Cost,availabilityandoperationhavelimitedthepro liferation of electric heavy construction equipment. Compact machines powered by electricity have been morevisibleonjobsitesoverthepastsixyears,where asbigrigshavepresentedmoreofachallengeforman ufacturers to roll out. That hasn’t stopped progress, though.

The bottom line, admittedly, is it’s proven costly to invest in electric construction machines.

Choices have been limited for fleet managers on a budget. And frequent battery recharging has made the see ELECTRIC page 88

The arrival of wireless jobsite charging will enhance the opportunity to charge a machine during idle times. The operator would top it off like a cell phone.

Sunbelt Rentals is committed to making it easy to get the equipment you need. Backed by a vast network of rental locations and the industry’s broadest fleet, our local team of resourceful problem solvers can deliver a trouble-free rental experience. No matter the project, we have the knowledge, experience and equipment to help you complete any job. At Sunbelt Rentals, we are here to Make It Happen for you. Visit sunbeltrentals.com

Mid Country Machinery threw a party to celebrate the company’s 25th year in business. More than 500 guests attended the festivities, held at the company’s Fort Dodge, Iowa, facility on Oct. 20.

Huber Maintainer recently introduced its new Huber M-850-E maintainer, which has kept the features and versatility of the legacy Huber maintainer, while incorporating modern components.

Gradall Industries and the Association of Equipment Manufacturers (AEM) hosted United States Representative Bill Johnson (OH-06) for an I MakeAmerica event at Gradall's facility in New Philadelphia, Ohio.

The Outdoor Power Equipment Institute’s (OPEI) Equip Exposition (Equip Expo) set records this year with both exhibit space and attendance reaching new highs for the show formerly known as the GIE+Expo.

The Historical Construction Equipment Association’s 36th annual International Convention & Old Equipment Exposition was held at the National Construction Equipment Museum in Bowling Green, Ohio, Sept. 23 to 25, 2022.

The Smart X-Care Machine Monitoring Center (MMC) is a centralized location that receives and disseminates machine telematics data as part of Doosan’s new and enhanced subscription-based offering to its customers.

After making a 1,500-ft. sidewalk on the back side of a pond, a community couldn’t build the accompanying bridges to connect the sidewalk to the rest of the complex.

AKenworth T680 Next Generation will transport the 2022 U.S. Capitol Christmas Tree from the National Forests in North Carolina to Washington, D.C., with stops en route to a full slate of community celebrations.

Jennifer Rumsey, president and chief executive officer of global power solutions technology leader Cummins Inc., will deliver the keynote address at Green Truck Summit during Work Truck Week 2023.

Kirby-Smith Machinery (KSM) has hired Dennis Cox as its new director of Smart Construction. Cox will be responsible for the KSM’s strategy and growth initiatives related to Komatsu Smart Construction.

Brad Mohns is the owner and president of HitchDoc, a manufacturer of consumer and industrial products for agricultural, construction and heavy equipment industries. A lot has transpired in three decades.

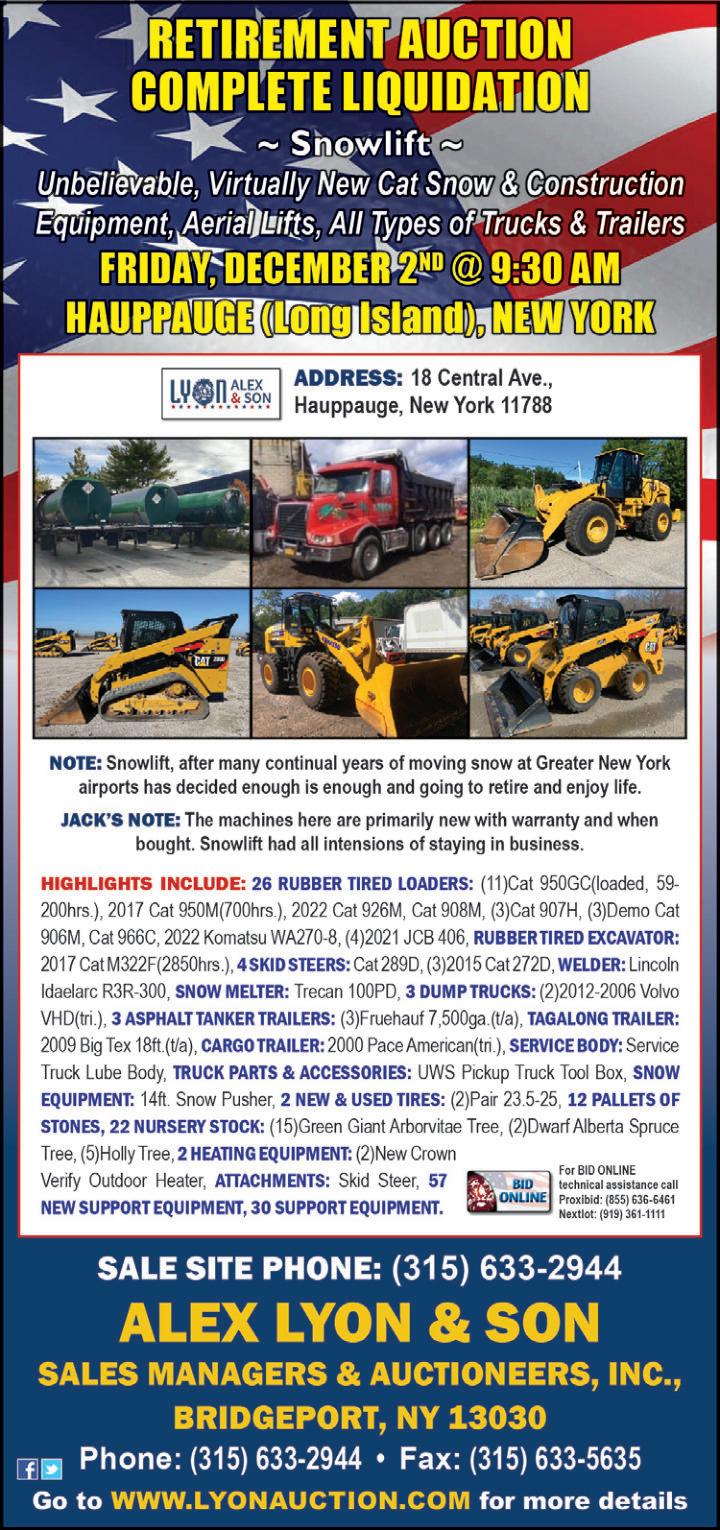

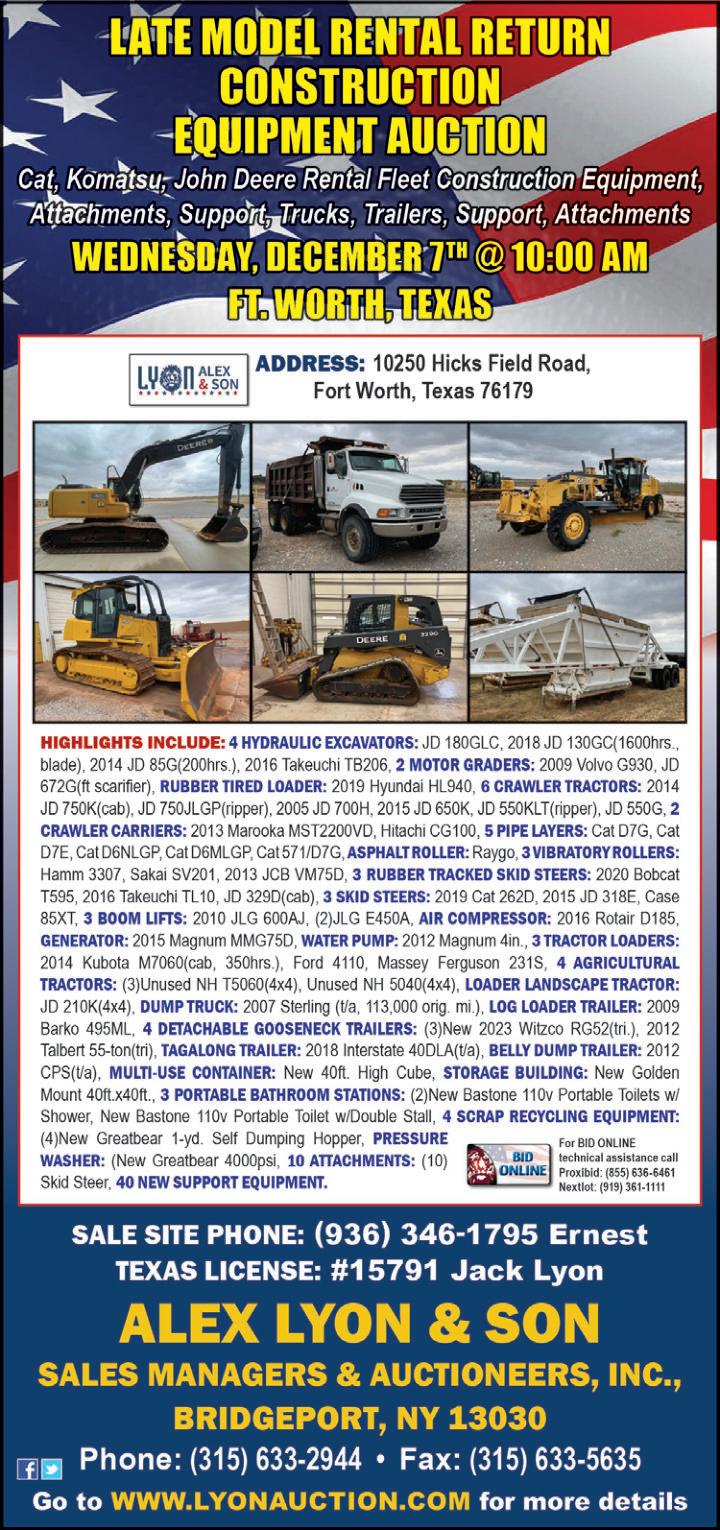

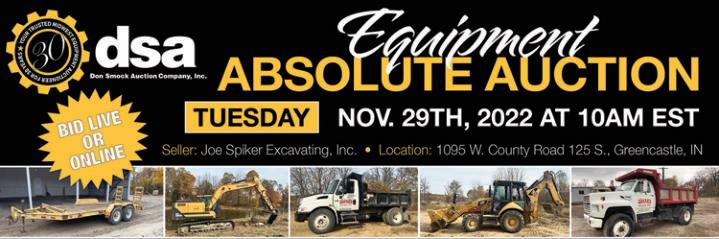

Jeff Martin Auctioneers’ Northeast Ohio Construction and Transportation

Construction Equipment Guide Midwest Edition (ISSN 1081-7034) is published bi-weekly by Construction Equipment Guide Ltd. Advertising and Editorial Offices are located at 470 Maryland Dr., Ft. Washington, PA 19034. Toll Free 800/523-2200 or Fax 215/885-2910. Annual Subscription Rate $65.00. Call for Canadian and foreign rates.

