Welcome to issue #24 of Demolition Hub, marking our fourth anniversary as your indispensable bimonthly read for the demolition industry.

We might be tempted to pop some bubbly in celebration, but the whirlwind between issues means we’re already hard at work on the next edition. Plus, the sixth annual British Demolition Awards is just around the corner!

Recently, we’ve been busy promoting and attending events like the ‘NFDC Talks’ in collaboration with the IDE and HSE, as well as the Hillhead event, which, though recent, feels like ages ago.

I also attended the UKATA convention and toured numerous supplier premises across the country.

An attempted two-flight trip to Belgrade for my second EDA Convention ended with an unexpected overnight stay in Amsterdam (a true travel mishap, I assure you).

During this time, Demolition Hub joined the National Demolition Association, significantly expanding our North American readership and bolstering our international presence.

In addition, we’ve been setting up the PowerPlant Podcast in new London studios and I’m eager for some of you fascinating and outspoken individuals to join me in the studio soon. Read all about it inside – reach out and let’s chat!

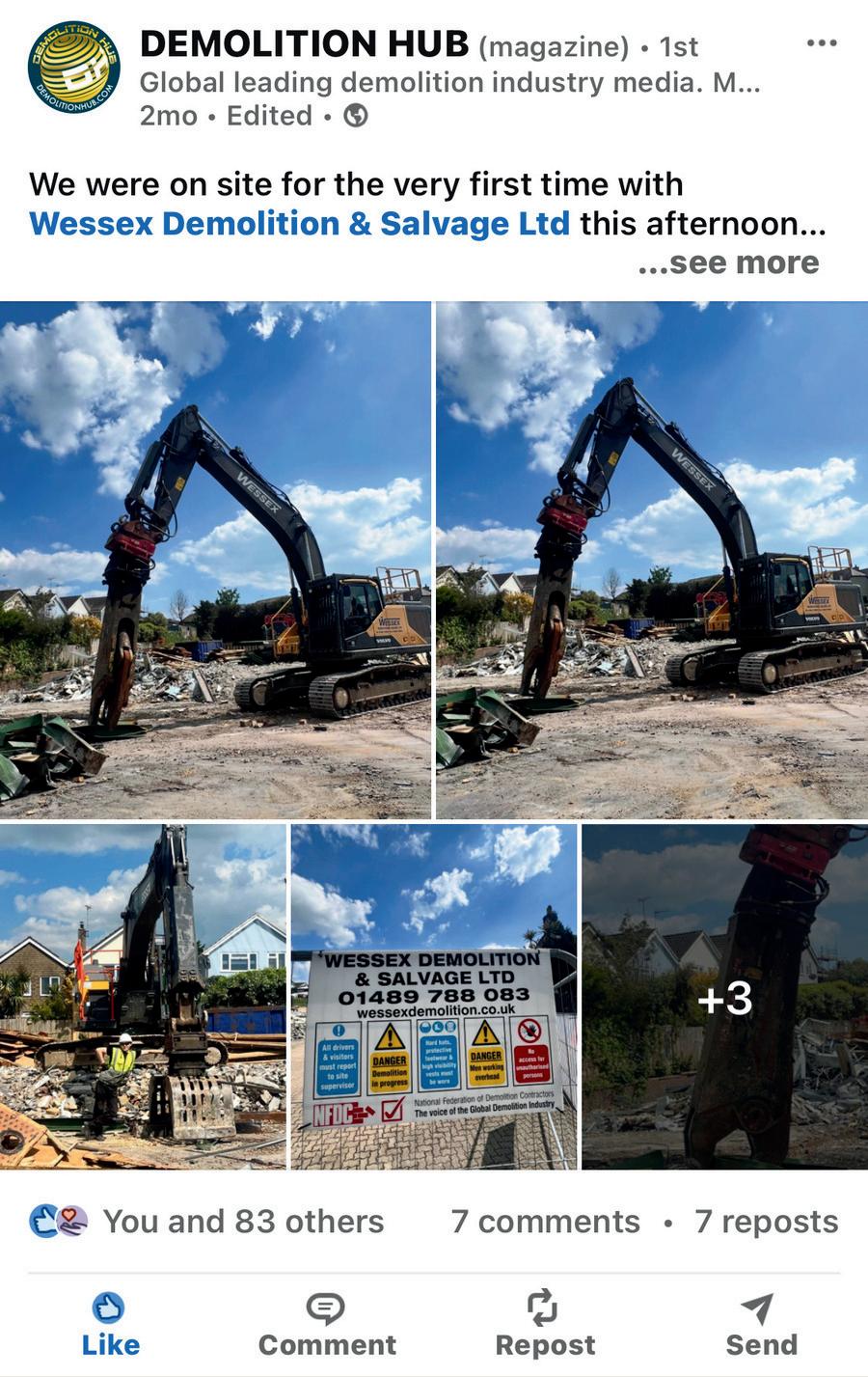

Amid all this activity, I’ve hit the milestone of having attended 30 site visits so far in 2024, with the 31st just around the corner as I aim for 50 this year. This underscores our commitment to supporting and championing the demolition industry. A genuine thank you to all who have welcomed me on site.

We were also delighted to host a work experience placement for a week in which Annie came on board as a media student. Part of her week was out with me, and Downwell Enabling graciously showed Annie and me around their Twickenham demolition site. She has written a piece for this issue, for details see the contents page. Thank you Downwell Group, you certainly turned that young lady’s head towards demolition.

Annie’s enthusiasm for demolition has actually accelerated our plans. Originally slated for 2025 as another ambitious Demolition Hub campaign, we are excited to announce its launch right now – Demolition 4 Ambition: NXT GEN.

This initiative aims to inspire the next generation to join this fantastic industry and we need your support. Discover our plans inside.

Impressed with Annie’s skills, we’ve offered her a part-time junior writer role. She will also assist in this campaign, using innovative approaches to engage her demographic while continuing her college studies.

As we gear up for the British Demolition Awards, we are nearing full capacity. This year sees many contractors attending for the first time. My plea to you is to submit your entries – your great work deserves recognition. Enter now at BritishDemolitionAwards.com.

Oh and our socials continue to hit ridiculous numbers, so why not go have a look at them, in particular see our TikTok where more than 25,000 people watched me absolutely terrified as I was raised in a cage up 16-odd storeys.

Thank you for your continued support and enjoy this gold standard issue!

Publisher,

PUBLISHER

Ben Chambers ben@chambers.media 01903 952 648

EDITOR

Toby Wilsdon toby@chambers.media 01903 952 645

JUNIOR WRITER

Annie Davey annie@chambers.media

COLUMNISTS

Howard Button Richard Dolman Richard Vann Terry Lloyd Dr Terry Quarmby

ADVERTISING SALES

Ben Chambers ben@chambers.media 01903 952 648

Daniel Christmas dan@demolitionhub.com 01903 952 642

DESIGN

Nicki Chambers nic@chambers.media

Joe Bers joe@chambers.media

PRODUCED & PUBLISHED BY Demolition Hub Ltd Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX demolition@demolitionhub.com 01903 952 640

Demolition Hub is a proud member of the National Demolition Association

Demolition Hub is the media partner for the European Demolition Association and the Indian Demolition Association

Demolition Hub is published six times a year. The subscription rate is £60 per year. Subscription records are maintained at Demolition Hub Ltd, Suites 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX

Articles and information contained in this publication are the copyright of Demolition Hub Ltd and may not be reproduced in any form without the written permission of the publishers. The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

BRV holds annual conference in Vienna

Do you want to be part of the EDA Yearbook 2024?

