By Chuck MacDonald CEG CORRESPONDENT

Maintaining a major urban bridge is no small job, especially one as vital as the Commodore Barry Bridge.

Spanning the Delaware River and connecting Chester, Pa., to Bridgeport, N.J., this heavily traveled structure supports nearly 15 million vehicles annually through the Philadelphia region.

Named after Revolutionary War hero Commodore John Barry of Philadelphia, the bridge stretches 2.6 mi., making it the fourth longest cantilever bridge in the world. Soaring nearly 200 ft. above the Delaware River, the bridge has served the region since construction began in 1969.

Over the decades, it has undergone multiple cycles of repair and maintenance to ensure its long-term safety and performance. In January 2025, the Delaware River Port Authority (DPRA) awarded Skanska the latest phase of this ongoing effort, a $220 million contract for Phase Three painting and structural rehabilitation. The

see BARRY page 106

By Lucy Perry

Work has begun on revitalizing New Jersey’s Newark Liberty Airport’s aging AirTrain — one part of the larger plan to rebuild the international airport. The $3.5 billion project is part of the Port Authority’s EWR Vision Plan.

Construction on the third and final phase of the transformative $1.7 billion Hunts Point Access Improvement Project in New York City’s South Bronx has been completed, Gov. Kathy Hochul announced Nov. 17, 2025.

Every holiday season, Eagle Power & Equipment gets in the spirit and creates a festive light display in front of its Montgomeryville, Pa., headquarters for customers and motorists on busy Route 309.

20 N.J. OKS JERSEY CITY’S LIBERTY SCIENCE CENTER FOR $39.8M

The New Jersey Economic Development Authority announced its approvalof up to $39.8 million in support for the Liberty Science Center’s Project Supernova, a far-reaching and visionary planned transformation of the facility.

For more than a century, the Benevento family has worked this same piece of ground, gradually turning a patch of land in Wilmington into one of New England’s best-known names in stone, hot mix and concrete.

30 NEW BRUNSWICK STARTS WORK ON $70M DOWNTOWN TRAIN UPGRADE

Commuters passing through the heart of Middlesex County are about to get an enhanced experience designed to complement the growth of New Brunswick as work has begun to renovate the city’s historic, 122-year-old train station.

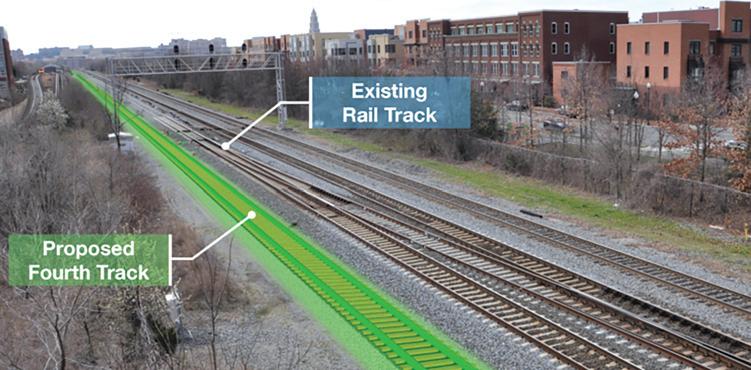

32 FAY, S&B LAND CSX CONTRACT FOR ALEXANDRIA FOURTH TRACK

Fay, S&B USA Construction (Fay), a Pittsburgh-based firm specializing in heavy civil infrastructure projects in the Mid-Atlantic region, has been awarded a contract by CSX for the Alexandria Fourth Track project.

Stellar Industries announced it has entered into a definitive agreement to acquire Elliott Equipment Co. The transaction is expected to close in the first quarter of 2026, subject to customary closing conditions.

52 DOOSAN BOBCAT EYES ACQUISITION OF GERMAN-BASED WACKER NEUSON

The deal under consideration would see Doosan Bobcat purchase approximately 63 percent of Wacker Neuson’s shares from major shareholders — followed by a potential public all-cash takeover offer to the remaining shareholders.

88 AEDF, ASE PARTNER TO STRENGTHEN PATH FOR EQUIPMENT TECHS

AEDF and ASE announced a new partnership designed to expand access to industry-recognized credentials and strengthen the connection between high school technical programs and careers in the equipment distribution industry.

KAGE MARKS 15 YEARS OF SNOWFIRE PLOW & PUSHER SYSTEM

KAGE Innovation celebrates the 15th anniversary of its SnowFire 2-in-1 Plow & Pusher System for compact tractors — celebrating a legacy of durability, innovation and versatility that began in 2008.

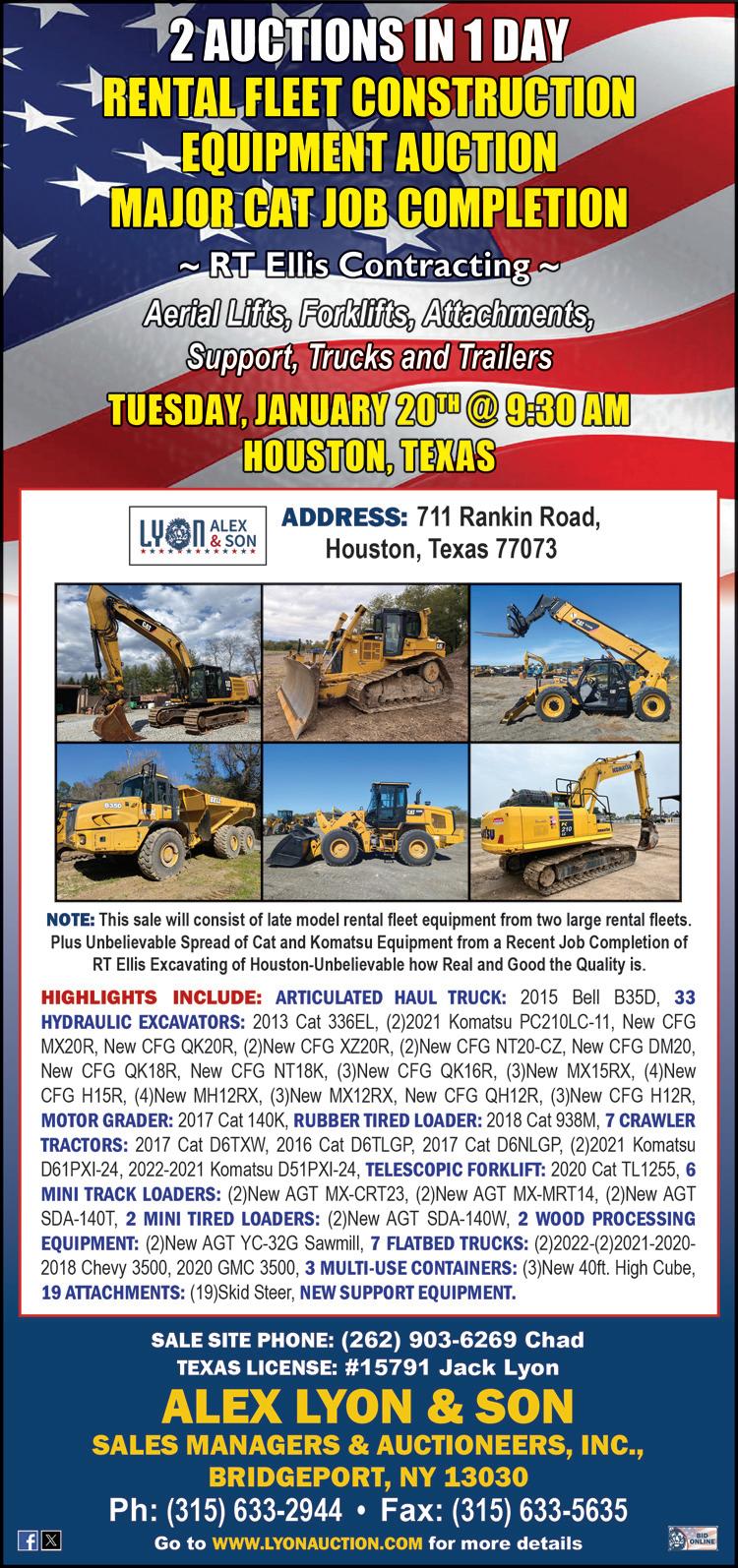

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..$88,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE............................................................................$99,995

CHIPPERS:

2020 BANDIT 15XP CHIPPER, 1322 HOURS, 15" CAPACITY, 4.3 PSI GAS ENGINE, AUTO FEED, HYD FEED WHEEL LIFT. NO WINCH................................................................................$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH........................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP........................................................................$64,995

DOZER:

2022 CASE 850M, 850 HRS, WIDE TRACK, CAB, HVAC, COLD WEATHER START KIT, DRAW BAR, 24” TRACKS, 112”DOZER BLADE, HYD PUMP W/PTO..............................................

