Groundwater Monitoring Report

Independence, Missouri

Prepared for Independence Power & Light

Prepared by Barr Engineering Co.

February 2025

Groundwater Monitoring Report

Independence, Missouri

Prepared for Independence Power & Light

Prepared by Barr Engineering Co.

February 2025

Table 1 IPL Well Construction Summary

Table 2 Groundwater Elevation Summary

Table 3 Groundwater Analytical Summary

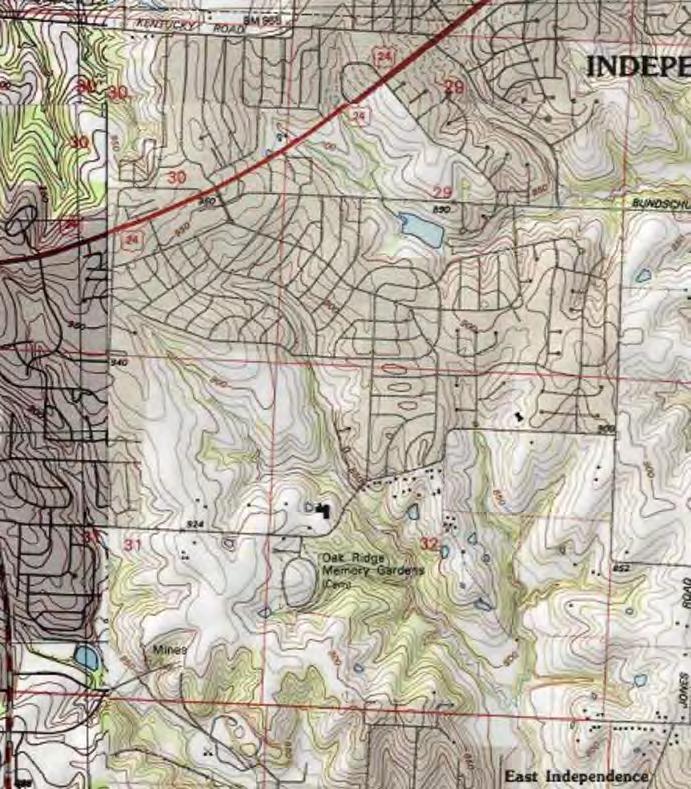

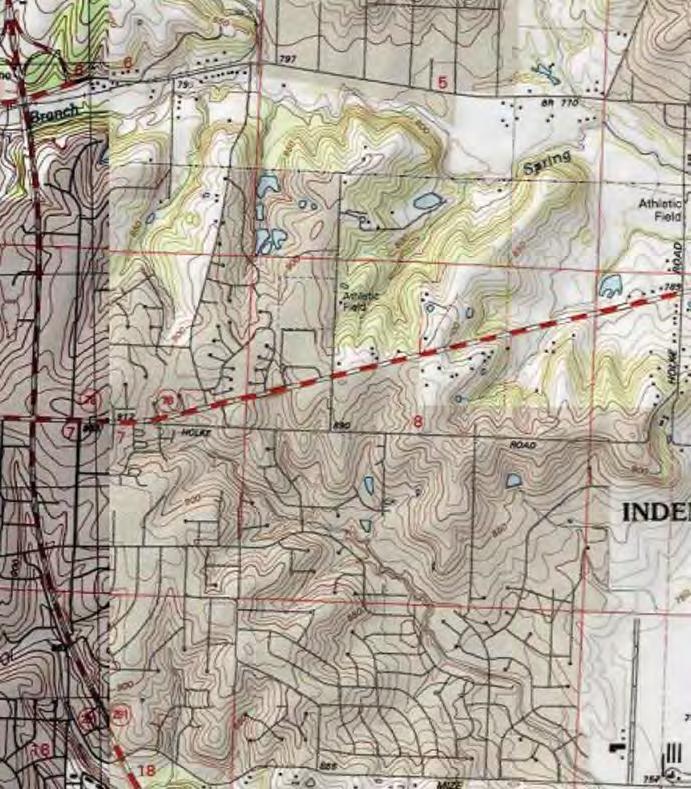

Figure 1 Site Location

Figure 2 Site Layout

Figure 3 Monitoring Well Locations

Figure 4 Groundwater Contours – June 2024

Figure 5 Groundwater Contours – December 2024

Figure 6 June 2024 Groundwater Concentrations

Figure 7 December 2024 Groundwater Concentrations

Appendix A Hydrographs

Appendix B Field Notes

Appendix C Laboratory Analytical Data

CCR coal combustion residual

COC chain of custody

GMSAP Groundwater Monitoring Sampling and Analysis Plan

gpm gallons per minute

IPL Independence Power and Light

MCL maximum contaminant level

MDNR Missouri Department of Natural Resources

MRBCA Missouri Risk-Based Corrective Action

MSL mean sea level

MSOP Missouri State Operating Permit

ORP oxidation-reduction potential

QC Quality Control

USDA United States Department of Agriculture

USEPA United States Environmental Protection Agency

Independence Power and Light (IPL) owns three closed and capped, former coal combustion residuals (CCR) impoundments totaling approximately 54-acres, at the Blue Valley Power Plant (Site) in Independence, Missouri (Figure 1). The Missouri State Operating Permit (MSOP), MO-0115924, Part C. Special Condition 16., for the facility outlines a list of requirements that includes groundwater monitoring for the site.

On behalf of the Independence Power and Light (IPL), Barr Engineering Co. (Barr) has prepared this 2024 Groundwater Monitoring Report for the IPL Blue Valley Power Plant Facility located at 21500 East Truman Road in Independence, Missouri.

Project sampling activities conducted in June and December 2024 included routine groundwater monitoring and well inspections. This report presents the field data and analytical results for both of the 2024 monitoring events.

The Facility was constructed in 1958 as a tri-fuel steam electric power plant that burned coal, diesel, and natural gas until 2015, when it ceased power production from coal and diesel and was converted to a natural gas facility. Two of the original CCR impoundments, the south fly ash pond, and bottom ash pond were built in 1978. The north fly ash pond was constructed in 1989. The Facility sluiced bottom ash and fly ash into the ponds until 2015. Upon the discontinuation of ash sluicing into the CCR impoundments, the former impoundments became “inactive surface impoundments” subject to the requirements of the Federal CCR Rule, 40 CFR 257.100, Subpart D. The Notice of Closure Completion for all three former impoundments was submitted to MDNR on December 19, 2017.

The Site is located approximately seven miles south of the Missouri River in the north central portion of Jackson County at 21500 East Truman Road in Independence, Missouri in Section 3, Township 49N, and Range 31W. Figure 2 displays the Site location and impoundment boundary. The Site is located within the Central Irregular Plains Ecoregion of west central Missouri. Potential natural vegetation of this ecoregion includes a mix of grassland and forest, with forested areas particularly located along streams (Purdue, 2020). Land use adjacent to the Site, displayed on Figure 2, is primarily industrial and agricultural, with industries located north, south, and west of the Site and agricultural land located to the east. An isolated residential area is also located north of the Site.

Regional topography is characterized by hills and associated dendritic drainage patterns with approximately 150 feet of relief within one mile of the Site. Hills north and west of the Facility have elevations as high as 900 feet above mean sea level (MSL). The Site has features with elevations that range from approximately 750 to 800 feet above MSL and slope from the northwest to southeast (Figure 1). A topographic divide, located in the southwest portion of the Site, separates the Little Blue River and Burr Oak-Creek-Little Blue River subwatersheds (Hydrologic Unit Code 12).

The surficial soils of the region and portions of the Site outside the former impoundments consist primarily of unconsolidated alluvial sediments known as the Sibley Silt Loam series. According to the Soil Survey of Jackson County, Missouri (1984) developed by the United States Department of Agriculture (USDA), the Sibley Silt Loam is a friable, moderate permeability soil with naturally high fertility (USDA, 1984). The

surface layer is generally dark brown, the middle sections can be dark brown to grey, and the lower sections are generally more clayey and dark yellowish-brown with various mottles.

Based on the report, City of Independence, Missouri, Blue Valley Generating Station Ash Pond Addition and Other Improvements (Burns and McDonnell, 1977), the subsurface soil in the proximity of the former impoundments consists primarily of silty clay with interbedded seams of fine-grained, uncompacted sandy silt. The report provides descriptive logs for 27 borings drilled in a grid pattern encompassing the area of the former fly ash and bottom ash ponds. The borings ranged in depth from 10 feet to 64 feet bgs.

The bedrock underlying the region and Site consists of Pennsylvanian aged shales, limestones, sandstone, and siltstones with interbedded coal seams. Naturally occurring crude oil was identified in upgradient borings during the Site Characterization performed in 2020. The Pennsylvanian-aged shales overly older Mississippian aged formations (MDNR, 1997).

The Pennsylvanian-aged Pleasanton Group is the first bedrock unit encountered in the region, located approximately 25 feet bgs. The Pleasanton Group is predominantly a thick unit of shale with limestone and a basal unit of siltstone or very fined-grained sandstone. Two additional sandstone units, which combined are known as the Warrensburg Sandstone, are sometimes present in the upper half of the group depending on the location. The base of the Pleasanton Group marks a break in the depositional sequence occurring in the Pennsylvanian time. This break in the depositional sequence forms a regional disconformity. Underlying the Pleasanton Group bedrock unit is the Marmaton Group. The Marmaton Group is comprised mainly of thick shales with intervening thin layers of limestone and sandstone.

