December 2022 | Issue #14 DeMOLITION HUB MAGAZINE UK, European & worldwide demolition matters ASSOCIATIONS ANGLE All their goings on in here... DEMOLITION DISCUSSION #championingdemolition

info@liugong.co.uk 02392 123 392 www.liugong.co.uk FROM 1.8 TO 95 TONNES THE ALL NEW F-SERIES BREAKS THE MOULD. SCAN THE QR CODE TO DISCOVER THE DIFFERENCE GROUND BREAKING DESIGN TOUGHNESS CONTRÔL INTELLIGENCE

Closing yet another year of industry reporting, case studies, interviews and events seems to come around so frequently, with this now our sixth and final issue of 2022.

It has been a busy and productive year, having what seems like yesterday celebrated those working in British demolition at the British Demolition Awards in September. It was there among the awards, networking and frivolity that we inaugurated the Demolition Hall of Fame, with one of the two inductees being William Crooks, who in three months will hand over the reins of power as his two-year NFDC Presidency comes to an end. Well done William – a brilliant President with a difficult role.

Also, a huge well done to Richard Dolman who I witnessed chair his last IDE AGM last Friday for his two years of stellar work as IDE President.

Speaking of associations, 2022 has seen us work closer with both the EDA and NDA as they understand our no agenda reporting and tone. We were invited to both San Diego (the NDA Conference) and Paris (the EDA Conference). We continue these partnerships into 2023, allowing for both the European and North American continents to learn how the Brits do it (brilliantly) with, of course, many techniques to be learned in return.

We can boast that our LinkedIn channels are unrivalled in terms of demolition industry followers and connections and our follower numbers on Instagram are organically growing, now approaching 2,000 accounts of those with an actual interest in demolition.

In this issue we are delighted to welcome MB Crusher for our regular SUPPLIER TALK interview. I had to double check we had not featured them for this before as they have been long term supporters of the magazine and offer some very impressive bespoke bits of kit. We welcome our 14th contractor for the DEMOLITION DISCUSSION; this time Bradley Harris from Northeast Demolition takes the hot seat.

So with another 12 months behind us, it would be remiss of me not to thank from the bottom of my heart those who pick up this mag and give it a little or a long read, those who support us and those who advertise within.

Finally, as I make the first draft of this the BBC is showing the demolition of the Redcar steelworks blast furnace live on BBC One, a faultless demolition job done, and almost as importantly, a positive piece on demolition for the masses. We will continue to offer the same positivity.

To another good year.

Demolition Hub ben@chambers.media

Demolition Hub ben@chambers.media

Publisher,

DemolitionHUB Magazine | 3 PUBLISHER Ben Chambers ben@chambers.media 01903 952 648 EDITOR Toby Wilsdon toby@chambers.media 01903 952 645 DEMOLITION EDITOR Paul Argent paul@chambers.media 07813 064 590 COLUMNISTS Richard Dolman Jacqueline O’Donovan Terry Lloyd SALES Ben Chambers ben@chambers.media 01903 952 648 Luke Chaplin luke@chambers.media 01903 952 643 DESIGN Nicki Chambers nic@chambers.media Alex Jarrett PRODUCED & PUBLISHED BY Global News Media Ltd Suites 5 & 6, Chapel House,

Chapel Road, Worthing, West Sussex

ben@chambers.media 01903 952 640

1-6

BN11 1EX

Demolition Hub are proud supporters of the National Demolition Association Demolition Hub are the media partner for the European Demolition Association

Demolition Hub is published six times a year. The subscription rate is £60 per year. Subscription records are maintained at Global News Media Ltd, Suite 5 & 6, Chapel House, 1-6 Chapel Road, Worthing, West Sussex BN11 1EX.

Articles and information contained in this publication are the copyright of Global News Media Ltd and may not be reproduced in any form without the written permission of the publishers. The publishers cannot accept responsibility for loss of, or damage to, uncommissioned photographs or manuscripts.

demolitionhub.com

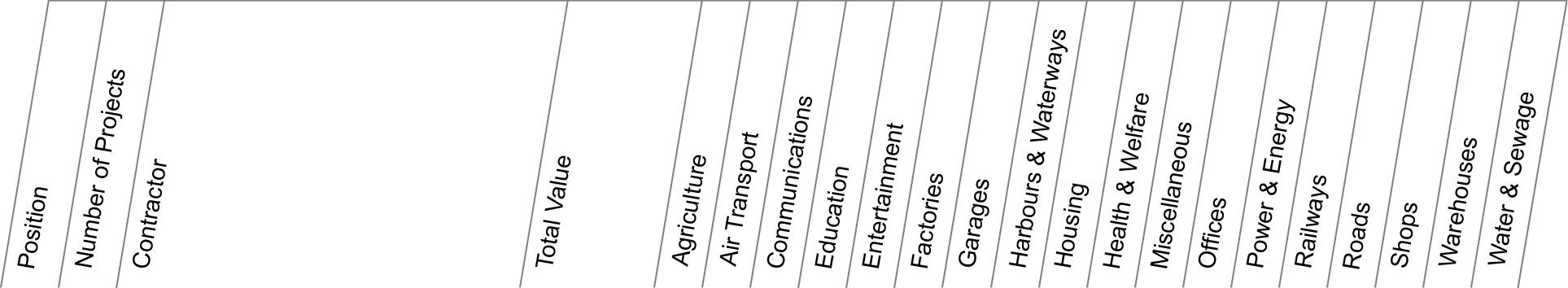

36 SUPPLIER TALK With Giovanni Achille, UK Country Manager of MB Crusher demolitionhub.com 82 4 | DemolitionHUB Magazine 45 CONTENTS 6 NEWS 150 jobs up for grabs as JCB apprentice and graduate scheme opens to applicants British Demolition Awards & Demolition Hub’s Mates in Mind Campaign CJ Charlton buys Volvo The CEA’s response to the Autumn Statement CPA response to Autumn Statement UK construction equipment sales show strong growth in October World Demolition Summit 2022 award winners NFDC statement on the handover of Presidency Demolition Hub reports from the IDE’s AGM 16 EUROPEAN DEMOLITION ASSOCIATION NEWS VERAS’ Annual Convention 2023 EDA Think Tank 2022 24 CASE STUDY From civic to domestic – Sunderland Civic Centre 28 DEMOLITION DISCUSSION With Bradley Harris, Contracts Director at Northeast Demolition 32 CASE STUDY Swantest works over water in concrete renovation project at Brighton Marina 18 NATIONAL DEMOLITION ASSOCIATION NEWS Priestly takes the high road in Toronto NASA HQ meets its maker 42 CASE STUDY Sky Revolutions captures Thompsons of Prudhoe’s demolition of Redcar Basic Oxygen Steelmaking Plant 76

demolitionhub.com Magazine | 5 Industry leaders in design and manufacture of bespoke excavator equipment and modifications Kocurek Excavators Ltd. 24 Arkwright Road Hadleigh Road Ind Est, Ipswich, Suffolk IP2 0UB t: +44 (0) 1473 217477 e: sales@kocurek.co.uk www.kocurek.com ALWAYS IN REACH 46 EVENTS • Plantworx gains traction as exhibitors book for 2023 event • British Demolition Awards 2023 84 INDUSTRY KKB Group inaugurates Volvo hybrid excavator fleet Not a waste 90 CONTRACTS Builders’ Conference CEO Neil Edwards reports back on the UK construction sector for October 98 OPINION Richard Dolman Jacqueline O’Donovan Terry Lloyd 50 BAUMA • AUSA • Bobcat • Brokk • Cat • CDE • Doosan • Epiroc • Goldhofer • HSM Buckets • MB Crusher • ROCO • Rototilt • Rotar – Our Demolition Editor, Paul Argent, spoke to Rotar at bauma about its history and latest products • SANY • SENNEBOGEN • Thwaites 76 CASE STUDY Shear Power by Paul Argent 80 CASE STUDY “The latest tech at a reasonable cost” by Paul Argent

news NEWS

150 jobs up for grabs as JCB apprentice and graduate scheme opens to applicants

demolitionhub.com 6 | DemolitionHUB Magazine

Professional Practice in Management graduate and JCB Government and Defence Contracts Manager, Hannah Hurdley

More than 150 new jobs for apprentices and graduates are up for grabs at JCB as the company launched the application process for its hugely successful Early Careers Programme in October.

The Staffordshire digger giant has begun inviting applications for its 2023 intake, with competition expected to be fierce after more than 2,000 people applied for places last year.

Opportunities for 2023 include graduate careers in Design and Development, Future Technologies, Electrical and Controls, Software Development and Sales and Marketing. There will also be degree apprenticeships in Business and Engineering alongside Level 3 apprenticeships in areas such as Manufacturing Engineering, Purchasing, Mechatronics and businesswide technician opportunities.

In addition, Level 2 assembly and welding apprenticeships will be offered for recruits from aged 16+, while the company will be partnering with The JCB Academy to offer new T-Level qualifications.

Group HR Director Max Jeffery said: “JCB is one of the world’s largest construction and agricultural machinery manufacturers and we offer huge scope to develop very

rewarding careers. JCB has ambitious growth plans over the next five years and nurturing new talent will be a key to success.”

JCB has invested more than £8m in developing its Early Careers Programme, and since 2008 more than 1,300 people have joined the company through the scheme. Among them are Hannah Hurdley, who joined as a Business Degree Apprentice aged 18 after her A levels. She completed a degree in Professional Practice in Management and, immediately after coming off scheme, secured a job as JCB Government and Defence Contracts Manager.

Former Derby High School student Hannah, of Burton-onTrent, said: “I am still only 22 and I have a very interesting and responsible job with great career prospects. What is amazing is that I continue to be supported by some of the most experienced senior people at JCB as my career develops. To anyone thinking of applying for the 2023 apprentice and graduate intake I would say one thing: go for it. It is a decision I have never regretted.”

Anyone interested in applying for the JCB Early Careers Programme should visit earlycareers.jcb.com.

British Demolition Awards & Demolition Hub’s Mates in Mind Campaign.

We have recently received our third certification of appreciation award gifted from Mates in Mind post the 2022 British Demolition Awards.

This has our branding on it, but this award is for everyone that has attended an event of the years and donated to this most worthwhile of cause.

Through all of your generosity (and possibly after a little tipsy bidding) we have now raised over £12,000 for Mates in Mind at the past three British Demolition Awards events.

You should be proud; I know I am.

I met with Mates in Mind recently to inform them that they would be our charity of choice once again for 2023 at the 1st September event at the Tottenham Hotspur Stadium.

Join us.

