By Chuck MacDonald CEG CORRESPONDENT

The Riverside Freeway (S.R. 91) in Southern California is an essential part of the complex freeway system that carries beachgoers, workers, residents and students to their various destinations.

S.R. 91 works with its close neighbors, the Costa Mesa Freeway (S.R. 55) and Orange Freeway (S.R. 57), along with its big brother, Interstate 5, to enable travelers to get where they need to go.

Granite Construction is now replacing the Lakeview Avenue Bridge in Anaheim, which

will help alleviate congestion and enhance safety in this busy region. The job is part of the SR-91 Improvement Project led by the Orange County Transportation Authority (OCTA) and the California Department of Transportation (Caltrans).

see BRIDGE page 36

By Lucy Perry CEG CORRESPONDENT

tion

The infrastructure sector “is entering the latter half of the 2020s with solid growth prospects,” according to portfolio management firm Loan Analytics.

Fueled by government investment to address critical infrastructure needs, the industry will see sustained demand from funding programs such as the

2018 Bomag BW145D-5, Stk#: HR1669, 54" Smooth Drum w/Pad Drum Shell Kit, 889 hrs. $42,500

2024 John Deere 210P, Stk#: HR1593, EROPS, A/C, 2,247 hrs., GP Bucket $189,500

2023 John Deere 700L LGP, Stk#: HR-1461, EROPS, A/C & Heat & Heat, Radio, 2,686 hrs., 6 Way Blade, 30" Pads, 12 ft. Wide ..............$189,500

2021Linkbelt 145X4LC, Stk#: HR1733, EROPS, A/C & Heat, Radio, 2,938 hrs., 60% U/C, 36" Bucket w/Hyd. Thumb, 24" Pads, Aux. Hyd. ............................................$78,500

2023 John Deere 450P LGP, Stk#: HR-1531, EROPS, A/C & Heat, 985 hrs., 6 Way Blade, 24" Pads, 9' 7" Wide ..................................$119,500

2022 Skytrak 6036, Stk#: HR-1389, OROPS, 6,000 lbs., 36 ft., 802 hrs., 60" Forks, 74" Frame, 370/75-28 Foam Filled Tires $99,500

2023 John Deere 650P LGP, Stk#: HR-1555, EROPS, A/C & Heat, Radio, 1,176 hrs., 6 Way Blade, 24" Pads, 10' 4" Wide ..............$159,500

2023 John Deere 75G, Stk#: HR1465, EROPS, A/C & Heat, Radio, 1,443 hrs., 24" Bucket, 91" Blade, 17" Rubber Pads. $89,500

2023 John Deere 26G, Stk#: HR1493, OROPS,

At its November regular business meeting, the Wyoming Transportation Commission awarded six contracts valued at approximately $24.3 million for Wyoming Department of Transportation construction projects.

JCB announced a charity auction featuring a one-of-a-kind, customer hand-painted 3TS-8T teleskid, with proceeds benefiting veterans across the country, through VetsAid.

The newly installed leadership team will guide AEM as the association tackles a transformative agenda of advocacy, workforce development, sustainability and innovation in the off-road equipment industry.

The Consumer Technology Association (CTA) announced Joe Creed, Caterpillar CEO, as a keynote speaker at CES 2026. Combining a century of experience and technology, Caterpillar is redefining what heavy equipment can do.

18 BUILDING STRONGER SOLUTIONS FOR MARINE, INDUSTRIAL PROJECTS

After more than 18 years in the industry as a heavy and highway foreman and superintendent, Chad Cailteux saw the challenges contractors faced sourcing reliable, specialized equipment for marine and industrial projects.

31 DIAMOND MOWERS REENGINEERS MID-MOUNT BOOM MOWER

When it comes to maintaining miles of roadway, safety and control are non-negotiable. Diamond Mowers reengineered its mid-mount boom mower to deliver control, comfort and confidence for roadside maintenance professionals.

32 AMULET MANUFACTURING CO. RELEASES DITCHING BUCKET LINE

Amulet Manufacturing Co. has released a full line of ditching buckets for small excavators and most backhoe loaders up to 20,000 lbs., with larger bucket sizes planned for 2026.

37

The fully integrated solution represents Summit’s commitment to advancing technology, designed to upgrade the experience of operators in the field through enhanced equipment performance and streamlined to improve jobsite safety.

38

MGX Equipment Services, through its “Upfits by Aspen Equipment” brand, is redefining work truck versatility with Palfinger articulated crane boom attachment solutions.

38 STELLAR BOLSTERS PRODUCT EXPERTISE WITH NEW MANAGERS

Stellar introduced two new product managers, Kasey Lammers and Phil Boeckman. Lammers will be responsible for mechanic trucks and accessories, and Boeckman will be responsible for hooklift, roll-off and container trucks.

40 OFFUTT FAMILY FOUNDATION TOPS

IN DONATIONS

A unique initiative designed for R.D. Offutt Co. team members to nominate nonprofits to receive a grant, the Offutt Family Foundation Community Builder program demonstrates commitment to investing in the community.

Willbee Transit Mix operates a fleet of front discharge redi-mix trucks to service pours. For Willbee, maintaining the efficiency of concrete washouts between deliveries is important to his operation.

As you prepare for another winter of snow removal, perhaps you’re tuning up your skid steer or compact track loader or adding a blade to a truck. But have you ever considered a wheel loader for this type of work?

1090 W 2181 N Salt Lake City, UT 84116 801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021 480-463-4999

5401 S. Arcadia Avenue Tucson, AZ 85706 520-307-1435

Equipmentshare.com

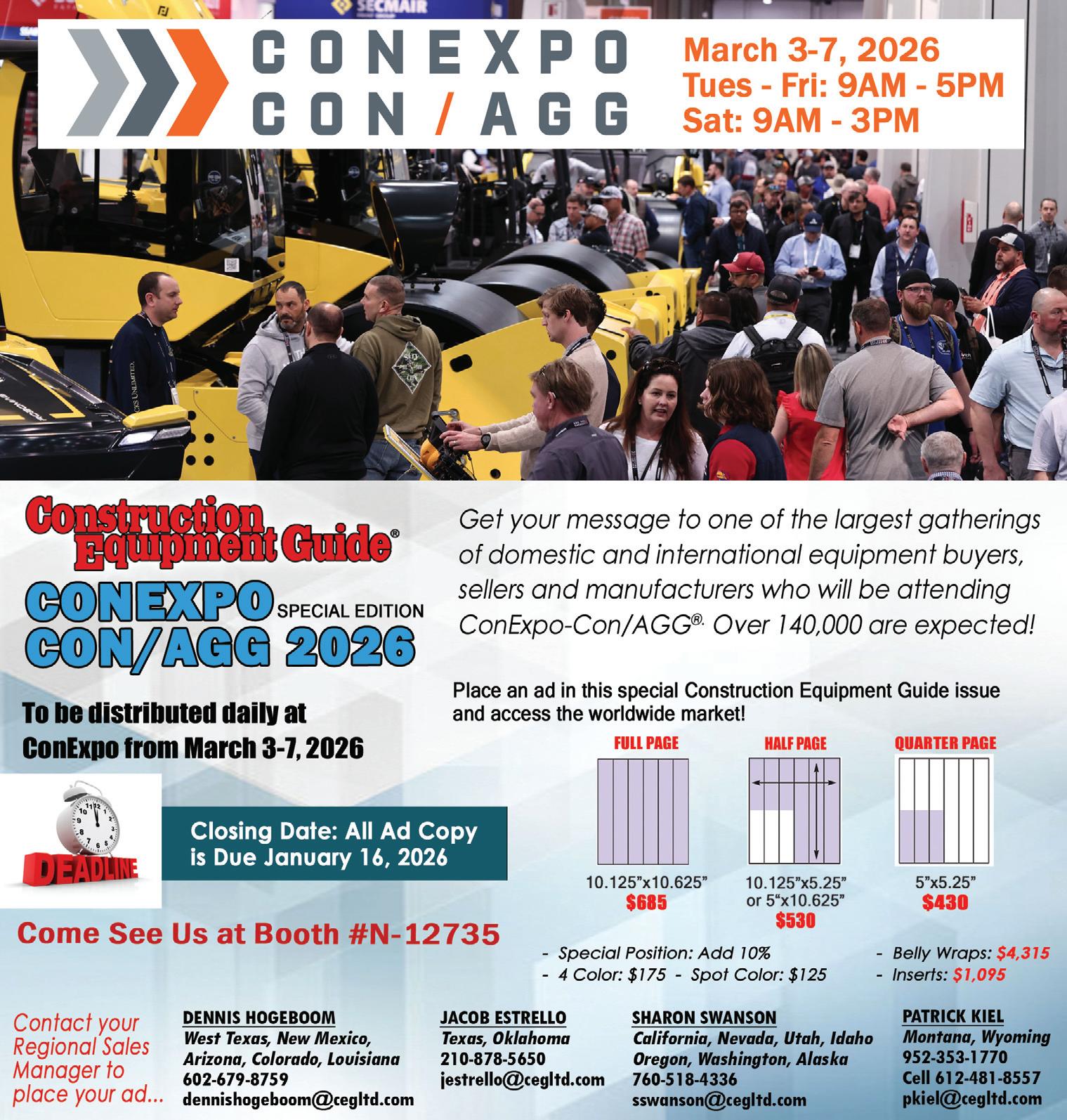

EXHIBITS: JANUARY 20-22, 2026

EDUCATION: JANUARY 19-22, 2026

LAS VEGAS CONVENTION CENTER

Push limits. Smash barriers. Break boundaries. And when you’ve conquered all those obstacles? You discover your full capacity for greatness. World of Concret e delivers all the real-world solutions that will crush your challenges and ta ke your exp ertise to new heights. Growth opportunities are everywhere, whether you’re getting hands-on with game-changing tools and tech or shaking hands with your future partners. Ready for maximum success? Nothing’s standing in your way.