EDA is part of the CEN/TC 350

Reflecting on a successful EDA Annual Convention in Belgrade

EDA signs collaboration agreement with ESS for CLR Expo 2024

EDI attends Asbestonomy in Madrid

EDI welcomes newest member, SEG UMWELTZSERVICE

Flesan joins EDA as a new member

Get to know the new RILEM Technical Committees

Exciting lineup of panellists for EDA Think Tank 2024

Grupo Mitre joins EDA as a new member

Impact of the circular economy on demolition industry

Dickson’s robots shine in assisting Bellevue 600 Project

Innovative use of protection screens manages debris at Nashville medical site

Walsh Group relies on Volvo excavators to remake downtown Chicago transit system

Cautious optimism by Robbie Blackhurst, Founder and Director of Black Capital Group

Opportunities for engagement by Viki Bell, Director of Operations, CEA

What a new government must change for companies like the Collard Group

Construction Plant-hire Association’s priorities for the incoming government

National Federation of Demolition Contractors

More uncertainty? by Richard Dolman

Striving towards a greener future by Terry Lloyd, Head of Vendor in the SME Lending Division at Paragon Bank

32

With Lee Rowbotham, Managing Director of DEMEX

Downwell Enabling Solutions: Soft strip and full mechanical demolition of Richmond College

MGL Demolition: Controlled asbestos removal and demolition of Castlegate Shopping Centre

DEMOLITION4AMBITION NXT-GEN – promoting demolition as an outstanding career choice for those leaving education

58

With Andy Leaver, Product Development Director at DIGGER GUARD®

Introducing the Powerplant Podcast

Adamo Group: Asbestos abatement and demolition of Eastland Shopping Centre 20 FINGER ON THE BUTTON by Howard Button 14

• Husqvarna

• Bobcat – RogueX2 Autonomous Loader Concept

• Brokk UK

• DEVELON

• Core-ect Diamond Drilling Ltd

The 2024 British Demolition (and Asbestos) Awards 2024

78

Getting on site with the best of Britain’s contractors

84

Snapshots of Ben and the Demolition Hub team’s activities between issues

90

• Casella

• Odour and Dust Solutions

• Bosstek

• Brendon Powerwashers

• Corgin

98

Laurini Officine Meccaniche: Bringing Italian innovation to the UK with Robustrack

Jocker wins Italian Demolition Recycling Award

Modified excavator for disabled workers: A triumph in accessible innovation

104

Exclusive new Cat® Track Wear Sensor provides remote, no-touch wear monitoring and alerts at key wear percentages

Liebherr premieres first large wheel loader with hydrogen engine

JCB powers into Monster Trucks

Komatsu unveils new cab for crawler excavators

Richard Vann: Should decommissioning experts have a voice in financial planning talks?

Michael Freeley: Could sustainability lead to the fall of the demolition industry?

Demolition Hub is the media partner for the European Demolition Association

We are pleased to share a highlight from the Austrian association, BRV. Its Annual Conference 2024 took place on 22 May at the Austria Trend Parkhotel Schönbrunn in Vienna. During the event it was presented the technical guide on Recyclable Construction and Demolition Materials, prepared by the European Demolition Association and the French C&D management system.

Under the theme New ways of recycling building materials in the circular economy, the conference gathered over 250 participants who explored innovative approaches to recycled building materials, circular tendering and the promotion of building material recycling. The event addressed key challenges of the circular economy within the construction sector, emphasising the

importance of tendering as a crucial lever for the adoption of sustainable and circular building materials.

With the EU Taxonomy Regulation demanding high recycling rates for various construction sectors and the EU Construction Products Regulation highlighting the recyclability and increased use of recycled building materials, the Austrian construction industry is proactively preparing to meet these requirements.

A notable moment of the event was the presentation of the EDA Guide on Recyclable Construction and Demolition Materials, which provided valuable insights into sustainable practices and advancements in the recycling of construction and demolition materials.

Do you want to be part of the EDA Yearbook 2024?

We are excited to announce that we are already hard at work on the EDA Yearbook 2024, which is set to be an invaluable resource, offering visibility and recognition to participating companies and professionals. Each edition is crafted with the participation of industry leaders, ensuring that the content is relevant, innovative and reflective of the latest trends and advancements in demolition, decontamination, and recycling.

The annual publication, renowned for its in-depth technical articles and insightful dialogues, will once again feature insights and expertise from our esteemed colleagues and members.

If you have valuable knowledge

or experience related to the demolition industry that you would like to share, we invite you to contribute a technical article. This is a fantastic opportunity to showcase your expertise and contribute to the collective knowledge of our industry.

To submit your article or discuss potential topics, please contact us at your earliest convenience. We are eager to collaborate with you and feature your contributions in this year’s edition.

Don’t miss the chance to be a part of this important industry

EDA’s commitment to advancing the circular economy in construction is evident through its involvement in numerous projects. With a dedicated Working Group on Circular Economy, EDA aims to establish and promote European standards and develop fundamental guidelines for sustainable practices in the industry.

Recognising the importance of setting standardised practices across Europe, EDA is part of the CEN/ TC 350, the Technical Committee responsible for developing standardised methods for the assessment of the sustainability of construction works. This move underscores EDA’s dedication to contributing to the development of standards that will guide the construction industry towards a more sustainable future.

The scope of CEN/TC 350/SC 1 is to standardise the field of circular economy in the built environment by specifying circular principles, guidelines and requirements to facilitate the transition to a more sustainable circular economy.

On 20 June, EDA participated in a crucial meeting focused on the sustainability of construction works. This meeting was part of the broader efforts of CEN/TC 350/SC 1 to discuss the principles and guidelines necessary for the circular economy in the construction sector.

As a member of CEN/TC 350, EDA will be in a strategic position to influence European policies and regulations related to the circular economy. This influence will ensure that the demolition and recycling sectors are adequately considered in

publication. We look forward to your participation. Stay tuned for more updates as we continue to work on bringing you the best insights and information in the sector.

For more information, visit the EDA Yearbook 2024 website and check out previous editions.

legislative developments.

This marks a significant milestone in EDA’s mission to lead the demolition, decontamination, and recycling sectors towards a sustainable future. By contributing to the development of European standards, EDA is not only supporting its members but also promoting a broader shift towards a circular economy in construction. The meeting on 20 June reaffirmed EDA’s commitment to this cause, setting the stage for impactful collaborations and advancements in sustainability practices.

After months of hard work, the EDA is pleased to reflect on the success of this year’s Annual Convention. From 13 to 15 June, more than 200 participants gathered in the Serbian capital Belgrade for a dynamic exchange of insights and innovations in demolition, decontamination, and recycling.

The convention also featured engaging panel discussions, workshops, and networking sessions, providing attendees with valuable opportunities to exchange knowledge and forge new partnerships.

One of the highlights of the convention was the presentation of the winner of the European Circular Economy Awards 2024 and we had the opportunity to learn about three exceptional projects, each recognised as finalists in their respective countries for their innovation and dedication to advancing the demolition and recycling sectors.

Thijs Noordhoek, representing VERAS Sloopaannemers, showcased a ground-breaking project that underscored new standards in high-quality reuse of materials in the building sector. His presentation highlighted innovative techniques.

Dr Ana Nadaždi from the Serbian Demolition Association (SDA) presented a project that demonstrated exemplary approaches to circular economybased model for assessing the sustainability of construction and demolition waste management. Her expertise and research are pivotal in setting benchmarks for industry best practices.

Raquel Arias, representing Association AEDED, shared

insights into a project focusing on the efficient recovery of material resources contained in construction and demolition waste based on advanced hyperspectral vision techniques. Her presentation emphasised the importance of sustainability and resource efficiency in shaping future industry trends.

Each project represented a commendable commitment to innovation and sustainability in our field, resulting in Ana Nadaždi winning this year’s award. Congratulations Ana, and thank you for sharing you inspiring project in the EDA Annual Convention 2024.

A further highlight of the convention was the Gala Dinner held at Belgrade’s White Palace, where attendees enjoyed an evening of cultural enrichment and entertainment. Traditional dancers and a talented cello quartet captivated the audience, making it an unforgettable experience.

Organising such a significant event presented challenges that were met with great enthusiasm and dedication. We extend our sincere appreciation to our co-organiser, the Serbian Demolition Association, SDA, whose expertise and collaboration were instrumental in ensuring the convention’s success.

As the convention drew to a close, participants left with renewed inspiration and a shared commitment to continuing advancements in demolition and recycling practices across Europe and beyond.