Ben@globalnews.media 14 1 / 022 £ 4 0 0 7 8 8 D e m o l i t i o n H u b news demolitionhub.com DemolitionHUB Magazine | 7

Charlton buys Volvo

by Chris Charlton

CJ Charlton Group recently added Volvo EC145 and EC380 crawler excavators to our demolition equipment fleet. We bought our first EC380 back in early 2022 and have received great feedback from our operators. The machines have slew ring guards, boom ram guards and track roller guards that help minimise any accidental damage when working in harsh environments where there is a lot of concrete, making them very well suited for demolition work.

Having the added reinforcing bars at the bottom of the dipper arm is a good feature to help prevent damage when excavating old foundations.

The machines have a very operator friendly cab, with air suspension seats that are adjustable in many ways and easy-to-use computers for adjusting attachment modes and monitoring things like fuel consumption. Refilling the adblue is easy too thanks to the location of the filling cap.

demolitionhub.com 8 | DemolitionHUB Magazine

CJ

CEA response to the Autumn Statement

by Suneeta Johal, Chief Executive of the CEA

There were no great surprises from Jeremy Hunt’s Autumn Statement in November – many of the announcements relate to years that fall after the next general election so much of the impact will not be felt for years to come – however, the government’s commitment to invest in infrastructure and energy efficiency is very welcome.

The Chancellor says the government will focus on economic growth, despite having to find budget savings. A silver lining for our sector was the announcement that energy, infrastructure, and innovation are high on the government’s priorities.

We welcome the government’s decision to proceed with a new nuclear power plant at Sizewell C, which will help to provide reliable low-carbon power. This new power plant will create 10,000 skilled jobs, however, there was no mention of the chronic skills shortage we are already facing. The sector is struggling to recruit people – due to competition but also a lack of awareness and perceptions among younger generations. There is significant work to be done on this and the CEA continues to feed back to government through its

position on the National Manufacturing Skills Taskforce.

The go-ahead for Sizewell C is on the proviso that the plans receive final government approvals, which we expect to be signed by relevant parties in the coming weeks.

Hunt confirmed that as part of the government’s commitment to growth and infrastructure – they will deliver the core Northern Powerhouse Rail, HS2 to Manchester, East-West rail, the new hospitals programme and gigabit-broadband roll-out. These will be funded with over £600bn of investment in the next five years, which Hunt said “will connect our country and grow our economy”. The CEA welcomes the Chancellor’s continuing commitment to major investment in infrastructure.

By 2030, the government wants to reduce energy consumption from buildings and industry by 15% – and from 2025, there will be a further £6bn in funding to deliver the UK’s new energy efficiency ambition. Let’s just hope that whoever is in power

at that time commits to fulfilling this funding.

The Energy Price Guarantee (EPG) will be maintained through the winter, limiting typical energy bills to £2,500 per year. Disappointingly, from April 2023 the EPG will rise to £3,000 with prices forecast to remain elevated throughout next year. In addition, there was no further mention of support for business and the CEA calls for the Energy Bills Relief Scheme for non-domestic users to be extended beyond six months.

The employers’ national insurance contributions threshold is frozen until April 2028 and the employment allowance will be

demolitionhub.com news 10 | DemolitionHUB Magazine

retained at its new, higher level of £5,000 until March 2026, which is good news for small businesses.

A positive announcement was the plan to help make Britain the “new Silicon Valley”, which will see public funding for R&D increased to £20bn by 2024-25. This is crucial for future growth.

However, the challenges manufacturers face in the years ahead remain substantial and opportunities were missed to support manufacturers through this extremely turbulent time. Therefore, it’s up to us as a sector to lobby government for the support we so greatly need. This includes a coherent and long-term international trade strategy to stimulate economic growth. This is especially important in our sector where an average of 65% of output is exported yet support for trade associations and our members is minimal.

CPA response to Autumn Statement

Following Chancellor Jeremy Hunt’s Autumn Statement, Kevin Minton (right), Chief Executive of the Construction Plant-hire Association (CPA) said: “In what will be challenging economic times, it is welcome that the government has committed to Hinkley Point C, HS2, the East West rail link and Northern Powerhouse Rail.

“This echoes our call for the Autumn Statement to provide stability and confidence for the construction sector, utilising construction as a driver of economic growth. It follows the move to make the Annual Investment Allowance set permanently at £1m. The construction

plant-hire industry has a critical role to play in these projects. Moving into 2023, the CPA will be working closely with our members to realise these ambitions.”

news demolitionhub.com DemolitionHUB Magazine | 11

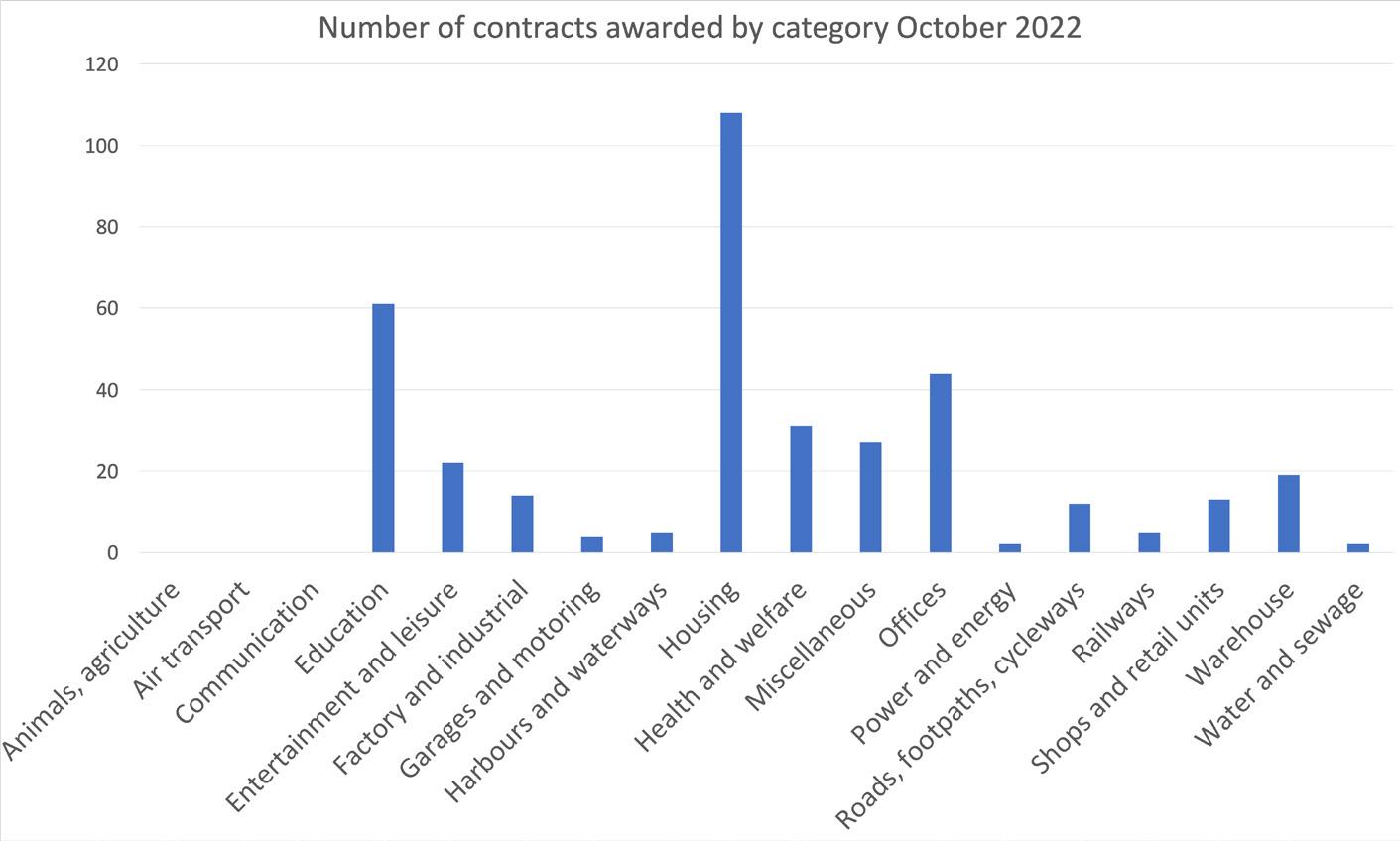

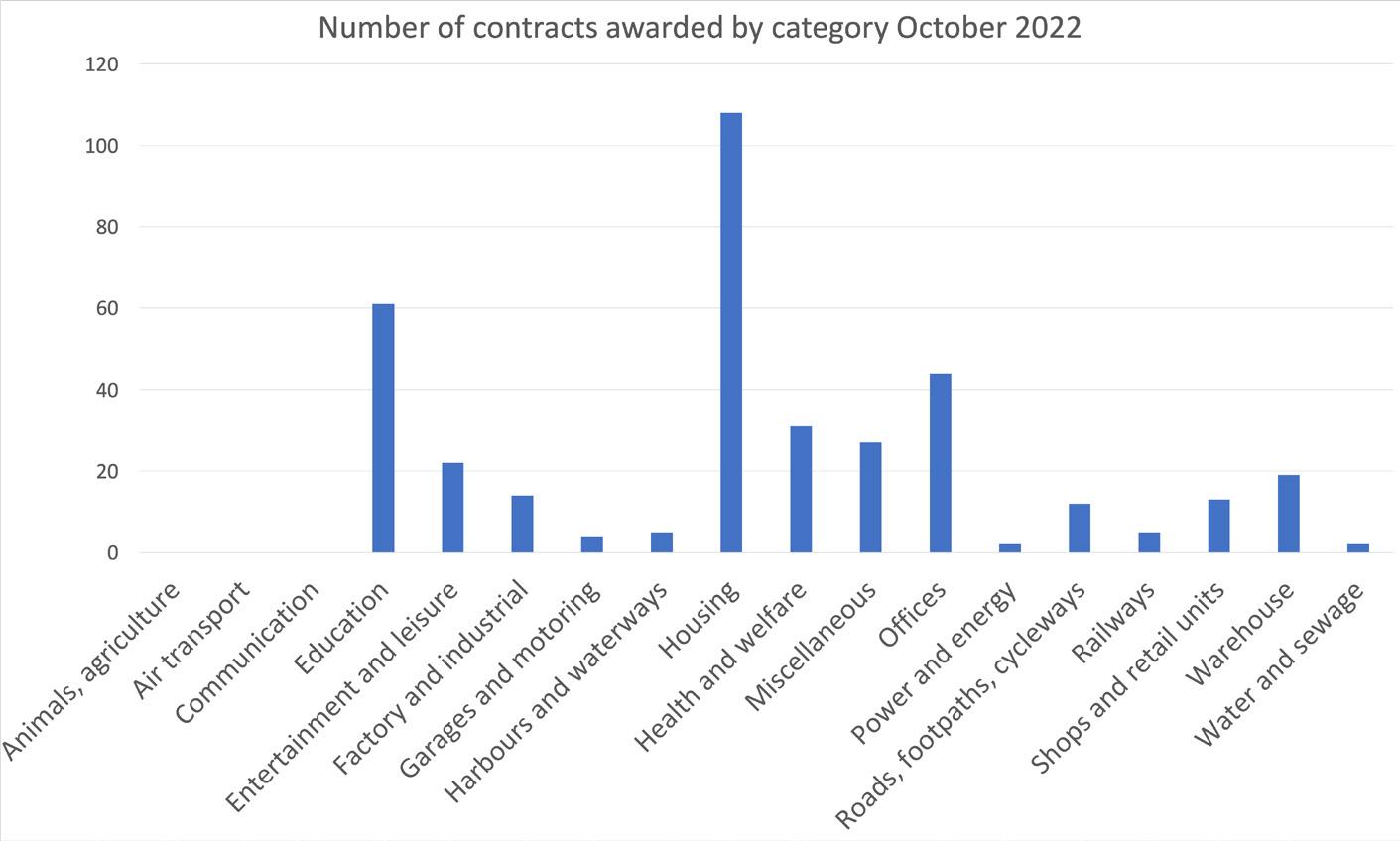

UK construction equipment sales show strong growth in October

Retail sales of construction and earthmoving

in October were 11% above sales in the same month last year. As a result, sales in the first 10 months of the year have almost caught up with last year’s levels, reaching 31,400 units, only 0.7% below last year during the same time period.

