Despite the monsoon-like rains the contractor has faced, “Mathiowetz has always been a great contractor and partner that keeps moving and pushing to meet deadlines,” said Alison BerrethSandberg, MnDOT construction engineer. By the time the project wraps up, approximately 1 million cu. yds. of common excavation will have been removed.

By Dick Rohland CEG CORRESPONDENT

Minnesota’s Carver County teamed up with the Minnesota Department of Transportation (MnDOT) to put to rest a vision that has been years in the making when highway construction crews complete a $60 million highway upgrade on this 100-year-old highway.

When highway workers walk off and leave the project site behind them this fall, the last 5-mi. segment of 40 mi. of Minnesota’s Hwy 212 between Minneapolis and the small rural town of Glencoe will finally be operating to expressway standards. And they leave behind them a much safer highway with double the capacity for the thousands of commuters and truckers driving it daily.

MnDOT awarded the contract to Mathiowetz Construction based in Sleepy Eye, Minn. The company is a heavy-highway, commercial and agricultural construction company, now moving into its fourth generation of family ownership and just celebrated its 100-year anniversary last fall.

By Lucy Perry CEG CORRESPONDENT

or

BONDURANT

3410 Henry St SW Bondurant, IA 50035

515-454-8626

BONDURANT

3509 Franklin St SW Bondurant, IA 50035 515-410-9900

3478 5th Ave South Fort Dodge, IA 50501 515-574-2302

SERGEANT

112 8th St Sergeant Bluff, IA 51054 712-943-4470

IN THE 78

Chicago Fire FC announced City Council approval for its new, privately funded, $650 million stadium in The 78 — a transformative project that will anchor Chicago’s newest neighborhood.

The Sanco Sandbox West 2025 event, hosted in Mankato, Minn., Sept. 18, offered a hands-on experience with leading equipment brands like XCMG, Bobcat, KAGE Innovation, MUSKOX and Diamond Mowers.

Brooks Tractor is celebrating its 80th year in business. To mark the occasion, an open house was held at its Sun Prairie, Wis., headquarters. Customers, friends and family gathered kick off the company’s next 80 years.

Exact Crane of Solon, Ohio, secured the last remaining SPX309 units to meet ongoing contractor demand. To showcase the SPX309, Exact Crane is hosting its first “countdown sale” campaign which began Oct. 2, 2025.

HD Hyundai Construction Equipment North America announced Sept. 25, 2025, the addition of DSR Equipment to its dealer network. DSR has full-service locations in Watertown and Piedmont, S.D.

While landfills may not be the first thing that comes to mind when a person thinks about the birth of civilization, these areas existed in the earliest days of humans living, growing food and doing business together.

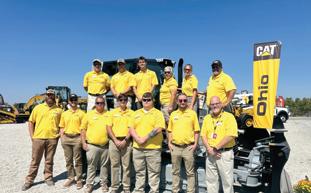

42 FARM SCIENCE REVIEW 2025 FOCUSES ON PRODUCTIVITY

Farm Science Review returned to the Molly Caren Agricultural Center in London, Ohio, Sept. 16–18, 2025, drawing producers, dealers and students for three days of field demonstrations and hands-on equipment showcases.

46 NDK SCRAPER BUILDS ON STRONG FOUNDATION WITH NEW ESOP

NDK Scraper of Spencer, Ohio, has been synonymous with quality and commitment in the heavy equipment industry. What began as a modest operation has grown into a company known for delivering reliable scrapers.

54 HCEA’S 39TH ANNUAL CONVENTION DEBUTS NEW MUSEUM

The Historical Construction Equipment Association staged its 39th Annual International Convention & Old Equipment Exposition Sept. 18–20, 2025, on the grounds of the National Construction Equipment Museum in Bowling Green, Ohio.

56 FELLING ANNOUNCES ITS 2025 ‘TRAILER FOR A CAUSE’ AUCTION DATES

A nine-day online auction, running Oct. 24, 2025 through Nov. 1, 2025, will feature a specially manufactured FT-3 drop deck utility trailer painted in custom “Ivy Green” with black pinstriping, bearing the Ivy’s Legacy Foundation emblem.

58 TOWMASTER CELEBRATES CHRIS POKORNOWSKI’S 30-YEAR CAREER

Towmaster announced Chris Pokornowski, who has served the company with distinction for 30 years, most recently as general manager has stepped down as of Sept. 26, 2025.

Schweiss Doors was contracted by Dosteen Doors and Engineering Services to provide 228 liftstrap bifold doors for Nad Al Sheba Gardens. The bifolds will be used as garage doors for the new homes.

Plenty of equipment was on the block, including skid steers, compact track loaders, utility trucks and more. Attachments and parts also were available for bid. The event offered both live and online bidding.

Cape Girardeau, MO

STK# KM2022307, 4628 HRS, Bridgeton,

KM2024119,

HRS, Franksville, WI 2020 Komatsu PC170LC-11 $139,500 stk# KM2024104 1404 hours, Slinger, WI

2021 Takeuchi TL12R2, S/N 412104134 2883 Hours, CAB/AIR/HEAT, TWO SPEED, HIGH FLOW HYDRAUICS, HYDRAULIC COUPLER, 84" GP BUCKET $44,900

2022 Case SV280B, 171 Hours, S/N JAFSV280HMM403668, CAB/AIR/HEAT, HYDRAULIC COUPLER, 72" GP BUCKET, 2 SPEED, RADIO, EXCELLENT CONDITION

Garrard • (630) 492-9115 Bolingbrook, IL Contact us at Used@McCannOnline.com

our complete Used & “Like New” inventory at

2022 Case 521G, S/N 253822, 266 Hours, CAB/AIR/HEAT, RIDE CONTROL, THIRD VALVE, LIMITED SLIP DIFF, JRB COUPLER2.5 YARD GP BUCKET, DELUXE CAB .. $129,900

2019 Case Cx130D, S/N DAC130K7NKS7D1558, 358 Hours, CAB/AIR/HEAT, HYDRAULIC COUPLER, 18" BUCKET, AUX HYDRAULICS $109,900

2022 Case 321F, S/N NNHP04331, 241 Hours, CAB/AIR/HEAT, HIGH SPEED TRANSMISSION, SKID STEER STYLE COUPLER, 1.7 cu yd BUCKET, LIMITED SLIP DIFFERENTIAL, THIRD VALVE HYDRAULICS TIRES LIKE NEW, PREMIUM CAB $82,500

2023 Case TR270B, S/N JAFTR270LNM421971, 281 Hours, CAB/AIR/HEAT, E-H CONTROLS, HYDRAULIC COUPLER, 78" GP BUCKET, RIDE CONTROL, SELF LEVEL, HIGH FLOW HYDRAULICS, REARVIEW CAMERA, PREMIUM DISPLAY MODULE, FULL MACHINE WARRANTY UNTIL 1-30-25, JUST SERVICED READY TO GO $54,900

2023 Case TV370, S/N 2023 Case TR370B, 176 Hrs, CAB/AIR/HEAT, HYDRAULIC COUPLER, 84" GP BUCKET, DELUXE CAB, PREMIUM DISPLAY PANEL, GOOD TRACKS

$72,500

2018 Case CX245DSR, S/N NJS7K1152, 1306 Hours, Cab/Air,

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

Sakai R2H-4 - ’19, approx. 900 hrs. 83” triple drum static $85,500 ROADTEC RP195 PAVER - ’08, approx. 8890 hrs. Carlson EZIV 10 screed, Moba grade & slope controls ....................................$35,200

Sakai R2H-4 static roller - ‘23, approx. 120 hrs., #C002897

$108,800

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd

$P.O.R.

AGGREGATE EQUIPMENT

ASTEC GT205MF, (’18), 3,296 Hrs, 5 x 20 top deck, 5x18 bottom deck, 8 cu. yd. hopper, 5' wide double deck multi-frequency screen w/hydraulic vibrators, #C005896 $229,900

HAUL TRUCKS

LIEBHERR TA230 LITRONIC, (‘23), 361 Hrs, #C005550 $CALL

Sakai SW884ND - ‘19, approx. 2900 hrs., #C002777, Double drum Oscillatory

$148,400 Sakai SW300 - approx. 450 hrs, 39” drum, #C000211

Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd

$P.O.R.

$26,850.

