By Cindy Riley

As the crucial first segment of the West Alabama Highway initiative, the $139 million Linden Bypass is designed to enhance safety, boost regional connectivity and promote economic growth.

The Alabama Department of Transportation (ALDOT) is overseeing construction of the roadway, which will become a four lane divided highway linking U.S. 43 north and south of Linden in the state’s rural Black Belt.

“Work on both the south Linden Bypass and north Linden Bypass has been a success by all measures,” said John Graham, ALDOT Grove Hill area construction engineer. “From the beginning, it was apparent the importance of these projects. They had been talked about for years and have finally come to fruition. Being the first leg of the west Alabama Highway, it was critical these projects be delivered successfully to set the tone for the remainder of the corridor.”

The $55.6 million south project in Marengo County runs from U.S. 43 south of Linden to SR-28, while the $83.5 million north project extends from SR-28 to SR-69. In total, they span 7.7 mi. Once complete, this route will become SR-303.

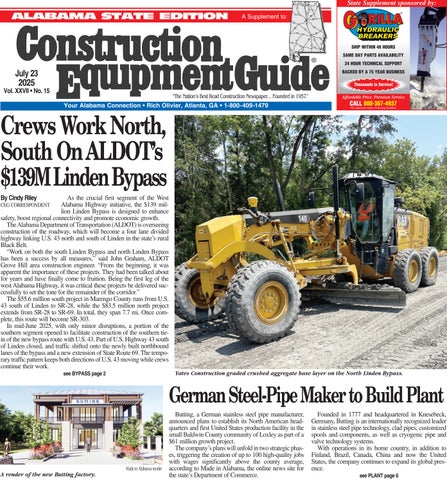

In mid-June 2025, with only minor disruptions, a portion of the southern segment opened to facilitate construction of the southern tiein of the new bypass route with U.S. 43. Part of U.S. Highway 43 south of Linden closed, and traffic shifted onto the newly built northbound lanes of the bypass and a new extension of State Route 69. The temporary traffic pattern keeps both directions of U.S. 43 moving while crews continue their work.

Butting, a German stainless steel pipe manufacturer, announced plans to establish its North American headquarters and first United States production facility in the small Baldwin County community of Loxley as part of a $61 million growth project.

The company’s plans will unfold in two strategic phases, triggering the creation of up to 100 high-quality jobs with wages significantly above the county average, according to Made in Alabama, the online news site for the state’s Department of Commerce.

Founded in 1777 and headquartered in Knesebeck, Germany, Butting is an internationally recognized leader in stainless steel pipe technology, clad pipes, customized spools and components, as well as cryogenic pipe and valve technology systems.

With operations in its home country, in addition to Finland, Brazil, Canada, China and now the United States, the company continues to expand its global presence.

“W.S. Newell & Sons, Yates Construction and construction management support from consultant engineer Volkert have contributed greatly to make these projects what they are,” said Graham. “This new route around Linden will help cut down on large trucks traveling through the downtown area.

“In addition, it will provide overhead crossings over the two railroads in lieu of the at-grade crossings that exist on U.S. 43 in Linden. This will eliminate congestion that occurs from frequent stoppages of trains across 43.”

Work began on the south project in December 2022, while the north project commenced in March 2023. On the south project, grading and work on the AGR and MNBR railway overpasses is finished, with paving nearly done. On the north section, all bridges are complete. Grading has been performed on 50 percent of the route and paving continues.

Graham noted that access has been an issue for crews working on the south bypass.

“With two separate railroads crossing the project, along with two streams requiring concrete bridge box culverts, this project could not be worked in a linear manner,” he said. “The contractor, W.S. Newell & Sons, aided in this by securing permits for a temporary at-grade rail crossing at both railroad locations. With a borrow pit located on the north end of the project, this allowed material to be moved in off-road equipment north to south through the project in lieu of onroad trucks.

see BYPASS page 6 BYPASS from page 1

“On the north bypass, the most challenging part was the topography on the southern end of the project.” He added. “The work was more linear in fashion on this project, and the southern end was balanced as far as earthwork went; however, the topography proved challenging from an erosion control/stormwater perspective.”