Periodicals postage paid at Ft. Washington, PA and at additional mailing offices. POSTMASTER: Send address changes to Construction Equipment Guide Midwest Edition, 470 Maryland Dr, Ft. Washington, PA 19034.

Contents Copyrighted ©2022, by Construction Equipment Guide, which is a Registered Trademark, registered in the U.S. Patent Office. Registration number 0957323. All rights reserved, nothing may be reprinted or repro duced (including framing) in whole or part without written permission from

Mid Country Machinery threw a party to celebrate the company’s 25th year in business. More than 500 guests attended the festivities, held at the company’s Fort Dodge, Iowa, facili ty on Oct. 20.

Vendor representatives from JLG, Bell, Sany, BOMAG, Kobelco, Hitachi,Leica,Sidump’r,Etnyreand more were present, and food was provided byAmigos of Fort Dodge.

Inaddition,guestsenteredadraw ing for various door prizes. Winners of the grand prize drawings for a brand new 2022 SANY SY35 miniexcavator were Nate Galles of Jensen Builders of Fort Dodge, Iowa, and Quality Communications of Dennison, Iowa.

Mid Country Machinery’s story

began in 1997, when Bud PeCoy and Lucas Peed realized there was a need for used heavy equipment in Iowa. Their enterprise has grown to include four locations in Iowa: Des Moines, Fort Dodge, Sioux City and Waterloo; and one location in Syracuse, N.Y.

“When we started, we never looked back,” said PeCoy, speaking onbehalfofthecompany’sfounding executive team. “There were predic tions that we would be broke in the first year of business, but that just motivated me. I never looked back.”

PeCoy credits his business part ners — co-founder Lucas Peed and longtime partners Mark Swedlund and Bob Conaway — with helping to grow the company from a used equipment outlet to a five-location

dealership.

Mid Country is an authorized dealer of ASV, Bell, Bergmann, BOMAG, Etnyre, Terex Fuchs, Gehl, Hitachi, JLG, Kobelco, LinkBelt, Magni, Manitou, RSS, Sakai, SANY, Sideump’r, Skytrak and Yanmar.

PeCoy attributes the company’s success to his team and to customer service.

“One thing that we as a team have inagreementistonotslowdownand to make sure we remain focused on our customers first, to try to give them the best and easiest experience possible,” he said. “We truly value our relationship and without them we have nothing. We fully intend on taking Mid Country Machinery to a higher level.” CEG

Mid Country Machinery threw a party to celebrate the company’s 25th year in business. More than 500 guests attended the festivities, held at the company’s Fort

Iowa, facil ity on Oct. 20.

HuberMaintainerrecentlyintro duced its new Huber M-850-E maintainer, which has kept the fea tures and versatility of the legacy Huber maintainer, while incorpo rating modern components and manufacturing processes to satisfy safety, dependability, productivity and operating costs expected of today’s construction equipment.

The Huber maintainer provides precision blade control, ease of operation, a small stable footprint, closeturningcapability,transporta bility and reliability, according to the company. Contractors who presently own Huber maintainers believe that the machine is an indispensable asset on large or smallprojectsdeliveringacompet itive advantage over other rock grading solutions.

“For 50 years the Huber main tainer has been our precision grad ing solution,” said John Reynolds of ST Paving in Waterbury, Vt. “We have not found a skid steer, small motor grader or other two axle solution that performs as well or is as easy for new operators to master.”

Edward Huber founded the Huber Manufacturing Company in Merion, Ohio, incorporating the business in 1875. Huber’s first machines were a steam engine and a grain thresher. From there, the company began manufacturing road construction equipment in

Safety features include seat belt engine start interlocks; park/drive lever and drive pedal interlock; back up alarms; high way lighting systems; amber beacon; fully adjustable seat, allowing sitting or standing operation; slow moving vehicle sign; DOT reflectors; maintenance-free wet disk service and parking brakes; and a fire extinguisher.

1905, introducing its steam road roller. In 1920, Huber’s self-pro pelled maintainer, an early prede cessor of today’s M-850-E was introduced.

Following World War II, the company made the decision to switch its focus solely to road con struction equipment. Its offerings included motor graders, rollers, cranes and maintainers.

By the late 1960’s, A-T-O Corporation purchased Huber and soon moved operations from

Marion, Ohio, to Goose Creek, S.C., eventually selling Huber to Figgie International.

In 1994, Don Braden, former engineer and service manager of Huber, purchased the Huber line and returned Huber to its roots in Ohio,asadivisionofhisnewcom pany, Enterprise Fabrications.

As the company grew, Huber moved to a new facility in Iberia, Ohio, only 20 mi. from its original home in Marion. Currently, the companyoperatesnearFargo,S.D.

The M-850-E features a new drive train including a Tier IV Final 74-hp Cummins 3.8-L engine (no DEF required); a digital engine monitor display; Linde hydrostatic drive pump and motor; a Dana two speed transmission; and a Dana 45 percent limited slip drive axle.

The M-850-E features a new drive train including a Tier IV Final 74-hp Cummins 3.8-L engine(noDEFrequired);adigital engine monitor display; Linde hydrostatic drive pump and motor; a Dana two speed transmission; and a Dana 45 percent limited slip drive axle. This drive package and a ballasted machine weight of 13,300 lbs. delivers traction and pushing power that far exceeds application requirements, accord ing to the company.

The electronic foot controlled hydrostatic drive makes travel operationeasyandsmooth.Amax imum travel speed of 18 mph enables the maintainer to move along in traffic from one job site to another and allows the operator to select a precise travel speed in “grade mode” from 0-6 mph on a touch screen display.

Safety features include seat belt engine start interlocks; park/drive lever and drive pedal interlock; back up alarms; highway lighting systems; amber beacon; fully adjustable seat, allowing sitting or standing operation; slow moving vehicle sign; DOT reflectors; maintenance free wet disk service and parking brakes; and a fire extinguisher.

Standard equipment includes all

safety features, a 6-ft. bull blade, white powder coat finish and van dalismprotection.Availableoptions include a 9- or 10-ft. moldboard; moldboard hydraulic float; front work lights; rear work lights; turf orlugdrivetires;rearwheelballast; tow hitch; and special paint colors.

Huber Maintainer is looking for dealers interested in representing its products in many territories. The company is forecasting sales of 50 to 100 units per year and believes there are additional untapped market segments includ ing government sales, forestry, concrete, general construction and rental applications that will ensure continuedgrowthwithpropermar keting attention.

TheHuberMachineryMuseum, located at 220 East Fairground St. Marion,Ohio,detailsthehistoryof the company, its machines and how Edward Huber’s inventions received more than 100 patents for farming and road construction equipment.

Visitors are invited to see and touch the machines on display, which include tractors, steam shovels and maintainers.

For more information, visit hubermaintainer.com.

I Make America, AEM’s national grassroots campaign, is the voice of the 2.8 million men and women of the equipment manufacturing industry who make the equipment that build, power and feed the world.

Gradall Industries and the Association of Equipment Manufacturers (AEM) hosted United States Representative Bill Johnson (OH-06) for an I Make America event at Gradall's facility in New Philadelphia, Ohio.

I Make America, AEM’s national grass roots campaign, is the voice of the 2.8 mil lionmenandwomenoftheequipmentman ufacturing industry who make the equip ment that build, power and feed the world. Each year AEM and its member companies hosts dozens of lawmakers at equipment manufacturingfacilitiestohighlightthepoli cies needed to strengthen U.S. manufactur ing and move the industry forward.

“In Ohio, the equipment manufacturing industry supports 164,000 jobs and con tributes $16 billion annually to our state’s economy,” said Johnson. “Currently, the manufacturing industry is facing steep chal lenges—includingsupplychainissues,chip shortages and inflation. Elected officials mustcontinuetosupportlegislationthatbol

sters America’s manufacturing industry. That’s why I voted in support of the CHIPS PlusAct that would build, expand and mod ernize semiconductor chip manufacturing here in Ohio and help alleviate the strain chip shortages are putting on manufacturers that require microchips for their end prod ucts.ThankyoutoGradallIndustriesandthe Association of Equipment Manufacturers forhostingmeandprovidinginsightonhow Congress can better support the manufactur ing industry.”

Johnson toured Gradall’s New Philadelphia headquarters, where he saw the manufacturing operations firsthand. During the visit, Johnson met with employees and touched on the importance of American manufacturing and discussed the policies he has championed in Congress, including the CHIPSandScienceAct,theOceanShipping Reform Act and the United States-MexicoCanadaAgreement (USMCA).

“On behalf of all the team members of

Gradall Industries, a company of the Alamo Group, and the Association of Equipment Manufacturers (AEM) hosted United States Representative Bill Johnson (OH-06) for an I Make America event at Gradall's facility in New Philadelphia, Ohio.

