks 40 years with the company.

“I learned on the job because there weren’t really diesel tech school programs back when I started,” said Stephens. “The equipment has changed a lot during the past 30-some years. I never would have dreamed that I’d use a computer so much. Now, it’s all electronic, so it’s a lot different today. Fortunately, Roland has always been committed to training and giving us the tools and technology that we need to stay updated, as well as a service truck that basically allows me to do anything in the field that can be done in the shop.”

Stephens emphasized the service truck’s importance because it helps limit customers’ downtime as he’s working to diagnose and fix an issue. He’s had to do that at all hours of the day and in all types of conditions.

“A big reason I enjoy what I do is that there is not a typical day,” said

Stephens. “Some days, I come into the shop to start the day, and sometimes, I just go straight to the job site. Some jobs are as easy as replacing a sensor, and some get really complex. Occasionally, there is an emergency response that has to be done in the middle of the night. Whatever the situation, I treat it the same and look at it from my own standpoint. If it was my machine, I would want it up and running as fast as possible and fixed right.”

He added that the variety of jobs makes a service technician career an attractive one.

“I definitely encourage people to look at it, and it’s good to see that more younger people are coming in and are excited about it like I was,” Stephens said.

(This article is reprinted from Roland Machinery Industry Scoop with permission of Roland Machinery.)

martinequipment.com

Goodfield, IL 309-965-2502

Peru, IL 815-224-4711

Rock Island, IL 309-787-6108

Springfield, IL 217-528-4347

Tolono, IL 217-485-6755

Cedar Rapids, IA 319-365-0515

Dubuque, IA 563-588-1950

Columbia, MO 573-657-2154

Palmyra, MO 573-769-2274

murphytractor.com

Park City, KS

316-942-1457

Great Bend, KS 620-792-2748

Humboldt, KS 620-473-7020

Olathe, KS 913-298-7373

Topeka, KS 785-233-0556

Ulysses, KS 620-356-1071

Dodge City, KS 620-227-3139

Gering, NE 308-436-2177 Omaha, NE 402-894-1899

Lincoln, NE 402-467-1300

Grand Island, NE 308-381-0741

North Platte, NE 308-534-7020

Kansas City, MO 816-483-5000 Springfield, MO 417-863-1000

Des Moines, IA 515-263-0055

Fort Dodge, IA 515-576-3184

Sioux City, IA 712-252-2753 Waterloo, IA 319-235-7085 Brunswick, OH 330-220-4999 Cambridge, OH 740-439-2747 Canton, OH 330-477-9304 Cincinnati, OH 513-772-3232 Columbus, OH 614-876-1141 Jackson, OH 740-688-4100 Lima, OH 419-221-3666 Painesville, OH 440-639-0700

Poland (Youngstown), OH 330-629-6299 Rossford, OH 567-352-7001 Vandalia (Dayton), OH 937-898-4198

www.aisequip.com

Bridgeport, MI 989-777-0090

Grand Rapids, MI 616-538-2400

Lenox, MI 586-727-7502

New Hudson, MI 248-437-8121 Williamsburg, MI 231-267-5060

www.brookstractor.com

Madison (Sun Prairie), WI 608-837-5141 Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Crosse (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700 Sparta,WI 608-351-2101

www.lec1.com

Beaver, WV

304-255-1525

Cowen, WV 304-226-3299

Cross Lanes, WV

304-204-1818

Pleasant Valley, WV 304-534-5454

Norton, WV

304-636-6421

Marietta, OH 740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

www.westsidetractorsales.com

Lisle, IL

630-355-7150

Rockdale, IL 815-730-9011

Rockford, IL 815-961-3160

South Holland, IL 708-331-6362

Wauconda, IL 847-526-7700 Bloomington, IN 812-333-9677

Fort Wayne, IN 260-482-8576 Indianapolis, IN 317-544-3411

Lafayette, IN 765-447-6933

South Bend, IN 574-232-1461

Terre Haute, IN 812-645-7160

When you have big-time projects and little time to get them done, you need a machine that rises to the occasion. With impressive blade width and capacity, our large P-Tier Dozers can help you doze, grade, and move earth to the max. And with enhanced visibility to the blade edge, you’ll see your jobsite like never before.

