By Cindy Riley CEG CORRESPONDENT

As part of a broader effort, construction crews in North Carolina are replacing Bridge 142 on I-40 over the Pigeon River. The $70.5 million undertaking centers on a critical link for both local and commercial traffic between the Tar Heel state and Tennessee.

“Bridge 142 is a vital interstate structure that has served the region for decades,” said Kenny McCourt, North Carolina Department of Transportation (NCDOT) Division 14 resident engineer. “Like many bridges built during its era, it’s reached the end of its service life. Deterioration from age, increased traffic loads and evolving safety standards have made full replacement the safest, most cost-effective option to ensure long-term reliability and structural integrity.”

McCourt explained that timing aligns with available federal and state infrastructure funding. Replacing the bridge now avoids escalating repair costs and unplanned shutdowns. In addition, regional coordination efforts and environmental considerations made this window ideal for minimizing impact to travelers and the river ecosystem.

“This is part of the very first CMGC project for NCDOT. It began as a larger program to replace five bridges with early work packages that allowed the contractor to share ownership and assist in design. Three of the bridges in the contract have already been completed.

By Lucy Perry CEG CORRESPONDENT

Prefab or modular construction can be the solution to eliminate risk and changeability on construction projects. With the use of this construction method, contractors can avoid the possible impacts of fickle weather, transportation glitches and jobsite staging challenges — if the process, from start to finish, is well thought out. Prefabrication demands planning down to the smallest detail, and consideration of every possible project threat.

MEMPHIS, TN

3930 E. Raines Rd Memphis, TN 38118

800-432-8902 | 901-260-2310

MURFREESBORO, TN

2115 N. Thompson Ln Murfreesboro, TN 37129

877-200-5654 | 629-335-3077

GRAY, TN

364 Bob Jobe Rd Gray, TN 37615

855-201-7453 | 423-282-5462

COVINGTON, GA

10110 Roberts Way Covington, GA 30014

844-532-1110 | 770-788-0888

BIRMINGHAM, AL

825 31st Street N. Birmingham, AL 35203 844-344-8658 | 205-323-6108

THEODORE, AL

7651 Theodore Dawes Rd Theodore, AL 36582 844-891-6480 | 251-653-5955

SHREVEPORT, LA

5200 Hollywood Ave Shreveport, LA 71109

800-548-3458 | 318-621-0854

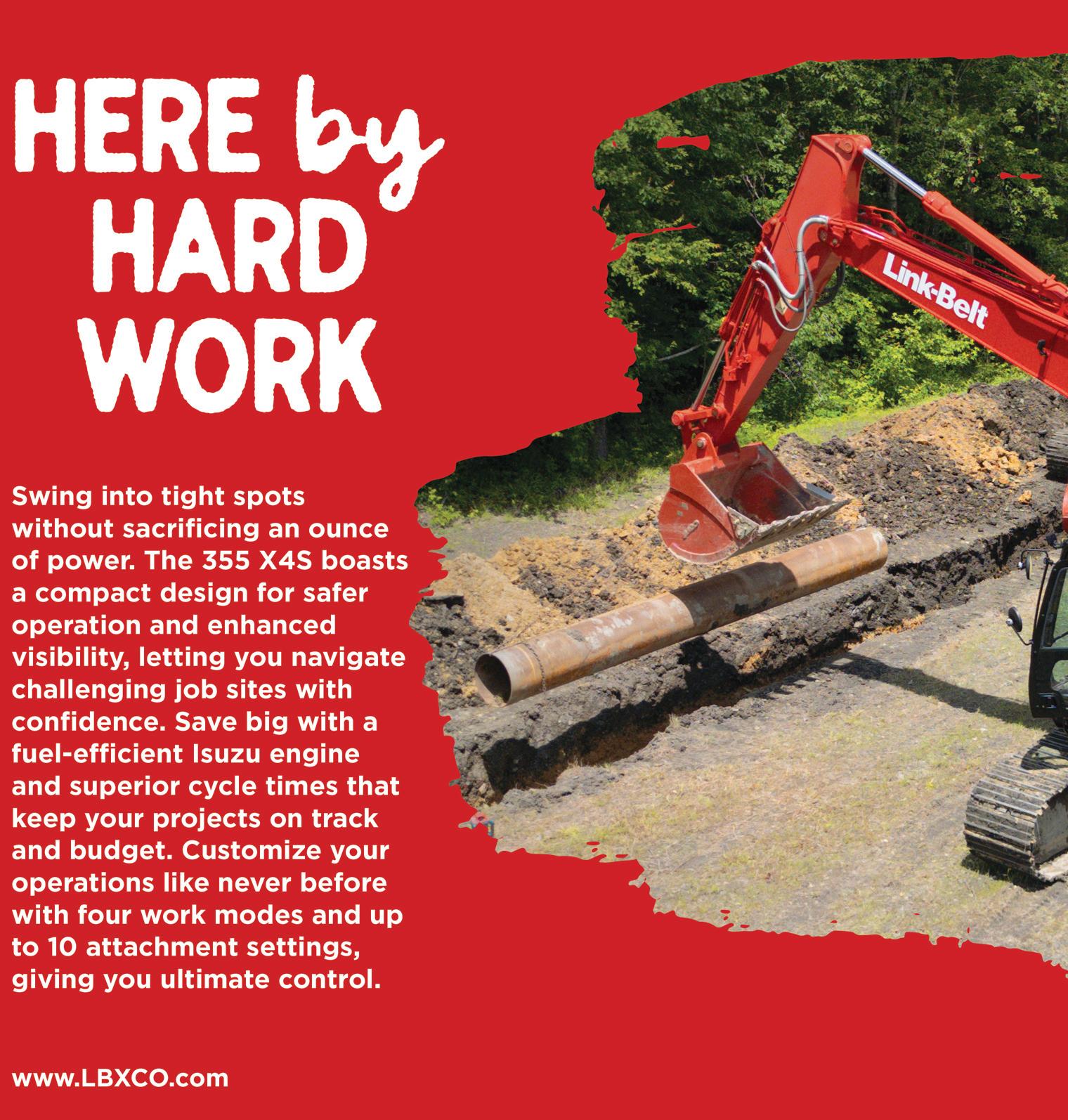

Liebherr completely redesigned its basic concept to offer customers more comfortable and intuitive products with even higher performance. The new Generation 8 crawler excavators feature more powerful engines for shorter load cycles and higher productivity, heavier counterweight for higher digging power and bucket capacities, all this while maintaining reduced fuel consumption.

The Jacksonville District of the U.S. Army Corps of Engineers held a ribbon cutting ceremony to celebrate the completion of Contract 10A for the Everglades Agricultural Area Reservoir Project in South Bay, Fla.

12 L&L CONTRACTING

One of the keys to building a successful small business from the ground up is establishing a rock-solid support system, someone who acts as a partner in helping your enterprise reach its full potential.

Operators from across the U.S. and Canada gathered Sept. 23 and 25 for the start of the 2025 North American Regional Finals of Caterpillar’s Global Operator Challenge (GOC).

18 BOMAG, LINDER GOLF CLASSIC BENEFITS CONSTRUCTION ANGELS

BOMAG and Linder Industrial Machinery held their second annual golf classic, Oct. 3, 2025, to benefit the Construction Angels at Legends Golf Resort in Myrtle Beach, S.C.

20 CENTRAL ATLANTA TRACTOR CELEBRATES 30TH ANNIVERSARY

A large crowd of customers, vendors, Central Atlanta Tractor representatives and their associates gathered to celebrate the 30th anniversary of Central Atlanta Tractor Sales Inc.

NDK Scraper of Spencer, Ohio, has been synonymous with quality and commitment in the heavy equipment industry. What began as a modest operation has grown into a company known for delivering reliable scrapers.

The Golf Gods smiled on the 3rd Annual Werk-Brau Golf Outing to benefit Construction Angels, as the weather was great, smiles were plenty and there were many memorable shots (good and bad) — including a hole-in-one.

62

Stellar Industries announced that it is a 2025 Employer of Choice Award recipient. The Employer of Choice Award recognizes northern Iowa businesses that create a work environment where employees feel valued and supported.

Towmaster announced Chris Pokornowski, who has served the company with distinction for 30 years, most recently as general manager has stepped down as of Sept. 26, 2025.

64

A nine-day online auction, running Oct. 24, 2025 through Nov. 1, 2025, will feature a specially manufactured FT-3 drop deck utility trailer painted in custom “Ivy Green” with black pinstriping, bearing the Ivy’s Legacy Foundation emblem.

76 J.M. WOOD HOLDS THREE-DAY AUCTION IN MONTGOMERY, ALA.

J.M. Wood held a three-day Fall auction Sept. 23-25, 2025, in Montgomery, Ala. The auctions brought in more than $80 million and featured sellers included Georgia Power Company, Thorne Excavating and more than 300 other sellers. 77 YODER & FREY — BACK

Yoder & Frey Auctioneers holds its second sale, relaunching its Atlanta, Ga., sale site, with a new team, providing vendors and buyers local service in the Southwest.