The hydrogeology around the Site is represented by the Missouri River alluvium and Lake City alluvium, two groundwater subprovinces of the West-Central groundwater province. The Site is primarily located within the Missouri River alluvium, which borders the Lake City alluvium just east of the Site near the Little Blue River. Information describing the West-Central groundwater province and each subprovince is provided below.

The West-Central groundwater province is bounded by the Missouri River to the north, the Springfield Plateau groundwater province to the south and east, and the Kansas state boundary to the west. The greatest potential for groundwater yield within this province is from the alluvial deposits along the northern edge of the province, which include the Missouri River alluvium and Lake City alluvium, further described below. Pennsylvanian-aged formations comprise the bedrock surface units for most of this groundwater province, specifically the Pleasanton and Marmaton Groups in the area of the Site. The Pleasanton and Marmaton Groups in the region have low recharge potential due to their extremely low horizontal and vertical permeabilities and are not considered to be water bearing; the Pleasanton Group is considered to be less productive than the Marmaton Group (MDNR, 2021). Of the small amounts of groundwater that may potentially be drawn from these groups, the groundwater is expected to be of poor quality.

The Missouri River alluvium province is located at the northern portion of the West-Central groundwater province and extends for the entire length of the Missouri River throughout the state with an aerial extent of approximately 440 square miles in the vicinity of the Site. The Missouri River alluvium formed from glacial meltwater runoff during the Pleistocene epoch (Ice Age); the melt water transported a significant amount of sediments that ranged in size from clay particles to boulders, which carved a river channel much wider than the channel occupied by the Missouri River today. Following the Pleistocene epoch, over-bank flooding of present-day rivers has deposited additional alluvium on river floodplains. The

Missouri River and the Missouri River alluvium province experience delayed recharge; studies of wells within the alluvium indicated a delayed response of several days between river stages and groundwater levels. Under normal flow conditions in the Missouri River, groundwater gradients in the Missouri River alluvium are toward the river (MDNR, 1997).

In the report Groundwater Resources of Missouri (MDNR, 1997), the Missouri River alluvium is divided into four segments from the Iowa border to St. Charles, prior to the Missouri River and Mississippi River confluence. For the purpose of this project, the portion of the Missouri River alluvium province discussed in this section is the Kansas City to Miami, Missouri segment. The Missouri River alluvium in this segment composed primarily of fine sand, silt, and clay with coarse sands and gravels comprising the deeper portions of the alluvium. The alluvium has a maximum thickness of 140 feet and an average thickness of 85 to 90 feet. The average saturated thickness of the alluvium is approximately 75 feet for this area. Groundwater from wells within the Missouri River alluvium supplies a majority of the potable water in the Kansas City area. Yields from the Missouri River alluvium may reach 1,000 to 1,500 gallons per minute (gpm) in the more permeable areas of the alluvium (MDNR, 1997).

The Lake City alluvium groundwater subprovince is a 16-mile-long, 1-2-mile-wide channel that begins at the southern edge of the Missouri River alluvium in central Jackson County near the town of Atherton, extends southeast to Lake City, and then trends northeast until it again intersects with the Missouri River alluvium in northeastern Jackson County near the town of Levasy. The Lake City alluvial channel likely formed as a result of an ice damming event on the ancestral Missouri River, which forced the river south of the existing channel and eroded the new channel, which currently serves as the river valley for the Little Blue River from Lake City to the Missouri River. The Site is located on the western edge of the Lake City alluvium channel. A study of this alluvium aquifer at the Lake City Army Ammunition Plant in the early 1940s estimated the alluvium’s thickness to 80 to 90 feet with a depth to water of 15 to 20 feet bgs. Well pumping rates during this study reached 300 to 400 gpm (MDNR, 1997).

Hydrogeologic monitoring at the Site includes the collection of groundwater elevation data from Site monitoring wells. The monitoring well locations at the Site are shown on Figure 3 and well construction information is located in Table 1.

During the two Quarterly 2024 monitoring events, water-levels were collected from the eight (8) routinely scheduled groundwater monitoring wells. The resultant elevation data were used to develop potentiometric surface flow maps, assess flow direction, and calculate gradients for the shallow groundwater. A summary of all groundwater elevation data is included as Table 2.

The groundwater elevation data from the Site’s shallow monitoring wells were contoured to construct potentiometric surface maps for each quarterly event. As graphically illustrated on Figures 4 and 5 groundwater flows generally towards the east which is consistent with historic water elevation data for the Site.

The calculated hydraulic gradient for each of the Quarterly 2024 monitoring events is provided below:

Hydraulic gradients measured across the Site range from 0.002 to 0.004 (range of gradients from three different areas of the Site) for the Quarterly 2024 groundwater elevation data (Table 2). The hydraulic gradient measured across the northwestern portion of the Site (MW-6 to MW-8) was calculated to be0.004 for June 2024 and 0.003 for December 2024. The hydraulic gradient measured across the northeastern portion of the Site (MW-1 to MW-8) was calculated to be 0.002 for June 2024 and 0.002 for December 2024. The hydraulic gradient measured across the central portion of the Site (MW-6 to MW-1) was calculated to be 0.004 for June 2024 and 0.003 for December 2024. It should be noted that water levels measured in the upgradient wells may not be representative of actual static water levels since stabilization subsequent to purging can take several weeks.

The average hydraulic gradient is towards the east with a slope of approximately 0.004 for June and 0.003 for December across the entire Site. This slope is relatively shallow as compared to previous years likely due to the varying water elevations in the upgradient monitoring wells. An approximate average interstitial velocity across the Site has been estimated to range from 1.6 x 10-3 feet/day to 5.7 x 10-4 feet/day (i.e. 2.1 to 0.58 feet/year) for June 2024 and 4.5 x 10-3 feet/day to 1.2 x 10-3 feet/day (i.e. 1.6 to 0.45 feet/year) for December 2024 as calculated by the following equation and input data:

v = Ki/n, where

v = average interstitial velocity

K = hydraulic conductivity (ranges from 0.388 to 0.171 feet/day)

i = average hydraulic gradient across the Site (0.004 and 0.003)

n = effective porosity (estimated to range from 0.25 to 0.4)

Overall, groundwater elevations measured in wells during the two Quarters of 2024 monitoring events were relatively consistent with the data from the measurements taken during the previous sampling events (Barr, 2024). Hydrographs of the groundwater elevations are provided in Appendix A.

Due to the relatively higher recharge rates the downgradient well groundwater elevations have not changed significantly from previous monitoring periods. The greatest variance of water level elevations observed in the downgradient wells during 2024 is a water level decrease of 2.97 feet in monitoring well MW-5. This groundwater elevation change represents measurements with seasonal flux and significantly drier/wetter periods. Additionally, water levels within MW-2 are generally higher than other downgradient wells. The elevated water level is thought to be connected to an impoundment let-down structure located northwest of the well. The let-down structure can be the cause of increased runoff or focused recharge near MW-2, which can create the presence of a groundwater mound.

The groundwater elevation fluctuations in the upgradient wells are significantly more prominent than the changes observed in the downgradient wells, however this may be primarily due to the slow recharge times of the upgradient wells. During several monitoring events the water levels measured immediately prior to sampling in the upgradient wells did not appear to be completely stabilized subsequent to purging. The groundwater elevations for the upgradient wells have been observed to change up to 1.76 feet at MW-7 and 3.37 feet at MW-6 between groundwater sampling events in 2024. It should be noted that the groundwater levels observed in MW-8 over the last nine monitoring events differs from the levels of the other wells. The hydrograph for MW-8 indicates that since the first quarterly monitoring event the water levels in MW-8 have potentially not completely recovered after purging. The water levels for MW-8 during the second through eighth quarterly events are on average 11 feet lower than the water level measured during the first quarterly event. Either MW-8 has been experiencing significantly reduced recharge for that time period, there was an influx of groundwater immediately prior to the first quarterly event, or the well has not been completely recharging between the quarterly sampling events.

Groundwater levels for active monitoring wells are presented in Table 2.

No modifications have been made to the monitoring network since well installation in 2019.