$159,995

EXCAVATORS:

SCREENERS:

2021 VIBROSCREEN SCM40 $79,995

2021 VIBROSCREEN SCM27 $62,995 NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........ $179,995

$98,500

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER........................................

MISCELLANEOUS:

$149,995

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER..........................................................................

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB

$169,995

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $14,900

HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT. HEAPED..................................................................................

2012 BANDIT 990XP CHIPPER, 949 HOURS, 12" CAPACITY, 99HP KUBOTA DIESEL ENGINE, WINCH, AUTO FEED, HYD FEED WHEEL LIFT....................................................................................

SKID STEER LOADERS:

$29,995

2013 NEW HOLLAND L230, 2303 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS, BLOCK HEATER..................................$26,500

2018 BOBCAT T770 TRACK SKID STEER, CAB HVAC, 2011 HRS, HIGH FLOW, 2 SPEED, KEYLESS $41,500

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................

$295,000

2011 KUBOTA KX080R, 2068 HOURS, THUMB, COUPLER ,RUBBER TRACKS, ANGLE BLADE, PRE-EMISSION MACHINE..$48,000

TRACTOR:

1988 KUBOTA L2550GST, NEW KUBOTA ENGINE(400 HRS), 1880 HOUR ON TRACTOR, NEW BUCKET AND QUICK COUPLER, LOADER, 3 PT HITCH, 4WD, AG TIRES, GLIDE SHIFT TRANSMISSION....................................................................................

$9,995

2022 NEW HOLLAND WORKMASTER 40, 35 HOURS, 4WD, LOADER, INDUSTRIAL TIRES, HYDRO TRANS, REAR REMOTE VALVE, REMAINDER OF FACTORY WARRANTY................$27,000

2009 NEW HOLLAND T5040, CAB AND ALAMO 62" SIDE FLAIL, 2WD. 6605 HOURS............................................................$21,995

Work has begun on revitalizing New Jersey’s Newark Liberty Airport’s aging AirTrain — one part of the larger plan to rebuild the international airport.

On Oct. 7, 2025, Kevin O’Toole, chair of the Port Authority of New York and New Jersey, announced the groundbreaking for the new AirTrain, kicking off a long-awaited refresh of the 1990s-era system that will speed up and improve travel to the airport via public transit.

The $3.5 billion project is part of the Port Authority’s EWR Vision Plan, a long-term effort to rebuild the airport, including a new Terminal B, upgrades to Terminal C, fixes to the airport’s complex roadway network and replacement of the AirTrain.

The joint venture firm of Tutor Perini/O&G was awarded the $1.184 million contract to build a new 2.5-mi. elevated rail structure, known as the guideway, and three new stations for the new AirTrain system that will align with the ongoing redevelopment of Newark Liberty.

In addition, the Port Authority selected Doppelmayr USA, a Utah company and market leader in cable-propelled transport systems, for the design, construction, oper-

ation and maintenance of the automated people mover system and its vehicles.

The New York/New Jersey agency also contracted with Boston-based Stantec, an engineering firm, to design the new maintenance and control facility, the pedestrian connectors, and to decommission the existing AirTrain.

Initially built in 1996, the existing AirTrain is nearing the end of its useful life, according to the Port Authority, demanding constant maintenance and repairs while struggling to accommodate the airport’s growing number of visitors.

When the transit service first opened, the airport served roughly 30 million passengers annually. By 2024, that number had grown to nearly 50 million, and ridership is projected to rise another 50 percent by 2040, far exceeding the system’s current capacity.

AirTrain also provides access to the Northeast Corridor Rail Link Station while connecting terminals, parking lots and rental car facilities.

Today’s transit system at

Newark Liberty, however, cannot be expanded or upgraded with modern technology, and its route would limit future airport growth, reported 6sqft, an online real estate news site serving the New York metropolitan area.

In contrast, the new AirTrain is designed to be expandable and accommodates plans for future development.

To address these challenges, the new transit fleet will include seven five-car trains, each carrying 135 to 160 passengers — including luggage — more than doubling the current capacity. Passengers also will benefit from spacious walkthrough cars, aesthetic lighting, real-time signage and comfortable seating — all created to enhance the overall travel experience.

The new transit system will include three new stations, each connected by pedestrian pathways to existing airport facilities as well as a 70,000-sq.-ft. maintenance and control facility to support and manage the equipment.

The new route also will provide direct access to the airport’s new Terminal A, eliminating the current 15-minute walk between the AirTrain station and the terminal.

Ralph D’Apuzzo, senior pro-

gram director of Newark Development for the Port Authority and one of the engineers behind the AirTrain’s original design, highlighted the system’s upgrades while speaking to 6sqft.

“We’re designing not just a transit system, but an experience, with spacious platforms, intuitive dynamic signage, natural light and local art throughout the three new stations that will be built,” he said.

“It’s about functionality and accessibility for every passenger, and a system the region can be proud of.”

The AirTrain project is designed with the EWR Vision Plan in mind, including the new and revamped Terminals A and B.

Revealed in October 2024, the vision plan aims to accommodate the airport’s projected growth while bringing it up to par with the region’s other major airports, LaGuardia and JFK International, both of which have undergone significant transformations in recent years.

Under the $19 billion “JFK Vision Plan,” work on the new international Terminal One at that

facility began in September 2022, while the new Terminal 6 broke ground in February 2023.

Other projects linked to the transformation of JFK include the $1.5 billion expansion of Terminal 4, led by Delta and JFK, and a $425 million expansion of Terminal 8, led by American Airlines, 6sqft previously reported.

LaGuardia also has undergone a modernization following an $8 billion project that began in 2016 and was largely completed by June 2022 with the opening of Delta’s $4 billion Terminal C.

“Breaking ground on a new AirTrain system marks another milestone in the complete transformation of Newark Liberty International Airport into a worldclass gateway,” O’Toole said. “This project is about more than just replacing outdated infrastructure. It’s about building the capacity, reliability and customer experience that millions of travelers will depend on for decades to come as we complete a top-to-bottom reimagining of Newark Liberty.”

If all goes to plan, the first passenger service on the new AirTrain transit system should take place in early 2030.

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN STOCK!

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint........IN STOCK

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

Rogers TAG25's, 24' or 26' deck. Wood or Ladderbar Style 6' Tail. Wood or Ladderbar Style 8' Air Ramps Full floor or Custom Bucket Pocket in the deck. Safety Lighting Package........ In Stock and In Production!

New Rogers 35 ton CR35GR Gentle Risers In Stock, No-Foot Neck w/ tool box, Gooseneck work lights, 24' deck, 16* slope, adj. width bi-fold ramps, side reinforcing full length, chain boxes, outriggers, 275's on alum. outers, Air Ride, Air Dump, Aux. Night Light Battery, Extra Markers & Turns, Rear Strobes. Side Strobes Viper Red and Black................In Stock!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

Construction on the third and final phase of the transformative $1.7 billion Hunts Point Access Improvement Project in New York City’s South Bronx has been completed, Gov. Kathy Hochul announced Nov. 17, 2025.

It represents the final milestone in the transformation of the South Bronx, which was designed to strengthen neighborhoods, improve mobility and provide new recreational opportunities and access to the area’s green space

Managed by the New York State Department of Transportation (NYSDOT), the six-year project streamlined access to the Hunts Point Market and directed thousands of heavy commercial vehicles away from neighborhood streets to ease congestion, enhance safety and improve air quality by reducing vehicle emissions.

At the same time, the project also created new shared-use paths and provided new connections to area parks and the Bronx River waterfront that will strengthen communities and improve quality of life, according to a news release from Hochul’s office.