Gradall,Iwouldliketoexpressmythanksto Congressman Johnson for visiting our New Philadelphia facility,” said Mike Haberman, executive vice president, industrial equip ment division of the Alamo Group, parent company of Gradall Industries. “It allowed us the opportunity to emphasize to the Congressman how important workplace development is for the future growth of U.S. manufacturing. Additionally, we were able to discuss the importance of low cost and available energy in order for U.S. manufac turing to remain competitive in an everdeveloping worldwide market,”

“AEM is grateful to Congressman Johnson for his leadership and strong sup port for the equipment manufacturing indus try and the policies that safeguard the fami ly-sustaining jobs our industry supports in Ohio,” said Kip Eideberg, AEM’s senior vice president of government and industry relations. “Now more than ever we need our elected officials to work in a bipartisan fash

ion to tackle our nation’s biggest challenges and advance pro-manufacturing policies that will strengthen domestic manufacturing, bolstersupplychains,investintheAmerican worker and ensure our continued global competitiveness.”

At a time when America is facing one of thegreatesteconomicchallengesinitshisto ry,AEM and I MakeAmerica have brought a record number of state and federal law makers to shopfloors across the country to send a clear message:The equipment manu facturing industry is counting on elected officials to put policy ahead of politics and advance an agenda that will address the highestrateofinflationindecades,persistent supply chain challenges, the need for more workers, and the opportunity to create more family-sustaining jobs and make the United States more resilient.

AEM has more I Make America events planned for Indiana, Louisiana, Minnesota and Ohio before the end of the year.

Each year AEM and its member companies hosts dozens of lawmakers at equipment manufacturing facilities to highlight the policies needed to strengthen U.S. manufacturing and move the industry forward.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR . . . . . . . . . .$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500 (4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready . . . . . . . . . . . . . . . . . . . . . . .From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote . . . . . . . . . . . . . . . . . . . . . . . .$4,000 to $10,000

(8) Sheepsfoot, 48" and 60", double drum & single drum, tow type . . . . . . . . . . . . . . . . . . .$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready . . . . . . . . . . . . . . . . . . .$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday . . . . . . . . . . . . . . . . . . . . . .$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready . . . . . . . . . . . .$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition . . . . . . . . . . . . . . .$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites . . . . .$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs . . . . . . . . . . . . . . . .$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean . . . . . . . . . . . . . .$49,500

IR 185’s, JD diesels . . . . . . . . . . . . . . . . . . . . . . .CALL

(12) Allmand Light Plants,

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready . . . . . . . . . . . . . . . . . . . . . .$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready . . . . . . . . . . . . . . . . . . . . . .$224,500 Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR . . . . . . . . .$179,000

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR . . . . . . . . . . . . . . . . . . . . . . . . . . . .$72,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites . . . . . . $89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$122,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR . . . . . . . . . . . . . . . . . . .$82,000

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads . . . . . . . . . . . . . . . . . . . . .$49,500

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR . . . . . . . . . . . . . . . . . . . . . . . . . . . .$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR . . . . . . . . . . . . . . . . . . . . .$142,500 Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR . . . . . . . . . .$229,500

w/Liftgates, Good Condition . . . .CALL

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR . . . . . . . . . . . . .$152,500

The Outdoor Power Equipment Institute’s (OPEI) Equip Exposition (Equip Expo) set records this year with both exhibit space and attendancereachingnewhighsfortheshowformer ly known as the GIE+Expo. Held Oct. 18 to 21 at Louisville’s Kentucky Expo Center, the show was once again collaborated with Hardscape North America, an Interlocking Concrete Pavement Institute (ICPI) event.

Billed as the largest trade show for outdoor power, lawn and garden, light construction and landscape equipment, the Equip Expo is geared toward providing a forum in which industry profes sionals can gather, learn and share knowledge, net workanddemoequipmentfromtheindustry’slead ing manufacturers.

The event opened with a Welcome Reception at the Louisville Slugger Field. The show encom passed more than 1 million sq. ft. of trade show exhibit space, including a nearly 30-acre outdoor equipment display and demonstration yard, where attendeeswereencouragedto“Tryitbeforeyoubuy it.” The event also featured a host of educational seminars, certification courses, panel discussions andpresentationscoveringtheissuesofmostimpor tancetothecontinuedsuccessandsafetyofbusiness owners and their employees.

see EXPO page 66

Caterpillar’s Greg Worley spoke about Caterpillar’s focus on versatility, such as this 305 CR mini-excavator equipped with Caterpillar’s newly available TRS (tilt rotate system) for mini-excavators with a grapple attachment.

Tobroco Giant of Cedar Falls, Iowa, was in the demo area for people like Nolan Parsons, owner of Parsons Property Services, Fort Wayne, Ind., to give this Giant G1200 HD a test run. With its low weight (2,750 lbs.), compact dimensions and excellent maneuverability, the Giant G1200 telescopic wheel loader operates with ease in tight spaces.

DEALERS

IOWA

515-986-0262 doosandealers.com/Grimes 319-857-4045 doosandealers.com/Swisher KENTUCKY

BOBCAT OF BOWLING GREEN 270-842-4253 doosandealers.com/Bowling-Green MICHIGAN

CARLETON EQUIPMENT COMPANY 888-380-6420 doosandealers.com/Byron-Center 888-380-6420 doosandealers.com/Chesterfield 888-380-6420 doosandealers.com/Kalamazoo 888-380-6420 doosandealers.com/Saginaw ELLENS EQUIPMENT 989-436-8181 doosandealers.com/Ithaca 231-825-2416 doosandealers.com/McBain OHIO ALTA EQUIPMENT 440-439-4000 doosandealers.com/Oakwood-Village

ILLINOIS

BOBCAT OF MARION 618-985-8920 doosandealers.com/Carterville

BOBCAT OF SPRINGFIELD 217-525-0349 doosandealers.com/Springfield-IL

SARGENT’S EQUIP & REPAIR SERVICES 708-758-2062 doosandealers.com/Chicago-Heights 847-844-4131 doosandealers.com/Gilberts

BOBCAT OF ST. LOUIS 618-397-1847 doosandealers.com/Fairview-Heights

NEBRASKA

BOBCAT OF OMAHA 402-895-6660 doosandealers.com/Omaha

CENTRAL NEBRASKA BOBCAT 308-384-9222 doosandealers.com/Grand-Island 925-606-2451 doosandealers.com/Hastings 925-606-2451 doosandealers.com/Kearney

NORTH DAKOTA

BOBCAT OF MANDAN 701-663-0903 doosandealers.com/Mandan

IRONHIDE EQUIPMENT

701-662-5331 doosandealers.com/Devils-Lake 701-772-5006 doosandealers.com/Grand-Forks 701-572-5050 doosandealers.com/Williston

KANSAS

CENTRAL POWER SYSTEMS & SERVICES 785-462-8211 doosandealers.com/Colby 620-765-3118 doosandealers.com/Garden-City-KS 785-825-8291 doosandealers.com/Salina 316-789-7370 doosandealers.com/Wichita

MISSOURI

BOBCAT OF COLUMBIA 573-886-9435 doosandealers.com/Columbia-MO

BOBCAT OF ST. LOUIS 636-240-9020 doosandealers.com/O’Fallon 636-225-2900 doosandealers.com/Valley-Park

CENTRAL POWER SYSTEMS & SERVICES 816-415-6700 doosandealers.com/Liberty 417-865-0505 doosandealers.com/Springfield-MO

WISCONSIN

SWIDERSKI EQUIPMENT

715-623-4668 doosandealers.com/Antigo 715-693-3015 doosandealers.com/Mosinee 715-669-5255 doosandealers.com/Thorp 715-258-3266 doosandealers.com/Waupaca 715-675-2391 doosandealers.com/Wausau

INDIANA BOBCAT OF ANDERSON 765-643-4222 doosandealers.com/Anderson-IN

B & W EQUIPMENT 800-242-4819 doosandealers.com/Fort-Wayne

BOBCAT OF BLOOMINGTON 812-287-8042 doosandealers.com/Bloomington

BOBCAT OF COLUMBUS 812-775-1470 doosandealers.com/Columbus

BOBCAT OF EVANSVILLE 812-422-8200 doosandealers.com/Evansville

BOBCAT OF KOKOMO 765-628-2800 doosandealers.com/Greentown

BOBCAT OF INDY 317-787-2201 doosandealers.com/Indianapolis

BOBCAT OF INDY NORTH 317-769-4946 doosandealers.com/Whitestown

RONSON EQUIPMENT CO. 219-696-5680 doosandealers.com/Lowell MINNESOTA LANO EQUIPMENT 952-445-6310 doosandealers.com/Shakopee THECO 763-263-0505 doosandealers.com/Big-Lake

ThenewDoosan® dozerdeliversmorehorsepower,bettervisibilityand easieroperationtohelpyoupushthroughyourbiggestchallenges. Contact your local Doosan dealer for details.

Ron Brenny is operations man ager of the largest of seven scrap recycling yards owned by Cimco ResourcesinIllinoisandWisconsin.

The 26-acre facility in Sterling, Ill., can receive as much as 800 tonsofmaterialaday,fromplastics to electronic waste, but the bulk of it is destined for the site’s Metso mega-shredder. Cars and farm equipment, demolition scrap and industrial metals are meticulously sorted to match orders for shred from nearby mills.

As Brenny said, “We’re pretty full most of the time. We’re using our whole 26 acres. I have a lot of piles.”

But with the arrival of Sterling’s new SENNEBOGEN electricdrive 870 Hybrid material handler, the entire landscape of Brenny’s yard is changing.

Cimco’s current fleet of 17 SENNEBOGEN scrap handlers is comprised of the mid-range units typical for scrapyard applications: 830and835modelsweighinginat 85,000 to 120,000 lbs. In compari son, the new 870 Hybrid is a mon ster: more than 220,000 lbs.

“Our main objective was to get the reach,” Brenny explained. Mounted on a 9-ft. pedestal with a tracked undercarriage, the 870’s 90-ft. boom can reach multiple piles of sorted material without maneuvering. It’s this extended working radius that has changed Sterling’s material handling and stockpiling processes.

Until now, trucks were offloadedatthefarsideoftheyard. To feed the shredder, required material was loaded into trailers and moved up to the shredder’s infeed area, where it was offloaded into piles again. One of the 830 or 835 machines could then move it

onto the infeed belt. Now, with the 870, several steps are removed from the flow of material through the yard.