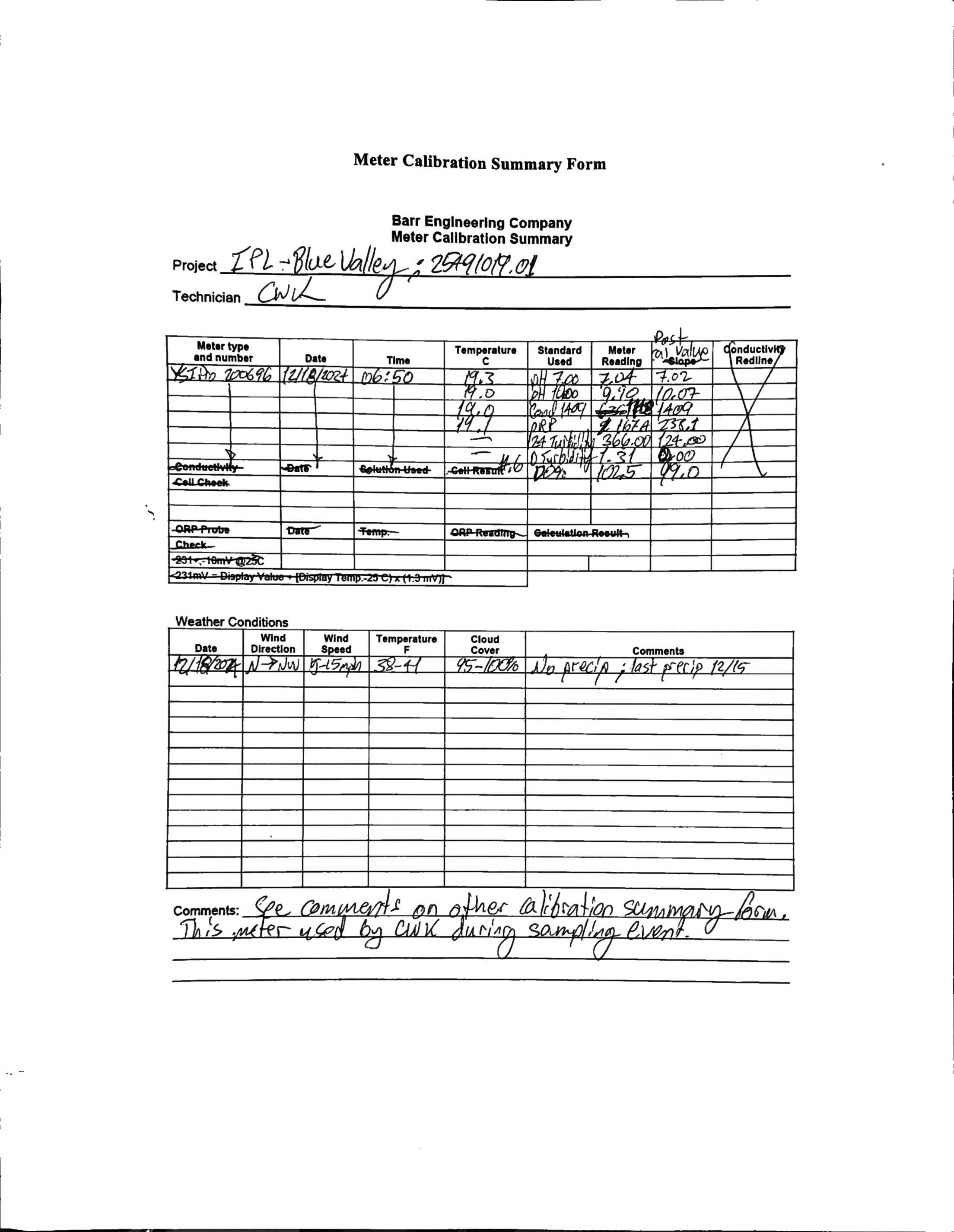

The field methods for the collection of the samples are described in the Groundwater Monitoring Sampling and Analysis Plan (GMSAP) (Barr, 2021).

During the 2024 monitoring events, the sampling crew measured the static water levels in each of the eight active monitoring wells at the site and visually inspected each well’s condition. Any evidence of well damage was documented in the field documents (Appendix B). Table 1 contains a summary of the monitoring well construction including well number designation, measured total depth, elevation for top of screen, and the measured static water level for each well.

Prior to the December 2024 sampling event, all eight active monitoring wells at the Site were redeveloped. The well redevelopment was conducted using a surge block to break down any potential sediment or disturbed zones where fine-grained particles may be concentrated in the well screen and overpumping via a submersible pump. All wells were pumped until the water became visibly clear or the well purged dry.

Groundwater samples were collected at two quarterly sampling events (June 2024 and December 2024) from the eight active monitoring wells at the Site. Groundwater sampling was conducted using bailers and low stress (low flow) methodology in compliance with the GMSAP (Barr, 2021). For the wells sampled via low stress (low flow) methodology, a submersible pump was lowered into the well screen and pumped at the lowest possible rate until measurements of temperature, pH, specific conductivity, dissolved oxygen, turbidity, and ORP stabilized. These parameters can be found on the field logs in Appendix B. The low flow sampling was performed in compliance with Section 3.0, Section 4.0, and Appendix D of the GMSAP.

For the wells sampled via bailers, the wells were purged at least three weeks prior to the sampling events. During the sampling event the bailers were extracted from the wells and the samples collected. Water quality parameters were collected via bailer immediately subsequent to the sample collection.

For quality control (QC) purposes duplicate samples were collected during each sampling event. During both sampling events, duplicate samples were collected from downgradient well MW-5 for the June sampling event and MW-4 for the December sampling event.

Groundwater samples were collected at all monitoring wells installed at the Site. Table 3 summarizes the groundwater concentration data from the wells and compares the concentrations against EPA’s MCLs (40 CFR 141.62 and 257.95). Groundwater samples from the June 2024 sampling event that exceeded EPA’s MCLs are shown on Figure 6. The laboratory analytical results are provided in Appendix C.

Groundwater concentration exceedances of the United States Environmental Protection Agency (USEPA) MCLs for total/dissolved arsenic and total/dissolved lithium were identified in some of the samples both upgradient and downgradient of the closed impoundments. The following list summarizes the exceedances for each constituent:

• Total and dissolved arsenic: Groundwater concentrations exceeded the arsenic MCL of 10 µg/L at downgradient monitoring wells MW-3 and MW-4. Total arsenic concentrations at the wells ranged from 53.7 to 61 µg/L. Dissolved arsenic concentrations in these wells range from 14.3 to 16.4 ug/L.

• Total and dissolved lithium: Groundwater concentrations exceed the lithium MCL of 40 µg/L at upgradient monitoring wells MW-1, MW-6, MW-7, and MW-8. Total lithium concentrations at the wells ranged from 48.5 to 141 µg/L. Dissolved lithium concentrations at the wells ranged from 55 to 79.1 µg/L.

During the December 2024 sampling event, groundwater samples were collected from all eight monitoring wells installed at the Site. Groundwater samples from the December 2024 sampling event that exceeded EPA’s MCLs on Figure 7.

Groundwater concentration exceedances of the USEPA MCLs for total/dissolved arsenic and total/dissolved lithium were identified in some of the samples in wells both upgradient and downgradient of the closed impoundments. The following list summarizes the exceedances for each constituent:

• Total and dissolved arsenic: Groundwater concentrations exceeded the total arsenic MCL of 10 µg/L at downgradient monitoring wells MW-2, MW-3, and MW-4. Total arsenic concentrations at these wells ranged from 13.8 to 89.5 J µg/L. Groundwater concentrations exceeded the dissolved arsenic MCL of 10 µg/L at downgradient monitoring wells MW-3 and MW-4. Dissolved concentrations in these wells range from 31.5 to 63.2 ug/L.

• Total and dissolved lithium: Groundwater concentrations exceed the lithium MCL of 40 µg/L at upgradient monitoring wells MW-6 and MW-8. The total lithium concentrations for wells MW-6 and MW-8 were 54.8 and 95.5 µg/L respectively. The dissolved lithium concentrations for wells MW-6 and MW-8 were 73 and 100 µg/L respectively.

The results of the 2024 groundwater sampling events at the Site have been summarized in the previous sections and the conclusions and recommendations based on those results are outlined in the following paragraphs.

Upgradient and downgradient groundwater sample concentrations indicate that the groundwater contains metals concentrations for arsenic and lithium that exceed the MCLs in some of the upgradient and downgradient wells. As discussed in the Site Characterization Report (Barr, 2020), the native materials at the Site contain concentrations of metals that exceed the Missouri Risk-Based Corrective Action (MRBCA) Default Target Levels and are naturally occurring metals in the native materials that are typically associated with CCR material. Therefore, the native soil around the former impoundments is likely to be a source for metals in the groundwater.

The upgradient wells MW-6, MW-7, and MW-8 have lithium concentrations that exceed the USEPA MCLs. Since these wells are upgradient of the CCR impoundments, it is unlikely that these concentrations are a result of the impoundment materials. As discussed above, the lithium concentrations are very likely natural occurring from the native materials. Also, the detection of lithium in downgradient wells would represent continued presence of lithium in the groundwater is it moves downgradient as is not likely related to the impoundments.

Historically the dissolved arsenic concentrations in the downgradient monitoring wells have been below or slightly over the total arsenic MCL of 10 µg/L. In comparison, the total arsenic concentrations in the downgradient monitoring wells with the exception of MW 5 have exceeded the total arsenic MCL of 10 µg/L and typically range from 20 to 40. µg/L. The disparity between the dissolved and total concentrations is usually due to fine-grained suspended particulates in the water column that are included with the sample volume. These fine-grained particulates bias the sample and result in an elevated total concentration. The December 2024 sampling event resulted in elevated arsenic concentrations for both the dissolved and total samples. As this is the first occurrence of this situation in the groundwater program, it is unclear as to what may be the reason for the increase in arsenic concentrations. It should be noted that arsenic was not detected above 10 ug/L in the furthest downgradient well, MW5, during either June or December 2024 sampling events. Since the elevated arsenic concentrations have only been detected during a single event, it is recommended that continued groundwater monitoring in compliance with the proposed GMSAP will be utilized to continue monitoring these and other parameters to identify their potential source, concentrations trends, and representativeness in the shallow groundwater as needed.