A notable feature in October was the strength of sales for the two most popular equipment types, mini/midi and crawler excavators. Both recorded higher levels of sales compared with last year, having fallen short in earlier months. Mini/midi excavator sales

were 9% ahead of October last year and crawler excavators were higher by 19%. This suggests that some of the supply chain issues associated with these products are beginning to ease.

The pattern of sales for the major equipment types January to October year-on-year continues to show a mixed pattern for different machine types. Telehandlers (for the construction industry), continue to show very strong demand and are 20% up on 2021 levels. Sales of road rollers remain the weakest, at 8% down on last year’s levels. Sales of mini/midi

excavators and crawler excavators have improved and are now only between 2% and 6% below last year’s levels in the first ten months of the year.

Sales on a regional basis from January to October compared with the same period in 2021 continue to show a mixed pattern. The strongest region so far this year remains the West Midlands, at over 14% up on last year’s levels. In contrast, three regions are still seeing sales below last year’s levels; London (-12.5%), the southeast of England (-8%) and the north-west (-8.4%).

Equipment sales in the Republic of Ireland are also reported in the statistics exchange. Sales in October were very weak at 25% below last year’s levels. This leaves sales in the first ten months of the year at just under 10% below last year’s levels.

World Demolition Summit 2022 awards winners 16-17 November 2023 1. Civils: Priestly Demolition 2. Collaboration: P Olesen 3. Contract of the Year under $1m: Mainline Demolition 4. Contract of the Year $1m or over: Brandenburg Industrial Service Co 5. Explosive Demolition: Controlled Demolition 6. Industrial Demolition: Despe 7. Manufacturer Innovation, Plant and Equipment: Kobelco Europe 8. Manufacturer Innovation, Tools and Attachments: Arden Equipment 9. Recycling and Environmental: Grupo Mitre 10. Safety and Training: Delsan-AIM 11. Urban Demolition under £10m: Ward Demolition 12. Urban Demolition $10m or over: Erith Contractors 13. New Entrant Award: Aceco 14. World Demolition Award: Brandenburg Industrial Service Co

equipment

demolitionhub.com 12 | DemolitionHUB Magazine

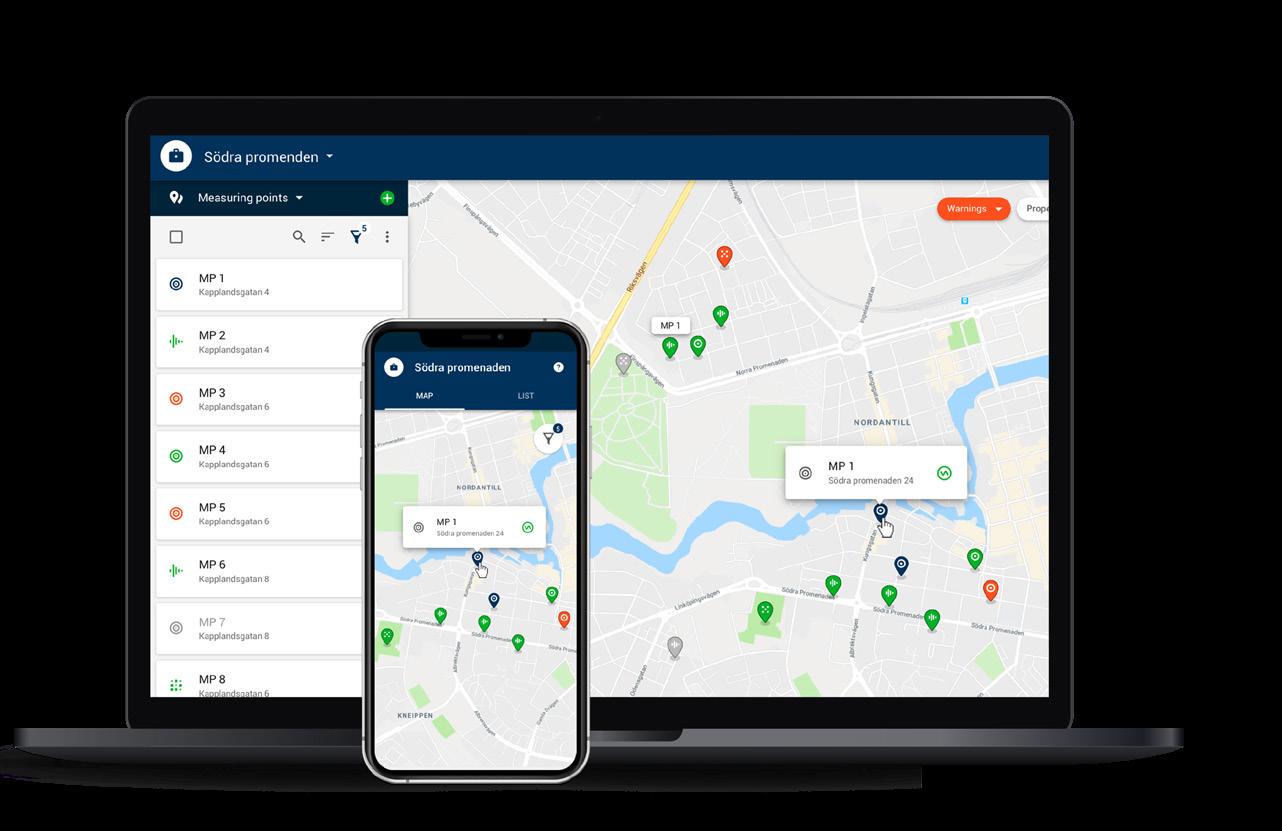

Brokk Connect is your entryway to more profitable business and increased Uptime! The online platform enables you to locate and manage the entire robot fleet with precise information, hour by hour. Whether your goal is to grow your business or optimize your fleet, Brokk Connect is the tool for you to take control.

Brokk UK | www.brokk.com/uk

NFDC statement on handover of Presidency

Following agreement between the Vice-President, Gary Bishop and 2nd Vice-President, John Lynch, the National Council has ratified the following changes to the incoming President position for the 2023-25 term, effective from the NFDC AGM on Friday 24 March 2023:

• John Lynch will progress from the position of 2nd Vice-President to President of the NFDC,

• Gary Bishop will remain in place as Vice-President, to assist with the smooth running of the Federation.

Vice President of the NFDC, Gary Bishop

Vice President of the NFDC, Gary Bishop

news demolitionhub.com 14 | DemolitionHUB Magazine

Incoming President, John Lynch

Demolition Hub attends Institute of Demolition Engineers 46th Annual General Meeting

by Ben Chambers

by Ben Chambers

The morning AGM was completed within an hour and was the last chaired by outgoing IDE President Richard Dolman, who gave a brief President’s report.

In it, Richard stated how well the Foundation Degree has been going under his Presidency and how he will always champion the foundation course.

The IDE now has a vision to be able to deliver two thirds of all the modules for the foundation degree.

Richard thanked the day’s sponsors, exhibitors and speakers and he encouraged donations and sponsorship as the IDE looks to raise in the region of £50,000 to £100,000. Richard and his company

pledged a £5,000 donation as he hopes the course spreads globally.

Richard also mentioned the IDE’s CPD sessions and the full programme that will be available in 2023. Sponsorship opportunities are available from £350.

The outcome of the elections were as follows: President: Gary Vernon Vice President: Toby Comley Honorary Treasurer: Stuart Appleton New council members: Mark Jack Brown Carroll Terry Quarmby news demolitionhub.com DemolitionHUB Magazine | 15

EDA Think Tank 2022

The EDA Think Tank 2022 held in October was a great success. Throughout the morning we were able to share our questions and curiosities to learn even more about the demolition sector.

In the first part, Kate Bester from Jet Demolition, Kurt Van Stappen of Tractebel and Tomás Romagosa of the Spanish wind energy association AEE (Asociación Empresarial Eólica) answered these questions:

• What are the main challenges to be faced when planning the endof-life of assets?

• Which steps should be taken during the normal operation of a facility to prepare for its end-of-life?

• Should external experts

be engaged in the end-oflife planning and bidding process?

• Who should be involved in the decommissioning and closure activities?

• Highlights and lessons learned

In the second part of the webinar, Stefano Panseri of Despe, Simon Carroll of Vattenfall, Ángel Fudili of Naturgy, Erik Sandonis of Lezama Demoliciones and Stéphane Ponçet of Curium took the reins.

There was time to discuss the most frequent problems in the demolition of industrial plants, planning projects, and how clear communication between parties can influence the success of projects.

VERAS’ Annual Convention 2023

We are firing up our engines in preparation for the next EDA 2023 Annual Convention, from Thursday 15 to Saturday 17 June in Amsterdam.

It will be held in collaboration with Dutch Demolition Association, VERAS, and the European Decontamination Institute, EDI. We have chosen the Corendon Village Hotel Amsterdam and the National Maritime Museum to stage the events.

The convention itself takes place on the Thursday and Friday with the leisure programme held on the Saturday.

The event will be held in collaboration with Dutch Demolition Association, VERAS, and the European Decontamination Institute, EDI.