“Sothatwasourgoal:insteadof transloading everything up to the infeed, we can simply unload right there at the infeed and just grab whatweneedwhenwewanttorun it.”

The new setup is efficient for equipment and for manpower, he said, and it greatly simplifies scheduling the movement of mate rial and really simplifies his life.

Withthe870inservice,notonly can they position more stockpiles close to the infeed, but it can also pile more material.

“We’re actually able to increase ouryardspacebecausewecanpile higher,” said Brenny. “That means we’re using less ground, so we’re opening up more yard now.”

Seeing the impact the 870 has made, Brenny now looks forward tobringinginasecond870toserv

ice the north end of the yard, adding further to Sterling’s total capacity.

When Cimco first decided to look into upsizing its shredder loading equipment, the Sterling team was open to all options. Initially, Brenny and his Yard Superintendent, Mike Kapple, and Cimco CEO John Gralewski were attracted to a tower crane. However,avideodemonstrationof the 870 changed their minds.

“They were just showing the machines at work side by side, loading a barge. And I started counting. And I could see how many cycles the 870 made com pared to the other crane. And I’m like, well, that’s a no brainer, guys. That tower crane won’t be able to keep up with my shredder.”

According to Brenny, his opera tors felt the same way when the 870 was finally onsite.

“They’ve been feeding the shredder with an 835 for 15 years; they know the cycle times. We were all impressed with how fast it is for a big machine, with so much stickoutthere.Theygotupinthere and were amazed how fast it goes. It’s been in operation since July and they’re still ecstatic with it.”

While the Sterling yard is now handling material more efficiently, Brenny also is seeing direct sav ings in operational costs with his newest SENNEBOGEN.

The 870 Hybrid features SENNEBOGEN’s distinctive GreenHybridenergyrecoverysys tem. Its simple hydraulic design usestheweightoftheboomtocap ture hydraulic pressure on each downstroke,thenreleasesthepres sure on the next upstroke to assist the lift. As a result, Green Hybrid modelssaveupto30percentofthe machine’s operating cost for ener

gy, according to the manufacturer.

Brenny said that the company made a significant investment in infrastructure to deliver the neces sary power to the 870’s location at the infeed, but he has no regrets.

“That money up front, we’re getting that back every day,” he said, “just by not pulling up to the diesel barrel every day. And we have no downtime for refueling either. The operator just gets in it, hits the button and he’s ready to go all day.

“With the electric, I can say it’s justabigsuperbonusforthemain tenance side. It’s quiet. There are somanymoreissuesinvolvedwith a diesel engine; you got DEF and oil changes and everything else, you know.And that’s all gone.”

Uptime and dependability were key factors for Cimco when the firm began renewing its fleet in recent years.

“We’re all SENNEBOGEN now.Thatwasagoodmoveonour part.”

Brenny also credits the SEN NEBOGEN distributor in his area, Alta Equipment, for its role in keeping his scrap handlers on the job.

“We try to do most servicing ourselves,” he said, “but when it gets into stuff a little over our heads, we can talk to them, and they help us out over the phone or sometimes come out and get the answers and we’re going again. The whole organization is good to work with: the salesman and the mechanics, they’re good.And they have the parts that you need when you need them. That’s pretty impressive. If we say overnight, we get it the next day.”

For more information, visit www.sennebogen-na.com.

Hundreds of dealer representatives and cus tomers from coast-to-coast and a few interna tional dealers converged on the U.S. headquar ters of FAE USA Inc. in Flowery Branch, Ga., for a massive open house event on Oct. 6.

Machine and attachment displays of virtually all of FAE’sproductswereexhibited,andFAEproductman agers and management were on hand to provide their expertise on the line. Giorgio Carera, FAE USA Inc. CEO, provided an update on the latest marketplace news and trends and product manager, and Lee Smith unveiled and gave a brief presentation of the all-new FAE RCU-55 and RCU-75 remote control mulchers. Attendees had the opportunity to be the first in the United States to operate them.

Keynote speakers included AED’s Vice-President Jon Cruthers and Mossy Oak’s Bobby Cole and Gregory Sugg. Outstanding live music came from country music star Lance Stinson and celebrity guest singer Edwin McCain, who also is an FAE spokesman and customer.

Aterrific selection of catered food and deserts were served at lunch time. Midafternoon and beyond meant cocktail and networking time. An array of prizes and exclusive giveaways were presented, including the grand prize of an all-expense paid trip to ConExpo 2023 in Las Vegas, including airfare, hotel and show ticket, which was won by Amanda Campos of L&S Land Clearing and Rock Milling, Boerne, Texas. CEG

ALTA

Bloomington • 855-594-0475

Orand Park • 877-823-4965

Ottawa • 815-324-3697

South Elgin • 877-823-4965

Spring Grove • 815-581-1530

Wauconda • 877-823-4965

A-Z ATTACHMENTS

Lemont • 815-348-2166

CHRISTOFANO EQUIPMENT

Chicago Ridge • 708-425-6466

DIAMOND EQUIPMENT, INC.

Mt. Vernon • 618-242-2273

O’LEARYS

Chicago • 773-252-6600

REXCO

Quad Cities • 563-381-1200

INDIANA

ALTA

Gary • (219) 240-0946

B & W EQUIPMENT CO., INC.

Fort Wayne • 260-422-0945

CONSTRUCTION MACHINERY CO.

Jeffersonville • 812-850-6160

DIAMOND EQUIPMENT, INC.

Evansville • 812-425-4428

Terre Haute • 812-299-4747

RPM MACHINERY, LLC

Fort Wayne • 260-888-3735

Lafayette • 765-300-4572

IOWA

JW BELL

Cedar Rapids • 319-362-1152

MIDWEST UNDERGROUND SUPPLY

Bondurant • 515-967-5656

REXCO EQUIPMENT, INC.

Cedar Rapids • 319-393-2820

Davenport • 563-381-1200

Des Moines • 515-287-4910

TITAN MACHINERY

Sioux City • 712-239-4941

WISE EQUIPMENT

Council Bluffs/Omaha • 402-597-0860

G.W. VAN KEPPEL COMPANY

Garden City • 620-272-0535

Kansas City • 913-281-4800

Topeka • 785-357-2652

Wichita • 316-945-6556

CONSTRUCTION MACHINERY CO.

Carrollton • 502-732-4661

Louisville • 866-901-2262

Owensboro • 877-683-2262

DIAMOND EQUIPMENT, INC.

Bowling Green • 270-781-1061

MCKEEL EQUIPMENT CO., INC.

Paducah • 270-444-0110

RUDD EQUIPMENT

Louisville • 502-456-4050

MICHIGAN

ALTA

Burton • 810-744-4840

Bryon Center • 616-878-7450

New Hudson • 248-356-5200

Sterling Heights • 586-977-6000

Wixom • 248-449-6700

MICHIGAN CAT - CORPORATE

Brownstown Twp. • 734-479-5800

Grand Rapids • 616-827-8000

Kalkaska • 231-258-8265

Mason • 517-699-4800

Novi • 248-349-4800

Portage • 269-383-7880

The Rammer Excellence line of hydraulic hammers gets the job done, strike after strike. Visit rammer.com See The Rammer Hammers

MIDWEST

HIGHWAY EQUIPMENT CO. OF OHIO

Canton • 330-915-8391

LESLIE EQUIPMENT COMPANY

Marietta • 740-373-5255

RECO EQUIPMENT, INC.

Belmont • 740-782-1314

Columbus • 614-276-0001

Monroe • 513-539-5255

BROOKS

De Pere • 920-336-5711 Milwaukee • 414-462-9790 Plover • 715-254-2777

Sun Prairie • 608-837-5141 West Salem • 608-786-2644

L.F. GEORGE, INC. Waukesha • 800-242-9559

NORTH DAKOTA

ASCENDUM MACHINERY Bismark • 701-250-4882 Fargo • 701-271-2360 Williston • 701-577-1249

FARGO TRACTOR Fargo • 701-282-5290

TITAN MACHINERY

Bismarck • 701-250-7925

Dickinson • 701-227-5309

Fargo • 701-237-3333

Grand Forks • 701-775-8108

Minot • 701-852-3188

Williston • 701-577-0024

Richfield • 330-659-0800 Toledo • 419-874-6001

MCCOY CONSTRUCTION & FORESTRY

Ashland • 715-682-5522

Chippewa Falls • 715-834-2924 Merrill • 715-536-0633

1160 McCabe Ave. Elk Grove Village, IL 60007 847-678-3640

Mokena, IL 708-596-8050 Wauconda, IL 847-526-4255

West Chicago, IL 630-293-0606 Yorkville, IL 630-553-0150

Merrillville, IN 219-381-3006

www.atlasbobcat.com

1200 East Highway 13 Burnsville, MN 55337 952-894-0894

Now open Saturday 8am-12pm CST

71 Minnesota Avenue Little Canada, MN 55117 651-407-3727

588 Outpost Circle Hudson, WI 54016 715-531-0801

Now open Saturday 8am-12pm CST

Coming Soon! St. Croix Falls, WI www.tristatebobcat.com

Cincinnati, OH 513-874-8945

Mt. Orab, OH 937-444-3865 Hillard, OH 614-876-1116

Reynoldsburg, OH 614-863-1300 Zanesville, OH 740-313-0087 Lexington, KY 859-254-3936

www.bobcat-ent.com

Bobcat of Indy

2935 Bluff Road Indianapolis, IN 46225 866-442-3052

2075 E CR 67 Anderson, IN 765-643-4222

4489 S Indianapolis, Road Whitestown, IN 317-769-4946

2002 West 3rd Street Bloomington, IN 812-287-8042

www.bobcatofindy.com

Madison (Sun Prairie), WI 608-837-5141 Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Croose (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700

Sparta, WI 608-351-2101

www.brookstractor.com

BS,AND

ATTCH FORA BAN rom roadways to right-of-w o road clearing, get your wo more efficiently than ever be machinery! Choose from diff izes to suit your needs. Cal oursortorequestademon

ours or to request a demonnstration.