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154

HAZEMAG APPH1515QL, (’93), Primary Impactor Portable Plant, 400HP electric crusher drive, 15 cu. yd. hopper, #C005559 $370,000

LIEBHERR TA230 LITRONIC, (‘23), 367 Hrs, #C005511 $CALL LOADERS AND EXCAVATORS:

Superior DT74J - ’19, approx. 1300 hrs. AC, Side shift, gutter brush, #C001774 $35,400

BOMAG BM600 - ‘16, 565 Hrs, 24” Drum, Load Out Conveyor

$152,800

Roadtec RX-300 - ’18, approx. 600 hrs. 4’ drum

$311,400

$148,900 KPI FT2650 – ’19, approx. 1800 hrs. Tracked jaw crusher

$546,950

Mauldin 1560 paver – ’22, approx. 600hrs. 8-14’, electric

HAZEMAG APS1315, (’10), 7'x20' triple deck screen, #C005792

$362,500

SIMPLICITY 6203, (’96), Dual Portable Screening Plant, 6’ x 16’ Triple Deck Primary Screen, 6’ x 20’ Triple Deck Secondary Screen, #4873

$295,000

SUPERIOR BROOM SM80K, (‘17) 2,250 Hrs, Enclosed Rops, AC, #C006107 $CALL

SUPERIOR BROOM SM80K, (‘17) 2,090 Hrs, Enclosed Rops, AC, #C006106 $CALL

GROVE GHC85, (’23), 164 Hrs, #C005208 $CALL

LIEBHERR L550 XPOWER, (’17), 2,722 Hrs, innovative machine concept which combines performance, fuel efficiency, robustness and comfort. Power split driveline, #C003118 $125,747

LIEBHERR R924 LITRONIC, (‘23), 10 Hrs, The R 924 (Tier IV) crawler excavator replaces the predecessor R 924 (Gen 6) model. Its completely updated design is characteristic of the new range of "generation 8" machines, #C005679 $CALL LIEBHERR R934 LITRONIC, (‘23), 485 Hrs, The new R934 weighs approx. 35 tons, completely updated design is characteristic of the new range of "generation 8" machines, #C005399 $CALL

$1,099,000

GROVE GHC130, (’19), 932 Hrs, 130-ton lift capacity, #C004141

LIEBHERR R936 COMPACT LITRONIC, (‘18), 1,042 Hrs, Convenient and service-friendly, the R 936 Compact makes for safe working. With its tight slewing radius, this machine is especially well suited to urban applications, #C003377$CALL

$679,552

GROVE GRT880, (’22), 807 Hrs, 80-ton lift capacity, #C005002

GROVE GRT880, (’18), 2,476 Hrs, 80-ton lift capacity, #C004982

$447,711

LIEBHERR R956 LITRONIC, (‘22), 1,800 Hrs, 35' boom and 21' stick, #C004867 $CALL SAKAI SV544TB, (‘23), 2 Hrs, #C005470 $CALL

Chicago Fire FC announced City Council approval for its new, privately funded, $650 million stadium in The 78 — a transformative project that will anchor Chicago’s newest neighborhood and redefine the future of sports and entertainment in the city.

This marks the first major stadium built in Chicago in more than 30 years, and it’s being delivered entirely through the private investment of Joe Mansueto, the club’s owner and chairman. His vision and commitment will give the Club a world-class home while creating a year-round destination for the entire city.

“We’re grateful to have received City Council’s approval for our new stadium, a transformative project that will anchor Chicago’s newest neighborhood, The 78,” said Dave Baldwin, president of business operations. “We’re grateful to the residents, community members and public leaders whose support and input have shaped this

project. With their partnership, we remain on track to open in time for the 2028 MLS season. This is more than just a stadium — it’s a catalyst for the growth of both our club and Chicago. We look forward to taking the next steps in this exciting journey and continuing to invest in the future of our great city. We’re just getting started.”

The new 22,000-capacity stadium is expected to break ground in early 2026 and open in time for the 2028 MLS season.

According to an earlier press release, the stadium will anchor The 78, Related Midwest’s 62-acre development located along the Chicago River just south of Roosevelt Road.

The new stadium, designed by Gensler, will seat approximately 22,000 fans, striking a balance between an electric, high-demand atmosphere and a world-class matchday experience.

The stadium, announced in early June, will offer sweeping riverfront views to open public plazas, every element of the stadium design is being thoughtfully considered to honor Chicago’s classic and historic identity while igniting an exciting modern era for the Club and its supporters.

“I love this city and its architecture,” said Mansueto. “This stadium is adding to Chicago’s iconic skyline, so I want it to look timeless. It will look like it’s always belonged here, but with the modern innovations required for a world-class soccer club.”

The brick, steel and glass facade will wrap an interior designed to deliver unmatched comfort, style and service, reimagining what it means to not only experience a Fire match in Chicago, but to experience a soccer match in the United States.

The bowl is designed to prioritize the match viewing experience with seating positions that are dramatically lower and closer to the action. The stadium will feature a variety of best-in-class hospitality spaces, amenities and premium seating options across multiple tiers. An exposed steel canopy over the seating bowl will help enhance the intimacy of Fire matches by directing light and crowd noise back to the pitch, creating an environment that will enhance the Fire’s home-field advantage.

For more information, visit dearchicago.com.

715-752-8112

JD 50G, A/C, Hyd Thumb, 5’7” Long Arm, Blade, Aux, #292872 ......................................$45,000

Kubota KX057-5, A/C, Hyd Thumb, Angle Blade, Aux Hyd, #296470 ........................$76,000

JD 331G, A/C, Hi Flow Aux, 2 Speed, Ride Control, #262952 .. $65,000

JD 310SL, A/C, 4X4, Ext Dipper, Ride Control, #262892 .... $99,000

JD 130G, A/C, Hyd Thumb, Aux, 9’11” Stick, 24” Shoes, #261469 ....................................$119,000

Komatsu PC138LC-11, A/C, Long Arm, CPLR, Rubber Pads, #298908 ......................$165,000

Bobcat T76, A/C, Joysticks, 2 Speed, Ride Control, Radio, Camera, #291427 $57,000

JD 320P, A/C, 4X4, Ext Dipper, Aux, 19.5 Tires, Coupler, #302479 $119,000

JD 135G, A/C, 9’11” Arm, 24” Shoes, Reduced Tail Swing, #249203 ........................$87,000

New Holland E57C, A/C, Hyd Thumb, Cplr, Aux Hyd, Blade, #293430 ........................$64,000

JD 650K, A/C, LGP, 28” Pads, 6 Way 128” Blade, Rev Fan, IGC, #262371 $114,000

CAT 430F2, A/C, Pilots, Ext Dipper, 4X4, Aux, 19.5 Tires, #299832 $95,000

JD 210G, A/C, Hyd Thumb, Coupler, 9’7” Arm, Rev Fan, #261276 ......................$127,500

CAT 306CR, A/C, Hyd Thumb, Coupler, Blade, Long Arm, #262710 ........................$58,000

JD 750K, A/C, LGP, 34” Pads, PAT 156” Blade, Drawbar, #294289 $118,000

JD 544K-II, A/C, Rev Fan, 20.5 Tires, Air Seat, GP Bucket, #262551 $127,000

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ......................$198,000

JD 325G, A/C, Joysticks, 2 Speed, Aux Hyd, #293433 ......................................$52,000

Komatsu HM400-3, A/C, 40 Ton, Tailgate, Bed Heater, #262951 $165,000

JD 624L, A/C, 3rd Spool, Ride Control, Roll Out BKT, Rev Fan, #292312 $85,000

(L-R): Ward Brothers’ Jacob Ward, operator; Nathan Ward, owner; Roger Ward, owner; with Kyle Melin, sales of KAGE Innovation, check out this wing plow. The 10-ft. plow expands to 18 ft.

The Sanco Sandbox West 2025 event, hosted in Mankato, Minn., Sept. 18, offered a hands-on experience with leading equipment brands like XCMG, Bobcat, KAGE Innovation, MUSKOX and Diamond Mowers. Attendees had the opportunity to test excavators, loaders, rollers and attachments, with trained professionals on-site. The event included live demonstrations, giveaways, swag and free lunch.

item

track loaders are

It was the second Sanco Sandbox of the year, giving industry professionals, students and community members the chance to explore the latest equipment and technology in an interactive setting.

For more information, visit sancoequipment.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

From

Ty Ciolkosz, owner of Dirty Graphix, Stillwater, Minn., showed off his wraps on some Bobcat compact track loaders.

Matt Greibrok, vice president of business development, Sanco Enterprises, grills to perfection for the big turnout.

(L-R): MUSKOX’s Noah Bergman, sales engineer; Mike Anderson, dealer and sales manager; and Travis Smith, head of operations, brought its new MUSKOX 26-84 Snowblower with an 84-in. wide shroud for quick clearing. The group also showed off its new T-Tach that fits between a skid steer and almost any implement, acting as a quick attach plate.

Attendees had the opportunity to test excavators, loaders, rollers and attachments, with trained professionals on-site.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires . . . . . .$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$21,500 Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

$49,500 IR 185’s, JD diesels

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500 (2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

$229,500

Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

310SL HL Stk #C99399-5, Cab/AC, 3 Spool, Dual Diff Lock, Coupler, Bucket, 272 Hrs $209,000

Brooks Tractor is celebrating its 80th year in business. To mark the occasion, an open house was held at its Sun Prairie, Wis., headquarters on Sept. 25 and 27, 2025.

Long-time customers, new customers, friends and family gathered to see the newest equipment, latest technology and kick off the company’s next 80 years.

In 1945, Lewis Peil Brooks and Lewis E. Kraft opened an ag equipment dealership in Sun Prairie, Wis., Brooks’ hometown. The company was named Brooks & Kraft, with Brooks the majority owner after he and his wife invested $4,500.