mccoycf.com

JohnDeere.com/Dozers

Bemidji, MN 218-759-1996

Duluth, MN 218-722-7456

Grand Rapids, MN 218-326-9427

Ashland, WI 715-682-5522

Chippewa Falls, WI 715-834-2924

Merrill, WI 715-536-0633

Escanaba, MI 906-789-9054

Marquette, MI 906-789-7689

Fenton, MO 636-349-0200

Foristell, MO 636-463-2500

Mitchell, IL 618-931-1034

Mt. Vernon, IL 618-244-6800

Cape Girardeau, MO 573-334-0563

Paducah, KY 270-554-1131 Cuba, MO 573-885-0500

Owensboro, KY 270-684-2339

Evansville, IN 812-473-0484

Kingsport, TN 423-349-5001

Knoxville, TN 865-546-3207 Chattanooga, TN 423-855-0633

Nashville, TN 615-501-8600

Bowling Green, KY 270-842-3400

Louisville, KY 502-253-3721

Lexington, KY 859-788-3950

London, KY

606-862-8447

By Katherine Petrik CEG EDITORIAL ASSISTANT

Altorfer Cat and Plote Construction teamed up on July 9, 2025, to celebrate 100 years of Caterpillar at Plote headquarters, 1100 Brandt Dr. Hoffman Estates, Ill. The event featured an equipment showcase, which included a new D5 dozer and a rebuilt 980H wheel loader, both in Cat’s limited edition centennial grey.

Plote Construction has 30 Caterpillar 980 wheel loaders in its fleet. Because the cost to rebuild is significantly less than purchasing new, this isn’t the company’s first rebuild with Altorfer.

“We’ve done five 980 rebuilds over the past eight years,” said Dan Plote, president of Plote Construction Company. “We’ve had a lot of success with it and it’s more affordable than a brand new 980. We had some machines that were worn out — 25,000 hours — and we talked to Altorfer, who gave us a quote to rebuild. The reason we painted it battleship gray is that coincidentally, we were able to get one of the centennial D5 dozers sitting next to it, so we came up with the idea to paint the rebuild the same way.”

Altorfer offers four variations of rebuilds. Certified machine component rebuild (CMCR), which varies from engine, transmission, torque, axles and pumps; certified powertrain (CPT), which covers standard powertrain components; CPT + Hydraulics, which is for CPT components plus all major hydraulic components (pumps, valves, hoses, etc.); and certified machine rebuild (CMR), which takes the machine down to its frame and then built up from there with all new components.

“Our rebuild process takes about nine weeks to complete,” said Sam Will, product support representative of Altorfer Cat. “Typically, we run two or three technicians on rebuilds at a time. It is a grueling process, so having more hands is better.”

The CPT + Hydraulics rebuild of Plote’s machine included the option to rebuild existing components or replace them with new or reman (remanufactured) parts. Plote chose reman due to cost.

“Altorfer took about three months to rebuild — stripped it all the way down to the frame, replaced all the components — planetary gears, transmission, engine, rebuilding the cylinders, all new hoses, all new wiring,” said Plote. “It was super high-houred and past its first life.”

The rebuilt machine also comes with a Caterpillar equipment protection plan (EPP). Each warranty varies depending on the rebuild.

Plote Construction recently purchased this D5 LGP dozer, which celebrates 100 years of Caterpillar with the limited edition centennial grey paint.

Altorfer Cat and Plote Construction teamed up on July 9, 2025, to celebrate 100 years of Caterpillar at Plote headquarters, 1100 Brandt Dr., Hoffman Estates, Ill.

Derek Altorfer (L), president of Altorfer Cat, presents a plaque commemorating Caterpillar’s centennial and Plote Construction’s 980H rebuild to Dan Plote, president of Plote Construction.

Dan Plote (L), president of Plote Construction, shows the D5 LGP dozer to Ron Schroeder of Schroeder Asphalt Services.

“Cat offers a 3-year, 5,000-hour warranty,” said Will. “The CMCR warranty is just for the component you choose; CPT is all powertrain related parts that were replaced; and CPT + Hydraulics is powertrain and hydraulics.”

Plote’s machine will have a 4-year, 6,000hour CPT + Hydraulics warranty.

“We’ve had five certified rebuilds over the past eight years that were super successful,” said Plote. “We’ve had zero issues. We’re very interested in doing the certified rebuilds again which also gives us a warranty.”

With such a large fleet of machines, Plote needs reliable service to minimize downtime.

“Altorfer does a great job,” said Plote.

“They’re kind of new to the neighborhood — they bought out Patten Tractor about seven years ago. We formed a great relationship with them. We had been with Patten for many, many years.