This level of investment is a game changer in the South Bronx, restoring east-west connections throughout the borough that were not in place before the initiation of the project.

“For far too long, residents of the South Bronx have contended with heavy truck traffic in their neighborhoods and all the problems that resulted, including high asthma rates and poor health outcomes,” Hochul said. “Thanks to this project we have taken thousands of trucks headed to the Hunts Point Market off local streets every day and added further fuel to the growing resurgence of the South Bronx with less congested streets, cleaner air and exciting new recreational opportunities along the Bronx River waterfront.”

The Hunts Point Market is the nation’s largest food distribution center and plays a vital role in New York City’s food chain, supplying more than 60 percent of its meat, fish and produce. It also is a vital economic engine for the Bronx, generating more than $2 billion in annual economic activity.

The completed project created direct access to Hunts Point from both the Bruckner Expressway and Sheridan Boulevard, removing tens of thousands of commercial vehicles from local streets and alleviating congestion.

The Hunts Point Project builds on the success of a $75 million project that converted the Sheridan Expressway into Sheridan Boulevard, completed in 2019 at the request of local officials who pushed for new east-

west connections and pedestrian facilities in the area.

Despite carrying relatively little traffic for an interstate, the old Sheridan Expressway walled off the neighborhoods of Crotona, West Farms and Soundview from nearby green space and forced residents to take long routes to reach Starlight Park. By replacing an underused highway with a neighborhood-friendly boulevard, the project restored access to the Bronx River waterfront and other vital public green spaces.

The effort was completed under budget and accomplished in three overlapping phases.

The initial phase, which concluded in October 2022, focused on:

• Removing heavy truck traffic from local streets by constructing three new ramps to Edgewater Road. These included a new two-way ramp from Sheridan Boulevard and a connection from the eastbound Bruckner Expressway.

• Edgewater Road also was resurfaced and outfitted with new traffic signals at Seneca and Garrison Avenues to enhance safety.

A new 111-space parking lot with 24 electric vehicle charging stations, including four rapid charge spots to better accommodate electric vehicles, was constructed under the Bruckner Expressway to help enhance air quality in the South Bronx.

• Four bridges over Amtrak and CSX rail lines were replaced and the Bryant Avenue pedestrian bridge was reconstructed.

• Garrison Park was upgraded with new landscaping, Bronx River overlooks and a formal entrance featuring a signalized rail crossing.

• A new shared-use path was created to connect Garrison Park with Concrete Plant Park, extending the Bronx River Greenway.

• Another 15,000 sq. ft. of “Bronx River Open Space” also was created beneath the rehabilitated Bronx River Avenue viaduct for residents to enjoy.

The second phase, which ended in the summer of 2023, included:

• The reconstruction of 1.25 mi. of the old Bruckner Expressway and new ramps linking the westbound Bruckner to Leggett Avenue, providing a more direct route into Hunts Point.

• A 1.75-mi. stretch of Bruckner Boulevard was rebuilt with 15 intersections, which were upgraded with new sidewalks, curbs, medians and crosswalks.

• A 1.5-mi. shared-use path was added along Bruckner Boulevard that connects to Randall’s Island, Manhattan and the Bronx River Greenway.

In Phase 3, which started in late 2022, the state’s focus was on eliminating long-standing bottlenecks and preparing the corridor for the future. Work in this portion of the Hunts Point Access project Included:

• A complete reconstruction of the Bruckner Expressway and Sheridan Boulevard with relocated ramps to simplify traffic movements in each direction;

• Upgraded signage for greater clarity;

• New pavement, sidewalks and bikeways were installed along the eastbound and westbound Bruckner Boulevard;

• Improved local street designs to enhance pedestrian safety with shorter crosswalks and better signalization and lighting; and

• A shared-use path to connect a variety of other paths from 141st Street to the Bronx River bikeways.

In addition, a new 111-space parking lot with 24 electric vehicle charging stations, including four rapid charge spots to better accommodate electric vehicles, was constructed under the Bruckner Expressway to help enhance air quality in the South Bronx.

“Governor Kathy Hochul is making historic transportation infrastructure invest-

ments in the South Bronx that are moving people and goods more efficiently, enhancing public safety, improving health outcomes and quality of life and in doing so, fundamentally connecting and strengthening the entire Hunts Point community,” said Marie Therese Dominguez, NYSDOT’s commissioner.

She added that New York State “is leading the nation in transformative infrastructure investments to connect communities, and this project does exactly that — getting trucks off neighborhood roads, creating pedestrian connections so residents can safely access Concrete and Starlite parks and the Bronx River.”

By working with the South Bronx community, Dominguez said, her department under Hochul “is investing in infrastructure solutions that make a positive and meaningful difference in the lives of Bronxites.”

New York Assemblymember Emérita Torres represents the South Bronx, including Hunts Point. She applauded the state’s attention to her district and its efforts to bring the much-needed project to a successful conclusion.

“The completion of the Hunts Point Access Improvement Project’s third and final phase marks an important moment for the South Bronx,” she said. “Our communities have historically carried the burden of truck congestion, poor air quality and dismal health disparities thanks to poorly planned transportation infrastructure. This project changes that.

“Notably, this investment reconnects communities, creates new pathways to our Bronx River Waterfront and offers recreational spaces that will improve our quality of life for generations,” Torres added. “I’m grateful to Governor Hochul, NYSDOT Commissioner Dominguez. and all our partners for prioritizing environmental justice and delivering a project that … corrects the poor urban infrastructure of the past and delivers for our community’s future.”

As the Hunts Point Access Improvement Project concludes, NYSDOT remains committed to continuing its engagement with the community in the South Bronx.

The state agency is currently advancing the environmental process for a future project to replace or rehabilitate five bridges on the Cross Bronx Expressway to enhance public safety and preserve a vital travel artery that serves approximately 150,000 vehicles each day.

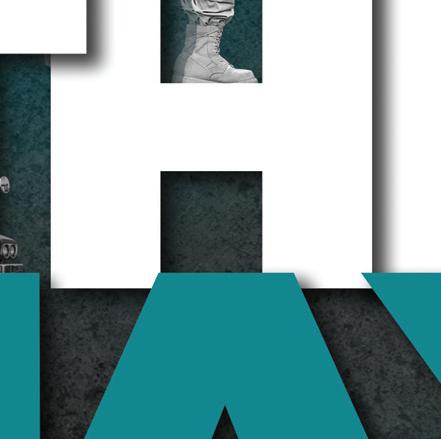

Every holiday season, Eagle Power & Equipment gets in the spirit and creates a festive light display in front of its Montgomeryville, Pa., headquarters for customers and motorists on busy Route 309. Thanks to our friends at Eagle Power for sharing this wonderful Case-themed holiday photos.

2024 YANMAR VIO17-1E MINI EXCAVATOR: 39” WIDE IN NARROW POSITION, HYDRAULICALLY EXPANDING UNDERCARRIAGE, AUXILIARY HYDRAULICS, OPEN ROPS, 55 HOURS!..........................................................................................................CALL FOR PRICE

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......CALL FOR PRICE

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1381........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS, 6 UNITS IN STOCK........................................................CALL FOR PRICE

ANACONDA FTR150 UNIT AG1353: MID SIZE FEED LOADER RANGE. FULLY EQUIPPED WITH 50' STOCKPILING CONVEYORALLOWS DFOR STOCKPILING OR FEEDINGA WIDE RANGE OF APPLICATIONS. INCLUDES OPTIONAL 2 DECK VIBRATING GRID......................CALL FOR PRICE

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 300 HRS, UNIT# 4310............................................................CALL FOR PRICE

2022 CASE CX130D: HYDRAULIC THUMB, AUTO GREASER, AUXILIARY PLUMBING. 8’6” WIDE, LOW HOURS EXCELLENT CONDITION VERY CLEAN MACHINE..........................................$95,625

2024 KOBELCO SK17SR-6E: 14.5 YANMAR POWER, 3671 LBS, EXPANDABLE UNDERCARRIAGE 3'1" TO 4'2", 12" & 36" SMOOTH LIP BUCKET, TWO WAY AUXULIARY HYDRAULICS, PATTERN CHANGER, UNIT# N4997 ....................................................................................CALL FOR PRICE