Brooks brought to the company his experience selling farm implements. Before World War II, he had been encouraged by Louis Allis, a member of the founding family of Allis-Chalmers equipment, to work at an Allis dealership in Sun Prairie. Brooks did so for eight years before the Army called.

The post-war partnership with Kraft lasted just a year. After Kraft pulled out, “Brooks Implement” plowed ahead, first selling Ford-Ferguson tractors and then Oliver tractors — both brands highly valued in their heyday. The first construction machines sold were Oliver bulldozers, followed by Insley excavators, Lorain rough-terrain cranes and other construction brands.

see BROOKS page 20

1956

an open

flat mounting plates incorporated into the frame for bolt-on implements and increased horsepower. This machine was sold by Brooks Implement.

John Stephenson (L) of Merlo America introduces this Merlo 5035 rotating telehandler to Jake Zignego of Zignego Co. Merlo.

(L-R): Swinehart Plumbing’s Jacob Ayers and Tom Ayers, president, congratulate Lewis Brooks, vice president of sales and marketing of Brooks Tractor, on the company’s 80th anniversary.

Rollie Aspenson (L) of Brooks Tractor catches up with Jesse Janzen of Janzen Concrete in

(L-R) are Will Nikolai of Nikolai Construction; Glen Rogowski of Brooks Tractor and Rob Nikolai of Nikolai Construction, general contractor for two Brooks Tractor locations —Plover and Sparta. Don Nikolai, founder of Nikolai Construction, worked with Lewis P. Brooks, founder of Brooks Tractor; Rob Nikolai works with Lew Brooks; and the third generation of both families — Will Nikolai and Lewis Brooks — continue the relationship.

(L-R): Lew Brooks, president and CEO of Brooks tractor; Terry Wenger of Tri-County Paving; Mary Kay Brooks, general manager of Brooks Tractor; and Lewis Brooks, vice president and director of sales of Brooks Tractor. Wenger has been a Brooks Tractor customer since 1986 when he made his first purchase — a John Deere 570 motor grader.

of

Bill Kepke of Badger Contractors Rental and Supply maneuvers this John Deere 320 loader backhoe in the putting contest.

from page 19

“After they picked up the John Deere industrial line in the 1960s, growth was tremendous,” said Lew Brooks, son of the company founder and president and CEO.

In 1983, the company completed its transition from agriculture products to construction products and was poised for growth.

Since then, Brooks Tractor has added many other equipment lines in addition to John Deere, including Atlas Copco, Bandit Industries, Bergmann, Dynapac, Etnyre, Felling Trailers, GiANT, Merlo, Rubble Master, STIHL, Thunder Creek Equipment and Wacker Neuson.

As the company grew, new locations were opened. Today, Brooks Tractor, headquartered in Sun Prairie, Wis., also has facilities in De Pere, Milwaukee, Mount Pleasant, Plover, Sparta and West Salem, Wis.

For more information, visit brookstractor.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

With Jekko introducing a new version of its minicrane, Exact Crane of Solon, Ohio, secured the last remaining SPX309 units to meet ongoing contractor demand. To showcase the SPX309, Exact Crane is hosting its first “countdown sale” campaign which began Oct. 2, 2025.

Exact Crane moved quickly when a new model was announced, recognizing the value and opportunity the SPX309 still offers customers.

The Countdown sale, also known as a “Dutch Auction” or a “Reverse Auction” is intended to let buyers claim a crane at a price point they control. One unit will be included in the sale, and the offer ends immediately, once it is sold.

The Countdown Sale opened at $90,000 on Oct. 2, 2025, and drops by $1,000 per day until a buyer commits. The first firm commitment at the day’s posted price, secures the crane, and that day’s price is final. (Contact Exact Crane for complete rules and regulations).

cranes struggle — supporting interior picks, plant maintenance, industrial installs, glazing and urban work with efficient setup and precise handling, according to the manufacturer.

The SPX309 is built 2.5 ft. wide and able to fit through a standard doorway. At a max capacity of 1,950 lbs., it does not require a licensed operator but still provides excellent power throughout the chart. It weighs approximately 4,000 lbs. and has easy-to-use technology. The crane is built with a standard battery, remote control operation, a 330-degree rotation and has a max reach of 31.2 ft.

Prospective participants may inspect the unit, monitor the daily price and act when the value aligns with their budget and schedule. According to Exact Crane, this is a once-in-a-lifetime opportunity with the purpose to increase the Jekko mini-crane brand exposure and show the value these cranes provide customers.

For weekly updates, follow Exact Crane on social media: Facebook, Instagram and LinkedIn.

Compact and versatile, the Jekko SPX309 is engineered for tight, complex job sites where conventional

For more information, call 888/635-5636 or email sales@exactcrane.com. CEG

HD Hyundai Construction Equipment North America announced Sept. 25, 2025, the addition of DSR Equipment to its dealer network. DSR has full service locations in Watertown and Piedmont, S.D.

DSR Equipment will sell and service the full line of Hyundai construction equipment to customers in eastern South Dakota through its Watertown store, while the Piedmont location will serve construction equipment customers in western South Dakota.

Construction Equipment photo

(L-R) are Connor Reddig, DSR Equipment; Randy Reddig, founder and owner of DSR Equipment; Ed Harseim, North Central district manager, HD Hyundai Construction Equipment North America; and Trevor Reddig, DSR Equipment. Harseim presented a plaque to welcome DSR to the dealer network.

the Piedmont location, where Randy and Connor each runs one of DSR’s fleet of four service trucks.

The dealership’s business is split roughly 60/40 between construction and agriculture customers, respectively.

martinequipment.com

Goodfield, IL 309-965-2502

Peru, IL 815-224-4711

Rock Island, IL 309-787-6108

Springfield, IL 217-528-4347

Tolono, IL 217-485-6755

Cedar Rapids, IA 319-365-0515

Dubuque, IA 563-588-1950 Columbia, MO 573-657-2154 Palmyra, MO 573-769-2274

murphytractor.com

Park City, KS

316-942-1457

Great Bend, KS 620-792-2748

“As a Hyundai dealership, DSR now offers a more complete product line of wheel loaders, dozers and excavators to our customers,” said Randy Reddig, DSR founder and owner. “We’re a 28-year-old business with a reputation built on service. Hyundai is known for high-value, durable, reliable equipment and our customers can expect not only high-quality equipment, but high-quality service from DSR.”

Reddig manages DSR along with his sons, Trevor and Connor, and his wife, Carol. Trevor manages the Watertown store, and Carol manages

“Hyundai is happy to add DSR Equipment to our North American dealer roster,” said Ed Harseim, North Central district manager, HD Hyundai Construction Equipment North America. “DSR fits the profile of successful Hyundai dealerships, with long-established customer relationships, a growing sales operation and a focus on providing excellent service.”

For more information, visit dsrequipment.com and na.hdhyundaice.com.

Joe Kiskunas marked his approaching 10-year anniversary with the ALL Family of Companies in a big way: he was promoted to branch manager of the Kaukauna, Wis., branch of Dawes Rigging & Crane Rental. He fills the large shoes of Scott Jerome, who retired after a more than four-decade career with ALL.

Kiskunas most recently served as the branch’s operations manager after spending his career in dispatch and logistics. “I’m excited to continue the tradition of Dawes and the Kaukauna branch,” said Kiskunas. “Dawes has a rich history of excellence throughout the Midwest. My job, and the job of everyone here, is to keep that story alive while adding our own chapters to it.”

The four branches of Dawes (in Kaukauna, Madison, Milwaukee and Elk Mound) have experienced a flood of personnel changes in recent years, as a generation that came up through the ranks together also reached retirement age at about the same time. The result? Dawes: The Next

Generation. Kiskunas believes Kaukauna, and all the Dawes branches, are well positioned to navigate growing markets and a changing economy.

“For years, the Kaukauna branch has had a reputation as the home of the crawlers. We’re well known for working in wind energy. We’ve been in fields all over Wisconsin, Iowa and the Dakotas,” said Kiskunas. “Now, we’re seeing opportunities open in other energy sectors. We’re seeing a lot of work in the construction of corporate campuses and the data centers that have been sweeping this part of the country.”

In recent years, Kiskunas worked closely with outgoing branch manager Jerome to prepare for an eventual ascendance to his new role.

“Scott was extremely focused and detail-oriented,” said Kiskunas. “I learned by his side, plus he left me voluminous notes from throughout his career. It will all contribute to a continuity of service for our customers.”

For more information, visit allcrane.com.