ACHIEVE PEAK PERFORMANCE VIEW GLOBAL EVENTS

0% APR for up to 60 months on excavators or 48 months on loaders. BUILT TO PERFORM. BACKED BY WARRANTY. READY WHEN YOU ARE.

At its November regular business meeting, the Wyoming Transportation Commission awarded six contracts valued at approximately $24.3 million for Wyoming Department of Transportation construction projects.

The commission awarded a bid valued at approximately $14.5 million to Worland, Wyo.-based McGarvin-Moberly Construction Co. for a mill and overlay project.

It involves placing asphalt pavement and wearing course, applying bridge deck membrane and installing fence and temporary guardrail, along with placing temporary traffic control measures on approximately 9.80 mi. of eastbound and westbound lanes on Interstate 90 beginning at mile marker 168.31 between Moorcroft and Sundance in Crook County.

The contract completion date is Oct. 31, 2027.

The commission awarded a bid valued at approximately $3.1 million to Cheyenne, Wyo.-based JTL Group Inc., known as Knife River, for a mill and overlay project involving placing asphalt pavement and applying wearing course, placing temporary traffic control measures and milling plant mix on Grand Avenue in the city of Laramie beginning at mm 329.47 for approximately 2.73 mi. The contract completion date is Oct. 31, 2026.

The commission awarded a bid valued at approximately $2 million to Gillette, Wyo.-based S & S Builders LLC for a bridge replacement project involving placing precast box culverts, asphalt pavement, road base, temporary traffic control measures, structural concrete and removing one concrete bridge at mm 313.89 on U.S. Highway 30/287 between Bosler and Laramie in Albany County. The contract comple-

tion date is Oct. 31, 2026.

The commission awarded a bid valued at approximately $625,000 to Rock Springs, Wyo.-based DeBernardi Construction Co. Inc. for a concrete slab replacement project involving replacing and repairing concrete slabs and placing temporary traffic control measures at various locations in Sweetwater County. The contract completion date is Oct. 31, 2026.

All the above projects are funded primarily with federal dollars.

Funded primarily with state dollars, the commission awarded a bid valued at approximately $3.2 million to S & S Builders for a bridge replacement project involving erecting and installing steel, placing concrete and road base, machine placing riprap, laying asphalt pavement, performing excavation, placing temporary traffic control measures and removing one steel bridge at mm 3.29 at the Bridge over Chugwater Creek on Wyoming Highway 314 in Platte County. The contract completion date is Nov. 30, 2026.

Also funded primarily with state dollars, the commission awarded a bid valued at approximately $834,500 to Cowley, Wyo.-based Wilson Bros. Construction Inc. for a culvert cleaning and lining project involving cleaning culverts, lining pipe, placing temporary traffic control, backhoe work, placing grout and placing erosion control measures at various locations in Crook, Johnson and Sheridan counties. The contract completion date is Oct. 31, 2026.

Almost all WYDOT projects are awarded to the lowest bid.

Helping the most inexperienced drivers look out for the most vulnerable road users is the goal of a new, national partnership announced today between the American Road & Transportation Builders Association (ARTBA) Foundation and Work Zone Safe — an Oklahoma-based nonprofit teaching teen drivers “there is a face and a family behind every flag, cone and flashing light.”

Adopted by the Oklahoma state legislature in 2023 as a component of driving certification, the Work Zone Safe program has since expanded into six more states, with a projected 250,000 teen drivers to be trained next year.

Through a major financial gift from ARTBA’s Foundation, and in partnership with the association’s state contractor chapter affiliates, the initiative aims to:

• encourage adoption of program requirements in other states;

• expand hands-on training opportunities for state transportation agencies to deliver their own “faces behind the flag” safety training;

• bring the “faces behind the flag” opportunity to community events; and

• recognize and reward teen drivers nationwide who demonstrate a commitment to safe driving in work zones.

“Teaching teens to respect work zones directly aligns with ARTBA’s goal to protect roadway workers during construction operations,” said Brad Sant, senior vice president of safety and education for ARTBA.

For more information, visit artbatdf.org/.

JCB is revving up its commitment to America’s veterans with a powerful presence and a meaningful mission during this year’s VetsAid charity concert.

At the concert, JCB announced a charity auction featuring a one-of-a-kind, customer hand-painted 3TS-8T teleskid, with proceeds benefiting veterans across the country, through VetsAid.

The exclusive teleskid was located near the main entrance of Intrust Bank Arena during the event, giving concert goers first look at this unique melding of art, purpose and horsepower. It was custom painted by the Monster Jam creative team known for designing iconic trucks like Grave Digger.

The only machine of its kind, it features patriotic styling, inspired by Joe Walsh’s father’s World War II fighter jet, and the same advanced performance capabilities found in JCB’s standard VetsAid edition. The auction, which will open the summer of 2026, will be hosted online through bidadoo, a heavy equipment auction house, giving fans and contractors alike a chance to own a piece of equipment with purpose.

The concert marked the latest milestone in JCB’s partnership with VetsAid. As a signature sponsor, JCB has pledged to raise $1

million to support United States military veterans and their families through VetsAid. The campaign centers on the special edition VetsAid teleskid, pledging $1,000 from each unit sold to the charity. VetsAid directly supports veterans services groups across the United States that provide myriad of types of care for veterans and their families.

“VetsAid isn’t just about raising money and awareness for America’s veterans and their families,” Walsh said. “It’s also about finding common ground amongst musiclovers of all backgrounds and coming together to build and rebuild communities around a shared love of country. It’s a privilege for us at VetsAid to expand upon this vision with Alice, Ann and the entire Bamford family, as well as our friends at JCB.”

“This partnership is deeply personal for us,” said Alice Bamford, senior vice president of JCB North America. “We believe in honoring veterans not just with words, but with real action. Through this collaboration with Joe Walsh and the VetsAid team, we’re helping create opportunities, rebuild lives and show America’s heroes that they’re never alone.”

Bamford recently announced JCB and the VetsAid machine sales have resulted in over $400,000 for the charity to date.

The VetsAid 3TS-8T teleskid is built to perform with the same dedication shown by the veterans it honors. Each machine features a military green exterior, a customstitched seat embroidered with the VetsAid logo and a set of commemorative dog tags.

The teleskid stands out for its telescopic boom, allowing operators to lift up to 13 ft., reach more than eight ft. forward and dig three ft. below grade. A 74-hp engine and JCB’s single-arm boom with side-door entry complete the package.

Adding to the spectacle at the Nov. 15 concert, JCB showcased JCB DIGatron and driver Tristan England — a 2025 Monster Jam World Finals champion — as a symbol of performance, pride and partnership. As the Official Heavy Equipment Partner of Monster Jam, JCB has used the high-energy world of competitive motorsports to spotlight both its machines and its mission at events across the country.

“Monster Jam has been a powerful platform for JCB — not only to demonstrate our equipment in action, but to connect with communities that value service, family and resilience,” Bamford said. “Bringing JCB DIGatron to VetsAid alongside this special edition teleskid is our way of combining that

energy with purpose. It’s a celebration of veterans and a commitment to their future.”

Founded in 2017 by Joe Walsh, VetsAid has raised more than $4 million by uniting rock legends and local communities to champion veteran causes. The 2025 concert in Wichita continues that tradition, with a star-studded lineup and an expanded role for JCB that reflects the company’s belief in partnership-driven impact.

By bringing together VetsAid, Monster Jam and bidadoo, JCB transformed this year’s concert into more than a night of music. It’s a rallying point for community, craftsmanship and cause. The debut of the custom-painted teleskid, the presence of JCB DIGatron and the energy of the crowd all served a shared purpose: supporting America’s veterans.

