August 27

2023

Vol. IV • No. 18

August 27

2023

Vol. IV • No. 18

A construction project that will result in the largest wildlife crossing of its kind in the United States is back on track, according to officials.

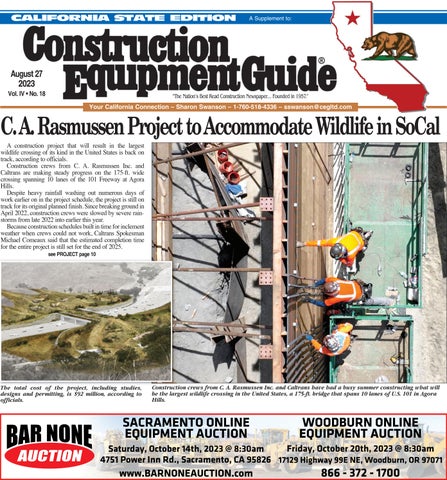

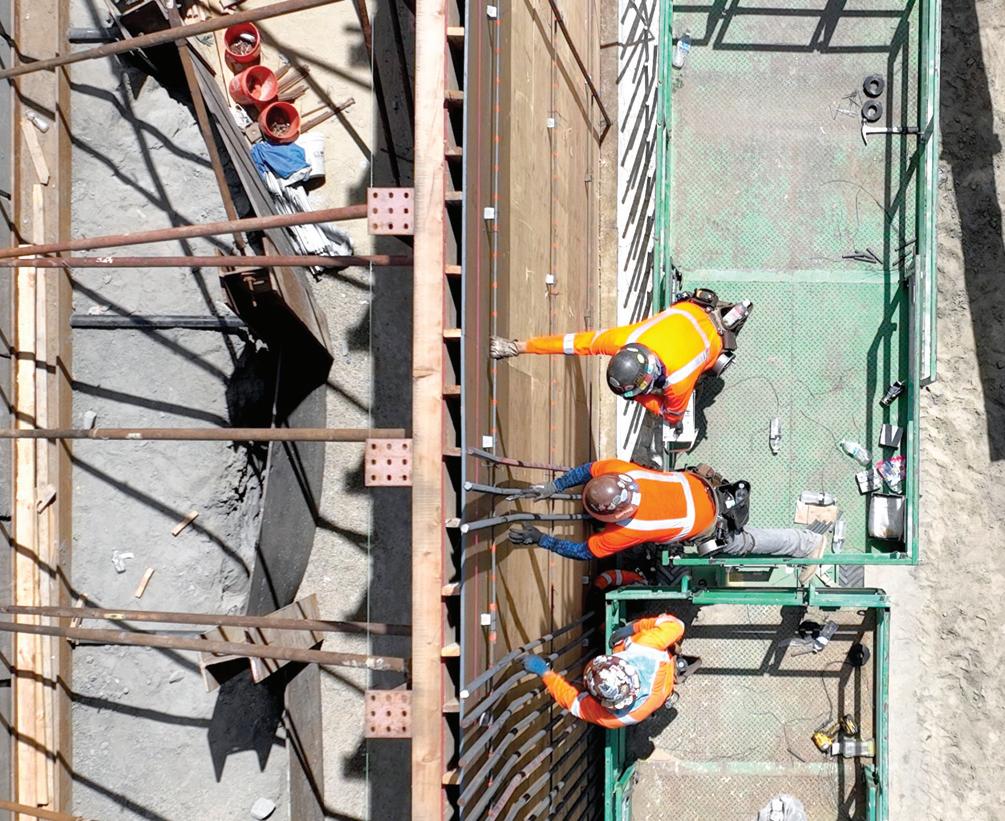

Construction crews from C. A. Rasmussen Inc. and Caltrans are making steady progress on the 175-ft. wide crossing spanning 10 lanes of the 101 Freeway at Agora Hills.

Despite heavy rainfall washing out numerous days of work earlier on in the project schedule, the project is still on track for its original planned finish. Since breaking ground in April 2022, construction crews were slowed by severe rainstorms from late 2022 into earlier this year.