Thursday 15th June

Corendon Village Hotel

3 pm – Workshop

5 pm – General Assembly 7.30 pm – Welcome cocktail

Friday 16 June

Corendon Village Hotel

9 am – Official opening

• Conference session 1

Coffee break, networking and exhibition

• Conference session 2 Lunch, networking and exhibition

• Conference session 3 Coffee break, networking and exhibition

• Conference session 4 5.30 pm – End of professional programme

National Maritime Museum

8 pm – Reception 8.30 pm – Museum visit 9 pm – Gala Dinner

Saturday 17 June

Leisure programme to be confirmed. For marketing opportunities see here: www.europeandemolition.org/cms/ files/EDA_AnnualConvention2023_ Amsterdam_Catalogue_221014_Office. pdf

Registration will be open soon. See the EDA website for details.

demolitionhub.com 16 | DemolitionHUB Magazine

Demolition Hub is the media partner for the European Demolition Association

The Erith Group have been providing sustainable enabling services for over 50 years. Asbestos Removal • Construction Solutions • Demolition • Earthworks and Infrastructure • Engineering and Geotechnical • Haulage and Logistics • Remediation and Gasholders 0370 950 8800 hello@erith.com www.erith.com E

Rapid success

by Alexa Schlosser

by Alexa Schlosser

For five weekends in the fall of 2021, Priestly Demolition Inc. (PDI) crews logged over 9,000 working hours demolishing Toronto’s Gardiner Expressway Eastbound ramp, part of the city’s waterfront redevelopment plan. It was a quick and challenging project, but it was also a successful one, according Brian Priestly, vice president of operations at PDI.

“It was a monumental job because it changed the city’s skyline,” Priestly says. “It was an awesome opportunity for us to showcase a super difficult, large project that we could complete in the time asked.”

Project pre-planning

As soon as NDA member PDI received the job, weekly team meetings began. PDI strived to find the most efficient solutions for not only the demolition, but also for the known job site challenges and potential scenarios that could arise.

The job’s key considerations were to ensure minimal disruption to regular projects; protect the environmentally sensitive waterways; protect the steel beam guide below; and make sure the roadway could reopen each Monday morning.

Weekend 1: Deck removal

Sixteen different crews got to work on the first weekend, logging over 3,400 working hours. Amid delays, noise and dust, the crews constantly communicated and worked together as a team to remove the asphalt and deck in preparation for the next phase. The goal of the first weekend was to expose as much steel as

possible before moving the cranes in for the second weekend. To achieve this, operators worked on both decks simultaneously east and west at either end.

During the first weekend, PDI implemented innovative solutions to address some of the challenges the job posed. For example, as a way to protect the Keating Channel waterway and guard rails, the company implemented “deflector shields”, a safe and efficient way to direct falling debris from the deck above. Outrigger shields were also put in place to protect utilities and rails.

“The fabrication of deflector shields onto the excavators made them very mobile. They could travel around the job site to precise locations to protect guardrails or the waterway, and then quickly move to the next location. This also helped speed up the cleanup for Monday morning reopenings,” Priestly says.

Weekend 2: Girder removal

Once all of the concrete deck was removed and the girders became accessible, removing the girders from the bents was the next priority. The operations team from Weekend 1 evaluated the progress made in those first few days and adjusted the plans for the second weekend. Weekend 2 included realistic targets, smaller crews and shorter shifts. Specialised teams were created to perform specialised tasks, and engineers were on-site to continually analyse the work as it went.

The work on the second weekend included removing bents on the west side to ground level. Crews also started the underground removal of bents on the east side and began to remove and process steel. Torch workers cut and separated the girders, and two 300-t cranes moved them. Overall, the second weekend crew of 45 workers per shift removed 1,500 t of steel and sorted and processed massive amounts of concrete, rebar and other materials.

Weekend 3: Bent removal

The third weekend involved removing the steel bents above the Keating Channel Bridge over the river and removing concrete bents on the east side of the Don Roadway. Crews also removed the abutment at the east end and continued to remove bents below grade and backfill.

demolitionhub.com 18 | DemolitionHUB Magazine

Weekends 4 and 5: Completion of tasks

The last two weekends of the job included completing all below-grade removals on the east side and backfilling. Over the course of the weekends, PDI used 1,750,000 L of water for dust control and 124,400 L of fuel. Crews also removed 2,400 t of asphalt, 2,500 t of steel and 15,000 t of concrete decking.

Key challenges

There were many challenges over the course of the five weeks. The restriction of only being able to work on the weekends was a particular challenge. “The biggest challenge was the timeline,” Priestly says. “We had to make sure we could close the traffic down on Friday evenings and reopen it without issue for Monday morning – with no traffic or pedestrians interrupted for the Monday morning commute.”

Article: http://bitly.ws/xfKT

Other challenges include ongoing construction work surrounding the expressway, making sure proper COVID-19 protocols were in place, getting the crews safely to the site with surrounding road closures, tight spaces for crane mobilisation, water and rails on either side of the bridge, noise bylaws, being able to plan smooth and safe shift turnovers, and protecting the sensitive waterways.

“All bridge demolition is challenging, and coordinating 100 people per shift the first weekend, 50 people per shift the second weekend, making sure the logistics of the job were in place, having fuel delivered...” Priestly says. “There are many challenges, but the team was able to rise to the challenge, whether it was planned or unplanned, and deal with it in such a manner that the job was never in jeopardy. That was really the secret of our success.”

Project highlights

In addition to completing 98% of the demolition work in five weekends and recycling 100% of the concrete, steel and asphalt, PDI is proud that the job was performed safely without incident, on time and on budget.

“PDI crew members were proud to be part of this rapid demo project and volunteered to work the weekend shifts on top of weekly Monday through Friday shifts,” Priestly says. “We took care of our crew with on site catering and accommodations for those from out of town. There were multiple generations of Priestly’s working together, side by side with the crew, which created a strong sense of family, teamwork and PDI pride.”

As a result of the successful work on the Gardiner Expressway Ramp, additional projects are in the works with EllisDon on the waterfront project.

Demolition Hub is a proud supporter of the National Demolition Association and credit to this article goes to the NDA. Thank you for working with us.

demolitionhub.com DemolitionHUB Magazine | 19

Another one bites the dust

by Larry Trojak

As NASA evolves into a leaner organisation with a changing role in today’s space industry, vestiges of its storied past continue to meet their fate. The latest, while not as recognisable as one of the vehicle assembly structures or the Mobile Launch Platform recently spotlighted in the NDA’s Demo on Demand online portal, was perhaps even more pivotal in driving every major facet of the organisation’s programme in its history.

The Kennedy Space Center (KSC) Headquarters Building is a sprawling 41,000 square metre structure that consists of a series of six, three-storey “L” and “U”-shaped wings that were continually added to accommodate the organisation’s rapid growth in the early 1960s.

It was here that all the major decisions regarding the various programmes that defined our dominance in the space race and afterward were made. Despite being named to the National Register of Historic Places in 1999, a mere 20 years later it was deemed outdated, oversized and beyond repair.

The complex is currently being demolished, already replaced by a new eight-storey KSC Headquarters Building with half the area that sits adjacent to it. For NDA member Frank-Lin Services of Brevard, the firm heading up the demo (as a subcontractor to Maverick Constructors), it is yet one more case of the old meeting the new as

they use some innovative tools and techniques to bring down another iconic symbol of our nation’s past space programme.

Different set of challenges

With KSC projects dating back to 1998, Frank-Lin is no stranger to working with NASA, having successfully completed work of both epic proportions (almost every structure associated with the shuttle programme) and more manageable size (the Central Instrumentation Facility structure). The HQ building, while falling into the latter category, brings with it an entirely different set of challenges, according to Pete Charamut, the company’s president.

“This demo is simpler than most we’ve done at KSC,” he says. “But while the structure is coming down a lot easier, the environmental aspect of this job is another matter entirely. One of the reasons the HQ building was not considered for rehab is that it was heavily contaminated with polychlorinated biphenyls (PCBs) and asbestos. And while a full asbestos abatement was done over the course of the last year, areas such as the roof remain contaminated. So, as it comes down and gets mixed together, the entire pile of debris is considered as PCB bulk product waste.”

With that as criteria, about 90% of all the debris from the MSC Headquarters project has been slated for the landfill.

A serious departure

That fact weighs heavily on Charamut for several reasons. First of all, in winning the bid for the project, the company also won the right to recycle everything it could. However, with the structural and other metals deemed off-limits, the company’s bottom line was seriously impacted, prompting a revisit of the existing contract.

“And it’s about more than just the money,” he says. “We pride ourselves in regularly recycling better than 85% of the material from most of our projects. But, while we hate to see good material taken to a landfill, I can see the point the engineers have made regarding material that is comingled as it comes down.

“They have allowed us, however, to take what we can before we start the actual demo of a structure. So, we are pulling material such as copper wiring, copper tubing, etc., and diverting it from the landfill. But the minute we start attacking that structure, everything is off limits.”

Starting with the CIF project done in 2018, KSC required that Frank-Lin purchase and maintain a truck scale to weigh every load of C&D debris and concrete before any material made its way to the landfill. That part of the job, says Charamut, is maintained on a daily basis by his daughter Lindsey and father-in-law Emilio Rogel.

He estimates that, by project’s end, approximately 65,000 t of general C&D debris, as well as an additional 18,000 t of concrete –including the concrete slab – will cross those scales prior to being dumped in the KSC-owned and operated Schwartz Road landfill.

It should come as no surprise that dust suppression is a priority at the KSC job, given concerns surrounding the hazardous nature

demolitionhub.com 20 | DemolitionHUB Magazine

of the debris as it comes down. To address that issue, Frank-Lin’s team relies upon a pair of misting units from BossTek: a DB-60 and an Atom. They also have a 2,000-gallon (75,000 L) water truck on-site to periodically soak the debris as it’s being brought down.

Dynamic duo

Considering the scope of the headquarters project, Frank-Lin’s on-site crew of three operators and five dump trucks might, at first sight, appear seriously undersized. What they lack in numbers, however, they more than make up for in productivity, thanks to a pair of hydraulic attachments – an LXP 400 multi-jaw processor, third membermounted on a Komatsu PC-490 and a GCP 610 concrete processor mounted on a Komatsu PC-360 –both from Genesis Attachments. With those at work, Frank-Lin’s team is systematically erasing remnants of NASA’s past.

Charamut says: “My son Frank is using the extended reach of that third-member unit to start at the top of each structure and work his way down, essentially collapsing each floor onto the one below. While all the wings are pretty much identical, one section featured a penthouse that housed the NASA director and upper-level management, and for that we brought in a rental excavator with a 23 m ultra-high, three-section, Hitachi demolition package from PowerTrac Machinery. But the overwhelming bulk of the job has been handled using the two Genesis attachments.”