The EDA would like to extend its deepest gratitude to all sponsors of the event, whose generous support

contributed to its resounding success.

We were honoured to have the support of 23 sponsors across Gold, Silver and Bronze levels. They played integral roles in enhancing attendee experiences with their branded stands and special contributions, such as Caterpillar’s sponsorship of the Gala Dinner, INDECO’s welcome cocktail., Demarec’s delegate bags, Epiroc’s lanyards and KTEG’s materials in the conference bags.

We are thrilled to announce that the EDA Annual Convention 2025 will be held in Italy. We will have a comprehensive professional programme that will be announced soon. Highlights include the return of the prestigious European Circular Economy Awards, recognising best practices and innovative solutions in demolition and circular economy.

There will be the usual roundtables with industry experts, where relevant topics will be discussed and valuable insights shared. This is the perfect time to connect with colleagues, learn from industry leaders, and explore new collaboration opportunities.

Stay tuned to the event website for more updates and details about the programme. Don’t miss any updates!

See you in Italy in 2025!

The premium wheel loader and the essential crawler excavator are ready for any challenge.

We are thrilled to announce that we have signed a collaboration agreement with the Environmental Services & Solutions Expo (ESS) for their highly anticipated event: Contamination and Land Remediation Expo. As part of this exciting partnership, we invite all EDA members to register and participate.

The ESS Expo is set to take place at the Birmingham NEC from 11-12 September 2024. Registration is now open and a limited number of early-bird free tickets are available.

Don’t miss this opportunity to secure your spot at one of the

industry’s premier events.

ESS Expo brings together key industry events, including the Resource & Waste Management Expo, the Energy, Fuels and Decarbonisation Expo, the Water Resource Management Expo and the Contamination and Land Remediation Expo.

Partnered with the Environment Agency, the ESS Expo is expected to attract over 12,000 visitors. We encourage all EDA members to take advantage of this unique opportunity to network, learn, and

collaborate with industry leaders. Don’t miss out on your chance to be part of this event. We look forward to seeing you there!

For more information and to register, please visit the ESS Expo website.

The European Decontamination Institute, EDI, is pleased to announce its successful participation in Asbestonomy 2024, held in June in Madrid.

This event, dedicated to asbestos management and abatement, aligned perfectly with EDI’s mission to promote safe and effective decontamination practices across Europe.

Our attendance at Asbestonomy provided valuable networking opportunities and insights into the latest advancements in asbestos management technologies and best practices. These connections and knowledge will enhance our efforts to develop and disseminate guidelines that ensure the highest standards of safety in decontamination projects.

By engaging with industry experts and sharing knowledge, EDI continues to strengthen its role as a leader in the

decontamination sector, advocating for safer practices and fostering a collaborative professional community.

With more than 30 years’ experience, SEG UMWELT-SERVICE GmbH specialises in providing comprehensive environmental services, including hazardous waste management, soil decontamination, and asbestos removal.

Founded in Germany, SEG UMWELT-SERVICE GmbH has built a strong reputation for its commitment to environmental protection and sustainable practices.

The company employs a team

of highly skilled professionals who use cutting-edge technology and innovative solutions to address complex environmental challenges. Their expertise in handling hazardous materials and dedication to maintaining the highest safety standards make them a valuable addition to EDI.

SEG UMWELT-SERVICE GmbH involvement promises to enhance collaborative efforts within the institute, promoting the highest standards of environmental

safety and best practices in the decontamination industry.

We look forward to the valuable contributions that they will bring to EDI, furthering our mission to advance the decontamination sector across Europe.

Flesan, a leading company in the construction sector known for its diversified units specialising in demolition, public works, geotechnics, mining, infrastructure, industrial assemblies, machinery, environmental services and restorations, has recently become a member of the European

Demolition Association (EDA). The company was founded in 1981 and operates in Chile and Peru.

Flesan’s commitment to sustainability, innovation, and continuous improvement is evident in its comprehensive approach to construction projects. With a robust portfolio that spans various phases

The International Union of Laboratories and Experts in Construction Materials, Systems and Structures, RILEM, an international partner of EDA, is delighted

of construction and building, Flesan integrates cutting-edge technology and machinery to meet project requirements efficiently within agreed timelines and budgets.

to inform you about Technical Committees working on research topics related to waste and recycled materials.

• UMW: Upcycling Powder Mineral “Wastes” into Cement Matrices

• APD: Alternative Paving Materials – Design and Performance

• RCC: Rolled compacted concrete for pavement applications

Joining these TCs is free and industry participants are highly welcome. If you’re interested, please feel free to complete the Join a Technical Committee form.

This collaboration between RILEM and EDA is based on the common objective of fostering and promoting international cooperation through general access to advanced knowledge.

We are excited to present the panellists for the EDA Think Tank 2024, set to take place on 9 October in Brussels.

This year’s central theme is the newly updated Construction and Demolition (C&D) Waste Management Protocol and Guidance. The event will feature two insightful roundtable discussions with industry professionals who will share their ideas, best and worst practices and insights about the industry’s current state and future directions. Join us for this unique opportunity to gain valuable insights, network with industry leaders, and contribute to shaping the future of C&D waste management.

Debate session 1: New C&D Waste Management Protocol

• Liesbet Van Cauwenberghe, TRACIMAT

• Florian Flacheneker, European Commission

• Stefano Panseri, NADECO

• Katrin Mees, DEUTSCHERABBRUCHVERBAND

• Marco Camboni, RPA EUROPE

Debate session 2: Guidance for resource audits before demolition and renovation works

• Thomas Kasper, BRV

• Philippe Moseley, European Commission

• Johan D’Hooghe, TRACIMAT

• Duncan Rudall, NFDC

For more details and to register for the event, please visit our EDA Think Tank 2024 website. We look forward to welcoming you to Brussels.

The company was founded 39 years ago by Miguel Ángel Ippolito, who transitioned from auto mechanics to the demolition industry, setting a firm foundation for a business committed to triple impact: economic, social and environmental.

Thanks to the founder’s legacy and the company’s continuous evolution, Grupo Mitre has achieved significant milestones, including becoming the world’s first B Corporation demolition company. This certification highlights their positive impact on the environment and community.

With a strong dedication to the circular economy, Grupo Mitre stands out for its efforts to minimise landfill waste by recovering demolition aggregates and reintegrating as many building materials, such as doors and windows, back into the market.

In 2015, they further solidified their commitment to sustainability by incorporating their first on-site aggregate crusher, enabling the reprocessing of materials directly at the demolition site and reintroducing them into the construction production cycle. We at the EDA are proud to welcome Grupo Mitre as a new member, recognising their exemplary leadership in responsible demolition and recycling practices.

At the European Demolition Association we foresaw the rise of the circular economy and the accompanying legislation at national and member state levels. This prediction has now become a reality.

The circular economy is enhancing the relevance of our industry, particularly in demolition, decontamination, and recycling (DDR) activities, by creating new business opportunities. However, it also presents challenges.

The movement began in the UK, with calls from green organisations, media, the public and legislators to ban demolition and favour retrofitting existing buildings. This trend is now spreading across mainland Europe, posing significant challenges for our industry.

While we support a greener future, resource efficiency and product reuse, these goals must be pursued logically, practically and economically. Many of the calls for change come from well-meaning individuals outside the construction industry, who may not fully grasp

the practical implications, or from interested parties looking to benefit from recycled materials.

In response, we are developing a long-term strategy. At our recent convention in Belgrade, we emphasised the need to position our industry as part of the solution, not the problem.

We have identified an opportunity through the United Nations’ Urban Regeneration initiative, led by the Habitat Directorate. This initiative focuses

on improving urban spaces and reshaping communities by adapting the built environment.

Our goal is to ensure that the demolition sector contributes positively to the circular economy and urban regeneration efforts, aligning with environmental objectives while maintaining practical and economically viable practices. We believe that by working together, we can secure a sustainable future for our industry and the communities we serve.