Deutz Corp. has entered into an agreement to acquire the assets of OnSite Diesel, a Texas-based provider of heavy equipment repair services. The transaction is expected to close Oct. 1, 2025.

The Jacksonville District of the U.S. Army Corps of Engineers (USACE) held a ribbon cutting ceremony Sept. 23, 2025, to celebrate the completion of Contract 10A for the Everglades Agricultural Area (EAA) Reservoir Project with its federal, state and local partners in South Bay, Fla.

The critical work was an intricate piece of the puzzle for the EAA Reservoir, a major component of the Comprehensive Everglades Restoration Plan (CERP) that reconnects Lake Okeechobee water to the central Everglades.

Col. Brandon Bowman, commander of the USACE’s Jacksonville District, said that although Contract 10A “may not be the flashiest part of this massive undertaking … make no mistake, it is essential. It’s the quiet work, the initial effort, that makes the entire reservoir function.”

With the backdrop of a newly constructed 8.3-mi. inflow/outflow canal, a seepage canal and a maintenance road that together provide the essential conveyance as well as protection features for the EAA Reservoir — a project that began in 2023 — the first piece of the massive 10,500-acre reservoir is set.

“The EAA reservoir is called the ‘Crown Jewel’ of CERP — and rightly so,” Bowman said. “The entire project spans 17,000 acres and represents billions [of dollars] in investment. But more importantly, it represents hope. Hope for restoring the Everglades. Hope for sending water south

when Lake Okeechobee rises too high. Hope for improving water quality, timing and distribution across South Florida.”

In a news release, the USACE said that when fully complete, the reservoir will store up to 240,000-acre-ft. of water — equivalent to more than 118,000 Olympic-sized swimming pools — reducing harmful discharges to coastal estuaries and delivering clean, fresh water south to the Everglades and Florida Bay.

The massive project spans approximately 16 sq. mi., an area equivalent to the Florida cities of Stuart and Fort Myers put together.

Another key component includes a 6,500-acre stormwater treatment area (STA), which is a central part of the state and federal CERP effort and the Central Everglades Planning Project (CEPP).

More than 17 million cu. yds. of earthen material was used to construct embankments 37 ft. tall with the ability to store water 23 ft. deep.

Bowman said that beyond their structural importance, the EAA canals will serve a vital protective role by helping to shield neighboring landowners from elevated water tables when the reservoir is full — a testament to the thoughtful planning behind every phase of the effort.

“This isn’t just about infrastructure — it’s about resilience,” said Bowman. “It’s about turning what once seemed impossible into reality. And that reality is being built every day by the dedicated teams at the U.S. Army

Corps of Engineers and our incredible partners at the South Florida Water Management District.”

Among the featured speakers at the event commemorating the wrap up of Contract 10A were Connor Tomlinson, the special assistant to Adam Telle, the Assistant Secretary of the Army for Civil Works; Dr. Larry McCallister, the USACE’s South Atlantic Division programs director; Adam Blalock, deputy secretary of the Florida Department of Environmental Protection (DEP); and Drew Bartlett, executive director of the South Florida Water Management District (SFWMD).

McCallister highlighted the scale of the Everglades EAA 10A project and lauded the accomplishments of the USACE team, SFWMD, the community, legislators and contractors for their hard work to get to this point.

“It will likely be one of the largest aboveground reservoirs in the nation, and it’s only possible because of strong partnerships between the Corps, the South Florida Water Management District and our contractors,” he added.

The total cost of the Central Everglades Planning Project’s EAA phase is estimated at $3.9 billion, a huge investment in the restoration of the Everglades.

The EAA Reservoir Project benefits both

Florida’s environment and economy. In addition to more clean water for the Everglades, the effort is creating jobs and providing a significant boost to the nearby local economies south of Lake Okeechobee.

Work on the storm water treatment area began in 2020 and remains ongoing, with reservoir component construction also progressing. USACE estimates the Everglades Agricultural Area reservoir project may be finished by 2029, years earlier than first thought.

In late August, Telle accompanied Maj. Gen. Jason Kelly, the USACE’s deputy commanding general for Civil and Emergency Operations, on a visit to the Everglades Agricultural Area project.

“The complexity of this huge project effort requires the best of us and that’s what we have… a team compiled of the best of the United States Army Corps of Engineers working … in collaboration with the State of Florida, [and] a very capable partner in the South Florida Water Management District, and there’s a lot of work yet to be done,” Kelly said. “But I’m confident that we are getting the engineering right, getting the project management right and we’ve got the right team working on this project.”

The EAA project site is located 27 mi. south of Lake Okeechobee, 45 mi. west of West Palm Beach, 75 mi. east of Fort Myers and 75 mi. northwest of Miami, according to the USACE news release.

l e and oving, id hlt oncrete utilities, c earthm ork tasks ewsit ving, and asphalt pa s. agener

By Eric Olson CEG CONTRIBUTING EDITOR

One of the keys to building a successful small business from the ground up is establishing a rock-solid support system, someone who acts as a partner in helping your enterprise reach its full potential.

L&L Contracting LLC’s founder, L.J. Duncan, was able to secure just such an alliance with Power Equipment, a Knoxville-based dealership serving Tennessee, Arkansas and Mississippi, when he began buying construction machines from the distributor. Their association has proven to be an asset in advancing the fortunes of the Knoxville site preparation business.

Duncan, as the firm’s vice president, has crafted L&L Contracting into an upwardly trending company specializing in excavation, land clearing, utilities and demolition work. His wife, Donna, is the company’s president and majority owner.

Since Duncan took a gamble and decided to leave his previous job as a construction manager of a Tennessee Valley Authority (TVA) subcontractor in March 2018 to work for himself, his work ethic — along with his faith — also have been among the reasons the company is today a thriving concern in the eastern and central areas of the state.

Make no mistake about it, though, Duncan knew at the time that going out on his own was a very risky move.

“I just got tired of traveling at my old job, and I wanted to be home more,” he said on one of L&L Contracting’s current projects at the site of a new forensic center in Knoxville.

“One Thursday night after I had been working 14-hour days, I came home and told my wife I didn’t think I was going to go back. When I told her what I was planning to do, of course, she asked what I was going to do for money and I told her that I wasn’t going to borrow any cash, sell anything or take anything out of my retirement.

“Instead, I was going to see what I could do with the $400 I had in my pocket, and if it didn’t work out after three months, I knew I could go back to my old job,” Duncan added. “That was seven years ago and now L&L Contracting does about $10 million worth of business a year. Our aim is for 10-20 percent more annually.”

When asked just how he was able to shepherd the construction firm to that kind of success from such humble beginnings, he confessed, “I’ll be honest with you, if it weren’t for the grace of God there was no way we could have done it because I had no college background nor any idea how to build a company. The only thing I knew was hard work and determination.”

see KOMATSU page 70

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

For the D4 Dozer Challenge, the operator begins by dozing a tire down a narrow path into the goal zone.

Operators from across the U.S. and Canada gathered Sept. 23 and 25 for the start of the 2025 North American Regional Finals of Caterpillar’s Global Operator Challenge (GOC).

Set against Caterpillar’s signature centennial gray, the event showcased not only the latest in construction equipment but also the talent and skill of the men and women who operate them.

Helping to emcee the event via livestream was Jarryd McNeil, who is an X Games/motocross athlete and heavy equipment enthusiast. McNeil is a motocross champion, track builder and three-time X-Games Best Whip medalist.

Brian Hayden, Hayden Excavating and Welding Inc. of Maine, representing dealer Milton Cat, was crowned Eastern Region semifinal champion. Hayden finished the four GOC events with the lowest point total of 1,313, which is a combina-

Using the Cat 938 wheel loader contestants load and haul material and dump it into the articulated truck; then, swap out the bucket for forks and transport pipes across the route and place them on a flatbed trailer.

tion of time and penalties.

“What makes me proud is just, you know, nothing to do with me,” said Hayden. “It’s bringing recognition to the operators that devote their time and lives to what they do and then showcasing them with their skills.”

Brock Leclerc, Quattro Constructors of British Columbia, representing dealer Finning Canada, was crowned Western Region semifinal champion. He completed the same four challenge events with 1,540 points.

“It’s beyond exciting what we’ve accomplished here as a group,” said Leclerc. “Everybody working with great sportsmanship ... it’s been an unreal, awesome day and amazing experience.”

Both champions will advance to the final round of the Global Operator Challenge in March 2026.

The event’s competition kicks off the regional finals for North America, split geo-

graphically: Sept. 23’s event saw competitors from dealers mainly east of the Mississippi — including Toromont CAT, Caterpillar’s eastern Canada dealer. On Sept. 25, operators from mainly west of the Mississippi stepped up, joined by Finning, representing western Canada.