NDIT® ways, lot clearing ork done faster and efore with Bandit® ferent styles and l today to reserve nstration

Ashland, KY 606-327-1709

Cowen, WV 304-226-3299

Beaver, WV 304-255-1525

Cross Lanes, WV 304-204-1818

Pleasant Valley (Fairmont), WV 304-534-5454 Norton, WV 304-636-6421 Pikeville, KY 606-432-0321 Marietta, OH 740-373-5255 www.lec1.com

Valley Park, MO 63088 636-225-2900 O’Fallon, MO 636-240-9020

Columbia, MO 573-886-9435 Champaign, IL 217-607-1454

Effingham, IL 217-717-4550

Fairview Heights, IL 618-397-1847 Marion, IL 618-985-8920 Springfield, IL 217-525-0349 Evansville, IN* 812-422-8200

Bowling Green, KY* 270-842-4253 www.bobcatofstl.com *Also, Small

By Eric Olson CEG CONTRIBUTING EDITOR

By Eric Olson CEG CONTRIBUTING EDITOR

Foralmostfourdecades,GerryKennyhas established his name, and that of his compa ny, Sand Science Inc., as a source among contractors and company owners looking to get quality screening, conveying, crushing and recycling equipment.

From the dealership’s location in Beaufort, S.C., along the Interstate 95 corri dor, Sand Science has grown from being a local and regional distributor of material handling equipment to one that now serves customers across the United States.

During its entire history, beginning in 1985, Sand Science has offered a full line of new, used and rental equipment to solve a range of applications for its customers.

The makers of those product lines, including Roto-Screen, Revolver and Barford, among oth ers, have found Gerry, along with histwoadultsons,EoinandAdam, vice presidents of marketing/sales, to be experts at solving their mate rial processing problems.

The Roto-Screen company, for one, has been so impressed with SandScience’seffortsonitsbehalf that it has recently granted the South Carolina distributor with the maker’s entire U.S. sales territory, according to Gerry Kenny.

“We have been the top sellers of RotoScreen machines for many years, and after a change in ownership at the company during the past year, its new management decided that we would be their new master distribu tor,” he said.

In tandem with its burgeoning national reputation, Gerry Kenny also noted that Sand Science has experienced a growth spurt over the past 10 years coinciding with his sons joining the business.

“I think that is one of the keys to our suc cessandithasalsobeenatremendousbless ingtomepersonally,andagreatresourcefor Sand Science customers to keep that conti nuity,” he said. “Even during the pandemic, wewereabletoexpandandaddnewperson nel.”

Kenny added that another reason Sand Science was able to weather both the coron avirus and the economic recession so well was because of the company’s ability to solvematerial-handlingproblemsforitscus tomers — no matter their location.

“For example, in 2021 we sent a specific conveyor system to Hawaii to solve a prob lem, along with one of our technicians to

install it for the customer,” Kenny said. “Another application that comes to mind is becausewedoanincreasingamountofbusi ness with the growing biomass industry, meaning wood chips, mulch and wood pel lets. There was a large fire last year in a port warehousing facility in southern Georgia where a lot of wood pellets burned. Using our Roto-Screen equipment, the residual sawdust was turned into a useful product after our customer screened all the pieces of metal and trash out of it.”

Sand Science also aided one of his local

Beaufort customers. In that case, the owner has a per mitted incinerator to burn debris, but in the process discovered he was finding lots of soil mixed in with the debris while he was creating a useful ash byproduct from the incin erator. Kenny’s company was called in to set up a Roto-Screen for the cus tomer whereby he could screen the soil mix and combineitwithhisashtocreateanamended soil product.

“Another local customer, a garden center in Mt. Pleasant, S.C., recently bought one of our compact Revolver RT508 trommel screens,” Kenny said. “They are repeat cus tomers of ours. It allows them to accept rough soil in an opportunistic way, process it, and blend any other material they wish with it to supplement their choice of land scape products.”

To be ready at a moment’s notice to send trommel screens to wherever they are need

ed, Sand Science keeps a large supply of theminitsyard,locatedoffI-95’sExit33,in South Carolina’s Low Country, just north of Savannah, Ga.

“We always have a lot of machines in stock, including a long line of trommel meshes, probably totaling 200 feet long, as well as another 200-foot-line of spare drums,” Kenny said. “We get calls from all over the place, but, having said that, one of the wonderful things about a Roto-Screen is that it uses parts that are freely available. They are U.S. standard parts, and we are quite happy to tell a customer from Wisconsin or Missouri or Louisiana that, ‘Hey, the particular machine bearing you needisthissize,andyoucangotoyourlocal industrial parts store to get one.’We are not out to soak our customers for parts, but we havetheminstock,andwearehappytoship them out when necessary.”

In addition to selling trommel screeners from Roto-Screens and Revolver, plus Kafka feeders and various specialty unload ers and trans loader machines, Sand Science is in the business of supplying a line of Barford-made track jaw crushers/vibrating screeners and stackers to customers. The main Barford model in Kenny’s inventory is the powerful 750J, a legal-load track crusher that he said is ideal for contractors and is known for doing an excellent job of recy cling concrete.

“We have been in the crushing equipment business just about as long as we have been in operation. But we try to keep it simple with affordable, mid-sized jaw crushers becausetheyareeasierandsaferforcontrac tors — our main customers base — to use. Specialist machines like impact crushers,

East Peoria, Illinois 4299 N. Main St. East Peoria, IL 61611 Phone: 309-694-3764

Marengo, Illinois 18210 Beck Road Marengo, IL 60152 Phone: 815-923-4966

Portage, Indiana 6450 Melton Road Portage, IN 46368 Phone: 219-764-8080 Escanaba, Michigan 2600 S Lincoln Road Escanaba, MI 49829 Phone: 906-786-6920

DeForest, Wisconsin 604 Stokely Road

DeForest, WI 53532 Phone: 608-842-4151

DePere, Wisconsin 3275 French Road

DePere, WI 55115

Phone: 920-532-0165

Eau Claire, Wisconsin 7417 Margaret Lane Eau Claire, WI 54703 Phone: 715-874-5400

Franksville, Wisconsin 2916 N Sylvania Ave

Franksville, WI 53126 Phone: 262-835-2710

Schofield, Wisconsin 9808 Weston Avenue

Schofield, WI 54476 Phone: 715-355-9898

Slinger, Wisconsin

881 East Commerce Blvd

Slinger, WI 53086 Phone: 262-644-7500

Cape Girardeau, Missouri 3364 Percy Drive

Cape Girardeau, MO 63702

Phone: 573-334-5252

Columbia, Missouri 4110 I-70 Drive SE Columbia, MO 65201

Phone: 573-814-0083

Bridgeton, Missouri 4670 Crossroads Industrial Dr. Bridgeton, MO 63044 Phone: 314-291-1330

Palmyra, Missouri 701 Industrial Drive Palmyra, MO 63461 Phone: 573-769-2056

EQUIPMENT from page 40

shredders and cone crushers are available and dealt with on an ‘as needed’basis.”

For his part, Eoin Kenny said he sees Sand Science’s key to success as being its specialization in material handling and pro cessing equipment.

“Screening, crushing and conveying equipment is our focus,” he said. “We don’t sellexcavatorsordozers.Orgoalistorentor sellyouthecorrectequipmentforprocessing orhandlingyourmaterialandtogiveyouthe most affordable solution.”

Following their graduation from college, both Eoin and Adam came aboard Sand Science with a fresh perspective, in the process building upon their father’s success with the company.

“AdamandIhavebroughtenergytoSand Science, with new technology and develop mentofSandScience’sInternetpresencefor our core Southeastern marketplace, along with more of a focus on expanding our foot print throughout NorthAmerica,” Eoin said.

“I think the biggest thing we have seen during our time at Sand Science is our national growth,” he added. “I have flown

across the country to install our systems for new customers in Maryland, Oklahoma, Oregon, Louisiana and the Northeastern states.”

With three talented people handling sales now instead of one, Eoin Kenny said they have been able to increase the business from their father’s initial footprint 37 years ago.

“Also, the market has changed consider ably because for so long it was done only through local dealers,” he said. “Now, because of the Internet, customers can reach us from further afield, and we can make them feel confident we are not just an online

sales company, but a full-fledged dealership that will back up customers from coast to coast.

“If you buy something from us, someone from Sand Science will come out to show you how to use that machine and teach you everything you need to know about it. Following that, we will remain as a resource for you on both that piece of equipment and others in the future. We are not going to just sell you a machine and leave you to it. Sand Science does business to create long-term relationships and that is why we have been successful at selling equipment all around

the country.”

For more information, call 843/525-6140 or visit www.sandscience.com. CEG

(Gerry Kenny has also followed in the footsteps of his fellow Irish in that he is a published author under the pen name “MichaelGerard.”Histhirdbook,ahistor ical novel, is due out in the spring of 2023. You can find him at www.MichaelGerardAuthor.com, and on AmazonBooks.)

(All photographs in this article are Copyright 2022 Construction Equipment Guide.AllRightsReserved.)

#510099-Tamrock DHA550 self-contained hydraulic drill with Deutz air cooled engine. Has 1185 impact hours. Good condition.

#530022-Joy RAM EXT air track drill with VCR 360 hammer. Hoses appear to be in working condition. U.C. approx 70%- overall good condition.

#580000-Furukawa HD712 drifter with approximately 4786 total impact hours and zero hours on complete reseal. Was used on 1200EDII. Ready to be installed for operation.

#520032-Ingersoll Rand 750CFM/300PSI high pressure compressor with Cat 3406 engine. Runs and operates good.

#132015-Continental Gin 48"x25.5' apron feeder. Large feed box. Flights are approx 80+%, good sprocket, & jackshaft drive gears. 60hp motor and gear box, but has removable mount (for transport). Heavy duty apron feeder. Shipping dims: 8' 7" tall & 30' long.

#131022 Hewitt Robbins 48"x20' vibrating grizzly feeder (E-11 mechanism) with hopper. Good condition.

#111078-Pioneer 153 (3042) jaw plant on factory 3axle chassis including 100hp AC electric motor, 4 hyd jacks & 42″x14′ grizzly feeder with 4′ grizzly section (bars pretty worn). Jaw plates are 90% on stationary & 40% on moveable. Jaw has hyd adjust. Tires and rims all poor on the chassis. Switch gear, belt scale, and 410 kw generator available.