Longer wear

TRUST THOMPSO WHERE YOUR SUC

C ESS R O ORE SS S S OR E RE COS F FE I L E LI O . E ZE LE E Z L C ERO ER ES R M COM T S OS O P PRO . R PR O I IS OM S M SE E

From grou O RO und-engaging tools to OM o undercarriage and cutting edges, the w wear parts you choose . e matter. groundengaging At Thompson Tractor, we back service that keeps you running k your machine with g.

Expert support when and wher ON TRACTORCCESS IS OUR PRIORITY. re you need it .

Lower opera parts engineered to outlast the rest – and r life ting cost provide

from page

The new Alabama facility will be constructed on a more than 50-acre site in Loxley’s established industrial corridor southwest of Mobile near Alabama’s Gulf Coast.

Positioned just south of Interstate 10, Loxley is a growing community of about 4,000 residents.

“Our decision to locate in Baldwin County was driven by the area’s overall attractiveness to live and work, a skilled labor force, proximity to key transportation routes and welcoming business environment,” Adrian Rochofski, Butting USA’s CEO and managing director, said in a statement.

“We’re excited to grow our footprint in the United States and call Loxley our home in North America.”

A formal project announcement event was held July 9, 2025, in Loxley with representatives from Butting, the Baldwin County Economic Development Alliance (BCEDA), the City of Loxley, the Baldwin County Commission and the Alabama Department of Commerce.

“Butting’s decision to launch its North American headquarters and manufacturing operation in Baldwin County is a powerful endorsement of Alabama’s strengths in workforce readiness, industrial infrastructure and global business relationships,” said Ellen McNair, secretary of the state Department of Commerce.

“This investment not only brings high-paying jobs to Loxley but also supports the growth of a German industry cluster that will generate long-term economic benefits across the region,” she said. “We’re proud to welcome Butting to Alabama, and we look forward to building a lasting partnership.”

The initial phase of the project will focus on establishing Butting’s North American headquarters, as well as its engineering functions, the fabrication of high-quality stainlesssteel spools, components and cryogenic pipe systems, Made in Alabama reported.

Following that, the second phase will see a vertical integration buildout of the U.S. production operations, in addition to integrating a pair of stainless-steel-welded pipe mills, an expansion to further its cryogenic production portfolio and expanded fabrication capabilities — all to serve key industrial sectors across the United States.

The official groundbreaking of Phase 1 is expected in fall

2025, with construction and hiring due to ramp up during July 2025.

Butting’s investment project marks a major milestone in Baldwin County’s rise as a hub for advanced manufacturing and international business, according to local officials.

“The project is the culmination of the hard work that we as partners have put in to develop our community, product, workforce and infrastructure,” said Lee Johnson, BCEDA’s executive vice president. “Butting’s decision to locate their North American headquarters in Baldwin County is evidence that we are a premier location in the United States for international companies.”

The addition of Butting not only enhances South Alabama’s industrial portfolio but also reinforces Baldwin County’s reputation for attracting world-class companies, high-wage job creation and supporting long-term economic development investments.

Work to repair and strengthen a leaking dam that provides drinking water to several Birmingham area suburbs will restart after being halted over cost concerns.

Leaders of the city’s regional water board on July 7, 2025, agreed to continue the $28 million first phase to repair Lake Purdy in Shelby County just days after pausing the construction.

“The board recognizes the seriousness of this project,” said Phillip Wiedmeyer, a member of the Birmingham Water Works Regional Board (BWWB) and a former engineer of Alabama Power. “We are certainly concerned about the safety of the public and we are not going to take any action that is going to jeopardize that.”

Lake Purdy Dam has been classified as a high hazard by the U.S. Army Corps of Engineers (USACE) due to the catastrophic impact that any breach to the structure would have on nearby communities.

Repair work also is intended to protect the drinking water supply source for suburban Birmingham suburbs, including Homewood, Hoover, Mountain Brook and Vestavia Hills.