KOBELCO SK350LC-10, APPPROXIMATELY 2400 HOURS, 31.5” TRACK SHOES, 10’10” ARM, 2 WAY AUXILLIARY HYDRAULICS, HAND CONTROL PATTERN CHANGER, HEATED AIR RIDE SEAT, VERY GOOD CONDITION, UNIT# N3651................................................................$183,000

AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION........................CALL FOR PRICE

30”X50’ ELECTRIC RADIAL STACKERS: 5 IN STOCK..........................................CALL FOR PRICE

2020 KOBELCO SK210LC-10: 2 WAY AUX HYDRAULICS, 31.5” SHOES, PATTERN CHANGER, 850 HOURS, 1 OPERATOR. UNIT# U5865............................................................CALL FOR PRICE

VERY CLEAN 2015 CASE CX80C: BOLT ON RUBBER TRACK PADS, AUX. HYDS, HYD BUCKET COUPLER, DOZER BLADE. EXCELLENT CONDITION 2100 HRS! MANY BUCKETS AVAILABLE..........$CALL FOR PRICE

2024 KOBELCO SK35SR-7: 100 HRS, ENCLOSED CAB W/ HEAT, AC, RADIO W/ BLUETOOTH, SUSP. SEAT, LOW FLOW ROTATION CIRCUIT & 2-WAY AUX. HYDS, 23.1HP YANMAR POWER, DOZER BLADE W/ FLOAT, COLOR MONITOR, 9255 LBS, 5'7" WIDE, 8'3" TALL, ORIEL HYD COUPLER & THUMB. MANY BUCKETS AVAILABLE, UNIT# N4999..................$CALL FOR PRICE

2023 ANACONDA TR100 TRACK CONVEYOR: 42”X100’ TRACK MOUNTED CONVEYOR, LESS THAN 500 HOURS, INCLUDES A WEIGHT SHARK BELT SCALE................................$CALL FOR PRICE

2023 KOBELCO SK25SR-6E: ENCLOSED CAB W/ HEAT, 19.7HP YANMAR POWER, 5930 LBS, 4'11" WIDE, 8'4" TALL, DOZER BLADE, AUX. HYDS, PATTERN CHANGER, GRYB COUPLER, GRYB HYD THUMB. 12", 18", 24" & 30" BUCKETS AVAILABLE. UNIT # N4747..............................$CALL FOR PRICE

The New Jersey Economic Development Authority (NJEDA) announced its approval Nov. 14, 2025, of up to $39.8 million in support for the Liberty Science Center’s Project Supernova, a farreaching and visionary planned transformation of the facility’s physical spaces and programs.

The Liberty Science Center is a 300,000-sq.-ft., not-for-profit learning center located in Liberty State Park on the Jersey City bank of the Hudson River close to the Statue of Liberty.

As the Hudson River and its surrounding areas, including Jersey City, are home to river otters, this new habitat for the North American river otter will enable the center to expand and enhance the story of the ancient river told in the existing but soon-to-be reimaged River Rising exhibition.

Dedicated to inspiring the next generation of scientists and engineers and bringing the power, promise and pure fun of science and technology to people of all ages, the LSC houses the largest planetarium in the Western Hemisphere, 11 museum exhibition halls, a live animal collection with 110 species, giant aquariums, a 3D theater, live simulcast surgeries, a tornado-force wind simulator, K-12 classrooms and labs and space for teacherdevelopment programs.

Through NJEDA’s new Cultural Arts Facilities Expansion (CAFE) program, the funding, via tax credits, will allow the LSC to undergo an ambitious expansion designed to increase visitor attendance and engagement in key demographics, in addition to improving accessibility and sensory inclusion and showcasing cutting-edge science, the museum noted on its website.

The largest cultural institution in New Jersey, LSC is the first to receive the backing of the CAFE program.

Its strategic expansion, which involves both indoor and outdoor renovations and new activations, will celebrate the state’s scientific heritage and broaden LSC’s appeal for New Jersey families, tourists and visitors from New York.

The LSC’s new features will include:

• A combined — and highly unique — kids corner, a playground for goats and human children. Visible from nearby Phillip Street and taking advantage of the natural slope and pitch of the landscape, this play structure will feature parallel areas for kids and animals. A designated ground-level area will house a barn and allow trained staff to facilitate supervised interactions between the two groups, bringing an engaging educational component to the experience.

• A River Otter Habitat, new to LSC. As the Hudson River and its surrounding areas, including Jersey City, are home to river otters, this new habitat for the North American River Otter will enable the center to expand and enhance the story of the ancient river told in the existing but soon-tobe reimaged River Rising exhibition. Designed as an outdoor experience, the

building and habitat is designed to work in tandem to create a seamless and engaging environment. The building will be strategically positioned along both the pool and dry land areas of the habitat, offering visitors unique views of the otters from inside, regardless of weather conditions.

• The best Physics Mini Golf Course in the world, according to the center. From world-class theoretical and experimental physics out of nearby Princeton University to the invention of the transistor at Bell Labs, New Jersey has a rich legacy in physics research and education, with roots in both academic institutions and industry. By bringing together artists and scientists on the design and construction of a physics-based miniature golf course, LSC will bring this legacy to life. Each hole will demonstrate a core physics principle, making for a hands-on science learning experience unlike any other in the world.

‘Vibrant Fusion of Science, Ecology, Culture’

With the recent commitment by the New Jersey Economic Development Authority, LSC plans to start the construction of Project Supernova in the first quarter of 2026.

To accompany the NJEDA announcement that it had approval the project’s funding, New Jersey Gov. Phil Murphy explained the importance of the CAFE program to the state, noting that, “New Jersey is home to a thriving arts and culture sector that strengthens our state’s economy and highlights our incredible diversity and talent. The expansion of vibrant cultural institutions like the Liberty Science Center and the Mayo Performing Arts Center will serve as an economic catalyst for communities across the state, increasing quality of life for New Jerseyans and expanding economic opportunities for arts and culture organizations.”

• A replacement of its existing Our Hudson Home exhibition with the aforementioned River Rising exhibit. The renovation of that space will be made to breathe new life into a dated exhibit, while offering a fresh, immersive experience that deepens visitors’ understanding of the Hudson River and the urgent challenges it faces due to climate change. The new gallery will surround visitors with the power of the river and the human power in shaping it.

Also being upgraded and enhanced through the CAFE program will be the reconfiguration of the museum’s building layout to better support high-impact and technologically advanced premium exhibitions.

Currently, the gallery housing special temporary exhibits is located on the fourth floor in a space that limits the scale and types of exhibits LSC can host. To address this, the

traveling gallery will be relocated to a much larger, more flexible and prominent location on the first floor. This will allow LSC to host brand name blockbuster experiences that draw large crowds, such as The Van Gogh Expo and The Harry Potter Experience.

Plans also call for other spaces to be renovated, refurbished and re-imagined, including:

• The Jennifer Chalsty Planetarium, the largest of its kind in the Western Hemisphere.

• The giant “Science on a Sphere” projection globe within the Weston Family Lab for Earth and Space Exploration.

• New outdoor spaces so that LSC can offer all-weather activities and programming beyond the current and ever-popular Jack Horner Dino Dig Adventure.

• The design and build of a 9/11 Memorial Garden featuring two original World Trade Center beams relocated from the former “Skyscraper! Exhibition,” which were donated to LSC by the Port Authority of New York and New Jersey.

• The expansion of the Wild About Animals habitat, which is home to more than 100 species of animals and one of the museum’s most popular exhibitions.

Paul Hoffman, LSC’s president and CEO, expressed his profound gratitude to Murphy and the NJEDA for their long-standing commitment to the Jersey City museum and their conviction that the state should be home to the most engaging science learning center in the country for instilling and fostering a lifelong love of STEAM (Science, Technology, Engineering, Arts and Math).

“This project is a vibrant fusion of science, ecology and culture,” Hoffman said.

“It’s presented through new immersive environments that are interactive and educational, and upgrades to existing iconic experiences that LSC is famous for. The project celebrates the intersection of science and culture, honoring New Jersey’s famous scientific legacy and natural ecosystems. And true to the DNA of Liberty Science Center, the project is bold, forward-looking and inclusive, and transforms the center into an all-weather campus where learning is fun, hands-on and accessible to all.”

