One of the most traveled roadways in the Birmingham area is undergoing a transformation.

A $70 million Alabama Department of Transportation (ALDOT) reconstruction and widening project will provide three travel lanes northbound and southbound on I-59 between I-459 and Chalkville Mountain Road.

“There is a significant delay to the traveling public on a daily basis,” said Todd Connell, ALDOT construction engineer. “This project will significantly reduce or eliminate congestion at peak travel times.”

The project was designed to alleviate gridlock on I-59 in the Trussville community. The average daily traffic (ADT) through this area is more than 135,000.

Connell explained that motorists appear to be adjusting to the construction, either by taking alternate routes or changing their arrival and departure times to account for any delays.

“Any lane closures that are required have been at night between the hours of 7 p.m. and 6 a.m. during the week, and 9 p.m. to 6 a.m. on

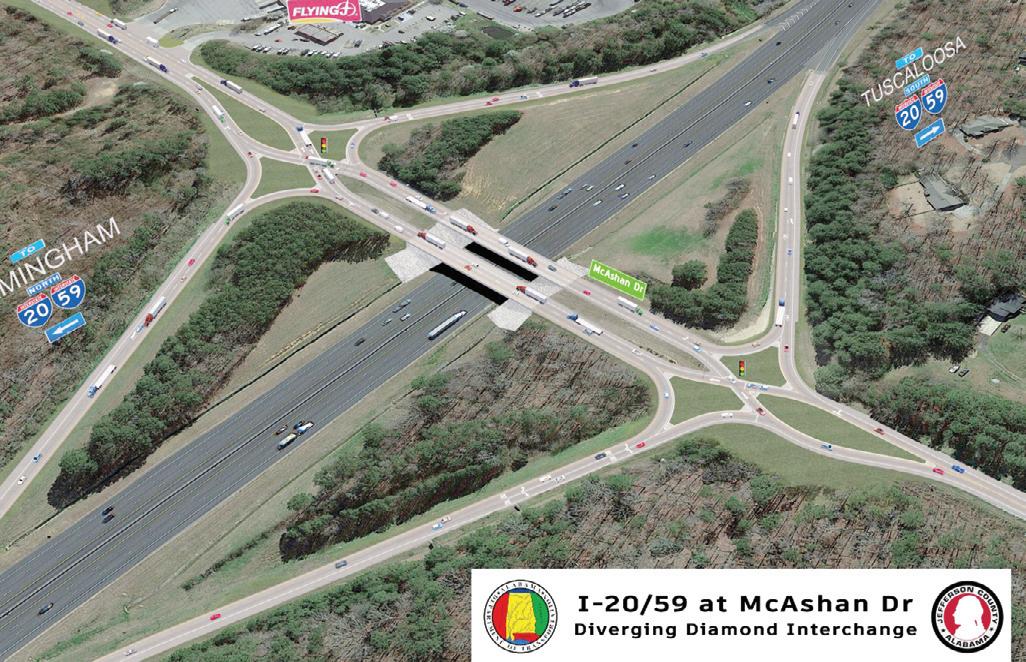

The Alabama Department of Transportation (ALDOT) has begun construction on Jefferson County’s first diverging diamond interchange (DDI) at Exit 104 on Interstate 20/59 and McAshan Drive in the town of McCalla, southeast of Birmingham, a $22 million project to accommodate rising traffic due to increased local economic development.

The interchange is located near the Jefferson Metropolitan Park (JeffMet McCalla), home to more than a dozen industrial campuses, including the $1.1B JM Smucker Uncrustables plant which opened late last year. Together, they contribute to the congested traffic at the busy interstate exit.

In addition, McAshan Drive offers access

to the nearby Rock Mountain Lakes community.

Jefferson County Director of Roads and Transportation Chris Nicholson confirmed to WVTM-TV in Birmingham that the industrial park has led to a rise in truck traffic, particularly from the Smucker factory, and the number of vehicles on the road continues to grow, making navigation increasingly difficult through the corridor.

“We’ve seen spikes in residential developments in the southwestern portion of the county towards Tuscaloosa,” he said. “So that in itself, and really that exit as a whole, has had some issues with left hand turns over the years. So, a diverging diamond really eliminates those conflict points.”

The new design will transform McAshan Drive by redirecting traffic to resolve those issues, but it may also cause some confusion among commuters.

“You are definitely driving on the wrong side of the road, but it doesn’t feel that way,” Nicholson said, adding that the current stop signs will be replaced to allow for a smoother traffic flow without the need to cross traffic again.

