INTEGRATED MANAGEMENT SYSTEM MANUAL

REV.09 | 05-06-2024

REV.09 | 05-06-2024 CONTENT CONTENT................................................................................................................................ 2 MANAGEMENT SYSTEM MANUAL FLOWCHART........................................................................... 4 PRESENTATION............................................................................................................................... 6 MECWIDE GROUP ....................................................................................................................... 7 BUSINESS UNIT............................................................................................................................ 7 TECHNICAL ASSISTANCE.......................................................................................................... 7 MINING & CEMENT 8 MODULAR SYSTEMS 8 OIL & GAS............................................................................................................................... 8 INDUSTRY & ENERGY .............................................................................................................. 9 DATA CENTERS 9 MISSION 14 VISION ...................................................................................................................................... 14 VALUES 14 ANALYSIS OF THE ORGANISATION'S CONTEXT 15 CODE OF CONDUCT 16 STAKEHOLDERS............................................................................................................................. 17 CLIENT FOCUS 19 WORKERS CONSULTATIONS 19 RISKS AND OPPORTUNITIES 20 CONTEXT, NEEDS AND EXPECTATIONS (INTERNAL AND EXTERNAL........................................ 20 ENVIRONMENTAL ASPECTS AND OCCUPATIONAL HAZARDS (14001 e 45001) 20 LEGAL REQUIREMENTS (14001 e 45001) 20 ACTION PLANNING (14001 e 45001) 21 STRATEGY..................................................................................................................................... 22 STRUCTURE................................................................................................................................... 24 MECWIDE GROUP ORGANISATION CHART 25 CERTIFICATIONS........................................................................................................................ 26 PRODUCTION CAPACITY ............................................................................................................... 27 MECWIDE BARCELOS 28 MECWIDE MATOSINHOS........................................................................................................... 29 EQUIPMENT AND CHARACTERISTICS..................................................................................... 30 MECWIDE SINES – ZIL 31 EQUIPMENT AND CHARACTERISTICS 32 MECWIDE SINES – PAVILHÕES 33 EQUIPMENT AND CHARACTERISTICS..................................................................................... 33 MECWIDE MOÇAMBIQUE 34 EQUIPMENT AND CHARACTERISTICS 35 MECWIDE ANGOLA 36 MECWIDE ANGOLA – VIANA...................................................................................................... 37 MECWIDE ESPAÑA – SEVILLA 38 MECWIDE ESPAÑA – GIJÓN 39 RESOURCES AND TECHNICAL MEANS ........................................................................................... 41

Integrated Management System Manual REV.09 | 05-06-2024 3 HUMAN CAPITAL 42 CULTURE AND COMMUNICATION 43 TECHNICAL DEPARTMENT AND PROJECT ................................................................................... 45 QUALITY CONTROL 46 QUALITY 46 WELDING 46 CONSTRUCTION CODES AND STANDARDS ................................................................................. 47 CONTINUOUS IMPROVEMENT................................................................................................... 49 CULTURE OF PROCESS MONITORING 49 INTEGRATED MANAGEMENT SYSTEM .......................................................................................... 50 IMS SCOPE ................................................................................................................................ 51 ORGANIZATIONAL STRUCTURE OF IMS MANAGEMENT 51 POLICY 52 RESPONSABILITIES AND AUTHORITY.......................................................................................... 53 ORGANIZATIONAL STRUCTURE BY GEOGRAPHY......................................................................... 53 PROCESS INTERACTION MAP..................................................................................................... 53 PROCESSES AND ACTIVITIES ......................................................................................................... 54 OBJECTIVES OF THE INTEGRATED MANAGEMENT SYSTEM AND PLANNING................................ 56 MANAGEMENT SYSTEM OBJECTIVES ......................................................................................... 59 ENVIRONMENTAL AND OCCUPATIONAL HEALTH AND SAFETY 60 MANAGEMENT INDICATORS, OF PROCESSES AND SUPPORT ACTIVITIES 60 MANAGEMENT OF CHANGES (9001).......................................................................................... 60 PLANNING OF ENVIRONMENTAL AND OCCUPATIONAL HEALTH AND SAFETY ACTIONS AND OBJECTIVES (14001 E 45001) ........................................................................................................................ 60 PLANNING CHANGES 61

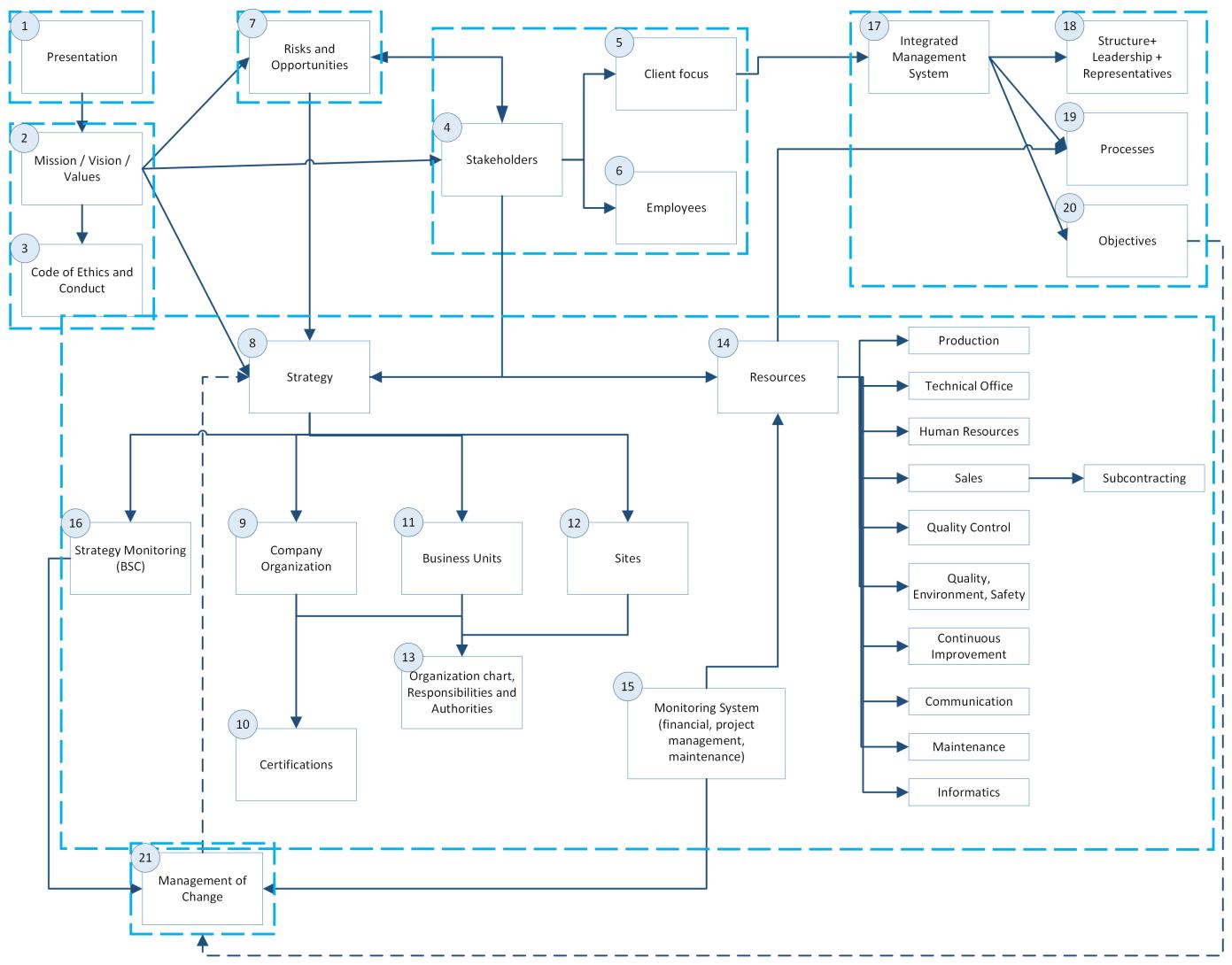

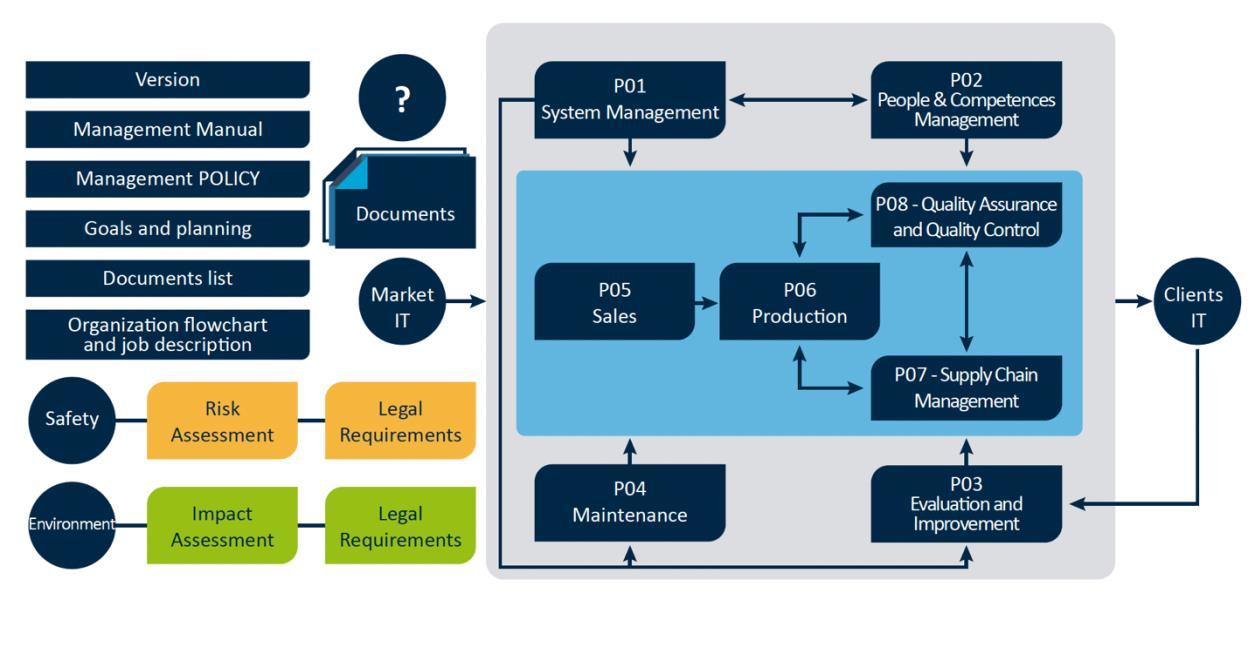

MANAGEMENT SYSTEM MANUAL FLOWCHART

Integrated Management System Manual REV.09 | 05-06-2024 4

.