Results of the Site Characterization Report (Barr, 2020) indicates that the shallow groundwater underlying the site migrates slowly, particularly in the upgradient wells, due to the fine-grained nature/low permeability of the unconsolidated units underlying the former impoundments.

The groundwater data continues to be consistent with previous observations made regarding groundwater flow and direction. The groundwater flow at the Site is primarily to the east/southeast and groundwater underlying the former impoundments migrates primarily through the sand layers in the unconsolidated units.

Since groundwater contact with the impoundment material is limited, it is unlikely that leaching of metals from CCR materials is occurring via lateral groundwater movement through the former impoundment. In addition, to date, groundwater elevations measured from groundwater wells do not indicate that groundwater is migrating through CCR materials in the northwest corner of the impoundment area. Therefore, the potential for COCs to migrate is primarily via vertical leaching of the low volumes of meteoric water that infiltrates through the engineered cap.

Barr, 2024. Blue Valley Coal Combustion Residuals Impoundment Baseline Monitoring Statistical Summary Report, Independence Power and Light Blue Valley Power Plant, Independence, Missouri. February 2024.

Barr, 2021. Blue Valley Coal Combustion Residuals Impoundment Groundwater Monitoring Sampling and Analysis Plan, Independence Power and Light Blue Valley Power Plant, Independence, Missouri. July 2021.

Barr, 2020. Blue Valley Coal Combustion Residuals Impoundment Site Characterization Report, Independence Power and Light Blue Valley Power Plant, Independence, Missouri. May 2020.

Burns and McDonnell, 1977. City of Independence, Missouri, Blue Valley Generating Station Ash Pond Addition and Other Improvements, May 1977.

Freeze, R. A. and J. A. Cherry, 1979. Groundwater, Prentice-Hall, Inc., Englewood Cliffs, New Jersey, 604p.

Missouri Department of Natural Resources, 2021. Geosciences Technical Resources Assessment Tool Website, URL: https://dnr.mo.gov/geology/geostrat.htm. Accessed January 2020.

Missouri Department of Natural Resources Division of Geology and Land Survey, 1997. Groundwater Resources of Missouri, Don E. Miller, 1997.

Purdue University, 2020. Primary Distinguishing Characteristics of Level III Ecoregions of the Continental United States Website, URL: https://hort.purdue.edu/newcrop/cropmap/ecoreg/descript.html#40.

Accessed July – September, 2019.

US Department of Agriculture, 1984. Soil Survey of Jackson County, Missouri. September 1984

(1) Elevations were surveyed on 5/5/2020.

LocationMW-4MW-5 Date12/18/20246/11/2024

ParameterUnits

Last Updated 04/01/202408/28/2020 Exceedance KeyBold Underline

General Parameters

Carbon, total organicug/l33001200100018001800180062006800710013001500210028003300<

Chemical Oxygen

Chlorideug/l630005050047000584002000017700<

Fluorideug/l4000270<

Hardness, as CaCO3ug/l4500004020005990007450004910006380002850003320002780002550002940003240001980002070006260054500141000200000 Nitrogen, nitrate + nitrite, as Nug/l10000<

Nitrogen, nitrate, as

Nitrogen, nitrite, as Nug/l1000<

Solids, total dissolvedug/l780000514000888000852000726000750000514000610000630000422000450000434000898000884000614000658000584000556000 Sulfate, as SO4ug/l1680006600029600012300027000<

Dissolved Metals

Arsenicug/l

Bariumug/l200065.593.861234447976426755754226625931858259213715815838.4

Boronug/l3790151028.5<

Calciumug/l156000103000175000187000134000143000756008230080800778007890081000548005120014200157005310013600

Cobaltug/l62.91.6<

Copperug/l1300 TT(12)<

Ironug/l1430125047910400668139004522120020200<

Lithiumug/l4051.410.817.711.47.56.914.213.513.43.43.63.458.354.852.837.683.395.5

Magnesiumug/l164001410031400346003120033800168001810018000188001710017500131001210037704240<

Manganeseug/l60803500471065702310222014201560153014001470160020911935.449.0<

Molybdenumug/l1002.7<

Nickelug/l4.1<

Sodiumug/l557003430010300148007240077600706008150078500454004460048500220000230000202000226000171000202000

Total Metals

Aluminumug/l<

Arsenicug/l 10

Bariumug/l200087.41537438129271130632740558288

Boronug/l3990199032.754.784.6125170185149<

J411616786188150173218

Calciumug/l15300014000018300025000014000019700079100106000798007380077600101000570006280017000146005660079600

Cobaltug/l63.12.3<

Copperug/l1300

Ironug/l7420209017300118001860014500236002140022600<

Lithiumug/l4055.015.520.016.28.610.616.919.414.33.83.85.255.373.060.038.179.1100

Magnesiumug/l16700128003430029600341003550021200165001920017100 J24400 J17400134001210049104350<

Manganeseug/l107003420494070902580245018602320

Molybdenumug/l1003.61.8<

Sodiumug/l536002790010400119007480063900681006700087300432004240050400216000251000187000228000166000197000 Sample Type

Not analyzed/Not available.

NSample Type: Normal

FDSample Type: Field Duplicate

BThe analyte was detected in the associated laboratory blank sample(s).

HRecommended sample preservation, extraction or analysis holding time was exceeded.

J

Estimated detected value. Either certain QC criteria were not met or the concentration is between the laboratory's detection and quantitation limits.

J-The result is an estimated quantity and may be biased low.

J+The result is an estimated quantity and may be biased high.

UThe analyte was analyzed for, but was not detected.

UB

UH

The analyte was detected in one of the associated laboratory, equipment, field or trip blank samples and is considered non-detect at the concentration reported by the laboratory.

The analyte was analyzed for, but was not detected. The recommended sample preservation, extraction or analysis holding time was exceeded.

UJ-The analyte was analyzed for, but was not detected. The result is an estimated quantity and may be biased low.

(19)At no time can turbidity go above 5 NTU.

TT(12)Treatment technique; Copper action level 1.3 mg/l; lead action level 0.015 mg/l.

EPA Maximum Contaminant Levels Page 1 of 1 2/7/2025

North Fly Ash Impoundment (Closed)

South Fly Ash Impoundment (Closed) Bottom Ash Impoundment (Closed)

Bottom Ash Impoundment (Clean Closure and Converted to a Sedimentation Basin) Independence

6/11/2024 Dissolved

6/11/2024 Dissolved

6/11/2024

6/11/2024

6/11/2024

MW-4 6/11/2024

12/18/2024

12/18/2024

DissolvedArsenic 63.2 ug/l

June 19, 2024

Andrea Nord Barr Engineering Company

http://www.teklabinc.com/

Illinois100226

Illinois1004652024-2

KansasE-10374

Louisiana05002

Louisiana05003

Oklahoma9978

TEL: FAX:

1001 Diamond Ridge Suite 1100 Jefferson City, MO 65109 (952) 832-2893 (573) 638-5001

WorkOrder: 24060969 #25491019 RE:

Dear Andrea Nord:

TEKLAB, INC received 10 samples on 6/12/2024 12:15:00 PM for the analysis presented in the following report.

Samples are analyzed on an as received basis unless otherwise requested and documented. The sample results contained in this report relate only to the requested analytes of interest as directed on the chain of custody. NELAP accredited fields of testing are indicated by the letters NELAP under the Certification column. Unless otherwise documented within this report, Teklab Inc. analyzes samples utilizing the most current methods in compliance with 40CFR. All tests are performed in the Collinsville, IL laboratory unless otherwise noted in the Case Narrative.

All quality control criteria applicable to the test methods employed for this project have been satisfactorily met and are in accordance with NELAP except where noted. The following report shall not be reproduced, except in full, without the written approval of Teklab, Inc.

If you have any questions regarding these tests results, please feel free to call.

Sincerely,

Patrick Riley Project Manager

(618)344-1004 ex 44 patrickriley@teklabinc.com

Client: Barr Engineering Company

Client Project: #25491019

AbbrDefinition

*Analytes on report marked with an asterisk are not NELAP accredited

http://www.teklabinc.com/

Work Order: 24060969

Report Date: 19-Jun-24

CCVContinuing calibration verification is a check of a standard to determine the state of calibration of an instrument between recalibration.

CRQLA Client Requested Quantitation Limit is a reporting limit that varies according to customer request. The CRQL may not be less than the MDL.

DFDilution factor is the dilution performed during analysis only and does not take into account any dilutions made during sample preparation. The reported result is final and includes all dilution factors.

DNIDid not ignite

DUPLaboratory duplicate is a replicate aliquot prepared under the same laboratory conditions and independently analyzed to obtain a measure of precision.

ICVInitial calibration verification is a check of a standard to determine the state of calibration of an instrument before sample analysis is initiated.

IDPHIL Dept. of Public Health

LCSLaboratory control sample is a sample matrix, free from the analytes of interest,spiked with verified known amounts of analytes and analyzed exactly like a sample to establish intra-laboratory or analyst specific precision and bias or to assess the performance of all or a portion of the measurement system.

LCSDLaboratory control sample duplicate is a replicate laboratory control sample that is prepared and analyzed in order to determine the precision of the approved test method. The acceptable recovery range is listed in the QC Package (provided upon request).