#112046-Metso Nordberg LT1213S Loko Track mobile crushing & screening plant x47". 12 cubic yard hopper w/ vibrating grizzly feeder. Screening module is 2005. Conveyor width 47" & feed width 43".

#111075 Portable Portec/Pioneer SM3042 jaw plant Cummins C-N14 engine (runs good), 42"x16' apron feeder (good flights), & 4x8 2-deck Mesabi w/ reversable 30" underconveyor, 36" undercrusher front delivery conveyor. All on a factory 3-axle chassis. Has onboard electric hydraulic pump & reservoir w/ controls to operate a 4-point hydraulic leveling system for fast set up with legs, onboard fuel tanks, operator platform & controls. Disassembled for transport, ready for work when re-assembled. Will need approx 100kw gen set for electric motors.

#610132-1989 Cat 980C wheel loader with 265 hp Cat 3306 engine (Hr meter not working), power shift transmission, and 5.5 yard spade nose bucket.

#610137-1995 John Deere 644G Loader with unknown hours and 3 3/4 yard bucket. Good rubber and runs great, overall good condition.

#410063-CAT D9H w/ EROPS cab w/ A/C, straight blade w/tilt. Single shank, 4-barrel ripper. 24" pads. U/C (overall approx 70%). Rebuilt engine, trans, and finals (HMR 2994) Left Trunnion is available but needs to be installed. Overall good condition.

#700001 CAT 12F MOTORGRADER (1970) power shift, hydraulic side shift, & scarifier. 14.00-24TG tires approx 30-40%. Everything works and runs good. Good condition.

#410079 (2008) Komatsu D51PX-22 Crawler Dozer pre-emmissions engine (3246 hours), new rails and sprockets (rest of U/C approx 60%), 6-way blade, clean cab with good seat & good glass. Overall, good, tight machine.

#141120-Nordberg 6x20 3-deck incline screen with ball tray on bottom deck. No motor, but was a running take out. Good condition.

#142003-Deister 5x16 2-deck horizontal, underslung screen with new bearings

#121033-Universal 150/230 impactor with completely rebuilt rotor, new shoes, new hammers, and some new liners (inside looks very good). (2) new 350hp electric motors and new drive sheave. Crusher and motor only, no stand.

#121029-Humbolt Wedag secondary impact (42" wide/14" max feed) with new set of hammers and some new liners (not installed). 4 bar rotor. No power. Crusher is in good condition.

#121053-Cedarapids 5040 Hammermill secondary crusher with 5x16 3-deck screen. Has rotovator, 36" return and 36" front discharge conveyors. All mounted on tandem axle chassis. Plant is all electric except the hammermill is diesel jack shaft driven. No power on mill. Power unit and control panel are available separately for $12,000. Engine runs, but needs to be rebuilt.

#123025-Portable Telsmith 48" STD cone w/ 30" feed conveyor w/ 20 HP motor, Dodge TDT5 reducer, 36" undercrusher conveyor w/ WEG 20HP electric motor. Cone has 125HP 1150RPM motor, mounted on factory tandem axle chassis. Good brakes, very good rubber. Good running cone.

#121058-Spokane model 74 vertical shaft impact crusher with stand and 250hp electric motor. Has 4shoe table and anvil ring with good shoes and near new anvils.

#122002-Pioneer 4030 triple roll portable w/ 36″ feed conveyor, 4×10 Portec Pioneer scalping screen, 36″ discharge

Tires on chassis are good. No motor included for the rolls.

Astec announced that heavy equipment dealer Aggregate Manufacturing International LLC (AMI) is expanding its product offering to include additional crush ing and screening lines, as well as the BTIbranded rock breaker technology lines in the state of Indiana.

“AMI has been a long-time dealer of Astec,” said Ron Earl, group vice president of sales and marketing ofAstec. “They start ed several years ago with representing the Telsmith product and we are excited to offer them the rest of our traditional, stationary crushingandscreeninglinesandrockbreak ing equipment.”

“Westrivetobeafull-servicesupplierand partnertotheaggregateandindustrialindus tries,” said Mike Garard of AMI. “With the expansion of our Astec equipment offering, we will be able to continue our growth and enhance our long-term relationships.”

AMI has locations in Martinsville and Bedford, Ind.

Since 1972, Astec has been connecting

Mike Garard Aggregate Manufacturing International LLCcommunities by providing innovative rockto-road solutions for its customers. United by its purpose — “Built to Connect.”

Astec is a global manufacturer of special ized equipment for asphalt road building, aggregate processing and concrete produc tion. Operations are divided into two pri marybusinesssegments.Infrastructuresolu tions includes road building, asphalt and concrete plants, thermal and storage solu tions. Materials solutions includes aggregate and other material processing solutions.

“We strive to be a full-service supplier and partner to the aggregate and industrial industries.”

www.companywrench.com

4805 Scooby Lane NW Carroll, OH 43112 866-262-4181

4510 East 71st Street Cleveland, OH 44105 440-439-4567

920 Deneen Avenue Monroe, OH 45050 513-649-8105

1515 W. Epler Avenue Indianapolis, IN 46217 317-782-8850 1330 KY-151 Frankfort, KY 40601 502-699-2681

www.rolandmachinery.com

816 North Dirksen Parkway Springfield, IL 62702 217-789-7711

220 E Frontage Road Bolingbrook IL 60440 630-739-7474

1505 Donna Drive Carterville, IL 62918 618-985-3399

4299 N Main Street, Unit A East Peoria, IL 61611 309-694-3764

18210 Beck Road Marengo, IL 60152 815-923-4966

6450 Melton Road Portage, IN 46368 219-764-8080

4670 Crossroads Industrial Drive Bridgeton, MO 63044 314-291-1330

4110 I-70 Drive South East Columbia, MO 65201 573-814-0083

3364 Percy Drive Cape Girardeau, MO 63702 573-334-5252

701 Industrial Drive Palmyra, MO 63461 573-769-2056

The Historical Construction Equipment Association’s 36th annual International Convention & Old Equipment Exposition was held at the National Construction Equipment Museum in Bowling Green, Ohio, Sept. 23 to 25, 2022.

Despite a weather scare and high diesel prices affecting how many machines were brought in, the show was a great success.

Several thousand attendees from all overtheUnitedStatesandseveralother countries enjoyed perfect weather on Friday and Saturday. Approximately 120 antique machines and vehicles were brought in from as far away as New England, Louisiana and Colorado, joining the museum’s fleet

The big moment, as a Link-Belt HTC86100 and Grove RT880E lower the Titan’s dump bed into place. The Taylor 26-ton forklift assisted one crane in rolling the bed into lifting position after its halves were welded together.

of 185 machines and additional mod ern equipment.

The show featured major reassem

bly of the Museum’sTerex 33-15Titan 170-ton capacity end dump. The work was done entirely with donated labor and loaned equipment. Two local con tractors provided crane and operator services valued at $25,000.

It also featured the debut of the museum’s newly restored Manitowoc 3500 dragline and the first use of its new late 1960s Cat dirt spread — a D9G pushloader, two 631B motor scrapers and a 631B water wagon, all immaculately restored, donated and transported from New Jersey by the Mahan Collection Foundation.

Many other rare and unusual con struction and agricultural machines, trucks, cars, engines and military vehi cles were shown.

The museum will again host the show in 2023, on Sept, 22 to 24.

For more information, visit www.hcea.net.

3478 5th Ave S Fort Dodge, IA 50501 800-206-5936

4734 Sergeant Road Waterloo, IA 50701 319-234-8710

106 8th Stree Sergeant Bluff, IA 51054 866-539-8106 www.midcountrymachinery.com

W250 N6851 Hwy 164 Sussex, WI 53087 262-246-5700 Fax: 262-246-5719

DeForest, WI 608-222-9191

Eau Claire, WI 715-832-3443

De Pere, WI 920-338-5800

Marathon, WI 715-443-6000 Negaunee, MI 906-475-4181 www.miller-bradford.com

Corporate Office 10874 East Pike Rd. Cambridge, OH 43725 740-432-6303

1356 3rd Street Brilliant, OH 43913 740-598-3400

1500 Industrial Parkway Brunswick, OH 44212 330-225-6511

6390 Shier-Rings Rd. Dublin, OH 43016 614-889-1073

228 SR 7 North Gallipolis, OH 45631 740-446-3910

3875 W Fourth St Mansfield, OH 44903 419-529-4848

26580 St. Rt. 7 Marietta, OH 45750 740-374-7479

8757 Tyler Blvd. Mentor, OH 44060 440-255-6300

404 Breaden Rd. Monroe, OH 45050 513-539-9214

6415 Promler Ave. N. Canton, OH 44720 330-494-3950

27207 N. Dixie Hwy Perrysburg, OH 43551 419-874-0331

7444 Enterprise Park Circle Evansville, IN 47715 812-476-7321

3333 W. Coliseum Blvd. Fort Wayne, IN 46808 260-483-8868

429 Haven Hill Road

Shelbyville, KY 40065 502-633-9928 www.reprents.com

4951 West 96th St. Indianapolis, IN 46268 317-872-4877

1982 Florence Pike Burlington, KY 41005 859-586-6133

1776 S. Cedar Street Holt, MI 48842 517-694-0471

48545 Grand River Novi, MI 48374 248-349-9922

1505 Hebron Rd. (Rt. 79) Heath, OH 43056 740-522-3500 www.southeasternequip.com

Earthmoving 1960s style as the D9G sets to work push ing an Allis-Chalmers 260 while one of the 631Bs swings into the cut. All are owned by the museum.

Doing it the old-fashioned way! A 1918 Russell & Company 30/90 traction engine is pulling two 1920s Baker Maney D wheeled scrapers and a 1929 Galion Leaning Wheel E-Z Lift No. 10 pull grader.