The Liberty Science Center welcomes over 280,000 students each year, and tens of thousands more participate in the museum’s off-site and online programs. In all, more than 800,000 people visit LSC annually, making it the most popular cultural institution in New Jersey and the largest interactive science center in the New York City-New Jersey metropolitan area.

Ted McKeon

Joe McKeon

Richard McKeon

Barry McKeon

Teddy McKeon

Kent Hogeboom

Rich Olivier

Patrick Kiel

Dennis Hogeboom

Sharon Swanson

Natalie Spain

Jacob Estrello

Amanda Guilfoyle

Rich Thompson

Judy Nixon

Theresa Vickers

Jill DePoy

Deby Hogeboom

Denise Giaccio

Mary DeRosa

John Pinkerton

Matt Seslow

Jennifer Hood

Craig Mongeau

Andy Gotlieb

Katherine Petrik

Adam Zeenkov

Cathy Printz

Caitlin Murphy

Maria McKeon

Donna Prendergast

Kathy McDonnell

Kathy Miller

Terry Mazza

Andrea Pinkerton

Stephen Collins

Rob Tredinnick

EXHIBITS: JANUARY 20-22, 2026

EDUCATION: JANUARY 19-22, 2026

LAS VEGAS CONVENTION CENTER

Push limits. Smash barriers. Break boundaries. And when you’ve conquered all those obstacles? You discover your full capacity f or greatness. World of Concret e delivers all the real-world solutions that will crush your challenges and ta ke your exp ertise to new heights. Growth opportunities are everywhere, whether you’re getting hands-on with game-changing tools and tech or shaking hands with your future partners. Ready for maximum success? Nothing’s standing in your way.

ACHIEVE PEAK PERFORMANCE VIEW GLOBAL EVENTS

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

If you pull onto the scale at Benevento Companies in Wilmington, Mass., on any given weekday, there’s a decent chance the person you meet won’t be tucked away in some distant corner office. It might be Tim Allard, the general manager of the Sand and Stone Division, or it might be Johnny Benevento, the fourth generation of the family now helping run the business as chief operating officer.

For more than a century, the family has worked this same piece of ground, gradually turning a patch of land in Wilmington into one of New England’s best-known names in stone, hot mix and concrete. Today, that same family also is quietly building a strong relationship with Equipment East and a growing fleet of DEVELON machines.

According to family history, Michael Benevento came to the United States from Montemarano, Italy, in 1916. Like countless immigrants of that era, he came looking for opportunity.

The land that is now the Wilmington home base has been in the picture almost from the start. Early on, the family operated what was essentially a mushroom farm there. They lived on the property in a camp back in the woods, growing mushrooms, working the soil and selling their products through local farm stands and markets.

Over time, they discovered that the sandy soils and underlying ledge had value of their own. Some relatives and acquaintances with masonry backgrounds recognized that the sand was well-suited to masonry work. The mushroom operation slowly gave way to retail sand sales and those simple sand piles gradually turned into a small-scale sand and stone business.

“They came over for the American Dream and started a mushroom farm,” Allard said. “From there they realized the soil and sand had value, then they hit ledge, and it just evolved into what we have today.”

The Wilmington property has been the anchor ever since. As the years went by, each generation put its own stamp on the business, but always on the same patch of land.

The second generation developed the sand and stone business. The third generation, led by Charles “Charlie” Benevento, moved the company firmly into the commercial materials space and began the transition from a local supplier into a larger, regional operation.

“Charlie’s vision has always been to mirror his father’s image,” Johnny Benevento said. “Hard work, loyalty, dedication to customers and employees and growth that still feels like a family business.”

Under Charlie’s leadership, Benevento expanded beyond Wilmington and into addi-

tional markets and product lines. The asphalt plant on the property, once owned by Heffron Materials, was acquired and folded into the operation. That was one of the company’s first major expansions beyond raw stone. From there, Benevento began adding facilities.

In Plaistow, N.H., Benevento acquired and now operates an asphalt plant. In Georgetown, Mass., they purchased a concrete plant that remains a ready-mix facility today. Those two moves extended the com-

pany’s reach on both the asphalt and concrete sides, tying nicely back to the Wilmington quarry and production operation.

At Wilmington today, the company runs two concrete plants, an asphalt plant, a quarry, and a large recycling operation for both concrete and asphalt. Trucks come in loaded with old concrete and reclaimed asphalt and leave with new hot mix or crushed aggregate.

One of the company’s biggest strategic moves came around 2015, when Benevento bought a sand and gravel operation in Pembroke, N.H.

“At that time, we were strictly ledge producers,” Allard said. “We realized that if you want to be serious in concrete, you have to control your sand. It’s a main ingredient. If you can control that, you can control pricing and be more competitive.”

The Pembroke site started modestly with a screening plant and a small crew. It didn’t stay small for long. Over the years, see BENEVENTO page 34

Trucks & Heavy Equipment Also Available

Commuters passing through the heart of New Jersey’s Middlesex County are about to get an enhanced experience designed to complement the growth of New Brunswick as work has begun to renovate the city’s historic, 122-year-old train station.

The county, in partnership with NJ Transit, held a groundbreaking ceremony to mark the beginning of the construction phase for the rail station. Plans call for the modernization and expansion of one of the busiest transit hubs along transit system’s Northeast Corridor line.

The endeavor is currently out to bid for construction, Jersey Digs reported Nov. 3, 2025, with the primary work slated to begin toward the end of the year. Officials with the county and NJ Transit expect the station’s overhaul to be completed by 2028.

Construction on the multi-phase project will begin with sidewalk and exterior improvements along Easton Avenue and Albany Street surrounding the station, followed by the building of a new ticketing center featuring an elevator and waiting areas.

Other highlights of the train station upgrade include renovations to the westbound and eastbound platforms and expanded pedestrian transfer passages.

The platforms will be extended to accommodate trains with up to 12 cars, with the goal of serving more than 4,000 daily travelers and anticipating growth from new developments, such as the nearby Health and Life Science Exchange

(HELIX) complex and expansion at Rutgers University.

In addition, modernized waiting areas and new entrance signage are part of the project, as are the installation of new trainway and building systems and extensive landscaping enhancements.

The project also will address existing problems, including a leaky roof, a basement that floods and an outdated sprinkler system.

Located just across the street from the passenger rail station in downtown New Brunswick, HELIX is a growing three-building complex and innovation district designed to foster collaboration between academia, private industry and government in the health and life sciences sectors. It features a mix of research labs, office and residential spaces and includes facilities for the Rutgers University medical school, a translational research center and a future home for Nokia Bell Labs.

In July, Nokia began building its new 370,000sq.-ft. facility in HELIX’s H2 development. When it is finished in late 2027, Nokia’s presence, along with the recently opened Jack & Sheryl Morris Cancer Center and the expanding Rutgers University footprint, will significantly increase the number of people to the city in the coming years.

breaking. “As the HELIX brings thousands of innovators to our state-of-the-art hub at the heart of [the Rutgers] campus, we will meet this influx of workers with safe, modern and reliable transportation.”

Despite the 21st century improvements to the train station, built in 1903, its iconic orange-brick facade will remain, blending modern amenities with historical elements, according to a news release from the city.

‘Front Door’

NJ Transit has partnered with Rutgers on a three-year agreement that makes the university the train station’s official sponsor. The deal aims to further promote and integrate New Jersey’s top public research university into the heart of the city’s transportation hub as it further strengthens its presence in the community.

“For more than a century, the New Brunswick Train Station has been the front door to our city,” noted Mayor Jim Cahill. “With this investment and modernization, we’re ensuring it remains a welcoming, accessible and forwardlooking gateway that supports the growth of New Brunswick, Middlesex County and the entire region for generations to come.”

“Upgrading and expanding one of the busiest hubs along the Northeast Corridor is part of our commitment to modernizing New Jersey’s transportation infrastructure for commuters and residents — preserving historic spaces while investing in improving quality and accessibility to move the regional economy forward,” New Jersey Gov. Phil Murphy said at the ground-

The renovation effort was designed by Dallas-based AECOM, a global infrastructure consulting firm. It was awarded a $7 million contract for the work in November 2023.

New Brunswick is one of several major transit hubs in the Garden State to get overhauled in recent years. In 2021, Newark Penn Station built a $160 million renovation, while Hoboken Terminal is currently undergoing a sprawling revitalization as part of a public-private partnership.