Bellevue 600 – Phase 2 is one of the most unique and noteworthy projects NDA member Dickson Company has ever worked on. In the process of abating and demolishing this 10-storey, 40-m-tall building, the company encountered different challenges on all four sides that required creative problem-solving and specialised equipment to address.

Located in downtown Bellevue, Washington, this 21,000-m3 building, once home to the regional office of Honeywell, was set to be demolished to make way for a new office tower. The site had active uses tucked close in on all sides, most notably a crew working on the adjacent Bellevue 600 – Phase 1 project just five metres from the east wall, working 25 metres down preparing the foundation for a new neighbouring building.

During the bid process, the general contractor and its client made it clear that any debris entering the excavation was unacceptable. Dickson Company took this seriously and with a team of engineers and demolition professionals, the company decided

Demolition Hub is a proud member of the National Demolition Association

against relying solely on high-reach machinery to do the demolition. Instead, it formed a plan to demolish the building in two parts, first by using robotic demolition machines and support equipment to demolish the sections of the building closest to the transit hub to the south and the excavation to the east. Once the most critical parts of the building were demolished, the rest of the building was taken down using a 50-metre high-reach excavator.

Upon completion, Dickson Company was able to deliver the client a clean site, on time and under budget, with no injuries and no uncontrolled debris ever leaving the job site or entering the excavation.

Once hazardous materials were abated, Dickson Company used small equipment and demolition attachments to size, reduce and separate out all possible recyclable materials.

One of the additional efforts made on this project was to extract all acoustical ceiling panels prior to any demolition activities so they could be recycled rather than go into the landfill waste stream. Ninetythree percent of debris was reused or recycled.

This project presented a unique challenge for Dickson Company. The nearby excavation was an active worksite with construction personnel working continually for the duration of the project.

Dickson Company brought together a team of demolition professionals and engineers to come up with a plan that would enable it to meet the schedule and keep them safe. When the company concluded that using a traditional high reach approach for this demolition wasn’t feasible, it pivoted to a hybrid

approach that would allow it to demolish approximately one-third of the building, which was closest to the excavation, using remote control demolition equipment and small support equipment floor by floor. Only then did the company deploy high-reach equipment to demolish the less sensitive portions of the building.

• Occupied office building to the north

• Active roadway 15 metres to the west

• Transit hub and bus terminal 12 metres to the south

• Active excavation 4.5 metres from the east wall

Dickson Company was a 2024 Excellence in Demolition Category 2 Finalist for this project.

Demolition Hub is a proud member of the National Demolition Association

On the compact Vanderbilt University Medical Center (VUMC) campus in Nashville, Tennessee, crews were challenged to safely demolish the Oxford House, a 12-storey administrative building. The demolition was part of VUMC’s expansion of the Vanderbilt University Hospital, which includes the construction of a 44,000 m2 tower and connected parking structure.

NDA member Spirtas Worldwide based in St. Louis, Missouri, was awarded the demolition project.

VUMC is one of the busiest health systems in the mid-south, recording more than 3.2 million patient visits per year. It was critical that all demolition material from the Oxford House be safely contained and removed without impact to the nearby active work zones or the adjacent hospital.

To further complicate the effort, the Oxford House structure was built in the 1960s using a jack-slab or lift slab technique. In this method, each floor is cast on top of a previous slab and then raised by hydraulic jacks into position. Unfortunately, the steel

reinforcements within the Oxford House slabs had deteriorated over time, a weakness that had the potential to cause a slab to fail during demolition.

In addition, the compact site came with limited space to set up equipment and stage protective screening materials. In some areas, crews on nearby projects were only inches away. As planning progressed, it became clear that the screens would need to be delivered, installed and removed in stages as demolition progressed from floor to floor, requiring considerable coordination.

A tight timeline added another layer of complexity. All protection screens had to be designed and approved by the engineer-of-record and the first screens installed within two months.

While protection screens are most often associated with construction not demolition, Spirtas Worldwide found them to be the ideal safety solution for the Oxford House project.

“This demolition job does not provide any room for error,” said Chris Hancock, Project Manager for

Spirtas Worldwide. “We have hospital pedestrian and vehicle traffic incredibly close and, at times, under the building we are demolishing. Controlling material during the demolition process is essential to keep our workers and the public safe in a highly sensitive environment.”

Doka developed a protection screen solution that essentially climbs down, from top to bottom –not up, like the more familiar highrise screen systems. The screens were designed in 12-metre-long segments that could be lifted by the on-site crane then connected together to reach the required 30-metre height. Deliveries were often scheduled at night to minimise the impact on tradespeople working on-site during the day.

As a demolition contractor, Spirtas had limited experience working with formwork or protection screens. Doka experts facilitated hands-on training, guiding the Spirtas team through the step-bystep installation. Doka’s dedicated field supervisor continued to check in to support the crew as additional layers were installed and they became more familiar with the process.

By closely partnering with the Spirtas team, Doka was able to deliver an effective, efficient and high-performing solution that met the unique safety needs of the Vanderbilt University Medical Center job site.

Just north of downtown Chicago, Walsh Group is hard at work demolishing elevated train tracks and concrete decks as part of the largest rehabilitation job in the history of the Chicago Transit Authority.

The Red and Purple Modernization project replaces century-old structures that carry the “L” train – a name given by locals to the public transit system because most of the rail lines are elevated above city streets. And with well over 300,000 daily passengers and climbing, the upgrades are sorely needed.

This $2.1 bn (£1.6 bn) project will deliver improved infrastructure and ridership capacity along Chicago’s most used transit lines. In addition

to modernising century-old junctions and rebuilding worn-down stations, it calls for new bridges, support structures, tracks and 3.2 miles of signal system upgrades.

Because the job site sits near the centre of a major metropolitan area, space is incredibly limited. Rick Anderson and his team of about 50 people are relying on versatile excavators and wheel loaders that keep the job moving along while helping crew members and those living and working near the job site remain safe.

“There’s a lot going on, and everything’s tight,” says Anderson, general superintendent for Walsh Group. “For this demolition job, we’ve got sheet removal. We’re

breaking up concrete. Haul trucks are moving material in and out, plus there’s general cleanup. One of the biggest challenges is logistics –getting equipment in and out while trying not to affect the surrounding neighbourhood. People aren’t used to construction in their backyard.”

To manage the tight spaces and get the job done with minimal impact on the community around them, the Walsh team relies on a fleet of Volvo CE heavy equipment, including 13 ECR235 excavators, two EC355 excavators and four wheel loaders from L90s to L120s, all supplied by local Volvo CE dealer Alta Equipment Company.

“The decision about what equipment we needed was determined by the amount of space we have,” Anderson says. “Naturally, with excavators, you want the reach, and it would’ve been great to have massive machines in here to tear it up. But you can’t; it has to be sized for what will fit.”

Machine availability makes it happen

To get the right sized machines for the job, Walsh turned to Alta Equipment, which currently has a wide range of large and midsize excavators ready to go at a moment’s notice.

“We have an outstanding relationship with Walsh,” says Alyssa Van Baren, Alta Equipment Account Manager. “We like to sit down with

our customers, get a scope of the project and see exactly what they need. We look at the big picture so we’re prepared to give them the proper equipment, service and rentals at the exact time it’s needed. And that’s what we’ve done here.”

Anderson agrees. “Even with the bidding process up front, we have to make sure machines are available to provide an accurate price,” he says. “Alyssa and the Alta team have been outstanding at letting us know what’s available and getting us exactly what we need when we need it.”

“With this particular job, there are a lot of changes going on,” says Kevin Berger, Midwest Regional Equipment Manager for Walsh Construction.

“From the start, we were looking at buying a certain number of machines, but the job changed significantly and rentals became critical. It was all unplanned. That’s why we have about 17 excavators out here working right now. Alta helped make that happen.”

With so many machines running simultaneously, performance and safety have been paramount for the entire crew.