The charity auction for the custom VetsAid Teleskid will run during the summer of 2026. Interested parties can find out more at bidadoo.com/VetsAid-JCB. Proceeds go directly to VetsAid to support veteran-focused services nationwide.

For more information, visit jcb.com/enUS/explore/engage/sponsorship-and-partnerships/vetsaid/.

Bingham Equipment

binghamequipment.com

Tucson, AZ 520-889-6396

Cisco Equip

cisco-equipment.com

Artesia, NM 575-748-1314

Lubbock, TX 806-745-9595

Odessa, TX 432-550-9181

Ditch Witch of the Rockies

*Compact Equipment Only ditchwitchrockies.com

Nampa, ID 208-376-8394

Pocatello, ID 208-646-4360

Farm Equip USA

farmequipmentusa.com

Fruitland, ID 208-941-6000

G4 Const Equipment, LLC

g4hyundai.com

Commerce City, CO 888-987-3352

Jet City Equip

jetcityequipment.com

Oak Harbor, WA 360-675-4441

Marysville, WA 360-651-9079

Mecom Equipment

mecomequipment.com

Stockton, CA 209-466-5135

National Equipment Dealers

nedealers.com

Houston, TX 800-234-5007

Dallas TX 866-270-1700

Nueces Power Equip

nuecespower.com

Corpus Christi, TX 361-289-0066

Laredo, TX 956-725-0066

San Antonio, TX 210-310-0066

San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

El Paso, TX 915-541-0066

Oklahoma Territory

Const Equip callotce.com

Oklahoma City, OK 866-339-6827

Oregon Tractor oregontractor.com

Roseburg, OR 541-679-6211

Porter Rents

porterrents.com

Corona, CA 951-674-9999

Lakeside, CA 619-390-1197

Pacoima, CA 818-834-0102 Wildomar, CA 951-678-9902

Powerscreen of Washington, Inc.

powerscreen-wa.com Helena, MT 253-236-4153

Powerscreen of Northern California, Inc.

powerscreenofcalifornia.com Dayton, NV 888-797-7276

Dixon, CA 707-253-1874

Rifle Equipment, LLC

*Compact Equipment Only rifleequipment.com

Rifle, CO 970-625-2580

R&S Industries Inc. rsindinc.com

Amarillo, TX 806-737-9410

Clovis, NM 575-769-8659

Tri-State Equipment

*Compact Equipment Only tristateequipmentrentals.com

Lake Havasu, AZ 928-680-6748

Fort Mohave, AZ 928-704-0101

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

The Association of Equipment Manufacturers (AEM) announced the election of its 2026 officers and board directors during its annual business meeting in Aventura, Fla.

The newly installed leadership team will guide AEM as the association tackles a transformative agenda of advocacy, workforce development, sustainability and innovation in the off-road equipment industry.

“As we usher in this distinguished group of officers and board members, we’re not simply filling seats, we’re elevating the engine drive behind AEM’s mission,” said Megan Tanel, president and CEO of AEM.”

• Phil Kelliher, senior vice president, Cat rental and used, Caterpillar, AEM chair

• Kurt Coffey, vice president, Case IH, North America, CNH Industrial America, AEM vice chair

• Melvin Porter, president and CEO, Link-Belt Cranes, AEM treasurer

• Greg Petras, president, Kuhn North America, Ag Sector board chair

• Erica Baird, executive director — global sales and service, Cummins, CE Sector board chair

• Megan Tanel, president and CEO, AEM, secretary

2026

• Jason Andringa, president and CEO, Vermeer Corp.

• Erica Baird, executive director, Cummins

• Brian Bieller, president, Bomag Americas

• Stephen Bullock, president, Power Curbers Co.

• Kurt Coffey, vice president, Case IH, North America, CNH Industrial America

• Jason Daly, vice president of earthmoving sales, marketing and customer success, Deere & Co.

• Richard Fox-Marrs, president and CEO, JCB

• Grant Godbersen, president, Gomaco Corp.

• Linda Hasenfratz, executive chair, Linamar Corp.

• Bill Hurley, vice president, global government affairs,

• Keith Johnson, president, Kondex Corp.

• Phil Kelliher, senior vice president, Caterpillar

• Greg Petras, president, Kuhn North America

• Melvin Porter, president and CEO, Link-Belt Cranes

• Austin Ramirez, CEO, Husco

• Jeff Reed, chairman, Reed International

• Eric Sauvage, president and CEO, LBX Co.

• Kristie Stern, president, Green Mountain Lion Corp.

• Todd Stucke, executive officer, Kubota Corp.

• Pat Weiler, president and CEO, Weiler

• Grant Adolph, chairman of the board and chief operating officer, Buhler Industries

• Tim Bucher, CEO and co-founder, Agtonomy

• Kurt Buehler, group president, Linamar Corp.

• Shane Coates, executive vice president of North America dealer CE and ag sales, JCB

• Kurt Coffey, vice president, Case IH, North America, CNH Industrial America

• Mark Core, executive vice president, Vermeer Corp.

• Fernando Cuccioli, executive vice president, Cluster Americas, DeLaval

• Luke Gakstatter, senior vice president, sales and marketing, ag and turf division, Deere & Co.

• Doug Griffin, partner, Kearney

• Bill Hurley, vice president, AGCO Corp.

• Keith Johnson, president, Kondex Corp.

• Todd Kniffen, senior vice president of engineering and global product management, Kinze Manufacturing

• Dietz Lankhorst, president and CEO, Krone North America

• Darryl Matthews, president, global agriculture, Valmont Industries and Valley Irrigation, Valley Irrigation

• Anthony Montag, CEO, Montag Manufacturing

• Yannick Montagano, president, Kubota Canada

• Brian Nelson, CEO and chairman, HCC

• Greg Petras, president, Kuhn North America

• Viren Popli, president and CEO, Mahindra USA

• Eric Raby, senior vice president, Claas of America

2026 AEM Construction Sector Board

• Jay Allen, president and CEO Allen Engineering Corp.

• Erica Baird, executive director — global sales and service, Cummins

• Dean Barley, president and CEO, Tadano America Corp., Manitex International and Tadano Mantis Corp/; CEO, Tadano Europe, Tadano America Corp.

• Glen Calder, president and vice president of operations, Calder Brothers Corp.

• Susanne Cobey, CEO, Eagle Crusher Co.

• Steve Corley, executive vice president, Deutz Corp.

• Ivan Di Federico, president and CEO, Topcon Positioning Systems

• Terry Dolan, head of CNH construction brands, commercial for North America, CNH Industrial America

• Mike Gidaspow, chief digital officer, Komatsu America Corp.

• Doug Gilbert, vice president of global sales and marketing, Parker Hannifin Corp.

• Jim Glazer, president and CEO, Elliott Equipment Co.

• Dave Hughes, vice president of global sales, McElroy Manufacturing

• Jim McEvoy, president and CEO, Wirtgen America

• Melvin Porter, president and CEO, Link-Belt Cranes

• Pete Moeller, group vice president, construction and international businesses, The Toro Co.

• Eric Sauvage, president and CEO, LBX Co.

• Robert Strong, senior vice president, Caterpillar

• Kevin Thomas, executive vice president, industrial equipment division, Alamo Group

• John Thornton, president, GS Global Resources

• Scott Young, president / head of sales region North America, Volvo Construction Equipment North America For more information, visit aem.org/.

The Consumer Technology Association (CTA) announced Joe Creed, Caterpillar CEO, as a keynote speaker at CES 2026.

Combining a century of experience and technology, Caterpillar is redefining what heavy equipment can do, creating new, better and safer ways for its customers to dig, mine, build, power and evolve, according to Caterpillar.

Caterpillar will unveil its latest developments in AI, machine learning and autonomous functionality, announcing new innovations, partnerships and investments.

“CES is where innovators show up and bold ideas come to life,” said Gary Shapiro, CEO and vice chair of CTA. “I’m thrilled to welcome CEO Joe Creed and Caterpillar to the CES keynote stage to show how technology is transforming the way we build.”

Celebrating its centennial in 2025, Caterpillar will use its CES 2026 keynote to launch the next 100 years with a clear focus on technology. Creed and other company leaders

in digital and technology will outline how new tech approaches will meet today’s needs and anticipate tomorrow’s challenges, delivering continuous value to customers.

From dirt to data, Caterpillar will cover its evolution in autonomous machines and the tangible impact of AI on the industry.

Caterpillar also is equipping its workforce with tech tools that allow them to focus on customer service, product development and operational efficiency.

“We are building on our strong legacy of innovation, rapidly expanding our tech capabilities in new ways that help solve our customers’ toughest challenges,” said Creed.