From there, three winners — one from each sub-region including the Americas South program — will join forces to represent the Americas team at the Global Finals in Las Vegas in March.

Among those leading the charge at the GOC was Jason Hurdis, global industry solutions manager and execution lead for the 2025–2026 Global Operator Challenge Series.

“We launched the Global Operator Challenge in 2019 to spotlight the skilled trades,” Hurdis said. “Yes, our machines are becoming more advanced — but at the end

GLOBAL page 42

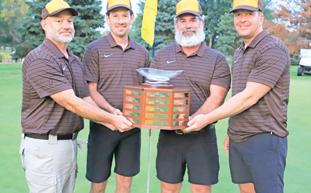

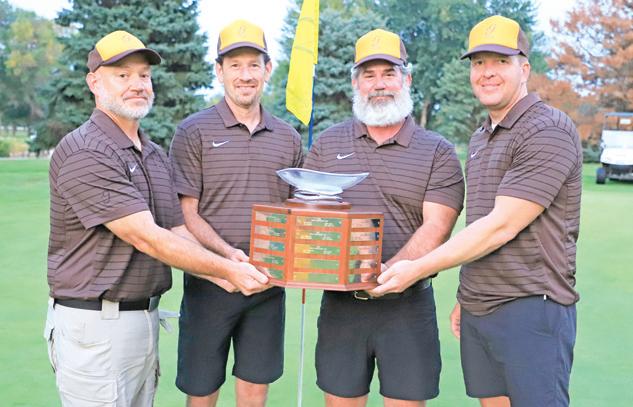

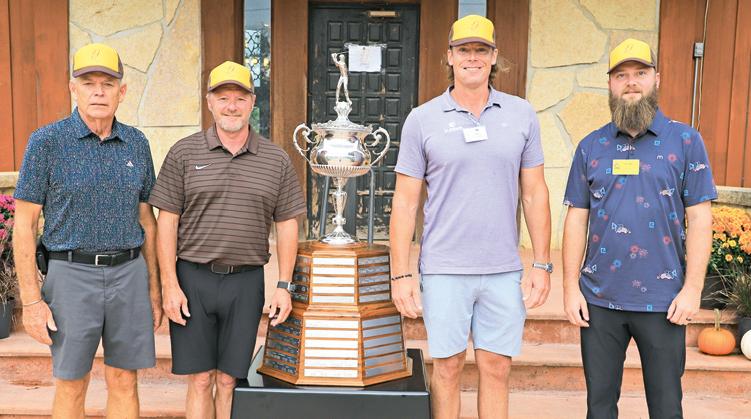

(L-R): Representing Barfield Grading in Fort Mill, S.C., are Trey Tarlton, Devon Pattison, Mel Goodman and Austin Mackey.

BOMAG and Linder Industrial Machinery held their second annual golf classic, Oct. 3, 2025, to benefit the Construction Angels at Legends Golf Resort in Myrtle Beach, S.C.

The event was a huge success, raising $50,000 for Construction Angels to support families of fallen construction workers.

Construction Angels is a 501(c)(3) nonprofit charity that provides immediate financial assistance and grief counseling to the spouse and children left behind when a construction worker involved in an accidental workrelated fatality. The charity also provides scholarship opportunities to surviving children, as well as qualifying applicants.

Kristi Ronyak is CEO and founder of Construction Angels and is a third-generation member of an asphalt family business from Ohio that started in 1939.

“My family is now on the fourth generation and continues business in northeastern Ohio,” she said. “I went to the World of Asphalt with my family in 2009 when I met a woman who was walking around collecting money for ‘one of our own.’ When I asked her what that was, she said, a construction worker was killed and left behind a spouse and children. Of course, I donated to this family, but I wanted to continue donating to a charity that helped construction workers.”

After some research, Ronyak discovered there was no charity for construction workers’ families affected by work-related fatality, so after a fatality in Miami, she was asked to start one, which she did in 2011.

“It took me about a year and a half, and we finally got our 501(c)(3) and started in south Florida,” she said. “Fourteen years later, we are in 33 states and growing, helping as many families as we can across the United States. I get asked all the time if something personal happened that made me start the charity, but unfortunately, my family had a fatality in 2021. Nobody is exempt from having a construction fatality, it could happen to anybody.”

There are approximately 3.5 construction fatalities every day in the United States, she added.

“And the majority of families we helped out in 2024 were due to reckless drivers or people hitting our construction workers on the road. I’m a big advocate for putting cameras in our work zones to give speeding tickets to have people slow down. Hopefully, we can improve the statistics of fatalities one family at a time.”

CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

(L-R) are Greg Reynolds and Jermaine Wilson, both of D.H. Griffin Infrastructure in Charlotte, N.C.; Michael Moore, Linder Industrial Machinery; Mark Newcomer and Matthew Cook, also of D.H. Griffin; and Rob Tavenner and Chris Russell, both of Linder Industrial Machinery.

Corey Robinson of SEC Construction in Greenville, S.C., put the ball inches from the cup.

(L-R) are Daniel Powell, Cohn Construction in Columbia, S.C.; Jason Durstine, Loveless Contracting in Columbia, S.C.; Jamie Frost, senior vice president of Alliance Consulting Engineering in Columbia, S.C.; and Brian Pattison, also of Cohn Construction.

Dustin Jones of Delta Contracting in Haw River, N.C., hits another long drive down the center of the fairway.

(L-R) are Rob Tavenner, Carolinas vice president of Linder Industrial Machinery; Kristi Ronyak, CEO and founder of Construction Angels; and Brian Bieller, president, BOMAG Americas.

BOMAG had its newly-introduced asphalt distributor on hand for customers to check out.

Daniel Verhine of RH Moore Company in Murrells Inlet, S.C., made the putt and was happy to spend the day with friends on the course.

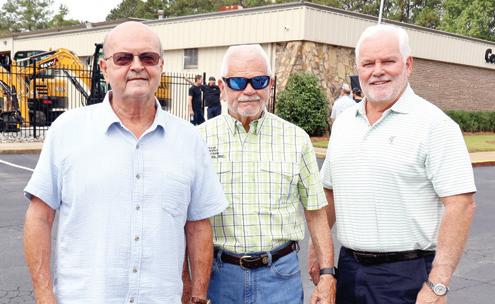

Alarge crowd of customers, vendors, Central Atlanta Tractor representatives and their associates gathered to celebrate the 30th anniversary of Central Atlanta Tractor Sales, Inc. The event, held Sept. 26, 2025, also served as a day of appreciation for the company’s valued customers and dedicated employees.

The celebration featured food trucks, numerous prize giveaways and a variety of raffle items. Attendees had the opportunity to tour the facility, including the offices, sales, parts and service departments, and to speak one-on-one with the team members who supply parts and service their machines.

A highlight of the day was the mini-excavator rodeo, which included a few unique twists that added an extra level of challenge — even for the most skilled operators.

Central Atlanta Tractor Sales Inc. began operations in 1995 as a used equipment and rental dealer. In 2014, the company became an official distributor and quickly made a strong impact in the Georgia market as a SANY dealer. A strong factory presence from SANY America contributed significantly to the success of the event, along with representatives from several other manufacturers.

Today, Central Atlanta Tractor Sales Inc. is a full-line distributor of SANY equipment, Bell trucks, IROCK crushers and screeners, Allied Construction Products and various other attachment lines. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

see CENTRAL page 22

A new

up a

to an otherwise straight-forward

using a

and place it on a

and

Enjoying the events of the day (L-R) are Gary Duke, Central Atlanta Tractor; James O’Kelly, Alexander Contracting, Columbus, Ga.; and Brandon Hess, Central Atlanta Tractor’s COO.

the

A variety of sizes of SANY compactors are in stock and ready for delivery from Central

THE BEST PARTS ALL IN ONE PLACE B N HE BE O T PAART EST P TS

Border Rents borderequipment.com

Augusta, GA 706-737-7253

Norcross, GA 770-609-8299

*Ditch Witch of Virginia ditchwitchva.com

Seaford, DE 302-629-3602

Chesapeake, VA 757-424-5960

Glen Allen, VA 804-798-2590

Manassas, VA 571-359-6081

*Ditch Witch Worx ditchwitchworx.com

Fort Lauderdale, FL 877-935-3656

Jacksonville, FL 866-254-1102

Plant City, FL 855-704-6828

Albany, GA 866-581-4914

Atlanta, GA 866-709-3712

Savannah, GA 888-298-0429

*Don Allison Equipment, Inc. donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

*Forsythe Tractor forsythetractor.com

Shreveport, LA 318-687-1341

National Equipment Dealers

Carolinas nedealers.com

Ashville-Fletcher, NC 828-628-3004

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

Wellford-Spartanburg, SC 843-501-0566

National Equipment Dealers

Florida

nedealers.com

Apopka, FL 407-401-8956

Fort Myers, FL 407-754-4646

Fort Pierce, FL 772-212-4043

Jacksonville, FL 904-664-0899

Tampa, FL 813-940-4405

National Equipment Dealers

Georgia nedealers.com

Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

State Machinery statemachineryeq.com

Kenner, LA 504-464-0431

Taylor Construction Equipment

taylorconstructionequipment.com

Bessemer, AL 205-428-7050

Huntsville, AL 205-428-7050

Montgomery, AL 205-428-7050

Louisville, MS 833-773-3421

New Albany, MS 304-550-9825

Richland, MS 601-922-4444

LaVergne, TN 304-550-9825

Maryville, TN 662-773-3421

Van Keppel

vankeppel.com

North Little Rock, AR 501-945-4594

Van Buren, AR 479-474-5281

Booth W42500, West Hall

March 3-7, 2026

Meet the contractor-strong, feature-rich machine that’s ready to carry the load for your crew. The all-new Hyundai HT38 CTL delivers 115 HP, a 3,807-lb. rated operating capacity, and 10’9” of lift height. All backed by Hyundai’s 3-year / 3,000-hour warranty.