The Management System aims to provide a framework for the Mecwide Group.

It is reviewed periodically by top management at least once a year, during the first quarter

Integrated Management System Manual REV.09 | 05-06-2024 5

PRESENTATION

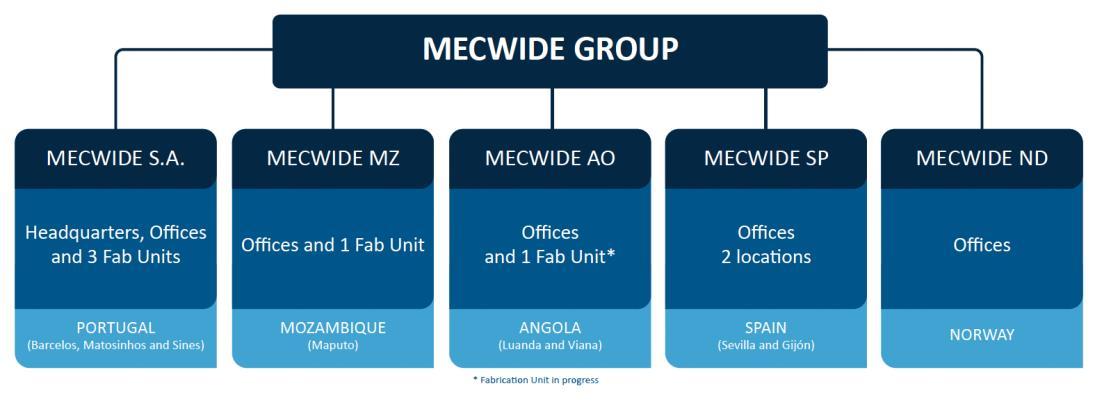

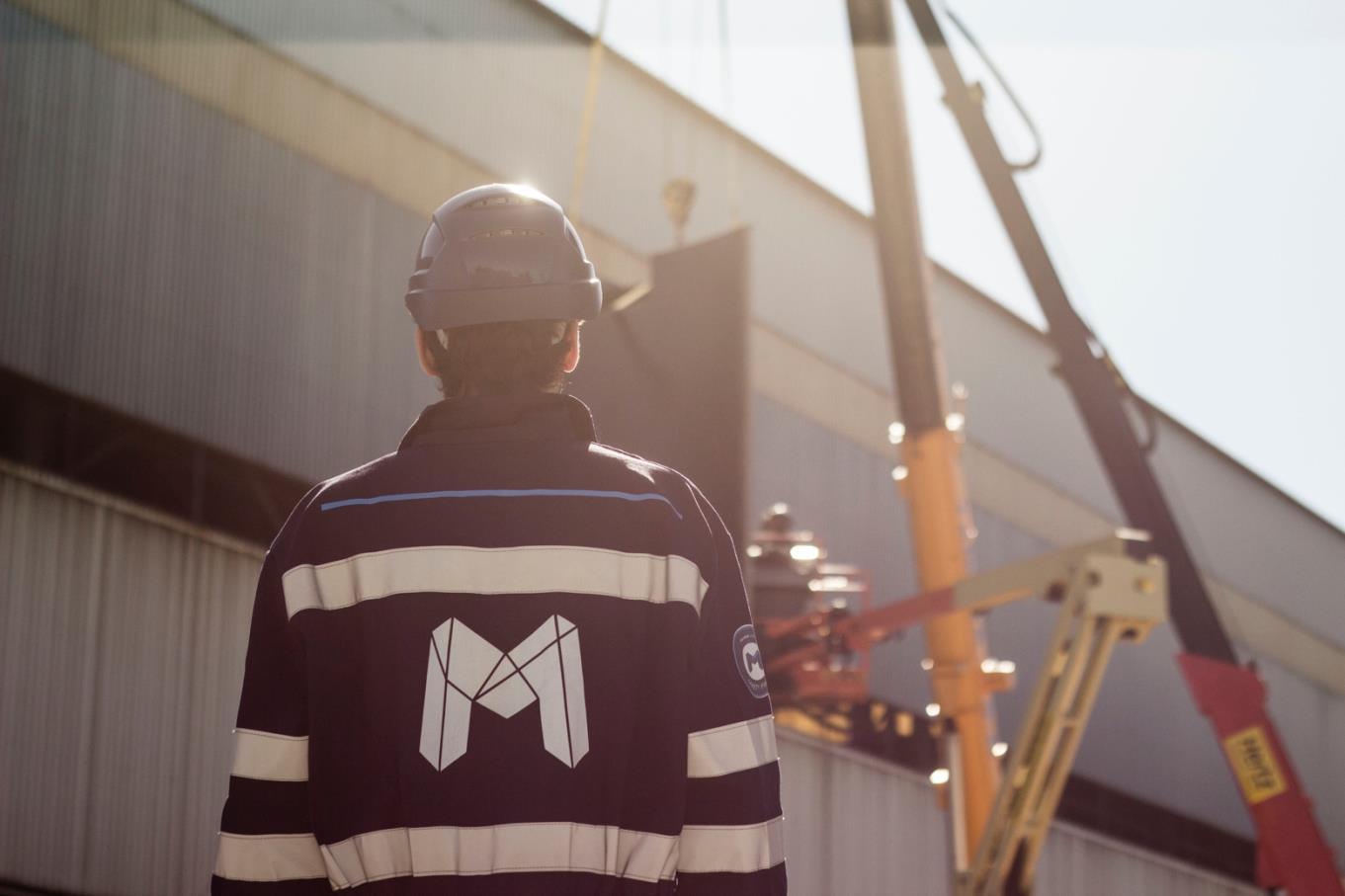

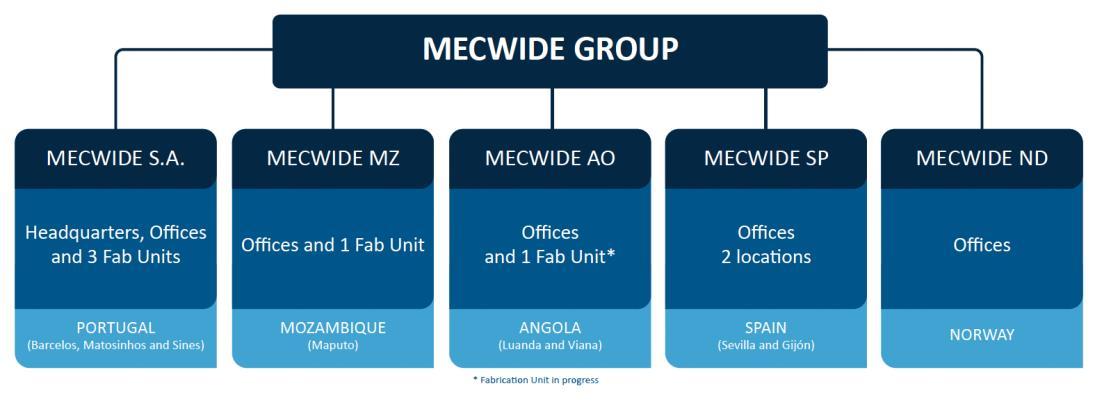

MECWIDE GROUP

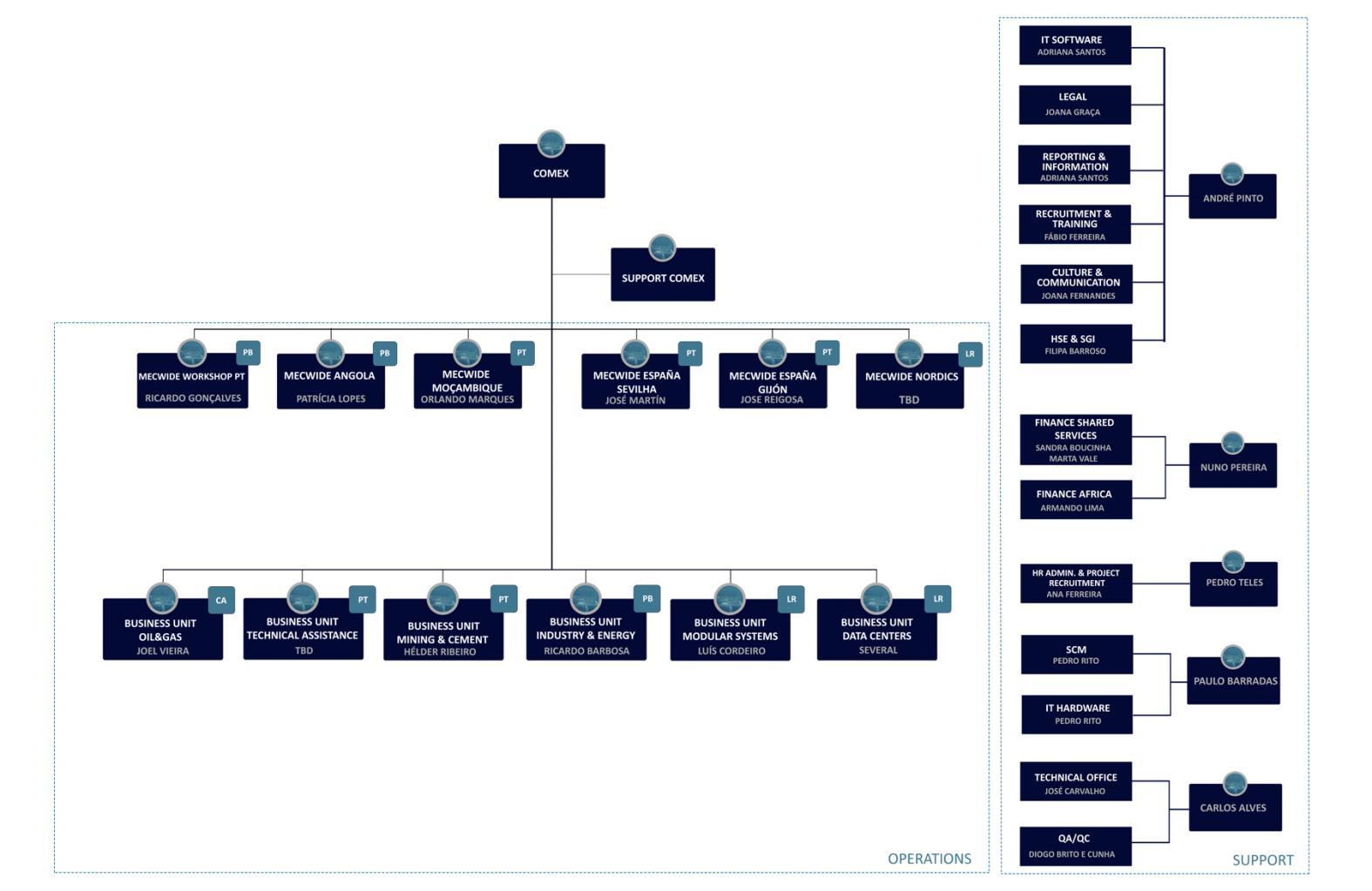

MECWIDE GROUP is organized and operates under a matrix organization of Business Units and Organic Sites.

Our operations span throughout Europe, from our Portuguese head office and workshops, with the support of our local operations in Spain (Seville and Gijon) and Norway (on top of a number of permanent establishments in several European countries). In Africa, our footprint is mostly established in Angola and Mozambique, with occasional projects in other regions. In terms of technical capabilities, we have chosen to set up our organization in specialized Business Unit, able to provide the most adequate technical response to our clients - Oil & Gas, Mining and Cement, Industry and Energy, Modular Systems, Technical Assistance, and the most recent unit – Data Centers.

This matrix organization allows us to have the best balance between the dedicated and swift response to the market and our clients, whist at the same time taking advantage of the synergies of corporate central services and common work methods.

BUSINESS UNIT

TECHNICAL ASSISTANCE

Based on the experience gained, and on an integrated management of the facilities, the Technical Assistance business unit stands out for its highly specialized and qualified recruitment and follow-up. It optimizes spaces, processes and technologies, and guides each industrial project in a focused and particular way.

Our assistance includes the full or partial provision of technical maintenance services, either under a contract, or occasional intervention, maintenance contracts under an outsourcing regime and industrial mountaineering.

We take advantage of the experience, technical competence, rigor and specialization to gather the best professionals for creating value in the following areas:

• Oil & Gas (On-shore / Off-shore);

• Refineries;

• Chemical and pharmaceutical industry;

• Naval Industry.

Integrated Management System Manual REV.09 | 05-06-2024 7

MINING & CEMENT

The Mining & Cement business unit focuses on two main areas of operation: mechanical maintenance for specialized industries and execution of EPC.

The high international experience combined with a wide range of operations in the market guarantees the client a robust solution for its business and ensures a high capacity to develop projects from the engineering phase, through construction, assembly and commissioning of the facilities.

This business unit offers tailored solutions, on a contract basis or occasionally within the scope of mechanical maintenance of the facilities.

MODULAR SYSTEMS

The Modular Systems Business Unit is strongly geared towards the engineering and manufacturing of skids and modular systems. Well-established with a proven track record of providing customized integrated solutions and internationally recognized by its experience in project execution, we encompass various international standards.

We are focused on customer satisfaction by meeting their requirements & quality standards at all times. We are committed to maintain the quality control in the comprehensive areas of design, development, manufacturing, installation and service.

The projects are executed from an engineering stage, through manufacturing and complementary activities (Painting, Insulation, Electricity & Instrumentation, Heat Treatment, Hydraulic Tests and non-destructive tests), ending with Factory Acceptance Tests and Final Delivery / Installation.

OIL & GAS

The Oil & Gas business unit is in the genesis of the Mecwide group, expanding permanently its scope of action, seeking to respond to the current industrial diversification. Through the provision of services of great added value and high level of demand, the foundation of its execution strategy is the rigor and commitment to the objectives required by its various customers.

Integrated Management System Manual REV.09 | 05-06-2024 8

Among the various activities we develop, we highlight the construction and maintenance of complex industrial units and the development of projects of highly demanding interventions, through specialization and consolidated experience in mechanical construction and metalworking services, developed under the context of oil refineries, petrochemical plants, storage/distribution parks and various others complex industrial facilities.

INDUSTRY & ENERGY