MBLKMethod blank is a sample of a matrix similar to the batch of associated sample (when available) that is free from the analytes of interest and is processed simultaneously with and under the same conditions as samples through all steps of the analytical procedures, and in which no target analytes or interferences should present at concentrations that impact the analytical results for sample analyses.

MDL"The method detection limit is defined as the minimum measured concentration of a substance that can be reported with 99% confidence that the measured concentration is distinguishable from method blank results."

MSMatrix spike is an aliquot of matrix fortified (spiked) with known quantities of specific analytes that is subjected to the entire analytical procedures in order to determine the effect of the matrix on an approved test method’s recovery system. The acceptable recovery range is listed in the QC Package (provided upon request).

MSDMatrix spike duplicate means a replicate matrix spike that is prepared and analyzed in order to determine the precision of the approved test method. The acceptable recovery range is listed in the QC Package (provided upon request).

MWMolecular weight

NCData is not acceptable for compliance purposes

NDNot Detected at the Reporting Limit

NELAPNELAP Accredited

PQLPractical quantitation limit means the lowest level that can be reliably achieved within specified limits of precision and accuracy during routine laboratory operation conditions.

RLThe reporting limit the lowest level that the data is displayed in the final report. The reporting limit may vary according to customer request or sample dilution. The reporting limit may not be less than the MDL.

RPDRelative percent difference is a calculated difference between two recoveries (ie. MS/MSD). The acceptable recovery limit is listed in the QC Package (provided upon request).

SPKThe spike is a known mass of target analyte added to a blank sample or sub-sample; used to determine recovery deficiency or for other quality control purposes.

SurrSurrogates are compounds which are similar to the analytes of interest in chemical composition and behavior in the analytical process, but which are not normally found in environmental samples.

TICTentatively identified compound: Analytes tentatively identified in the sample by using a library search. Only results not in the calibration standard will be reported as tentatively identified compounds. Results for tentatively identified compounds that are not present in the calibration standard, but are assigned a specific chemical name based upon the library search, are calculated using total peak areas from reconstructed ion chromatograms and a response factor of one. The nearest Internal Standard is used for the calculation. The results of any TICs must be considered estimated, and are flagged with a "T". If the estimated result is above the calibration range it is flagged "ET"

TNTCToo numerous to count ( > 200 CFU )

Client: Barr Engineering Company

Client Project: #25491019

# - Unknown hydrocarbon

C - RL shown is a Client Requested Quantitation Limit

H - Holding times exceeded

J - Analyte detected below quantitation limits

ND - Not Detected at the Reporting Limit

S - Spike Recovery outside recovery limits

X - Value exceeds Maximum Contaminant Level

http://www.teklabinc.com/

Work Order: 24060969

Report Date: 19-Jun-24

B - Analyte detected in associated Method Blank

E - Value above quantitation range

I - Associated internal standard was outside method criteria

M - Manual Integration used to determine area response

R - RPD outside accepted recovery limits

T - TIC(Tentatively identified compound)

Client: Barr Engineering Company

Client Project: #25491019

Cooler Receipt Temp: 4.1 °C

http://www.teklabinc.com/

Work Order: 24060969

Report Date: 19-Jun-24

Collinsville

5445 Horseshoe Lake Road

Collinsville, IL 62234-7425 (618) 344-1004 (618) 344-1005

jhriley@teklabinc.com

Collinsville Air

5445 Horseshoe Lake Road Collinsville, IL 62234-7425 (618) 344-1004 (618) 344-1005

EHurley@teklabinc.com

Locations

Springfield 3920 Pintail Dr Springfield, IL 62711-9415 (217) 698-1004 (217) 698-1005

KKlostermann@teklabinc.com

Chicago

1319 Butterfield Rd. Downers Grove, IL 60515 (630) 324-6855

arenner@teklabinc.com

Kansas City 8421 Nieman Road Lenexa, KS 66214 (913) 541-1998 (913) 541-1998

jhriley@teklabinc.com

Client Project: #25491019

Client: Barr Engineering Company Report Date: 19-Jun-24

State

Work Order: 24060969

Dept

Illinois 100226

1/31/2025 Collinsville NELAP IEPA

Illinois 1004652024-2 4/30/2025 Collinsville NELAP IEPA

Kansas E-10374 4/30/2025 Collinsville NELAP KDHE

Louisiana 05002 6/30/2024 Collinsville NELAP LDEQ

Louisiana 05003 6/30/2024 Collinsville NELAP LDEQ

Oklahoma 9978 8/31/2024 Collinsville NELAP ODEQ

Arkansas 88-0966 3/14/2025 Collinsville ADEQ

Illinois 17584 5/31/2025 Collinsville IDPH

Iowa 430 6/1/2026 Collinsville IDNR

Kentucky 0073 1/31/2025 Collinsville UST

Mississippi 4/30/2025 Collinsville MSDH Missouri 930 1/31/2025 Collinsville MDNR Missouri 00930 10/31/2026 Collinsville MDNR

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-001 Client Sample ID: MW-1

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

9251 (TOTAL)

3005A, 6020A, METALS BY ICPMS (DISSOLVED)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 10:25

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-001

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 10:25

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-002 Client Sample ID: MW-2

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

SW-846 9251 (TOTAL)

3005A, 6020A, METALS BY ICPMS (DISSOLVED)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 11:35

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-002

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 11:35

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-003 Client Sample ID: MW-3

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

Certification

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

SW-846 9251 (TOTAL)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 14:35

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-003

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 14:35

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-004 Client Sample ID: MW-4

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

SW-846 9251 (TOTAL)

SW-846 3005A, 6020A, METALS BY ICPMS (DISSOLVED)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 13:30

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-004

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 13:30

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-005 Client Sample ID: MW-5

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 12:03

Matrix spike recovered outside upper control limits. Sample results are below the reporting limit. Data is reportable.

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

9036 (TOTAL)

Matrix spike did not recover within control limits due to matrix interference.

9251 (TOTAL)

STANDARD METHODS 2340 B, HARDNESS (TOTAL) 1997

3005A, 6020A, METALS BY ICPMS (DISSOLVED)

Client Project: #25491019

Client: Barr Engineering Company Report Date: 19-Jun-24 Work Order: 24060969 http://www.teklabinc.com/

06/11/2024 12:03 Lab ID: 24060969-005

Matrix spike did not recover within control limits due to sample composition. Matrix spike control limits are not applicable due to high sample/spike ratio.

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-006 Client Sample ID: MW-6

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

Certification

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

SW-846 9251 (TOTAL)

3005A, 6020A, METALS BY ICPMS (DISSOLVED)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 9:20

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-006

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 9:20

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-007 Client Sample ID: MW-7

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

Certification

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

9251 (TOTAL)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 8:55

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-007

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 8:55

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-008 Client Sample ID: MW-8

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

Certification

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

SW-846 9251 (TOTAL)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 9:50

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-008

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 9:50

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-009

Matrix: GROUNDWATER

http://www.teklabinc.com/ Analyses

Certification

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

9251 (TOTAL)

3005A, 6020A, METALS BY ICPMS (DISSOLVED)

Work Order: 24060969

Report Date: 19-Jun-24

Client Sample ID: Dup-1

Collection Date: 06/11/2024 12:03

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-009 Client Sample ID: Dup-1 Matrix: GROUNDWATER

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 12:03

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-010 Client Sample ID: EB-1

Matrix: AQUEOUS

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

SW-846 9036 (TOTAL)

SW-846 9251 (TOTAL)

SW-846 3005A, 6020A, METALS BY ICPMS (DISSOLVED)

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 14:55

Client: Barr Engineering Company

Client Project: #25491019

Lab ID: 24060969-010

Work Order: 24060969

Report Date: 19-Jun-24

Collection Date: 06/11/2024 14:55

Client Project: #25491019

Client: Barr Engineering Company Report Date: 19-Jun-24

Sample IDClient Sample ID Collection DateReceived Date

Test Name

24060969-001AMW-1

Standard Methods 2540 C (Total) 1997, 2011

06/11/2024 10:2506/12/2024 12:15

Work Order: 24060969

06/14/2024 10:01

Standard Methods 4500-F C (Total) 1997, 2011 06/13/2024 10:32

SW-846 9036 (Total)

SW-846 9251 (Total)

24060969-001BMW-1

06/13/2024 17:47

06/13/2024 17:47

06/11/2024 10:2506/12/2024 12:15

Standard Methods 4500-NO2 B (Total) 2000, 2011 06/12/2024 18:06

Standard Methods 4500-NO3 F (Total) 2000, 2011 06/12/2024 16:39

Standard Methods 4500-NO3 F (Total) 2000, 2011 06/12/2024 16:39

24060969-001CMW-1

Standard Methods 2340 B, Hardness (Total) 1997

SW-846 3005A, 6020A, Metals by ICPMS (Total)

06/11/2024 10:2506/12/2024 12:15

06/18/2024 0:00 06/13/2024 7:16

06/14/2024 17:13 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 15:28 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 15:51 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/18/2024 9:10 06/13/2024 7:16

24060969-001DMW-1

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

06/11/2024 10:2506/12/2024 12:15

06/13/2024 11:25

06/14/2024 14:49

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved) 06/17/2024 12:54 06/13/2024 11:25