“It certainly does,” Anderson concludes. “If we ever get in a bind and need something quick, they go out of their way to help us. That’s something you just can’t put a price on.” Demolition

“I like to see exactly what’s going on, and the 360° camera and short tail swing on the ECR235 help me work more confidently,” says operator Nathan Lawyer. “And I like running Volvo equipment because my machine does exactly what I tell it to do. A lot of brands have a delay in the joysticks, but this machine is very smooth.”

Anderson says: “We also added tiltrotators so that our operators can angle the attachments and turn them easier while working in such cramped spaces. It helps us stay productive and prevent potential accidents.”

Anderson says Walsh is incomparable in their focus on safety, providing every possible avenue to create a safe working environment.

Exceptional manoeuvrability is only one of the advantages the Walsh team is experiencing with their machines.

“With demolition, you never know when machine service will be needed,” Anderson says. “And with Chicago traffic, it’ll likely take a while to get someone in. On this particular

job, we hired one of Alta Equipment’s mechanics on-site. He’s here every day, which takes the drive time and delays out. Not breaking down and keeping the job moving – that’s all that matters, and Alta’s support has been the difference maker.”

It’s this kind of out-of-the-box service and support that keeps the Walsh Construction team on task and on time.

“We have guiding principles here at Alta that are at the core of everything we do,” Van Baren says. “One team; mutual respect; invest in the best; and have a passion for excellence to create customers for life. I think we’re doing that with Walsh – and we’ll continue building long-term customer relationships just like this one. Uptime matters.”

by Howard Button

I recently returned from a lovely holiday in Newquay, where I haven’t been for what must be getting on for forty years. At least the old roads have been upgraded and the journey was far quicker than I can remember. But one thing that has not changed is that there are still plenty of caravans en-route. This got me thinking about electric vehicles, so I decided to do some research.

The Zero Emission Vehicle (ZEV) Mandate and CO2 Regulations, more commonly known as the Z mandate, is starting to kick in and like many others, I have taken the plunge and bought a hybrid car, side-stepping the range anxiety that full electric cars give.

The Z mandate, published in consultation form in March 2023, lays out some pretty tight restrictions for manufacturers of cars and vans. The objective is zero emissions vehicles, with a commitment to ending the sale of all new petrol and diesel cars and vans by 2030 and for all new cars and vans to be fully zero emissions at the exhaust by 2035.

We may all think we are ok, that’s a long way away, but the manufacturers need years to plan and develop new vehicles and sell old stock, while we struggle with a lack of charger station networks and many home owners wonder just how they will charge their ZEV from their home, which may be a terraced house with no driveway or a block of flats without any dedicated

resident charging points let alone a guaranteed parking spot.

Clause 24 of the Z mandate consultation document is a clear indication of how seriously the government is taking this proposal, with the possibility of huge fines for non-compliant manufacturers.

“If a manufacturer cannot meet their non-ZEV CO2 emissions standard after trading and/or the transfer of ZEVM allowances, they must make a payment equivalent to £86 per gram of CO2 per kilometre exceedance over the non-ZEV fleet multiplied by the number of vehicles. This is equivalent to the fine structure under existing UK CO2 emissions regulation.”

Taking all of this into consideration I move back to my original thoughts. Will the demise of petrol and diesel cars and vans also see the demise of caravans and trailers? I know my own hybrid car cannot be fitted with a tow bar as the battery pack takes up all of the rear end of the car and half the boot.

My local parish council recently purchased a new fully electric van for the village warden. This has already flagged up a battery issue as we cannot get as many tools and equipment inside and cannot fit a tow bar due to the size of the battery pack.

Will the Z mandate extend to vanderived pickup trucks and stop the practice of towing the mini digger to site for a small ground works job or

“Ending the sale of all new petrol and diesel cars and vans by 2030”

utilities road works gang?

These are all big questions that don’t seem to have been considered or included within the Z Mandate. Who knows which way successive governments will go with this legislation, but I doubt any will attempt to make significant changes. What next? Are we looking at zero emissions for our HGV fleets? Thankfully, many of the big engine manufacturers are working hard to achieve net zero. With names such as JCB developing hydrogen internal combustion engines, that might just be the fuel of the future.

Perhaps roads with no caravans is just as much of a dream as a motorway without roadworks and lane closures.

Happy holidays.

If you have something to say and would like to submit a column for publication in Demolition Hub, please email: toby@chambers.media

The UK wakes up to a new government after 14 years of Conservative rule. For the built environment, Labour’s return will be met with wary anticipation. While its manifesto pledges made a good read for a sector that has experienced ongoing skills shortages, rising costs and lacklustre growth, delivering on them will be another matter. Just think back to the success of the Conservatives’ new deal promise to “Build, build, build…”

Labour’s vowed rollout of a 10year infrastructure strategy to “end the chaos” of the UK’s “crumbling infrastructure” has some interesting, though not necessarily revolutionary, ideas. Delivering 1.5 million new homes in England sounds impressive, but there is already a backlog of 4.3 million homes. Regardless, it is a good starting point if Labour can overcome

the challenges faced by previous governments.

Housebuilding has long been stifled by planning policy, However Labour’s promise to slash red tape and give combined authorities much needed new powers are to be welcomed, though have yet to be tested by locals and environmentalists furious about green belt land being redesignated for development.

To meet its housing target, Labour must help the construction industry get back on its feet. Its first step will be addressing the ongoing skills crisis. The Apprenticeship Levy, for example, has not been fit for purpose for some time. Apprenticeship starts have severely declined and completion rates have plummeted.

Its replacement, the Growth and Skills Levy, will certainly prove very attractive for employers, who

“Labour has created a rod for its own back with promises to “hit the ground running”. It has inherited a very difficult challenge and must deliver”

have long complained they cannot spend their levy payments on apprenticeships. Given that UK employee investment has been falling, this levy, combined with the creation of the new Skills UK body, could be instrumental for the longterm health of the sector, attracting and retaining much needed new talent.

Labour has created a rod for its own back with promises to “hit the ground running”. It has inherited a very difficult challenge and must deliver, but if their ambitions are supported, our sector, the built environment, may experience the green shoots of recovery, sooner rather than later.

As the CEA, we are ready to engage actively with the new Labour Government to address the crucial challenges and seize the opportunities highlighted in our 2024 Manifesto. The commitment to decarbonisation, digital transformation and skills development outlined in Labour’s platform aligns closely with our industry’s goals.

Labour’s plans to introduce a new industrial strategy, developed in partnership with businesses through an Industrial Strategy Council, will leverage Britain’s strengths in life sciences, digital, creative industries, financial services and clean power. This collaboration will drive growth and innovation, benefiting the construction equipment industry and the wider economy.

The party’s promise to build 1.5 million new homes in England over the next five years is a remarkable initiative that will stimulate demand

The Construction Equipment Association (CEA) congratulates the Labour Party and the new prime minister, Keir Starmer on their historic election win. This significant change in leadership presents a unique opportunity to propel the UK construction equipment industry into a new era of innovation and sustainability.

in the construction equipment sector, a level of housebuilding not seen since the 1960s. This very ambitious target and reforms in housebuilding economics and bureaucracy will likely boost private sector participation, benefiting our industry significantly.

Decarbonisation remains a critical priority for us. Labour’s substantial investment of £23.7bn in green measures during the next parliament emphasises the central role of green policies in driving growth and prosperity. We anticipate robust support from the Labour government in advancing innovative technologies, including electric and hydrogen-powered machinery. Establishing a national alternative fuel infrastructure is essential and we look forward to contributing to these transformative efforts.

The party’s plan to allocate £1.7bn a year for the Great British Energy company aims to accelerate

the rollout of renewables and nuclear power, creating 650,000 jobs by 2030. This initiative will drive industrial renewal, lower energy bills, and ensure secure, clean energy supplies, promoting a stable environment for construction projects.

The digitalisation of our industry is another important area. We are ready to collaborate on harmonising digital legislation and enhancing cybersecurity measures. Addressing the skills gap is imperative for maintaining our competitive edge and we are eager to work with Labour to attract and develop the next generation of talent.

Lastly, we urge the new government to ensure regulatory stability and alignment with European standards, vital for maintaining our international competitiveness. Together, we can adopt a sustainable, innovative and prosperous future for the UK construction equipment sector.