“CES is the place to showcase Caterpillar as an advanced technology leader in industrial equipment with expertise that extends beyond moving earth to include intelligent systems and integrated digital platforms that anticipate, evolve and optimize customer outcomes for a better tomorrow.”

In his nearly 30 years across multiple divisions of the corporation, Creed has developed a deep understanding of the diverse operations and strategic opportunities crucial to enhancing Caterpillar’s global leadership. As the company embarks on its second century, he is dedicated to honoring the company’s rich legacy, leveraging the tech that will drive its future and focusing on its greatest competitive advantage, Caterpillar’s people.

“I look forward to a dynamic Caterpillar keynote at CES, exploring AI’s transformational power and potential as we build the world,” said Kinsey Fabrizio, president of CTA. “We can’t wait to see how Caterpillar is moving the mobility tech ecosystem forward.”

Creed will deliver his keynote at 9 a.m. on Jan. 7, in the Palazzo Ballroom at the Venetian. Lisa Su of AMD, Yannick Bolloré of Havas and Vivendi and Yuanqing Yang of Lenovo also will keynote at CES 2026.

For more information, visit cat.com

Ted McKeon

Joe McKeon

Richard McKeon

Barry McKeon

Teddy McKeon

Kent Hogeboom

Rich Olivier

Patrick Kiel

Dennis Hogeboom

Sharon Swanson

Natalie Spain

Jacob Estrello

Amanda Guilfoyle

Rich Thompson

Judy Nixon

Theresa Vickers

Jill DePoy

Deby Hogeboom

Denise Giaccio

Mary DeRosa

John Pinkerton

Matt Seslow

Jennifer Hood

Craig Mongeau

Andy Gotlieb

Katherine Petrik

Adam Zeenkov

Cathy Printz

Caitlin Murphy

Maria McKeon

Donna Prendergast

Kathy McDonnell

Kathy Miller

Terry Mazza

Andrea Pinkerton

Stephen Collins

Rob Tredinnick

By Katherine Petrik CEG EDITORIAL ASSISTANT

Founded in 2015 by Chad Cailteux, 5R Enterprises, Morris, Ill., was created to provide contractors working on lakes, rivers and ports with the right tools and lasting partnerships.

After more than 18 years in the heavy equipment industry as a heavy and highway foreman and superintendent, Cailteux saw the challenges contractors faced sourcing reliable, specialized equipment for marine and industrial projects. His goal was to offer better solutions supported by stronger relationships.

What began as a regional operation on the Illinois River has grown into a nationwide business serving clients across the Gulf, Atlantic and Pacific coasts, as well as the Great Lakes and inland waterways throughout the United States.

The strength of 5R lies in its products and its people.

Tom Ellis, vice president of PLM Products, brings more than 50 years of experience in construction, heavy equipment and material handling. A former U.S. Navy Seabee and past president of Howell Tractor, Ellis joined 5R to help redefine the dutycycle crane market.

Alan Johnson, area manager, contributes a lifetime of experience in heavy construction equipment rental and sales consulting, offering practical insights and solutions to clients.

John Kissner, area manager, adds expertise from his years with Anvil and Bateman, specializing in heavy material handling attachments.

Nick Klein, territory manager, joined 5R in 2018 after a career in crane and rigging operations and national equipment rentals.

His field experience continues to drive the company’s growth and success.

5R Enterprises supports a wide range of markets, including dredging and marine construction; demolition; heavy industry and construction; scrap metal operations; and lake and river terminals.

The company is an active member of several key industry organizations, including Inland Rivers, Ports & Terminals (IRPT); Recycled Materials Association (ReMA); National Demolition Association (NDA); and Western Dredging Association (WEDA).

5R Enterprises’ offers a variety of equipment from PLM Cranes, Atlas, Mantsinen, HDK Blue, OTH, GRYB, Minnich and C. Norris Manufacturing.

A cornerstone of 5R’s success is its partnership with PLM, a company with more than a century of engineering heritage. Founded in 1920 in the Netherlands, PLM began as a transport and construction company and later shifted its focus to crane manufacturing after the Dutch floods of 1953.

By 1954, PLM was producing specialized cranes to rebuild the nation’s waterways. The business continued to expand internationally and, under the leadership of the third generation, Pieter Pulleman, evolved into a global name in crane innovation.

Today, PLM designs and builds both series and custom cranes, combining oldworld craftsmanship with modern engineer-

ing. This shared focus on quality and innovation led to the partnership between PLM and 5R Enterprises, which introduced the PLM duty-cycle crane line to North America. Together, they deliver performance and customization that meet the needs of dredging, scrap and marine construction professionals.

Mantisinen, a division of SMH Group, offers a diverse range of hydraulic material handlers and attachments. The company strives to design machines that are economical and ecological without compromising safety, according to the company.

Mantsinen’s HybriLift is an energy-saving system that can decrease energy consumption up to 50 percent, according to Mantsinen.

These machines are available from 150,000 to 900,000 lbs. with rubber tire, crawler and specialty undercarriage mounts. Engines are available in diesel and full electric.

A division of SMH Group, Atlas, founded in 1919, offers material handlers for scrap, wood, bulky goods, special recycling, port and vacuum operations.

These hydraulic material handlers from 35,000 to 126,000 lbs. are equipped with rubber tire, crawler and specialty undercarriage mounts. The machines can be designed to use diesel, full electric and battery-powered engines.

A variety of attachments available include the load hook, log grab, clamshell grab, orange peel gran and load lifting magnet. A wide selection of booms and arms also are available.

see MARINE page 25

Dennis Howard SPECIAL TO CEG

We are in the full swing of fall sports seasons. After a long week on job sites, we’re sitting on the couch and turning on the TV to watch our favorite team.

Much like a football team driving toward the end zone before the clock runs out, a job site crew works together to complete specific tasks on time and on budget. In both football and construction, success depends on skilled players and the right equipment.

On a crushing site, the crusher plays the role of the running back — powerful, reliable and essential for driving production forward. But the machine that delivers material to the crusher is where the play begins, much like a quarterback handing off the ball. Choosing the right support machine, whether an excavator or a wheel loader, can affect the accuracy and efficiency of the crusher machine.

Before diving into the excavator vs. wheel loader debate, let’s break down the different types of crusher machines. Crushers are developed for different materials and loading capacities. Kleeman crushers, for example, come in three major types.

• Jaw Crushers: Designed for primary crushing of hard stone and recycling materials with high throughput and mobility.

• Impact Crushers: Ideal for soft to medium-hard stone and recycling, producing high-quality, well-shaped aggregates.

• Cone Crushers: Used for secondary and tertiary crushing of hard and abrasive stone with precision and efficiency.

While some contractors like TKB Excavation, based in southern Utah, opt to use all three models to produce the materials they need to deliver to their customers, others choose the crusher based on the orders they’re filling. Once the main crusher machine has been selected, the contractor can choose an excavator or wheel loader that will deliver consistent material and keep the crusher producing the desired output(s), whether that’s gravel, sand or specific rock sizes for landscapers. While both excavators

Once the main crusher machine has been selected, the contractor can choose an excavator or wheel loader that will deliver consistent material and keep the crusher producing the desired output(s), whether that’s gravel, sand or specific rock sizes for landscapers.

and wheel loaders have their place on the job site, one clearly earns the MVP title when it comes to optimizing crusher performance.

Excavators allow operators to pick out and move uncrushable or oversized material before it hits the crusher rotor. In tight spaces and uneven terrain, an excavator’s reach and maneuverability make it the ideal choice for in-place crushing applications.

Excavators’ ability to maintain a consistent material bed depth and feed rate into the rotor improves throughput and reduces wear on some components to potentially lower material production costs.

Wheel loaders can handle high-volume and fast-paced operations. In such instances, operators need to pay attention to Kleeman’s Constant Feed System (CFS) so they keep

the faster pace and act as finished material movers when the crusher produces the final product.

One thing to note, though, is that on asphalt and concrete rubble applications, wheel loaders can pose a higher risk of bridging, leading to uncrushable material entering the crusher, which can cause increased wear and downtime.

Watch this episode of “The Track” to hear Crushing Product Specialist Ronnie Trushenski explain how he works with contractors to choose the right machine for the desired material outcome.

There’s no one-size-fits-all answer. Excavators are the best bet for crews working in tight spaces or needing precision feeding. They’re like the nimble ball carrier, avoiding obstacles and operating efficiently. On the flip side, like a power back whose role is just to hit the line hard time and time

RDO

Dennis Howard

again, wheel loaders can come in clutch for bulk material handling, though they may carry some risk. For more information, visit RDOEquipmentCo.com. (Article reprinted with permission of RDO Equipment.)