ALDOT awarded the DDI building contract to Carcel & G. Construction in Hancel, Ala.

The project’s funding was provided by three sources: Jefferson County kicked in $14 million, another $6 million came from a construction financing source within the

Federal Highway Administration (FHWA), and $2 million was awarded by the Alabama Transportation Rehabilitation and Improvement Program-II (ATRIP-II). Crews are currently building a new parallel bridge to handle the configuration while the existing overpass across I-59/20 will remain, according to ALDOT.

As motorists approach one side of the bridge, the DDI design allows traffic to gently transition from the right side to the left and then back again at the other end of the bridge. Drivers will make all left turns without crossing opposing traffic since it travels on the left side of the structure.

FHWA research shows DDIs are more

cost effective, efficient and safe. Its data shows that construction costs can be up to 75 percent less, vehicle conflict points are often reduced by half and traffic efficiency increases of up to 30 percent have been observed.

The Jefferson County Economic and Industrial Development Authority (EIDA) has been advocating for similar roadway investments, which are expected to spur further development in the area, WVTM-TV noted.

“It will definitely help bring business to the area because … the number one thing [site selectors] look at is ingress and egress and closeness to the interstate and infrastructure,” said Othell Phillips, executive director of the EIDA.

“With the amount of property that we have available still left at JeffMet McCalla Industrial Park, it would be a huge asset for the recruitment process.”

The multi-million-dollar road project is anticipated to be completed by April 2027 and is the first of three planned diverging diamonds in the greater Birmingham area. Others are slated for the Lakeshore exit on I-65 and the future Exit 9 on I-459.

Phillips emphasized the impact of these projects when he said, “For years and years, this agency has tried to make an impact and the biggest impact [is] to give people jobs and to create jobs. The deep foresight of the commission has been a huge help in us trying to achieve our goal.”

During the I-20/59/McAshan Drive building project, ALDOT cautions motorists to expect temporary lane closures and traffic shifts.

A Mississippi chemical products producer plans to invest $34 million to expand and upgrade its Tuscaloosa, Ala., facility, a project that will create seven new jobs with salaries averaging $45 per hour.

Southern Ionics first opened its Tuscaloosa plant in 1995, and today manufactures sodium bisulfite, a product used as a reducing agent, antioxidant and preservative in water treatment, chemical manufacturing and food processing.

Although headquartered in West Point, Miss., the company was started in Milton Sunbeck’s Mobile, Ala., garage in 1980. 45 years later, it employs more than 350 people manufacturing and distributing chemical products throughout North America. Its facilities can be found in several states.

Sundbeck still serves as board chair and CEO of Southern Ionics.

The new investment will be used at the company’s plant at 5410 Reichhold Rd. in the Holt region of

Tuscaloosa to upgrade equipment, add a new product line, expand production and enhance safety and efficiency, the Tuscaloosa News reported Sept. 26.

Southern Ionics has operated at the site since 1994.

“We are pleased to make this investment and look forward to growing our business at Tuscaloosa,” Joe Stevens, president and chief operating officer of Southern Ionics, said in a company news release. “Our sulfur chemicals business serves industries that improve everyday life with uses in municipal water and wastewater treatment, pulp and paper production and chemicals manufacture. The addition of sodium metabisulfite is a natural extension of our sulfur chemicals business that strengthens our product offering for applications in the food, animal feed, chemicals and pharmaceuticals industries.

He added that there is a shortage of sodium metabisulfite manufacturing capacity to adequately sup-

ply the North America market, a fact which Stevens said forces users to rely upon imported products.

A larger sulfur chemicals manufacturing facility in the Alabama city should allow Southern Ionics to ramp up its production capacity and make infrastructure improvements, in addition to meeting its sodium metabisulfite production goals, he asserted.

“We’ve been proud to operate in Tuscaloosa for many years, and this expansion represents our confidence that we can continue to be successful here,” Stevens said.

“We appreciate the partnership we’ve experienced in Tuscaloosa and look forward to continued growth.”

The new factory expansion is expected to begin in October 2025 and will build on the footprint of the existing plant. Company officials expect the updated facility to be in full operation by the second

quarter of 2027.

“This expansion brings highquality jobs and significant investment to our community,” Steven Rumsey, chair of the Tuscaloosa County Economic Development Authority (TCEDA), said in the news release, “and highlights what makes Tuscaloosa special: our skilled workforce, supportive leadership and a community that values both business success and quality of life.”