When you’ve got job that requires a site to be prepped or cleared, you need attachments you can trust to get the job done right the first time. At Blue Diamond Attachments, we’ve got your back.

Our family of brush cutters are purpose built to provide optimal performance on your skid and compact track loaders, mini loaders and full line of excavators. Providing you exactly what you need to get to the next phase of your project on – or even ahead of schedule.

So, whether the job is large, small or somewhere in between, Blue Diamond brush cutters are designed to handle it. Choose Blue Diamond – where all we do is elevate everything you do.

Fay, S&B USA Construction (Fay), a Pittsburgh-based firm specializing in heavy civil infrastructure projects in the MidAtlantic region, has been awarded a contract by CSX for the Alexandria Fourth Track project.

This project will construct six miles of railroad track and related infrastructure in Arlington County and the city of Alexandria, Va., to separate passenger and freight trains.

The Alexandria Fourth Track project will construct six miles of a new fourth railroad track extending south from Long Bridge Aquatics and Fitness Center of Arlington to just west of Alexandria Union Station. In this rail corridor where five tracks converge into three, the new track will be built within the existing railroad right-of-way to enable more railroad capacity between Northern Virginia and the District of Columbia. The new fourth track will be dedicated to passenger trains, while remaining interoperable for freight traffic during maintenance or construction activities. The north end of this project will connect to the southern end of VPRA’s Long Bridge project in Arlington, Va.

Serving as the general contractor to CSX, Fay’s scope of work includes: site prepara-

tion; six miles of track construction; excavation; construction of a bridge; building retaining walls; modifying an existing crash wall at Telegraph Road; installing reinforced concrete culvert structures and drainage pipe; and building a new maintenance-of-way at-grade crossing for CSX crews. The anticipated duration of construction is approximately two years.

“Backed by 75 years of heavy-civil experience, Fay brings proven rail expertise and

disciplined execution to advance the Alexandria Fourth Track project safely and seamlessly,” said Ryan Surrena, president of Fay. “Strong partnerships and reliable field performance will define how we deliver this work.”

As one component in a portfolio of projects in Northern Virginia supporting the Transforming Rail in Virginia (TRV) initiative, the Alexandria Fourth Track will enable more railroad capacity and increase

the efficiency of train operations. The Virginia Passenger Rail Authority (VPRA), the city of Alexandria, Amtrak, Virginia Railway Express (VRE) and CSX are partners in these rail infrastructure investments.

This new award builds on Fay’s ongoing projects for VPRA and CSX. Fay is currently part of Long Bridge Rail Partners (LBRP) — a joint venture of Trumbull Corp.; Fay, S&B USA Construction; and Wagman Heavy Civil, Inc. — as the designbuild contractor for the Long Bridge South package. The joint venture is constructing a new two-track railroad bridge and an adjacent bicycle-pedestrian bridge over the George Washington Memorial Parkway and Potomac River.

In addition, Fay is delivering two other contracts for CSX to create clearance for double-stack freight trains to pass through the city of Baltimore. The first is currently converting two arches of the North Avenue Bridge over CSX tracks into a single-span bridge. In an adjacent project over the same tracks, a Skanska-Fay joint venture recently substantially completed a project increasing the clearance of the historic Howard Street tunnel.

For more information, visit shikunusa.com.

Stellar Industries announced it has entered into a definitive agreement to acquire Elliott Equipment Co.

The transaction is expected to close in the first quarter of 2026, subject to customary closing conditions.

This acquisition strengthens Stellar’s long-term growth strategy by expanding its lifting equipment and work-at-height solutions, widening its presence across core vocational markets and creating additional opportunities for distributors, customers and employee-owners.

Founded in 1948, Elliott Equipment pioneered the first truck-mounted telescoping aerial platform and continues to design equipment for utility transmission, commercial construction, municipal services and fleet maintenance applications.

“Stellar has always pursued growth opportunities that align with our culture, vision and commitment to excellence,” said Dave Zrostlik, president of Stellar. “The addition of Elliott Equipment Co. represents an exciting step forward as we continue to build upon our shared values of quality, innovation and customer service. We’re

proud to welcome Elliott to the Stellar team.”

Following the close of the transaction, Elliott Equipment will operate as a distinct

business unit of Stellar, maintaining its current employees, facilities, brand identity and dealer relationships in Omaha, Neb. Jim Glazer, president of Elliott Equipment, will

continue to lead the organization.

“We are thrilled to continue the Elliott Equipment Co. story with Stellar,” said Glazer. “This acquisition represents a strong cultural fit between two organizations that share a commitment to people, product integrity and long-term growth.”

Stellar’s 100 percent employee-owned structure aligns employee success directly with company performance. Through the ESOP, employee-owners share in the organization’s long-term growth, reinforcing a culture of collaboration, innovation and accountability.

With the addition of Elliott, Stellar will broaden its capabilities in aerial work platforms, utility lifting solutions and materialhandling technologies, enabling both companies to better serve existing customers and pursue new opportunities in adjacent markets. Both organizations remain committed to United States manufacturing, exceptional service and engineering.

For more information, visit stellarindustries.com.

from page 28

Benevento grew that foothold into a much larger New Hampshire presence.

The company now operates a large sand and gravel and quarry operation on approximately 1,100 acres in Loudon, N.H., and works under a mining rights agreement in Belmont. Two additional gravel pits in the Loudon area are in the process of being opened.

Pembroke was the company’s introduction to the New Hampshire sand and gravel market; Loudon is now the centerpiece. Material from Belmont is excavated and hauled back to Loudon for processing.

“It’s different from what we were used to,” Allard said. “But controlling your own sand makes you more self-sufficient and more competitive. It’s made us stronger overall.”

Because concrete and asphalt are perishable, Benevento views its realistic delivery radius at approximately 30 miles from each plant. Stone can travel farther, but for hot mix and ready-mix concrete the company focuses on serving jobs within that core radius, using its own trucks and a sizable pool of third-party haulers.

Benevento supplies a mix of municipal customers and private contractors, but it does not operate paving crews or sitework crews. “We’re strictly a supplier,” Allard said. “We don’t compete with our customers.”

The volumes are large enough that Benevento has been recognized among the top 50 aggregate producers in the United States. The company chooses not to publish tonnage, but the ranking speaks for itself in terms of the scale they’ve reached while still operating as a family-owned organization.

Talk to Benevento employees and two themes repeatedly come up: family and flexibility.

Allard has been with the company as an employee for approximately 18 years, with another decade before that as a contractor. He has watched three generations of the family steer the operation and has raised his own children while working there.

“One thing I was told from the very beginning was family comes first,” he said. “Don’t miss your kid’s play. Don’t miss the game. Don’t have regrets when they’re grown. If you need to leave at 10 a.m. to go see something at the school, you go. Then you come back and finish the work.”

That philosophy, he said, traces back to earlier generations and remains intact today. The expectation is that people work hard and take care of the business — but in a way that allows them to take care of their families, too.

The company also has also made a point of keeping people year-round rather than running a large seasonal work-

force. Over the past five years, approximately 90 percent of employees have been year-round, due in part to milder winters and a deliberate strategy of building inventory in the offseason. Running some plants and pits through the winter creates stockpiles so there is always material on hand when spring hits.

Inside the operation, there are no rigid walls between divisions. The leadership team — stone, asphalt, concrete — meets weekly, talks about what’s going right, what’s going wrong and figures it out as a group. When someone has a family issue or an unexpected problem, others step in. Johnny Benevento will get in a loader. Allard will jump in a loader. People get moved around to cover gaps.

“Charlie expects us to treat this like it’s ours,” Allard said. “And we do. That’s how we run it.”

Johnny Benevento added another key point: the family is present.

“My dad and I are here every day,” he said. “A truck driver can come in, get on the scale and talk to Tim [Allard]. Or he can walk into the office and have the same conversation with my dad or with me. People like knowing the owners are here and listening.”

On the fleet side, Benevento runs an impressive amount of iron and rubber. The company owns one of the largest fleets

of triaxles, dump trailers and concrete mixers in the New England market. In addition, Benevento has a large network of third-party trucks it can call in when demand spikes.