806-364-5687

613 S. 4th Ave Mansfield, TX 76063 817-473-2110

3871 IH - 10 W. Freeway Exit 693 Columbus, TX 78934 979-732-6902

www.texasbearing.com

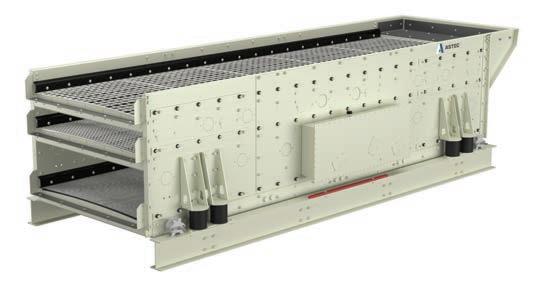

Astec Industries announced the launch of its groundbreaking Vari-Frequency technology implemented on our 6203 LP Horizontal Screen, a solution built to boost screening performance. The new design minimizes blinding and maximizes uptime, giving producers a smarter, more reliable way to keep processing material.

Installed on the bottom deck of a horizontal screen, the vari-frequency deck significantly increases throughput and efficiency while minimizing plugging and blinding — two of the most common challenges in screening operations. The live portion of the deck’s flexible surface is supported by a system of tensioned cables that create rapid, localized g-force spikes across the screen, stimulating the screen media and material to maintain throughput.

erates screen media vibration spikes to minimize buildup.

• Low maintenance: Cleaner screen media reduces the need to climb between decks for manual cleaning and downtime.

• Energy independent: Operates without external power for cost-effective performance.

Built for standard side-tensioned screen cloth and requiring no external power source, the vari-frequency technology provides an adaptable, energy-independent solution that integrates into existing systems, according to Astec. Its development was driven by testing and customer collaboration to ensure performance in demanding conditions.

Metso is celebrating the 50th anniversary of its Nordberg C Series jaw crushers.

Introduced in 1975, the Nordberg C Series was developed by a team of engineers in Tampere, Finland, to bring a new level of performance and durability to jaw crushers. Based on engineering research rather than traditional rules of thumb, the C Series quickly set a new standard in the industry with its modular design and optimized crushing geometry that revolutionized the market, according to Metso.

Since then, Metso has delivered more than 13,000 Nordberg C Series jaw crushers worldwide. Known for their reliability, safety, high performanc, and long service life, the crushers have become a cornerstone of primary crushing operations in aggregates quarries, mining sites and industrial installations globally, acccording to Metso.

The first Nordberg C Series crushers had non-welded, bolted frame construction and aggressive motion, ensuring optimal material flow. Since the original design the C Series has evolved with a range of features that enhance safety and simplify maintenance, reducing downtime.

Significant advancements in automation and digital connectivity have further transformed the C Series, enabling more efficient crusher control and condition monitoring, according to Metso.

Decades of experience behind the Nordberg C Series extend well beyond the crusher itself, shaping the design of Metso’s OEM wear parts to deliver maximum performance and uptime. The comprehensive range of wear part profiles and alloys means that customers can find the ideal solution for their specific feed material and end-product requirements while achieving the lowest cost per ton.

To ensure the Nordberg C Series continues to deliver value throughout its lifecycle, Metso provides support through its global network of service experts and parts distribution centers. This ensures fast response times, expert maintenance and ongoing operational reliability wherever our customers operate.

For more information, visit metso.com/campaigns/nordberg-c-series-jaw-crushers.

Key features include:

• Increased efficiency and throughput: New deck design delivers significantly higher throughput.

• Reduced blinding: Flexible, cable-supported deck gen-

vari-frequency

• Seamless integration: Screens with vari-frequency technology will be interchangeable with standard units requiring replacement or a performance upgrade.

As part of Astec’s broader commitment to continuous innovation, the company plans to incorporate vari-frequency technology into additional screen models across its robust product portfolio. Attendees of ConExpoCon/AGG 2026 will have the opportunity to preview the 8-ft. model, the next piece of equipment in the technology rollout.

The vari-frequency horizontal screen continues Astec’s legacy of designing durable, practical and forward-thinking equipment that meets the evolving needs of producers worldwide.

For more information on Astec’s screening solutions, visit astecindustries.com/products/details/vari-frequencyscreen?b=/screens-feeders/screens/horizontal-screens.

Introducing the new Jo Beau brand of small, tracked chippers and stump grinders to the United States, Miniloaders.com is now offering a remote control 7-in. chipper with adjustable tracks.

The M600 Gorilla chipper was introduced in 2023 by Jo Beau (Belgium) and features a 40 hp (EFI) Vanguard engine; radio remote control to move the machine and operate the “Stabilizing X-tracks,”; and an adjustable feed hopper that can be moved up and down hydraulically.

The adjustable tracks make it possible to position and maneu ver the chipper in uneven terrain, allow ing the operator to chip sticks and small diameter branches in any terrain condition. Jo Beau also implemented its drum technology which includes a heavy-duty feed roller and a feed system that works in tandem with engine RPM.

The M600 chipper is ideal for property management, and low-impact tree care such as pruning and backyard cleanup. With a weight of only 1,880 lbs., it is easy to transport on a small trailer. Its width of 29 in. allows it to be moved through small (garden) gates, according to the company.

In addition to the chipper, Miniloaders.com added the Jo Beau B37110RC to its line-up. The Jo Beau B37 is a

small, 37hp tracked stump grinder featuring the most compact transport dimensions in the stump grinding market. It also is the smallest remote control stump grinder currently available in the United States. Featuring a width of only 29 in. and a weight of 1,345 lbs., it is easy to transport the machine from rental yard to job site, according to the company. The remote control allows the operator to see the grinding process from a safe and comfortable position, without exposure to heat and exhaust fumes from the engine.

Miniloaders.com will be present at the 2026 ARA show in Orlando, Fla., to display these machines to rental companies, explain their advantages in a rental fleet and present a rental-store only discount to prospective buyers.

For more information, visit miniloaders.com.

VE MSS502 OVE MSS802 forKLEEMANN'smobilecoarsescreeningplantsThe and new applications can be a challenge for many scr C Even more selection to match your requirements! ey'rebuilttotakeon reening plants. Not so hanging locations nnameelk-neercsibom/moc.puorg-negtriw.www coarse screening plants. compact – it's up to you: The MOBISCREEN MSS 502 EVO | MSS 802 EVO were designed for outstanding flexibility and operability. Full-size or 802 EVO can easily adapt to new operating conditions. These machines screening parameter adjustment, the MOBISCREEN MSS 502 EVO and MSS pretty much anything. With their wide range of screening media and simple

for KLEEMANNs mobile coarse screening plants. Theyre built to take on Oklahoma City, OK 405-495-7820 Tulsa, OK 918-438-1700 McAlester, OK 918-310-1550

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826

Odessa, TX 432-333-7000 www.kirby-smith.com

Chico, TX 940-678-5046 Dallas, TX 214-371-7777

Ft. Worth, TX 817-378-0600 Hewitt, TX 254-261-1370

Corpus Christi, TX 361-289-0066

Lubbock, TX 806-745-2112

Vinton, TX 915-541-0066 Houston, TX 713-247-0066 San Antonio, TX 210-310-0066 www.nuecespower.com

Laredo, TX 956-725-0066 San Benito, TX 956-361-0066 Victoria, TX 361-576-0066

HKD Blue began as a snowmaking company until the Port of Quebec contacted the company to help with its dust problem. Now, HDK offers dust suppression solutions for the steel production, metal recycling, waste and recycling, demolition, mining and aggregates industries.

The compact units project 150 ft. with area coverage of 100,000 sq. ft., while large units project 225 ft. with area coverage of 145,000 sq. ft. The units can be skid and trailermounted and a self-contained trailer mount includes the power source.

Founded in 1989 in Collingwood, Ontario, Bateman Manufacturing, now a division of GRYB International, provides attachments for the scrap and recycling, port, forestry, demolition, railway and scrap, dredging and marine industries.

Types of attachments include a variety of grapples, clamshell buckets, magnets, skip pans, fork racks and more.

5R offers a variety of marine equipment for rent, including twin screw, 610 hp Truckable tugboats as well as crew and push boats.

Barges available for rent are 5- and 7-ft. sectional and 55ft.x120-ft.x7-ft. crane barges with spuds and a wide variety of other marine items.

By combining decades of experience, craftsmanship and a unique rental and sales model, 5R Enterprises continues to shape the future of heavy equipment solutions — one partnership, one project and one river at a time.

For more information, visit 5rents.com and PLMAmericas.com.

0% for 60 months, 0.99% for 72 months or up to $7,500 off, each on select models. All backed by a

602-463-3772

3300 E. Michigan Street Tucson, AZ 85714 520-649-2858

But that demand will be “tempered by challenges such as rising costs and labor shortages,” the firm believes.