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

24060969-001EMW-1

Standard Methods 5310 C 2000, 2011, Organic Carbon

24060969-001FMW-1

Standard Methods 5220 D (Total) 1997

06/11/2024 10:2506/12/2024 12:15

06/11/2024 10:2506/12/2024 12:15

24060969-002AMW-2 06/11/2024 11:3506/12/2024 12:15

Standard Methods 2540 C (Total) 1997, 2011

Standard Methods 4500-F C (Total) 1997, 2011

SW-846 9036 (Total)

SW-846 9251 (Total)

24060969-002BMW-2

Standard Methods 4500-NO2 B (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

06/11/2024 11:3506/12/2024 12:15

06/17/2024 13:16 06/13/2024 11:25

06/14/2024 15:37

06/13/2024 13:54

06/14/2024 10:02

06/13/2024 10:34

06/13/2024 17:55

06/13/2024 17:50

06/12/2024 18:07

06/12/2024 16:42

Standard Methods 4500-NO3 F (Total) 2000, 2011 06/12/2024 16:42

24060969-002CMW-2

Standard Methods 2340 B, Hardness (Total) 1997

SW-846 3005A, 6020A, Metals by ICPMS (Total)

SW-846 3005A, 6020A, Metals by ICPMS (Total)

06/11/2024 11:3506/12/2024 12:15

06/18/2024 0:00 06/13/2024 7:16

06/14/2024 17:19 06/13/2024 7:16

06/17/2024 15:34 06/13/2024 7:16

Client: Barr Engineering Company

Client Project: #25491019

Sample IDClient Sample ID

Test Name

SW-846 3005A, 6020A, Metals by ICPMS (Total)

Collection DateReceived Date

Work Order: 24060969

Report Date: 19-Jun-24

06/13/2024 7:16

06/17/2024 15:57

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/18/2024 9:16 06/13/2024 7:16

24060969-002DMW-2

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

24060969-002EMW-2

Standard Methods 5310 C 2000, 2011, Organic Carbon

24060969-002FMW-2

Standard Methods 5220 D (Total) 1997

24060969-003AMW-3

Standard Methods 2540 C (Total) 1997, 2011

Standard Methods 4500-F C (Total) 1997, 2011

06/11/2024 11:3506/12/2024 12:15

06/11/2024 11:3506/12/2024 12:15

06/11/2024 11:3506/12/2024 12:15

06/11/2024 14:3506/12/2024 12:15

06/14/2024 14:55 06/13/2024 11:25

06/17/2024 13:22 06/13/2024 11:25

06/14/2024 16:07

06/13/2024 13:55

06/14/2024 10:02

06/13/2024 10:37

SW-846 9036 (Total) 06/13/2024 17:58 SW-846 9251 (Total) 06/13/2024 17:58

24060969-003BMW-3

Standard Methods 4500-NO2 B (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

24060969-003CMW-3

Standard Methods 2340 B, Hardness (Total) 1997

SW-846 3005A, 6020A, Metals by ICPMS (Total)

SW-846 3005A, 6020A, Metals by ICPMS (Total)

SW-846 3005A, 6020A, Metals by ICPMS (Total)

06/11/2024 14:3506/12/2024 12:15

06/11/2024 14:3506/12/2024 12:15

06/12/2024 18:07

06/12/2024 16:44

06/12/2024 16:44

06/13/2024 7:16

06/18/2024 0:00

06/14/2024 17:24 06/13/2024 7:16

06/13/2024 7:16

06/13/2024 7:16

06/17/2024 15:40

06/17/2024 16:02

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/18/2024 9:21 06/13/2024 7:16

24060969-003DMW-3

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

24060969-003EMW-3

Standard Methods 5310 C 2000, 2011, Organic Carbon

24060969-003FMW-3

Standard Methods 5220 D (Total) 1997

24060969-004AMW-4

Standard Methods 2540 C (Total) 1997, 2011

Standard Methods 4500-F C (Total) 1997, 2011

SW-846 9036 (Total)

SW-846 9251 (Total)

06/11/2024 14:3506/12/2024 12:15

06/13/2024 11:25

06/13/2024 11:25

06/11/2024 14:3506/12/2024 12:15

06/11/2024 14:3506/12/2024 12:15

06/11/2024 13:3006/12/2024 12:15

06/14/2024 15:01

06/17/2024 13:28

06/14/2024 16:19

06/13/2024 13:55

06/14/2024 10:32

06/13/2024 10:39

06/13/2024 18:06

06/13/2024 18:06

Client Project: #25491019

Client: Barr Engineering Company Report Date: 19-Jun-24

Work Order: 24060969 http://www.teklabinc.com/

Sample IDClient Sample ID Collection DateReceived Date

24060969-004BMW-4 06/11/2024 13:3006/12/2024 12:15

Standard Methods 4500-NO2 B (Total) 2000, 2011 06/12/2024 18:07

Standard Methods 4500-NO3 F (Total) 2000, 2011 06/12/2024 16:46

Standard Methods 4500-NO3 F (Total) 2000, 2011 06/12/2024 16:46 24060969-004CMW-4

Standard Methods 2340 B, Hardness (Total) 1997

06/11/2024 13:3006/12/2024 12:15

06/18/2024 0:00 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/14/2024 17:30 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 15:45

06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 17:06 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/18/2024 9:27 06/13/2024 7:16

24060969-004DMW-4 06/11/2024 13:3006/12/2024 12:15

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

06/14/2024 15:47 06/13/2024 11:25

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved) 06/17/2024 13:33 06/13/2024 11:25

24060969-004EMW-4

Standard Methods 5310 C 2000, 2011, Organic Carbon

24060969-004FMW-4

06/11/2024 13:3006/12/2024 12:15

06/11/2024 13:3006/12/2024 12:15

06/14/2024 17:01

Standard Methods 5220 D (Total) 1997 06/13/2024 13:55

24060969-005AMW-5 06/11/2024 12:0306/12/2024 12:15

Standard Methods 2540 C (Total) 1997, 2011

Standard Methods 4500-F C (Total) 1997, 2011

SW-846 9036 (Total)

SW-846 9251 (Total)

24060969-005CMW-5

Standard Methods 4500-NO2 B (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

24060969-005EMW-5

Standard Methods 2340 B, Hardness (Total) 1997

SW-846 3005A, 6020A, Metals by ICPMS (Total)

SW-846 3005A, 6020A, Metals by ICPMS (Total)

06/11/2024 12:0306/12/2024 12:15

06/11/2024 12:0306/12/2024 12:15

06/14/2024 10:33

06/14/2024 10:54

06/13/2024 18:17

06/13/2024 18:43

06/12/2024 18:08

06/12/2024 16:48

06/12/2024 16:48

06/19/2024 0:00 06/18/2024 10:28

06/14/2024 17:36 06/13/2024 7:16

06/17/2024 16:08 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/19/2024 8:40 06/18/2024 10:28

24060969-005GMW-5

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

06/11/2024 12:0306/12/2024 12:15

06/14/2024 16:15 06/13/2024 11:25

06/17/2024 14:48 06/13/2024 11:25

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved) 06/18/2024 10:59 06/13/2024 11:25

24060969-005HMW-5

06/11/2024 12:0306/12/2024 12:15

Client: Barr Engineering Company

Client Project: #25491019

Work Order: 24060969

Report Date: 19-Jun-24

Sample IDClient Sample ID Collection DateReceived Date

Standard Methods 5310 C 2000, 2011, Organic Carbon

06/14/2024 17:13 24060969-005JMW-5 06/11/2024 12:0306/12/2024 12:15

Standard Methods 5220 D (Total) 1997 06/13/2024 13:56 24060969-006AMW-6 06/11/2024 9:2006/12/2024 12:15

Standard Methods 2540 C (Total) 1997, 2011

06/14/2024 10:33

Standard Methods 4500-F C (Total) 1997, 2011 06/13/2024 10:43

SW-846 9036 (Total)

06/17/2024 8:59

SW-846 9251 (Total) 06/13/2024 18:59 24060969-006BMW-6

Standard Methods 4500-NO2 B (Total) 2000, 2011

9:2006/12/2024 12:15

06/12/2024 18:08

Standard Methods 4500-NO3 F (Total) 2000, 2011 06/12/2024 16:57

Standard Methods 4500-NO3 F (Total) 2000, 2011 06/12/2024 16:57

24060969-006CMW-6 06/11/2024 9:2006/12/2024 12:15

Standard Methods 2340 B, Hardness (Total) 1997

SW-846 3005A, 6020A, Metals by ICPMS (Total)

06/18/2024 0:00 06/13/2024 7:16

06/14/2024 18:33 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 17:11 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total)

24060969-006DMW-6

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

24060969-006EMW-6

Standard Methods 5310 C 2000, 2011, Organic Carbon

24060969-006FMW-6

Standard Methods 5220 D (Total) 1997

24060969-007AMW-7

Standard Methods 2540 C (Total) 1997, 2011

Standard Methods 4500-F C (Total) 1997, 2011

SW-846 9036 (Total)

SW-846 9251 (Total)

24060969-007BMW-7

Standard Methods 4500-NO2 B (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

