Page 4 • June 23, 2021 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Job Represents Firm’s First Spliced Concrete Beam Bridge

(Thomas French photo)

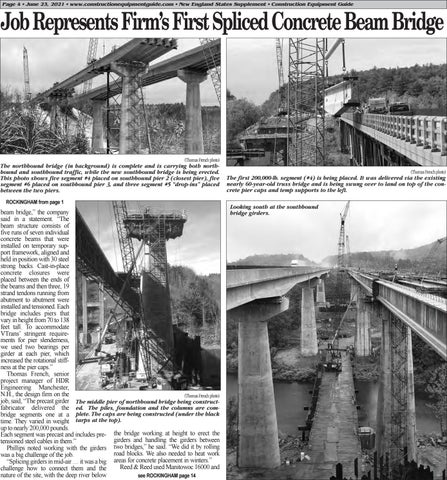

The northbound bridge (in background) is complete and is carrying both northbound and southbound traffic, while the new southbound bridge is being erected. This photo shows five segment #4 placed on southbound pier 2 (closest pier), five segment #6 placed on southbound pier 3, and three segment #5 “drop-ins” placed between the two piers. ROCKINGHAM from page 1

beam bridge,” the company said in a statement. “The beam structure consists of five runs of seven individual concrete beams that were installed on temporary support framework, aligned and held in position with 30 steel strong backs. Cast-in-place concrete closures were placed between the ends of the beams and then three, 19 strand tendons running from abutment to abutment were installed and tensioned. Each bridge includes piers that vary in height from 70 to 138 feet tall. To accommodate VTrans’ stringent requirements for pier slenderness, we used two bearings per girder at each pier, which increased the rotational stiffness at the pier caps.” Thomas French, senior project manager of HDR Engineering Manchester, N.H., the design firm on the (Thomas French photo) job, said, “The precast girder The middle pier of northbound bridge being constructfabricator delivered the ed. The piles, foundation and the columns are combridge segments one at a plete. The caps are being constructed (under the black time. They varied in weight tarps at the top). up to nearly 200,000 pounds. Each segment was precast and includes pre- the bridge working at height to erect the girders and handling the girders between tensioned steel cables in them.” Phillips noted working with the girders two bridges,” he said. “We did it by rolling road blocks. We also needed to heat work was a big challenge of the job. “Splicing girders in mid-air … it was a big areas for concrete placement in winters.” Reed & Reed used Manitowoc 16000 and challenge how to connect them and the nature of the site, with the deep river below see ROCKINGHAM page 14

(Thomas French photo)

The first 200,000-lb. segment (#4) is being placed. It was delivered via the existing nearly 60-year-old truss bridge and is being swung over to land on top of the concrete pier caps and temp supports to the left. Looking south at the southbound bridge girders.