BWWB leaders have long discussed the need for upgrades at Lake Purdy Dam, according to Al.com.

Still, some board members told the statewide online news source that there remain concerns over the overall cost of the project, in addition to previous assessments of the structure, and how the utility would pay for recommended fixes and improvements.

Last year, the former iteration of the current BWWB approved a $78.7 million contract with Thalle Construction Co., based in North Carolina; and $6.8 million in management fees for Arcadis North America, which maintains an office in Birmingham; Virginia-based Schnabel Engineering; and A.G Gaston Construction in Birmingham.

Much of that project was to be financed through bond proceeds along with a $171 million loan program through the federal Water Infrastructure Finance and Innovation Act loan.

However, leaders of the new BWWB have questioned the structure of the federal loan.

Water Works Regional Board Chair Tommy Hudson said on July 7, 2025, that Mac Underwood, the board’s general manager, would return with possible options to restructure the loan.

The unanimous vote to resume work came after board members met in a closed-door executive session that lasted about 40 minutes, Al.com noted.

BWWB members agreed that current work at the dam must continue, especially since some site preparation during the construction process has further weakened the centuryold structure.

Halting construction and restoring the area to previous conditions would also cost about $10 million, officials have said in the past.

Patrick Flannelly, an engineer with Arcadis North America, the BWWB’s independent engineering firm, had urged them to resume work on the dam.

“Failure of this dam results in possible loss of life,” he warned board members during a work session July 2. “This dam is not safe enough.”

While some work could be delayed, Flannelly urged the board to take immediate action to fortify the dam to prevent an overflow disaster that would impact thousands of homes.

BYPASS from page 2

Workers on the south project still must complete the transition at the southern tie-in with existing U.S. 43. Crews on the north project must finish work adjacent to existing SR-69 on the north end. This will allow temporary traffic shifts to complete the remaining phases of the project.

There are five sets of twin bridges, for a total of 10 structures. South project bridges consisted of spread footers with 12 by 53 H piles. Decking consisted of three simple spans supported by Type III AASHTO girders. All bridges on the south project were of this design.

For the north project’s Chickasaw Bogue, Whirl #1 and Whirl #2 bridges, foundations called for 24-in. steel galvanized pipe piles. There were five at each bent.

Graham said pipe piling required driving resistance of 432.5 tons. Static and dynamic testing revealed actual inplace resistance at 940 tons. The estimated pile lengths were 110 ft. Production piling was 83 ft. in length. This put

tip elevations at 14 ft.

Regarding site work, on the south project, the natural material consisted of high shrink/swell Black Belt clays.

“This made work very challenging in wet conditions,” said Graham. “Material would really ball up in equipment, requiring additional horsepower to move. On the north project, the material was more sandy clay in nature. There is a ridge of sandy material that crosses through the project on the north side of SR-28. This ridge is the location of borrow pits for both projects.”

Between the two efforts, approximately 2 million cu. yds. of borrow was needed, along with 1.5 million cu. yds. of unclassified/cut material. As much as 10,320 cu. yds. of concrete has been required on the projects, as well as 183,000 tons of asphalt.

Heavy equipment used on the projects has included Cat, Deere and Komatsu dozers; Cat, Deere, Komatsu and Hitachi trackhoes; Link-Belt and Kobelco cranes; rigid frame Cat off-road trucks; Volvo articulating frame trucks;

and Cat scrapers.

Graham said that, as with any construction project, the weather has played a big role in the slowdown of schedules.

“The first summer season of work was challenging, due to above average rainfall, much like this year. Combining that with the stage of work we were in at that time of cut/fill and trying to get borrow lifts in, work would shut down for days at a time. Thankfully, we have had some dry fall seasons which allowed us to catch up and keep the overall schedule on track. The stage of work we are at now has insulated us from the lingering effects of rainfall.”

All work should be completed later this year. Graham said he’s thankful to work on a project of this magnitude.

“Being in a rural area, these types of projects are few and far between. It makes it even more special to be a resident of this area, knowing the lasting impact it will have for generations.” CEG

(All photos courtesy of John Graham/ALDOT.)