Because construction schedules built in time for inclement weather when crews could not work, Caltrans Spokesman Michael Comeaux said that the estimated completion time for the entire project is still set for the end of 2025.

see PROJECT page 10

As mandated by SB 1, the Road Repair and Accountability Act of 2017, Caltrans is required to achieve at least $100 million in efficiencies each year to invest back in the maintenance and rehabilitation of the state highway system. In fiscal year 2021-22, the department set record highs for the number of new efficiencies (14) and total number of efficiencies (38).

Those efficiencies added up to $124 million, or 24 percent more than is required by SB 1.’

Although every efficiency is achieved through teamwork — a collaboration of people with innovative ideas, expertise, persistence, support and funding, among other qualities and factors —sometimes there is good reason to shine the spotlight on an individual employee’s contributions. Such is the case with Allen Cripe, lead heavy equipment body worker/painter in the Division of Equipment (DOE).

The DOE purchases, fabricates, maintains and repairs Caltrans’ fleet equipment, which is composed of more than 12,000 pieces of equipment. The division employs about 730 workers, including more than 400 heavy equipment mechanics around the state who maintain and repair equipment, and a Headquarters staff that includes Cripe.

As part of the paint preparation process for vehicles, the DOE must prepare several items by sanding and grinding steel parts. The amount of time, effort and cost to produce finished quality parts for the production line represented a challenge that Cripe wanted to address. Each piece required mechanical grinding and sanding to remove mill scale and sharp edges before sending to the paint booth. Getting into the small corners to produce a smooth finish was difficult with a 6-in. orbital sander.

The potential for employee injury due to the constant vibration from the hand sanders over a prolonged window of time was a concern, as well as handling parts that were not smooth or finished in the interior areas. Mechanics on the

assembly line were at increased risk of hands getting injured or cut.

About a decade ago, Cripe began to research options on his own after work hours. He researched vendors that manufacture equipment to improve the paint preparation process. He contacted steel shot manufacturers across the United States to get a competitive bid.

Eventually, Cripe came upon L.S. Industry in Wichita, Kansas, which manufactures custom pieces of equipment to produce finished “shot” (smooth/sanded) material parts. This vendor had a solid reputation and offered a warranty that would protect the DOE.

After Cripe creatively addressed a potentially costly side issue involving the machine’s ventilation system, in 2015 he received his supervisors’ approval to order the new equipment.

Cripe worked closely with the vendor determining the turn table size, drive motors’ power and the interior liner of the blast cabinet. In 2016 he flew to Kansas to inspect and test the efficacy and efficiency of the equipment and approve the final process of the purchase. The equipment arrived in Sacramento that July.

“Slingshot Suzie,” so named by Cripe because “shot” is the material that is used to spin around the interior creating smooth finishes, is housed in Headquarters’ production yard.

Suzie’s life expectancy is 40 years, which is projected to save Caltrans $53,950 per year, or $2,158,000 through the year 2056. Having cost $271,195 seven years ago, Suzie by now has paid for “herself.”

Another example of a big money-saver reflected in the 2021-22 Efficiencies Report is the Cone Penetration Test (CPT) technology that Caltrans used extensively on the Interstate 405 project in Orange County. The project has a budget that tops $2 billion. It is listed as the largest state roadway project currently under construction, rebuilding what many consider to be the country’s busiest freeway.

CPT technology allowed Caltrans to define the project’s geotechnical site characteristics. Thirty bridge structures are either being replaced or newly constructed along a 16mile-long stretch of highway, and through the use of CPT no soil samples were needed to determine the geotechnical engineering properties of soils, delineating soil stratigraphy and characterizing subsurface conditions.

Caltrans credits CPT with shaving a bit more than $7 million from this mega road-rehabilitation project in District 12 (San Diego County).

“It is vital for our executive staff to continue to engage with and encourage everyone to contribute to the efficiencies effort,” said SB 1 Program Manager Angel Pyle.

Some of the other noteworthy efficiencies that Caltrans chalked up in the 2021-22 fiscal year:

• Most dollars saved — Division of Design;

• Most efficiencies ideas submitted — Division of Procurement & Contracts;

• Most approved efficiencies — Division of Environmental Analysis;

• Most new efficiencies — Division of Engineering Services;

• Most dollars saved through district submissions — North Region.