What sets it apart? The features others charge extra for come standard:

•Hi-Flow Hydraulics•Lift-Arm Float

•Torsion Suspension•Auto Self-Leveling

•Reversible Fan•Rearview (Backup) Camera

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

•Pressurized Cab with Heat & A/C•Bluetooth + 8” Smart Touch Display

•Ride Control

PREFAB from page 1

“Embracing prefab technology can mitigate risk and diminish uncertainties within any given construction project,” said Makenna Ryan, a civil engineer of Procore.

In a blog post on the construction software provider’s website, Ryan and writer Cait Bladt talked about the pros and cons of modular construction.

“By adopting this approach, contractors can reduce the impact of inclement weather conditions and other factors that delay the project timeline,” they said.

Prefabricated components have become mainstream in the transportation industry for bridge construction, drainage systems and modular pavement installs.

On bridge projects, the most common modular components include beams, girders, deck segments and pier caps, according to Ryan.

The various pieces are manufactured off site and transported to the job for onsite assembly.

On water and wastewater projects, said Ryan, concrete pipes, boxes and drainage structures are installed to manage water flow around infrastructure.

Modular sections of pavement are quickly assembled on road and high projects to create durable driving surfaces, he said.

Prefabrication offers advantages in keeping a project on track, especially when schedule management is critical.

Prefabrication enhances site logistics by “streamlining the construction process,” said Ryan, particularly on job sites with limited space.

“Since prefabricated components are manufactured in controlled factory environments, the need for onsite storage of raw materials is drastically reduced.”

These components can be delivered just in time for installation, he said, minimizing the duration and extent of onsite material handling and storage.

The just-in-time delivery model benefits urban construction sites, where space is at a premium. Plus, the storage of excess materials on an urban site can impede traffic flow and increase safety hazards.

Ryan also pointed out that with immediate installation upon arrival of prefab parts, the construction timeline is accelerated. This rapid installation also reduces the environmental impact of material waste, he said.

“The reduction in onsite activity correlates with fewer disruptions to the surrounding community and a more organized and efficient job site,” said Ryan.

Precision, in both the manufactured component and the installation phase is improved with modular construction.

Ryan said building elements in a factory with precision equipment allows for greater control over measurements and tolerances.

This control, in turn, ensures each component is produced to exact specifications and with uniform quality, he said.

“Design tools and manufacturing technologies further enhance this accuracy, reducing human error and material discrepancies,” said Ryan.“This meticulous attention to detail guarantees that the components fit together seamlessly during installation.”

Quicker and more accurate installation results on the job site when modular components are assembled there as all parts are designed to connect perfectly

“The result is an overall increase in the quality of the fin-

Adobe Stock photo

Transporting and storing project components can be the greatest hamstrings in prefab construction. The challenges of trucking oversized components requires careful planning and coordination.

ished structure, with reduced need for adjustments and rework,” said Ryan.

Risk management involves controlling variables and prefabrication offers control of nearly every variable in the component’s construction.

By shifting component construction from the job site to the “predictable confines” of a factory, prefabrication allows for a more methodical approach.

The timeline for construction “becomes more reliable, and quality checks can be conducted more thoroughly in a dedicated facility,” said Ryan.

With prefabrication, the risks associated with weather, site conditions and labor are mitigated before the components

reach the building site, he added.

“These proactive measures ensure that potential problems are identified and resolved in advance.”

This, in turn, reduces the likelihood of costly and timeconsuming issues arising during the crucial stages of on-site assembly, said Ryan.

The construction method can virtually eliminate delays caused by adverse weather conditions or the need for specific environmental settings for materials.

“Moreover, the ability to conduct comprehensive testing and refine aesthetic details within a factory setting ensures that components arrive on-site,” said Ryan.

It also guarantees they arrive “in a state of near perfection, ready for immediate assembly.”

Frontloading the production and quality assurance phases in modular construction allows for parallel site prep, said Ryan, and expedites build time.

“The culmination of these factors is a streamlined construction process where speed is matched by an uncompromised commitment to quality,” he said.

Labor issues plague the construction industry. But one of the biggest benefits of prefab construction, in Ryan’s eyes, is maximized labor efficiency.

“By bringing together specialized labor in a controlled setting, construction teams can focus on precision and quality,” he said.

And they can operate in tandem without the distractions and variables found at traditional construction sites.

“This not only improves the quality of work but also enhances safety and reduces overall project costs, allowing specialists to focus on their craft,” he said.

For more than two decades, NDK Scraper of Spencer, Ohio, has been synonymous with quality and commitment in the heavy equipment industry. What began as a modest operation has grown into a company known for delivering reliable scrapers and customer service to contractors and site developers across the region.

Founded in 2004 by Nick Kostecki, NDK Scraper combined vision, determination and job site insight to modernize operations while preserving its core values. From the outset, NDK became a trusted K-Tec dealer, giving contractors access to a full line of high-performance earthmoving scrapers.

That partnership helped define NDK’s reputation for quality equipment solutions and laid the foundation for long-lasting relationships with contractors.

NDK is entering an exciting new chapter. The company recently transitioned to an Employee Stock Ownership Plan (ESOP), giving employees direct ownership in the business.

This reflects NDK’s belief that its people are the heart of its success — when employees have a stake in the company’s future, customers benefit from even greater dedication and pride in the work being done.

The NDK team is enthusiastic about the ESOP, knowing their efforts are more directly rewarded.

“Being part of the ESOP makes everyone feel truly invested in NDK’s success. When the company grows, we all grow,” said an employee.

In addition, NDK is investing in a more than 10,000-sq.ft. facility expansion featuring new office space, a wash bay, additional service bays, a larger inventory lot and an expanded parts warehouse. These improvements will increase production capacity, speed up service turnaround and enhance efficiency, according to the company.

Looking ahead, NDK is positioning itself for long-term stability. The ESOP ensures the company remains in the hands of those who know it best — its employees — while the new facility expansion supports improved product development, faster delivery and expanded service offerings, including parts restoration.

With a proud history shaped by Kostecki ’s leadership, strong employee ownership guiding the present and a focus on growth for the future, NDK Scraper is well-prepared to serve the construction industry for generations to come.

see NDK page 72

in Teamwork

in front of their

customers with onsite diagnostics and repairs for rapid response at

Shop personnel perform final checks on a block assembly, demonstrating the hands-on expertise and precision engine work that define NDK Scrapers’ service capabilities.

PREFAB from page 26

For all its rewards, prefabrication is not without its risks. The process requires careful planning and consideration to fully realize the benefits.

Number one of Ryan’s list is interface management — ensuring prefabricated components from different production sites fit together perfectly upon assembly.

Some materials are more forgiving when it comes to misaligned connection points, said Ryan. Wood and steel are two examples.

But, he said, regardless of the material prefabrication requires meticulous planning and precision engineering to avoid costly on-site adjustments.

“Successful interface management eliminates potential errors in manufacturing and is pivotal in maintaining project timelines and budgets.”

The next modular construction con is liability, which Ryan said can be challenging in prefab construction.

This challenge happens particularly when issues arise from interface management discrepancies.

“The responsibility for components that do not seamlessly integrate … should be clearly defined by the contractual agreements,” he said. “It is important for all parties involved, from the general contractor to the modular fabricator, to understand where liability rests for each element.”

Contractors should make sure project contracts clearly outline responsibility for defects or mismatches. This will ensure that parties are aware of their obligations and potential liabilities from the outset, said Ryan.

“In industries such as oil and gas, it is common for the general contractor to assume the bulk of the risk,” he said.

“This centralized liability model ensures accountability but also empowers the contractor to factor this risk into their pricing structure.”

