Manure Handling

BE ENVIRONMENTALLY responsible

BE ENVIRONMENTALLY responsible

BE ENVIRONMENTALLY responsible

With over 50 years of experience in manure handling, BouMatic is an indispensable contributor to the environmental transition.

Manure handling in agriculture is a very demanding task and requires robust, high-performance equipment.

On the strength of its expertise, BouMatic is keen to accompany you in your own environmental transition by providing you with the tools you need to recycle your organic waste.

Our mission

The wide range offered by BouMatic ensures you have a robust, technical and economical solution at your disposal for handling organic waste. In order to achieve this, our experts are constantly searching for solutions to respond to future demands.

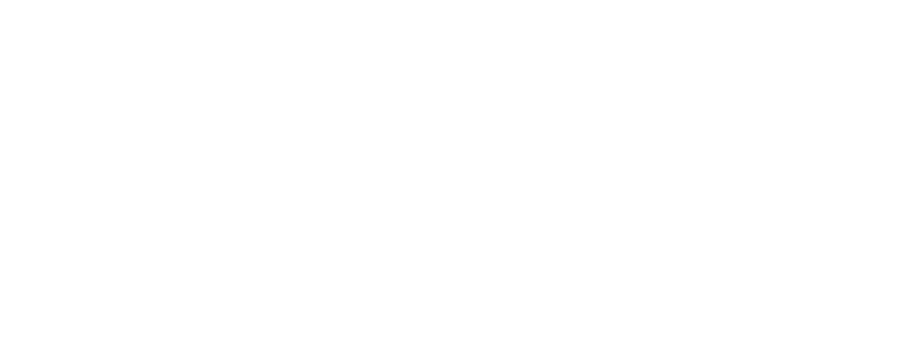

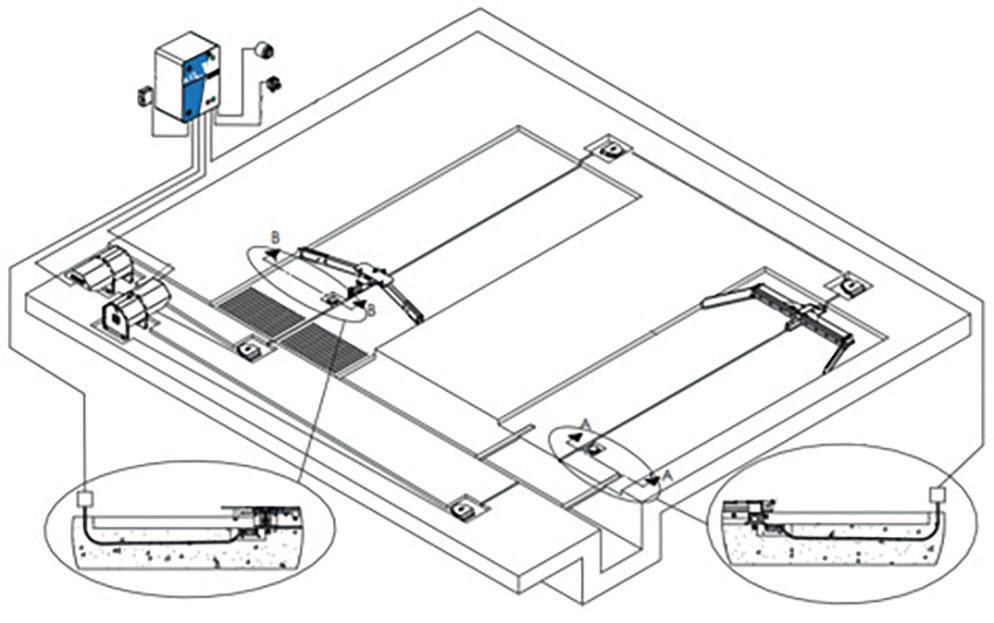

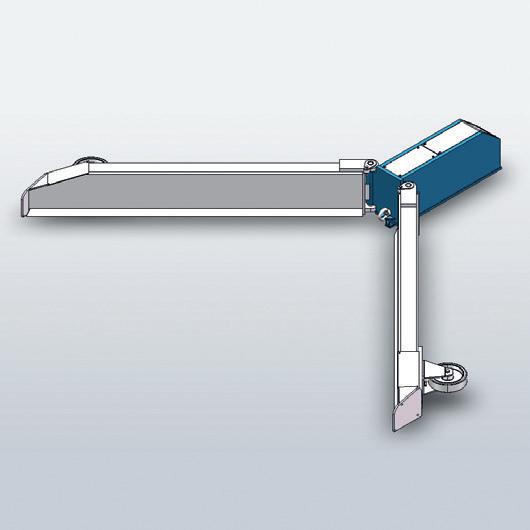

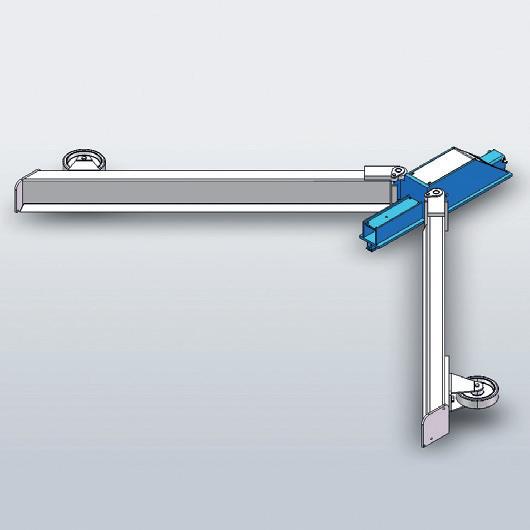

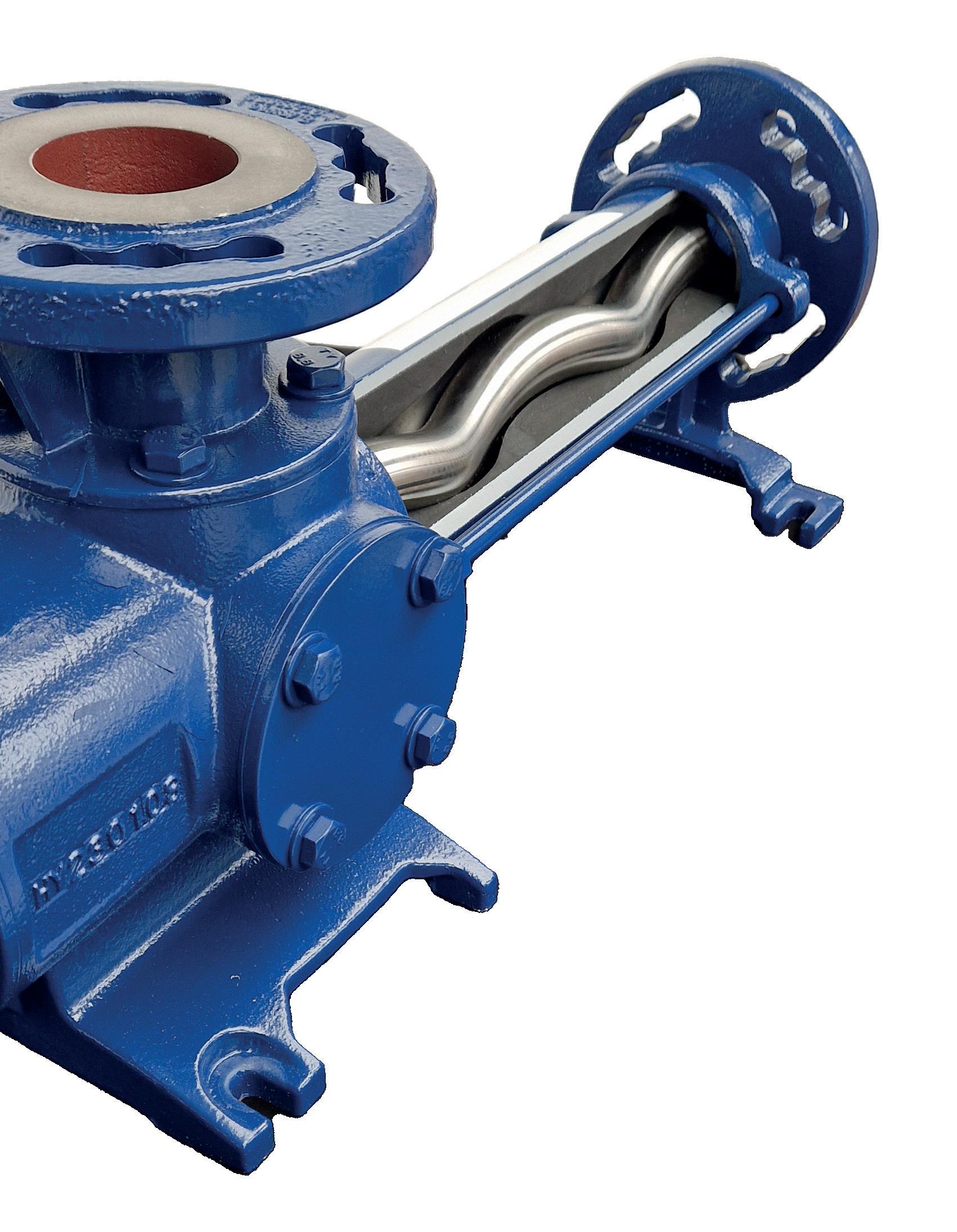

Mechanical reversal: simple and effective.

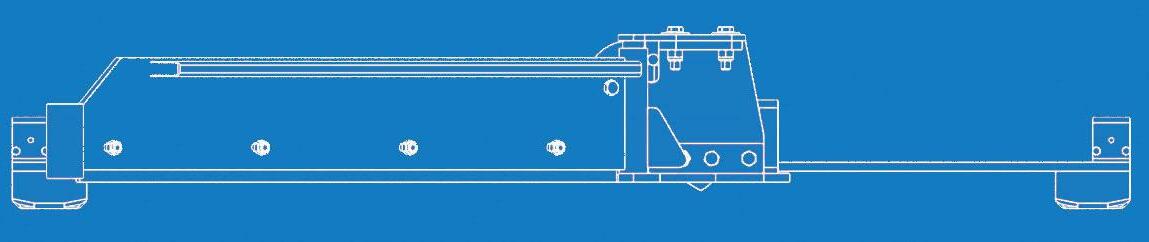

The hydraulically-driven Falcon scraper is incredibly powerful and has an exceptionally long service life.

It is designed for dairy farmers looking to make a long-term investment.

With this powerhouse on your farm, you can rely on our 30 years of experience in manure removal systems. It is powerful, has no distance limit, is easy to use and low maintenance.

Collects solid manure - ideal for straw-bedded pens.

Reliable - UPN rail with external stops to protect hooves Simple and robust reversal system.

11 to 6 scrapings per day - with the operator present.

Powerful - single- or multi-corridor hydraulic power unit.

Solid – rails can be added with no length limit.

Adaptable – heavy straight or V scrapers, asymmetric mounting possible.