Loan Analytics projects moderate but steady growth in this sector, as the industry works to bridge the nation’s large infrastructure gap.

“Contractors that adapt by embracing new technologies, workforce development and efficient practices are poised to benefit from the ample work.”

The firm believes policy support remains crucial. “Continued infrastructure funding and supportive regulations will underpin the industry’s success,” it said.

In a five-year construction industry outlook report, Loan Analytics noted that robust public funding has been the sector’s “primary engine of growth.”

A surge in federal, state and local government budgets for transportation infrastructure has helped.

Most notable was a $350 billion bump in federal funding for highways over 2022-2026 due to the bipartisan IIJA, signed by President Joe Biden in 2021.

“This infusion, largely distributed to states, ensures a pipeline of projects for contractors,” said Loan Analytics.

But state and local governments also have maintained healthy highway spending, leveraging federal grants and their own gas-tax revenues, it said.

As a result, construction firms have enjoyed a strong backlog of road work through the mid-2020s.

Prices for key inputs like steel, asphalt, cement and fuel have risen, as have costs for lumber and machinery.

Last year, the USDOT cautioned the industry that up to 40 percent of the remaining IIJA federal highway funds could be lost to inflation, reported Loan Analytics.

“Contractors are operating with tight profit margins, as they often locked in bid prices before the inflation surge and must absorb higher expenses. In response, firms are seeking escalation clauses in contracts and more efficient construction methods to control costs.”

Another seemingly perpetual challenge for the construction sector is the skilled labor shortage. In states experiencing a surge of highway and data-center projects, contractors are competing for the same pool of skilled workers, the firm found.

The labor crunch is driving construction wages, up 4.4 percent as of early 2025, as well as greater investment in workforce development.

“Contractors are also adopting new technologies, like automation, robotics and project management software, to improve productivity with fewer workers.”

On the flip side, technological and environmental trends are creating new opportunities, noted the firm.

“There is growing use of advanced project management tools, drones for surveying and AI for optimizing construction schedules.”

In fact, business management firm Deloitte notes AI is expected to drive “a profound transformation” in the construction sector over the next few years.

“This shift will redefine how work is delivered, moving from a labor-intensive, fragmented industry to a digitally enabled and augmented ecosystem,” said the firm. “AI-driven tools will optimize

designs, automate calculations and manage schedules in real time, enabling smarter and faster project outcomes.”

On construction sites automation will become increasingly visible, partially addressing labor shortages, enhancing safety and improving performance, it said.

And as AI integrates into everyday workflows, firms will start to see improvements in cost estimation, risk management and decision-making. This, in turn, will help them to anticipate and resolve issues before they escalate, the firm said in its 2026 engi-

neering and construction outlook.

On job sites, sustainable construction practices — recycled asphalt using low-carbon concrete, smart highway sensors and EV charging infrastructure — are more common.

“Some road builders are investing in green equipment and methods, aligning with government priorities to reduce emissions,” said Loan Analytics. “These innovations not only help meet environmental regulations but can also lower long-term costs and position contractors for new types of projects.”

The Birmingham Group reports that federal contracts now require Environmental Product Declarations and lifecycle tracking of key materials.

“The direction is clear,” said the recruiting firm. “Sustainability has moved from marketing phrase to baseline requirement.”

Firms ignoring the practice risk disqualification from public bids, the company noted.

“Those investing early in green design and compliance teams are positioning themselves for a decade of steady work.”

The portfolio management firm Loan Analytics is cautiously optimistic about the next five years and expects moderate growth.

“Industry revenue is projected to continue rising over the next five years as government funding remains strong and aging infrastructure demands attention.”

But even after the current IIJA funds are spent by 2026, it said, there will still be strong demand for infrastructure construction. In addition to federal funding, several states have passed their own transportation funding measures in the form of increased fuel taxes, tolls or bonds. Loan Analytics believes these initiatives will continue supplementing federal programs.

“Regions with fast population growth — Sun Belt states like Texas, Florida, Georgia — are projected to invest heavily in new highways and urban loop roads.” The projects are on the books through 2030 and will create regional hotspots of construction activity, reported the firm.

“Conversely, states facing budget strains may scale back, so growth will not be uniform nationwide.”

Typically, one of the most visible projects in the works are bridge repairs or replacements.

Strategic Partnerships, a government procurement advisor, sees new bridge projects proliferating rapidly. Mary Scott Nabers, the firm’s founder, reports that the IIJA earmarked $40 billion over five years to address the backlog of bridge work.

When it comes to maintaining miles of roadway, safety and control are non-negotiable.

That’s why Diamond Mowers has reengineered its mid-mount boom mower to deliver control, comfort and confidence for roadside maintenance professionals. Refined based on real-world field input, the reconfigured attachment introduces a new standard in boom mowing precision, transportability and uptime.

“This evolution is about putting power and protection directly into the hands of the people who keep our roads safe,” said Nate Cleveringa, vice president of engineering and product management of Diamond Mowers. “Every inch of this boom mower was shaped by real feedback from municipal operators and technicians. We’ve addressed their pain points and translated their input into a safer profile with smarter controls and thoughtful enhancements that help crews do more with less effort and less risk.”

The reimagined midmount boom mower features a narrower profile that reduces the machine’s overall width without compromising stability.

By repositioning the hydraulic tank to the front left of the cab and adding an axle stabilizer that reduces the amount of counterweights needed, Diamond has created a more streamlined attachment that minimizes lane encroachment during operation, according to Diamond Mowers. The mower system now sits within inches of the tractor’s tire on the traffic-facing side, an

tions or when servicing, the system can be disengaged at the push of a button for added safety.

Additional built-in safeguards reinforce Diamond’s commitment to operator safety and uptime. These include:

• Relocated hydraulic cooler — moved to the rear of the tractor for unobstructed headlight visibility in low-light conditions.

• Hydraulic level sensor — alerts the operator and disables mower and boom controls if oil levels are too low, reducing the risk of cavitation and preventing equipment damage.

The reimagined mid-mount boom mower features a narrower profile that significantly reduces the machine’s overall width without compromising stability.

intentional adjustment that gives operators more breathing room and drivers more peace of mind.

“This upgrade gives crews more confidence when working near traffic, on tight roadways or in confined roadside corridors,”

Cleveringa said. “It’s a machine built for the realities of municipal mowing.”

Precision meets performance in the midmount boom mower with upgraded components, customizable joystick sensitivity and a smart screen interface. Operators can adjust boom responsiveness in real time with the flip of a switch by speeding up for open-area coverage or dialing down for careful work around signs and fences. Fleet managers also can restrict speed settings and limit access to advanced controls for less experienced operators, according to Diamond Mowers.

“This is the first and only midmount boom mower in the industry to offer this level of adaptability

and control,” said Cleveringa. “Whether you’re fine-tuning boom speed around a light pole or gearing up performance for wide-open stretches, the responsiveness is instant and tailored to the operator. It’s fingertip precision that empowers productivity.”

In addition, the Smart Screen provides rapid diagnostics and access to system data. This allows operators to identify and resolve issues in minutes instead of hours, which reduces downtime and enables faster service and support, according to Diamond Mowers.

With the hydraulic drive disengage option, operators can shut off the mower when not in use to help reduce wear, fuel consumption and heat buildup. In emergency situa-

• Premium hydraulic valve — engineered to resist contamination and ensure smoother, more responsive boom movement.

“Our mission is to eliminate as many pain points as possible — from overheating components to blind spots that compromise safety — and provide a smarter way to work,” Cleveringa said.

Whether clearing highway shoulders, ditch lines, utility corridors or public park perimeters, Diamond Mowers’ redesigned mid-mount boom mower is built to thrive in municipal and commercial applications, according to Diamond Mowers.

From real-time boom control to advanced diagnostics and safetyfirst features, it delivers durable, precision performance for the professionals who maintain the nation’s infrastructure.

“This new and improved mower represents a thoughtful evolution in boom mowing,” said Cleveringa. “It’s purposefully built to be a partner in the field for the pros who keep our roads open and our communities connected.”

For more information, visit diamondmowers.com.

Amulet Manufacturing Co. has released a full line of ditching buckets for small excavators and most backhoe loaders up to 20,000 lbs., with larger bucket sizes planned for 2026.

Built 100 percent in the United States with U.S.-made steel and a full 2-year warranty, the new Amulet ditching buckets are built to last, according to Amulet.

years foreign-made buckets flooded the market putting small companies like Amulet at a competitive disadvantage, but the tide is slowly turning, and we are now hearing from folks looking for a quality, American-made bucket built here in the U.S.”

For nearly 45 years, Amulet has been known for its thumbs, rippers, rakes, couplers, hydraulic tilt buckets and railroad buckets, according to the company.

For more information, visit amulet.com.