By proactively managing contracts and liabilities, said Ryan, prefab construction can maintain its efficiency advantage.

At the same time, the construction method can assure equitable risk distribution among stakeholders.

The transportation and storage of project components are often the greatest limitations to prefab construction.

“Virtually anything can be prefabricated with the right equipment, sufficient space and adequate infrastructure to transport it,” Ryan said.

But the unique challenges of transporting oversized components, such as wind turbine blades or bridge sections, requires careful planning and coordination.

Ryan believes the success of a prefab project can be credited to logistics as much as the actual construction.

“For example, the average prefabricated blade for a wind turbine is about 120 feet long,” he said.

That is more than double the length of a typical tractor tailor, already difficult to navigate through turns in many suburban areas, he said.

“Transporting an item of this size requires specialized route planning, considering the increased turning radius and weight of the item.”

Ryan believes that most often the limitations of prefabrication are due to restraints in both manufacturing and transportation.

“If an item is being carried across a bridge, will it support the weight?” he said.

And, if the item has to be hoisted into place, is the crane powerful enough to get it there?

“These are the types of questions that need to be answered before committing to a specific prefab project,” said Ryan.

Finally, there are design changes. “If there’s one thing that is virtually guaranteed on any construction project, it’s change,” said the civil engineer.

Whether it’s differing site conditions, material availability or design considerations, even small changes can render prefab components unusable, he said.

“Prefabricated components are manufactured based on design specifications and site assessments.”

As a result, said Ryan, any discrepancies between the expected and actual site conditions can lead to complications.

“For instance, unusual soil characteristics or subterranean obstructions may require on-the-fly adjustments to prefabricated foundation elements,” he said. “Similarly, design changes made after the commencement of prefab production can lead to costly rework.”

Changes can even render existing components unusable if they no longer align with the revised design.

That’s why stringent design freeze policies are often implemented on construction projects, in addition to thorough and regular site evaluations.

“Despite these challenges, the key to successful prefab construction lies in diligently managing the design phase,” said Ryan.

It also lies in ensuring comprehensive site analysis to prevent expensive and time-consuming setbacks, he added.

Florida Bradenton • 941/755-5722

Ft. Myers • 239/337-1313

Jacksonville • 904/786-6710

Ocala • 352/629-7585

Orlando • 407/849-6560

Pembroke Pines • 954/433-2800

Plant City • 813/754-2727

West Palm Beach • 561/863-0570

North Carolina Asheville • 828/681-5172

Charlotte • 980/777-8345

Fayetteville • 910/483-3892

Greensboro • 363/792-3412

Greenville • 252/695-6200 Raleigh • 919/851-2030 Wilmington • 910/254-2031

South Carolina Columbia • 803/794-6150 Greer • 864/877-8962 Myrtle Beach • 843/486-8090 North Charleston • 843/486-8080 Virginia Bealeton • 540/439-0668 Chesapeake • 757/485-2100 Chester • 804/748-6411 Fishersville • 540/887-8291 Salem • 540/380-2090

662/869-0283 Little Rock, AR • 501/823-4400 Springdale, AR • 479/927-1672

Alabama

• 205/621-2489

• 256/831-2440

• 205/591-2131 Decatur • 256/355-0305 Dothan • 334/678-1832 Huntsville • 256/851-2222 Mobile • 251/457-8991 Montgomery • 334/288-6580 Tuscaloosa • 205/752-0621 Florida

City • 850/763-4654 Pensacola • 850/505-0550 Georgia

• 229/435-0982

• 404-366-0693 Augusta • 706/798-7777 Calhoun • 706/879-6200 Columbus • 706/562-1801

Hoschton • 706/654-9850

Kennesaw • 678/354-5533 Macon • 478/745-6891 Savannah • 912/330-7500 www.wpi.com Louisiana Alexandria • 318/408-3099 Baton Rouge • 225/800-3711

Kenner • 504/467-5906

Broussard • 337/362-4331

Bossier City • 318/746-5272

Sulphur • 337/287-9455

“This project also supports an NCDOT initiative to modernize infrastructure along the I-40 corridor near the Tennessee line, where mountainous terrain, weather and heavy freight traffic present unique challenges. It complements nearby bridge replacements aimed at improving safety, traffic flow and emergency access.”

Bridge 142 carries I-40 motorists over the Pigeon River, spanning approximately 365 ft. and standing about 50 ft. above the water in a rugged section of Haywood County. The original structure consists of multiple steel girders with a concrete deck, crossing a scenic but logistically difficult gorge.

The new bridge will be wider and designed to meet current interstate standards, including full shoulders, improved crash barriers and increased vertical clearance. It will use modern concrete girders and reinforced substructures to enhance durability and resilience to flooding and seismic activity.

The project began in October 2021, with early construction efforts focused on the first bridges. Bridges 124 and 142, which are located near each other, are scheduled to be completed in 2026.

Kiewit Infrastructure South Co. serves as the prime contractor for the bridge project, which will provide safer, smoother travel with fewer maintenance-related disruptions.

“It will support tourism, freight and emergency services throughout western North Carolina, while preserving access to scenic routes and public lands,” said McCourt. “For drivers, it means peace of mind and reliable passage for decades to come.”

The biggest challenges for crews on the job include working within the steep terrain between the river and live traffic, as well as coping with unpredictable mountain weather. Maintaining traffic flow during demolition and construction phases requires precise coordination and safety measures.

Crews are completing the substructure of Bridge 142 and finishing work on the eastbound portion of Bridge 124. Key

tasks remaining include completing bridges 124 and 142, performing final grading and paving and transitioning traffic into its final alignment.

For bridge work, the outside spans will require coordination between tracked cranes and gantry crane systems.

“The center span will require two gantry cranes working in tandem due to limited access,” said McCourt. “This is notable because, to our knowledge, it’s the first time gantry cranes are being used in DOT bridge construction in the southeastern United States.”

Mountainous terrain and unpredictable soil conditions have made foundation work especially difficult, requiring multiple redesigns. Since Tropical Storm Helene, river conditions have changed significantly, causing water levels to rise and fall quickly. Several work suspensions have occurred due to flooding.

The eastbound portion of the original bridge has already been demolished, and traffic now runs one lane in each direction on the old westbound bridge. Once the new eastbound structure opens, the westbound section will be demolished. This involves deck removal, steel girder cutting and careful deconstruction with protective measures to prevent debris from entering the river.

When replacing multiple bridges along Interstate 40, workers must coordinate efforts across several sites, maintain steady traffic flow, manage shared equipment and labor resources and stay on schedule. Total cu. yds. on the entire project are approximately 120,472 and 46,317 for bridges

142 and 124.

Main equipment being used to complete the work includes gantry cranes, tracked cranes, excavators, concrete pump trucks and paving machinery. Primary materials include reinforced concrete, prestressed concrete girders, high-strength steel girders and asphalt.

According to McCourt, keeping an eye on the forecast is always crucial.

“Heavy rain, snow and freeze-thaw cycles delay paving, excavation and concrete work. River levels can rise rapidly, sometimes halting activity with little warning. Weather-related delays have been accounted for in the schedule, but adaptive planning is essential.”

Despite the obstacles that have surfaced during construction, McCourt is pleased with the progress made so far.

“It’s extremely satisfying to contribute to a lasting piece of infrastructure that will improve safety and mobility across the region. This bridge will stand as a long-term investment in North Carolina’s transportation future.” CEG

For more information on concrete news, visit CEG's Web site at www.constructionequipmentguide.com.

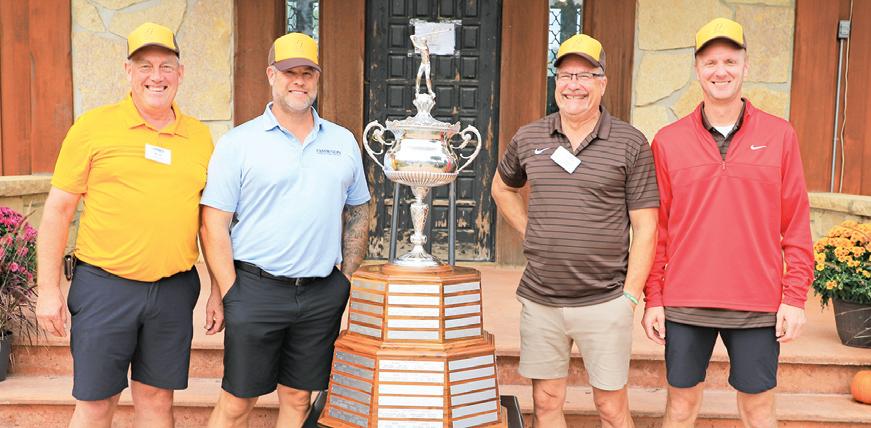

Approximately 328 guests from the United States and Canada were welcomed to Ida Grove, Iowa, Sept. 16 and 17, 2025, for GOMACO Invitational #43. The event consisted of two days of golf and camaraderie, as well as to celebrate GOMACO’s 60th anniversary.