Plote Construction is 61 years old now, and we’re carrying on the tradition with Altorfer.”

For more information, visit altorfer.com, plote.com and cat.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

“We’ve done five 980 rebuilds over the past eight years,” said Dan Plote, president of Plote Construction Company. “We’ve had a lot of success with it, and it’s more affordable than a brand new 980.”

AXCS Equipment, a manufacturer of aerial lift equipment, announced Paul Michaels as the company’s new group product manager. One of Michaels’ primary responsibilities will be to work on the development and deployment of the company’s new and expanding product portfolio.

He will be responsible for overall customer experience and product strategy by translating market needs and determining how both legacy and AXCS Equipment products ideally exceed market expectations in each segment to fulfill customer requirements.

“AXCS Equipment has an amazing growth outlook, with plans to add a significant number of new aerial products in the coming years,” Michaels said. “Safety and quality are two of our core principles and that will be a primary focus as we roll out these new products. We want to ensure that not only can customers safely use our products, but that they’re also benefiting from equipment that provides world-class quality.”

As group product manager, Michaels will deploy the AXCS Equipment product portfolio strategy, which entails the existing portfolio and new product categories including larger-capacity scissor lifts, vertical mast lifts, articulated booms, telehandlers and other products.

Michaels brings more than 25 years of product management experience to his new role. He most recently worked with Briggs & Stratton in its commercial lawn mower equipment product line division. Previously, he spent 12 years with Rexnord, a heavy power transmission company, in various global and senior product manager positions. In each

role, Michaels developed product strategies and solutions to make equipment more innovative, safer and more efficient — a mindset he carries with him as AXCS Equipment’s group product manager.

“Paul’s established record of enhancing brands will be a great asset to the AXCS Equipment team and will directly benefit our customers,” said Eric Liner, CEO of AXCS Equipment. “His strategic approach to product management will be valuable in growing our new brand identity and our expanding product offering. There are big happenings on the horizon for AXCS Equipment and Paul’s role will be largely connected to helping shape our future.”

For more information visit axcs.com.

By Katherine Petrik CEG EDITORIAL ASSISTANT

As of July 1, 2025, one of the Midwest’s most successful organizations rebranded as DIGIN Midwest.

“I get this question, ‘Why DIGIN Midwest?’,” said Chris Glassing, of American Cast Iron Pipe Company and DIGIN Midwest member. “Why are we rebranding?”

Glassing explained that it isn’t changing the organization — “Its better identifying who we serve and what we’re doing.”

tions. MUCA also became a chapter of the National Utility Contractors Association (NUCA).

“MUCA has done a great job and has become a model for other organizations like us across the country,” said Glassing. “As we continue to grow, we want to be able to continue to serve and

In addition, DIGIN Midwest provides online and in-person courses on safety, training, certification and management for pipelaying and erosion control.

“MUCA’s been around for a long time, and with the rebrand of DIGIN Midwest, that broadens us,” said Luke Minger of Minger Construction.

The Minnesota Utility Contractors Association (MUCA) was founded in the 1970s to better represent utility workers in the larger construction industry. Goals included representation and promotion of utility workers and better relationships between contractors, government agencies, labor and engineers, as well as improving business condi-

expand in those capacities.”

DIGIN Midwest lobbies at the state and federal level to increase funding for projects; advocates to avoid harmful legislation and regulations; and works to increase support for the underground utility industry.

“It doesn’t hold us just to Minnesota. It doesn’t hold us just to utility contractors. We want to be able to help the industry as a whole.”

“We Do Good Work” is not only the organization’s motto but is the core of DIGIN Midwest.

“That hard work. That dedication. The passion of our contractors. The passion of our leadership is still there,” said Matt Brenteson of Brenteson Companies. “We just want to share that with a broader group of people.”

For more information, visit diginmidwest.org. CEG

McCann Industries Inc. 543 S Rohlwing Rd. Addison, IL 60101 630-627-0000

1360 N Rand Rd. Wauconda, IL 60084 847-526-9444

23921 S Northern Illinois Dr. Channahon, IL 60410 815-467-4480

www.McCannOnline.com

Miller-Bradford & Risberg, Inc. W250 N6851 Hwy 164 Sussex, WI 53087 262-246-5700 Fax: 262-246-5719