Featuring AR400 serrated “grip” side plates and AR400 smooth or toothed bucket edges, the new Amulet ditch bucket’s design allows for longer bucket lifespan than standard excavator buckets, as well as a more positive gripping capability when used opposite of any type of thumb, according to Amulet.

“We have had countless requests by customers asking that Amulet bring back their general-purpose bucket line”, said Mark Elliott, Amulet’s national sales manager. “For a number of

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA

EMPIRE CAT

www.empire-cat.com

1725 S Country Club Mesa, AZ 85210

800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA

EMPIRE CAT

www.empire-cat.com

3300 St. Rose Parkway, Henderson, NV 89052

702-649-8777

Elko • 775-738-9871

Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Worland • 307-347-4747

MONTANA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

Billings, MT • 406-656-0202

Billings-Sgt. • 406-245-4426

Bozeman • 406-585-5800

Great Falls • 406-761-7900

Helena • 406-442-2990

TEXAS

MUSTANG CAT

mustangcat.com

Beaumont • 409-892-8412

Bryan • 979-775-0639

El Campo • 979-543-3389

Houston • 713-460-2000

Lufkin • 936-639-5551

WASHINGTON

NC MACHINERY

www.ncmachinery.com

800-562-4735

Seattle • 425-251-5800

Chehalis • 360-748-8845

Fife • 253-896-0878

Monroe • 360-805-6000

Mt. Vernon • 360-424-4292

Wenatchee • 509-886-5561

Yakima • 509-248-2371

In addition to replacing the bridge, the Granite team will add a new direct ramp to the Costa Mesa Freeway and improve connections to S.R. 91.

The work is planned for completion in 2027. The cost of the project will be slightly under $80 million.

Michael Kuhns is Granite’s project manager for the job. He outlined the need for the work on this portion of the Riverside Freeway.

“During peak travel periods, local and regional traffic demands exceed the freeway’s capacity,” he said. “Those demands are expected to increase. In addition, weaving and short merging distances via Lakeview Avenue causes congestion and delays.”

Kuhns and his team intend to recycle and repurpose much of the material from the excavation. The concrete and asphalt will be processed or crushed and used as fill for the construction of the new freeway on-ramp and off-ramp.

Lakeview Avenue Bridge is concrete, built with prestressed, precast concrete girders. When finished, the bridge will be 324 ft. long, 113 ft. wide and will carry three lanes of traffic in each direction. The bridge will carry traffic over

The construction teams intend to recycle and repurpose much of the material from the excavation. The concrete and asphalt will be processed or crushed and used as fill for the construction of the new freeway on-ramp and offramp.

from page 1 see BRIDGE page 48

S.R. 91. Granite’s construction team has poured two of the three footings and is scheduled to pour the concrete columns and abutment walls before the end of the year.

Building a bridge in a high-traffic environment like this requires carefully staged construction.

The construction team will shut down the freeway for three weekends to complete the building project. At that time, the eastern half of the bridge will have been built and traffic moved over to the newly built bridge. After the demolition of the existing bridge, the western half of the new bridge will then be built. The western and eastern halves of the bridge will then be joined with a concrete deck closure pour.

The construction team also will build a drop ramp for S.R. 55 off the western half of the new bridge. Finally, workers

will build the pavement for the new bridge and open it to traffic.

In addition to the bridge work, the Granite team and subcontractors will build new pavement and retaining walls. The construction team will use approximately 26,000 cu. yds. of concrete, 18,000 tons of asphalt and some 2 million lbs. of reinforced steel.

Granite will emphasize safety as workers will be moving in a busy area with multiple freeways nearby. Important safety measures will include:

• Nighttime closures will reduce disruptions and risk during peak hours.

Summit Truck Bodies introduced its high-performance 829 Hydraulic Crane and Advanced Safety Electronics (ASE) Phase 5 Control System at a press conference at Utility Expo 2025.

The fully integrated solution represents Summit’s commitment to advancing technology, designed to upgrade the experience of operators in the field through enhanced equipment performance and streamlined to improve jobsite safety.

With its 29-ft. maximum horizontal reach, the 829 Crane delivers a 48,000-ft.-lb. rating and an 8,000-lb. maximum lifting capacity, making it Summit’s highest-capacity crane in its 7 Series truck profile.

Despite increased strength, the crane weighs 30 percent less than previous models while providing 37.5 percent greater strength through advanced engineering and high-strength steel construction.

“These innovations continue to improve the overall experience for operators in the field,” said Chris Walter, plant manager of Summit Truck Bodies. “Our mission is to engineer the best service trucks and truck-mounted equipment that any operator can have, and we believe the new 829 and ASE Phase 5 meet our objectives and then some.”

Walter emphasized Summit’s collaborative development approach. The process starts with the feedback that Summit’s sales and service department receives from customers, which is then conveyed directly to the company’s R&D team and ultimately to every department in its plant.

“The 829 Crane and ASE Phase 5 incorporate significant technological advancements that elevate the operator’s experience and overall jobsite efficiency,” said Christian Glascock, product development engineer of Summit. “Our engineering team focused on creating the lightest and strongest crane possible, using an optimal, manufacturable configuration with high-strength steel and a new profile.”

Key innovations include a fully proportional control valve that enables seamless movement of all functions simultaneously.

“It gives users the ability to command multiple functions at once, and to increase their positioning speeds by as much as three times,” Glascock said.

The crane features a redesigned rotational assembly that weighs more than 100 lbs. less than its predecessors and allows for continuous rotation.

“The new design enables us to reduce the overall height and weight of the truck while also incorporating the continuous rotation feature,” said Glascock. “This provides incredible flexibility, allowing users to deploy the crane quickly and stow it just as fast after completing a job. Additionally, it seals the compartment from water, dust and road chemicals, protecting the valuable assets inside.”

A relocated winch and the lowered crane height, provide customers access to more locations. Added user safety is provided by the new anti-two-block system, which requires zero adjustment and features modular components for easier maintenance.

With its updated screen, the ASE Phase 5 offers enhanced

customization, ease of use and access to diagnostic capabilities encompassing all devices within the truck’s electrical environment. “The new system supports greater user customization capabilities, allowing increased maintenance and event logging and tracking for fleets or operators, and saves them up to 150 percent in replacement part costs,” Glascock said.

Summit Truck Bodies photo

With its 29-ft. maximum hor izontal reach, the 829 Crane delivers a 48,000-ft.-lb. rating and an 8,000-lb. maximum lifting capacity, making it Summit's highest-capacity crane in its 7 Series truck profile.

The updated ASE Phase 5 control system features a dedicated maintenance menu that enables operators to track service intervals and access diagnostic data directly through the main control interface.

The system also features an integrated vehicle alarm that provides theft deterrence when equipment is unattended. An enhanced wireless remote enables users to operate key crane functions such as auto-deploying, auto-retracting of outriggers and auto-stowing of the crane without returning to the truck, thereby improving efficiency and jobsite safety.

“Summit’s new crane and next-gen controls address key features requested by our customers and the industry at large,” said Dan DeAces, national sales manager of Summit Truck Equipment. “Power truly does meet precision with our newest crane offering.”

“The system provides significant and measurable ROI for fleet managers, helping to protect assets from damage and technicians from injury,” DeAces said. “We have a simple but

profound motto at Summit: ‘Start safe. Work safe. Stay safe.’”

“Summit’s unique factory-direct sales model starts with our sales team working directly with customers and our engineers to design and deliver the right truck for their needs,” DeAces added. “Once that truck is in service, customers have a direct line to our factory parts and service professionals, who can troubleshoot in real time and ship parts directly from our warehouse. Summit also supports every customer with training, detailed documentation and true 24-hour availability.”

The 829 Crane and ASE Phase 5 are byproducts of Summit’s direct and intimate understanding of its customers, the environments they work in and their specific needs, according to Summit.

“We are in a position to hear firsthand the pros and cons of how equipment performs in the field,” said DeAces. “Our customers’ work is challenging and changing daily, and they deserve a partner willing and able to change with them.”

The 829 Hydraulic Crane and ASE Phase 5 Control System will be available for purchase beginning in early 2026. The technologies represent the foundation for broader product line enhancements, with plans to integrate many of the related innovations across Summit’s entire hydraulic crane lineup. For more information, visit summitbodies.com.

Stellar Industries introduced two new product managers, Kasey Lammers and Phil Boeckman.

Lammers will be responsible for mechanic trucks and accessories, and Boeckman will be responsible for hooklift, roll-off and container trucks.

Lammers brings experience in product marketing, customer engagement and new product launches to his role at Stellar. As product manager for mechanic trucks and accessories, he will collaborate with crossfunctional teams to develop and introduce new products, features and processes by using market research and customer interaction to meet consumer needs.