As a result of the excellent location that makes maritime transport possible, the Industry & Energy Business Unit ensures the execution of the project’s manufacturing through our three workshops in Portugal, ensuring all aspects of logistics, regulation and engineering.

From piping, metal ducts, metal structures, equipment and diverse boilerwork, we maximize prefabrication, thus managing to optimize the efficiency and control of processes, as well as all quality parameters. With this, we ensure the delivery to each client of a complete service of higher quality and at competitive prices.

Always in close contact and alignment with the client, the on-site assembly is guaranteed by highly qualified teams, with recognized national and international experience, capable of managing the different phases and specialties of demanding and multidisciplinary projects.

DATA CENTERS

The Data Centers business unit is the youngest unit of the Mecwide group.

Mecwide's step into this new business area allowed it to solidify the company's strategy of entering projects still in the design stage, and to considerably increase procurement activity.

Integrated Management System Manual REV.09 | 05-06-2024 9

The services provided are very wide, but include the following specialized activities: detail engineering;

• Procurement of all piping and equipment (valves, heat exchangers, inertia tanks, pumps, deaerators, flow meters, instruments) of the cooling network;

• Procurement of all piping and equipment for the fire protection network;

• Installation of piping and supports; Testing and flushing of the lines;

• Commissioning and start-up of the installation

Integrated Management System Manual REV.09 | 05-06-2024 10

Working in Technical Assistance in the country since 2009, and with a company incorporated since 2013, Mecwide works daily with the goal of becoming a reference in the sectors where it operates, focused on safety, customer satisfaction, high quality and development of local labor.

With a strong growth potential, the Angolan market develops an important role in the strategy of the Mecwide Group, being a support base for the growth of its operations in neighboring markets.

Mecwide Angola is dedicated to EPC projects of piping, mechanical construction, support structures, as well as renewable energy projects and preventive and corrective maintenance of onshore and offshore installations. We currently have offshore and onshore employees working for leading companies in the market such as Grupo Ponticelli, SPIE Oil&Gas and Cegelec.

In 2015, Mecwide expanded on the African continent, establishing a presence in Mozambique.

The investment on the integration of local employees at a technical and operational level, together with expatriate experience, has proven to be a very assertive formula, both in the integration of the company in the country and in the enhancement of the provision of qualified services with higher levels of knowledge and demand.

Throughout our presence in the Mozambican market, we have participated in projects in different areas of activity, focusing on Technical Assistance, Mining & Cement, Oil & Gas, Industry & Energy and also in the construction of various infrastructures and buildings.

Integrated Management System Manual REV.09 | 05-06-2024 11

Present in Spain since 2013, our office in Seville is mainly focused on the mining and cement industries. It´s from this office that we have managed several turnkey projects, turning Mecwide a reference player in these sectors in Spain.

Recently, we opened a new office in Gijón focused on Oil & Gas and Industry & Energy projects.

The incorporation of Mecwide Nordics, in partnership with a Norwegian company, started our operations in January 2023. Specialized in the construction of data centers, this company will be dedicated exclusively to the execution of metalworking projects in data centers in the scandinavian market.

Integrated Management System Manual REV.09 | 05-06-2024 12

Integrated Management System Manual REV.09 | 05-06-2024 13

MISSION

To create value, anticipate needs and implement successful solutions for everyone. We want to guarantee the full satisfaction of the expectations of demanding clients, strengthen its presence in the international competitive context and highlight the excellence of all its products and services.

VISION

Consolidate our global quality of services provided and be recognized as a reference in the industry, permanently innovating business through a qualified team, motivated to achieve excellence.

VALUES

The values we undertake are crosscut to all professionals and to the different business areas. They guide our behaviour and define our attitude and what we want to be as a Group.