06/11/2024 9:2006/12/2024 12:15

06/18/2024 9:32 06/13/2024 7:16

06/13/2024 11:25

06/13/2024 11:25

06/11/2024 9:2006/12/2024 12:15

06/11/2024 9:2006/12/2024 12:15

06/11/2024 8:5506/12/2024 12:15

06/11/2024 8:5506/12/2024 12:15

06/14/2024 15:53

06/17/2024 14:20

06/18/2024 10:25 06/13/2024 11:25

06/14/2024 17:43

06/13/2024 13:57

06/14/2024 10:34

06/13/2024 10:46

06/13/2024 19:02

06/13/2024 19:02

06/12/2024 18:09

06/12/2024 16:59

06/12/2024 16:59 24060969-007CMW-7

Standard Methods 2340 B, Hardness (Total) 1997

06/11/2024 8:5506/12/2024 12:15

06/18/2024 0:00 06/13/2024 7:16

Client Project: #25491019

Client: Barr Engineering Company Report Date: 19-Jun-24

Sample IDClient Sample ID

Test Name

SW-846 3005A, 6020A, Metals by ICPMS (Total)

Work Order: 24060969

06/13/2024 7:16

06/14/2024 18:39

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 17:17 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total)

06/18/2024 9:38 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/18/2024 12:08 06/13/2024 7:16

24060969-007DMW-7

06/11/2024 8:5506/12/2024 12:15

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved) 06/14/2024 15:58 06/13/2024 11:25

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

06/17/2024 14:25 06/13/2024 11:25

06/18/2024 10:31 06/13/2024 11:25 24060969-007EMW-7 06/11/2024 8:5506/12/2024 12:15

Standard Methods 5310 C 2000, 2011, Organic Carbon

24060969-007FMW-7 06/11/2024 8:5506/12/2024 12:15

Standard Methods 5220 D (Total) 1997

24060969-008AMW-8 06/11/2024 9:5006/12/2024 12:15

Standard Methods 2540 C (Total) 1997, 2011

06/14/2024 17:55

06/13/2024 13:57

06/14/2024 10:35

Standard Methods 4500-F C (Total) 1997, 2011 06/13/2024 10:48

SW-846 9036 (Total)

06/13/2024 19:10

SW-846 9251 (Total) 06/13/2024 19:15

24060969-008BMW-8

Standard Methods 4500-NO2 B (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

24060969-008CMW-8

Standard Methods 2340 B, Hardness (Total) 1997

06/11/2024 9:5006/12/2024 12:15

06/11/2024 9:5006/12/2024 12:15

06/12/2024 18:09

06/12/2024 17:14

06/12/2024 17:14

06/13/2024 7:16

06/18/2024 0:00

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/14/2024 18:45 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total)

SW-846 3005A, 6020A, Metals by ICPMS (Total)

24060969-008DMW-8

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

06/11/2024 9:5006/12/2024 12:15

06/13/2024 7:16

06/13/2024 7:16

06/13/2024 11:25

06/13/2024 11:25

06/13/2024 11:25 24060969-008EMW-8

Standard Methods 5310 C 2000, 2011, Organic Carbon

06/11/2024 9:5006/12/2024 12:15

06/17/2024 17:23

06/18/2024 9:44

06/14/2024 16:04

06/17/2024 14:31

06/18/2024 10:36

06/14/2024 18:37 24060969-008FMW-8

Standard Methods 5220 D (Total) 1997

06/11/2024 9:5006/12/2024 12:15

06/13/2024 13:57 24060969-009ADup-1

Standard Methods 2540 C (Total) 1997, 2011

06/11/2024 12:0306/12/2024 12:15

06/14/2024 10:59

Client: Barr Engineering Company

Client Project: #25491019

Sample IDClient Sample ID

Test Name

Standard Methods 4500-F C (Total) 1997, 2011

SW-846 9036 (Total)

SW-846 9251 (Total)

24060969-009BDup-1

Standard Methods 4500-NO2 B (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

24060969-009CDup-1

Standard Methods 2340 B, Hardness (Total) 1997

SW-846 3005A, 6020A, Metals by ICPMS (Total)

Collection DateReceived Date

06/11/2024 12:0306/12/2024 12:15

Work Order: 24060969

Report Date: 19-Jun-24

06/11/2024 12:0306/12/2024 12:15

06/13/2024 11:04

06/13/2024 19:18

06/13/2024 19:39

06/12/2024 18:10

06/12/2024 17:17

06/12/2024 17:17

06/18/2024 0:00 06/13/2024 7:16

06/14/2024 18:50 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 17:28 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total)

24060969-009DDup-1

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

06/11/2024 12:0306/12/2024 12:15

06/18/2024 9:49 06/13/2024 7:16

06/14/2024 16:10 06/13/2024 11:25

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved) 06/17/2024 14:37 06/13/2024 11:25

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved) 06/18/2024 10:42 06/13/2024 11:25

24060969-009EDup-1

06/11/2024 12:0306/12/2024 12:15

Standard Methods 5310 C 2000, 2011, Organic Carbon 06/18/2024 8:20

24060969-009FDup-1

Standard Methods 5220 D (Total) 1997

24060969-010AEB-1

Standard Methods 2540 C (Total) 1997, 2011

Standard Methods 4500-F C (Total) 1997, 2011

SW-846 9036 (Total)

SW-846 9251 (Total)

24060969-010BEB-1

Standard Methods 4500-NO2 B (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

Standard Methods 4500-NO3 F (Total) 2000, 2011

24060969-010CEB-1

Standard Methods 2340 B, Hardness (Total) 1997

SW-846 3005A, 6020A, Metals by ICPMS (Total)

06/11/2024 12:0306/12/2024 12:15

06/11/2024 14:5506/12/2024 12:15

06/11/2024 14:5506/12/2024 12:15

06/11/2024 14:5506/12/2024 12:15

06/14/2024 14:38

06/14/2024 10:59

06/13/2024 11:06

06/13/2024 19:42

06/13/2024 19:42

06/12/2024 18:10

06/12/2024 17:19

06/12/2024 17:19

06/18/2024 0:00 06/13/2024 7:16

06/14/2024 18:56 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total) 06/17/2024 17:34 06/13/2024 7:16

SW-846 3005A, 6020A, Metals by ICPMS (Total)

24060969-010DEB-1

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

06/11/2024 14:5506/12/2024 12:15

06/18/2024 10:19 06/13/2024 7:16

06/14/2024 16:56 06/13/2024 11:25

Client Project: #25491019

Client: Barr Engineering Company Report Date: 19-Jun-24

Sample IDClient Sample ID

Test Name

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved)

Work Order: 24060969 http://www.teklabinc.com/

06/17/2024 14:42 06/13/2024 11:25

SW-846 3005A, 6020A, Metals by ICPMS (Dissolved) 06/18/2024 10:48 06/13/2024 11:25

24060969-010EEB-1

Standard Methods 5310 C 2000, 2011, Organic Carbon

06/11/2024 14:5506/12/2024 12:15

06/14/2024 14:43

24060969-010FEB-1

06/11/2024 14:5506/12/2024 12:15 Standard Methods 5220 D (Total) 1997 06/14/2024 14:38

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

SampID: MBLK

Client Project: #25491019 Client: Barr Engineering Company Report Date: 19-Jun-24 Work Order: 24060969 http://www.teklabinc.com/

STANDARD METHODS 4500-F C (TOTAL) 1997, 2011

SampID: MBLK SampType:

SampType: LCS mg/L Units R348671 Batch

SampID: LCS

SampType: MS mg/L Units R348671 Batch

SampID: 24060969-005CMS

Client Project: #25491019

http://www.teklabinc.com/

Client: Barr Engineering Company Report Date: 19-Jun-24

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

SampID: 24060969-005CMSD

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011 SampID: ICB/MBLK

Work Order: 24060969

STANDARD METHODS 5220 D (TOTAL) 1997 SampID: MBLK

Client Project: #25491019 Client: Barr Engineering Company Report Date: 19-Jun-24 Work Order: 24060969 http://www.teklabinc.com/

Batch

Client: Barr Engineering Company

Client Project: #25491019

Received By: LM Carrier: Crossroads

Completed by:

Reviewed by: On: 12-Jun-24 On: 12-Jun-24

Lindsey Maddox

Chain of custody 1 Extra pages included 0

Ellie Hopkins

http://www.teklabinc.com/

Work Order: 24060969

Report Date: 19-Jun-24

Shipping container/cooler in good condition? Yes No Not Present

Type of thermal preservation? None Ice Blue Ice Dry Ice

Chain of custody present? Yes No

Chain of custody signed when relinquished and received? Yes No

Chain of custody agrees with sample labels? Yes No

Samples in proper container/bottle?

Sample containers intact?

Sufficient sample volume for indicated test?

All samples received within holding time?

Yes No

Yes No

Yes No

Yes No

Reported field parameters measured: Field Lab

Container/Temp Blank temperature in compliance?

Yes No

When thermal preservation is required, samples are compliant with a temperature between 0.1°C - 6.0°C, or when samples are received on ice the same day as collected.