DeForest, WI 608-222-9191

Eau Claire, WI 715-832-3443

De Pere, WI 920-338-5800

Marathon, WI 715-443-6000

Negaunee, MI 906-475-4181

www.miller-bradford.com

429 Haven Hill Road

Shelbyville, KY 40065 502-633-9928

www.reprents.com

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

An operator completes the tasks in the “Stay On Track” course with a Cat 265

FABICK from page 25

“From hosting today’s Global Operator Challenge to showcasing our autonomous equipment for hands-on demos, it’s been an exciting and engaging event. We’re grateful for the strong turnout and proud to recognize the vital role our customers play — not only in our success at Fabick Cat, but in the communities we serve.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

The “Precision Tracktor” course included pushing a barrel into a designated area with a Cat D3 dozer. One winner will move on to the next stage of the Cat Global Operator Challenge.

are

vice president of sales, Fabick Cat; and Bret Buchmann of A&B Lawncare and Snow Removal, Rhinelander, Wis.

Tim Bosman, who teaches technology education at Gresham High School, looks over the demonstration of a Cat compact track loader with Cat Command remote operation.

Barry Poole (L) of South Park Metal Works, Alpine, Wyo., and Jim Radtke of Radtke Farms were impressed with the work Fabick Cat did to restore this Cat 980G wheel loader.

INDIANA MACALLISTER MACHINERY Heavy Equipment Rental Locations www.macallister.com Indianapolis HQ 317-545-2151 Fort Wayne 260-483-6469 Lafayette 765-449-8191 Terre Haute 812-478-3155 South Bend 574-288-6622 Washington 812-254-1712

KENTUCKY OHIO CAT www.OhioCAT.com Richwood 859-372-4665 859-282-4343 (Rental)

MINNESOTA ZIEGLER CAT www.ZieglerCAT.com Minneapolis 800-352-2812 Brainerd 877-829-9850 Buhl 800-446-9795 Columbus 866-982-5656 Crookston 800-422-5782 Duluth 800-421-3831

740-636-2429 740-636-2430 (Rental) Youngstown 330-530-9010 330-799-1800 (Rental) Zanesville 740-453-0563 740-455-8400 (Rental)

With increased construction activities worldwide, rapid urbanization and an expanding mining sector, the global excavator breaker market is projected to grow significantly to an estimated $3.5 billion by 2032.

As a result, hydraulic breaker technologies in mining and aggregate applications have evolved rapidly to include advancements that are focused on optimizing breaking efficiency, reducing operating costs and minimizing downtime on the job.

To deliver performance and reliability options for this growth trajectory, Toku America Inc. developed its Striker rock breaker system consisting of heavy duty, mid-range and mobile system options. The systems feature a versatile boom that allows the powerful hydraulic breaker to reach into the crusher’s mouth — effectively reducing oversized boulders and clearing any blockages in the hopper, according to Toku.

All systems are custom engineered to meet specific crusher and aggregate material application demands in a wide range of sizes and reach — nominal max horizontal reach ft., max horizontal reach ft. and max vertical reach ft.

Heavy Duty Rock Breaker: Essential for permanent rock breaking in demanding environments, these systems provide the safest solution for managing bridging, material build-ups and oversized rocks.

Features include:

• maximizes the hydraulic hammer’s performance potential;

• shock-absorbing pedestal mount improves stability;

• advanced control system ensures safety and reliability while remaining user-friendly;

• constructed from high-strength steel alloys — ensuring durability and resistance to torsion and buckling; and

• durable, heavy-duty hydraulic cylinders enhance productivity over extended periods.

Mid-Range Rock Breaker: Designed to strike an optimal balance between lightweight construction and high capacity. The boom pedestal’s larger footprint enhances stress distribution and strengthens the foundation structures. Generally installed above the opening of a primary crusher.

Features include:

• user-friendly remote controls for smooth and agile operation;

• shock-absorbing pedestal mounting;

• heat-treated conical pins;

• anti-lunge cushioning in the hydraulic system;

• unrestricted visibility from the cabin or the operator stand; and

• easy assembly with safe, quick and straightforward operation.

Mobile Rock Breaker: Compact design ideally integrated into portable crushing plants — attaching directly to the

• fits within transport dimensions;

• crafted with precision from high-quality materials;

• turntable-mounted base;

• heat-treated conical pins;

• low-profile height and width design — efficient use of space; and

• stable and easy to install.

Installed at the end of the boom system, Toku’s Striker TNB hydraulic breakers feature a uniquely simple, yet efficient design with only two moving parts — requiring no maintenance, according to the company. Its advanced “accumulator free” technology delivers exceptional impact energy, long life, and low operating costs, according to Toku. Based on the same design philosophy, it also features a complete range of 15 breakers to match a myriad of demanding aggregate application needs.