Integrated Management System Manual REV.09 | 05-06-2024 14

ANALYSIS OF THE ORGANISATION'S CONTEXT

Integrated Management System Manual REV.09 | 05-06-2024 15

CODE OF CONDUCT

Mecwide has a Code of Conduct that applies to all group companies. It is based on the personal and business conduct of the employees, defining clear guidelines on the conduct of business, the promotion and respect of diversity, the relationship with customers, external suppliers, and other stakeholders.

Mecwide makes the Code of Conduct available to all its employees and expects each of them to be familiar with and comply with its guidelines.

Failure to comply with the Code of Conduct may lead to disciplinary action. Mecwide expects its suppliers and subcontractors to comply with the rules and principles set forth in the Code of Conduct.

Employees, customers, suppliers, and any other interested parties may request clarification of the Code of Conduct guidelines, as well as report any events that may be in violation of the Code of Conduct via email: codeofconduct@mecwide.com

The Board of Directors of Mecwide assures maximum confidentiality as to the origin of such information. Likewise, Mecwide will not tolerate any retaliation for reporting actual or potential violations of the Code of Conduct if they are made in good faith.

The Code of Conduct is available on the company's website and accessible to all interested parties.

Integrated Management System Manual REV.09 | 05-06-2024 16

STAKEHOLDERS

Mecwide aims to create value for its customers by reducing costs and increasing the efficiency of its operational processes. The creation of value occurs with the use of the solutions offered by the company, composed by methodologies, hardware, software, and services. We are committed to the success of each of clients because we believe that growth will also be ours and, consequently of our employees.

We aim to build long-term relationships in accordance with defined ethical values.

Our philosophy is based on the principle of back-to-back operation, for lower taxation, greater agility of goods and resources, greater agility for better financial planning and cost reduction.

Therefore, for Mecwide the creation of value is a necessary condition, for our customers and consequently investors, employees, external suppliers and for the development of the local cultures where we operate.

Integrated Management System Manual REV.09 | 05-06-2024 18

CLIENT FOCUS

Mecwide Integrated Management System has as one of its goals to meet Customer expectations, aiming at their satisfaction. To this end, it uses as one of its input requirements for the evaluation of the services provided the Customer Satisfaction indicator, which determines the level of Customer satisfaction by project.

Action plans are established to improve the effectiveness of the system regarding Customer Satisfaction.

WORKERS CONSULTATIONS

Mecwide establishes and maintains procedures for employee consultation and participation, at all applicable levels and functions, for the development, planning, implementation, evaluation and performance and improvement actions of the Integrated Management System, also in matters of occupational health and safety management.

In this sense, Mecwide has several mechanisms for employee consultation, and in accordance with Procedure PSA.11 - Employee Consultation, such as:

• S15 – HSE Verification Report;

• S29 – LMRA;

• S61 – Safety Ideas and Safety Deviations;

• Q43 –DL50/2005 Verification Report / or Safety Verification Report.

Records concerning employee participation are kept in the minutes of the Management Review Meeting, as well as the respective annual Employee Consultation Report.

Integrated Management System Manual REV.09 | 05-06-2024 19

RISKS AND OPPORTUNITIES

CONTEXT, NEEDS AND EXPECTATIONS (INTERNAL AND EXTERNAL)

In planning the Integrated Management System, Mecwide’ s management considers the context (internal and external) of the organization and the needs and expectations (internal and external) of the stakeholders.

In identifying risks and opportunities, Mecwide determines and prioritizes the ones that need to be addressed to ensure that the management system can achieve its objectives, enhance desirable effects, prevent, or reduce undesirable effects (including the potential for external environmental conditions affecting the organization) and achieve improvements.

Mecwide plans actions to address risks and opportunities by integrating and implementing actions into its management system processes, considering risks and opportunities related to environmental aspects and impacts, legal requirements, occupational health and safety hazards and risks, and evaluating the effectiveness of these actions. The actions taken to address the risks and opportunities are appropriate to the potential impact on compliance of the products, services, and activities we provide.

ENVIRONMENTAL ASPECTS AND OCCUPATIONAL HAZARDS (14001 e 45001)

Mecwide has a methodology for determining its environmental aspects, in accordance with the activities, products and services, taking into consideration the aspects that can be controlled, influenced and the perspective of the life cycle of the product, which runs from the acquisition of raw materials to its final destination

LEGAL REQUIREMENTS (14001 e 45001)

The identification and updating of legal requirements (occupational Health and Safety) applicable to Mecwide are carried out by the IMS/HSE Department. Relevant information on legal requirements and other requirements are communicated to Mecwide employees, through the company's internal communication tools, and through safety awareness, procedures, work instructions and other processes associated with the Integrated Management System.

Integrated Management System Manual REV.09 | 05-06-2024 20

ACTION PLANNING (14001 e 45001)

Mecwide takes actions to address the significant environmental aspects and hazards, its legal requirements others, and the risks and opportunities, to respond and frame emergency situations, integrating and implementing actions in the processes of the Integrated Management System, as well as the business processes. To achieve this, every year activity plans are developed to monitor the Integrated Management System and shared with the entire organization.

Integrated Management System Manual REV.09 | 05-06-2024 21

STRATEGY

Mecwide´s strategy revolves around sustainable growth, based on the vertical integration of its companies in the metalworking industry, though the active engagement of all employees in continuous improvement and their commitment to support an integrated management.

Mecwide focuses on consolidating the position acquired by the companies that compromise it in markets where they operate, by promoting cross-selling among them, creating new business opportunities and taking advantage of emerging synergies while rationalizing costs in its operations and management.

Integrated Management System Manual REV.09 | 05-06-2024 23

STRUCTURE

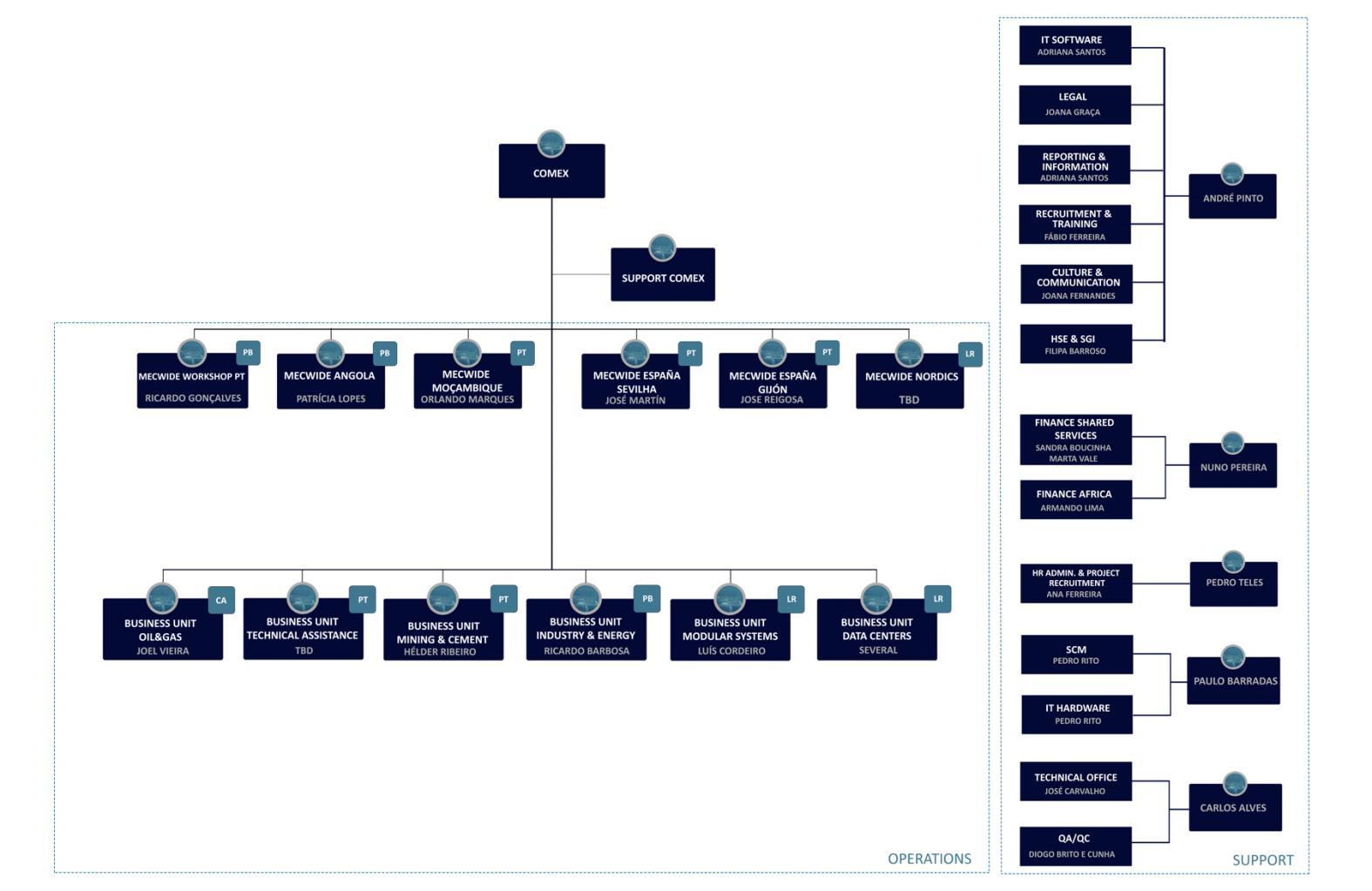

MECWIDE GROUP ORGANISATION CHART

Integrated Management System Manual REV.09 | 05-06-2024 25

CERTIFICATIONS

ISO 9001 QUALITYMANAGEMENT

ISO 14001 ENVIRONMENTALMANAGEMENT

ISO 45001 SAFETYAND OCCUPATIONALHEALTHMANAGEMENT

EN1090-EXC3 METALSTRUCTURESCEMARKING

ISO 3834-2 WELDING

VCA INTERNATIONAL CERTIFICATION IN SAFETY AT WORK, FOR PROFESSIONALS AND COMPANIES WHO WORK OR INTEND TO WORK OUTSIDE PORTUGAL