Caltrans continues steady progress on repairs at a sinkhole created on Route 118 freeway in Chatsworth.

Crews are rebuilding drainage pipeline, placing sections of concrete pipe that weigh 6.5 tons each and 5 ft. in diameter.

Crews are replacing multiple utility lines damaged at the sinkhole. Currently, crews are reconstructing a pipeline in the drainage system which carries rainwater off the freeway. After that, a water main, a sewer line and communications lines will be replaced.

(All photos courtesy of Caltrans.)

The DOE purchases, fabricates, maintains and repairs Caltrans’ fleet equipment, which is composed of more than 12,000 pieces of equipment.

At a storage site in Beaumont, Southern California, aggregates are recycled for the construction industry. The customers range from general contractors such as the government, cities and local authorities to homeowners and on to companies from the film industry.

The extracted concrete and asphalt is crushed and processed at the storage site or on site at the customer’s location. The impact crusher MOBIREX MR 130i EVO2 from Kleemann is used for the crushing process, the material is crushed from a feed size of around 19.7 in. to approximately 1 in.

The MR 130i EVO2 from Kleemann achieves high throughputs rates, combined with excellent product quality. Due to short setup times before startup and maintenance, the machine is readily available. Furthermore, the machine is easy to transport. This flexibility allows the crusher to be deployed wherever the customer needs it.

“Working with the Kleemann machine is fantastic. It has numerous excellent functions. If we have to process large volumes, we take the MR 130i EVO2 to the customer and crush on site,” said Dallas Jones, vice president of operations at the operating company Ramco.

The impact crusher MR 130i EVO2 has a diesel-directdrive that provides a high output combined with low fuel consumption. To prevent narrowing of the material flow, the plant’s system widths are increased in the material flow direction for all components. This prevents material bridging and increases productivity.

The feed control CFS (Continuous Feed System) controls the frequency of the vibrating feeder and the prescreen depending on the crusher feed. The CFS thus reduces work for the operator because the machine controls the material flow automatically and guarantees the best possible loading of the crusher, according to the manufacturer.

The MR 130i EVO2 can be operated conveniently from a safe distance with the radio remote control.

The operating concept SPECTIVE from Kleemann makes handling of the MOBIREX MR 130i EVO2 very easy. The machine is controlled via a 12-in. touch panel. Clearly arranged operating instructions and pictographs help the user to find the correct setting for each task quickly and precisely per touch screen. This way operating errors are avoided and occupational safety is improved. Important functions, e.g. the crusher gap adjustment, are executed in a simple manner — fully hydraulic and in ongoing operation.

“SPECTIVE is very simple. Operation does not require a lot of experience,” explained Darrel Burroughs, operator at Ramco. “Overall, the Kleemann MR 130i EVO2 impact crusher is extremely user-friendly and easy to handle.” For more information, visit www.wirtgen-group.com.

4191 Power Inn Road, Suite D Sacramento, CA 95826

916-737-7777

San Leandro

1997 Burroughs Ave

San Leandro, CA 94577

510-568-5000

San Francisco, CA 650-532-9200

Now in its fourth year, Build California continues to advance its vision to create a steady, motivated, and skilled workforce pipeline for California’s construction industry.

Helping drive this effort is a team of over 60 Build California Ambassadors who connect with students at school and career events across California each month. Passionate about educating and supporting the next generation of construction workforce, these industry professionals themselves represent many divergent pathways into construction careers. And they are united in a common goal: to inspire interest in the industry by sharing their own journeys and vision for why construction should be considered a top career choice.

“Ambassadors play a crucial role in our Build California program by serving as advocates, educators, and connectors. They help to promote the program’s mission,

inspire the next generation of builders, and provide guidance to those who are just starting out,” commented Senior Build California Manager Abigail Palomares.

“Our Ambassadors bring a wealth of knowledge, experience, and enthusiasm to the program,” she added. “They are passionate about sharing their stories and encourage students to explore a path in our industry that best fits their unique interests. By sharing their expertise and career journey, they help to debunk all the misperceptions young people and society have about our industry and reflect how dynamic, rewarding, and impactful the 21st century construction industry is.”