Humboldt, KS 620-473-7020 Olathe, KS 913-298-7373

Topeka, KS 785-233-0556

Ulysses, KS 620-356-1071

Dodge City, KS 620-227-3139

Gering, NE 308-436-2177 Omaha, NE 402-894-1899

Lincoln, NE 402-467-1300

Grand Island, NE 308-381-0741

North Platte, NE 308-534-7020

Kansas City, MO 816-483-5000

Springfield, MO 417-863-1000 Des Moines, IA 515-263-0055

Fort Dodge, IA 515-576-3184

Sioux City, IA 712-252-2753 Waterloo, IA 319-235-7085 Brunswick, OH 330-220-4999 Cambridge, OH 740-439-2747 Canton, OH 330-477-9304 Cincinnati, OH 513-772-3232 Columbus, OH 614-876-1141 Jackson, OH 740-688-4100 Lima, OH 419-221-3666 Painesville, OH 440-639-0700

Poland (Youngstown), OH 330-629-6299 Rossford, OH 567-352-7001

Vandalia (Dayton), OH 937-898-4198

www.aisequip.com

Bridgeport, MI 989-777-0090

Grand Rapids, MI 616-538-2400 Lenox, MI 586-727-7502

New Hudson, MI 248-437-8121 Williamsburg, MI 231-267-5060

www.brookstractor.com

Madison (Sun Prairie), WI 608-837-5141

Milwaukee, WI 414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Crosse (West Salem), WI 608-786-2644

Stevens Point (Plover), WI 715-254-2777

Racine (Mt. Pleasant), WI 262-898-6700 Sparta,WI 608-351-2101

www.lec1.com

Beaver, WV 304-255-1525

Cowen, WV 304-226-3299

Cross Lanes, WV 304-204-1818

Pleasant Valley, WV

304-534-5454

Norton, WV 304-636-6421

Marietta, OH

740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

www.westsidetractorsales.com

Lisle, IL

630-355-7150

Rockdale, IL 815-730-9011

Rockford, IL 815-961-3160

South Holland, IL 708-331-6362

Wauconda, IL 847-526-7700

Bloomington, IN 812-333-9677

Fort Wayne, IN 260-482-8576

Indianapolis, IN 317-544-3411 Lafayette, IN 765-447-6933

South Bend, IN 574-232-1461

Terre Haute, IN 812-645-7160

In the aggregates business, you need machines that are strong enough to do the heavy lifting and smart enough to do it efficiently. The 744 X-Tier Loader was built with that in mind, featuring optional SmartWeigh™ capabilities and an Advanced Vision System that helps you see the jobsite in a brand-new way. So you’re always ready to rock — and roll over the competition.

JohnDeere.com/Loaders

mccoycf.com

Bemidji, MN 218-759-1996

Duluth, MN 218-722-7456

Grand Rapids, MN 218-326-9427

Ashland, WI 715-682-5522

Chippewa Falls, WI 715-834-2924 Merrill, WI 715-536-0633

Escanaba, MI 906-789-9054

Marquette, MI 906-789-7689

Fenton, MO

636-349-0200

Foristell, MO 636-463-2500

Mitchell, IL 618-931-1034

Mt. Vernon, IL 618-244-6800

Cape Girardeau, MO 573-334-0563

Paducah, KY 270-554-1131 Cuba, MO 573-885-0500 Owensboro, KY 270-684-2339

Evansville, IN 812-473-0484

Kingsport, TN 423-349-5001

Knoxville, TN 865-546-3207 Chattanooga, TN 423-855-0633

Nashville, TN 615-501-8600

Bowling Green, KY 270-842-3400

Louisville, KY 502-253-3721

Lexington, KY 859-788-3950

London, KY

606-862-8447

Metso is launching data-driven performance services to empower the mining industry with faster, fact-based issue resolution.

Metso’s data-driven performance services are a set of innovative equipment performance solutions designed to help customers prevent production losses, avoid safety risks and ensure consistently optimized operations. data-driven performance services offer harmonized service capabilities that cover the entire minerals processing flowsheet.

Metso’s transformative data-driven solutions are a combination of intelligent thresholds, advanced analytics and AIenabled diagnostics capable of capturing and describing complex cases for faster action. The analytics and AI capabilities are complemented by Metso’s continuously expanding global network of data-driven experts to ensure consistent and responsive service delivery. The enhanced remote monitoring and troubleshooting capabilities reduce the need for on-site inspections and resident experts.

“Data-driven performance services empower mining operations to move from reactive to predictive, insight-driven decision making,” said Arttu-Matti Matinlauri, vice president of minerals segment digital of Metso. “Based on our analysis from live customer cases, the data-driven performance services solutions have cut issue resolution times up to 50 percent by having the data available for analysis when issues arise. Whilst proactively monitoring the equipment on behalf of our customers, on average, we have identified a potential risk every 1,400 hours of operation, saving over 8 hours of production per solved case. These risks would have otherwise been missed by our customers.”

According to Metso, the data-driven performance services are designed for site maintenance and operations teams to maximize equipment availability, reliability and performance through two scalable service levels:

• Data-driven technical support provides fast and factbased troubleshooting and issue resolution. Through live equipment data, Metso’s experts can improve first-time fix rates and reduce production losses. The expanded data-driven expert network ensures consistent delivery of services.

• Data-driven condition monitoring enables early detection of equipment related issues and failures through continuous remote monitoring. AI-powered analytics and expert diagnosis ensure prioritized actions, reducing unplanned downtime and safety risks, improving availability, uptime and performance. Combined with life cycle services, Metso can conduct the corrective actions efficiently on-site.

“As an original equipment manufacturer, Metso is in a unique position to understand the multitude of different operating modes and equipment related failure mechanisms impacting performance and how they are identifiable from

data,” said Matinlauri. “This knowledge has been accumulated over decades of valuable collaboration with our customers and complemented with data from connected equipment and processes. We are excited to deepen our collaboration by harnessing our vast knowledge base to improve our customers’ performance through data-driven performance services.”

Metso is committed to advancing the digitalization of the mining industry. Data is at the core of fact-based decision making. Analytics and AI enable minerals processing and metals refining plants to maintain and improve their performance. Metso believes in empowering plant operators,

metallurgists, maintenance crews and site management with data-driven solutions to get the most out of combining site and OEM expertise with insights.

Metso’s data-driven minerals processing and metals refining solutions help plant operations and maintenance take the next leap on five levels: Measurements allow accurate data to be collected. Stability is achieved through managed control systems. Availability is enhanced with algorithms continuously monitoring equipment ensuring reliability. Productivity is maintained by automating process and equipment control adjustments in real-time. Optimization and planning provides a view to the future through simulations to adapt to changing conditions.

For more information, visit metso.com/portfolio/ data-driven-performance-services/.

www.aisequip.com

3600 N Grand River Ave Lansing, MI 48906

517-321-8000

Grand Rapids

600 44th Street SW Grand Rapids, MI 49548

616-538-2400

Northeast Detroit 65809 Gratiot Avenue Lenox, MI 48050 586-727-7502

Saginaw 4600 AIS Drive Bridgeport, MI 48722 989-777-0090

Traverse City 8300 M-72 East Williamsburg, MI 49690 231-267-5060

West Detroit 56555 Pontiac Trail New Hudson, MI 48165 248-437-8121 800-457-8121

www.butlermachinery.com

3630 Miriam Ave Bismarck, ND 58502

701-223-0890

7910 US-2

Devils Lake, ND 58301 701-665-3800

2803 I-94 Business Loop E Dickinson, ND 58601

701-456-1400

3402 36th St SW Fargo, ND 58104 701-280-3100

1201 S 46th St Grand Forks, ND 58201 701-775-4238

1910 27th Ave SE Jamestown, ND 58401

701-251-1400

4950 U.S. Highway 12 Aberdeen, SD 57401 605-225-6240

3601 Deadwood Ave N Rapid City, SD 57702 605-342-4850

20571 Truck Stop Ave Pierre, SD 57501 605-224-5400

3201 N Louise Ave Sioux Falls, SD 57107 605-336-3010

603 10th St NW Watertown, SD 57201 605-954-7100

1715 US Hwy 14 W Huron, SD 57350 605-353-1200

1505 Hwy 2, Bypass E Minot, ND 58701 701-852-3508

www.centralsands.com

4219 E 50th St • Des Moines, IA 50317 800-247-2400 • 515-964-8600

www.rbscott.com

1011 Short St Eau Claire, WI 54701 715-832-9792

17403 County Road 75 NW Clearwater, MN 55320 320-558-8100

www.roadbuildersmachinery.com

1001 S 7th St Kansas City, KS 913-371-3822

4115 S 90th St Omaha, NE 402-331-9200

5601 Fletcher Ave Lincoln, NE 402-325-0447

4949 Juergen Rd Grand Island, NE 308-384-2620

1303 S Chestnut St Norfolk, NE 402-316-4640

www.rolandmachinery.com

Escanaba, MI

906-786-6920

DePere, WI

920-532-0165

DeForest, WI

608-842-4151

Eau Claire, WI

715-874-5400

Franksville, WI

262-835-2710

Schofield, WI

715-355-9898

Slinger, WI

262-644-7500

www.rmsequipment.com

Savage, MN

800-888-9515

Des Moines, IA

800-555-1445

Cedar Rapids, IA

800-616-6615

Sioux City, IA

800-633-9104

East Moline, IL

800-633-9114

Duluth, MN

800-888-9535

Virginia, MN 800-752-4304

www.vlpco.com

4100 Gardner Avenue

Kansas City, MO

64120

866-928-4055

816-241-9290

Garden City, KS

800-511-1435

Joplin, MO

417-781-8222

Topeka, KS

785-267-4345 Wichita, KS

316-838-3346

www.brandeismachinery.com

Bowling Green, KY

270-780-3004

Corbin, KY

606-528-3700

Lexington, KY

859-259-3456

Louisville, KY

502-491-4000

Paducah, KY

270-444-8390

Stanville, KY 606-478-9201

Evansville, IN 812-425-4491

Ft. Wayne, IN 260-489-4551 Indianapolis, IN 317-872-8410

Right Lane Industries announced that it has signed an agreement to sell TerraSource Holdings LLC to Astec Industries for $245 million.