What a new government must change for companies like the Collard Group

It’s been several weeks since the UK voted in a new government. Labour seems to offer benefits for our sector, but there are also opportunity gaps that must be prioritised.

Labour’s ‘Get Britain building again’ is a welcome priority for us at the Collard Group – as an enabling partner for construction works nationwide.

They’ve pledged to build 1.5 million homes over the next parliament, invest in crucial infrastructure, uncomplicate the planning process, and release ‘grey belt’ land for development. These are promising commitments.

In particular, their strategy to reform planning will hopefully streamline and speed up new development, unlocking building projects currently stuck in red tape.

We hope Labour will prioritise the construction sector’s significant skills and labour shortage. They could do that by equipping the unemployed with the right training and providing grants to help businesses upskill

“Labour’s ‘Get Britain building again’ is a welcome priority for us at the Collard Group – as an enabling partner for construction works nationwide”

their existing workforce or recruit additional employees.

With that in mind, seeing how things like Skills England affect our industry will be interesting. This initiative brings together companies like ours with education and training providers, unions, migration experts and the government to ensure we have people with the skills we need in this country. Having worked with Basingstoke College of Technology, for example, to attract students to our company, we’ve seen the value of partnership working, so there’s hope there.

Labour’s view on immigration isn’t always popular. However, any immigration strategy they introduce must help to plug the sector’s skills and labour gap.

At the Collard Group, we have a solid environmental purpose. We call this ‘recycling the past for the future’, where we demolish buildings, prepare land for development and process waste to make it useful again.

While the new government will favour businesses like ours with a serious sustainability agenda, we want this parliament to prioritise and better explain its commitment to reducing waste by moving to a circular economy.

Each year, we invest millions of pounds in fleet, plant, technology, and training to ensure we keep growing and innovating. In the past, the government has provided incentives to do this, for example, the ‘super-deduction’ initiative, where we could claim 130% capital allowances on plant and machinery investments. As a company keen to use greener, higher-performing and more fuel-efficient tools, we’re waiting to hear if the new government will prioritise something similar.

A change in priorities is on the horizon for our industry, and we’ve recently seen an increase in tenders arrive through our door, which may indicate developers are beginning to regain confidence now that inflation has stabilised. We’ll know soon whether the interest rate is lowered, too, as predicted [the Bank of England dropped the base rate to 5% on 1 August]. This should hopefully reinvigorate the economy, presenting even more opportunities for our sector.

At Romax Solutions, finding the best candidates is our driven desire and passion, we aim to meet the recruitment needs of a diverse range of clients within the construction & demolition industry, leaving them happy, everytime. Romax Solutions is also fully accredited by the Recruitment and Employment Confederation and the National Federation of Demolition Contractors.

With a depth of knowledge, our experienced and trusted staff are on-hand to deliver a bespoke service, supplying reliable and talented staff of all levels both nationally and locally. Specialising to demolition contractors to NFDC guidelines. As Members of the NFDC we offer Internal training to all our candidates whether starting their career in demolition or to help further their skill set.

Without the plant-hire industry, the UK’s construction sector cannot function. Contractors and subcontractors hire most construction equipment. Very few contractors own their own plant. CPA members operate and represent all the different types of construction equipment available.

The plant-hire industry also invests heavily in the workforce of the future. The sector is responsible for a vast array of apprenticeships within the industry and is a leader in the recruitment of young people and those looking for a major career change.

Offering long-term roles with the ability to train, progress and build a sustainable career, the plant-hire industry is playing its role in making construction a more attractive industry to have a career in.

Chris Cassley, Policy Manager of the Construction Plant-hire Association (CPA) said: “The new government must work with the construction industry in addressing critical issues such as decarbonisation and reaching net zero, improving productivity and

business investment, building the new homes that we desperately need, and renewing our ageing infrastructure.

“All of this requires a longterm vision and consistency from government in how policies are developed and implemented. Providing the stability and economic foundations needed for lasting economic growth comes only from engagement with industry in understanding the challenges companies face - and how they can be overcome. The CPA looks forward to working with the new government in achieving this aim.”

These are our core priorities for the next government.

Reinforce business investment and future house building programmes

Establish a credible timetable for the extension of the Full Expensing Allowance to every aspect of the construction plant-hire industry. When ‘fiscal conditions allow’ is too vague and undermines confidence in business investment decisions.

“Without the planthire industry, the UK’s construction sector cannot function”

Reforms to the planning system must be realistic and proportionate. Learning from past failures at both central and local levels are important if we are to build the future homes we need.

Decarbonisation of construction plant

There should be one single government department responsible for decarbonisation of construction plant. Current policies and roles are split between at least three government departments.

Temporarily reintroduce the rebate for Hydrogenated Vegetable Oil (HVO) to the construction industry for at least the next two years.

Develop a trial scrappage scheme for NRMM (Non-Road Mobile Machinery) businesses operating in Freeport zones, with a view to widening the scheme on a national basis.

Publish the Low Carbon Fuels Strategy as soon as possible and develop a road map for the decarbonisation of NRMM.

The position of construction minister must be solely dedicated to the sector and not split among a range of different ministerial responsibilities across different industrial sectors.

The current approach by the police on abnormal loads and embargo times are having an adverse effect on the efficient movement of construction plant – especially mobile cranes. Some companies are facing an existential threat. The government must get the Home Office and Department for Transport to work with the industry and police chief constables to outline concerns and ensure the current lack of flexibility amongst police forces is addressed.

Build on current work with the construction industry to grow the domestic skills base, improving both apprenticeship funding and retention rates amongst apprentices, while also making the industry an attractive career option for people already in the workforce. Realism is needed in recruiting from overseas, with the Migration Advisory Committee working with the construction sector in addressing current skills gaps.

The legislative impasse on the creation of Great British Railways (GBR) must be resolved as soon as possible. A growing rail plant and rail maintenance industry is at the heart of a successful rail sector. The current delays have undermined progress, with the supply of future work bank visibility fragile.

We support the new government’s commitment to sustainable development and commitment to provide a significant improvement in planning for new housing. We firmly believe that prioritising brownfield development is a critical step in protecting our green spaces and promoting sustainability.

By focusing on the redevelopment of brownfield sites, we can significantly reduce the need for new construction on greenfield locations, which will in turn preserve valuable agricultural land.

The demolition process plays a vital role in this, as it allows us to unlock and recycle materials that can be reused in the creation of new housing and infrastructure projects. This approach not only minimises the consumption of new resources but also enhances the overall sustainability of development projects.

We are enthusiastic about continuing our work with the Ministry of Housing, Communities and Local Government (formerly the Department of Levelling Up, Housing, and Communities) to support this cause by enhancing understanding of demolition’s role in sustainable development. Often misunderstood, the demolition industry is dedicated to sustainable practices that contribute to the efficient and responsible

redevelopment of our urban areas.

We also welcome Sarah Jones to her new role as Construction Minister in the Department for Business and Trade, alongside her role within the Department for Energy Security & Net Zero. We welcome the opportunity to collaborate with the minister and her team.

The NFDC looks forward to working closely with the government and other stakeholders to promote the benefits of brownfield development and to highlight the significant contributions of the demolition sector to a sustainable future.

“The NFDC looks forward to working closely with the government and other stakeholders to promote the benefits of brownfield development and to highlight the significant contributions of the demolition sector to a sustainable future”

By Richard Dolman

Are you feeling a little unsure of the market as we are in a period of political change?

At the time of writing this, a new government is being formed. So, what does this mean for us as business leaders, employees and the industry as a whole?

Whether we are in demolition, housebuilding, contracting or the wider construction industry, there are several factors that affect our ability to plan effectively and confidently, that impact our sales pipeline and directly influence our bottom line. Consumer confidence –that is confidence of the end users, confidence of contractors, main contractors and financers.