There were 258 participants in the two-person Putting

Tournament and 328 in the four-person Scramble Tournament. The GOMACO Invitational is the company’s annual golf event, which was held at the Ida Grove Golf and Country Club and three surrounding golf courses, including Holstein, Mapleton and Schleswig.

The GOMACO Invitational began at the Ida Grove Country Club with the Putting Tournament. Teams of two

putters were computer generated to participate on four different greens on the course, with the top team from each green advancing to the Putting Championship. This year’s championship team was Jeremy Bahe of Croell, Inc., in New Hampton, Iowa, and Ashleigh Johnson of A Concrete in Johnstown, Colo.

see GOMACO page 38

The Concrete Foundations Association (CFA) announced the installation of three distinguished leaders to its Legacy Committee: Lance Jordan, formerly of Stephens and Smith Concrete Construction; Mark Saldana of Saldana Concrete; and Van Smith of Hudson Valley Concrete Pumping Inc.

The appointments honor their significant contributions and long-standing service to the concrete foundation industry and the association.

These individuals have demonstrated exceptional leadership and commitment throughout their careers, particularly during their service on the CFA board of directors. Their efforts have been instrumental in advancing the association’s mission, supporting its members and driving industrywide progress. Each has left a lasting impact through their dedication to CFA events, resources and strategic development, making them exemplary additions to the legacy committee.

Jordan’s tenure on the board was marked by his stabilizing leadership during the economic recession, a critical period for the association. His persistent efforts helped ensure the CFA’s continuity and fostered a collaborative environment for members.

Saldana’s service was defined by his passionate involvement in strategic planning, which formalized the mission and vision that guides the association today.

Smith brought dynamic energy to the board, championing the “Projects of the Year” program and passionately sharing his expertise in construction education and technology.

“We are excited to announce these individuals as new members to the legacy committee,” said James Baty, CFA executive director. “Their lifelong devotion to the industry inspires us all. We are thrilled to have the opportunity to honor these hardworking CFA members as new legacy com-

mittee members and acknowledge their dedication and contributions.”

Nominations for the legacy committee are conducted each spring, with the final list of candidates ratified by the board of directors to recognize leaders who have built a lasting legacy within the CFA.

In 2018, the Concrete Foundations Association’s (CFA) board of directors established a legacy committee to honor the rich tradition of service to the association on behalf of the industry. This committee, comprised of association leaders, cultivates awareness for the industry, is dedicated to the mission of the association, and elevates the service of the members to the entire industry. Members of this committee maintain this service through their organization’s commitment to membership and participation and are nominated to this service opportunity by the board of directors.

The purpose of CFA’s legacy committee is to safeguard and cultivate institutional knowledge, framed by history and held visible toward the future. By preserving the collective wisdom shared by vigorous networking, institutionalizing historical insights and honoring the best practices throughout CFA membership, this committee aims to ensure continuity, excellence and innovation in the concrete contracting industry. By challenging the board of directors, CFA staff and the membership at large through resources and mentorship opportunities, the committee endeavors to empower the current and future generations of CFA members, inviting them to build upon this foundation of legacy, impacting the concrete profession and enhancing CFA’s reputation.

For more information, visit cfaconcretepros.org/

Power Curbers Cos. announced the acquisition of Miller Formless Systems.

The acquisition was finalized on Aug. 29, 2025, marking a significant milestone in the continued growth of both organizations.

Founded in 1970, Miller Formless has a long history of manufacturing slipform machines that have served contractors worldwide. By joining forces with Power Curbers Cos. home to the Power Curbers, Power Pavers and Anvil American brands, this acquisition strengthens the combined company’s market leadership, expands product offerings and enhances service and support for customers worldwide.

Miller Formless will continue to operate under its own brand name.

Power Curbers Cos. remains committed to preserving the company’s legacy while introducing operational efficiencies that will benefit customers in the areas of machine delivery, parts availability and after-sales support, according to Power Curbers.

“This acquisition represents more than just growth- it’s about uniting two businesses that share a deep commitment to quality and customer success,” said Stephen Bullock, president of

Power Curbers Cos. “Miller Formless has been a trusted name in the industry for over five decades, and we are honored to carry that legacy forward while offering an even greater range of solutions to contractors.”

Together, Power Curbers, Power Pavers, Anvil American and Miller Formless will now provide contractors with a comprehensive lineup of concrete paving solutions, from extruded curb machines to mainline highway pavers.

“We’re thrilled to couple the 5700-D multi-purpose machine, the compact M1000 and the M8800 barrier machine, giving contractors an unmatched lineup of machines designed to meet a wide range of project needs,” said Bullock.

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

STOWERS MACHINERY CORPORATION www.stowerscat.com/gomaco

Chattanooga, TN 423-698-6943

Crossville, TN 931-484-4040

Knoxville, TN (East) 865-546-1414

Knoxville, TN (West) 865-218-8800

Sevierville, TN 865-595-3750 Tri-Cities, TN 423-323-0400

Austell, GA 800-282-1562 Albany, GA 800-768-2892 Augusta, GA

800-446-5131 Brunswick, GA 800-299-5010

The Contractors’ Shoot-Out featured six teams of three GOMACO contractors competing in a five-hole competition, with the highest scoring team eliminated on each hole. This year’s Contractors’ Shoot-Out Champions were Tim Grethey of Millstone Weber LLC, in Saint Charles, Mo.; Jeremy Bahe of Croell Inc., in New Hampton, Iowa; and Todd Horky of Concrete Plus, in Sioux City, Iowa.

The Invitational Scramble Tournament, a best ball competition, was held on four area golf courses. Computer-generated teams of four golfed 18 holes, with each course crowning a champion. The champion team from each of the four courses then played in a three-hole shootout at the Ida Grove Country Club to earn the title of GOMACO Invitational #43’s “Grand” Champion.

The highest scoring team was eliminated on each hole until only one remained. The “Grand” Champion team was from the Mapleton golf course and included Joe Stoltz of Turck Inc., Bondurant, Iowa; David Martin

Winning the Holstein tournament were Ryan Hanson of Endeavor Business Media, Naperville, Ill.; David Barthel of Faris Machinery, Commerce City, Colo.; Joe Schmidtlein of the Rasmussen Group, Des Moines, Iowa; and Drew Roberts of Absolute Concrete Construction, Granger, Iowa. They finished the Holstein tournament with a score of 60, which was 10 under par.

The champion team from Schleswig included Steve Baker of Baker Enterprises, Waverly, Iowa; Eric Striegel of IFP Motion

of Northstar Power LLC, Ankeny, Iowa; Dane Peters of TOPCON, Livermore, Calif.; and Tyler Hansen of Power Systems Inc., in Chanhassen, Minn. They won the Mapleton tournament with a score of 60, which was 10 under par.

The Ida Grove tournament champion team members included Brad Pohlmeier of Clarkson Construction Co., Kansas City, Mo.; Chris Kipp of Murr Inc., Edwardsville, Kan.; Kevin Van Den Top of State Steel Supply Company, Sioux City, Iowa; and Brad Zobel of GOMACO. They finished the Ida Grove tournament with a score of 61, which was nine under par.

Solutions, Cedar Rapids, Iowa; J.B. Closner of Closner Equipment Co., Rhome, Texas; and Cody Oswalt of Kiewit Corporation, Omaha, Neb. They finished the Schleswig tournament with a score of 62, which was eight under par.

GOMACO Corporation is a leader in concrete construction equipment with headquarters in Ida Grove, Iowa. GOMACO equipment will slipform concrete streets and highways, airport runways, curb and gutter, sidewalks and recreational trails, safety barrier, bridge parapet and irrigation canals. Support equipment includes grade trimmers, concrete placers, concrete placer/spreaders and texturing and curing machines.

The company also offers equipment to finish flat slabs, bridges and slopes. GOMACO will consult on unique concrete paving applications and equipment needs. Products are offered through a worldwide distributor network for local sales, parts and service expertise.

For more information, visit gomaco.com. (All photographs in this article are courtesy of GOMACO.)

www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235

TRACTOR & EQUIPMENT www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 931-388-7273

MID SOUTH MACHINERY, INC. www.gomidsouth.com 3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

GLOBAL from page 16

of the day, it all comes down to the operator in the seat.”

That focus on human talent is the heart of the event.

Caterpillar’s Global Operator Challenge was built to honor skilled labor, promote the career path of machine operation and inspire the next generation to consider a future in the trades.

“We’re bringing together champions from three major regions globally, North and South America combined, Europe-Africa-Middle East and Asia Pacific,” said Hurdis. “Each will send three operators to compete for the global title.”