TerraSource is a provider of material handling equipment and related aftermarket parts and services for crushing and separating applications globally.

Right Lane acquired a 51 percent interest in TerraSource from Hillenbrand Inc. in October 2021, and worked to enhance the scale, profitability and competitiveness of the company. Right Lane combined an aligned management team with targeted operational improvements and transformative acquisitions to create an attractive global business with significant growth prospects, ultimately delivering exceptional value for all stakeholders involved.

“We are proud of what we achieved together at TerraSource,” said Eric Mara, Right Lane’s CEO. “This transaction showcases the strength of our entrepreneurial management style, operational playbook and partnership approach, particularly in complex carveout scenarios. We look forward to applying our model to similar opportunities in the future, creating significant value through close collaboration with our partners, counterparties and management teams.”

Kim Ryan, CEO of Hillenbrand Inc., said, “The partnership with Right Lane was the right choice for us and has positioned TerraSource very well for continued growth. We are confident that TerraSource will continue to flourish under Astec’s ownership, and we wish them every success.”

Kevin Hambrice, TerraSource CEO, said,

“Congratulations to our exceptional colleagues at TerraSource, Right Lane and Hillenbrand for this successful collaboration. The transformation journey has been remarkable, and I’m confident our partnership with Astec will enable us to continue our extraordinary trajectory, further enhance our market leadership and deliver exceptional products and services to our customers.”

The transaction is expected to close by July 1, 2025, following receipt of customary regulatory approvals and other normal closing conditions. Key Banc Capital Markets advised TerraSource on the transaction, and Taft served as legal counsel.

For more information, visit rightlaneindustries.com, terrasource.com/ and astecindustries.com.

Superior Industries Inc., a United States-based manufacturer and global supplier of bulk material processing and handling systems, has partnered with Midwest Mine Services to repre sent its full line of equipment throughout Ohio.

With decades of experience serving aggregate and industrial producers, Midwest Mine Services will now offer and support Superior’s complete portfolio of crushing, screening, washing and conveying equipment. This includes

portable, modular and stationary systems for a wide range of bulk material handling and processing applications.

“Midwest Mine Services

focused and invested in the long-term success of their customers.”

aligns perfectly with our priorities,” said Jeff Gray, Superior’s director of sales. “They’re hands-on, solutions-

Superior’s partnership with Midwest Mine Services strengthens its dealer network and brings closer access to premium products for producers across Ohio. Known for a commitment to service and engineering-driven support, Midwest Mine Services is poised to bring a new level of value to the region’s producers.

For more information, visit superior-ind.com.

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem , BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

OH 740-373-5255

TOMRA Recycling has launched Finder Color, a new high-throughput solution designed to meet the evolving needs of the scrap metal recycling and e-scrap processing industries.

The next-generation color sorting system is engineered to deliver exceptional purity and recovery levels at high throughput across a broad spectrum of metals sorting tasks, according to TOMRA Finder Color is particularly effective for recovering valuable materials such as copper and brass from mixed heavy metals, cleaning stainless steel fractions (including those from endof-life vehicles) and achieving high-level purification of printed circuit boards (PCBs) from mixed e-scrap, according to TOMRA.

maintenance platform and accessible valve block are engineered for simple and efficient servicing. The machine can be connected for optimized, data-driven sorting through TOMRA Insight, an optional cloudbased data platform.

5255 N Deere Rd Park City, KS 67219 316-942-1457

6100 Arbor Rd Lincoln, NE 68517 402-467-1300

It is capable of processing grain sizes from 0.2 to 4.7 in. and delivering throughput of up to 22.4 tons per hour on Zorba material.

Building on TOMRA’s legacy of innovation in metal sorting, the new Finder Color solution is a flexible system that combines proven hardware and software with AI algorithms to adapt to changing material streams and market demands. Its core features an ultra-precise RGB camera and an AIpowered object singulation technology, enabling accurate, object-level sorting down to a few millimeters, even when objects are overlapping, adjacent or the same color as the belt, according to TOMRA. This single-camera system sorts materials by color, size and shape, providing operators with full control and unmatched accuracy.

For enhanced purification, an optional electromagnetic (EM) sensor can be added. This is particularly useful for sorting materials with similar colors. The optional high-sensitivity EM sensor enhances metal recovery from mixed streams in batch mode, supporting PCB classification in e-scrap, or complementing the RGB sensor to add an extra purification layer against plastic contamination.

The system also offers easy configuration for both batch and continuous flow sorting, with fast switching between different fractions. This allows operators to quickly change which material they are sorting, such as switching from copper one day to brass the next.

Finder Color’s compact and simple design ensures easy integration into existing sorting lines, while its

“Feedback from our metals customers highlighted the need for a highly flexible sorting machine to cover a wide range of sorting tasks,” said Tom Jansen, head of metal segments of TOMRA Recycling. “After 25 years of offering color sorters, we continue to see strong demand for versatile, highly accurate, reliable and costefficient solutions. Finder Color pushes the boundaries of what color sorting machines can achieve with applications like separating stainless steel from a mixed fraction of other grey metals, such as zinc and aluminum, and purifying e-scrap to help customers maximize their output and stay competitive.”

“North American market feedback echoes this call for a flexible machine that delivers superior performance for a wide range of sorting tasks,” said Giuseppe Granara, area manager, metals segments, of TOMRA Recycling. “Color sorting with the new Finder Color offers more competitive and cost-effective ways to sort valuable metals and materials than other technologies currently available on the market.”

Developed by the same in-house engineering experts behind TOMRA’s comprehensive portfolio of metal sorting machines, Finder Color can be used as a standalone machine, following magnetic separation or to extract value from heavy metals removed by XRT technology such as TOMRA’s X-Tract. It also is the ideal last-step sorting solution for extracting value from PCBs in escrap and can be used to sort stainless steel and wire from material recovered using TOMRA’s Finder unit. These integration options optimize the entire sorting process, helping customers refine performance, reduce operational complexity and drive greater business value.

Finder Color and other TOMRA Recycling metals recovery solutions are made available in North America through our exclusive metals partner, Wendt Corporation. Recyclers are encouraged to test their materials using Wendt Corporation’s new cutting-edge Test Center for metals. For more information, visit tomra.com/recycling.

325 S Highway 281 Great Bend, KS 67530 620-792-2748

1141 Kanza Drive, Humboldt, KS 66748 620-473-7020

15854 S US 169 Hwy Olathe, KS 66062 913-298-7373

1621 NW Gage Blvd Topeka, KS 66618 785-233-0556

1410 W Oklahoma Ave Ulysses, KS 67880 620-356-1071

10893 112 Rd Dodge City, KS 67801 620-227-3139

220810 Hwy 92 Gering, NE 69341 308-436-2177

9751 S 148th St Omaha, NE 68138 402-894-1899

3204 S Engleman Rd Grand Island, NE 68803 308-381-0741

3701 S Jeffers St North Platte, NE 69101 308-534-7020

8600 NE Parvin Rd Kansas City, MO 64161 816-483-5000

1401 S State Highway MM Springfield, MO 65802 417-863-1000

5087 E Broadway Ave Des Moines, IA 50317 515-263-0055

1303 3rd Ave NW Fort Dodge, IA 50501 515-576-3184

4900 Harbor Dr Sioux City, IA 51111 712-252-2753

3469 W Airline Hwy Waterloo, IA 50704 319-235-7085

1801 Watterson Trail Louisville, KY 40299 502-491-4000

17000 Highway 41 North Evansville, IN 47711 812-425-4491

7310 Venture Lane Fort Wayne, IN 46818 260-489-4551

NEO MR100

direct D-DRIVE. The MO safe crusher opening in 3 features such as automat and versatile. The MR 10 With its compact dimens MR 100

Efficient when & where

0 seconds. Choose between ic crusher gap adjustment or

BIREX MR 100 NEO: ready, s

0 NEO sets an all-new bench ions and low transport weigh - the MOBIREX you need it et, crush!

two drive versions: the elec Lock & Turn Quick Access fo mark in the compact class - w ht, this machine is amazingly fl MR 100 NEO mobile impact

tric E-DRIVE or r tool-free, ith highlight exible, fast crusher!

Coming In: (2019) Sandvik DX800, with approx 8700 hrs & 3100 impact hrs on HF820 hammer. Running & working currently.