Features include:

• short, fully enclosed tie rods;

• long-stroke piston: the most efficient design for energy transfer and recoil reduction;

• control valve: “flow through” design reduces hydraulic surge and efficiently controls the breaker operating cycle;

mobile crusher’s structure. By clearing bridged rock and breaking oversized materials in the hopper (without the need to halt operations or reposition equipment), these versatile boom systems can boost productivity by up to 30 percent.

Features include:

• 50/50 piston to tool weight ratio: efficiently transfers the blow energy into the material and reduces recoil;

• dual retainer pins: correct tool alignment and evens tool wear for longer tool and bushing life; and

• cushion chamber: each blow is isolated from the carrier and operator-energy recycled and used for the next blow.

Identifying today’s technologies that can help reduce the effects of the constant beating breakers take in the high-psi conditions associated with mines and quarries are essential to the bottom line. Key factors to consider when choosing the right breaker system include the type of crushing plant, the plant’s tonnage capacity and the size and hardness of the materials being processed.

According to Toku America President, Matt Gruden, “Toku’s Striker rock breaker systems boast three models with a wide array of sizes, reaches and capacity configurations. By customizing these system parameters, mine and quarry operations can easily matchup to their unique aggregate demands — optimizing performance, safety and material output.” Toku also has an engineering team available with more than 40 years of experience to provide guidance and technical support in choosing the rock breaker system specific to customers’ needs, according to the company. The company’s service profile also offers hydraulic breaker rebuild options which include: master seal kit, front tool bushing, spring pins/stopper

retainer pins, labor and return freight. For more information, visit toku-america.com

www.aisequip.com

3600 N Grand River Ave Lansing, MI 48906

517-321-8000

Grand Rapids

600 44th Street SW Grand Rapids, MI 49548

616-538-2400

Northeast Detroit 65809 Gratiot Avenue Lenox, MI 48050 586-727-7502

Saginaw 4600 AIS Drive Bridgeport, MI 48722 989-777-0090

Traverse City 8300 M-72 East Williamsburg, MI 49690 231-267-5060

West Detroit 56555 Pontiac Trail New Hudson, MI 48165 248-437-8121 800-457-8121

www.butlermachinery.com

3630 Miriam Ave Bismarck, ND 58502

701-223-0890

7910 US-2

Devils Lake, ND 58301 701-665-3800

2803 I-94 Business Loop E Dickinson, ND 58601

701-456-1400

3402 36th St SW Fargo, ND 58104 701-280-3100

1201 S 46th St Grand Forks, ND 58201 701-775-4238

1910 27th Ave SE Jamestown, ND 58401

701-251-1400

4950 U.S. Highway 12 Aberdeen, SD 57401 605-225-6240

3601 Deadwood Ave N Rapid City, SD 57702 605-342-4850

20571 Truck Stop Ave Pierre, SD 57501 605-224-5400

3201 N Louise Ave Sioux Falls, SD 57107 605-336-3010

603 10th St NW Watertown, SD 57201 605-954-7100

1715 US Hwy 14 W Huron, SD 57350 605-353-1200

1505 Hwy 2, Bypass E Minot, ND 58701 701-852-3508

www.centralsands.com

4219 E 50th St • Des Moines, IA 50317 800-247-2400 • 515-964-8600

www.rbscott.com

1011 Short St Eau Claire, WI 54701 715-832-9792

17403 County Road 75 NW Clearwater, MN 55320 320-558-8100

www.roadbuildersmachinery.com

1001 S 7th St Kansas City, KS 913-371-3822

4115 S 90th St Omaha, NE 402-331-9200

5601 Fletcher Ave Lincoln, NE 402-325-0447

4949 Juergen Rd Grand Island, NE 308-384-2620

1303 S Chestnut St Norfolk, NE 402-316-4640

TOMRA Recycling has launched its latest generation X-TRACT unit.

The new X-TRACT harnesses the power of X-Ray Transmission (XRT) technology to detect and separate wood waste from impurities like inert materials, metals, heavy plastic and glass based on atomic density.

The sorting system is capable of processing up to 33.6 tons of wood chips per hour, depending on material conditions like moisture content and grain size. It delivers speed and accuracy in removing contaminants, thereby producing high purity recycled wood content to meet industrial production standards, according to TOMRA. The unit comes with a 16,000hour warranty on critical components like the X-Ray source and sensor, demonstrating TOMRA’s confidence in the robustness and longevity of the X-TRACT.