DGERT CERTIFIEDTRAINING

NEN LABOURCOMPLIANCECERTIFICATION

● Certification completed

◦ In process of certification

Integrated Management System Manual REV.09 | 05-06-2024 26

MECWIDE S.A. MECWIDE MOZAMBIQUE MECWIDE ANGOLA MECWIDE ESPAÑA MECWIDE NORDICS

PRODUCTION CAPACITY

PORTUGAL

MECWIDE BARCELOS

Office Accomodations Workshop Wharehouses

Integrated Management System Manual REV.09 | 05-06-2024 28

1240

554

Storage Covered Area Total land area 482 M2 1318 M2 3477 M2

M2 -

M2

MECWIDE MATOSINHOS

Integrated Management System Manual REV.09 | 05-06-2024 29

Office Accomodations Workshop Wharehouses 102 M2 1277 M2Storage Covered Area Total land area 500 M2 2553 M2 2553 M2

EQUIPMENT AND CHARACTERISTICS

Guillotine

Press Brakes

Plasma Cutter

Capacity: 3080*13mm

Strokes per minute: 9 a 17

Minimum Thickness: 0,5mm

Maximum Thickness: 13mm

Capacity : 3050*320 TON

Minimum Thickness: 0,5mm

Maximum Thickness: 20mm

Voltage: 230VAC 2Ph 50 Hz / 1Kw/h 380VAC 3Ph 50 Hz / 4Kw/h

Cutting Amperage: 80A/130A/260A

Minimum Thickness: 1mm

Maximum Thickness: 40mm

Maximum Measure:

1200*3000mm

Press Voltage: 400V 50Hz 11KW

Maximum Pressure: 250 TON

Approximate speed: 19mm/seg

Working speed: 7mm/seg

Roller Plate

Universal Ironworker

Small Manual Saw

Large Manual Saw

Radial Drilling

Capacity: 3000*20mm

Capacity: 110

Strokes per minute: 10

Maximum Pressure: 280 kg/cm2 4069 psi

Maximum Measure: 200*180

Maximum Measure: 825*530

Voltage: 400V 50Hz 3Ph

Pillar Drilling Voltage: 380V 50Hz 3Ph

Integrated Management System Manual REV.09 | 05-06-2024 30

MECWIDE SINES – ZIL

Integrated Management System Manual REV.09 | 05-06-2024 31

Office Accomodations Workshop Wharehouses 400 M2 2600 M2 270 M2 Storage Covered Area Total land area 4000 M2 3270 M2 7270 M2

EQUIPMENT AND CHARACTERISTICS

Guillotine

Press Brakes

Plasma cutter

Hydraulic press

Roller Plate

Universal Ironworker

Semi-automatic saws

Drilling machine

Overhead crane

Grua Torre

Capacity:: 42kg/mm2

Strokes per minute: 13

Minimum Thickness: 0,4mm

Maximum Thickness:13mm

Maximum Pressure: 240 bar

Capacity: 200 ton

Minimum Thickness : 0,5mm

Maximum Thickness 20mm

Pressure: 265 bar

Tension: 400V

Cutting Amperage: 58 A

Maximum Thickness: 20mm

Maximum Measure:1500*3000mm

Maximum Pressure: 50 ton

Capacity: 740*2520*1330mm

Capacity: 40*14mm

Maximum Pressure: 45 kg/m2

Punching Force: 80 ton

Maximum hight: 710mm

Cutting speed: 20-100m/min

Tension: 380 V

Capacity: 5ton a 10 ton

Capacity: 12m-6t | 24 – 3t Tension: 400V

Integrated Management System Manual REV.09 | 05-06-2024 32

MECWIDE SINES – PAVILHÕES

EQUIPMENT AND CHARACTERISTICS

Pickling Cabin

Compressor

Capacity: 14*5*5 m

Capacity: 12,95 m3 / min

Tension: 400 V +7- 10% Power: 75 kW

Integrated Management System Manual REV.09 | 05-06-2024 33

Workshop Wharehouses 271

3780

500 M2

Office Accomodations

M2

M2

Storage Covered Area Total land area 4600

4551

2 9151 M2

M2

M

MECWIDE MOÇAMBIQUE

Integrated Management System Manual REV.09 | 05-06-2024 34

Office Accomodations Workshop Wharehouses 720 M2 1560 M2 350 M2 Storage Covered Area Total land area 10117 M2 12747 M2 27000 M2

EQUIPMENT AND CHARACTERISTICS

Press Brakes

Plasma cutter

Capacity: 200 ton

Minimum Thickness: 1mm

Maximum Thickness: 12mm

Tension: 380V

Minimum Thickness: 1mm

Maximum Thickness: 120mm

Maximum

Measure:12000*3000mm

Press Voltage: 380V

Maximum pressure: 244 bar

Roller plate

Lathe

Radial drilling

Pillar drilling

Large manual saw

Small manual saw

SAW

Slotting machine

Milling machine

Capacity: 3000*20mm

Dimensions: 700*4500*1000mm

Voltage: KW4

Voltage: 230V 50 Hz 4 A P2

Voltage: 380 V

Maximum measure: 700mm

Voltage: 380V

Maximum measure: 150mm

Voltage: 100 Amp – 24V 1000-44

Stroke: 120mm

Voltage: 2.2 Kw

Integrated Management System Manual REV.09 | 05-06-2024 35

MECWIDE ANGOLA

Integrated Management System Manual REV.09 | 05-06-2024 36

Workshop

171,2 M2 -Storage Covered Area Total land area - 171,2 M2 171,2 M2

Office Accomodations

Wharehouses

MECWIDE ANGOLA – VIANA

Integrated Management System Manual REV.09 | 05-06-2024 37

Office Accomodations Workshop Wharehouses 180 M2 800 M2 400 M2 Storage Covered Area Total land area 300 M2 3855 M2 13870 M2

MECWIDE ESPAÑA – SEVILLA

Integrated Management System Manual REV.09 | 05-06-2024 38

Office Accomodations Workshop Wharehouses 121,76 M2 -Storage Covered Area Total land area - 121,76 M2 121,76 M2

MECWIDE ESPAÑA – GIJÓN

Integrated Management System Manual REV.09 | 05-06-2024 39

Office

Workshop Wharehouses 123,6

2 -Storage Covered Area Total land area - 123,6 M2 123,6 M2

Accomodations

M

In the manufacturing units of Matosinhos and Sines (ZIL) the processes are under CE marking according to the regulation 305/2011, normative references EN 1090-2 for execution class 3.

From the quality requirements of welded construction complying with EN ISO 3834-2 to demonstrate the quality of the product.

Integrated Management System Manual REV.09 | 05-06-2024 40

RESOURCES AND TECHNICAL MEANS

HUMAN CAPITAL

Mecwide has as a guiding principle and standard that organizations are the people, so it encourages the growth and individual development of its employees and seeks to promote a work environment where people feel welcomed and treated as a factor for success.

The HR recruitment and selection policy favors the technical and professional competence of people and has a tailored training policy, through the existing Training Academy in the group (Mecwide Learning Academy) that aims the enhancement and personal fulfillment of employees.

In order to capitalize on the human resources l in the Group, Mecwide develops strategic partnerships with training centers, universities and institutes of reference in various areas, in order to attract the best talent and continue the policy of sustainability of its human resources. We promote an internal recruitment and valorization policy when internal needs arise in the different sites.

As part of social initiatives aimed at encouraging creativity and participation among all its employees, Mecwide also invests in fostering an environment of equal opportunities and social actions, collaborating with institutions located in the different countries where it operates.

Regarding the human resources structure of Mecwide, it is composed of a structure characterized by a low average age and highly qualified profiles. It favors a corporate culture of people, open and flexible in the flow of communication, fostering an environment of dialogue with all its employees, social partners and stakeholders.

Integrated Management System Manual REV.09 | 05-06-2024 42

CULTURE AND COMMUNICATION

The Department of Culture and Communication plays a strategic role in building identity, involving employees, managing reputation and achieving the organization's objectives. It is an investment that goes beyond simple transmission of information and assumes a fundamental role in the success and sustainability of the company.

Its importance is reflected in various areas crucial for the overall success of the organization.

1. Defining and Maintaining Organizational Culture: This department helps to defining and maintaining the company's culture. A solid corporate culture, based on shared values and principals, helps to unify employees around a common purpose, influencing behavior and decisions, and reinforcing the company's identity.

2. Internal Communication: It facilitates effective communication across different hierarchical levels and departments within the company. This aids in aligning goals, disseminating critical information, and keeping employees informed and engaged. We use various traditional means, such as email, to facilitate the exchange of information between members of the organization. In addition, we encourage open communication and the sharing of ideas among our employees. We invest in numerous internal communication tools with the aim of establish the best possible interaction between the employees of the various group companies.

3. Attracting and retaining talent: A strong culture and communication department can highlight the company's unique culture and values, making it more attractive to potential talent. It also contributes to employee retention since a solid culture and transparent can increase employee satisfaction and commitment.

4. Crisis Management: In times of challenges or crises, this department plays a crucial role in communication management. It can help the company communicate effectively with employees, customers and external stakeholders, minimizing stakeholders, minimizing potential reputational damage.