So, what’s at stake? For starters, there’s a $10,000 prize — either in cash or a firstclass trip for two to any Caterpillar facility worldwide (depending on local laws) and, of course, recognition.

“They get trophies, custom belt buckles and beautifully etched glass containers with the machines they competed on,” said Hurdis. “But more than that — they earn something you can't buy — bragging rights.”

The competition puts operators through their paces on four key machines — all painted in Centennial Gray to celebrate Caterpillar's 100 years:

• 285 compact track loader,

• 320 Next Gen excavator,

• D4 track-type tractor, and

• 938 Next Gen wheel loader

Each machine challenge is designed to test precision, efficiency and control—critical skills for any seasoned operator.

Caitlin Maddock-Bahr, global social media manager and

marketing lead for the 2025–2026 Global Operator Challenge Series, echoed a common theme when asked why this event matters so much:

“Talk to any customer around the globe, and you’ll hear the same thing — the number one pain point is skilled labor,” she said. “That includes operators and technicians. We want to retain talent, celebrate these incredible professionals and recruit new operators into the industry.”

Maddock-Bahr added why choosing a career in operating heavy equipment is a rewarding career path.

“You get to work with your hands, be outside and see the real-world results of your labor. An operator has been on every interstate, golf course, housing subdivision and more before we even get to use it, drive on it or live in it.”

(All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

Epiroc has partnered with Luck Stone to deploy the first fully autonomous SmartROC D65 drill rig in the United States. This marks a historic milestone, as it is also the first fully autonomous surface drill delivered to the quarry market worldwide, according to the companies.

The SmartROC D65 MKII is equipped with Epiroc’s advanced automation technology and is capable of executing complete drill patterns without an operator in the cab. Compliant with the global mining guidelines group (GMG) Level 4 standard for full autonomy, the rig operates under remote supervision via Epiroc’s common automation panel (CAP) and link open autonomy (LinkOA) platform, enabling seamless data integration and fleet management.

“Luck Stone’s leadership and commitment demonstrate that autonomy in quarries isn’t future vision — it’s current reality,” said Ron Hankins, business line manager of Epiroc USA. “Our partnership is not about a proof-of-concept, it’s about meaningful operational gains that the next generation of drilling will bring in the U.S.”

Luck Stone, known for its early adoption of autonomous plants and autonomous haulage systems (AHS), continues to innovate for the industry, and the company views automation as a strategic investment in safety, operational excellence and talent attraction.

“Our philosophy has always been about doing the work in the best possible way,” said Chuck Stilson, senior director of engineering of Luck Stone. “Partnering with Epiroc on autonomous drilling aligns perfectly with that vision. We’re not only improving productivity and safety, we’re providing new opportunities for our associates and rethinking what’s possible in aggregates.”

James River Equipment, an Epiroc dealer, played a key role in facilitating delivery of the SmartROC D65 MKII and will be instrumental in providing the ongoing local service, training and technical support that are essential to ensuring the project’s long-term success.

The United States aggregate market is the largest globally and presents significant growth potential for autonomous technologies. Using the same automation platform proven in mining, the SmartROC D65 MKII makes it easy for any operation to scale toward full autonomy, according to the companies.

By enhancing operational safety, optimizing machine fleet size and addressing skilled labor shortages, this deployment represents a transformative shift in how quarries can operate.

Both Epiroc and Luck Stone have committed to sharing performance data following the implementation period, offering valuable insights for the broader industry and paving the way for future advancements in automation.

For more information, visit epirocgroup.com and luckstone.com.

Green-Tec, a Terex brand specializing in tree care and vegetation management solutions, showcased the SL5 Spider Lift at The Utility Expo in Louisville, Ky.

The SL5 provides access to restricted spaces, supporting safe work at height for operators using handheld tree care equipment. With rubber tracks, stabilizers with adjustable configurations and automatic leveling, the SL5 can be deployed safely and efficiently across a variety of conditions, according to Green-Tec.

Available at Terex Services branches across the United States, the SL5 is part of the GreenTec Spider Lift range, which also includes the SL6 and SL7. These compact lifts are designed to fit through alleys and backyard gates, narrowing to just 35 in. while offering working heights from 68 ft. to more than 100 ft. For more information, visit terex.com/green-tec/en/products/spiderlifts/spider-lifts/sl5. Terex Green-Tec photo Green-Tec showcased the SL5 Spider Lift at The Utility Expo in Louisville, Ky

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414

10644 Lexington Dr Knoxville, TN 37932 865-218-8800

9960 Airport Pkwy Kingsport, TN 37663 423-323-0400

4066 South Access Rd Chattanooga, TN 37406 423-698-6943

1825 Veterans Blvd Sevierville, TN 37862 865-595-3750

215 Interchange Dr Crossville, TN 38571 931-456-6543

541 Alfred Thun Rd. Clarksville, TN 37040 931-552-5496

667 Horace Lewis Rd. Cookeville, TN 38506 931-646-3200

4350 US-641 Camden, TN 38320 731-584-2732

1245 Bridgestone Blvd. LaVergne, TN 37086 615-256-2424

3565 New Tullahoma Hwy. Manchester, TN 37355 931-461-5000

1291 Corporate Ave. Memphis, TN 38132 901-332-3051

3199 S Frontage Rd. Columbus, MS 39701 901-401-7011

2000 Airways Blvd Jackson, TN 38301 731-988-4240

4545 Columbia Pike Thompson’s Station, TN 37179 615-744-7850

1808 US-82 Greenwood, MS 38930 662-453-5233

761 Hwy 6 West Oxford, MS 38655 662-371-4440

421 Wallace Dr Belden, MS 38826 662-680-8948

Remu has launched a new product range, crusher buckets, to its portfolio.

Manufactured in-house with Hardox steel, powered with Rock-Zone technology, this equipment comes as a response to the increasing demand and inquiries from customers seeking reliable and highperformance crusher solutions, according to Remu.

The jaw crusher bucket is engineered to crush rock, concrete and asphalt, providing users with an effective way to recycle and reuse construction materials. By integrating this equipment into operations, customers can reduce waste, lower costs and contribute to sustainable practices in the construction and demolition industries. Designed for durability and efficiency this crusher bucket boasts low maintenance requirements, ensuring minimal downtime and maximum productivity for users, according to Remu.

“We are thrilled to introduce this full range of crusher buckets in co-operation with Rock-Zone,” said Juha Salmi, CEO of Remu. “This addition to our product portfolio directly addresses the needs of our customers. By manufacturing it ourselves along with Rock-Zone technology, we ensure top- notch quality and performance while offering a practical solution for material recycling.”

For more information, visit remu.fi/en/.

The new upgraded Sandvik jaw crusher range is another step forward in ensuring performance for its customers’ crushing operations.

Merging new jaw crusher capabilities and design with the existing standards of the entire Sandvik range was a natural next step, according to Sandvik. Sandvik jaw crushers are now better equipped to deliver the performance customers expect from a global leader in mining and quarry solutions.

“Our new upgraded jaw crushers are now more aligned with the full Sandvik range,” said Martin Johansson, global product manager, jaw crushers. “They give our customers even more ability to secure safety, improve productivity and availability, reduce costs and accelerate sustainability with a partner they can count on.”

The latest Sandvik jaw crushers come complete with the features customers need for plug-and-play primary and tough material crushing. New and improved Sandvik jaw crushers now include even more of the safety, performance, availability and sustainability benefits customers expect from Sandvik solutions:

• new hydraulic wedge setting adjustment;

• synchronized retraction arrangement;

• improved power pack;

• upgraded guarding;

• new ACS-j monitoring and control system; and

photo

Upgraded Sandvik jaw crushers are engineered to the same specifications for seamless compatibility with the full range of Sandvik solutions and now come with a 3-year standard warranty.

crushing operations.

• clear role-based user documentation.

Upgraded Sandvik jaw crushers are engineered to the same specifications for seamless compatibility with the full range of Sandvik solutions and now come with a 3-year standard warranty.

The upgrades to Sandvik jaw crushers put focus on Sandvik’s commitment to safety. The ability for hydraulic wedge setting and retraction adjustments reduces operator exposure to unnecessary risk. An improved guarding system advances the unique Sandvik uniform safety-engineering integrated in past solutions, ensuring the new jaw crushers are as safety-first and foremost as our customers need them to be, according to Sandvik.

The new upgraded Sandvik jaw crushers come with a welded main frame and material quality improvements and are delivered complete with everything needed for fast and seamless integration with a customer’s existing operation. The smaller footprint, uniformity of structural components

and parts, logical service access points and clearer rolebased documentation ensure shorter times to full productivity with less need for local engineering or additional training.

The Sandvik jaw crushers also are now equipped with the new ACS-j system, simplifying monitoring and control of lubrication, hydraulic settings and eccentric shaft bearing temperature. The information is accessible through a web interface, providing customers with oversight and control of components and crusher metrics that help maintain optimal crushing performance and availability through troubleshooting.