TOMRA’s continuous investment in the global wood segment, combined with the expertise of its skilled in-house engineers and wood processing specialists, has resulted in the latest generation X-TRACT boasting numerous value-add features and capabilities. Many of these are as a direct result of the field-proven and unrivalled success of the X-TRACT in the global mining and metals recycling markets, according to TOMRA.

While X-TRACT effectively separates contaminants from waste wood, GAINnext — TOMRA’s deep learning-based technology for sorting wood by material type — takes sorting granularity to the next level by identifying objects by their shape, size and visual characteristics, enabling the differentiation between various types of wood or wood composites, according to TOMRA.

cent for metals (excluding foil), 98 percent for inert contaminants and 97 percent for heavy plastics.

Innovative features of the new XTRACT include:

• Up to 25 percent reduction in air consumption: X-TRACT now comes with a new standard ejection module which not only delivers greater precision but also reduces the amount of compressed air needed by up to 25 percent, depending on application and infeed material, according to TOMRA. As a result, customers can benefit from significant energy cost savings without compromising throughput rates.

• Sorting accuracy: TOMRA's latest innovation delivers high ejection rates, consistently exceeding 98 per-

This superior performance is the result of robust mechanical hardware, the new standard ejection module, carefully selected X-Ray components and TOMRA’s core technologies, ensuring consistently high throughput and exceptional sorting results, according to TOMRA.

• Enhanced reliability and stability: Engineered for high sorting accuracy and minimal downtime, the new XTRACT delivers long-term sorting stability, improved machine reliability and lower operational costs, according to TOMRA. For improved safety, a dust-resistant design prevents blockages and dust build-up.

The unit’s sensor also comes with a reinforced design that enables the extended component warranty of 16,000 hours. A redesigned catcher hood enables safer and faster maintenance, minimizing disruptions and maximizing uptime.

TOMRA introduced deep learning sorting technology for waste wood recycling in 2021, initially with a high-throughput application for sorting woodchips by type. Since then, its GAINnext technology, trained by TOMRA’s experts using thousands of photos, has evolved to meet the market's growing demand for advanced wood sorting solutions. GAINnext now enables a wide range of wood recycling applications, including the precision sorting of different wood types and composites. It can distinguish between nonprocessed wood (Wood A) and processed wood (Wood B) such as OSB, chipboard and coated materials, according to TOMRA. It also can recover high purity MDF for MDF-to-MDF processing. The purity of recycled wood from complex construction and demolition waste also can be enhanced by identifying and removing large objects of up to 15.7 in.

Jose Matas, head of waste emerging segments at TOMRA Recycling, said: “We understand the critical importance of uninterrupted 24/7 operations for our customers, and with the latest advancements in our X-TRACT, we are now even better equipped to support the industry. Furthermore, the combination of X-TRACT and GAINnext delivers an unprecedented level of purity, resulting in recycled waste wood of near-virgin quality and, ultimately, opening new profitable revenue streams for our valued customers.”

For more information, visit tomra.com/waste-metalrecycling/applications/waste-recycling/wood.

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem , BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

Finlay has introduced the J-1280 jaw crusher, a new addition to its tracked mobile crusher lineup.

Designed to bridge the gap between the J1175 and the larger J-1480, the J-1280 delivers performance in a more transport-friendly package, making it the ideal solution for medium-sized quarries and larger contractors seeking high capacity without the logistical challenges of heavier equipment.

Featuring a large 47 in. x 32 in. jaw chamber, the J-1280 offers a wide gape and throughput capabilities for hard rock applications. Despite its size, the machine is engineered for easier transport, weighing less than the J-1480 while maintaining strength and durability.

Martin Conway, global sales and marketing director of Finlay said, “This balance of size and mobility has been a direct response to strong feedback from the Finlay distribution network, who emphasized the need for a lighter, more transportable model yet with the same jaw dimensions of our highest-selling units in several key regions.”

One of the standout features of the J-1280 is its hydrostatic drive system, according to Finlay. Unlike direct drive alternatives, the hydrostatic setup allows the crusher to continuously operate in reverse. This functionality is critical for clearing blockages quickly and safely, without the need to manually lift mate-

rial from the chamber. The ability to unblock not only improves safety by reducing the need for working at height but also minimizes downtime by eliminating the need for lock-out/tag-out procedures during unblocking.