Bridgeton, MO (314) 291-1330

Cape Girardeau, MO (573) 334-5252

Columbia, MO (573) 814-0083

Palmyra, MO (573) 769-2056

Portage, IN (219) 764-8080

Bolingbrook, IL (630) 739-7474

www.rolandmachinery.com

Carterville, IL (618) 985-3399

East Peoria, IL (309) 694-3764

Marengo, IL (815) 923-4966

Springfield, IL (217) 789-7711

DePere, WI (920) 532-0165

DeForest, WI (608) 842-4151

Eau Claire, WI (715) 874-5400

Franksville, WI (262) 835-2710

Schofield, WI (715) 355-9898

Slinger, WI (262) 644-7500

Escanaba, MI (906) 786-6920

Corporate 9200 Liberty Drive

Liberty, MO 60468

(816) 781-8070

ALP Air, Light, Power Liberty, MO (816) 415-6700 Joplin, MO (417) 726-5373

Maryland Heights, MO (314) 427-4911 Springfield, MO (417) 865-0505

Colby, KS (785) 462-8211

Liberal, KS (620) 624-7274

Salina, KS (785) 825-8291

Wichita, KS (316) 789-7370

Woodward, OK (580) 256-6014

Yukon, OK (405) 324-2330

Tulsa, OK (918) 984-6565

www.brandeismachinery.com

1801 Watterson Trail Louisville, KY 40299 (502) 491-4000

Corbin, KY (606) 528-3700 Lexington, KY (859) 259-3456

Paducah, KY (270) 444-8390

Stanville, KY (606) 478-9201

Evansville, IN (812) 425-4491

Fort Wayne, IN (260) 489-4551

Indianapolis, IN (317) 872-8410

Fargo, ND (800) 369-0371 Minot, ND (800) 210-8766

Fergus Falls, MN (218) 739-4505 Alexandria, MN (320) 460-8773

Blackhawk Equip

*Compact Excavators Only blackhawkequip.com Lake Crystal, MN 507-375-5544

Buck & Knobby Equip Co. buckandknobby.com Ottawa Lake, MI 734-856-2811

CSTK cstkequipment.com Kansas City, KS 888-566-5743

Diamond Equip diamondequipment.com

Mt. Vernon, IL 618-242-2273 Evansville, IN 812-425-4428 Terre Haute, IN 812-299-4747 Bowling Green, KY 270-781-1061

First Choice Farm and Lawn firstchoicekubota.com Mayfield, KY 270-856-4355

G. W. Van Keppel vankeppel.com St. Louis, MO 314-872-8440

Hardings Heavy Equip hardingsinc.com Lowell, IN 219.696.8911

Hayden Machinery LLC haydenmachineryllc.com Springfield, MO 417-855-7057

Holbrook Equip holbrookequipment.com North, Campton, KY 606-668-7261

Holland Equip Services hesequipment.com Holland, MI 616-396-5535

J Gross Equip Inc. jgeinc.com Aberdeen, SD 605-229-4037

Midland Engine midlandengine.com Midland, MI 989-631-4608

Reco Equip, Inc. recoequip.com Belmont (Mt Pleasant), OH 724-696-4555 Columbus, OH 614-276-0001 Ft. Wayne, IN 260-255-3115 Monroe (Dayton Area), OH 513-539-5255 Toledo, OH 419-874-6001 Richfield, OH 330-659-0800 Florence, KY 859-727-7970 Indianapolis, IN 317-781-8100

Rueter’s rueterco.com Council Bluffs, IA 712-366-5221 Grand Junction, IA 515-738-2571 Carroll, IA 712-792-9294 Elkhart, IA 515-367-3054 Osceola, IA 641-223-8171 Sioux City, IA 712-266-3832 Neligh, NE 402-917-5604

St. Joseph Equip, Inc. stjosephequipment.com La Crosse, WI 608-788-1775 Eyota, MN 507-545-2000

Team Boone teamboone.net Bardstown, KY 502-369-2475

United Truck Sales utsmi.com Clinton Township, MI 586-630-0355

Universal Truck Sales utssales.com Roseville, MN 651-639-0017

West River Equip westriverequipment.com Mandan, ND 701-751-0995

Yes Equip & Services yesequipment.com Milwaukee, WI 414-263-9001 Madison, WI 608-243-9253

Loved for the features. Trusted for the performance. Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without longtime fans.

See the Hyundai difference yourself at your local dealer or hceamericas.com.

Doosan Infracore NorthAmerica recently unveiled its new Smart X-Care telematics monitoring facility at the heavy equipment maker’s headquarters in Suwanee, Ga.

The Smart X-Care Machine Monitoring Center (MMC) is a centralized location that receives and disseminates machine telemat ics data as part of Doosan’s new and enhanced subscription-based offering to its customers.

Through the DoosanCONNECT telemat ics system, engineers and employees at the facility keep track of a Smart X-Care sub scriber’s machine on the program’s Dashboard to check for issues such as criti cal fault codes, upcoming or overdue serv ice, and warranty expirations.

StojanArezina, an electrical engineer and the telematics division manager of Doosan, explained that the Korean manufacturer still offersmosttelematicsservicesfreeofcharge to its customers using their DoosanCONNECT smartphone app or by accessing the system on a Web browser.

Currently, the Smart-X Care service is available to owners of newly purchased Doosan construction equipment. The monthly fee is $19.99 per month, but once customers buy a new machine, they will receive a free, six-month introductory sub scription. Thirty days before the free service is up, Doosan will send a notice alerting them to its expiration.

“I feel that the way we are implementing Smart X-Care is anything but pushy,” said Arezina. “Since everyone gets a six-month trial period, they have time to decide whetheritissomethingfromwhichtheycan benefit.”

Prior to the Smart X-Care MMC, the same data existed in the DoosanCONNECT telematics systems available to contractors andoperators,hesaid.Thedifferencenowis the enhanced service has its own dedicated monitoring center and group of technicians as well as the Dashboard, or machine track ing system.

Arezina added that the MMC communi cates with telematics personnel at Doosan’s equipment distributors to deliver critical information.

“It is right there on our big screen, and we can always reference it and share it in real time,” he said.

To address a machine issue, he said, “The Smart X-Care system itself actively sends messages to the customer and dealer. Then, the Doosan Telematics [DTM] team has an opportunity, based on what we are seeing on the big screen, to reach out to customers and

dealers and see if they are not doing service because there are parts missing, or they are waiting on parts. It may be that we can pro vide more technical training. By getting more involved in that customer/dealer com munication, hopefully Smart X-Care MMC is speeding help to each side.”

Asheseesit,havingDTMrepresentatives engaged in the process shows Doosan’s “stepped up level of care for our customers and dealers,” according to Arezina. “It is more than we just sold you a machine and now you are on your own.”

Doosan also wants its Smart X-Care MMC to enable dealers to improve their service,generatemorerevenueviaparts,use data that it actively sends them to predict what their machines will need and manage their parts and stock levels better, he said.

“They can see when we send them a mes sage that ‘Hey, here is a list of the machines

that are coming up for service.’They can go back to their parts department and say, ‘Thesemachinesaredueforserviceandwill need these parts. Do we have them in stock, or do we need to order them?’”

Arezina joined the company last March, the latest engineer at the heavy equipment manufacturer to create solutions that save time and money for customers of Doosan’s diverse lines of construction and forestry machines.

Telematics provides dozers, excavators and other primary construction machines with onboard communication services and applications that communicate with one anotherviaGPSreceiversandotherdevices. Vehicle tracking, the most common applica tion, works by combining a GPS system

with onboard diagnostics, typically to map the exact location of a machine and the speed at which it is moving.

Althoughmanypeopleintheconstruction workforce have never known a world with out smart phones or touch screens, Arezina acknowledgedDoosanmustworktomakeit easier for older equipment owners and oper ators to embrace telematics and understand what the technology can do for them.

“The way we mitigate that is through training — starting small with basic func tions and improving the user interface and user experience designs of DoosanCONNECT,” he said. “That is why I work directly with Korea to suggest how to make it more approachable.”

Additionally,Arezinasaid,“Thebest-sell ing points are showing them the financial benefits of telematics. For example, let them see how DoosanCONNECT observes and uses data that can help them keep their machines longer and, therefore, enables them to make more money with their equip ment. Plus, reveal to them how DoosanCONNECT can aid them in spend ing less money on services, have less down time, and more operating hours.”

To aid in doing that, the Smart X-Care MMC began a pilot program in September called Dealer Principal Report, which it sends to a select group of Doosan dealers, according toArezina.

The report is designed to, among other things, capture missed revenue due to not addressing diagnostic trouble codes (DTCs), or not heeding an alert about a machine being overdue for service. The monthly dis patch also projects potential revenues gener

SECTIONAttachments

Pages 55-60

Werk-Brau buckets and attach ments are used all over the world, butwhentheprojectisinyourown hometown … well that hits a little differently. So, when the Weber Company of Archbold, Ohio, recently embarked on a project to control erosion along a drainage ditch that ran through nearby Findlay,Ohio,Werk-Brauemploy ees were proud to see their handi work used to improve their local community.

The Dalzell ditch is roughly 3 mi.longandwindsitswaythrough several areas of town, including residential neighborhoods, indus trial zones, commercial areas including restaurants and hotels, adjacent to Findlay High School and along Interstate 75.Weber was tasked by Hancock County with placing rip rap in roughly 2 mi. of the ditch — areas that were most susceptible to erosion as marked by county engineers. Weber crews would restructure the steeply sloped ditch banks, those with slopes approaching 2:1, to better accommodate the incoming rip rap, grooming both sides if neces sary to hold the sides in place and prevent further erosion and dam age.

Because of the winding nature of the drainage ditch and the extremelywetweather,whichboth precluded bringing heavy equip ment onto the jobsites and caused further erosion that they were try ing to eliminate, the project pre sented some peculiar challenges.

Armedwithuniquetoolsinclud ingaCaseCX250longstickexca vator with a Werk-Brau 2-yd. ditching bucket and a side dump trailer, Isaac Weber and his team made respectable progress and completed the project within their established timeframe.

Weber and his team began the projectinearlyNovember.Starting

in the residential areas posed some challenges as well as some oppor tunities. Since there was no place to stockpile material, they were runningitinasneeded,daybyday, which was a challenge as the Carey Quarry was about an hourand-a-half round trip from the job site.