“I’m excited to have the opportunity to grow both personally and professionally in this new role,” said Lammers. “I can bring a fresh set of eyes to the legacy product lines at Stellar, introducing new opportunities that benefit our customers.”

Boeckman offers extensive expertise in engineering and product management with a background in leading product updates and innovations at both Winnebago and Snapon. At Stellar, he will be responsible for planning and executing new innovations for the

“We’re excited to welcome both Kasey and Phil to Stellar and complete our product management team.”

Tim

hooklift product lineup.

“I can’t wait to experience the culture at Stellar and bring my expertise to the table,” said Boeckman. “Working with the product that is the cornerstone of Stellar is truly an amazing opportunity to keep the legacy moving forward.”

With both Lammers and Boeckman stepping into their new roles, Stellar looks forward to the experience and perspective they bring to the product management team. They join Jeran Pollock, director of product management and inside sales — fuel and lube products; Bryce McIntyre, product manager — LubeMate, FuelMate and trailers; and Adam Oppermann, product manager — tire trucks and manipulators.

“We’re excited to welcome both Kasey and Phil to Stellar and complete our product management team,” said Tim Worman, director of product management and inside sales of Stellar. “Their unique backgrounds and skills will be a perfect addition to our dedicated team, and we feel confident that the innovation and advancements to come across product lines will be exciting.”

For more information, visit stellarindustries.com.

MGX Equipment Services, through its “Upfits by Aspen Equipment” brand, is redefining work truck versatility with Palfinger articulated crane boom attachment solutions. As the authorized Palfinger distributor in Minnesota, Iowa and Nebraska for more than a decade, the upfits team brings deep expertise in delivering truck solutions to meet the specialized needs of customers.

Palfinger’s articulated cranes, also known as knuckle boom cranes, are available with a wide range of boom attachments to turn a single-function crane truck into a multi-purpose machine. One standout option is the hydraulically driven auger attachment which enables crews to dig holes for fence posts, road signs and utility poles without the need for additional equipment such as skid loaders or digger derricks, according to the company.

The upfits team at the Des Moines branch partnered with a municipality in Iowa to combine the Palfinger PK 12.501 SLD5 knuckle boom crane with 32-ft.

ing operations and reducing equipment needs.

The auger system features quick-attach couplers and a hydraulic hose track for easy integration. Multiple auger drive sizes

are available including compact options compatible with Class 5 truck chassis.

“Unlike a typical flatbed crane, [we] upfitted this truck with a heavy-duty steel utility body with customized sign storage, welder, workbench bumper and lighting to give the road crew the storage and functionality of a service truck,” said David Phillips, territory manager — Upfits by Aspen Equipment brand of Nebraska and Iowa. “For several decades, we’ve been a premier supplier of customized sign truck solutions for cities, counties and states that need a multi-functional tool to dig holes, set poles, install signs and more.”

Beyond augers, a full suite of Palfinger crane attachments including personnel baskets, pallet forks, rope winches and more are available. Service and mechanics bodies are available for upfitting on a variety of truck chassis. Turnkey upfitting services are available for direct purchase or through state and regional government procurement contracts.

Tucson, AZ

520-579-0261 Phoenix, AZ

602-437-0351 Spokane, WA

509-536-7300

El Cajon, CA

619-448-0770

Corona, CA

800-491-9004

Tukwila,

Lewiston, ID 208-743-0866

Snohomish, WA 360-863-2552

Richland, WA 509-578-5900

Petersandkeatts.net

nixonegli.com

Ditchwitchwest.com

The Offutt Family Foundation, with support from R.D. Offutt Co., awarded 59 grants totaling $409,400 to nonprofit organizations across the company footprint.

A unique initiative designed for R.D. Offutt Co. team members to nominate nonprofits to receive a grant, the Offutt Family Foundation Community Builder program demonstrates team members’ commitment to investing in their communities.

“The Community Builder program continues to be one of the most inspiring reflections of the shared values between the Offutt Family Foundation and RDO team members — our commitment to community, generosity and meaningful impact,” said Terry Brandt Offutt Family Foundation’s executive director.

R.D. Offutt Co. team members filled out grant applications on behalf of local charities with which they are affiliated for grant consideration. Grants are awarded based on the charity’s mission and those whose programming aligns with the focus areas of the Offutt Family Foundation, including health care, education or community development. Brandt said R.D. Offutt Co. team members showed their dedication through their rich and diverse applications.

“Each application submitted during the last 10 years shows the deep dedication team members have to the places they live and work,” Brandt said. “We’re proud to work alongside RDO to bring this program to life because we believe in investing in people and strengthening communities.”

Since 2015, the Community Builder program has donated more than $2 million to local nonprofits and community organizations nationwide.

For more information, visit RDOequipment.com.

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107 Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541

Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601

Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

www.kirby-smith.com

Oklahoma City, OK

405-495-7820

McAlester, OK 918-310-1550

Tulsa, OK 918-438-1700

Abilene, TX 325-692-6334

Amarillo, TX 806-373-2826

Chico, TX 940-678-5046

Dallas, TX

214-371-7777

Ft. Worth, TX

817-378-0600

Hewitt, TX 254-261-1370

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000

www.modernmachinery.com

Corporate Office

Missoula, MT

409-842-1754

Boise, ID 208-336-8670

Jerome, ID 208-324-4522

Pocatello, ID 800-829-4450

Billings, MT 800-735-2589

Columbia Falls, MT 800-434-4190

Eugene, OR 800-826-9811

Portland, OR 800-950-7779

Kent, WA

800-669-2425

Rochester, WA 800-304-4421

Spokane, WA 800-541-0754

www.clairemontequipment.com

San Diego, CA 858-278-8351

Escondido, CA 760-739-9100

Fontana, CA 909-429-9100

Imperial, CA 760-355-7700

Indio, CA 760-863-5558

San Diego, CA 858-278-8338

Willbee Transit Mix, a concrete supplier for Jackson, Mich.’s construction industry, currently operates a fleet of front discharge redi-mix trucks to service pours. For Willbee, maintaining the efficiency of concrete washouts between deliveries is important to his operation.

“For us … the cycle time [on concrete washouts] is critical … between loads, or between color loads, or on a state job when the trucks have to be empty every time, we re-batch” said Stephen Willbee, president of Willbee Transit Mix.

Efficient use of space also is essential for the fifth-generation family business that provides a range of ready-mixed concrete, bagged products, building supplies and tools. As a result of this and other factors, the company opted against employing a conventional settling pond, which occupies considerable real estate.

“It is important for us to keep [our concrete washout process] compact so we can utilize our property for additional products and more inventory,” said Willbee.

Settling ponds also require continual maintenance like sludge cleanup and repairing or replacing torn liners, which can strain scarce company resources.

To expedite the concrete washout process and reclaim valuable materials, Willbee Transit Mix has used a concrete washout

system for the past 22 years called a RediWash washout system, by Jadair International Inc., a manufacturer of concrete reclaiming and washout solutions.

Despite its decades of reliable service to the business, Willbee decided after 22 years it was time to replace the concrete washout system with a newer model. Recognizing the substantial technological advancements since its installation, he anticipated significant productivity gains from the upgrade.

“Our previous system was analog, with dials and switches,” said Willbee, noting the considerable improvements since his previous system was manufactured. “We had good luck with [our previous] system, so we went right back to Jadair for an updated model.

Like the original, the updated Redi-Wash washout system provides both concrete reclamation and water clarification in one self-contained, closed-loop unit. The machine separates and discharges the sand and stone, which enables the complete recovery of those items. The sand is not washed out of the aggregate. The water is clarified and reused for future washouts. Cement fines are discharged separately, and a loader can then handle them easily as a dry, clay-like product.

To perform a washout, a driver simply drives the concrete truck up to the machine and presses a button. The machine adds recy-

cled water to the truck’s rotating cylinder, which then mixes the water with any remaining concrete. The truck then dumps the water and concrete mixture back into the machine and the machine processes and reclaims the materials and recycles the water.

“The drivers pull up, push a button, wait for about 30 seconds and they’ve got their water. Depending on what they have in their truck, sometimes they’ll have to cycle another count, but it’s fast, it’s easy… I watched a driver [washout] three yards in about 3-1/2 minutes,” said Willbee.

Willbee points out that the streamlined concrete washout system aligns with his motto of “Keep it simple.”

According to Willbee, with the new, two station concrete washout system at their plant, their drivers washout, and are back at the plant quickly, ready for re-loading. The system allows them to cycle their trucks in and out of the yard much faster and more efficiently than they otherwise could.

The biggest factor for Willbee is the time and labor savings … “If I can save 10 minutes on every trip, by the end of the day that is 70 or 80 minutes. That gives us the opportunity to haul another load, so our overall efficiency improves,” said Willbee.