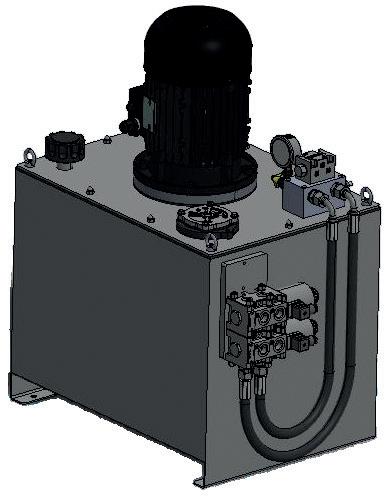

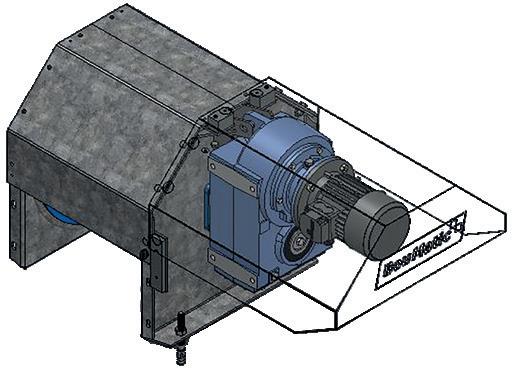

Hydraulic power unit

Power unit with an oil capacity of 100l - prevents oil overheating.

3 types of power unit available - 1 corridor, 2 - 3 corridor and 4 - 5 corridor

1 to 6 scrapings per day - with the operator present.

Powerful - 5,5 kw.

Safety- oil level.

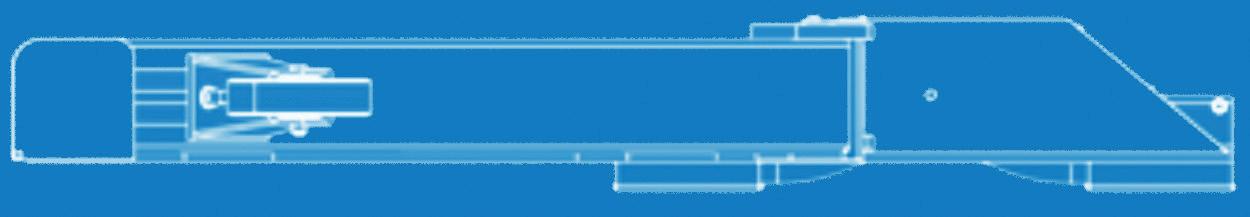

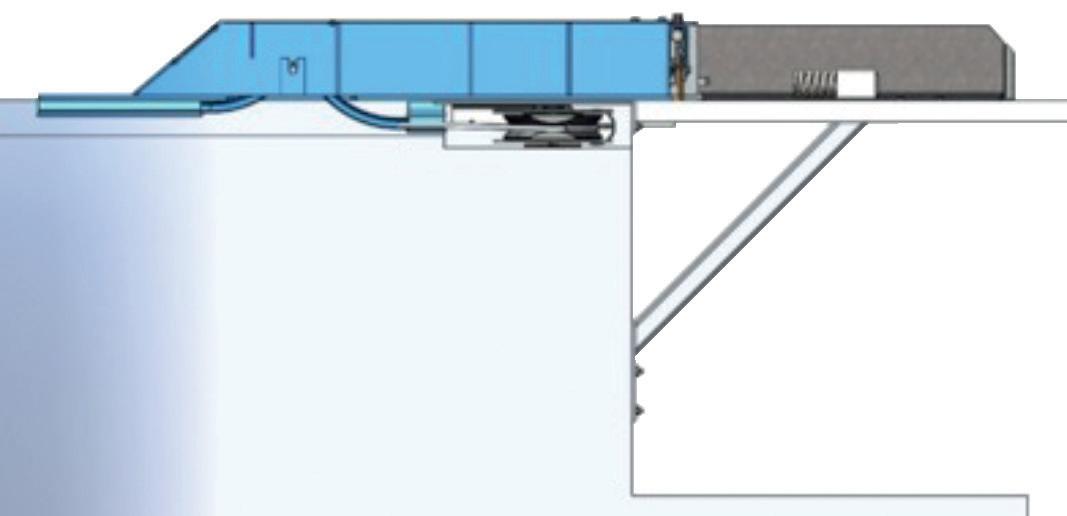

Surface : The cylinder is on the surface. The frame will be embedded 6 cm beneath the concrete of the scraping corridor. It can be used to pull or push the scraper.

Embedded : The cylinder is embedded and is used to push the scraper. The frame will be embedded 18 cm beneath the concrete of the scraping corridor and positioned to push, i.e. at the start of the scraping corridor.

Sub-rail : The cylinder frame will be embedded 22 cm beneath the concrete of the scraping corridor so that it can pull the scraper, i.e. after the discharge area.

Box : 4 models available

• Box for 80 mm rail

• Box for 100 mm rail

• Box for 120 mm rail

• Box for 140 mm rail

Installation at the end of the corridor for pulling the scraper with an opening onto the pit. Requires a water supply. The box must be installed next to the chute so that the liquid can run into the channel or manure pit.

Concrete : A rail embedded in concrete can be used to guide the traction rail and the scraper. The dimensions chosen depend on the traction rail..

Traction : Two types.

Surface rail with stops: one stop per metre, for use in the pen. Offers significant advantages in the event of frost or on drying ground as it allows the scraper to keep moving.

Special manure pit rail: for use in the flat discharge area so that the manure can be easily picked up with a tractor.

Contrôleur : Easy to use and available in 3 versions.

• ACL 1 : controls 1 corridor

• ACL 3 : controls up to 3 corridors

• ACL 5 : controls up to 5 corridors

Manual start

Automatic start max. 6 times per day

Automatic frost protection

Transverse channel start signal

“Drop in step” function

Operating hours counter

Service messages at regular intervals

1 corridor

Controls up to 3 corridors

Controls up to 5 corridors

The Triton 13 scraper is the simple solution for scraping slurry- or straw-covered aisles. Versatile and sophisticated, it guarantees perfectly clean aisles with scraping adapted to the conditions. This chain scraper adapts to all situations.

Motor: 1.1 kW

Hydraulic unit: 0.55 kW

Automatic or manual chain tensioning

Hardox drive pulley

Chain guide

For use between two corridors or at an angle

The motor is positioned high up so it is protected from animals and bad weather

Horizontal : The 250 mm diameter pulley is mounted on two rows of bearings with two “SPI” joints which help to protect the bearings from liquids and ensure a long service life. The pulley is made from stainless steel.

13 x 36 mm chain:

• Resistance: 22 T

• Weight: 3.8 kg / m

• Calibrated

• Special dip

• Limit of 200 m of chain per gear

The most functional control cabinet on the market, it offers range of options to relieve you of your day-to-day tasks.

Manual stop / start on the front of the controller

Up to 24 automatic starts per day

Option to park in an irregular position at set hours

Crowd gate function

Automatic antifreeze function

Transverse channel start signal

Incremental discharge of slurry into the transverse channel

Automatic chain tensioner

Operating hours counter

Message regarding service A, to be carried out by farmer

Message regarding service B, to be referred to a BouMatic maintenance technician

Real-time clock

Automatic transition from summer to winter time

Multi-pile

Alarm to announce each start-up

Reduction to half speed in a maximum of 3 user-defined zones

Encoder for the scraper position

Option to change the standard speed

The Triton XLM 10 chain scraper is a simple and functional solution for frequent scraping on concrete corridors and slotted floors.

• Motor: 0.75 kW

• Manual chain tensioning

• Reinforced drive

• Hardox drive pulley

• Chain guide

• For use between two corridors or at an angle

Horizontale STD : Robust steel, frame-mounted pulley

• Diameter of 250 mm

Horizontale HD : Robust HD composite, framemounted pulley

• Diameter of 350 mm

Common features

• Two rows of bearings

• Double “SPI” joint

• 25 mm axle

• Adjustable scraper

Manual stop/start on the front of the controller

Up to 24 automatic starts per day

Automatic frost protection

Evacuation channel start signal

Total operating hours display

Reminder message for service A, to be carried out by farmer

Reminder message for service B, to be carried out by a BouMatic service technician

Real-time clock

Automatic transition from summer to winter time

Alarm that sounds at each start-up

Crowd gate function (optional control unit)

Chain

10 x 32 mm chain :

• Resistance: 13 T

• Weight: 2.25 kg / m

• Calibrated

• Special dip

• Limit of 200 m of chain per gearr

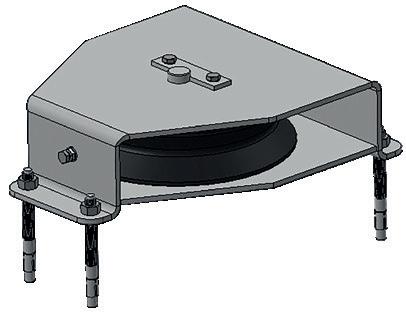

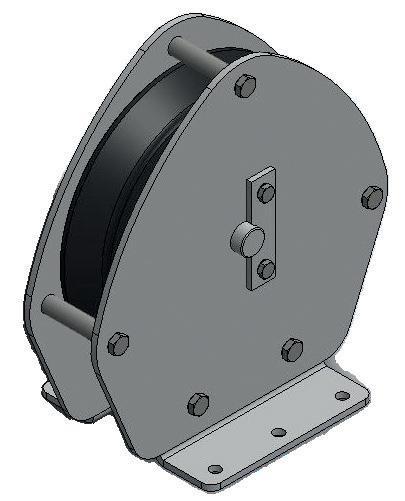

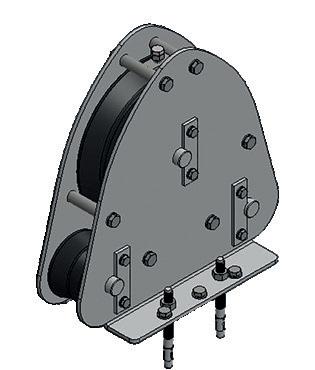

The Typhoon scraper is the simple solution for scraping slurry-covered or semistraw aisles. Versatile and sophisticated, it guarantees perfectly clean aisles with frequent scrapings.

The Typhoon rope scraper is the most simple and efficient solution for dairy cow pens.

Moter power : 0.55 kW or 0.75 kW for a limited energy consumption.

Winch:

• One large-capacity model that can roll up to 200 m of rope.

• Supported by two bearings for a longer service life and to reduce the effort required from the gears.

• Drum with a thickness of 8 mm that resists compression

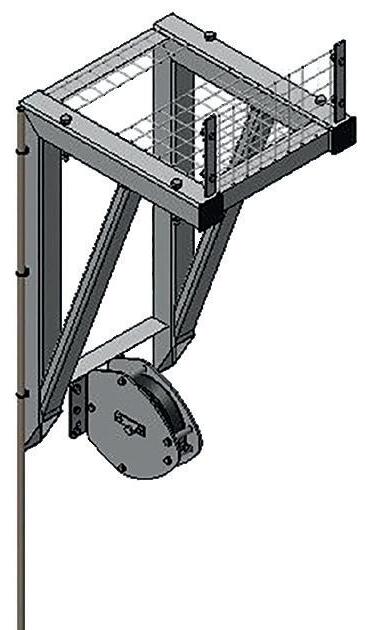

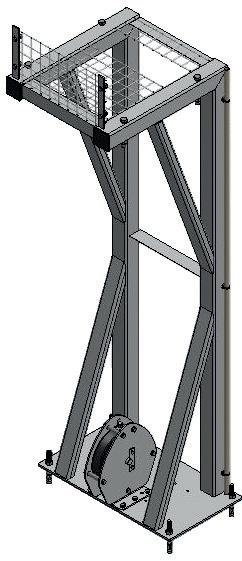

Floor bracket : The bracket helps you gain some extra space and lift the winch up to 2 m off the ground. The vertical pulley and winch access guard is included.