Political and economic changes hugely affect businesses, coupled with how our competitors react to

“There are several factors that affect our ability to plan effectively and confidently, that impact our sales pipeline and directly influence our bottom line”

these changes that impact your own business approach to pricing and sales mix. It has a domino effect. Arguably, this is completely understandable. Uncertainty changes our mindset. But in this latest wave of uncertainty, we knew an election was going to be called, then a date was set, then we entered purdah – the pre-election period of sensitivity.

According to The House of Commons Library, the period of pre-election purdah in which there is heightened sensitivity regarding decision making and publicity is not governed by law, but convention. Backbench and opposition MPs are not constrained by this, however, so why are we?

Convention has led to local authorities setting their own statutory guidance for purdah. In turn, when working with central government, we are also affected by these periods.

We’re all now waiting for the “what next”. What new policies are being implemented, which areas will have the greatest focus for the

incoming government, how will this affect our bottom line, ability to implement our own strategies, our labour supply and our orders? It all sounds very daunting, but does it need to be?

Policies are not usually implemented and actioned suddenly (unless as you read this we already have a new Act directly impacting us). Despite the inevitable declarations of change which will be implemented, it will take time. We have time to adapt with the potential changes, so why are we holding our breath? Wouldn’t it be better for us all to help instil confidence by sharing our plans and our (albeit considered) investments with our clients and the wider industry? This would show how we do still have plans for our businesses, we’re not shying away from progress because of political change, but trying to embrace it. Confidence drives consumer spending, and this is what we need. We all know this.

Let’s work together to keep our industry pushing forward. In recent years, the majority of us have overcome so many challenges, this is just another one. Change is inevitable. We shouldn’t be driven by the what ifs so significantly; we need to stand together to manage the next phase of change.

Lloyd, Head of Vendor in the SME

It’s been a busy few months for the industry. Like many in the sector we had been waiting in anticipation for the big event of the year – Hillhead. The Buxtonbased showcase is a great chance to catch up with friends and colleagues and to make new acquaintances.

It’s also a great opportunity to witness the constant innovation in the construction sector and see new technology emerging. There was everything from hydrogenfuelled equipment to autonomous machinery, showcasing the future of construction.

In addition to Hillhead, there has been another big event recently – the UK general election. It was evident that whoever won the election was going to need to do more for SMEs in the construction industry.

As previous columns have highlighted, it’s been difficult for

many in the sector over the past few years. External factors like supply chain difficulties, soaring labour costs and poor weather conditions affected the ability of many businesses to work to full capacity.

Therefore, it’s been a relief for many to hear policies announced so swiftly.

A welcome announcement has been the reintroduction of mandatory housing targets – this should be a huge support to all businesses operating in the construction sector. The focus on brownfield and greyfield sites is also a bonus as these will invariably require demolition skills.

Unfortunately, the previous removal of the housing targets was unhelpful for the industry as well as homebuyers. Therefore, the reintroduction of these targets and the pledge to deliver 1.5 million new homes over the next five

“It’s been a relief for many to hear policies announced so swiftly.”

years is encouraging.

In addition, there are wider signs that the economy is starting to bounce back. The ONS reported in July that there was 0.4% growth in GDP in May and the construction industry also reported an increase of 1.9%, a good sign after months of declining activity.

Further to this, the announcement of the National Wealth Fund – which has seen £7.3bn pledged to help drive investment in the UK and importantly unlock more opportunities in green energy will be welcomed by many in the industry as we continue to strive towards a greener future.

These new policies are encouraging positivity among those in the industry, however, we must hope that the new government continues to prioritise economic growth and see these policies through.

Our unique capability to repurpose virtually all construction and demolition waste from site helps our public sector, local authority, commercial and residential clients achieve zero-to-landfill targets.

Demolition

Structural alterations

Site clearance

Soft strip

Asbestos management

Remediation

Earthworks & civils

Temporary works

Demolition & Enabling Works Waste Management Aggregates & Concrete

Interviewee: Lee Rowbotham

Role:

Managing Director

Company: Demex

QSo how’s business?

I run Demex for the scrap metal merchants, CF Booth Group. They’re a family business with Demex as a subsidiary, but they leave me to run the Demex side of things. We’ve certainly been very busy.

We’re doing a job for Bradford College on one of the busiest streets in the centre of Bradford, taking down a four storey stone building. The building was full of asbestos so our licensed asbestos side has been in there for about 12 weeks. We did a basic soft strip to begin with, then they came in and removed all the asbestos. We then returned to do the final soft strip before we started demolition on Monday. We’re going

to salvage as much of the stone as we can for resale, it’s going well so far.

We’ve got a job demolishing a wing of a hospital in Harrogate, which is just a single storey building but it is attached to two other live sections of the building, so it’s separation then straightforward demolition.

Another inner city job attaches to a shopping centre right in the heart of Doncaster. Again that’s partly high reach work, partly lower level work. It’s got its own requirements including vibration, dust and noise monitoring.

We’re also taking down a large canopy outside of Rotherham

market and demolishing some buildings there, again city centre. And we’ve got a soft strip in a 23-storey student accommodation block in the centre of Leeds.

QTell us your own demolition story

If I’m totally honest, I wanted to be a policeman. So I stopped on at school and did some A Levels because I did quite well in my O Levels and was too young to join the police. When I did apply, I got to the final stages and went to London for my final interviews and medicals. I didn’t like those few days in London, so I decided not to join the police.

So suddenly, what next? My father was a contracts manager for a construction firm based in Sheffield, where I lived. They were after training up a civil engineer, putting them through college and university. So the first thing I said to my dad was, what’s a civil engineer?

They put me through the education, partly on the job, partly college and university and I became a civil engineer. I spent four or five years doing that and they made me a trainee site manager. My role was to do the civil engineering on the job and stop on to help run the site with the senior site manager to learn the ropes. They were clearing this housing estate of blocks of flats, so apart from the civil engineering, they asked me to keep an eye on the demolition company. I was just amazed at what they could do.

I was approached by a local demolition company. The contracts manager asked me to come in as a project manager, predominantly in charge of earthworks initially as that’s where my experience was but moving on to demolition. They showed me the ropes, estimating etc, and a few years in I became a project manager on the demolition side. I spent 12 or 13 years there and then I was offered a position as Contracts Manager with Demex, where I am now.

I was doing the Contract Manager’s role plus the estimating, pricing the work and method statements, spending six years here before being offered a role at a demolition company in Manchester. It was a lot larger firm and they specialised in nuclear, petrochemical and things like that, which I didn’t have a great deal of experience with – I wanted to spread my wings and learn it all.

So I went there for two years as Contract Manager and did various jobs around the country for them, including gas holder tanks in London, Peterhead power station, and then looking after a simple job at a nuclear plant, which gave me the ropes in the nuclear industry.

I’m a member of the Institute of

Demolition Engineers so I go to the annual seminar in Leeds and for a number of years I’d passed the time of day with a gentleman called Steve. When I’d got the nuclear project, I met Steve and dropped into conversation that I’d got a job starting there and it was a steep learning curve – I’d heard that getting RAMS, plans of works etc signed off with all stakeholders was quite difficult.

He laughed and said, “Believe it or not, I’m the health and safety officer there.” I said, “You’re joking. We’ve known each other for the last five or six years.” So he says, “You always make a beeline for me here, we have a chat and I really appreciate that, so I’ll return the favour. Come up and see me. I’ll spend a couple of days with you.”

That was the best two work days I’ve spent in my life. I went to the plant, met him and went through the job he was doing next. We sat down and literally wrote the RAMS together, so that went through fairly quickly – with nuclear jobs comments usually get passed back and forth and it might take three months before you get it signed off. So my employer thought, Lee’s good at this, he knows his stuff, and thanks to that two-day training on

how to present submissions they put me in charge of a few other nuclear jobs.

Then my old gaffer at Demex retired and the owner of the company rang me up and asked if I’d be prepared to come back and run it. I was more than happy where I was but the opportunity to go back and run a company I loved was a challenge I relished.

So for the last 12 years I’ve been back at Demex. Coming from civil engineering was a good foundation because appreciating how buildings are put together gave me the foundation on how to take buildings down. A lot of the time you’re just doing it in the reverse order.