Across all sites, the company has an impressive amount of equipment — loaders, excavators, haul trucks — and support machinery.

The company’s philosophy on equipment is straightforward: maintain it, train the operators and know when to rebuild versus replace. Preventive maintenance and operator training are stressed heavily.

Before DEVELON came into the picture, Benevento was not a single supplier, but it did lean heavily on a dealership relationship that went back to earlier generations. Over time, that relationship naturally changed as people retired or moved on.

At the same time, the Benevento family developed a longstanding personal relationship with Giovanni and Gilda Albanese of Equipment East. Long before entering the dealership business, they had done business together for many years.

There's nothing corporate about this story, according to Equipment East. It’s about real people standing by each other in their respective businesses through difficult business cycles and making the tough decisions that come when things do not go as planned.

In situ cold

particularly resource-friendly and cost-efficient and enables the completion of projects without long construction times.

In Markt Indersdorf, around 31 mi. north of Munich, technology meets long-term infrastructure planning considerations.

Here, a cold recycler from the CR series took only three days to produce a new base layer — and not only cut the construction time by six to eight weeks, but also significantly reduced the burden on local taxpayers.

Germany’s roads are plagued by an enormous backlog of planned or pending rehabilitation projects — especially in the case of communal infrastructure. The main causes of this are high traffic density, adverse weather conditions, and long

39 Jersey Street

West Babylon, NY 11704

631/643-2605

www.allislandequipment.com

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020

www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106 603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542 845/236-3000 www.hoffmanequip.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

8194 State Route 415 Campbell, NY 14821 607/739-8741 monroetractor.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY 3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Opens Jan. 2, 2026 Lancaster, PA 20 Stauffer Lane Ephrata, PA 800/325-6455 www.stephensonequipment.com

BOMAG photo

Offering a 5.5-in. plate width, superior compaction forces are generated by its 1.8in. jumping height and variable frequency reaching 790 vpm.

Weighing less than 70 lbs., the compact design and high compaction forces for the new BOMAG BT 30 tamper gives contractors a machine that works in confined area compaction.

Offering a 5.5-in. plate width, superior compaction forces are generated by its 1.8-in. jumping height and variable frequency reaching 790 vpm. Infinitely variable frequency settings allow compaction forces to be adjusted to suit job site conditions, ensuring precise and accurate compaction, according to BOMAG.

The new BT 30’s lightweight and ergonomic design makes it easier to transport to the job site and maneuver around obstacles or in the trenches, according to BOMAG. With its large stroke, variable frequency and ability to compact clay, silty or mixed soils, the BT 30 can be used on a wide range of applications from trench backfilling and foundation preparation to landscaping, hardscaping and pipeline construction.

A simple design means the new BOMAG BT 30 tamper is built to withstand rugged rental, commercial and landscaping jobs. It’s powered by a Honda 4-stroke gas engine that does not require fuel using special oil-to-gas mixtures. An engine cover protects external components from damage during transit or at the job site. BT 30 design features a two-stage air filter system with self-cleaning air filter to keep particles out of the engine. A dual fuel filter system helps to prevent downtime due to fuel contamination. The design is guaranteed by BOMAG’s 3-2-1 warranty.

This new BOMAG tamper boasts a vibration isolated steering handle that protects the operator’s hands and arms from vibration feedback for comfortable operation. Further simplifying transport to/from and around the job site, the handle features a single point lifting device.

The new Bomag BT 30 tamper has planned commercial availability of spring 2026.

For more information, visit bomag.com/ us-en.

stand rugged rental, commercial and landscaping jobs.

Selecting the right asphalt binder for airfield pavements has long been a challenge for design engineers.

Unlike highways, airfields must withstand heavier aircraft loads, slow or stationary runway and taxiway movement and strict Federal Aviation Administration (FAA) and Department of Defense (DOD) specifications. Choosing the wrong binder can cause pavement to resist one type of damage but fail prematurely from another or drive-up costs if the binder is difficult to source.

To address these challenges, the Airport Asphalt Pavement Technology Program (AAPTP), in partnership with FAA and the National Asphalt Pavement Association (NAPA), sponsored binder selection research, led by the National Center for Asphalt Technology (NCAT).

The project’s goal was to transform complex and sometimes inconsistent binder requirements into a standardized process and tool — saving engineers time, reducing errors and improving pavement performance.

“Although the engineering notes in FAA and DOD specifications are very useful, they can also be limited,” said Raquel Moraes, NCAT principal investigator. “Selecting the correct asphalt binder grade still requires sig-

nificant background knowledge from the design engineer, such as accounting for aircraft gross weight in FAA specifications or tire pressure in DOD projects.”

NCAT researchers surveyed all 50 state highway agencies, Puerto Rico and several Canadian provinces to document which binder grades were commonly specified and available in each region. This database was then cross-checked with Asphalt Institute specifications to ensure accuracy.

The team also reviewed FAA and DOD specifications, including FAA P-401, P-403 and P-404, as well as Unified Facilities Guide Specifications for airfield paving. The team mapped when and how binder grade “bumps” are required based on aircraft gross weight, tire pressure, pavement location, reclaimed asphalt pavement content and climate conditions.

The team then created step-by-step flowcharts that mapped the engineering decisions used when applying FAA and DOD standards. They compiled their findings into a final report, titled “Guidance for Selection of Proper Asphalt Binder Grade,” and then took the next step of turning the guidance into a practical tool.

“We wanted to capture all of the information in the guidance and make it available through an easy-to-use interface that helps

avoid the standard errors that occur when interpreting specifications,” said Ben Ciavola, managing director of software and data of WAP Sustainability Consulting.

The result is the Airfield Asphalt Binder Selection Tool, a free, web-based resource for pavement engineers. The tool guides users through selecting a base binder grade by state and county, applying grade adjustments for aircraft weight and movement and checking binder availability in the region. It also flags when additional requirements apply, such as polymer modification or elastic recovery testing.

In some cases, the recommended binder may not be part of the standard supply in that state or county. Rather than leaving users at a dead end, the tool directs them to the Association of Modified Asphalt Producers, which can connect engineers with suppliers able to provide specialty binders not typically specified but still required for certain projects. This ensures that even when a binder is difficult to source locally, engineers have a clear path to obtaining the right material for the job.

The tool, accessible on both desktop and mobile devices, generates clear, one-page reports that document every adjustment and can be shared with project teams. It gives engineers clear, research-based recommen-

dations they can trust by embedding FAA and DOD requirements into an interactive platform.

“Keeping the database updated will be a priority so the tool remains a reliable resource even as binder availability and standards evolve,” said Richard Willis, NAPA vice president of engineering, research and technology.

Future updates may also incorporate insights from ongoing studies, such as research into making airfield pavements more resilient to flooding and extreme weather.

The FAA has expressed support for the tool, viewing it as a practical way to bring greater consistency to binder selection across the aviation industry. While the agency will not mandate its use, the tool aligns closely with FAA specifications and gives engineers a reliable shortcut through what can otherwise be a complex and timeconsuming process.

By making binder selection more transparent and accessible, the FAA and its partners hope to reduce errors in project submittals, save time in design reviews and improve communication between contractors, suppliers and engineers.

For more information, visit asphaltpavement.org/web-172.

814-371-3600 McKean, PA 800-872-2390 Wilkes-Barre, PA 570-410-2123 Zelienople, PA 724-452-7800

construction times.

Traditional road rehabilitation methods are often pushed to the limit when it comes to cost-efficient project realization. Material and transportation costs are high, construction times are long, and the environmental footprint is frequently less than ideal. With in situ cold recycling, Wirtgen offers an alternative that is cost-efficient, resourcefriendly and quickly achievable– an ideal solution that also fulfills the road construction requirements of regional, local and communal authorities, according to Wirtgen.

Lead contractor Seizmeir from Scheyern used a CR series cold recycler with foamed bitumen technology for the rehabilitation of the ST 2045. Here, hot bitumen is foamed by the addition of precise amounts of air and water and added to the mixing process together with small quantities of a pre-spread cement binder.

As a rule, the surface layers, made up of asphalt or granular material, are taken up and mixed with binding agents in a single pass. In the mixing chamber of the W 240 CRi, the foamed bitumen forms fine micro-bonds within the material. These bonds are crucial for ensuring the long-term elasticity of the BSM (bitumen stabilized material) used as a new base layer.