Bracket with guard : We can add a guard to the bracket as an option. The guard stops people from accessing the rope and stops slurry from splashing the area around the bracket. Two models are available

Wall bracket : This bracket includes a vertical pulley and is fixed to the wall to hold the winch.

We carefully designed our pulleys so that they can work in abrasive environments, such as in sand, and not cost too much to maintain. We offer 3 types of pulley:

Horizontal standard et HD:

• Pulley with 250 mm diameter.

• A minimum distance of 2.5 m between the winch and the pulley is recommended

Verticale :

• Pulley with 250 mm diameter.

• For use with a floor or wall bracket.

Horizontal or vertical pulleys with a diameter of 250 mm do not require any servicing. They are mounted on a bearing with a TP-type “SPI” seal which means that they can be used in sandy environments and are low maintenance.

Rope Guide: This pulley is used when the winch is placed on the floor directly after the groove. During the winding, the rope is wound up on the drum from left to right and from right to left. The pulley prevents the rope from touching the edges of the recess and being cut.

• Pulley de diamètre de 250 mm.

Common features

• 25 mm axle.

• Two rows of bearings.

• 2 “SPI” seals to protect the bearings.

DYNEEMArope is incredibly resistant. Contrary to stainless steel or steel cables, farmers can easily repair the rope with a needle if it breaks. It is also easy to make loops to attach the scraper to the rope

• 10 mm: 10.8 T tensile strength. Available in rolls of 1, 200, 500 and 1,000 m.

• 12 mm: 16.5 T tensile strength. Available in rolls of 1, 200, 500 and 1,000 m.

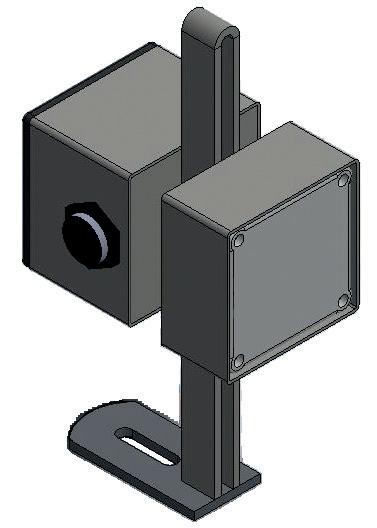

ACL control cabinets offer a range of functions to help make your day-to-day work easier.

Manual stop / start on the front of the controller

Up to 24 automatic starts per day

Automatic frost protection

Evacuation channel start signal

Incremental discharge of slurry into the evacuation channel

Total operating hours display

Reminder message for service A, to be carried out by farmer

Real-time clock

Automatic transition from summer to winter time

Selection of the number of cycle starts

Alarm that sounds at each start-up

Alternative parking position

Crowd gate function (optional control unit)

The SBC controller has been specially designed for brush scrapers. To prevent an accumulation of slurry between the brush and the flaps, the scraper stops and moves back to collect the slurry accumulated between the brush and the flaps. The frequency of this can be adjusted. This function guarantees an optimal cleanliness of the brushes and therefore a more effective scraping.

Manual stop / start on the front of the controller

JUp to 24 automatic starts per day

Automatic frost protection

Evacuation channel start signal

Incremental discharge of slurry into the evacuation channel

Total operating hours display

Real-time clock

Automatic transition from summer to winter time

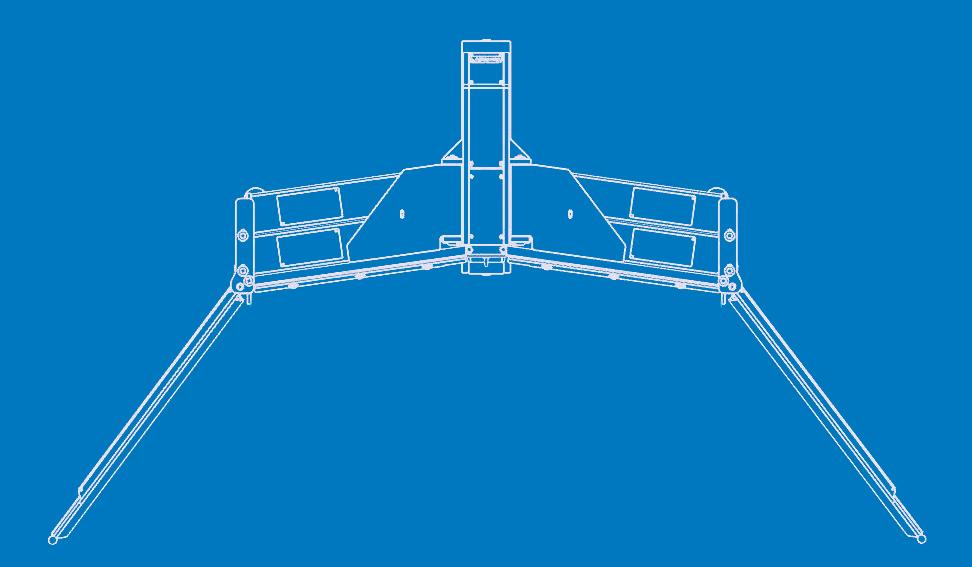

The TYPHOON SBC is the most efficient scraper on the market today. A patented piece of equipment, the automatic lifting brush helps farmers to achieve perfectly cleaned floors.

• The brushes, which are positioned under the planer at the back, are independent from the scraping blades on the front.

• It is a much more compact system.

• Thanks to this system, farmers can reduce their scraping frequency by 30% in comparison to a classic scraper.

• The brushes do not carry the weight of the blades and planer while the scraper is moving forwards.

• By reducing the scraping frequency, we are able to increase the service life of the scraper and the installation components.

• The “traditional” blades clean away the majority of the slurry and the brushes finish the job.

• Once the parameters have been set, the computer automatically controls the scraper to stop the brushes from becoming saturated.

• The result is a better scraping quality, less moisture and cleaner cows. All of this is a massive advantage for the farmer.

Whether it is smooth, scratched or grooved concrete or matting, you will definitely be satisfied with the results. Unlike with front brushes, the SBC always keeps the brushes clean and ensures optimal cleaning even on inclines. Equipped with steel blades on the front and brushes on the back, it will get dirt out from even the deepest corners of the aisle that you are scraping. Works on inclines of up to 2%.

This scraper cannot be used with a flat manure pit

We offer several different types of limit switches that stop the installation or reverse the scraper. Our dealers will help you to work out which limit switches are best for you depending on your installation.

Aerial : Limit switch for fixing to the ground. It will stop the scraper in its parked position or reverse it. Thanks to the design, the sensor is protected.

Concrete : Limit switch for setting in concrete. It will stop the scraper in its parked position or reverse it. Watertight box for optimal sensor protection..

Horizontal or vertical pulleys with a diameter of 250 mm do not require any servicing. They are mounted on a bearing with a TP-type “SPI” seal which means that they can be used in sandy environments and are low maintenance.

On a pulley: A spring is placed in the rope and when it passes in front of the sensor the scraper is reversed or stops if it is in the parking zone. For use in slurry installations without straw.

On a winch : A spring is placed in the rope and when it passes in front of the sensor the scraper is reversed or stops if it is in the parking zone.

On a spring: When the scraper reaches the discharge area or the parking zone, the spring compresses on a stop fixed into the concrete. This increases the intensity and reverses or stops the motor.

• Emergency stops

• Alarm (obligatory for the EEC standard (machine standard))

• Frost protection probe

• Electric cables

• Cables for the sensors

• Limit switch(es)

A large range of scrapers for every situation.They can be symmetrical or asymmetric.

HD : The straight HD scraper is perfect for farms that use straw and want to make manure. Its weight, CC blades and Hardox wear parts make this scraper a trusty partner that will be at your side for years.

• Limit switch for fixing to the ground

• It will stop the scraper in its parked position or reverse it

• Thanks to the design, the sensor is protected

Standard : The straight standard scraper is ideal for very aggressive environments (sand) as all the parts that come into contact with the ground are made from Hardox and can be easily replaced. In addition, it has been designed so that there is always a space between the arm and the edge of the cubicle so as to not disturb the animals. It is equipped with:

• Steel / CC blades

• Parts in contact with the ground are made of Hardox and can be easily replaced

• Works on inclines of up to 2%

• From 2 to 5 m

• Get in touch if you need a different size

Slim : Our slim scraper is designed for 100% slurry installations, the scraper blades are made from steel and can be optionally equipped with a CC band. It is available in widths from 2 to 5 m.

W1

W1

W1 W1

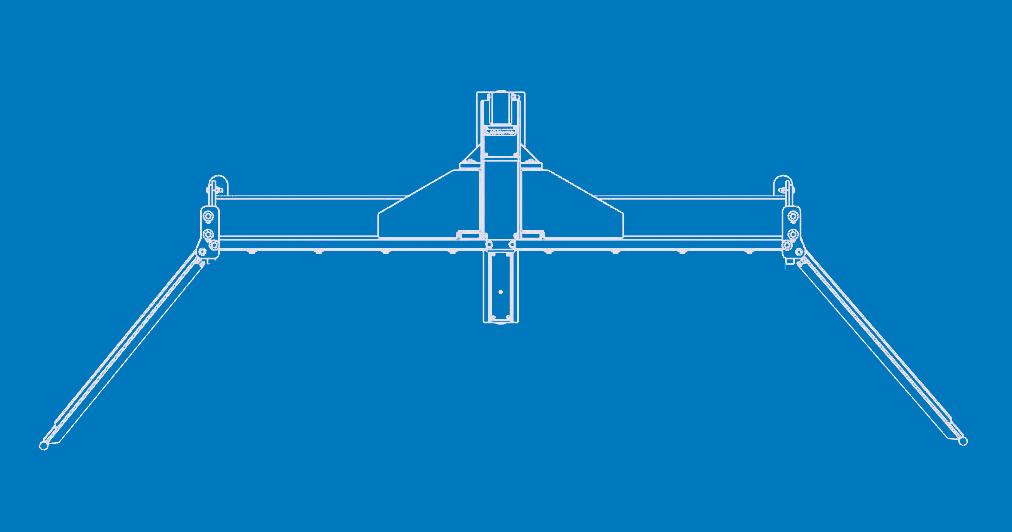

HD : The V HD scraper is perfect for farms that use straw and want to make manure. Its weight, CC blades and Hardox wear parts make this scraper a trusty partner that will be at your side for years.

• Hardox planer blade

• Arms can be weighed down

• Runner with or without arm blocking (without blocking: scraper can be opened fully at the discharge area)

• Parking zone = 1.5 times wider than the corridor

• Asymmetric (optional): offset from the centre of the corridor by 25 cm to the right or left

• From 2 to 6 m (Get in touch if you need a different size).

• Hauteur sous barrière 750mm

Standard : With the “V” slurry scraper, the load is moved into the centre of the scraper.

• The parts in contact with the ground are made from Hardox for a longer service life.

• When it returns to the parking zone, it leaves plenty of space to facilitate the flow of animals.

• From 2 to 5 m. Get in touch if you need a different size.

• It can be used asymmetrically.

• It cannot be used on inclines.

Find below the types of scrapers available depending on the desired model:

Straight HD

Straight Standard

Slim

HD

V Standard

V SBC

V Reversible

V Slotted floor

V Channel scraper

V Passage on a pulley

V Scraper for waiting area

Only for TYPHOON installations.