#510134 (2004) Furukawa 1200ED hydraulic drill, w/ 12,043 hrs on 5.9 Cummins engine (approx 600hrs on factory Re-man) & 5590 impact hours (114 hrs since re-seal). New injection pump at 11,394 hrs. New main hydraulic pump at 11,078 hrs. Overall Good condition.

#510099-Tamrock DHA550 self-contained hydraulic drill, Deutz air cooled engine. Has 1185 impact hours. Good condition.

#580000-Furukawa HD712 drifter, approximately 4786 total impact hours and zero hours on complete reseal. Was used on 1200EDII. Ready to be installed for operation.

#530029 Ingersol Rand ECM370, self-contained rock drill w/ VL140 hammer & Cummins engine.

#510138 (2022) John Henry JH20 drill on Komatsu PC210LC with 3489 hours & 1500 drifter hrs. John Deere compressor and 4045 Tier 3 engine. Set up for T51 steel w/ 20′ lead & 18′ changes. #510137 (2005) Atlas Copco ECM-585 MC with 9461 hrs on Cummins engine (been replaced) & 6782 impact hours.

#1111085 Portable Pioneer 3042 jaw with 42"x16' VGG, 42" underconveyor, & 150hp motor on shopbuilt chassis.

#131026 Simplicity 36"x16' Vibrating Grizzly Feeder, 4' grizzly section. Very good condition.

#118000-New/never used Universal 2036 jaw crusher parts, including: Jaw plates, toggle seats, toggle plates, spring loaders, and all thread rods.

#111083 (2015) KLEEMAN MZ110i TRACK-MOUNTED JAW CRUSHER, (27X43″) with 5374 HRS

#111080 (2023) RubbleCrusher RC150T portable, diesel/hydraulic, self-contained 26"x14" jaw crusher, on rubber tracks with 420 hours. 38hp Yanmar engine. 64"x50" feed hopper & discharge conveyor.

#141172 (New) Anaconda SR514 3-deck finishing screen hydraulic tip grizzly (4”) on 14’ hopper with 4-ply belt feeder and radio remote. 125 hp JCB 444 engine. Variable speed on all stockpile conveyors & reversable transfer conveyor.

#152027 Ortner model 3000 sandscrew. with 5hp electric motor. Rated at 50-125 TPH capacity. Very Good Condition.

#141175 (2023) Finlay 883T scalping screen, 1" screen in top deck & 3/4" screen on bottom. Good cond.

#142003-Deister 5x16 2-deck horizontal, underslung screen with new bearings

#141167 Deister BHT2616 (6x16 2-deck) screen, with 218 hrs on Deutz engine. Apron feeder & 3 discharge conveyors..

#142005 El Jay 5x14 2-deck screen on single axle chassis. electric motor & 36" x 24' underconveyor

#640055 (2021) Sany SY265CLR long-reach excavator (60'), 1750 hrs, Cummins QSB6.7 T4F engine, 190 hp, 70,000lb shipping weight. Has A/C, heat, & radio. Max reach at ground level 57' 9" & max digging depth 43'9", 31" track pads, 60" digging bucket, & plumbed for hydraulic mower. 1-owner machine. Remainder of 5 yr / 5000 hour warranty (though Jan 2026).

#610137-1995 John Deere 644G Loader, unknown hours and 3 3/4 yard bucket. Good rubber and runs great, overall good condition.

#410063-CAT D9H, EROPS cab w/ A/C, straight blade w/tilt. Single shank, 4-barrel ripper. 24" pads. U/C (overall approx 70%). Rebuilt engine, trans, and finals (HMR 2994) Left Trunnion is available but needs to be installed. Overall good condition. #700001 CAT 12F MOTORGRADER (1970), power shift, hydraulic side shift, & scarifier. 14.00-24TG tires approx 30-40%. Everything works and runs good. Good condition. #810142 (1998) Cat 769D 35 Ton Haul

FAE is upgrading its range of MTL multitask heads for the construction sector, making them compatible with tractors up to 300 hp and available in the new MTL-250 width.

The MTL enables soil stabilization, asphalt and rock slab shredding and stone crushing, down to a maximum operating depth of 11 in. The FAE MTL multitask head has been designed for the maintenance and upgrading of dirt, gravel and asphalt roads.

The variable-geometry grinding chamber, adjustable grille on the hood and adjustable Hardox counter blade consistently enable optimal crushing results. Internal protection plates on the frame, bolted both centrally and laterally, ensure the head is robust and reliable while also guaranteeing excellent resistance to wear, according to FAE.

The depth indicator allows users to check the operating level directly from the cab, and the central gearbox with universal-joint alignment system is designed to be compatible with a wide range of tractors on the market.

FAE photo

FAE photo

FAE is upgrading its range of MTL multitask heads for the construction sector, making them compatible with tractors up to 300 hp.

The new MTL is available in the following widths: MTL-150, MTL-175, MTL200, MTL-225 and MTL-250. The head comes standard with G/3 teeth, with the option of G/3/HD teeth and R/65 or R/65/HD picks on a dedicated rotor. For more information, visit fae-group.com/en_US/

The MTL enables soil stabilization, asphalt and rock slab shredding and stone crushing, down to a maximum operating depth of 11 in.

While landfills may not be the first thing that comes to mind when a person thinks about the birth of civilization, these areas existed in the earliest days of humans living, growing food and doing business together.

The earliest recorded landfill was in Knossos, Crete, around 3,000 BCE, where ancient Minoans buried refuse in large pits covered with dirt. In contrast, the first modern sanitary landfill is considered to be the Fresno Municipal Sanitary Landfill, opened in Fresno, Calif., in 1937. This landfill is considered the first modern, sanitary landfill, featuring trenching, waste compaction and daily covering with soil to prevent environmental pollution

A living ecosystem on its own, a landfill requires expert care. The people and the machines that manage landfill’s space have evolved to expertly maneuver waste and support a growing population.

As we in the industry consider what’s next, first we should remind ourselves how managing a landfill is much different than managing a dirt work project.

Unlike dirt, which is homogenous and behaves more predictably than waste, landfills are volatile. They contain organic material. They produce methane through aerobic or anaerobic digestion of organic material. They expand, contract and can pose real safety risks.

Landfills are full of unpredictable waste — from tires and mattresses to lithium batteries that can ignite under pressure.

Despite these risks, many operators still rely on instinct over data and machine control. Many operators say they can feel accurate and safe compaction in the seat of their pants, but why risk potential hazards or lost revenue?

Let’s reinforce every operator’s experiential knowledge with technological solutions that can save time, fuel and airspace.

Technology, data sets and machine control can aid landfill managers’ “gut feeling” which can only be learned through the experience of managing a crucial part of any American city, as important as efficient power transmission or clean water infrastructure. And in the landfill business, airspace is everything.

Airspace, or the total permitted volume of space available for the disposal of municipal solid waste and its related cover materials, can be maximized through accurate compaction despite the unique challenges of dealing with organic and nonorganic matter.

That’s why RDO Equipment Co. technology managers recommend landfill-specific technology solutions over repurposed GPS dirt system.

“We can’t adhere to the status quo of yesteryear when we in the industry recognize the need to maximize the airspace landfills currently must serve our growing communities’ needs,” RDO said. “Landfill technology solutions shouldn’t be considered bells and whistles but as a tool to do these vital jobs better. A regional waste manager who manages a large landfill near Billings, Mont., knows that machine control and monitoring technology work without extra wear and tear on compactors.”

“Carlson Landfill Grade gives us everything we need to know about compaction and what we’re doing all day long on that pile,” said Bart Twitchell, the Billings Landfill manager at

RDO Equipment photo

The Carlson Landfill System harvests landfill data in real time every second.

the time in the video below. “Operators know exactly where they are and where they need to go. It tells them exactly where and when they’ve done enough compaction, so they can move and go somewhere else.”

The Carlson Landfill System is a closed loop ecosphere. It harvests landfill data in real time every second. Operators see exactly where they’re compacting, managers can recognize insights for data-informed daily decisions and engineers review airspace capacity on a more regular basis, allowing for more proactive solutions.

When working in a living ecosystem, landfill professionals want the ability to respond in real-time. Carlson Landfill Grade technology and trusted equipment technology partners like RDO can provide a real-time grading and compaction control and monitoring system to optimize operations.

Carlson Landfill Grade provides real-time landfill compaction information to machine operators using global positioning and highly accurate onboard sensors. These sensors send data to an in-cab display that creates a visualization of compaction levels, including pass counts and vertical deflection.

By showing compaction progress in real time, an operator can be confident in their compactor’s performance without reducing machine burden and vastly improving operator efficiency.

Carlson Landfill Grade plus machine control eliminates the guesswork from the seat of the cab, preventing potential overfilling and damage to gas wells or eliminating sliver fills.

Whether you’re a public works director, operations manager or landfill engineer, it may be time to rethink how we manage landfills. in 2025, technology integrates into every industry, mining, farming, manufacturing and yes, America’s landfills.

Carlson software for Landfills, backed by the RDO team, delivers the right technology to dramatically improve site safety, operator efficiency and overall profitability, according to the company.