According to Charamut, they have two jaw sets for the LXP, a shear set and a concrete cracker set, and both have played a role at the HQ project. The composition of the building is mostly concrete

http://bitly.ws/xfUP

Article:

demolitionhub.com DemolitionHUB Magazine | 21

and heavy rebar, material that is easily being processed by either of the two jaw sets. Charamut says his team benefits from the unit’s bolt-on piercing tip, which can be replaced in minutes without grinding or welding, as well as the full range of indexable blades that, by providing four usable cutting edges, keep productivity up.

“There’s no denying that the LXP on that Komatsu is the real workhorse out here,” he says. “The Komatsu machines, purchased from and serviced by Linder Machinery, have been outstanding for us. That LXP is easily handling any rebar we’ve encountered and can cut through pipe up to 20 cm in diameter, so we are more than covered. In fact, if we had enough time on the project, that combination could easily handle the entire job.”

Family affair

Size and complexity of projects aside, Frank-Lin is still very much a familybased business, as evidenced by the daily presence of Pete Charamut, his

son Frank, his daughter Lindsey and extended family.

“My parents started this company back in 1988 and named it after their two grandchildren, Frank and Lindsey,” says Charamut. “They are both on the HQ demo site today and are very much a part of the reason for our success. We’ve also grown that list with the addition of Frank’s wife Krystin, who, after leaving a career in restaurant management, is today a very experienced operator capable of running everything on site, including the PC-490 with the LXP-400. Not surprisingly, she fits right in.”

Tenured performance

The Headquarters demolition will not be the last project Frank-Lin does for NASA – additional work is already either secured or being bid on. The contractor’s longevity and success working with the organisation is based on an ability to combine expertise, concern for safety and an ability to bring the latest technology to bear.

“We started using high reach equipment on our demo projects back in early 2000 in order to be competitive and stay away from costly crane work,” says Charamut.

“Once clients – like NASA –realised how safely and quickly we could complete demolition projects, it just made sense for them to stay with us. NASA jobs are bid based on past performance, experience and a criteria called “lowest technically accepted”, which means the company bidding must prove an ability to be able to perform the work.

We’ve been doing steady demo work for them since 2006, and in that time, took down about 90% of the shuttle facilities. I’d say the organisation has had a comfort level with us for some time now – our ability to successfully deal with the challenges of the Headquarters building just reinforces their decision to stay with us.”

The KSC Headquarters Building demolition was slated for an 11 January 2022, completion date.

demolitionhub.com 22 | DemolitionHUB Magazine

“CONEXPO-CON/AGG SHOWS US THE FUTURE OF OUR INDUSTRY, WITH INNOVATION, EQUIPMENT AND IDEAS YOU CAN’T FIND ANYWHERE ELSE.” — GRANITEROCK, AROMAS, CA TAKING CONSTRUCTION TO THE NEXT LEVEL. MARCH 14-18 / 2023 / LAS VEGAS / NEVADA 250,000 sqm of Exhibits 130,000 Attendees 1,800 Exhibitors 150 Education Sessions REGISTER at conexpoconagg.com Save 20% with promo code SHOW20

case study

From civic to domestic

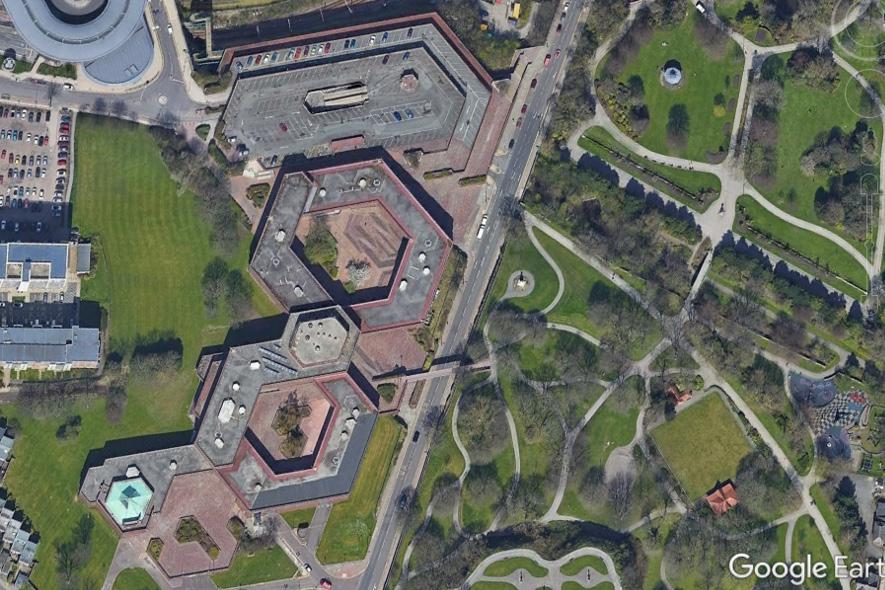

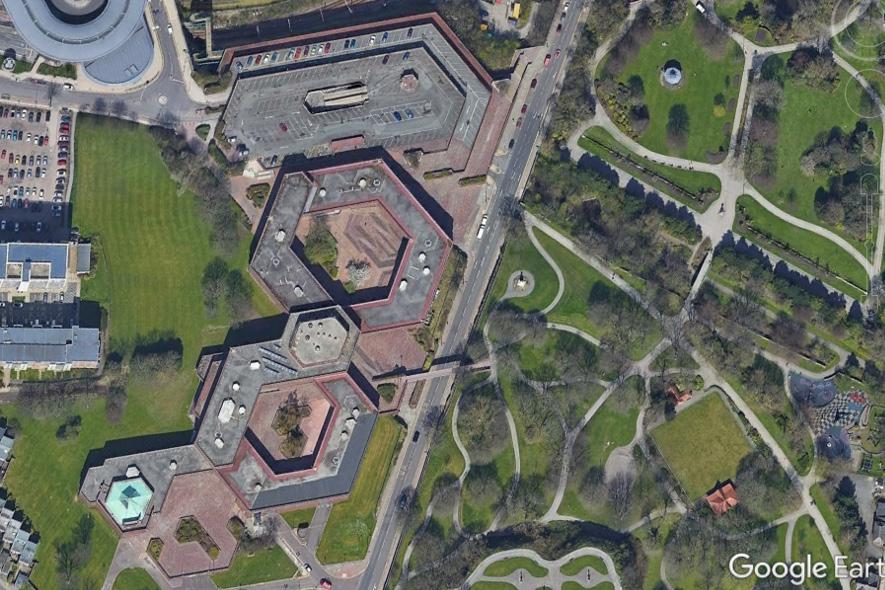

MGL Demolition (MGL) has started to dismantle Sunderland Civic Centre, paving the way for construction of 265 new homes.

The specialist contractor, part of MGL Group, is undertaking complex demolition and site clearance work on the old council offices site to enable future development as part of Sunderland City Council’s

MGL Demolition rends Sunderland Civic Centre to rubble demolitionhub.com 24 | DemolitionHUB Magazine

ambitious plans to regenerate its riverside and city centre.

MGL is working in phases to safely bring down the municipal building, which once provided accommodation for over 1,000 council employees. It was designed by architect Sir Basil Spence and was clad using brown brindle brick. It included two low-rise blocks that

formed a figure of eight around two hexagonal courtyards.

The two-storey civic suite included a central double height council chamber. The upper level accommodated a suite of committee rooms while the lower floor housed the council members’ rooms.

The 1960s building was deemed no longer fit for purpose and earlier this year it was vacated by the local authority after it moved to the new City Hall at Riverside Sunderland.

The scope of work also includes the deconstruction of the Civic Centre’s large multi-storey car park, which provided parking for staff and visitors as well as members of the public visiting the city centre. The footbridge connecting Mowbray Park to the main reception will also be demolished.

Initial works included stripping out the interior of the building and taking out the existing windows, along with removing a significant amount of asbestos-containing materials, which were commonly used in buildings constructed before the 1980s.

All main works are being delivered using MGL’s in-house resources, both plant and personnel, enabling tighter control over the demanding programme and opportunities for mitigation concerning any additional asbestos that is identified. As members of both the National Federation of Demolition Contractors (NFDC) and the Asbestos Removal Contractors

Association (ARCA), the MGL team is working to the highest standards of safety and quality using a mix of specialist techniques including progressive floor-byfloor deconstruction and remote demolition, with dismantling work taking place within the building’s plots.

To enable work to commence, a new emergency access link needed to be designed and installed by MGL’s appointed engineers to allow people using the Park Lane Interchange Bus Station to safely vacate the train platforms in the event of an emergency.

Below the car park there is a redundant train tunnel, which further complicates the sequence and methodology for demolition works. Access to the tunnel can only be gained through both Nexus and Network Rail infrastructure.

Prior to demolition works starting, the old tunnel had to be blocked off and MGL’s appointed engineers needed to design a permanent solution, which would also act as a retaining structure to enable the tunnel to be backfilled with recycled materials generated from the demolition works. A design statement was issued to Network Rail for review and approval.

All works within Network Rail’s boundary are being overseen by Network Rail engineers and all MGL operatives will be required to undertake PTS training.

This complex project has the

case

demolitionhub.com DemolitionHUB Magazine | 25

study

case study

added challenges of typical inner-city issues and meticulous planning and preparation is required.

Due to its scale, restrictions will be in place to protect the public and ensure the demolition can be safely undertaken. The demolition of the footbridge will require full road closure and MGL will consult with the council’s highways team and a traffic management company to minimise disruption.

Throughout the duration of this project, adherence to all stakeholders’ procedures and a cohesive interface to align requirements has been crucial to driving the project forward successfully. Regular communication with third parties has ensured a collaborative approach has been adopted.

Finishing works include site clearance, grubbing up the foundations and leaving the site clear and ready for Vistry Partnerships North East to transform

the site into a mixture of one to fourbedroomed homes.

The development is part of a wider programme in the city centre that seeks to double the number of people living and working in the area.

Mark Davison, Joint Chief Executive of MGL Group, said: “We have extensive experience delivering

city centre schemes and enabling vibrant and inviting places to live, work and visit.