5. External Communication: In addition to managing internal communication, this department is responsible for communicating with customers, suppliers, investors and the general public. Efficient external communication is essential to building and maintaining positive, trusting relationships with these stakeholders.

Integrated Management System Manual REV.09 | 05-06-2024 43

6. Innovation and Change: When a company faces change or seeks innovation, the culture and innovation, the culture and communication department can facilitate the transition, communicating the reasons behind the changes and helping with the adoption of new practices and processes.

7. Feedback and Continuous Improvement: Responsible for gathering feedback from employees and external stakeholders, identifying areas for improvement and promoting the ongoing evolution of the company's culture and communication.

Integrated Management System Manual REV.09 | 05-06-2024 44

TECHNICAL DEPARTMENT AND PROJECT

Mecwide has a technical office with qualified and experienced resources in the provision of engineering services, able to analyze the needs, problems and opportunities of each project, and propose solutions tailored to our customers.

Our multidisciplinary team develops the activities of planning, design, detailing and preparation for manufacturing and assembly of mechanical and hydraulic installations, including piping, equipment, tanks, atmospheric and pressure vessels, metal structures and boilers, in the different industrial processes.

We are prepared to respond to projects in EPC format, forming extended internal teams dedicated to the management and integration of all specialties, including civil construction, electricity and instrumentation, automation and control.

We also have advanced techniques and technologies that allow us to have robust processes and procedures in the development of the different projects, complying with the most demanding environmental, quality and safety requirements, in the most efficient and economical way for our customers.

Integrated Management System Manual REV.09 | 05-06-2024 45

QUALITY CONTROL

QUALITY

Over the years, Mecwide has been promoting Quality as a differentiating factor in the service provided, based on the various construction’s codes and requirements of our Customers.

Quality is a constant presence in our activity, from the definition of project quality requirements to compliance with the points defined in the Inspection and Testing Plan, through our dedicated QA/QC teams exclusively oriented to ensure that our products are within of the highest standards of quality and compliance.

Our Quality Control team has the means and qualified technicians to effectively comply with the "Inspection and Testing Plan", carrying out activities that can range from the dimensional control of a part to the compilation of all documentation for the CE marking of a structure or piping.

WELDING

Mecwide currently has the latest welding technologies with the aim of increasing productivity and the quality of the final product and is certified in accordance with the normative reference ISO 3834-2 "Quality requirements for fusion welding of metallic materials Part 2: Comprehensive quality requirements".

Equipped with a welding office and a qualified Welding Engineer (IWE/EWE), the most appropriate processes are defined specifically for each project, considering the customer's requirements, the increase in productivity and the required quality.

Mecwide is equipped with welding equipment for the following processes:

• Welding with shield gas and continuous solid electrode wire (131/135 according to EN ISO 4063/GMAW according to ASME IX);

• Welding with gas protection and continuous flux-cored electrode wire (136/138 according to EN ISO 4063/FCAW according to ASME IX);

• Welding with coated electrodes (111 according to EN ISO 4063/SMAW according to ASME IX);

• TIG welding (141 according to EN ISO 4063/GTAW according to ASME IX);

• Submerged arc welding (121/123/125 according to EN ISO 4063/SAW according to ASME IX).

Integrated Management System Manual REV.09 | 05-06-2024 46

CONSTRUCTION CODES AND STANDARDS

Over the years, Mecwide has been developing projects in specialized areas, being very familiar with several construction codes and standards, namely:

• Steel structures - EN 1090 (LRQA EXC.3 Certification), AWS D 1.1;

• Equipment and Pressure Vessels - ASME VIII, EN 13445; ASME PCC-2;

• Storage and Process Tanks - API 650, API 653, EN 14015, EN 12285;

• Piping - EN 13480, ASME B31.1, ASME B31.3, ASME B31.8;

• Boilers - EN 12952.

Integrated Management System Manual REV.09 | 05-06-2024 47

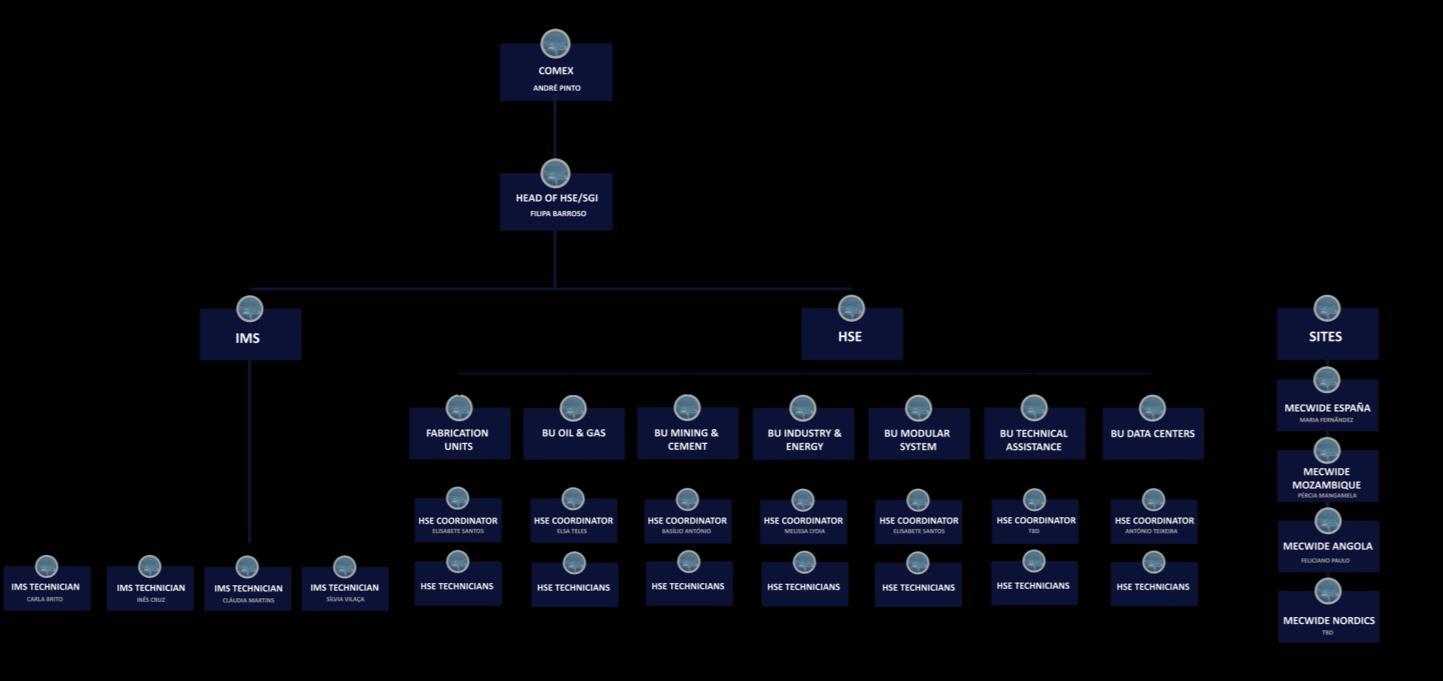

QUALITY, ENVIRONMENT AND SAFETY

Mecwide has a strong concern and focus on quality, environment, safety and health of our employees and stakeholders. For this reason, the Group has internal health and safety services. We have an IMS/HSE Department, composed of a large team of quality, safety and environment technicians located in the different countries where we operate.

Occupational Health is managed by an internal team of Doctors and Nurses, also in the different locations. In addition to the Internal Medicine services, we provide a free curative medicine service to our employees. We also promote an annual plan of Occupational initiatives that promote the safety, health, and well-being of our employees, based on awareness campaigns, screenings, and visits by the Internal Medicine Service to workplaces.

Environmental concerns are also integrated and led by the internal service of Quality, Safety and Environmental Technicians. All environmental impacts associated with the various activities carried out in the Group are identified and evaluated. For this purpose, operational control measures are defined and monitored, and environmental and occupational health and safety measurement and monitoring are conducted.

We promote environmental protection by using the best available technologies for the efficient use of natural resources (Siliamb, SIMCA, applicable in Portugal), this includes the minimization of raw material and energy waste, the minimization of pollution through proper waste management, the capture and treatment of gaseous emissions, the treatment of wastewater and the emission of environmental noise

The prevention and protection of our employees is also ensured through the awareness and annual training plans provided, as well as ongoing training in Quality, Safety and Environmental procedures, the implementation of measures for risk elimination or reduction, collective and individual protection systems, firefighting, evacuation and first aid training. The Group's companies also have procedures for action in case of emergency, with first and second intervention teams adequately equipped.

.

Integrated Management System Manual REV.09 | 05-06-2024 48

CONTINUOUS IMPROVEMENT

Mecwide, in a context of identifying opportunities and continuous process improvement, generating new knowledge and innovating products and processes, has a multidisciplinary group created to build and evolve the culture of continuous improvement, with a strong emphasis on process measurement and monitoring.

CULTURE OF PROCESS MONITORING

We have various indicators for monitoring daily, monthly and annual performance, as well as identifying, evaluating and managing opportunities and risks.

• Continuous Improvement Meetings (Type A and B);

• Daily, weekly, monthly departmental and interdepartmental meetings;

• Integrated Management System - standardization, process self-control, production planning and projects;

• Policy and 5S's Management.

• Project Management: Project Manager, Project Process, Mec PMS;

• MFC;

• Mecwide IMS Management and Safety System;

• Safety Behaviour Performance;

• WO´s Management;

• Monitoring financial indicators;

• Monitoring Human Resources Indicators

Integrated Management System Manual REV.09 | 05-06-2024 49

INTEGRATED MANAGEMENT SYSTEM

We consider fundamental the implementation and maintenance of an integrated management system in quality, safety, and environment, which allows us to define concrete and transversal methodologies, enabling greater independence and improved communication among the various team members.