With real-time data, better compaction and smarter operations, we can extend landfill lifespans, reduce environmental impact and make better use of every cu. yd. of airspace.

McCann Industries Inc. 543 S Rohlwing Rd. Addison, IL 60101 630-627-0000

1360 N Rand Rd. Wauconda, IL 60084 847-526-9444

23921 S Northern Illinois Dr. Channahon, IL 60410 815-467-4480

www.McCannOnline.com Miller-Bradford & Risberg, Inc.

W250 N6851 Hwy 164 Sussex, WI 53087

262-246-5700 Fax: 262-246-5719

DeForest, WI 608-222-9191

Eau Claire, WI 715-832-3443 De Pere, WI 920-338-5800

Marathon, WI 715-443-6000

Negaunee, MI 906-475-4181

www.miller-bradford.com

and Marty

at the Farm Science Review, highlighting the brand’s lineup of reliable excavators for agricultural and construction applications.

Aaron Hupp, Brent Chaivin and Kaleb Parkor of Murphy Tractor had an eye-catching display at Farm Science Review featured equipment hoisting a large American flag — a patriotic highlight for attendees walking the grounds.

Farm Science Review returned to the Molly Caren Agricultural Center in London, Ohio, Sept. 16-18, 2025, drawing producers, dealers and students for three days of field demonstrations and handson equipment showcases. The show spans a 2,100-acre site with a 100-acre exhibit area, giving attendees space to compare new machines, attachments and management tools side by side.

This year’s program emphasized productivity and data-driven operations, with autonomous tractors, AI-assisted sprayers and other precision platforms running throughout the day. Indoors and out, visitors could explore more than 4,000 product lines and sit in on more than 180 education sessions led by Ohio State’s College of Food, Agricultural and Environmental Sciences specialists.

see FARM page 83

Murphy Tractor featured a range of NPK Attachments on Deere

tors, demonstrating durability and productivity for demanding jobsite tasks.

(L-R): Stan Lyon, Clay Durham, Jess Wildermuth, Brett Angus, John Arnold, Matt Green, Jim Blower, John Gordon and Rich Phillips of Company Wrench presented JCB wheel loaders and compact equipment options.

Roland Machinery Co. www.rolandmachinery.com

Bridgeton, MO

(314) 291-1330

Cape Girardeau, MO (573) 334-5252

Columbia, MO (573) 814-0083

Palmyra, MO (573) 769-2056

Portage, IN (219) 764-8080

Bolingbrook, IL (630) 739-7474

Carterville, IL (618) 985-3399

East Peoria, IL (309) 694-3764

Marengo, IL (815) 923-4966

Springfield, IL (217) 789-7711

DePere, WI (920) 532-0165

DeForest, WI (608) 842-4151

Eau Claire, WI (715) 874-5400

Franksville, WI (262) 835-2710

Schofield, WI (715) 355-9898

Slinger, WI (262) 644-7500

Escanaba, MI (906) 786-6920

Joplin, MO (417) 726-5373 Maryland Heights, MO (314) 427-4911 Springfield, MO (417) 865-0505 Colby, KS (785) 462-8211 Liberal, KS (620) 624-7274 Salina, KS (785) 825-8291 Wichita, KS (316) 789-7370

1801 Watterson Trail Louisville, KY 40299 (502) 491-4000

Bowling Green, KY (270) 780-3004

Corbin, KY (606) 528-3700

Lexington, KY (859) 259-3456

Paducah, KY (270) 444-8390

Stanville, KY (606) 478-9201

Evansville, IN (812) 425-4491

Fort Wayne, IN (260) 489-4551

Indianapolis, IN (317) 872-8410 Brandeis Machinery & Supply Company www.brandeismachinery.com

Booth W42500, West Hall

March 3-7, 2026

Meet the contractor-strong, feature-rich machine that’s ready to carry the load for your crew. The all-new Hyundai HT38 CTL delivers 115 HP, a 3,807-lb. rated operating capacity, and 10’9” of lift height. All backed by Hyundai’s 3-year / 3,000-hour warranty.

What sets it apart? The features others charge extra for come standard:

•Hi-Flow Hydraulics

•Torsion Suspension

•Reversible Fan

•Lift-Arm Float

•Auto Self-Leveling

•Rearview (Backup) Camera

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

•Pressurized Cab with Heat & A/C•Bluetooth + 8” Smart Touch Display

•Ride Control

inside the

underscoring the team’s in-house

capabilities.

For more than two decades, NDK Scraper of Spencer, Ohio, has been synonymous with quality and commitment in the heavy equipment industry. What began as a modest operation has grown into a company known for delivering reliable scrapers and customer service to contractors and site developers across the region.

Founded in 2004 by Nick Kostecki, NDK Scraper combined vision, determination and job site insight to modernize operations while preserving its core values. From the outset, NDK became a trusted K-Tec dealer, giving

contractors access to a full line of high-performance earthmoving scrapers.

That partnership helped define NDK’s reputation for quality equipment solutions and laid the foundation for long-lasting relationships with contractors.

NDK is entering an exciting new chapter. The company recently transitioned to an Employee Stock Ownership Plan (ESOP), giving employees direct ownership in the business.

This reflects NDK’s belief that its people are the heart of its success —

when employees have a stake in the company’s future, customers benefit from even greater dedication and pride in the work being done.

The NDK team is enthusiastic about the ESOP, knowing their efforts are more directly rewarded.

“Being part of the ESOP makes everyone feel truly invested in NDK’s success. When the company grows, we all grow,” said an employee.

In addition, NDK is investing in a more than 10,000-sq.-ft. facility expansion featuring new office space, a wash bay, additional service bays, a larger inventory lot and an expanded parts warehouse. These improvements will increase production capacity, speed up service turnaround and enhance efficiency, according to the company.

Looking ahead, NDK is positioning itself for long-term stability. The ESOP ensures the company remains in the hands of those who know it best — its employees — while the new facility expansion supports improved product development, faster delivery and expanded service offerings, including parts restoration.

With a proud history shaped by Kostecki ’s leadership, strong employee ownership guiding the present and a focus on growth for the future, NDK Scraper is well-prepared to serve the construction industry for generations to come.

MUSKOX has released the T-Tach Torsion attachment, designed to deliver smoother, more efficient operations on uneven ground. First introduced in May 2025, the T-Tach is available to order direct from the company and through MUSKOX’s dealer network.

MUSKOX, based in Grand Forks, N.D., has built a reputation for durable, operatorfocused equipment. The company’s flagship MUSKOX Snowblower line showcases this commitment with back-drag technology, pivoting auger system, glide plates and rubber cutting edges that deliver safer, faster snow removal, according to MUSKOX. The T-Tach builds on that legacy of innovation.

The T-Tach is a torsion attachment engineered to complement, not replace, the equipment operators already own. It enhances performance and comfort while extending the life of existing implements, according to the company.

MUSKOX has released the T-Tach Torsion attachment, designed to deliver smoother, more efficient operations on uneven ground.

Key features include:

• Four independent torsion axles that flex to match uneven terrain, maintaining constant down pressure.

• Noise and vibration reduction, which improves operator comfort and reduces stress on the machine.

• Universal compatibility with any quick-attach plate up to 12,000 lbs., safe at speeds up to 20 mph.

• Enhanced ground contact, providing steadier, more consistent performance for snow removal, grading, scraping and more. Solving Common Challenges Operators often face equipment

bounce, loss of contact and fatigue when working over uneven surfaces. The T-Tach addresses these issues directly by improving stability and reducing vibration, according to the company. This results in more efficient jobsite operations and less wear on both the operator and the machine. The T-Tach allows users to get more out of their current buckets, blades, snowblowers or other implements — delivering better results without costly equipment replacement, according to MUSKOX. MUSKOX offers a 30-day risk-free trial, giving operators the chance to experience the benefits before committing. For more information,

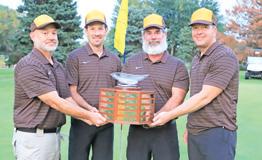

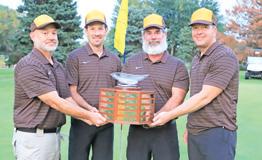

The Golf Gods smiled on the 3rd Annual Werk-Brau Golf Outing to benefit Construction Angels, as the weather was great, smiles were plenty and there were many memorable shots (good and bad) — including a hole-in-one.

Best of all, more than $100,000 was raised to aid families of fallen construction workers in Ohio. It was a beautiful day for golf and networking at the third annual event, which was held at Pinnacle Golf Club in Grove City, Ohio. The sold-out field of 32 foursomes included contractors across the state — from small operations to nationally known companies like Kokosing, Miller Brothers, George J. Igel, Ronyak Paving and The Shelly Company as well as construction suppliers and those allied to the industry.

In addition to the low score medalist honors, the day's festivities included a “closest to the pin” contest, as well as a unique putting contest — using a compact excavator fitted with a Werk-Brau Tiltrotator and a one-of-a-kind Werk-Brau putter head attachment.