“Sandvik is proud of the positive circularity impact we make through the design, manufacturing and operation of our jaw crushers,” said the company. “From the high energy efficiency of our main motor to the compact all-in-one footprint to the fully recyclable materials used in their design, manufacturing and operation, Sandvik jaw crushers are a natural fit in sustainable quarry and mining operations.”

For more information, visit home.sandvik/en.

5038 Buford Hwy. Norcross, GA 30071

770-582-0377

Blue Ridge, GA 706-632-3777

Cumming, GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037 Perry, GA 478-987-1173

Savannah, GA 912-208-5349

Waverly Hall, GA 706-582-3193

Tree Care

Stowers Machinery Corporation stowerscat.com/bandit

6301 Old Rutledge Pike Knoxville, TN 37924

865-546-1414

10644 Lexington Drive Knoxville, TN 37932 865-218-8800

1825 Veterans Boulevard Sevierville, TN 37862

865-595-3750

9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943

215 Interchange Drive Crossville, TN 38571

931-456-6543

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem , BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

A recent webcast titled “From AI to Dynamic LIBS: How new sorting technologies drive growth in aluminum recycling,” hosted by TOMRA Recycling in partnership with Novelis, unveiled advancements in aluminum recycling technologies.

Emphasizing that greater aluminum scrap use can significantly lower CO2 emissions, the webcast showcased the transformative impact of the latest sorting technologies on aluminum scrap, highlighting the considerable business opportunities these innovations present for aluminum recyclers and processors.

Experts from TOMRA Recycling and Novelis discussed the typical challenges in aluminum recycling and how the latest technologies — X-ray transmission (XRT), Dynamic LIBS and deep learning — are optimizing sorting processes, enhancing the purity of aluminum scrap fractions and creating new market opportunities.

A key takeaway from the webcast was the critical need to maximize both the use of aluminum scrap and the capacity for high scrap input in production and recycling processes. Success hinges not just on incoming material quality, but also on effectively generating the necessary scrap qualities. Consequently, material quality is emerging as a central focus in product development and operational strategies.

The webcast highlighted the aluminum industry’s significant shift toward sustainability, driven by such innovative sorting technologies and recycling initiatives. Companies like Novelis, with its 3x30 vision to advance aluminum as the material of choice with circular solutions, are at the forefront of this transformation, aiming to maximize circularity and shape a more sustainable world.

Key themes raised during the webcast included:

• the business opportunities and profitability enhancements the latest innovations, particularly Autosort Pulse (a Dynamic LIBS solution) and GAINnext (a deep-learningbased AI solution), offer aluminum recyclers and processors;

• insights into an end-user’s experiences regarding recycled content, as presented by Wilhelm Kiefer, metal optimization lead at Novelis; and

• the urgency and importance of improving the recycling infrastructure for metals and the technologies to keep pace with industry demand for recycled aluminum.

TOMRA and Novelis also shared findings from various test results conducted at TOMRA’s Test Center and in the field, highlighting a successful reduction of individual elements in Twitch using different sorting technologies. The optimal sequence for the best overall results was found to be XRT first, then deep learning, followed by Dynamic LIBS. From 100 percent Twitch — a widely available yet challenging scrap type due to its complex composition — 40 percent of wrought aluminum was successfully extracted as exceptionally high-quality 5xxx and 6xxx alloys. The test results further highlight the future potential for recovering a broader range of aluminum alloys, including the 2xxx, 3xxx, 7xxx and 8xxx series.

revealed that attendees felt the primary challenge in improving recycled aluminum content is material purity. The second highlighted that the most critical scrap grade to sort more efficiently in the future is Twitch, while the third found that participants’ primary goal when investing in sorting technology is increasing yield and purity. An interactive live Q&A session provided the opportunity to engage directly with experts from TOMRA and Novelis.

The webcast concluded with a call to action for the industry to implement optimized test sequences to enhance material digestibility and prioritize quality in production processes for improved outcomes. The ongoing innovation in scrap recycling, from processing to designing environmentally friendly alloys, is propelling the industry toward a circular

economy where products are designed with recyclability in mind from the outset.

Frank van de Winkel, business development manager — metal of TOMRA Recycling, said: “We were delighted to welcome attendees from across the globe to our recent webcast. It was a great opportunity to gather feedback from the industry on the challenges facing aluminum recyclers and post-shredder operators today, while at the same time demonstrating the unmatched levels of material separation available on the market today using a combination of X-ray transmission, Dynamic LIBS and deep learning technologies. Together with Novelis, we were able to demonstrate the realities of the paradigm shift toward a more sustainable and efficient future for scrap recycling, and we look forward to continuing this important dialogue.”

TOMRA Recycling’s metals recovery solutions are made available in North America through our exclusive metals partner, Wendt Corp. Recyclers are encouraged to test their aluminum and wrought materials using Wendt Corp.’s Test Center that features X-Tract X-ray transmission, GAINnext and Autosort Pulse sorting solutions, designed to maximize aluminum value.

Access the full webcast recording here: tomra.com/-aluminum-webcast.

jamesriverequipment.com

Asheville, NC 828- 667-0176

Charlotte, NC 704-597-0211

Garner, NC 919-772-2121

Greensboro, NC 336-668-2762

Greenville, NC 252-758-4403

Fayetteville, NC 910-424-1200

Wilmington, NC 910-675-9211

New Bern, NC 252-679-7590

Ashland, VA 804-798-6001

Chesapeake, VA 757-998-4880

Fishersville, VA 540-337-3057

Manassas Park, VA 703-631-8500

Richlands, VA 276-596-9440

Salem, VA 540-380-2011

Stephenson, VA 540-667-9777

beardequipment.com

Jacksonville, FL 904-296-5000

Lake City, FL 386-752-9544

Ocala, FL 352-732-4646

Palatka, FL 386-325-6268

Perry, FL 850-584-9200

Tallahassee, FL 850-575-5600

dobbsequipment.com

Riverview, FL Main office 813-620-1000 Parts 813-621-4902

Miami, FL 305-592-5740

West Palm Beach, FL 561-848-6618

Orlando, FL 407-299-1212

Fort Myers, FL 239-334-3627

Lutz, FL 813-995-0841

Daytona, FL 407-299-1212

Pompano Beach, FL

954-977-9541 (Parts)

Sarasota, FL 941-960-2004 (Parts)

Melbourne, FL 321-234-3344 Andrews, SC 843-983-7337

Aynor, SC

843-358-5688

Ladson, SC 843-572-0400

Simpsonville, SC 864-963-5835

Walterboro, SC 843-539-1420

West Columbia, SC 803-794-9340

www.tec1943.com

Birmingham, AL 205-591-2131

Alabaster, AL 205-621-2489

Anniston, AL 256-831-2440

Decatur, AL 256-355-0305

Dothan, AL 334-678-1832

Huntsville, AL 256-851-2222

Mobile, AL 251-457-8991

Montgomery, AL 334-288-6580

Tuscaloosa, AL 205-752-0621

Panama City, FL 850-763-4654

Pensacola, FL 850-505-0550

Atlanta, GA

MUSKOX has released the T-Tach Torsion attachment, designed to deliver smoother, more efficient operations on uneven ground. First introduced in May 2025, the T-Tach is available to order direct from the company and through MUSKOX’s dealer network.

MUSKOX, based in Grand Forks, N.D., has built a reputation for durable, operatorfocused equipment. The company’s flagship MUSKOX Snowblower line showcases this commitment with back-drag technology, pivoting auger system, glide plates and rubber cutting edges that deliver safer, faster snow removal, according to MUSKOX. The T-Tach builds on that legacy of innovation.

The T-Tach is a torsion attachment engineered to complement, not replace, the equipment operators already own. It enhances performance and comfort while extending the life of existing implements, according to the company.

MUSKOX has released the T-Tach Torsion attachment, designed to deliver smoother, more efficient operations on uneven ground.

Key features include:

• Four independent torsion axles that flex to match uneven terrain, maintaining constant down pressure.

• Noise and vibration reduction, which improves operator comfort and reduces stress on the machine.

• Universal compatibility with any quick-attach plate up to 12,000 lbs., safe at speeds up to 20 mph.

• Enhanced ground contact, providing steadier, more consistent performance for snow removal, grading, scraping and more.

Solving Common Challenges Operators often face equipment

bounce, loss of contact and fatigue when working over uneven surfaces. The T-Tach addresses these issues directly by improving stability and reducing vibration, according to the company. This results in more efficient jobsite operations and less wear on both the operator and the machine. The T-Tach allows users to get more out of their current buckets, blades, snowblowers or other implements — delivering better results without costly equipment replacement, according to MUSKOX. MUSKOX offers a 30-day risk-free trial, giving operators the chance to experience the benefits before committing. For more information,