The passage on a pulley has been designed for systems that use a manure pit with a chute or that discharge directly into the pit.

This means that the dealer or farmer can safely intervene when they need to service or clean the pulley.

The groove should be 40 mm wide and 90 mm deep.

The discharge area will need to be a little larger because of the slighter longer runner (+600 mm).

The special evacuation channel scraper is a slurry scraper that allows farmers to get rid of effluents while consuming little energy.

Max. width 1.1 m.

Makes it possible for you to have a manually operated or automatic backing gate in your waiting area (linked to the entrance gate) and to clean it after milking.

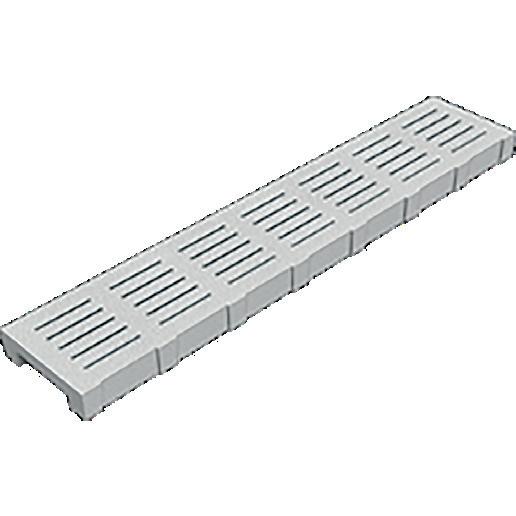

Specially developed not to interfere with the animal, it can be used to easily and efficiently scrape corridors with slotted floors. Available for corridor widths of 2 to 5 m.

The ideal scraper for when the channel is in the middle of the pen.

When the scraper passes over the cams positioned on the channel (2 on either side), the blades lift up and pass over the pin.

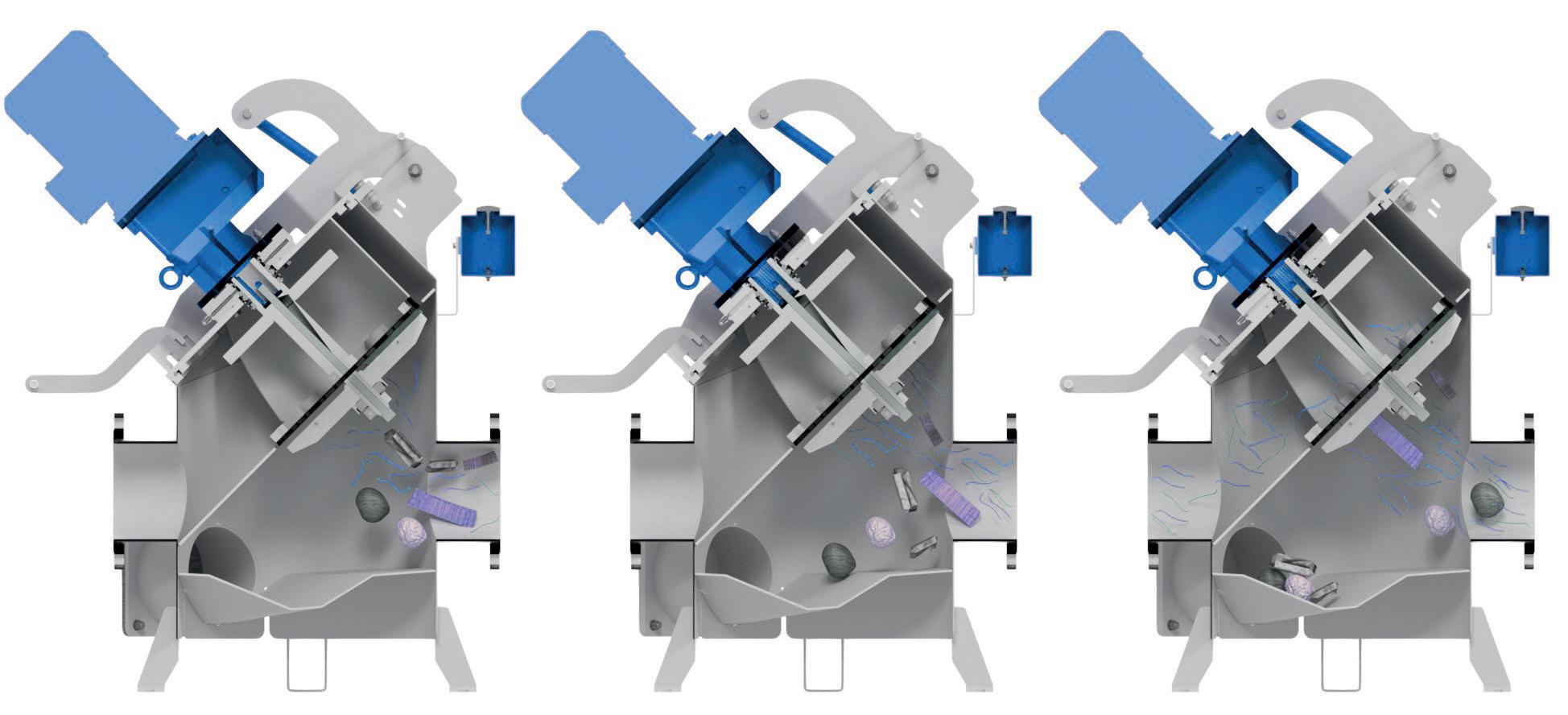

The BVS is a fully automatic robot that cleans livestock buildings by vacuuming up slurry. It helps to:

Keep animals cleaner

Keep cubicles cleaner

Decrease the working time needed for cleaning the passages between cubicles

Make animals more comfortable

Reduce the amount of liquid around the animals’ hooves and legs

Reduce the ammonia fumes released due to frequent passes

The two arms move the slurry towards the centre.

The build up of slurry around the tank’s suction mouth prevents any air from getting in.

As the tank is depressed (vacuum pump), the slurry is vacuumed up and stored in the tank.

When the BVS passes over areas with slotted floors, the tank empties because there is no slurry to block the suction mouth.

When it arrives at its charging point, the BVS empties and the vacuum pump reverses to push the slurry out of the tank.

The BVS is made entirely from painted stainless steel which protects it from corrosion and ensures an optimal service life.

Its rounded design allows it to turn 360°, reducing the need for manoeuvres when it reaches the edges of the building.

Minimum height under the barrier

mm

Electrical consumption 250 W/hour

Slurry tank volume 350 l

Water tank volume

l

Forward-moving speed 10 m/min

Autonomy with LITHIUM battery 14.5 hours/day

Permissible slope 8% (4% + 4%)

Empty weight

Filled weight

NOISE EMISSION (AT 1 M)

NOISE EMISSION (AT 10 M)

kg

dB

dB

Capacity / Robot* until 150 Milking cow

* depending on the battery, route and emptying point

WIFI coverage throughout the building will be required before installation to ensure optimal remote access.

No parts need to be installed in the ground to guide the robot. Thanks to its laser guidance system, the BVS moves around autonomously.

The first time that the robot is used, the operator (a qualified person approved by BouMatic) must create a virtual map by moving the robot throughout all areas of the building. Once the robot has learned its map, it will be able to move around freely in its area and the user will be able to adjust the frequency of the scrapings as they want.

The learning and the adjustment of any settings can be done from a PC or a smartphone. A remote control is provided for all movements in manual mode.

Any alerts are send by email and/or SMS and can be resolved remotely.

Several configuration options are available: On a reception pit On a channel On slotted flooring at the edge or in the middle of the building On a storage pit