Water – at least one vial per sample has zero headspace? Yes No No VOA vials

Water - TOX containers have zero headspace? No TOX containers Yes No

Water - pH acceptable upon receipt? Yes No NA

NPDES/CWA TCN interferences checked/treated in the field? Yes No

pH strip #96651. - lmaddox - 6/12/2024 2:37:15 PM

Samples were filtered and preserved with Nitric Acid (97737) for the dissolved parameters upon arrival at the laboratory. - lmaddox - 6/12/2024 2:37:17 PM

January 03, 2025

Tony Schroer Barr Engineering Company

1001 Diamond Ridge Suite 1100

http://www.teklabinc.com/

Illinois100226

Illinois1004652024-2

KansasE-10374

Louisiana05002

Louisiana05003

Oklahoma9978

Jefferson City, MO 65109 (573) 638-5021 (573) 638-5001

TEL: FAX:

RE:

25491019.01

Dear Tony Schroer:

WorkOrder: 24121766

TEKLAB, INC received 10 samples on 12/20/2024 1:05:00 PM for the analysis presented in the following report.

Samples are analyzed on an as received basis unless otherwise requested and documented. The sample results contained in this report relate only to the requested analytes of interest as directed on the chain of custody. NELAP accredited fields of testing are indicated by the letters NELAP under the Certification column. Unless otherwise documented within this report, Teklab Inc. analyzes samples utilizing the most current methods in compliance with 40CFR. All tests are performed in the Collinsville, IL laboratory unless otherwise noted in the Case Narrative.

All quality control criteria applicable to the test methods employed for this project have been satisfactorily met and are in accordance with NELAP except where noted. The following report shall not be reproduced, except in full, without the written approval of Teklab, Inc.

If you have any questions regarding these tests results, please feel free to call.

Sincerely,

Paul Schultz Project Manager

Pschultz@teklabinc.com

Client: Barr Engineering Company

Client Project: 25491019.01

AbbrDefinition

*Analytes on report marked with an asterisk are not NELAP accredited

http://www.teklabinc.com/

Work Order: 24121766

Report Date: 03-Jan-25

CCVContinuing calibration verification is a check of a standard to determine the state of calibration of an instrument between recalibration.

CRQLA Client Requested Quantitation Limit is a reporting limit that varies according to customer request. The CRQL may not be less than the MDL.

DFDilution factor is the dilution performed during analysis only and does not take into account any dilutions made during sample preparation. The reported result is final and includes all dilution factors.

DNIDid not ignite

DUPLaboratory duplicate is a replicate aliquot prepared under the same laboratory conditions and independently analyzed to obtain a measure of precision.

ICVInitial calibration verification is a check of a standard to determine the state of calibration of an instrument before sample analysis is initiated.

IDPHIL Dept. of Public Health

LCSLaboratory control sample is a sample matrix, free from the analytes of interest,spiked with verified known amounts of analytes and analyzed exactly like a sample to establish intra-laboratory or analyst specific precision and bias or to assess the performance of all or a portion of the measurement system.

LCSDLaboratory control sample duplicate is a replicate laboratory control sample that is prepared and analyzed in order to determine the precision of the approved test method. The acceptable recovery range is listed in the QC Package (provided upon request).

MBLKMethod blank is a sample of a matrix similar to the batch of associated sample (when available) that is free from the analytes of interest and is processed simultaneously with and under the same conditions as samples through all steps of the analytical procedures, and in which no target analytes or interferences should present at concentrations that impact the analytical results for sample analyses.

MDL"The method detection limit is defined as the minimum measured concentration of a substance that can be reported with 99% confidence that the measured concentration is distinguishable from method blank results."

MSMatrix spike is an aliquot of matrix fortified (spiked) with known quantities of specific analytes that is subjected to the entire analytical procedures in order to determine the effect of the matrix on an approved test method’s recovery system. The acceptable recovery range is listed in the QC Package (provided upon request).

MSDMatrix spike duplicate means a replicate matrix spike that is prepared and analyzed in order to determine the precision of the approved test method. The acceptable recovery range is listed in the QC Package (provided upon request).

MWMolecular weight

NCData is not acceptable for compliance purposes

NDNot Detected at the Reporting Limit

NELAPNELAP Accredited

PQLPractical quantitation limit means the lowest level that can be reliably achieved within specified limits of precision and accuracy during routine laboratory operation conditions.

RLThe reporting limit the lowest level that the data is displayed in the final report. The reporting limit may vary according to customer request or sample dilution. The reporting limit may not be less than the MDL.

RPDRelative percent difference is a calculated difference between two recoveries (ie. MS/MSD). The acceptable recovery limit is listed in the QC Package (provided upon request).

SPKThe spike is a known mass of target analyte added to a blank sample or sub-sample; used to determine recovery deficiency or for other quality control purposes.

SurrSurrogates are compounds which are similar to the analytes of interest in chemical composition and behavior in the analytical process, but which are not normally found in environmental samples.

TICTentatively identified compound: Analytes tentatively identified in the sample by using a library search. Only results not in the calibration standard will be reported as tentatively identified compounds. Results for tentatively identified compounds that are not present in the calibration standard, but are assigned a specific chemical name based upon the library search, are calculated using total peak areas from reconstructed ion chromatograms and a response factor of one. The nearest Internal Standard is used for the calculation. The results of any TICs must be considered estimated, and are flagged with a "T". If the estimated result is above the calibration range it is flagged "ET"

TNTCToo numerous to count ( > 200 CFU )

Client: Barr Engineering Company

Client Project: 25491019.01

# - Unknown hydrocarbon

C - RL shown is a Client Requested Quantitation Limit

H - Holding times exceeded

J - Analyte detected below quantitation limits

ND - Not Detected at the Reporting Limit

S - Spike Recovery outside recovery limits

X - Value exceeds Maximum Contaminant Level

http://www.teklabinc.com/

Work Order: 24121766

Report Date: 03-Jan-25

B - Analyte detected in associated Method Blank

E - Value above quantitation range

I - Associated internal standard was outside method criteria

M - Manual Integration used to determine area response

R - RPD outside accepted recovery limits

T - TIC(Tentatively identified compound)

Client: Barr Engineering Company

Client Project: 25491019.01

Cooler Receipt Temp: 3.1 °C

http://www.teklabinc.com/

Work Order: 24121766

Report Date: 03-Jan-25

Collinsville

5445 Horseshoe Lake Road

Collinsville, IL 62234-7425 (618) 344-1004 (618) 344-1005

jhriley@teklabinc.com

Collinsville Air

5445 Horseshoe Lake Road Collinsville, IL 62234-7425 (618) 344-1004 (618) 344-1005

EHurley@teklabinc.com

Locations

Springfield 3920 Pintail Dr Springfield, IL 62711-9415 (217) 698-1004 (217) 698-1005

KKlostermann@teklabinc.com

Chicago 1319 Butterfield Rd. Downers Grove, IL 60515 (630) 324-6855

arenner@teklabinc.com

Kansas City 8421 Nieman Road Lenexa, KS 66214 (913) 541-1998 (913) 541-1998

jhriley@teklabinc.com

Client: Barr Engineering Company

Client Project: 25491019.01

Work Order: 24121766

Report Date: 03-Jan-25

State Cert # Exp Date Lab Dept

http://www.teklabinc.com/ NELAP

Illinois 100226 1/31/2025 Collinsville NELAP IEPA

Illinois 1004652024-2 4/30/2025 Collinsville NELAP IEPA

Kansas E-10374 4/30/2025 Collinsville NELAP KDHE

Louisiana 05002 6/30/2025 Collinsville NELAP LDEQ

Louisiana 05003 6/30/2025 Collinsville NELAP LDEQ

Oklahoma 9978 12/31/2024 Collinsville NELAP ODEQ

Arkansas 88-0966 3/14/2025 Collinsville ADEQ

Illinois 17584 5/31/2025 Collinsville IDPH

Iowa 430 6/1/2026 Collinsville IDNR

Kentucky KY98050 1/31/2026 Collinsville KWLCP

Kentucky KY98006 1/31/2026 Collinsville KWLCP

Kentucky 0073 1/31/2025 Collinsville UST

Mississippi 4/30/2025 Collinsville MSDH

Missouri 930 1/31/2025 Collinsville MDNR

Missouri 00930 10/31/2026 Collinsville MDNR

Client: Barr Engineering Company

Client Project: 25491019.01

Lab ID: 24121766-001 Client Sample ID: MW-01

Matrix: GROUNDWATER

STANDARD METHOD

B 2000, 2011, LABORATORY ANALYZED

STANDARD METHODS 2540 C (TOTAL) 1997, 2011

STANDARD METHODS 4500-NO2 B (TOTAL) 2000, 2011

Sample analysis did not meet hold time requirements.

STANDARD METHODS 4500-NO3 F (TOTAL) 2000, 2011

STANDARD METHODS 5220 D (TOTAL) 1997

STANDARD METHODS 5310 C 2000, 2011, ORGANIC CARBON

Work Order: 24121766 http://www.teklabinc.com/

Report Date: 03-Jan-25

Collection Date: 12/18/2024 13:25

Client: Barr Engineering Company

Client Project: 25491019.01

ID: 24121766-001

Work Order: 24121766 http://www.teklabinc.com/ Analyses

Report Date: 03-Jan-25

Collection Date: 12/18/2024 13:25

Client: Barr Engineering Company

Client Project: 25491019.01

Lab ID: 24121766-002

Matrix: GROUNDWATER

http://www.teklabinc.com/

Work Order: 24121766

Report Date: 03-Jan-25

Client Sample ID: MW-02

Collection Date: 12/18/2024 14:30

B 2000, 2011, LABORATORY ANALYZED

STANDARD METHODS 2540 C (TOTAL) 1997, 2011