A

Th e

Component Manufacturing dverti$er

Don’t Forget! You Saw it in the

Adverti$er

November 2019 #11244 Page #38

How Smooth are Your Splices?

Q

uality trusses with smooth splices help ensure quality ceilings and floor finishes, but several factors may affect their execution.

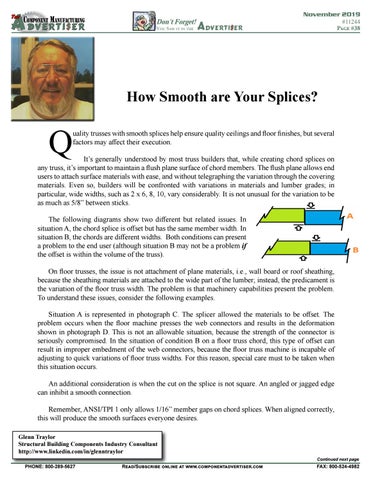

It’s generally understood by most truss builders that, while creating chord splices on any truss, it’s important to maintain a flush plane surface of chord members. The flush plane allows end users to attach surface materials with ease, and without telegraphing the variation through the covering materials. Even so, builders will be confronted with variations in materials and lumber grades; in particular, wide widths, such as 2 x 6, 8, 10, vary considerably. It is not unusual for the variation to be as much as 5/8” between sticks. The following diagrams show two different but related issues. In situation A, the chord splice is offset but has the same member width. In situation B, the chords are different widths. Both conditions can present a problem to the end user (although situation B may not be a problem if the offset is within the volume of the truss). On floor trusses, the issue is not attachment of plane materials, i.e., wall board or roof sheathing, because the sheathing materials are attached to the wide part of the lumber; instead, the predicament is the variation of the floor truss width. The problem is that machinery capabilities present the problem. To understand these issues, consider the following examples. Situation A is represented in photograph C. The splicer allowed the materials to be offset. The problem occurs when the floor machine presses the web connectors and results in the deformation shown in photograph D. This is not an allowable situation, because the strength of the connector is seriously compromised. In the situation of condition B on a floor truss chord, this type of offset can result in improper embedment of the web connectors, because the floor truss machine is incapable of adjusting to quick variations of floor truss widths. For this reason, special care must to be taken when this situation occurs. An additional consideration is when the cut on the splice is not square. An angled or jagged edge can inhibit a smooth connection. Remember, ANSI/TPI 1 only allows 1/16” member gaps on chord splices. When aligned correctly, this will produce the smooth surfaces everyone desires. Glenn Traylor Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor Continued next page

PHONE: 800-289-5627

Read/Subscribe online at www.componentadvertiser.com

FAX: 800-524-4982