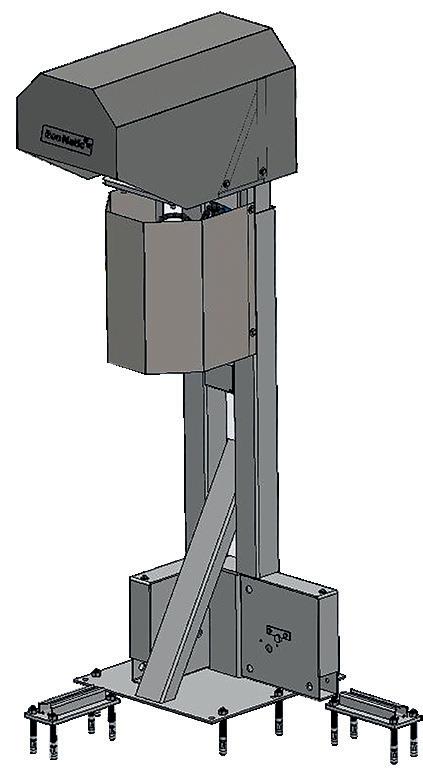

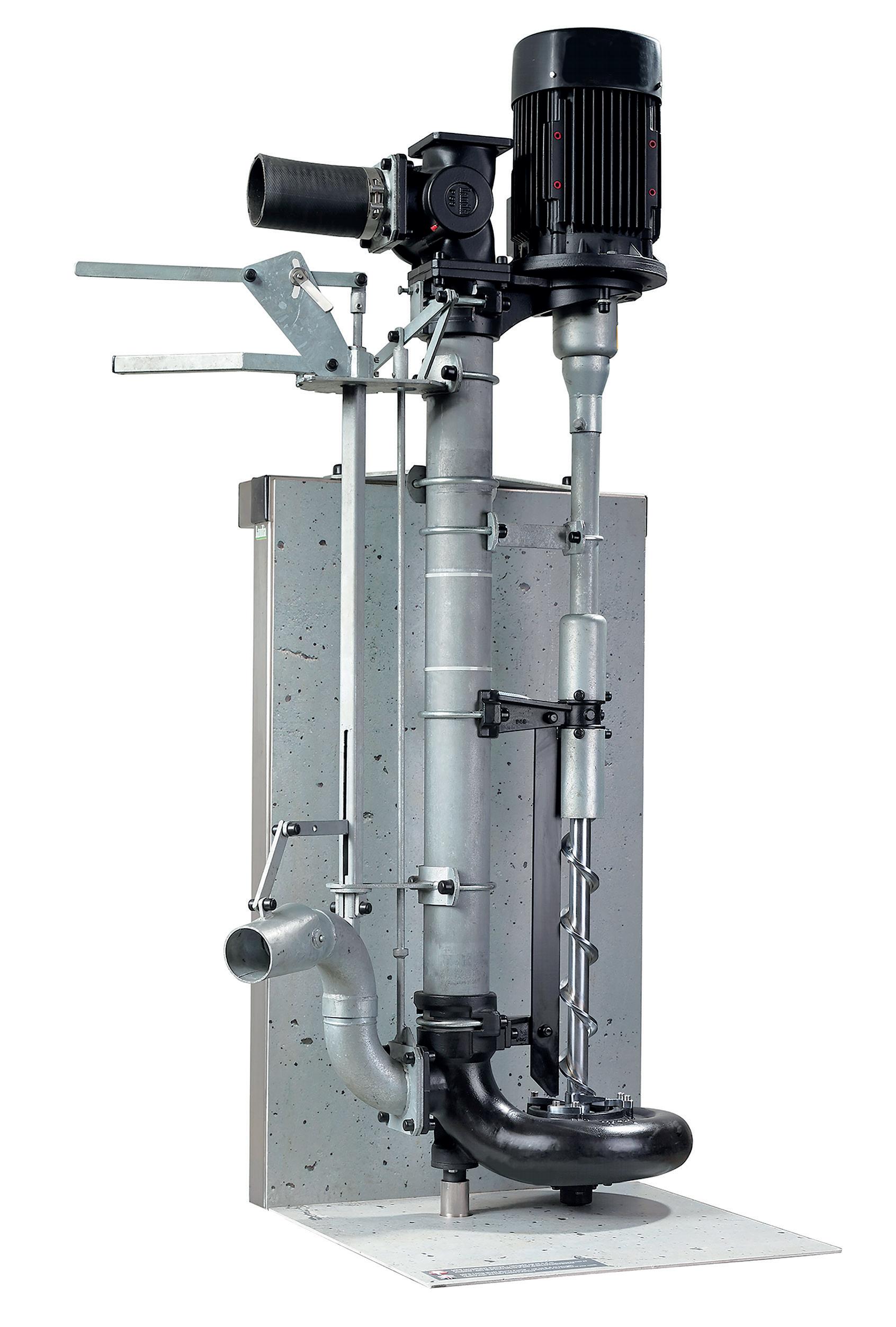

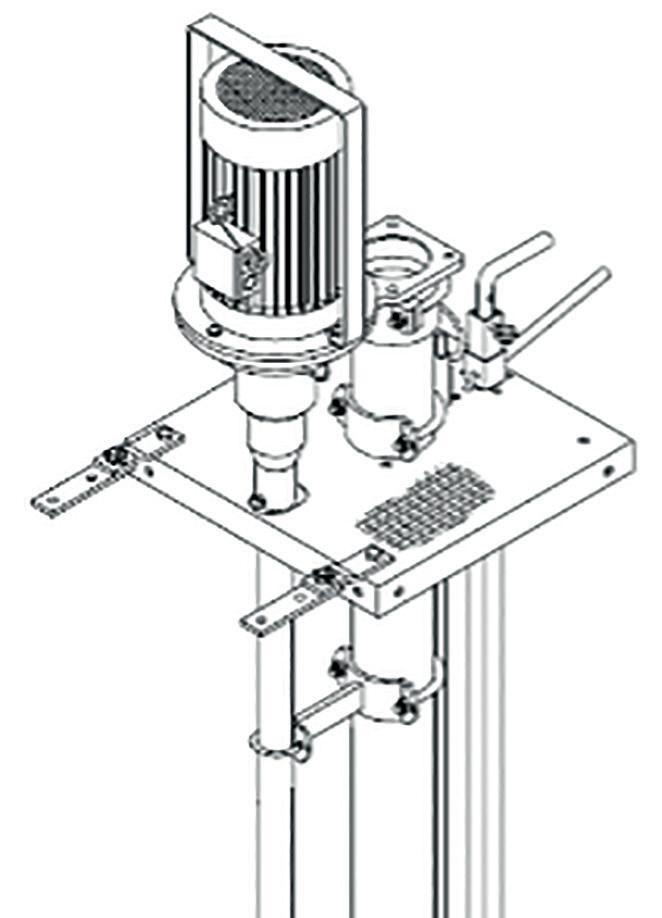

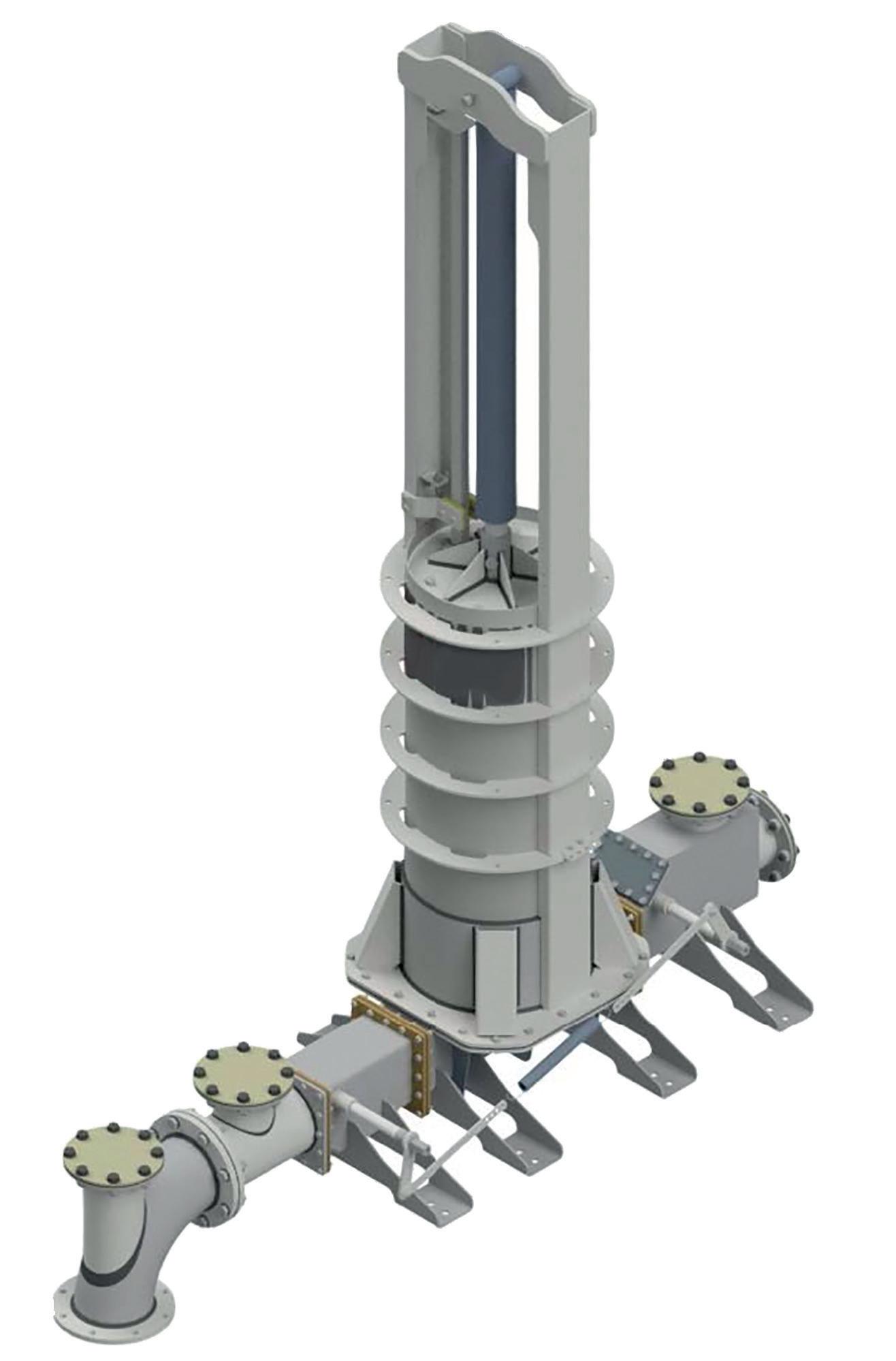

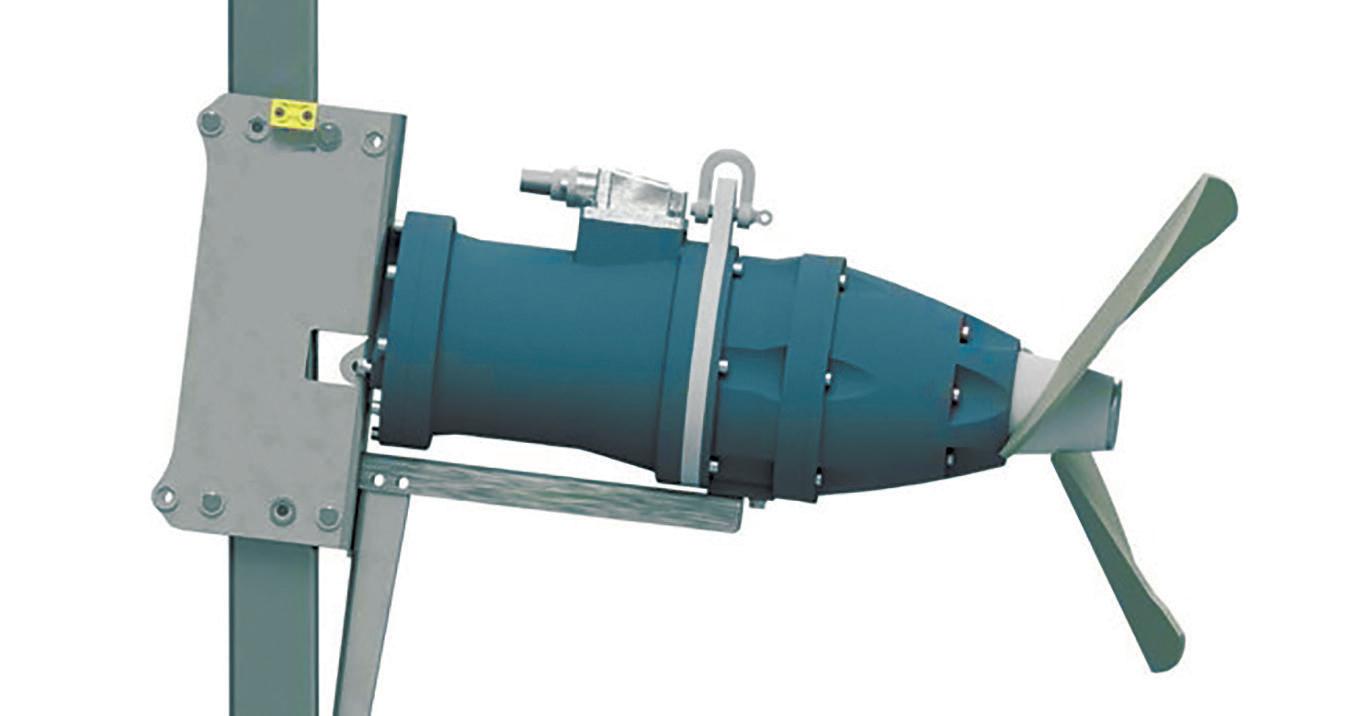

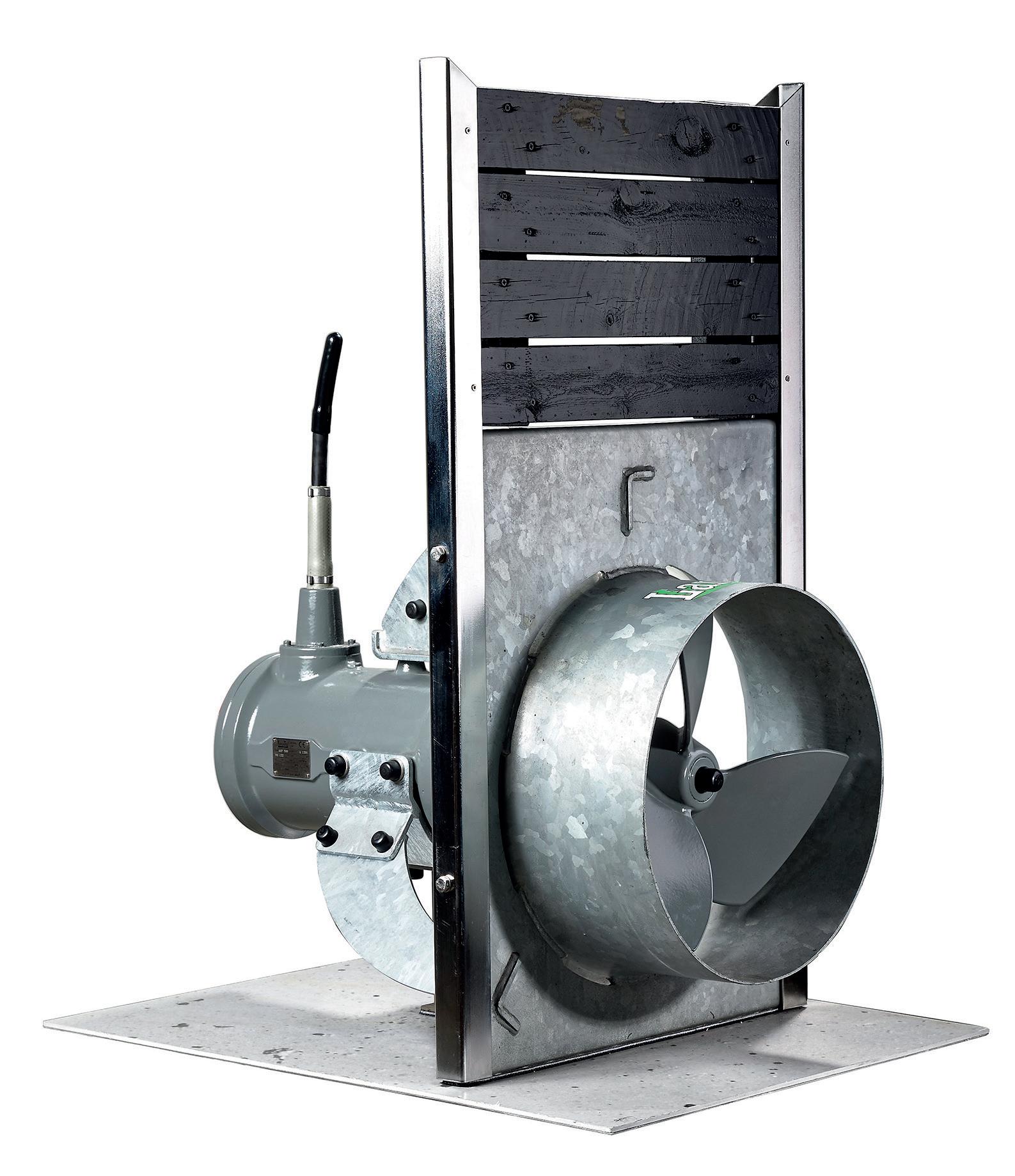

BouMatic MPG pumps with a long shaft for MPG-type organic waste (motor-driven pump) are mounted on the edge of a receiving pit or storage pit so that the lower part containing the pump housing is lowered into the liquid and the upper part containing the motor is in the open air.

The long-shafted pump can be supplied with a moving bottom agitator for mixing. Numerous sizes, fittings and pipings are available (4’’ – 5’’ – 6’’).

The hardened steel blade system for shredding coarse elements and the propeller providing consistent access to the pump ensure seamless pumping.

Pump housing made of hardened steel that is much better quality than the welded pump housing.

Superior strength, often 10 to 15 years of service without great expense.

Capacity up to 450 m³/h.

Suction via the top of the volute

Inlet auger with contra-rotating blade

Engine sizes from 5.5 to 30.0 kW

Lifting height up to 25 metres

Pump hose 4”, 5” or 6”

Available for pits of 1.8 to 5.4 m in depth

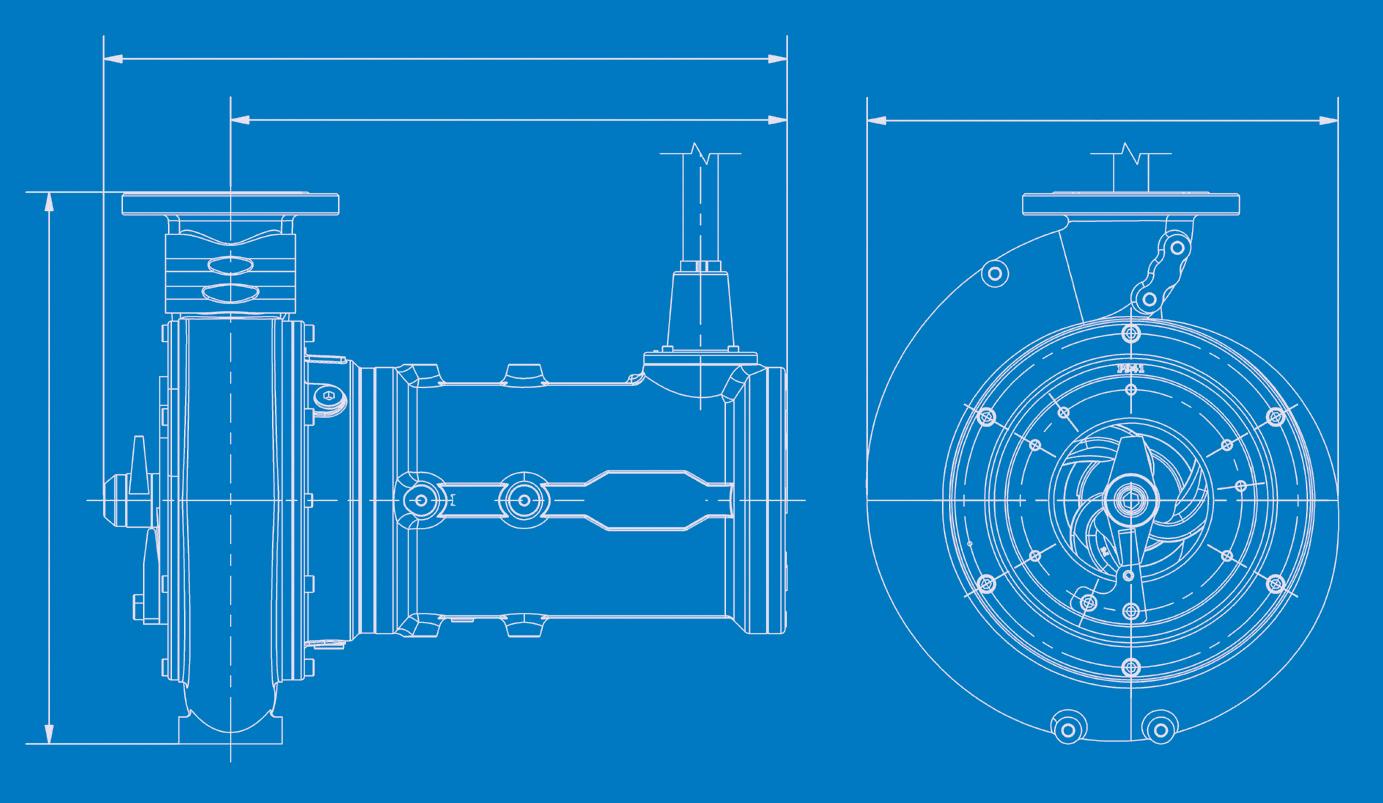