It is an integrated part of the Management System, the promotion of Continuous Improvement in the systems and processes for the improvement and optimization of performance and to contribute positively to the results of the organization

IMS SCOPE

Design, Construction, Pre-fabrication and Assembly of metal structures and fluid installations (metallic and non-metallic piping); Industrial maintenance; Provision of metalworking services.

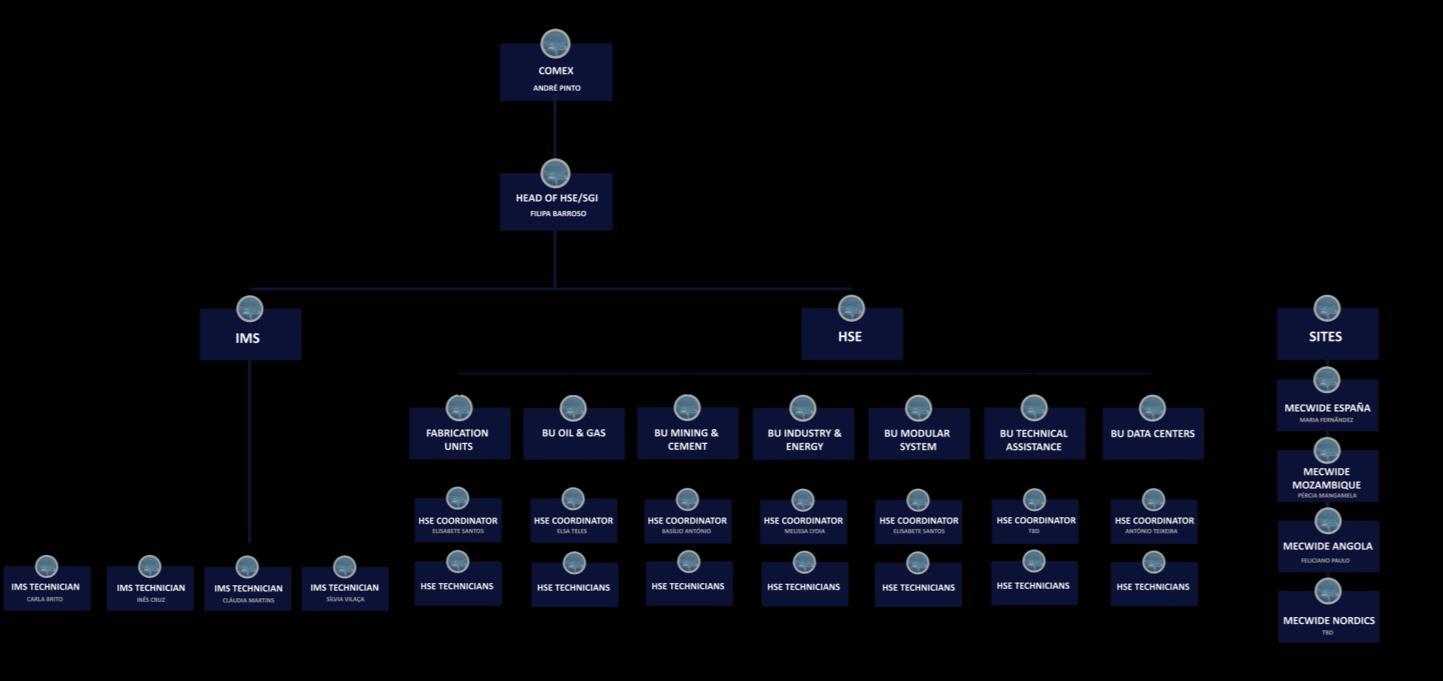

ORGANIZATIONAL STRUCTURE OF IMS MANAGEMENT

Integrated Management System Manual REV.09 | 05-06-2024 51

POLICY

Mecwide Group has an Integrated Management System Policy, in which it defines and documents the IMS Policy and Objectives, ensuring that they are communicated and understood throughout the organization.

Mecwide’ s Policy represents a commitment to all stakeholders and forms the basis of the continuous improvement of its processes

Mecwide´s Policy is available on the IMS Management and Safety System in SAGE, SharePoint and on the Group´s Website

Integrated Management System Manual REV.09 | 05-06-2024 52

RESPONSABILITIES AND AUTHORITY

Mecwide has an organizational structure to ensure the full development of the activities of each process, as well as to guarantee the interaction of the processes.

Furthermore, the functional descriptions, manuals, processes, procedures, and work instructions define the functions responsible for each activity.

