1

11

THE NEW ENGLAND EDITION

A Supplement to:

95

1

201 16 9

26

2

1 3

91

89

2

95 3

2 2 7

1

93

495

16

89 4

89

February 22 2017

FORMERLY

95

202

7

®

91

9

95

93

2

95 2

93 90

90

7

95 91

7

495 6 195

395

95

Vol. l • No. 4

91

3

84 6

84

95

E

Q

6

u

I

P

M

E

N

t

g

u

I

d

E

95

“The Nation’s Best Read Construction Newspaper… Founded in 1957.”

Your New England States Connection • Amanda Hogeboom-guilfoyle 1-800-988-1203 Specializing in:

Demolition, Portable Crushing, Material Sales, C & D Recycling, Land Clearing & 30-115 Yd. Trailers Call for Pricing

Crews Clean Up Contaminated Starmet Corporation Buildings

2208 Plainfield Pike • Johnston, RI 02919 401-943-7100 • Fax: 401-647-5041

www.jrvinagrocorp.com

LEED Accredited in Waste Management

2017 EZ-Screen 1200XLS

New Option Separate 3 Products

6’x5’ Screenbox Works with 1/2 to 1 3/4 Yd. Loaders, 25 H.P. Kohler Diesel Engine, 24” Conveyor Dumps Screened Product 9’ High

$41,900 plus freight. Other Screeners Available

ArguS INduStrIAl CO.

www.ez-screen.com

GIVE US YOUR HAMMER!

• Repairs • Rebuilds • Replacement Parts in Stock

30% off same class Ramfos hammer with competitor’s trade in

61 Silva Lane • Dracut, MA 01826

Call Today (978) 454-3320

WE STOCK RUBBER TRACKS for Over 6,000 Models! Some Used Tracks A & GA Available. NJ, TX, WOUSES WAREH • HIGH QUALITY • FAST SHIPPING • GUARANTEED TO FIT • UNDERCARRIAGE PARTS • FLATPROOF SKIDSTEER TIRES • RUBBER PADS FOR STEEL TRACKS

888-888-1248

866-745-5828

YOUR ONE-STOP HYDRAULIC HAMMER SHOP™ www.foleyengines.com Cat D7F

w NICE SHAPE VERY

Phil (413) 427-7171

New Hydraulic Hammers. Remanufactured Hammers. Hammer repairs/rebuilding with free area pickup. Hammer toolbits delivered to your site!

CALL 888-81-GORILLA(46745) *Some restrictions apply

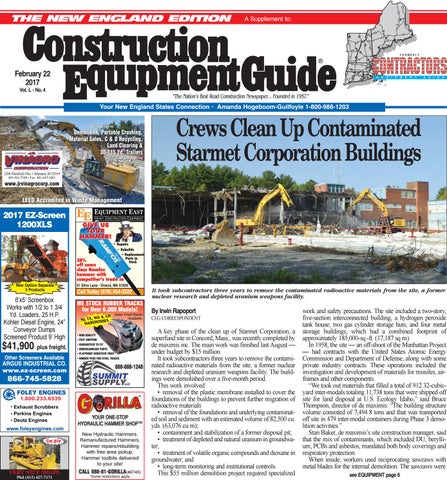

It took subcontractors three years to remove the contaminated radioactive materials from the site, a former nuclear research and depleted uranium weapons facility.

By Irwin rapoport

CEG CORRESPONDENT

A key phase of the clean up of Starmet Corporation, a superfund site in Concord, Mass., was recently completed by de maximis inc. The main work was finished last August — under budget by $15 million. It took subcontractors three years to remove the contaminated radioactive materials from the site, a former nuclear research and depleted uranium weapons facility. The buildings were demolished over a five-month period. This work involved: • removal of the plastic membrane installed to cover the foundations of the buildings to prevent further migration of radioactive materials • removal of the foundations and underlying contaminated soil and sediment with an estimated volume of 82,500 cu. yds. (63,076 cu m); • containment and stabilization of a former disposal pit; • treatment of depleted and natural uranium in groundwater; • treatment of volatile organic compounds and dioxane in groundwater; and • long-term monitoring and institutional controls. This $55 million demolition project required specialized

work and safety precautions. The site included a two-story, five-section interconnected building; a hydrogen peroxide tank house; two gas cylinder storage huts; and four metal storage buildings, which had a combined footprint of approximately 185,000-sq.-ft. (17,187 sq m). In 1958, the site — an off-shoot of the Manhattan Project — had contracts with the United States Atomic Energy Commission and Department of Defense, along with some private industry contracts. These operations included the investigation and development of materials for missiles, airframes and other components. “We took out materials that filled a total of 912 32-cubicyard inter-modals totaling 11,738 tons that were shipped off site for land disposal at U.S. Ecology Idaho,” said Bruce Thompson, director of de maximis. “The building structure volume consisted of 7,494.8 tons and that was transported off site in 479 inter-modal containers during Phase 3 demolition activities.” Stan Baker, de maximis’s site construction manager, said that the mix of contaminants, which included DU, beryllium, PCBs and asbestos, mandated both body coverings and respiratory protection. When inside, workers used reciprocating sawzaws with metal blades for the internal demolition. The sawzaws were see EQuIPMENt page 6