“Wow — a huge shoutout to everyone who made today such a resounding success,” said Werk-Brau regional manager and golf outing chairman Neil Recker. “Once again, the construction industry showed up big time. Thanks to the golfers, sponsors, customers, partners and volunteers who made it a great day. Many Ohio families of fallen construction workers will be helped because of you.”

The team from Rudd Equipment took home medalist honors with a 56 in the closely contested scramble format, while the team of George J Igel scored a hole-in-one to claim the $10,000 prize. The raffle included many summer essentials including grills, coolers, unique dining experiences and more.

Special thank you goes out to Platinum Angel sponsors, Murphy Tractor, Alta Equipment, Ronyak Paving and The Shelly Company.

Additional sponsors from across the state and throughout the industry supporting the event included Exact Crane & Equipment Corp., National Tube Supply, R & J Cylinder and Machine, IC-Fluid Power, Ritchie Brothers, Purple Wave Auction, Jarrett Logistics, ARIS GET LLC, O.F. Machining, Chicago Tube & Iron, Valley Tool and Manufacturing, Trucco Construction, Leeco Steel, Columbus Equipment, Southeastern Equipment, Reco Equipment, NPK Construction, Kalida Truck Equipment, Stoepfel Drilling, Black Cat Wear Parts, Bailey, Wahl Marketing Communications, Hylant, Surety Bonds and Clouse

Construction.

National sponsors of Fallen Angels include Advanced Drainage Systems, J. Alexander Law, John Deere, Dobbs Equipment, United Rentals, Friedman Legal, SimForMotion, Core & Main, Total Teks Group, Flagger Force, Wirtgen Group, GRH, U.S. Pipe, Heritage Construction & Materials, Werk-Brau, Case Construction, PSS Industrial Group, BOMAG FAYAT Group, Linder and American Traffic Safety Services Foundation.

Construction Angels is a nonprofit organization that provides immediate financial support and grief counseling to the children and spouse when a construction worker suffers a fatality on the job site. They are financially supported by many companies, organizations, unions and construction associations within the industry.

The Bureau of Labor Statistics estimated there are 7.2 million people working in the construction industry with projected steady growth over the next 10 years. OSHA reports there are well over 5,000 work site deaths each year in the United States, more than 20 percent are in the construction industry. This is approximately 4.5 construction workers killed per working day in the United States

“Huge thank you to the entire Werk-Brau team for another awesome event,” said Kristi Gibbs, Construction Angels CEO and founder/national executive director. “They really got the construction industry to show up and show out. Your hard work and dedication mean so much to the Ohio families that we serve. We are so grateful for your support and look forward to the years to come.”

For more information, visit constructionangels.us/.

Murphy Tractor & Equipment Co.

murphytractor.com

Park City, KS (316) 942-1457

Great Bend, KS (620) 792-2748

Humboldt, KS (620) 473-7020

Olathe, KS (913) 298-7373

Topeka, KS (785) 233-0556

Ulysses, KS (620) 356-1071

Dodge City, KS (620) 227-3139

Gering, NE (308) 436-2177

Omaha, NE (402) 894-1899

Lincoln, NE (402) 467-1300

Grand Island, NE (308) 381-0741

North Platte, NE (308) 534-7020

Kansas City, MO (816) 483-5000

Springfield, MO (417) 863-1000

Des Moines, IA (515) 263-0055

Fort Dodge, IA (515) 576-3184

Sioux City, IA (712) 252-2753

Waterloo, IA (319) 235-7085

Brunswick, OH (330) 220-4999

Cambridge, OH (740) 439-2747

Canton, OH (330) 477-9304

Cincinnati, OH (513) 772-3232

Columbus, OH (614) 876-1141

Jackson, OH (740) 688-4100

Lima, OH (419) 221-3666

Painesville, OH (440) 639-0700

Poland (Youngstown), OH (330) 629-6299

Rossford, OH (567) 352-7001

Vandalia (Dayton), OH (937) 898-4198

Required by 19 USC 3685

Title of publication: CONSTRUCTION EQUIPMENT GUIDE MIDWEST EDITION; Publication Number: 1081-7034; Date of filing: Sept. 19, 2025; Frequency: Bi-weekly, 26 issues annually; Annual Subscription price: $65.00; Complete mailing address of known office of publication: 470 Maryland Dr., Ft. Washington, PA 19034; Publisher’s general business office: 470 Maryland Dr., Ft. Washington, PA 19034; Publisher’s name and address: Joseph McKeon, 5875 N. Lincoln Ave. Suite 227, Chicago, IL 60659; Editor in Chief: Craig Mongeau, 470 Maryland Dr., Ft. Washington, PA 19034; Owner: CONSTRUCTION EQUIPMENT GUIDE MIDWEST EDITION, 5875 N. Lincoln Ave. Suite 227, Chicago, IL 60659; Joseph McKeon, 5875 N. Lincoln Ave. Suite 227, Chicago, IL 60659; Edwin M. McKeon Jr., 470 Maryland Dr., Ft. Washington, PA 19034; Richard McKeon, 3307 Indian Meadows Ln., Charlotte N.C. 28210; Known bondholders, mortgages, and other security holders: None, Issue date for circulation data below 09/27/25; Extent of circulation (Average number of copies during preceding 12 months): Net press run 19,417; paid circulation through agents 0; through mail subscription 19,301; free distribution 0; total distribution 19,301; copies not distributed 116; return from news agents 0; electronic copies 180; Total 19,597; Percent Paid and/or Requested Circulation 100%; Actual number of copies for issue published nearest to filing date: Net press run 21,376; paid circulation through agents, 0; through mail subscription, 21,084; free distribution, 0; total distribution, 21,084; copies not distributed, 292; return from news agents, 0; electronic copies 170; Total 21,546; Percent Paid and/or Requested Circulation 100%.

I certify that the above statements made by me are correct and complete.

/s/ Edwin M. McKeon, Jr., President/CEO

1st Choice Equipment LLC www.1stchoiceequipment.com

1555 Atlantic Drive West Chicago, IL 60185 630/510-6050

1305 Sentry Drive Waukesha, WI 53186 262/521-5802

ABC Equipment Rental & Sales www.abcequipment.com

29 Pearl Rd. Brunswick, OH 44212 888/572-3888

38525 Chester Rd. Avon, OH 44011 440/934-7368

Alta Equipment Co. www.altaequipment.com

18405 115th Avenue Orland Park, IL 60467 844/GO2-ALTA

Central Power Systems & Services www.kubotacentral.com

1285 Acraway Street Garden City, KS 67846 620/765-3118

Yes Equipment & Services www.yesequipment.com

7001 Manufactures Drive Madison, WI 53704 888/310-3902

11715 W Silver Spring Road Milwaukee, WI 53225 888/310-3902

Lano Equipment www.lanoequip.com

6140 Highway 10 NW Anoka, MN 55303 763/323-1720

23580 Highway 55 Loretto, MN 55357 763/479-8200

3021 West 133rd Street Shakopee, MN 55379 952/445-6310

McCullough Kubota www.mckubota.com

7225 Grand Ave. Gurnee, IL 60031 224/699-2200

1966 N. State Rt. 1 Watseka, IL 60970 815/432-3965

4620 W. US-6 Morris, IL 60450 815/942-6620

21730 LaGrange Rd Frankfort, IL 60423 815/658-2682

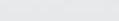

The Historical Construction Equipment Association (HCEA) staged its 39th Annual International Convention & Old Equipment Exposition Sept. 18–20, 2025, on the grounds of the National Construction Equipment Museum at 16623 Liberty Hi Rd. in Bowling Green, Ohio, where crowds took in running demonstrations of antique machinery.

The centerpiece of the weekend was the dedication of HCEA’s new 20,000-sq.-ft. museum. Designed with a vaulted clear-span hall and heated floor, the building allows cranes and shovels to be displayed with booms raised while improving year-round visitor comfort.

The project was fully funded through donations. Ken Taylor, president of Ohio CAT and an HCEA corporate member, played a pivotal role by launching the “Big Push” campaign and matching contributions dollar-fordollar up to $500,000. The effort surpassed its goal, with more than $727,000 raised.

HCEA’s collection now numbers more than 200 major machines, many of which are operated during the convention’s outdoor demonstrations — continuing the group’s mission to preserve and showcase the equipment that built America.

During the event, attendees toured the completed facility. After the show, HCEA planned to begin staging restored equipment in the new hall to create expanded, permanent displays.

With a larger, purpose-built home and strong industry support, HCEA’s convention continues to connect enthusiasts, contractors and families with living construction history — now under one roof designed for the next generation of preservation.

For more information, visit hcea.net. CEG (All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

and Margaret

and Kurt

Caterpillar dozers outside the

They’ll host HCEA’s “The Bigger Dig” in 2026 at Kurt Kocher Farm, Concordia, Kan.

The Historical Construction Equipment Association (HCEA) staged its 39th Annual

Convention & Old Equipment Exposition Sept. 18–20, 2025.

Leaders of the event (L-R) Joe Kotkowski, chairman of the board; Mike Androcich, show chairman; and Tom Berry, archivist/editor — take in the vintage Caterpillar and earthmoving equipment on display.