“We are proud to be working in partnership with Sunderland City Council and Vistry Partnerships North East on a key project for the city and to play our pivotal part in Sunderland’s regeneration.”

demolitionhub.com 26 | DemolitionHUB Magazine

For more information call us on 0370 950 7707 Website: www.swantest.co.uk Email: info@swantest.co.uk 52-54 St. John Street, Farringdon, London, EC1M 4HF Swanteest is a specialisst company prooviding structuraal testing, investigatioon, remedial and strengthhening solutionns for complex p projects We arre a teaam of multi-disciplined engineers who caan provide a wide range of sppecialist site servvices to the demolitioon and civil enggineering indusstry. We speecialise in: • Load capacitty tests • Geotechnicaal tests • Balcony & baarrier tests • Weld inspectiions • Nondestructivve Testing • Bespoke Testing When it t comes to site solutions, we w want to provide our clieents with a coomplete package of workks Therefore, Swwantest can caarry out all requiired eleements for any y complex project. Includinng initial site invvestigation and d surveys, structuural testting, subsequent remedial and strengthhening solutionns and design works if requiredd. We caan also providde ongoing monitoriing and inspections where necessary. Swanteest are part of a specialist temmporary works design coonsultancy; S Swanton Consulting Ltd. This s gives us the advantage of h having capabilitty to carry out compplex design solutions in house e We are UKAAS accredited a and have been working with industrry leaders for over 10 0 years Specialist Solutions for Complex Projects • Sttructural surveys & invvestigation • 3D D Point cloud surveys s • Sttructural alterations & strengthening • Hyydraulic c lifting & jackking • Prreloadinng & torque looading • Concrete e repair & remmediation • Composiite solutions Swantest FP.indd 1 24/05/2021 13:15 8691

DEMOLITION DISCUSSION

In 2004, I was 19 and worked for my dad to save some money for university during the summer. My dad thought I would hate it, the early mornings, working on a crusher (a long time ago) but I enjoyed it.

Earning money, working outside and the characters I met on site, many of them still work for Northeast Demolition. A lot of people say once you get into demolition, you will be in it for life. That’s true for me.

QHow did you start out in the industry and what attracted you to it?

Brentford Sky Sports News

Interviewee: Bradley Harris Role: Contracts Director Company: Northeast Demolition interview demolitionhub.com 28 | DemolitionHUB Magazine

Brentford FC’s old home, Griffin Park

QHow has your career developed to where you are now?

While on site at 19, I noticed that some of the people struggled to read or write, some pretended they couldn’t and some of them just hated doing it. So, I said to everyone I would do their paperwork. They didn’t need explaining, they’d been in demolition for many years and I learnt so much from them working on site.

Very quickly, I was doing LOLER, PUWER, daily briefings, TBTS and site diaries.

Over the years I have been a demolition supervisor, manager, health and safety manager and now contracts director. Qualifications include, NVQ level 6, NEBOSH, Asbestos Surveyor, IDE foundation degree, etc.

MD Shaun Harvey’s father-in-law started the company in 1968. His name was Peter Northeast, hence the company name. From what I have heard, Peter was a very hardworking person.

We employ 30 people and try to keep the company around this size. That way it’s easier to control and to provide more of a personal service. Someone once told me that in demolition, you are only as good as your last job. I aways remember that quote, it helps maintain our quality of work.

Tell us about your team and working culture. Is there a fundamental company philosophy or ethic?

Be loyal, honest, respectful, and work hard.

Northeast Demolition is a family run and family orientated company. Peter Northeast’s daughter and granddaughters all work for the company; our safety director Ronnie went to school with Shaun; we have three generations of one family working for us; one of our supervisors used to drive HGVs with my dad in the ‘80s and his sons Alex and Harry are now both site managers. My dad Wayne, my brother Ross and his partner also work for the company.

As you can see, I could name everyone who works for us and how we are connected.

etc. on site and carry out asbestos removal.

Post demolition, we crush materials on site to 6f2, carry out remediation works and install pile mats but that’s as far as we go.

From 2007 to 2017 we bought all JCBs. We bought the first high reach with a changeable arm (Kocurek). JCB had an amazing guy called Steve Bradley and he just made sure anything you asked got done. They would use our sites for marketing, as a lot of investors wanted to see the excavators working.

Being a small company, we basically give our drivers their own excavator, so they look after them and can’t blame someone else if it’s scratched, not maintained, filled with diesel, oil, adblue etc. I remember in 2011 we bought a JCB excavator and their photographer came to site and took photos. We had two JCB machines and he didn’t believe us at first when we told him we’d bought the other excavator in 2009.

In 2018 we bought a LiuGong. We were unsure about switching to LiuGong but the service they provide has been perfect. The price, buy back and warranty make it a nobrainer.

By the end of this year, we will have five LiuGongs. I highly recommend speaking to Simon Tobin if you’re looking at purchasing a LiuGong.

QWhat are the standout projects from Northeast Demolition’s history?

is the range?

Any project where the client is good at paying, mainly mechanical demolition of residential and industrial buildings in the city. We try to stick to what we are good at. Or what we think we are good at –demolition.

We soft strip all buildings, separate timber, metal, plasterboard,

I have been fortunate to work on many projects over the last 18 years. Some standouts include:

Brentford Football Stadium. Demolishing a football stadium had been on my bucket list. I still play football and coach two of my kids’ teams so it was a fun project to work on. Sky Sports News asked if they could do a report, Gary Cotterill came down to site for the filming and

QHow did Northeast Demolition start? How has it evolved in size, scope and services?

Q

QWhat kind of demolition projects does Northeast Demolition work on most frequently, and how broad

QDo you have any particular preferences in terms of the plant you use?

interview demolitionhub.com DemolitionHUB Magazine | 29

the day after he went to Barcelona to interview Lionel Messi.

Grand Tour – Jeremy Clarkson’s house. JCB asked if we could oversee the demolition of his house for the show. We said we would do it, but everything had to be done correctly – S80, ecology report, R&D survey, exclusion zones, etc. None of this had been done prior to our involvement.

Clarkson, May and Hammond were so much fun and very accommodating. It was nice to see that they are just big kids and up for having fun.

QWhat makes Northeast Demolition different?

I wouldn’t say we are different; I see many of the NFDC members and non members doing great demolition projects. We tell clients that we want to win their next project, so it shows we want longevity from our working relationship. We don’t advertise, we just work hard and try our best to deliver a good service.

QTell us about any apprenticeships, trainee schemes and the availability of labour, experienced and inexperienced. What can we do to attract young people into the industry?

Wow, good question. I honestly don’t know the solution to this and I think about it all the time.

Apprentices – we have none

currently. Labour – we have minimal. We try to provide training for labourers to allow them to promote themselves. We have a 68-year-old gate man and 71-yearold banksman, as we struggle to get younger people.

It’s clear to see that we are not attracting enough young people into the industry. I remember as an eightyear-old, during school holidays I would go to work with my dad in his roll-on-and-off lorry. I loved it. My brother was on site brick cleaning and labouring at 14. We also enjoyed getting cash to spend.

In the present day, due to insurance, age restrictions on site and H&S, obviously none of this can be done anymore.

At weekends, I take my three sons into our yard and they love playing on the crushed heap, weighbridge ramp and in the puddles. It’s a great way of them learning. I’m sure a lot of people are thinking its unsafe and I shouldn’t be doing this but I feel them being outside and active is better than them sitting at home on an Xbox.

This is where I feel it’s going wrong. We need to start off people younger. Most kids love digger-land but then they go back home and don’t have the opportunity to drive any plant.

AND FINALLY

What gets you out of bed in the morning?

A screaming kid at 4 am. I have three sons, an eight year old, five year old and a two year old.

Who is your favourite artist? Johnny Cash

Who do you most admire? My dad

When and where are you happiest?

Christmas Day with the wife, kids, family and switching off from work for a few days.

Brad’s kids – start them early

interview demolitionhub.com 30 | DemolitionHUB Magazine

SHREDDING – CRUSHING – SEPERATION SYSTEMS –METAL PROCESSING – CONVEYOR SYSTEMS DOYLE MACHINERY Limited Office +44 3330 433322 E: info@doylemachinery.co.uk www.doylemachinery.co.uk SALES - HIRE - SERVICE - SPARES, PROCESSING WASTE, BIOMASS, PLASTICS, TYRES, CONCRETE, SCRAP METAL AND WOOD

case study

demolitionhub.com 32 | DemolitionHUB Magazine

Working on water

Swantest undertakes a challenging structural repair scheme at Brighton Marina

Brighton Marina was constructed between 1972 and 1976. The harbour is exposed to waves from the south-west around to the southeast so is protected by the West and East breakwaters formed by circular caissons. These were installed by a specially built crane running along the top of the previously placed caissons. In situ concrete sealed any gap between the caisson base and the prepared chalk bed. Upper promenades and wave walls were cast on top once all caissons had been installed. The breakwaters provide essential shelter to approximately 1,000 dwellings and 1,600 boats together with extensive retail and leisure development.

Swantest was engaged by C. J. Thorne Ltd to undertake selected surveys and concrete repairs to the soffits of the cantilevered sections of the kilometre-long Eastern breakwater as part of a package of works to strengthen the structure to remove the imposed restrictive weight limits on the roadway over. There are long term plans to infill the caissons to prevent further deterioration. The main purpose of repairing the concrete on the soffit

demolitionhub.com DemolitionHUB Magazine | 33 case

study

case study

of the cantilever was to facilitate a temporary works propping scheme, which would facilitate a higher load rating for the walkway above. Before that could happen there were numerous areas of the soffit that had suffered significant loss of concrete and were unsafe.

Swantest assisted the client in developing the concrete repair strategy to better suit the physical and environmental conditions, and also assisted with the concept for access over the water. Repair works were taken off the critical path using bespoke techniques for the hydro-demolition works, thereby unlocking a significant programme constraint.

Hydro-demolition is a concrete removal technique that uses high pressure water containing an abrasive material to remove both deteriorated and sound concrete. This process provides an excellent bonding surface for repair material and new coating applications, while ensuring no damage to the existing steel reinforcing.

Swantest undertook initial condition surveys of the soffit areas and assisted in setting out the through bolts for the subsequent steel installation using GPR scanning to identify underlying steel from the roadway surface.

Due to the aggressive marine environment, corroded rebar was replaced and all repair areas had Sika Galvashield sacrificial anodes installed at the perimeter, prior to shuttering and gravity pouring with Sika Parex LA flowable micro-concrete. The sacrificial anodes are used to control ongoing corrosion and to prevent the new formation of corrosion sites on reinforced concrete structures. The specially formulated repair mortar surrounds and activates the sacrificial zinc core. When installed and connected the zinc anode corrodes preferentially to the surrounding steel, providing galvanic corrosion prevention and control to the adjacent reinforcement. This will further increase the lifespan of the structure.

Each repair area had to

demolitionhub.com 34 | DemolitionHUB Magazine

case study

be carefully prepared in readiness for the anodes and repair mortar. Once all defected concrete was removed, Swantest doweled in new reinforcing steel to the structurally sound concrete and fixed in new steel bars. Working from a cantilever platform that projected over the water, the company then installed shuttering and bracing to the soffit of each area. All repair concrete was mixed by hand on site and poured from the top of the walkway, by core drilling holes into the repair area. It was also necessary to drill a number of vent holes to ensure there was no trapped air in each location. A high strength, fast curing repair mortar, meant Swantest could strike the shutter after 24 hours. This was key to ensuring it completed its works on time.