“We have a side dump trailer so we can pull right up to the guardrailanddumpafullloadover the side,” said Nate Meyer, project coordinator. “One load will do one side and a little of the bottom, and the next load will do the other side and a little bit of the bottom.”

While awaiting the next trailer load of rip rap, excavator operators would distribute the rock as need ed, shoring up or restructuring the ditch sides as required.

The side dump trailer allowed

Weber crews to accomplish 40-ft. of the project at a time, helping them to average roughly 400 to 500 ft. per day depending on how fast they could get rock from the quarry.

After the ditch wound its way out of the residential areas where the side dump trailers were no longer feasible, Weber crews stockpiled material and moved it with a John Deere 624P wheel loader equipped with a 3.5-yd. bucket. Theloaderwoulddumpa load of rip rap into the ditch, favoring whichever side was being shored up at present. They would then go back for another load while the excavator distrib uted the rip rap along the ditch banks. A trio of excavators were used on the project — a Case CX130, a Case CX210 and a

Case CX250 — all fitted with Werk-Brau quick couplers and buckets.

“We trust Werk-Brau products. When I see that logo, I know I’m getting a high-quality, durable product that will do what it was designed to do,” said Weber.

Stockpiling materials kept the excavator and loader operators busy, but tight confines and space constraints required creativity in certain areas.

“We had a spot where the ditch ran in between the back yards of houses, so there was nowhere for an excavator to go,” said Meyer. “So, we built a ramp out of rip rap and drove the loader down there and dumped a bunch of stone. Then we brought in the Case CX130C excavator and placed it on the sides.”

While not ideal, the sce nario worked … for the most part.

“He did have a rock get caught in the track, and then it walked the track off in the ditch,”said Meyer. “That was a pain. We put a load of rock in his bucket, extended his arm way out sothathewasjusttraveling on one track, and he onetracked it out of there.”

Meyer had another Case CX 210 excavator pulling the CX130C to keep the limping excavator moving straight. He laughs about it now but said that it was “a nightmare” at the time.

You may have heard about a bridge to nowhere, but what about a sidewalk to nowhere?

Thiswasthepredicamentonecommunity north ofTampa, Fla., was facing.After mak inga1,500-ft.sidewalkonthebacksideofa pond, the community couldn’t build the accompanying bridges to connect the side walk to the rest of the complex.

The housing community of Connerton, Fla.,northofTampahadgrandplansforput tinginasidewalkaroundthebacksideofthe community’s pond and then connecting it to the community through boardwalks at each end.Unfortunately,aftercuttingthepathand puttingthesidewalkin,therestoftheproject was put on hold. Over the next 10 years, the sidewalk was overtaken on both sides by the Brazilian Peppertree, vines, crepe myrtles, and other undergrowth.

When the project got enough interest to start the second phase of work, Clear Cut Forestry Mulching owner Tim Hileman got the call.

“We had a drone out looking for the side walk and you couldn’t see it,” Hileman said, explainingthedegreeofovergrowthpresent. Collectively working off blueprints and with the engineers, the team believed they knew where the sidewalk was hiding. Now they just needed to find a way to get to it.

The shortest distance between two points is a straight line. So Hileman started at one of the community’s access points and cut

himself a half mile long trail through the woods to the suspected sidewalk location.

“We never would’ve been able to get in there any other way…Then we saw the beginningoftheslabandstartedfollowingit.”

Around 1,500-ft. later Hileman found the other end.

After freeing the sidewalk, Hileman cleared 10 ft. of room on either side. This allowed the engineers to finally access the sidewalk to assess it before working on the connecting bridges. Two and a half days of workgaveacommunitytheirsidewalkback.

The Brazilian Peppertree is so invasive and common in Florida that Hileman encounters it at nearly every job site. Thankfully for Clear Cut and its clients, this undergrowth is easily tamed by Hileman’s Fecon Bull Hog mulcher.

Fecon’sBullHogmulcherisanextremely durable mulcher with the ability to mulch up to6in.materialwitheaseduetoitsbite-lim iting rotor design and a variable speed motor which automatically adjusts to maximize rotor-speed and torque to changing material loads.

Thirty double-sided, Samurai knife edge cuttingtoolsaremountedontotheFGTstyle rotor, creating a 61 in. cutting width. The attachment requires 30 to 45 gpm flow at up to 6,000 psi, which is delivered by a Caterpillar high flow skid steer.

The FGT rotor system features a smooth rotor surface, spiral tool pattern and innova

tive tool shape for efficient cutting. Hileman sharpens his blades twice a week and flips them after every 15 running days.

When it comes to mulcher attachment maintenance, Hileman greases the head every morning with four pumps and then anotherfourpumpsatlunchonthebearings.

Hileman had such a good experience building his business with his Fecon mulchingattachmentthathedecidedtostick withthebrandwhenitcametimetogrowhis equipment arsenal. Pairing another used Fecon Bull Hog mulcher with a brand-new

Some say word of

WEBER from page 55

“There was a pipe that went underneath the fence on the far side of a wide section of the ditch. We wereabletoreachthepipe,digitout and put the new pipe in with the long reach excavator,” said Meyer, recallinghowtheyusedprettymuch all of the more than 60 ft. reach of the Case CX 250.

In addition to tight quarters, the wet terrain required some creativity from the machine operators as well. In the final section of ditch, along side I-75, the access point was off a side street, with a dirt path entryway roughly 1,000 ft. long. Near the roadway the footing was fine, but as it neared low lying area closer to the highway the ground became down right swampy. They stockpiled materi al — both rip rap and 57’s — but the loader had to travel another 1,000 to 1,500ft.totheditchareabeingworked on.Butfirsttheoperatorshadtorecon struct the pathway, removing mud to get to drier material, and placing rock where needed to shore up the footing toallowtheloaderandtheexcavatorto

safely and efficiently traverse the area. Despite unpredictably bad weather patterns, the region received near record precipitation over the project period, having the right tools at hand allowed the Weber Company to keep this project on track and moving for ward.Aftercompletion,thenextheavy rain would have water passing through the ditch but not carry any of the ditch

bankwithit.Knowingthattheyplayed a small part in this Hancock County erosion control effort, Werk-Brau employeesstandproudoftheircompa ny, their products and the impact that they have not only on the local com munity but in other communities across the country.

For more information, visit WerkBrau.com.

ommendation was powerful enough to con vince Hileman to drop what he was doing and follow a friend into the mulching busi ness. Hileman even purchased his first mulcher head attachment straight from him.

Mike Cram with Heavy Brush Mowing started his business in Brevard County, Fla., with a Fecon Bull Hog mulcher. Fast for ward seven years and Hileman realized he could do the same…with the same exact mulcher.

“I always saw Mike’s videos but never paid too much attention to them. Then one dayIhadameetingatoneofhisjobsitesand Isawthemulcherandwasjustblownaway.”

Hileman was impressed, and had such a goodfriendinCram,thathewasabletobor row Cram’s whole rig and trailer to do his first ever job in Brevard County. Cram then taught Hileman how to use the equipment to not only clear the land but also to make it look presentable after the fact. He provided Hileman with industry expertise in addition to equipment.

Hileman was so moved after getting to

use the equipment that he decided to pur chase the seven-year-old mulcher from his friend.

“As the bearings are good, the head’s bal anced,andthepumpsaregood,regardlessof what the attachment looks like, it’ll still run just as good as new.”

After adding a Caterpillar high flow skid steer to his arsenal, Clear Cut was born.Two years into operating and the business has added a Caterpillar 299D3 XE high flow skid steer and another used Fecon Bull Hog mulching attachment to its arsenal.

Both mulchers and Cat high flow skid steers are still working, clearing brush and undergrowth in the south Florida area. Hileman figures his business is split 50/50 between residential lot clearing/property improvement and commercial thinning.

While the act of mulching is an act of removal,Hileman’sworkissometimesaddi tion by subtraction, like when he gave a community their sidewalk (and future plans) back by removing the brush.

For more information, visit www.fecon.com.

Cabinet Secretary Jim Gray. “It’s a familiar corridor for visitors travel ing to eastern Kentucky to enjoy our world-class hiking and rock climbing. The parkway also serves as an important driver of economic developmentintheareaaswecon tinue to attract new investment.

“We’re opening up the region for economic opportunity. More economic opportunity leads to more economic vitality and more economic prosperity for the people of Appalachia, and the Mountain Parkway is a key piece of unlock ing the region’s full economic potential.”

The Bert T. Combs Mountain Parkway opened in 1963 and stretches 78 mi. across central and eastern Kentucky. The ongoing construction fulfills a promise to complete a four-lane, high-speed corridor linking the Appalachian region with the Bluegrass region and beyond. Gov. Andy Beshear has identified this effort as one of his top transportation priorities to support economic development, tourism and quality of life for Kentuckians. Prior to the start of the Mountain Parkway Expansion, only 46 mi. of the parkway had four lanes. Other portions are two or three lanes with some substan dard curves.

“Building better roads is at the heart of strengthening eastern Kentucky communities by making the region more attractive for future companies to build and grow their businesses,” said Gray. “Wider roads mean easier access for trucks to travel back and forth across the state, increasing the potential for freight companies to do future business in this region.”

Construction began in 2015. The work is divided into six seg ments, from west to east. They include Wolfe County, Morgan County, Magoffin County West, Magoffin County Central, Salyersville Restaurant Row and KY114 Segment. Morgan County, Magoffin Central and Salyersville RestaurantRowarenowcomplete, which represents roughly a third of the total project miles.

The 4.6-mi. Magoffin County West segment is currently under construction at a total cost of $75 million and is scheduled for com pletion in 2023. The 11-mi. Wolfe

County segment began construc tion this summer. Final planning for the KY114 segment is actively under way.

“This transformational project spans 46 total miles over moun tainous terrain and requires a con siderable amount of planning and coordination before construction can even begin,” said Gray. “Construction segments were established to advance the project as funding is available through the State Highway Plan, which is enacted every two years by the Kentucky GeneralAssembly. Bids for the Wolfe County segment were opened in April, six months aheadofouranticipatedschedule.”