BouMatic macerator pumps have been designed for the toughest applications.

Their reinforced housing for extreme applications (heatreinforced as optional for use with sand), cast iron body (stainless steel as optional) and blade system, make them the most effective pumps on the market.

The BouMatic DG pump is a highperformance pump that enables you to pump heavy loads at a high rate (350-400 m3/h)

The suction and maceration concept of BouMatic’s DG pumps offers optimum performance:

Macerator blade system comprising up to 3 blades (1 blade supplied as standard, if I’ve understood correctly)

Inlet designed to protect the pump body and seals

Reinforced propeller for unrivalled durability

*Values measured in water

The pump was designed to adapt to a range of effluents and is available in a variety of materials tailored to your specific needs:

Cast iron for robust resistance

Hardened steel for increased durability

Stainless steel for protection against corrosion

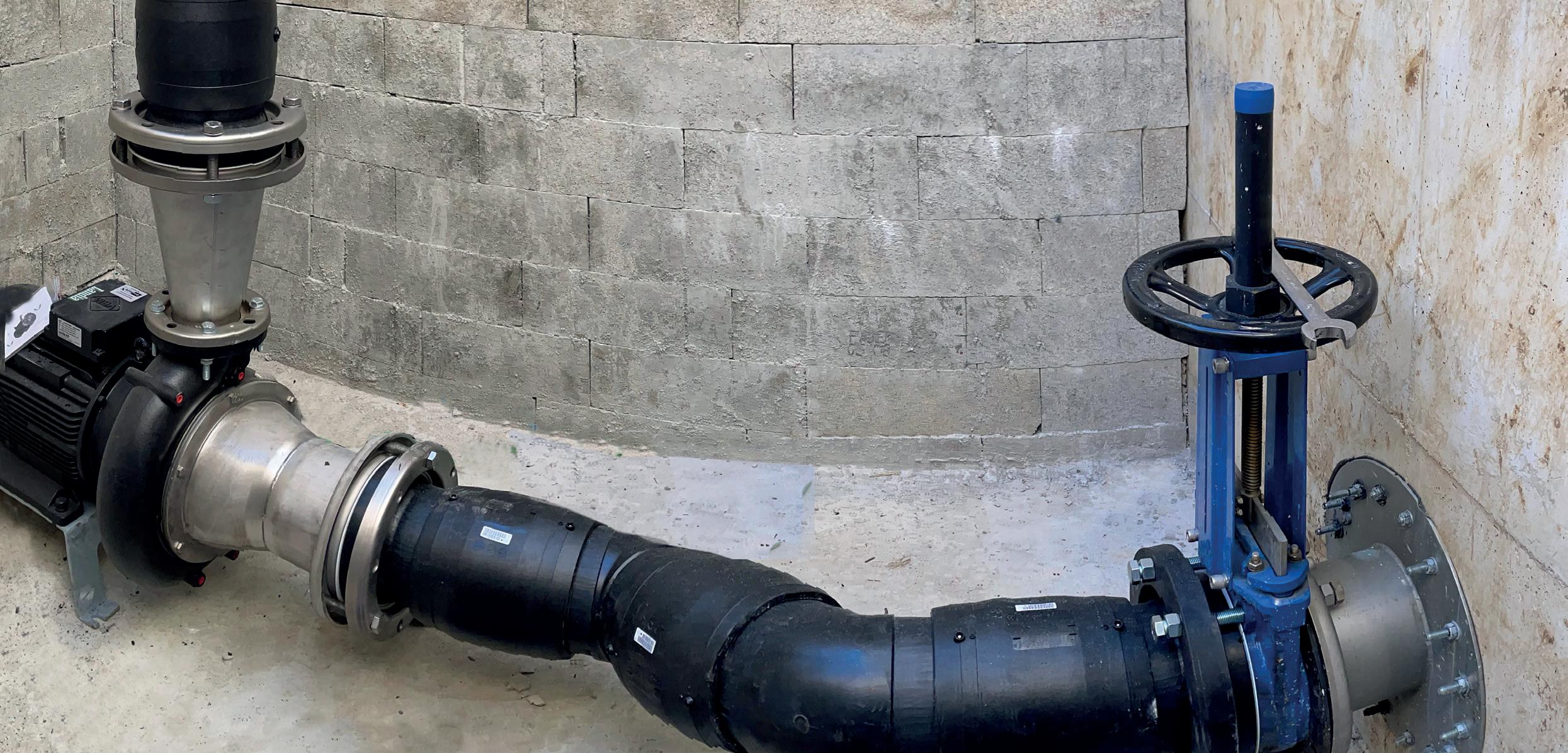

BouMatic offers two solutions for flushing out waiting areas, passages and scraping aisles:

DG heavy flow pump

Special flushing version of the FP vertical pump

The 160-diameter valves have been specially designed to not stem the flow so that a maximum flow rate can be achieved by reducing the energy.