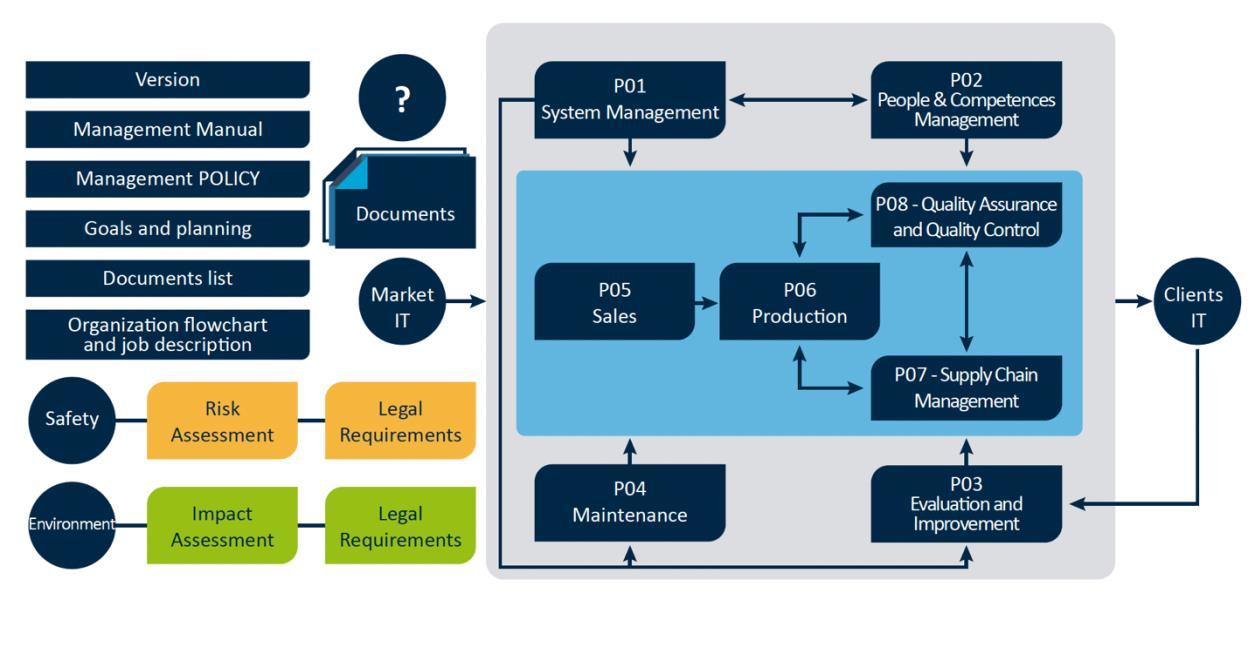

ORGANIZATIONAL STRUCTURE BY GEOGRAPHY

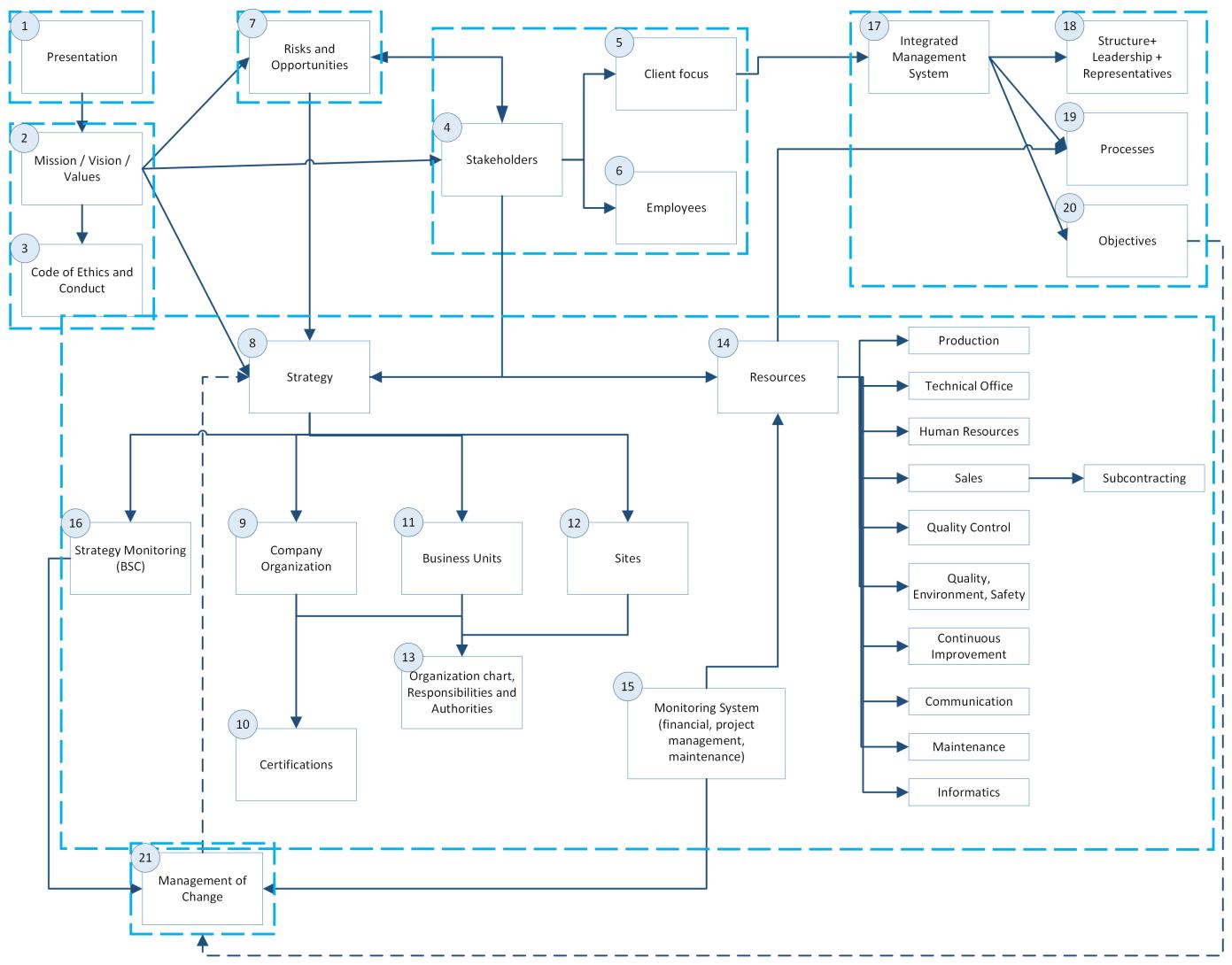

PROCESS INTERACTION MAP

Integrated Management System Manual REV.09 | 05-06-2024 53

PROCESSES AND ACTIVITIES

Integrated Management System Manual REV.09 | 05-06-2024 55

OBJECTIVES OF THE INTEGRATED MANAGEMENT SYSTEM AND PLANNING

The planning of objectives and targets of the Integrated Management System are a priority for those responsible for the indicators defined by Mecwide Group, to achieve success in the market in which we operate.

From the processes in place in the Mecwide Group, the Administration has identified a group of strategic indicators that according to their characteristics are those that add the greatest value and importance, presented, and discussed quarterly in the Balanced ScoreCard. These indicators are applicable to the group and are followed up, monitored, and reviewed by the respective manager.

The Balanced ScoreCard comprises four major areas, each of which encompasses its respective indicators. Each area corresponds to a group of indicators and their respective manager.

Integrated Management System Manual REV.09 | 05-06-2024 56

Learning and Growth

Culture and Performance

Performance Evaluation

Mecwide 1st Choice

Organizational Climate Index

Commitment and attitude in strategic alignment

No. of BSC status meetings

Culture and Practice of HSE

LTFR | Lost Time Frequency Rate

TRIF | Total Recordable Injury Frequency

SR | Severity Rate

Technical and Management Skills

Average number of cumulative training hours

Internal Processes

Optimising Critical Processes

Number of Improvement Continuous Meetings

Number of Completed Continuous Improvement Actions

Actions on schedule

Data books delivered on time

Non – Quality Costs

Business Innovation

Number of new ideas suggested and implemented for business innovation

Balancing products/services

Number of clients visits

Turnover by geography

New qualifications by vendors lists of clients

Intelligent Risk Management

Clients

Customer Satisfaction and Loyalty

Client Survey

Number of Customer Complaints

Be a reference in HSE

Client Survey (specific section)

Increasing differentiation

Differentiation index

Increase competitiveness

Quotation success rate

Integrated Management System Manual REV.09 | 05-06-2024 57

Financial Value creation

Economic Value Added

Increase levels of profitability

EBITDA

Increase the volume of business

Volume of Business (absolute value))

Balanced Liquidity

Balanced Solvability

Financial Autonomy

The Balance ScoreCard analysis meetings are held on a quarterly basis with the company’s executives, where the responsible individuals mus present the respective indicators and in specific cases, whenever justified, present the action plans, as well as collect, from those involved, important status updates and opinions on the process improvement and optimization.

All the indicators have defined targets, appropriate to the competitive market in which we find ourselves, by geography, which can be reviewed annually and/or whenever necessary see targets defined in Annex I.

Integrated Management System Manual REV.09 | 05-06-2024 58

MANAGEMENT SYSTEM OBJECTIVES

Simultaneously, the Integrated Management System also monitors, manages, and tracks a range of indicators and metrics based on information from various Mecwide processes. This includes generating reports and sharing them with the organization.

Inputs:

1. Actions arising from previous critical analyses by management;

2. Changes related to internal and external issues relevant to the IMS:

a. Changes in stakeholder needs and expectations, including legal requirements and other interests;

b. Changes in significant environmental aspects;

c. Changes in significant occupational hazards and risks;

d. Changes in risks and opportunities.

3. Performance and effectiveness of the IMS:

a. Customer satisfaction and feedback from relevant stakeholders;

b. Process performance and conformity of products and services provided;

c. Non-conformities, incidents, corrective actions, and continuous improvement;

d. Monitoring and measurement results;

e. Results of internal and external audits;

f. Supplier performance and respective qualification;

g. Employee consultation and participation;

h. Relevant communications with stakeholders;

i. Resource Sufficiency;

j. Effectiveness of actions taken to address risks and opportunities;

k. Opportunities for Continuous Improvement.

Outputs:

4. Opportunities for Continuous Improvement;

5. Changes needed in the IMS;

6. Need for Resources.

Others:

7. 5S’s Program;

8. Group Strategy

Integrated Management System Manual REV.09 | 05-06-2024 59

ENVIRONMENTAL AND OCCUPATIONAL HEALTH AND SAFETY

All activities of environmental interest that have an impact are covered and monitored in the group's policy. Due to the diversity of the scope of services carried out by Mecwide on the different sites and projects, the significant environmental impacts are identified and disclosed to employees.

Likewise, about health and safety at work, these are identified in the Evaluation of Occupational Hazards and Risks, assessed in accordance with the planned activities and duly communicated to employees.

For the hazards that require control, monitoring plans, routines and responsible parties are established for their tracking.

In the case of Risk and Aspect Assessment, we have internal methodologies for monitoring them, with respective action measures to minimize the impacts caused

MANAGEMENT INDICATORS, OF PROCESSES AND SUPPORT ACTIVITIES

Mecwide has indicators to support the performance of the group's policy and the integrated management system, which are also periodically monitored at the IMS meetings, so that improvement actions can also be established.

MANAGEMENT OF CHANGES (9001)

The Mecwide Group is prepared as a market player, for the necessary adaptations associated with the entrepreneurial and competitive market. We have methodologies for managing change and adapting processes that require changes and/or transitions.

PLANNING OF ENVIRONMENTAL AND OCCUPATIONAL HEALTH AND SAFETY ACTIONS AND OBJECTIVES (14001 E 45001)

A Mecwide has incorporated its environmental and occupational health and safety objectives into its planning. It has established defined action plans, allocated the necessary resources, and assigned responsible individuals. This approach allows us to develop indicators that track progress towards the environmental and occupational health and safety goals set within the group.

Integrated Management System Manual REV.09 | 05-06-2024 60

PLANNING CHANGES

The implementation of Kaizen within the Mecwide Group had as its main purpose the search for greater operational efficiency, waste and cost reduction, product quality enhancement and the increase of customer satisfaction.

The culture of continuous improvement implemented at Mecwide encourages the involvement of all its employees in identifying waste, optimizing and standardizing processes and suggesting small changes that generate significant benefits over time.

Integrated Management System Manual REV.09 | 05-06-2024 61

APPENDIX I

BALANCE SCORECARD

PERFORMANCE INDICATORS

LEARNING AND GROWTH

INDICATOR MANAGER

Performance Evaluation Culture & Communication Manager 6

Organizational Climate Index Culture & Communication Manager

Nº of BSC status meetings COMEX 4

Lost Time Frequency Rate Head of SGI/HSE <1

Total Recordable Frequency Rate Head of SGI/HSE <2

Severity Rate Head of SGI/HSE <10

Average number of cumulative training hours Head of SGI/HSE 40

INTERNAL PROCESSES

INDICATOR

Number of Improvement Continuous Meetings Head of SGI/HSE 6

Number of Completed Continuous Improvement Actions Head of SGI/HSE 36

Actions on schedule Head of SGI/HSE 30

Data books delivered on time QA/QC Manager 90% Non – Quality Costs QA/QC Manager <123k

Number of new ideas suggested and implemented for business innovation COMEX 9

Balancing products/services Head of SGI/HSE 9

Number of clients visits Site Manager 120 Turnover by geography COMEX – BU 30%

New qualifications by vendors lists of clients Head of SGI/HSE 20 Intelligent Risk Management CEO Action Plan

CLIENTS

Client Survey Head of SGI/HSE

Number of Customer Complaints Head of SGI/HSE 10

Client Survey (specific section) Head of SGI/HSE >4,2

Increasing differentiation Head of SGI/HSE <4,2

Quotation success rate Head of BU / Site Manager 20%

Integrated Management System Manual REV.09 | 05-06-2024 63

TARGET

85%

MANAGER TARGET

TARGET

INDICATOR MANAGER

>4,2

FINANCIAL

Integrated Management System Manual REV.09 | 05-06-2024 64

INDICATOR MANAGER TARGET Economic Value Added CFO 15% EBITDA Head of BU / Site Manager 9.115.755 € Volume of Business (absolute value) Head of BU / Site Manager 99.754.347 € EBITDA CFO 3,5 Financial Autonomy CFO 22,5%