There are many constraints on this type of project. As they were working over the water, removing deteriorated concrete and replacing with new repair mortar, Swantest had detailed processes and procedures in place to ensure there was no adverse environmental impact on marine life. The company successfully completed all works over a 10-week programme between June and August 2022.

demolitionhub.com DemolitionHUB Magazine | 35

SUPPLIER TALK

Interviewee: Giovanni Achille

Role: UK Country Manager Company: MB Crusher

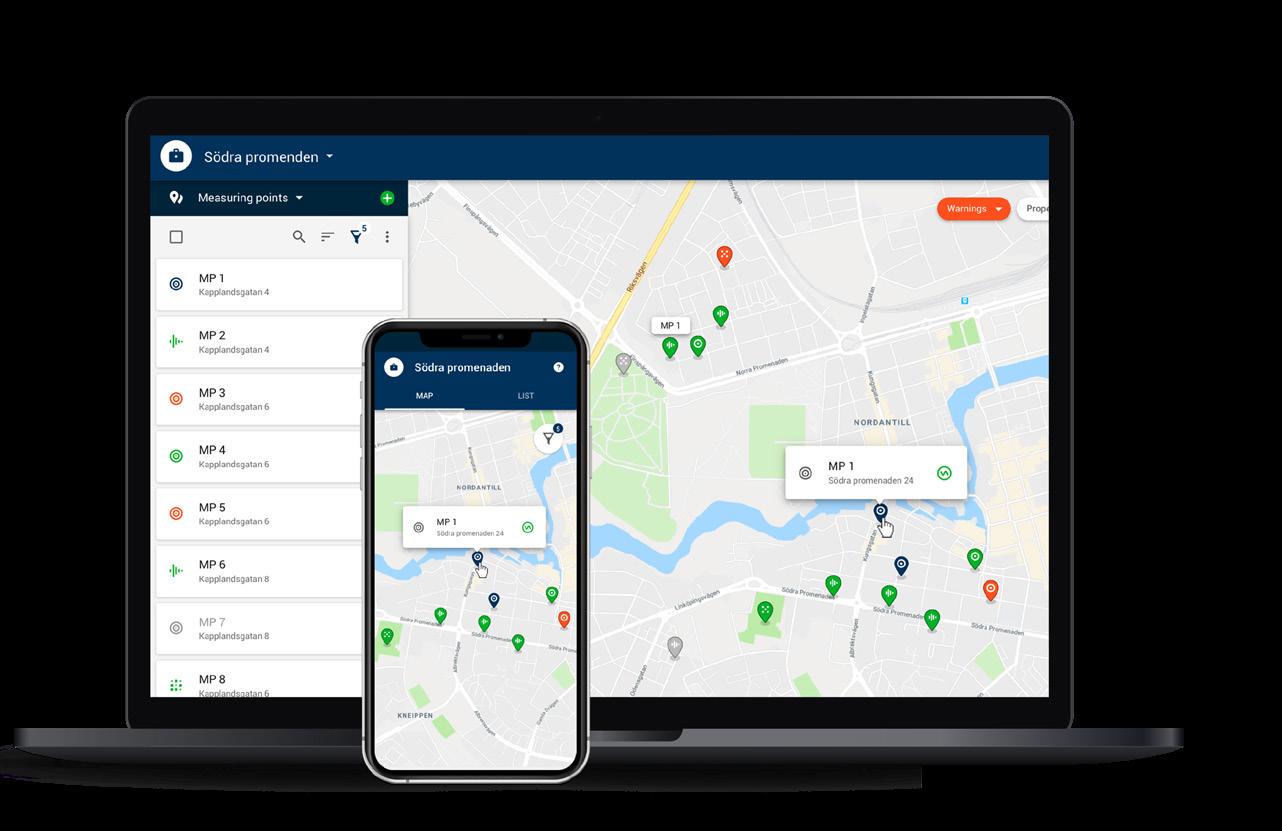

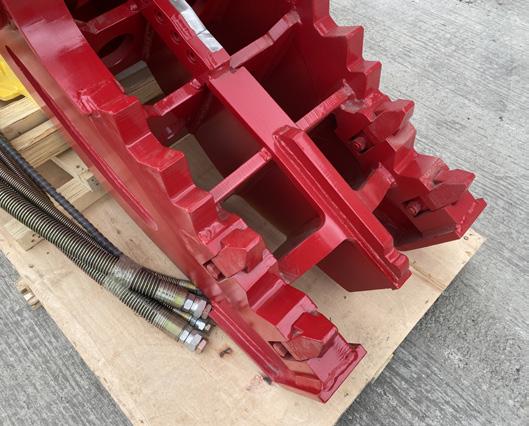

QGive us some background on MB Crusher

MB Crusher was founded in 2001, however, its roots are in the family business. The idea to create the first jaw crusher bucket comes directly from the necessity faced daily while the siblings were working in their father’s road construction business.

They took their first-hand experience in the field and created an attachment that is productive, cost-effective and works with the hydraulics of any carrier – excavators, loaders, skids and telehandlers.

demolitionhub.com

36 | DemolitionHUB Magazine interview

Years of creation and innovation have seen the family-owned business evolve into an international company with eight branch offices and a wide distribution network.

The line has now expanded to five different attachments: the iconic jaw crusher bucket has been complemented by the addition of trommel screeners, padding buckets, rotary grapple and drum cutters. All are designed and manufactured in Italy, using only the best materials to obtain the highest quality. Solid, durable and characterised by the

recognisable clean lines designed to resist wear and high stresses in the toughest working conditions.

revenue, the choice was easy to make. I haven’t looked back and I have been developing so many countries since.

I followed in my father’s footsteps; he worked at MB when it was first founded. He told me so many amazing stories of when he visited people’s job sites, of how the solution provided by MB Crusher units facilitated their jobs and added

MB Crusher provides and how your relationship with clients works

We make attachments for heavy machinery, any brand, any type can work with our units. It might seem like a cliche, but the customers are at the centre of everything we do. Listening to the customer’s needs

QHow did you start out in the industry and how has your career developed to where you are now?

QTell us about the services

demolitionhub.com DemolitionHUB Magazine | 37 interview

What are your USPs?

We make machines that work and facilitate the task ahead, simple to use yet effective. No more needs to be added besides. Do yourself a favour, see them at work and you will understand.

QTell us about your team and working culture. Is there a fundamental company philosophy or ethic?

Diversity and inclusion. These two terms best describe what you’ll see when you step into MB Crusher offices or come to our booth at the trade shows. This allows us to understand your customers’ needs and provide them with the solution they are looking for.

QHow has the scope of MB Crusher’s business developed over time and is it in the process of developing its range of services?

Our R&D department constantly works hard behind the scenes to make units that are more productive, better performing and easier to maintain. We will keep doing so for years to come.

QHow do you see the outlook for the demolition plant sector generally?

Urbanisation and the need for connectivity are only some of the reasons why the demolition sector will always grow and with it the efforts to reduce the environmental and economic impact of construction and demolition waste.

This growing worldwide awareness of recycling waste and conserving natural resources has seen a strong shift in demolition operations, as well as the necessity for more security at the demolition sites, as implemented with the use of the right tools. Making the

equipment work, a smarter labour approach and the addiction to innovative tools will keep growing.

The world is our oyster.

Older and hopefully wiser.

means producing units that will be essential for market growth.

QWhat makes MB Crusher different?

QHow do you envisage MB Crusher in five to 10 years?

QAnd how about you in a few years?

demolitionhub.com 38 | DemolitionHUB Magazine interview

THE WORLD IS OUR OYSTER

demolitionhub.com DemolitionHUB Magazine | 39 interview

PRODUCTS

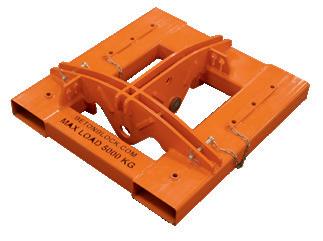

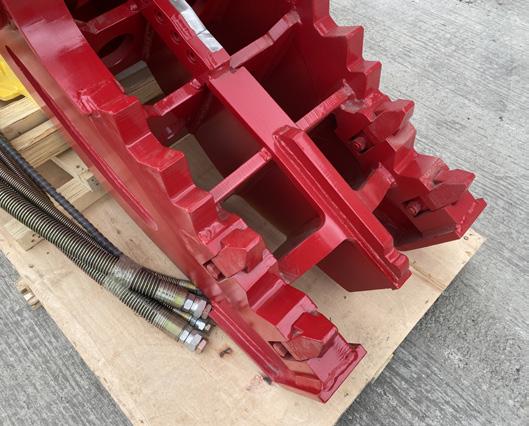

QTell us about one of MB Crusher’s key demolitionrelevant products

Our core business is the jaw crusher bucket. It is the first product that was created, moreover, we were the first to make and patent it. We have the biggest range of crusher buckets suitable for mini excavators from eight to over 70 tonnes. The is also a line suitable for backhoe loaders, skids and telehandlers. Whatever the carrier, there will be a unit suitable for it.

Q

Outline the key functions of the product

It transforms any carrier into a mobile jaw crusher, with the advantage that it offers the possibility to carry out a task in the one-man one-machine module.

QHow is it critical for demolition contractors?

Save money. Save time. Get the job done by transforming waste into a resource. All companies are always looking for ways to work better and faster and increase revenue; this is what we offer.

QTell us about the development of the products. Was it evolution or revolution?

QCan you quantify any of these benefits?

Each job site is different so there isn’t one answer that fits all. Some will benefit from simplifying logistics, some in eliminating costs others in speeding the process. This is where our consultant comes into play; when clients get in touch we will work together to pinpoint the biggest benefits.

Revolution when the first jaw crusher bucket got made. The idea came by working in remote areas where the transport of material was difficult but the raw material was largely available. The need to have a compact machine was also given by the fact that traditional machines were costly to transport and maintain.

Then came the evolution phase as we are now on series three, improving on performance in the field and we have a wide range of crusher buckets excavators fitting from eight to over 70 tonnes. There is also a line suitable for backhoe loaders, skids and telehandlers. Whatever carrier the customer has, there will be a unit suitable for it.

demolitionhub.com 40 | DemolitionHUB Magazine interview

And finally

Who is your favourite artist?

Jackson Pollock. I would not say that I am a fan of abstract painting in general, but his ‘’drip technique’’ is quite mesmerising. It does convey motion, fluidity and despite the apparent randomness there is purpose and structure behind it. Awesome.

What’s your bucket list activity?

I have more than 100 things on my bucket list, from joining a bike rave to going to Burning Man. But I am glad that many are already crossed off, some I am not sure I will still have the gut for. And let’s leave it at that.

What’s your favourite food/ cuisine?