When the pump is off, the valve is closed.

When the pump starts, the flow of liquid causes the valve to lift and send out a spray of water. The water creates a wave that cleans the surface.

BouMatic pumps are equipped with a unique combination of static and rotating blades, making them the ideal solution for finely shredding and transferring organic waste with a high dry matter content.

The blade system and shape of the pump housing ensure the pump’s smooth suction capacity.

Wearing parts such as pump gears and pump housing can be supplied in reinforced material so that wear is reduced by half when pumping sandy slurry or manure containing abrasive elements.

Capacity up to 475 m³/h.

In short

Motor sizes from 0.75 to 30.0 kW

Lifting height up to 50 metres

Compact design

measured in water

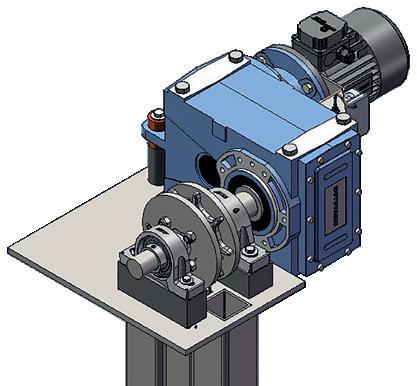

The BouMatic piston pump is a hydraulic drive unit used for pumping slurry, manure, and semi-solid and viscous digestate across long distances with minimal power.

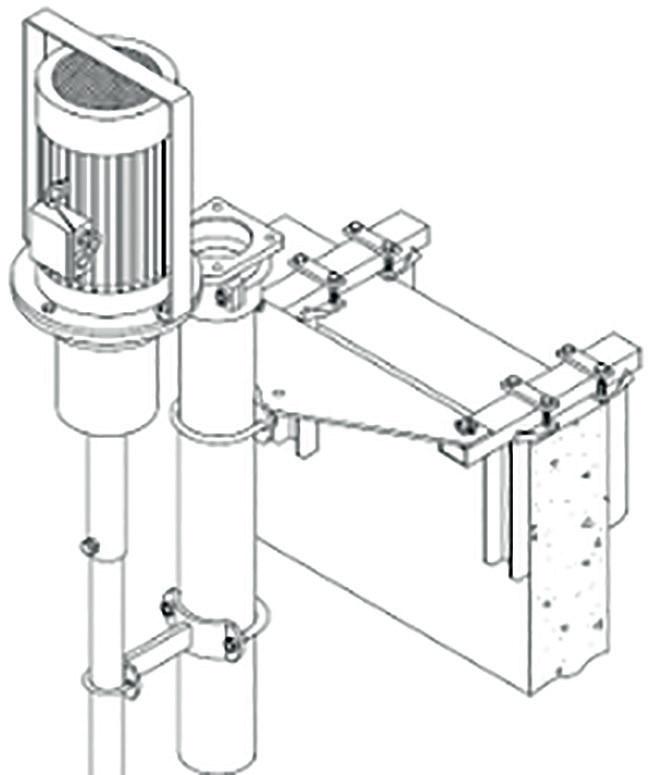

Several configuration options are available:

A hydraulic power unit for one pump

A hydraulic power unit for two pumps; two heights available

3.38 or 2.48 m

Top sensor

Hydraulic cylinder

Bottom sensor

Cleaning flange

Feeding hose

Discharge hose *Values measured in water

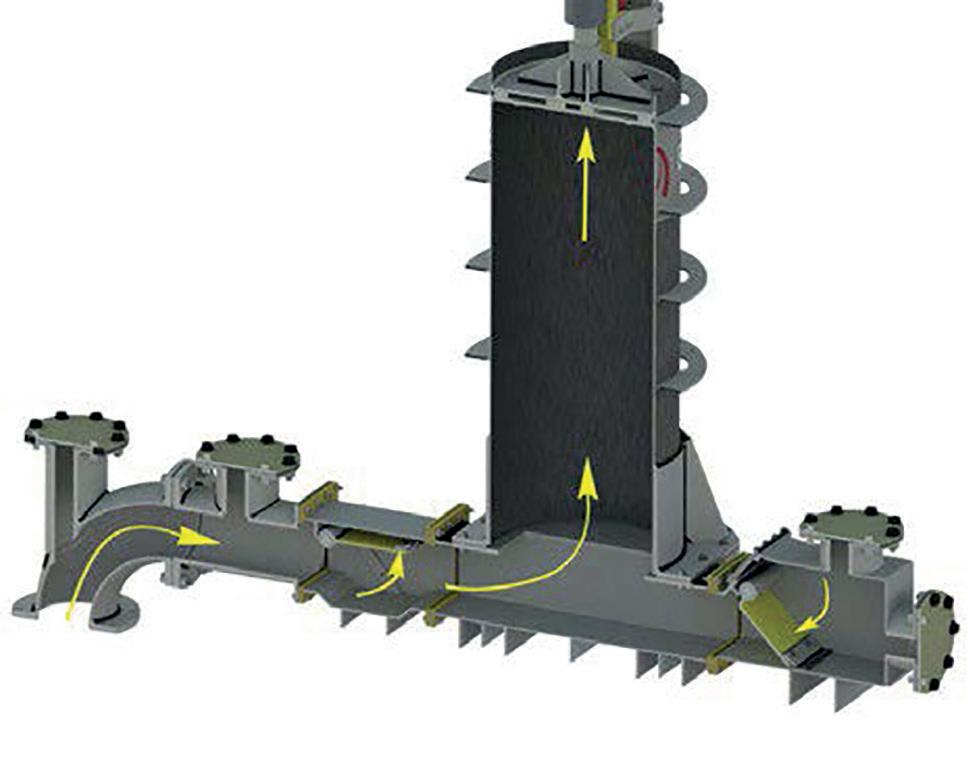

A simple yet effective mechanism for greater longevity.

Two sensors are integrated into the pump. They are activated by the position of the piston in the chamber. When the sensor at the bottom is activated, a signal is sent to the piston to return to the top.

During this phase, the waste is sucked into the chamber. Conversely, when the sensor at the top is activated, a signal is sent to the piston to return to the bottom. The waste is discharged from the chamber and pumped out.

With the BouMatic piston pump, you can pump manure without any risk of damaging the internal parts. No mechanical elements are in contact with the product. The pump is designed to have very few parts requiring maintenance. It also consumes less energy (compared to a rotary lobe pump). Its daily usage cost is very low.

BouMatic spiral pumps are unparalleled when it comes to performance. They are used to pump and transfer slurry, even thick slurry, to a separator or storage tank.

Their main features:

• Adapt well to both fragile and viscous products

• High suction and self-priming capacity

• Constant, non-pulsating flow

• Flow proportional to the speed of rotation

• Reversible

• Easy to maintain

Consists of a STATOR and a ROTOR

A spiral pump consists of a helical rotor which turns inside a helical stator. The stainless steel rotor is manufactured with a high degree of precision, the stator is made from a resilient elastomer.

The geometry and dimensions of these parts have been designed so that when the rotor is inserted into the stator, a double chain of watertight cavities in the form of air cells is formed. When the rotor turns inside the stator, the air cells move along the axis of the pump in a spiral without changing shape or volume. This allows the pump to transfer product from the entry to the discharge without damaging it.

Depending on the configurations and the type of manure to be pumped, BouMatic recommends installing a cyclone upstream in order to:

• Remove any foreign objects to protect the parts of the pump and separator, if there is one.

• Reduce the size of the stalks of straw for an installation with a separator.

Values measured in water

HIGH-PERFORMANCE ELASTOMERS PRODUCED IN OUR LABORATORY

WIDER INSPECTION HATCHES 250

BouMatic spiral pumps have been designed to pump and transfer thick slurry with a regular flow. There is also the possibilty to vary this flow.

INNOVATIVE MULTISTANDARD FLANGE

HOLDING RING

PATENTED CONNECTION

REVOLUTIONARY ARTICULATION

The BouMatic spiral pump has been designed to make maintenance work easier:

More space

• Connecting rod up to 80% shorter than other progressive-capacity pumps on the market

• Shorter and more resistant revolutionary articulation

• Patented connection system: only 7 cm of clearance needed to dismantle the stator on the largest models

• Replaceable in place of the PCM EcoMoineau™ M: The ground fixation system and the distance between the two flanges is the same which allows for an easy replacement

Easy and quick maintenance

• Patented, three-screw connection system

• Inspection hatches that facilitate access to the body for unblocking and cleaning of the monitoring function of the pump