To better understand why these Ambassadors choose to invest time and energy promoting the construction industry through Build California and what impact the program has had throughout the state, California Constructor spoke with Salena

Durrell with Tradeswomen Inc. and Brad Simmons with Royal Electric, along with the directors of two prominent high school construction Career Technical Education (CTE) programs.

Salena Durrell, Tradeswomen Inc.

The opportunity to collaborate and share resources and connections ranked high among the reasons why Salena Durrell embraced the call to become a Build California Ambassador in the spring of 2021. Serving as the Central Valley program coordinator with Tradeswomen Inc., she had initially become acquainted with Build California and its mission during a workforce event in Fresno two years earlier.

“As someone who has worked hands on in the trades and who is really passionate about educating and spreading the word about blue collar career choices, especially to the youth, I was interested in Build

California’s Ambassador program when they reached out,” she commented. “Since then, it has just been an amazing ride, and we have partnered on quite a few events. Our organizations tend to have many of the same goals.”

Durrell is herself a latecomer to the construction industry. She became aware of the many opportunities, great pay and benefits associated with the construction industry in her mid-30s when she was taking a construction class as part of a career retraining program. She applied to and was accepted into the Carpenters Local 152 apprentice training program in 2016 and later, into IUEC Local 8.

“It was literally one of the best decisions that I’ve ever made,” she said. “I got into construction in my 30s, but had I known about it at 18, I would have made that choice a long time ago.”

Durrell joined Tradeswomen Inc. in 2019,

covering the Fresno, Sacramento and Stockton areas for the grassroots support organization whose mission is “outreach, recruitment, retention and leadership development for women in blue-collar skilled craft.” In her current role she has collaborated with Build California on several outreach events, including a recent Rosie the Riveter “Rosie Reimagined” event at Delta College in Stockton this spring, among many others.

Her favorite part of being a Build California Ambassador? “Connecting with the youth” to share the value she has found working in and representing the trades, and the ability to leverage Build California resources to showcase the industry in her own presentations, Durrell said. Her “go-to” statement, adopted from Build California messaging: “Construction doesn’t have to be a fallback career; it can be a first-choice career.” Durrell estimates she has personally connected with “well over 1000” youth at outreach events during her time as Ambassador.

Currently a general superintendent with Royal Electric Company in Sacramento, Brad Simmons began his construction career 24 years ago when he began a five-year ABC electrical apprenticeship program in Northern California. He joined Royal Electric in 2003, moving up through the ranks over the years while working on and overseeing numerous commercial, industrial, multi-family and airport projects.

His company’s long and active participation in AGC of California (including CEO Dina Kimble’s current two-year stint as president) led Simmons to become more aware of the benefits of active membership in the association and in Build California. Simmons channeled his passion for helping develop construction workforce solutions to become a Build California Ambassador about a year-and-a-half ago.

“Our industry is currently lacking in enough skilled and experienced workers,” he commented. “So, it’s really encouraging when you get out there and people are interested and following up after we have visits to schools and conversations on these panel discussions (about workforce issues). I’ve found a lot of people I speak with are intrigued by what we build and the different technologies that we now have in construction. Others are intrigued by the kind of money they can make in a construction career.”

Simmons said his message to students and young people is simple: “There are definitely a lot of opportunities in the construction industry. College is a great path, but it doesn’t fit everybody. What Build California

is trying to do is create more visibility and opportunity for people who are coming out of high school and even college and who don’t know about all the career possibilities in construction.”

He has participated in a variety of outreach events as Ambassador, from speaking to high school students in the welding and construction programs at Eden Area ROP in Hayward, to participating in a career panel in San Jose this March, to hosting Interns Day on a Royal Electric jobsite, to name a few. He encourages other industry professionals to consider getting involved as a Build California Ambassador like he chose to. “That outreach, getting people to understand what they can achieve by being part of it and bringing really good individuals in to strengthen our industry as a whole, is just really rewarding,” Simmons said.

The impact that Build California and its Ambassadors are having in inspiring and activating the next generation of construction workforce is evident in the relationships forged with several Career Technical Education (CTE) programs across California. Two leading examples are Oakland Unified School District’s (OUSD) CTE program at Fremont High School in Northern California, led by Emiliano Sanchez, and Fontana High School’s Career Connections in Southern California, led by Lamar Hanger.