The material was transferred directly from the cold recycler to the material hopper of the Vögele paver and laid down as the train advanced. Here in Markt Indersdorf, the machines achieved an impressive production rate of 360 tons per hour. No removal of material in trucks, no intermediate stockpiling and no need for new base layer material were required.

The materials were tested in the construction materials laboratory before the start of the project to find the ideal recipe for the new base layer. In the course of this, it was determined that the existing 2 – 3 in. asphalt surface layer would be insufficient for the desired end result.

In view of this, additional reclaimed asphalt pavement (RAP) from nearby construction sites was mixed in during the cold recycling process to produce the desired 160 mm BSM base layer. The 6.3 in. layer of RAP augmented the existing asphalt surface layer and, together with the cement binder and foamed bitumen, became a further ingredient of the mix for the new base layer of the road. The result: a homogeneous, bitumen stabilized base layer.

In the first phase of the project, a John Deere 672 GP grader and a Hamm HD+ 140i tandem roller prepared the construction site by grading and compacting the additionally placed RAP.

At the start of the cold recycling process, precisely dosed quantities of cement were spread by a Streumaster SW 16

MC binding agent spreader. The existing roadway was premilled by W 150 CFi and W 130 Fi compact milling machines from Wirtgen to complete a wider working width. All the milled material was then processed by the addition of foamed bitumen in the Wirtgen cold recycler W 240 CRi. The paving of the BSM layer true to grade and slope by the Vögele paver Super 2100-5i was followed by compaction with the Hamm HD+ 140i tandem roller and final compaction by the HP 280i pneumatic-tire roller.

The surface layer also was paved by the Vögele Super 2100-5i, which was fed with asphalt mix by a Vögele MT 3000-2i mobile feeder.

The existing base layer consisted of the round gravel typically used in this region — a material that was assessed as unsuitable for inclusion in the cold recycling process. The cold recycler and the milling machines milled down precisely to the upper boundary of the gravel layer. This meant that the road bed remained untouched and the new 6.3 in. base layer was augmented.

The now thicker layer structure thus increased the loadbearing capacity of the road. In the final step, an only 1.6 in. thick surface layer of new asphalt was paved over the top of the BSM base layer.

“We are now rehabilitating the road with the cold recycling method with a complete recycling train of Wirtgen Group machines,” said Stefan Hausmann, senior site engineer of SSP Seizmeir Strassen- und Pflasterbau GmbH. “We are paving a new and stronger base layer with additional milled material from another construction site. The big advantage: It’s a lot faster than complete removal.”

The entire cold recycling train worked as a rolling construction site along the road, which meant that the sections in front of it and behind it could be used as normal, even by heavy agricultural machinery.

For more information, visit wirtgen-group.com.

LESLIE EQUIPMENT COMPANY www.lec1.com

6248 Webster Road Cowen, WV 26206 304/226-3299

2098 Lillian Lane Pleasant Valley, WV 26554 304/534-5454

19 Goff Crossing Drive Cross Lanes, WV 25313 304/204-1818

80 John Deere Lane Norton, WV 26285 304/636-6421

136 Clifftop Drive Beaver, WV 25813-1525 304/255-1525

www.monroetractor.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

7300 Eastman Road N. Syracuse, NY 13212 315/452-0000

8194 State Route 415 Campbell, NY 14821 607/739-8741

6 Equipment Drive Binghamton, NY 13904 607/754-6570

GROFF TRACTOR & EQUIPMENT www.grofftractor.com

800-33-GROFF 800-33-(47633)

6779 Carlisle Pike Mechanicsburg, PA 17050

210 Rolling Ridge Drive Bellefonte, PA 16823

963 South Center Ave New Stanton, PA 15672

179 Perry HWY Hamony, PA 16037

2550 East Cumberland St. Lebanon, PA 17042

640 Lowther Rd. Lewisberry, PA 17339

FORESTRY

www.unitedequip.com

80 Southbridge Rd. • Route 20 North Oxford, MA 01537

508/987-8786

2397 GAR Highway • Rte 6 & 136 North Swansea, MA 02777 508/379-9810

88 Camelot Drive • Unit 42 Plymouth, MA 02360 508/830-9997

1620 Page Blvd Springfield, MA 01104 413/543-5595

4 Sterling Road North Billerica, MA 01862 978/667-4345

34 Page Road West Hermon, ME 04401 207/947-6786

106 North Street Houlton, ME 04730 207/532-6517

1505 Caribou Road New Canada, ME 04743 207/834-6701

396 County Road Westbrook, ME 04092 207/773-3777

98 Sheep Davis Road Pembroke, NH 03275 603/225-2769

300 Clinton Street Springfield, VT 05156 802/885-6840

2019 Rosco Max 2B distributor, 1950 gallons, Max 2B computer, 12 ft spray bar, diesel burners, Freightliner M2, Cummins 6.7L dse eng, auto trans, front tires new $149,000

2022 Volvo PT125C pneumatic roller, 9 wheels, Volvo dsl eng, water system, tires 90%, 365 hrs $62,000

2014 Bomag BW11RH pneumatic roller, 9 wheels, Cummins dsl eng, water system $29,000

2019 Volvo DD30B double drum 49” vibratory roller, Kubota dsl eng, double drum drive, water system, 3 tons $26,000

JCB continues to invest in American infrastructure and innovation with the introduction of the CT380 and CT430 vibratory tandem rollers at Pave-X 2025.

Designed to meet the demands of U.S. paving professionals, these high-performance machines represent JCB’s dedication to delivering robust, dependable solutions for asphalt paving and site preparation, the company said.

“Our new rollers underscore JCB’s longterm investment in North America,” said James Gill, JCB product manager. “From our new manufacturing facility going up in San Antonio to the launch of products like the CT380 and CT430, we are laser-focused on meeting the needs of U.S. contractors with machines that are reliable, easy to operate and built to perform.”

(CT430) deliver centrifugal forces of up to 13,800 lbs. and 14,600 lbs. per drum, ensuring superior compaction.

• Efficient Operation: Both models feature maximum travel speeds of 6.2 mph, enabling swift, efficient movement across work sites.

• Exceptional Maneuverability: With a ±34-degree steering angle and ±13-degree oscillation angle, the rollers navigate tight turns and uneven terrain with ease.

• Operator-Centric Design: Adjustable seats, intuitive controls and exceptional visibility reduce fatigue and enhance operator productivity.

• Low Maintenance, High Uptime: Simplified service points and reduced maintenance intervals keep machines on the job longer.

New Marathon TPS250PT tack distributor, Briggs gas eng, 10GPM pump, 250 gal, spray wand w/50 ft hose, hose reel, propane burners, flushing system $18,650

2012 Etnyre Centennial II distributor, 2000 gal, BT-1 computer, 12 ft spray bar, diesel burners, PTO pump, Ford F750XL, Cummins 6.7L dsl eng, auto trans, 2 spd axle, 122,832 miles $100,000

With the addition of the CT380 and CT430, JCB has expanded its tandem roller lineup to four models, providing versatile options to match the diverse needs of American job sites. The lineup, which also includes the compact CT160 and mid-size CT260, ensures that contractors have the right tools for any paving or compaction task, whether working on tight urban spaces or large-scale infrastructure projects.

The CT380 and CT430 are equipped with features to tackle the toughest jobs, offering reliable compaction and operator-focused design, with:

• Versatile Compaction Power: Dualdrum widths of 51 in. (CT380) and 55 in.

• Smart Security: JCB LiveLink telematics provides advanced tracking and monitoring for added peace of mind.

Powered by efficient 48.9-hp, 3-cylinder engines, the CT380 and CT430 are built to handle rigorous daily use. Their operating weights — 8,820 lbs. and 9,920 lbs. respectively — strike a balance between easy transport and heavy-duty performance.

“Our philosophy is robust simplicity,” Gill explained. “These machines are easy to operate, easy to maintain and ready to work whenever you are. That’s what makes the CT380 and CT430 invaluable on American job sites.”

For more information, visit www.jcb.com.

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605 allislandequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W

Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787

ambroseequipment.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

8194 State Route 415 Campbell, NY 14821

607/739-8741 www.monroetractor.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810 203/775-1203 80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455