A

Th e

Component Manufacturing dverti$ dverti $ er

Don’t Forget! You Saw it in the

Adverti$$er

January 2026 #18318 Page #10

Home Building Technology, Part XIII: Truss Equipment Proliferates – Component Saws By Joe Kannapell

A

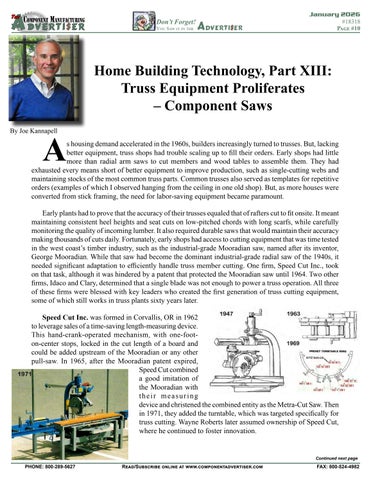

s housing demand accelerated in the 1960s, builders increasingly turned to trusses. But, lacking better equipment, truss shops had trouble scaling up to fill their orders. Early shops had little more than radial arm saws to cut members and wood tables to assemble them. They had exhausted every means short of better equipment to improve production, such as single-cutting webs and maintaining stocks of the most common truss parts. Common trusses also served as templates for repetitive orders (examples of which I observed hanging from the ceiling in one old shop). But, as more houses were converted from stick framing, the need for labor-saving equipment became paramount. Early plants had to prove that the accuracy of their trusses equaled that of rafters cut to fit onsite. It meant maintaining consistent heel heights and seat cuts on low-pitched chords with long scarfs, while carefully monitoring the quality of incoming lumber. It also required durable saws that would maintain their accuracy making thousands of cuts daily. Fortunately, early shops had access to cutting equipment that was time tested in the west coast’s timber industry, such as the industrial-grade Mooradian saw, named after its inventor, George Mooradian. While that saw had become the dominant industrial-grade radial saw of the 1940s, it needed significant adaptation to efficiently handle truss member cutting. One firm, Speed Cut Inc., took on that task, although it was hindered by a patent that protected the Mooradian saw until 1964. Two other firms, Idaco and Clary, determined that a single blade was not enough to power a truss operation. All three of these firms were blessed with key leaders who created the first generation of truss cutting equipment, some of which still works in truss plants sixty years later. Speed Cut Inc. was formed in Corvallis, OR in 1962 to leverage sales of a time-saving length-measuring device. This hand-crank-operated mechanism, with one-footon-center stops, locked in the cut length of a board and could be added upstream of the Mooradian or any other pull-saw. In 1965, after the Mooradian patent expired, Speed Cut combined a good imitation of the Mooradian with their measuring device and christened the combined entity as the Metra-Cut Saw. Then in 1971, they added the turntable, which was targeted specifically for truss cutting. Wayne Roberts later assumed ownership of Speed Cut, where he continued to foster innovation.

Continued next page

PHONE: 800-289-5627

Read/Subscribe online at www.componentadvertiser.com

FAX: 800-524-4982