“Build California has been a very strong supporter of our program,” according to Sanchez, director of CTE Trades & Apprenticeships with OUSD. “It has done everything from working with us to bring in guest speakers, to supporting our career events, attending, handing out swag and talking with students about the great career opportunities there are in the trades and construction.”

Sanchez is the recipient of AGC of

California’s 2023 Construction Education Friend Award, which recognized his work with OUSD supporting hands-on learning, the development of CTE pathways, and integration of internships into youth pathways in 18 high schools that serve a total of 9,500 students.

One of the recent events in which Build California was involved was the OUSD/ Cypress Mandela Skilled Trades Fair on March 16, 2023. The fair exposed some 290 students and staff from OUSD, San Leandro

Unified School District and Eden ROP to a full day of engagement and learning.

Sanchez noted that Build California has been closely involved in working with Fremont High School’s CTE program, involving close to 300 students. Ambassadors from AGC of California contractor members Turner, Webcor, Swinerton and others have visited the school to share information with students in the program about various trades and direct pathway opportunities into the construction workforce.

“Giving the students access to some direct entry pathways into the industry and to the people that actually hire is starting to change the narrative,” Sanchez said. “The students have been super receptive” when Ambassadors come in to speak, he added. “People have said OUSD is fortunate to have me, but (this program) only works if I have partners like Build California to bring in Ambassadors to connect with our students.”

(This article was reprinted with permission from AGC of California’s California Constructor Magazine; July/August 2023. All photos courtesy of AGC of California.)

PROJECT from page 1

The total cost of the project, including studies, designs and permitting, at $92 million, according to officials.

Progress on the crossing continued during the much drier summer, including a massive concrete pour that amounted to 850 tons of concrete or enough to build approximately 100 patios, according to Caltrans.

“We are glad things are going well and are hopeful to meet the completion date,” Comeaux said.

“They have been pouring concrete and getting the abutment pillars up,” said Beth Pratt, California regional executive director of the National Wildlife Federation, the group that spearheaded the project. “By fall, we should see the skeleton of the horizontal structure going up, the actual bridge structure.”

Landscape architects will vegetate the concrete crossing with 4 ft. of soil and plant locally collected seeds for grasses and plants.

“It will look like the mountains will have come back over the freeway,” Pratt said.

Vegetative sound walls will keep the freeway din to a minimum, otherwise wild critters will stay away and not use it. Light from car headlights also will be blocked out.

“You have to trick them into thinking they are not going over a freeway,” Pratt said.

The crossing will be built over a freeway that accommodates 300,000 to 400,000 vehicles per day.”

Contracts for a second stage have not yet been awarded. The second stage of the project will consist of a tunnel/bridge over Agoura Road; a tunnel/bridge structure over the service road Vendell Place to serve as a utility tunnel; and fill, grade and landscape between the bridge over U.S. 101 and the tunnel over Agoura Road. The schedule for Stage 2 is being developed.

The wildlife crossing connects two mountain lion roaming grounds, the Santa Monica Mountains and the Sierra Madre Range. It removes the large freeway barrier, allowing mountain lions as well as bobcats, deer, coyotes even birds and butterflies to safely cross, going from the Santa Monica range into the Simi Hills and Santa Susana Mountains to the

north of the 101 Freeway.

Freeway crossings have resulted in more than 35 mountain lion deaths. The most famous cougar, P-22, miraculously crossed the 101 and 405 Freeways making Griffith Park his home for 10 years until his death in December 2022, ironically from a vehicle-strike.

The massive crossing was first spearheaded by Caltrans, the National Park Service and the Santa Monica Mountains Conservancy to provide wildlife with a safe place to cross into other habitats. The current campaign for the wildlife crossing was launched in 2012.

(All photos courtesy of Caltrans.)

(530) 458-2166

2173 Blossom Street

Dos Palos, CA 93620-2313

(209) 392-2161

600 S. State Highway 59 Merced, CA 95341-6928

(209) 383-5888

1340 W. Charter Way Stockton, CA 95206 (209) 944-5500

20280 Main St. Stratford, CA 93266

(559) 947-3301

1215 West Glenwood Ave Turlock, CA 95380-5703

(209) 634-1777