Tax abatement packages were approved during the TCEDA’s September 2025 board of directors meeting. As a result, Southern Ionics will receive abatement of non-educational sales and use taxes to purchase equipment and building materials during the upcoming construction.

For up to 10 years, the company also will receive abatement of non-educational ad valorem taxes on specific real and personal property. Those abatements could reach about $1.7 million, according to TCEDA estimates.

During its first 10 years of oper-

ations, the expanded Southern Ionics plant should contribute more than $830,000 in property tax revenue from the initial investment for education, the Tuscaloosa News noted.

TCEDA believes the project’s tax contributions could reach more than $3.2 million from the manufacturer and from direct employee spending during its first 20 years.

A larger sulfur chemicals manufacturing facility in Tuscaloosa should also allow Southern Ionics to ramp up its production capacity and make infrastructure improvements, in addition to meeting its sodium metabisulfite production goals.

Along with sodium bisulfite, Southern Ionics produces sodium thiosulfate and sodium sulfite solutions from facilities located in Pasadena, Texas, Williamsport, Md. and Tuscaloosa. In addition, it is a leading producer of aluminum and ammonium chemicals.

TRUST THOMPSOON TRACTOR

WHERE YOUR SUCCCESS IS OUR PRIORITY. .

from page 1

the weekends. Travel lines have been shifted either to the inside or outside depending on the phase of the project, but two through lanes have remained open during high volume times to reduce the impact on traffic.”

In October 2024, work began on the existing roadway, which is at the end of its serviceable life. The project has reportedly been going relatively smoothly and is on schedule to be completed late next year.

In July, workers shut down the southbound off/on ramps at the Chalkville Mountain Road Exit. They were able to reopen the closed ramps a few days ahead of schedule.

“Closure of the I-59 southbound entrance and exit ramps was necessary to accomplish the outside widening in the vicinity of the interchange,” said Connell. “This presented a significant impact to those who typically use this interchange. Reopening these ramps in a timely manner was a significant accomplishment for contractor Wiregrass Construction Company Inc. and ALDOT.”

Once the initial shutdown of the I-59 southbound inside lane was completed, traffic shifted to the outside lane and newly constructed shoulder. There was a minor delay the morning of the traffic change, but there were only limited issues.

According to Connell, the main challenge for crews overall has been the large volume of traffic they must contend with. The aggressive schedule for completing the project also is a concern.

Currently, the southbound outside paving is being completed, along with the bridge deck construction of the I-59 bridge over Edwards Lake Road. The expected opening of I59 southbound is scheduled for this fall.

All of the existing concrete pavement on the southbound side of I-59 has been rubblized, and most of the grading and drainage work has been completed in the median. The inside widening, including grading, drainage, base, pavement and barrier wall, is finished on the southbound side. Work on the northbound side of I-59 will include grading, box culvert construction, rubblization of the existing pavement and

paving.

Much of the grading is being conducted in the median to prepare for the new lanes to be constructed in the median. Many of the pipes and culverts had to be extended to account for the widened lanes. The existing concrete pavement is being rubblized and then multiple layers of asphalt are placed on top of that rubblized pavement for the newly widened base to create the roadway.

The bridge deck replacement required removing the existing bridge deck down to the girders and constructing entirely new bridge deck consisting of stay-in-place forms, reinforcing steel and concrete. The bridge coatings will require the removal and containment of the old bridge paint and replacement of paint on all the steel portion of the structure.

Connell said project milestones include all work associated with the I-59 southbound inside widening that’s been completed, along with the construction tied to the I-59 southbound ramps at Chalkville Mountain Road. In addition, more than 75 percent of the I-59 southbound outside widening has been finished and is scheduled to open later this fall.

The project calls for approximately 90,000 cu. yds. of unclassified excavation and approximately 140,000 cu. yds. of aggregate surfacing. While weather has not been a major issue for crews, they have encountered minor utility conflicts, and additional lighting work has been added to the schedule.

Main equipment on site includes a crane, dozer, trackhoe, asphalt paver, rubblizer, material remixing device, rollers, sheepsfoot, steel drum and motor grader. Off-road dump trucks, dump trucks and a water truck also are on site. Aggregate, concrete and asphalt are among the chief materials being used.

Crews will begin working on the northbound lanes of the project in December, with completion of the project expected by 2026. Connell said the end of construction will have a significant impact on commuters.

“It’s very satisfying to know that the improved safety and reduced travel time and congestion will serve the residents of Alabama and those traveling through the state for many years to come.” CEG