I think the reason I’ve always loved demolition is that you’re always learning; anybody who tells you they know it all is a liar. Every job is different. It might look similar to the last job but it’s got different challenges and different approaches to how you’re going to demolish it. That’s what keeps me interested in the job.

QAnd what about the Demex story

The CF Booth group are scrap metal merchants based in Rotherham – once upon a time they were the largest family run scrap metal merchants. Obviously, they were having scrap metal brought in from all directions and they realised demolition people bring in a lot. So in 1976 they started Demex. We’ve got a licensed asbestos side and a recycling side, but predominantly we do demolition.

We don’t specialise in any particular type of demolition. It could be anything from a bungalow up to multi-storey blocks of flats, stadiums, ex-collieries etc. We have an abundance of excavators ranging from a 17-tonne rubber duck to 20 tonners, 30 tonners, 50 tonners. We’ve got a 32-metre high-reach and the largest of our excavators is a Hitachi 870, which is a 90 tonner that has an 11-and-a-half tonne shear on the end.

We’re not the biggest of companies but we do everything safely and get a good name for ourselves. We work for some blue chip companies but also for councils, Doncaster Council, Rotherham Council. Predominantly we’re the principal contractor, but we also work as a subcontractor.

QWhat kind of work culture do you like to foster?

The main thing is we work as a team, we all get on. I think you work a lot more efficiently like that. It’s a twoway street so they can come to me at any point and I listen to them and we help where we can. For instance, I might put a Method Statement together for a certain job, that goes out to the site manager, he cracks on with the job and then he might come back to me and say, “Do you think doing it like this might improve matters?” So I listen and if it’s true we’ll change it to suit.

One of the big issues at moment is mental health. We see each other as family, so we’re there to help each other, not just work with each other. That goes from me right down to the labourers on site.

Obviously, the most important thing is health and safety. It’s a must. If we need money to improve or maintain health and safety, then that is what it is, there’s no ifs and buts.

We must be doing something right because the average time spent at this company is probably 20 years plus. I’ve been here 12 years and I’m one of the newest members. We all know each other’s strengths and weaknesses, what makes each other tick.

QWhy choose Demex?

We’re the cream of the crop because we’re members of the National Federation of Demolition Contractors; we’ve been here since 1976, have very experienced, knowledgeable and well-trained staff and we’ve never failed at anything. We’ve done all types of work and the majority is done in house – if there’s asbestos on a job, it’s done in house,

all the transport is done in house. Where we do have to outsource, we know their health and safety standards are as good as good as ours.

We try and take all the weight off clients’ shoulders. Our attitude is, “You’ve given us the job, we’ll only involve you if and when it’s necessary. We’ll only contact you with a question, not a problem.”

We’re not one for advertising the company, it’s word of mouth – if we do a great job for people, they’ll pass that information on. You’re only as good as your last job so we say, let’s make that last job even better than the one before.

We don’t want upset clients, so we do a thorough estimate and are transparent in what we price. If that means that we don’t win the job because we are a little bit dear, then so be it.

Q

What certifications and accreditations do you have?

Demex is a member of the National Federation of Demolition Contractors, Constructionline Gold, SSIP and certain other things. Personally, I’m a full member of the Institute of Demolition Engineers, I’ve got my CSCS professionally qualified persons card in demolition; CCDO senior managers card (an NVQ 7); IOSH; UKATA licensed asbestos removal contracts and manager’s card.

I don’t have too much to do with the asbestos side of things but if I’m leading something I like to be knowledgeable in that field. So obviously back in the day, that’s when I went and got my UKATA contract manager’s certification, which I obviously annually review.

QHow do you bring new people on board?

It’s very difficult in our industry because the younger generation don’t want to commit to demolition because, well, it is hard work. So the NFDC and the industry are trying to bring younger people in through apprenticeships and things like that.

If we’ve got a young demolition labourer who’s keen, intelligent, ambitious, I’ll chuck all the money in the world at them to get them to the next level because it benefits us as a company. So willing people can go as far as they want in our company. But it is hard work getting the younger generation into the demolition world.

QDoes Demex have any engagement in the community?

We do. There’s a special needs school in Rotherham that can’t get funding to improve their buildings, which are really dilapidated. There’s a caretaker’s bungalow and some modular cabins that I’ve said we’ll demolish free of charge and remove from site.

Wherever we can help out, we do so. There are certain local charities that we’ve given to in the past and we sponsor a few youth football clubs. Whatever fundraising we do, we only give to children’s charities.

QWhere do you see things in terms of zero carbon machines?

We’ve not gone down that line yet as I don’t think the technology is there for your 30, 40 tonners that use a lot of power, but we certainly would do. But 50% of our company cars are electric. All our machines, our excavators and lorries are modern, we use HVO wherever we can, if we can get a supplier that supplies it locally to the job.

QWhere do you see Demex going over the next few years?

Offering what we offer now, keeping our good name and making progress within the industry. If we can grow, that’s brilliant, but what I don’t want to do is lose any quality.

I think we’re a nice size now and we can comfortably maintain that. We will try to get on board with any new techniques that emerge, especially if it saves time or makes life easier.

What do you do for fun?

Spend time with the family – my children are getting older and grandchildren are on their way

What would be your desert island (exile) luxury?

No mobile and internet reception

[No problem, that doesn’t just come as standard, it’s compulsory]

What gets you out of bed in the morning?

The love of my work, also knowing I will eventually be home to spend time with the wife and kids

When and where were you happiest?

Being present at all my children’s births

What’s the most expensive non-essential you’ve ever bought?

A Rolex

What’s your bucket list activity?

There is no dress rehearsal in life, so living it to its fullest, long enough to see my grandchildren grow into adults

M A XIMUM PERFORMANCE

LOWEST OPERATIONAL COSTS

HIGHEST RELIABILITY

Project (name/title): Richmond College

Structure: 1930s era school/college

Site area: Entire college

Scope of works: Soft strip, asbestos survey, full mechanical demolition including slab and foundation removal, crushing all hard arisings to 6F2 material for use within parmats on site, disconnection of services, asbestos removal, scaffolding

Contractor: Downwell Enabling Solutions

Client: London Square

Start date: February 2024

Completion date: Phase 1 completed soon with phase 2 commencing shortly

Future use: Affordable housing

A-Level student and budding journalist, Annie Davey experienced her first taste of demolition through a work experience placement with Demolition Hub. Accompanying Ben Chambers on a site visit to a Downwell Group project in Twickenham, she faced up to common preconceptions about the role of demolition in the human environment and society

I was fortunate enough to visit a demolition site for the first time as part of my work experience for college. Despite having very little knowledge of demolition before my visit, this experience was a real eye-opener for me and gave a great insight into the complex world of demolition. As a female college student with no family in the industry, I had previously only

been exposed to mainstream media’s mostly negative coverage of the industry and so naturally, as a media student, I wanted to get some first-hand experience and decide for myself what was fact and what was fiction about this, in my opinion, highly misunderstood industry.

My day was spent in Twickenham on Downwell Enabling’s demolition site where they are demolishing Richmond Upon Thames College to make room for new housing, with around 50% of the new homes being affordable for local people. We were greeted by the site managers, shown

around the site and talked through many of the processes taking place.

Working in demolition can be a dangerous job so unsurprisingly safety was clearly the number one priority on site, with all workers and visitors kitted out in high-visibility jackets, hard hats, steel-toed boots and with some even wearing masks and ear defenders. Fences surrounded the site, protecting members of the public, and metal barriers were placed throughout the site, showing where was safe/unsafe to go based on what machines were running and where.

The sheer scale of the site along with the numerous machines operating was, at first, slightly daunting to see but I soon grew used to it as I realised I was in safe hands.

My time on the demolition site provided invaluable insight into the fascinating world of demolition and allowed me to be fully immersed in it. I feel that I learned so much from the site visit and now have sufficient knowledge to form my own opinions and contribute to discussions around this industry with others, especially my peers, who may also not have much experience with demolition.