Huntsville

20 Decatur

State Supplement sponsored by:

231

65

72 Florence

2

72

565 59

43 231

31

5

ALABAMA STATE EDITION

431

Gadsden

78 59

A Supplement to:

Anniston

20

Birmingham Bessemer

82 Tuscaloosa

65 280

20 82 Auburn

80

85

Selma

Phenix City

Montgomery

82 65

231

43 84 431 331

84

84 52

SHIP WITHIN 48 HOURS

Dothan

31

45 65 98

SAME DAY PARTS AVAILABILITY

Mobile

10

®

October 9 2019

24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS Thousands in Service!

Vol. XX • No. 21

“The Nation’s Best Read Construction Newspaper… Founded in 1957.”

Affordable Price. Premium Service.

CALL 800-367-4937

Your Alabama Connection • Rich Olivier, Atlanta, GA • 1-800-409-1479

*On approved credit • Financing Available

Evolving Campus...

Auburn’s $83M ACLC Project Nears Completion By Cindy Riley CEG CORRESPONDENT

With the first of two iconic buildings on Auburn University’s campus now reduced to rubble, construction crews are one step closer to building the Academic Classroom and Laboratory Complex (ACLC). The $83 million ACLC project calls for a 151,000 sq. ft. building with seating for 2,000 students in 20 adaptable classroom/laboratories, six engaged active student learning classrooms and five lecture halls. A new dining hall serving 800 students also will be constructed. “The ACLC is needed to update and replace an aging classroom and instructional laboratory stock that cannot address the need for active student learning in today’s educational environment,” said campus architect Brad Prater. “It will serve the entire campus, and it’s anticipated that every Auburn student in the near future will have a class in it at some point. “The ACLC will stand out because it will provide a variety of learning environments — traditional auditoria, lecture halls, biology and geology labs and active learning classrooms. It will also stand out because of its goal to continue

Auburn University Facilities Management photo

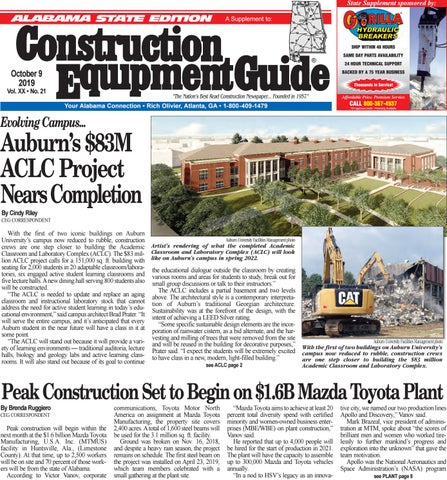

Artist’s rendering of what the completed Academic Classroom and Laboratory Complex (ACLC) will look like on Auburn’s campus in spring 2022.

the educational dialogue outside the classroom by creating various rooms and areas for students to study, break out for small group discussions or talk to their instructors.” The ACLC includes a partial basement and two levels above. The architectural style is a contemporary interpretation of Auburn’s traditional Georgian architecture. Sustainability was at the forefront of the design, with the intent of achieving a LEED Silver rating. “Some specific sustainable design elements are the incorporation of rainwater cistern, as a bid alternate, and the harvesting and milling of trees that were removed from the site and will be reused in the building for decorative purposes,” Prater said. “I expect the students will be extremely excited to have class in a new, modern, light-filled building.” see ACLC page 2

Auburn University Facilities Management photo

With the first of two buildings on Auburn University’s campus now reduced to rubble, construction crews are one step closer to building the $83 million Academic Classroom and Laboratory Complex.

Peak Construction Set to Begin on $1.6B Mazda Toyota Plant By Brenda Ruggiero CEG CORRESPONDENT

Peak construction will begin within the next month at the $1.6 billion Mazda Toyota Manufacturing, U.S.A. Inc. (MTMUS) facility in Huntsville, Ala., (Limestone County). At that time, up to 2,500 workers will be on site and 70 percent of those workers will be from the state of Alabama. According to Victor Vanov, corporate

communications, Toyota Motor North America on assignment at Mazda Toyota Manufacturing, the property site covers 2,400 acres. A total of 1,600 steel beams will be used for the 3.1 million sq. ft. facility. Ground was broken on Nov. 16, 2018, and despite a heavy rain season, the project remains on schedule. The first steel beam on the project was installed on April 23, 2019, which team members celebrated with a small gathering at the plant site.

“Mazda Toyota aims to achieve at least 20 percent total diversity spend with certified minority and women-owned business enterprises (MBE/WBE) on plant construction,” Vanov said. He reported that up to 4,000 people will be hired for the start of production in 2021. The plant will have the capacity to assemble up to 300,000 Mazda and Toyota vehicles annually. “In a nod to HSV’s legacy as an innova-

tive city, we named our two production lines Apollo and Discovery,” Vanov said. Mark Brazeal, vice president of administration at MTM, spoke about “the scores of brilliant men and women who worked tirelessly to further mankind’s progress and exploration into the unknown” that gave the team motivation. Apollo was the National Aeronautics and Space Administration’s (NASA) program see PLANT page 8