A nice roast with all the trimmings.

demolitionhub.com DemolitionHUB Magazine | 41 interview

case study

Sky Revolutions captures Thompsons of Prudhoe’s Redcar Demolition

A project full of firsts and eye-watering statistics, the Redcar Steelworks demolition is a blowdown story well worth reading

demolitionhub.com 42 | DemolitionHUB Magazine

study

Background

Sky Revolutions recorded the explosive demolition of the Basic Oxygen Steelmaking Plant in Redcar in October – the final blowdown of multiple buildings on the site. The steelworks – dormant since 2015 –was made up of a huge 110-m-high furnace building containing 105,000 tonnes of steel, together with structures demolished earlier this year, namely battery bunkers, two 85-m chimneys and a junction house.

The demolition contractor –Thompsons of Prudhoe – used 1.6 tonnes of explosives to demolish the furnace building – believed to be the biggest explosion in the UK for 75 years and one of the biggest ever UK demolition jobs.

The original blast furnace was the second largest in Europe when

it started operations in the late ’70s. The newly cleared site will become part of the major Teesworks regeneration project planned to create 20,000 new jobs over the coming 25 years. This project is the biggest ever economic regeneration exercise in the UK and will cover a vast 4,500 acres when complete.

The big image capture challenge

Filming demolitions, perhaps for obvious reasons, is not for the fainthearted. In years gone by, demolition events were hampered by the sheer danger of the explosions – keeping camera operators and aerial filming helicopters far at bay. Even the best zoom lenses would struggle to capture more than an approaching cloud of dust.

Now, with the aid of better camera technology generally and drones specifically, more of the world can appreciate the spectacle of an explosive demolition. But one-off events like the Redcar demolition, while captivating, require intensive planning – after all, if you can’t rehearse, you have to get it right first time.

Sky Revolutions already had a heritage of filming demolition events, with many films widely shared in the main UK media and online, one of which went globally viral in April this year. Having seen this content, Mike Stoddart, Thompsons’ Project Manager, commissioned Sky Revolutions in June to record the Redcar demolitions.

demolitionhub.com DemolitionHUB Magazine | 43 case

case study

Perfect preparation

Sky Revolutions is the UK’s largest construction aerial imaging company and has been a leading voice in the use of drones in construction imaging and surveying for nearly eight years. While capturing content from the air might sound simple, there is much to consider when filming demolitions.

Aside from the obvious safety

preparations, the impact of air movement from explosions must be taken into account, as well as the implications of weather and proximity to airfields, train tracks and roads. A comprehensive set of plans including RAMS, the main flight plan and a full communications plan are all created in advance to help ensure a smooth outcome.

The tech spec

The Sky Revolutions team was made up of five drone pilots and camera operators using:

Ì Matrice 300 drones with Zenmuse H20T cameras, Ì DJI Mavic drones filming in 4k at 120 frames p/s, Ì Black Magic tripod mounted cameras, Ì Sacrificial ground-based cameras filming in 4k with live transmission, Ì DJI FPV drones.

The camera combination allowed Sky Revolutions to capture incredible high quality imagery, thermal images, slow-motion and first person footage, all of which can be combined to produce a stunning record of the event – for PR and marketing use for years to come.

On the day

Sky Revolutions’ Managing Director Ben Gorham says: “The event went very smoothly from our point of view, helped by a full day’s on-site

demolitionhub.com

44 | DemolitionHUB Magazine

prep and camera testing, and by our normal pre-shoot planning processes.

“The team are highly skilled and thanks to our demolition filming experience, understand where to place the cameras, where to position drones and how to track the explosions in order to make the most of these events.

“Clear communication with Thompsons in advance is of course vital, as is communication with the site team on the ground on the day. We’re delighted with the outcome at this event and hope to work with Thompsons of Prudhoe again in the future.”

Contractor’s view

Thompsons’ Director of Operations Tom Koerner says: “We were delighted to be awarded the BOS Plant demolition contract last year as part of the Teesworks demolition framework. This award allowed us to use our knowledge and experience to deliver one of Europe’s largest demolition schemes to date.

“The successful blowdown on 1 October was a significant landmark in the project, which now allows us to progress with the demolition of the remainder of the structure. The success of this very technically challenging blowdown is testament to our team’s hard work and dedication throughout the planning and operational stages of the job.

“We were very happy to have Sky Revolutions on board to help capture this milestone in the site’s history. It was very much a “one take” event, which was handled with the utmost levels of professionalism and efficiency from all of the Sky Revolutions team. The explosive blowdown event in itself was spectacular to be a part of and witness, however to be able watch it again from some incredible angles within a superbly well edited video package is almost even better. We look forward to working with Sky Revolutions again on this site and hopefully many more to come in the future.”

demolitionhub.com

DemolitionHUB Magazine | 45

case study

events

The fifth biennial construction machinery exhibition will be held on 13-15 June at the East of England Arena and Events Centre, Peterborough.

Technology is changing the face of the construction landscape – the last four years have seen rapid growth in digital collaboration, electrification, connectivity, safety, telematics, real time-data, wearables, virtual and augmented reality. Coupled with automation, sustainability and the road to carbon zero, these make the construction site of today and of the future a very different place.

Plantworx 2023 will be the show where emerging and disruptive technologies will feature alongside construction equipment, innovation, technology products and services. The show remains the UK’s biennial showcase for the construction sector – and will lead visitors into the future of construction.

Spanning more than 150,000 m2 of exhibition space, Plantworx will give visitors an opportunity to see some of the latest plant and machinery operating in “real” construction site conditions, alongside compact/mid-range equipment, tools and services. Already over 145 companies have secured their stand space and 85% of the digging demonstration areas have been sold.

Many of the key machinery OEMs have already confirmed their presence at the show, including Hidromek, Takeuchi, SANY, LiuGong, Mecalac, John Deere, Avant, Kubota, Doosan and Bobcat and BOMAG. Also expect to see attachment specialists Auger Torque and BPH Attachments, and leading tiltrotator companies including Engcon, and Steelwrist.

Handling and lifting specialists Manitou and Merlo have also

confirmed alongside remote control demolition experts, Brokk, which will be at the event showing the company’s latest demolition robots.

The digital revolution is truly upon us and what started as a trickle has now become a flood of technology and connectivity companies coming to market. Plantworx has already attracted a number of these businesses to exhibit in 2023. These include, telematics specialists MachineMax; ABAX telematics and plant tracking; and connectivity solutions company, Onwave.

Plantworx will also be showing “The Future of the Connected Site”, which will feature the latest in site technology – more details of this initiative to follow in the next issue of Construction Worx.

Machine control and machine guidance will also be a big part of the show, these systems are now the norm on the majority of site

Plantworx gains traction as exhibitors book for 2023 event demolitionhub.com 46 | DemolitionHUB Magazine

machinery, whether factory or retrofitted – iDig 2D & 3D by Nasco Digtec will be demonstrating the very latest in dig technology.

Xwatch Safety Solutions, a leading provider of safety solutions for construction machinery, is a new exhibitor and a market leader in the design and supply of height and slew control for excavators rated capacity indicators. James Fisher Prolec, also a leader in its field of site safety systems, will be exhibiting its latest technology, as will award winning Spillard Safety Systems, which alongside showing sophisticated camera systems, will be demonstrating safety systems designed for the future of connected vehicle technology.

A full list of exhibitors can be found on the Plantworx website www.plantworx.co.uk.

More space for startups

At Plantworx 2023 the availability of inside exhibition space has increased by up to 20%. This will also accommodate many of the new technology companies

that have joined the sector since Plantworx 2019. A special offer has been designed to attract startup companies and emerging innovators with the Plantworx “Big Ideas” showcase concept.

CEE (Construction Equipment Events) Director Rob Oliver said: “We are looking for startup companies with products, technologies or services new to the construction industry – which can make a big impact on the sector, improving efficiency, sustainability, safety or security. We are encouraging companies who think they fit the criteria to get in touch to discuss the discounted package.”

events

The 2023 event is predicted to attract over 400 exhibitors from the world’s leading machine manufacturers, suppliers and service providers. Over the three-day event, a predicted 15,000+ visitors can expect to see the very latest in technological advancements and innovations that will impact the future of construction.

The venue

The CEA took the decision to host Plantworx once again at the East of England venue, following positive feedback from exhibitors and visitors who attended the 2019 event, which was deemed a resounding success.

The permanent exhibition facilities offered by the East of England Arena provided the perfect platform for exhibitors to showcase their products, equipment and services – introducing the latest plant and technology to the UK construction industry.

Visitors also applauded the Plantworx show’s new home, praising the all weather venue as a “definite winner”, with its permanent walkways, good communication signals and wifi facilities that allowed visitors to “do business – while doing business”.

The show, which will be the largest working event in 2023, is planning a comprehensive demonstration programme where exhibitors can put their machines through their paces in site conditions.

events

For those of you not to have seen our extensive social media coverage of this, we recently signed the contract that for one evening only we have the run of the Tottenham Hotspur Stadium for the fifth annual British Demolition Awards.

The awards is now partnered with and held alongside sister event The British Asbestos Awards, which was last held in September at the King Power Stadium in Leicester.

For the fifth year we are moving around the UK, having begun at the

Belfry in Sutton Coldfield before moving to Manchester, then down south to Brighton and back to the Midlands at the King Power, we have now selected London and the extremely impressive Tottenham Hotspur Stadium as the destination of choice for 1 September.

The world’s most technologically advanced stadium gives us an increased capacity of up to 500 contractors and suppliers whose business interest is in demolition and/or asbestos removal

I invite anyone to get involved and book a table to join me and my team and 500 industry professionals for an evening of awards, networking and fun.

While principal sponsorship has been taken for the British Asbestos Awards – thank you to Empire Asbestos for their second year of support – and has been pretty much been secured for the Demolition Awards, there are still plenty of options to sponsor an award and a lot more.

The 5th Annual British Demolition & Asbestos Awards 2023 1 September 2023

Tottenham Hotspur Stadium, London

Media Pack: issuu.com/chambers.media/docs/media_pack_proof

Last year’s official video: www.youtube.com/watch?v=vQqPrJBsAmg

Entry details launched in January

demolitionhub.com 48 | DemolitionHUB Magazine

events demolitionhub.com DemolitionHUB Magazine | 49

bauma

bauma returned to the Messe München on the outskirts of Munich in October. With almost half a million visitors passing through the gates of the week-long show, manufacturers and dealers alike have hailed the show a massive success despite it being moved from its more traditional April timeslot.

pad to show what they are doing to help the environment.

The hot topic for anyone associated with the construction and demolition industry is the desire to reduce the industry’s carbon footprint. As an industry we are known for leading the way in delivering sustainable projects, championing and developing new methods of recycling materials along with leading the UK in pushing for the use of green fuels.

We were encouraged to see many attachment manufacturers