• Seal can be changed from the rear by disconnecting the drive unit

• Standard maintenance system in place on all pumps

Pump with an eco-friendly design

• Lower energy consumption compared to the majority of spiral pumps

• Uses less raw materials

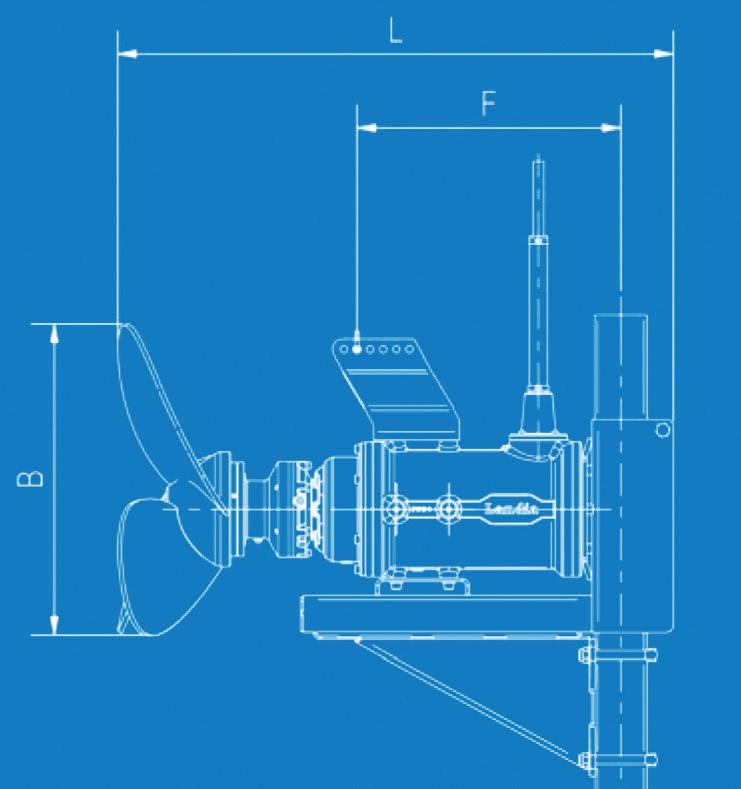

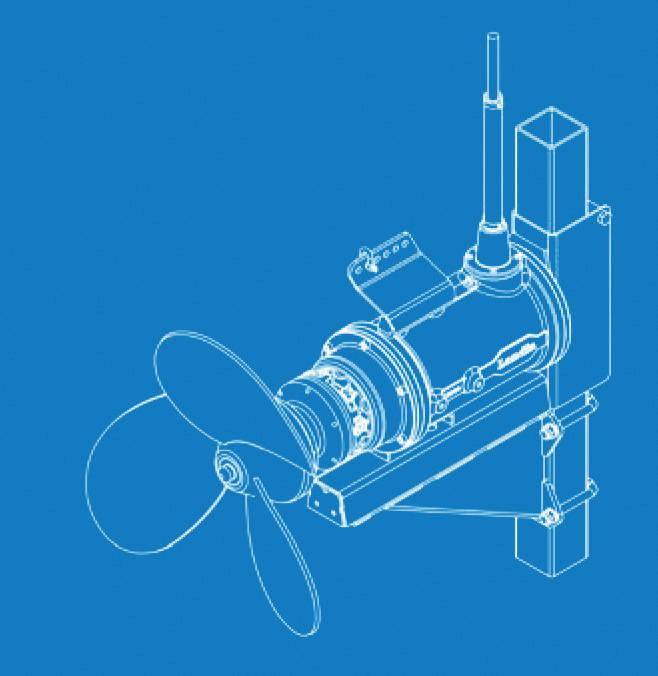

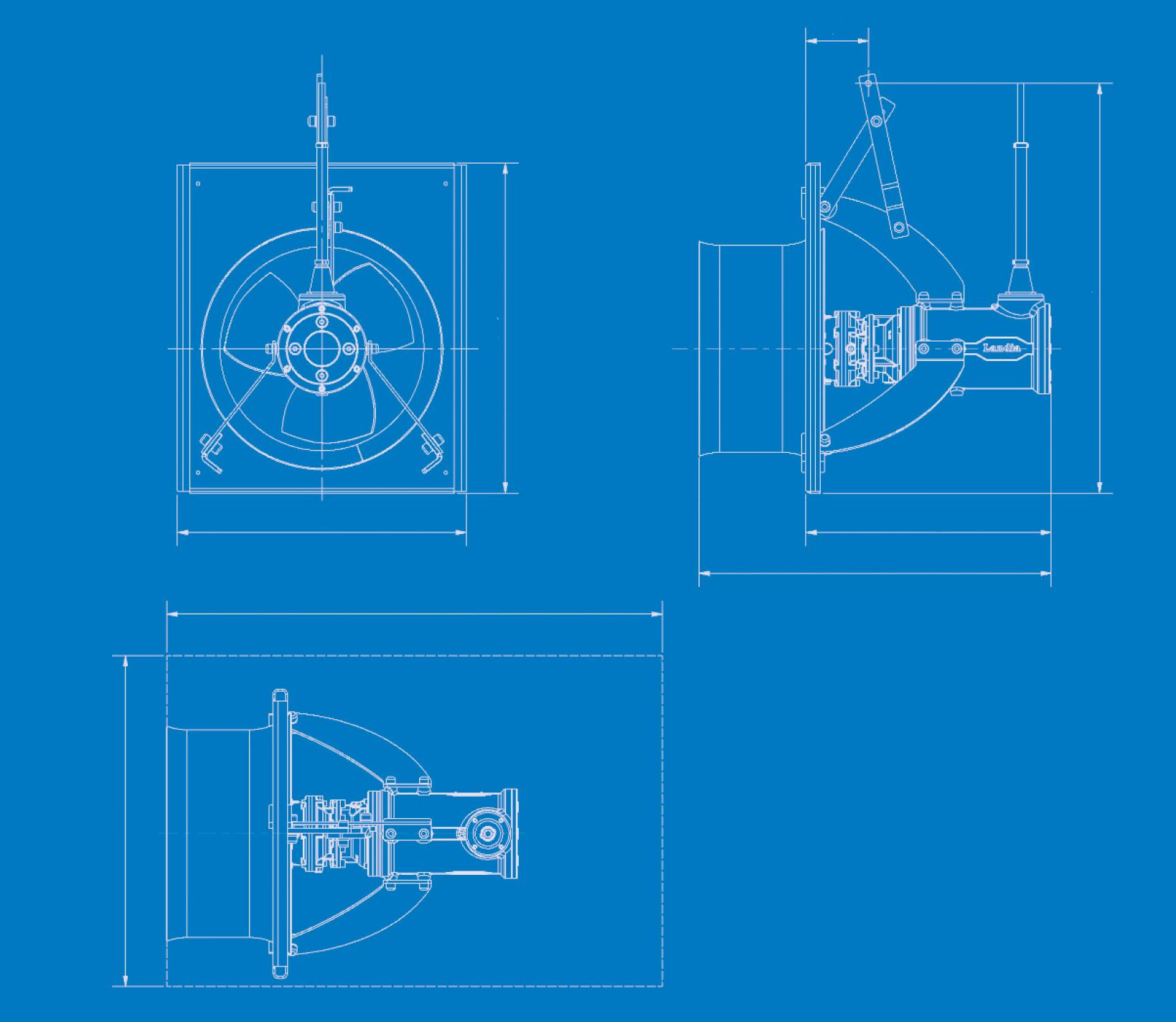

BouMatic DK and DK EX submersible agitators have a sleek, slim design thanks to their planetary gearboxes. The large propeller blades of the submersible agitator make it ideal for blending/ homogenising manure and biomass in slurry pits, pre-pits, slurry channels, biogas digesters, postdigesters, and so on. Submersible agitators are also suitable for use in industrial plants and waste water treatment plants due to their superior construction and design.

Stainless steel screws

IP68 level of protection

Propeller in stainless steel 1.4301

Leak sensor in the gearbox housing

10-m E cable incl. 8 parts

Cable clamp

Thermal sensor in the coils (PTC100)

Mechanical seal between the gear and the fluid

Mechanical seal between the gear and the electric motor

Stainless steel 1.4301 bracket (for 100 x 100-mm mast)

2 directions of travel

The BouMatic DK agitator has a three-blade propeller. The advantage of a three-blade agitator is that it stirs a greater volume per hour than a two-blade agitator using the same amount of power. This means faster stirring and an energy saving of up to 15%.

The blades can also be used in both directions of travel, i.e. to suck up or discharge the manure. This feature is particularly useful when working with a highly viscose material.

Once again, the agitator is designed with maximum longevity and minimal servicing in mind.

The BOUMATIC DK range provides impressive working results, practicality and flexibility to meet your high demands for mixing. Its robust construction, attention to detail and high-quality components guarantee the superior mixing results you expect on your farm.

Whether you are using it for aerobic or anaerobic applications. BOUMATIC submersible agitators guarantee a long service life with minimal maintenance.

Whatever the shape or size of your pit, we have the right submersible agitator to suit your needs. With models from 7.5 kW to 18.5 kW, we offer a wide range of submersible agitators to meet all your mixing needs.

Features

Propeller

*Values measured in water

The frame of the lagoon agitator is made entirely of stainless steel for robustness and enhanced durability.

The DK agitator series from 7.5 to 18.5 kW is made to fit the frame.

The BouMatic POP slurry agitator is a robust and effective full-service agitator. The propeller is specially designed with three low-speed blades, making it ideal for mixing even very thick slurry.

The shape of the propeller produces optimum mixing results. Up to 4000 m3.

Numerous sizes, fittings and hoist systems are available.

Easy to install. Even in a slurry-filled reservoir.

Can be repositioned for use in multiple reservoirs.

In short

Motor sizes from 3 to 30.0 kW

Triple-sealed system

Mixing capacity up to 4000 m3

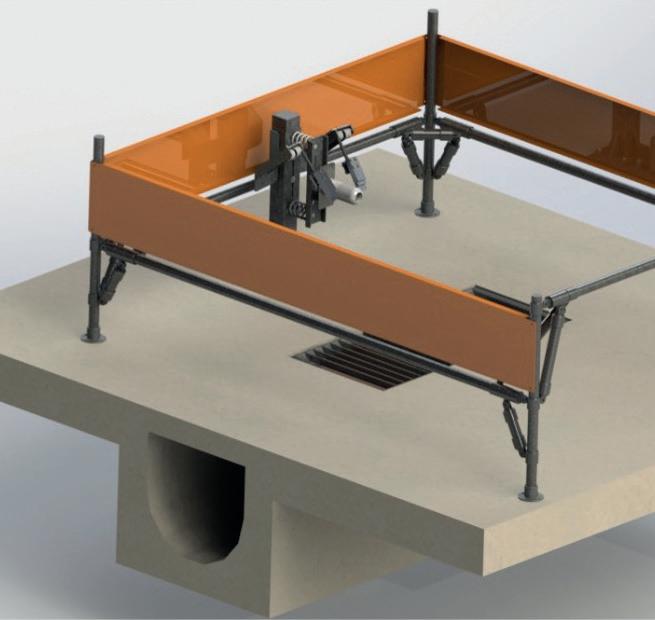

BouMatic AXP channel agitators are intended for circular stirring and for mixing slurry in the channels beneath slotted floors. They allow you to effectively mix your manure to ensure it is always of a smooth consistency.

The design of the propeller enables it to be adapted to applications such as a channel with low levels of liquid.

The agitator is also lightweight, allowing it to be repositioned and used in multiple locations.

The agitator can be mounted onto a mobile trolley.

In short Engine sizes from 5.5 to 18.5 kW Number of revolutions: 400 rpm

Stirring slurry beneath slotted floors. Effectively mixing floating sludge and sediment into the liquid phase improves the consistency of the slurry, making it easy to pump.

Push the agitator to the stirring site. Then lift up part of the slotted floor and immerse the agitator into the slurry using the winch. You can also lift, lower and turn the agitator. This allows the slurry to be easily and effectively homogenised in the various parts of the channel.

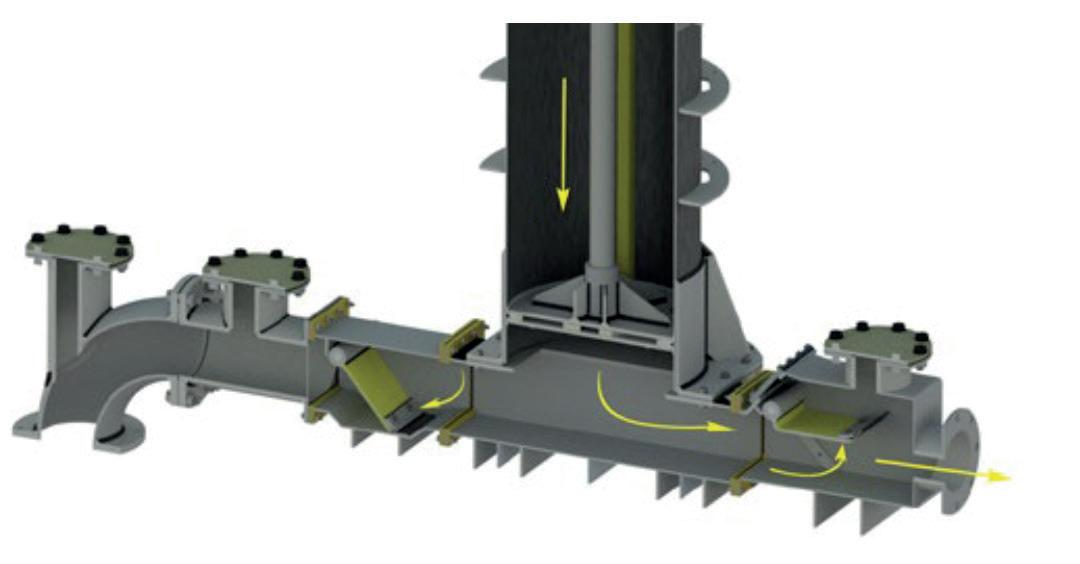

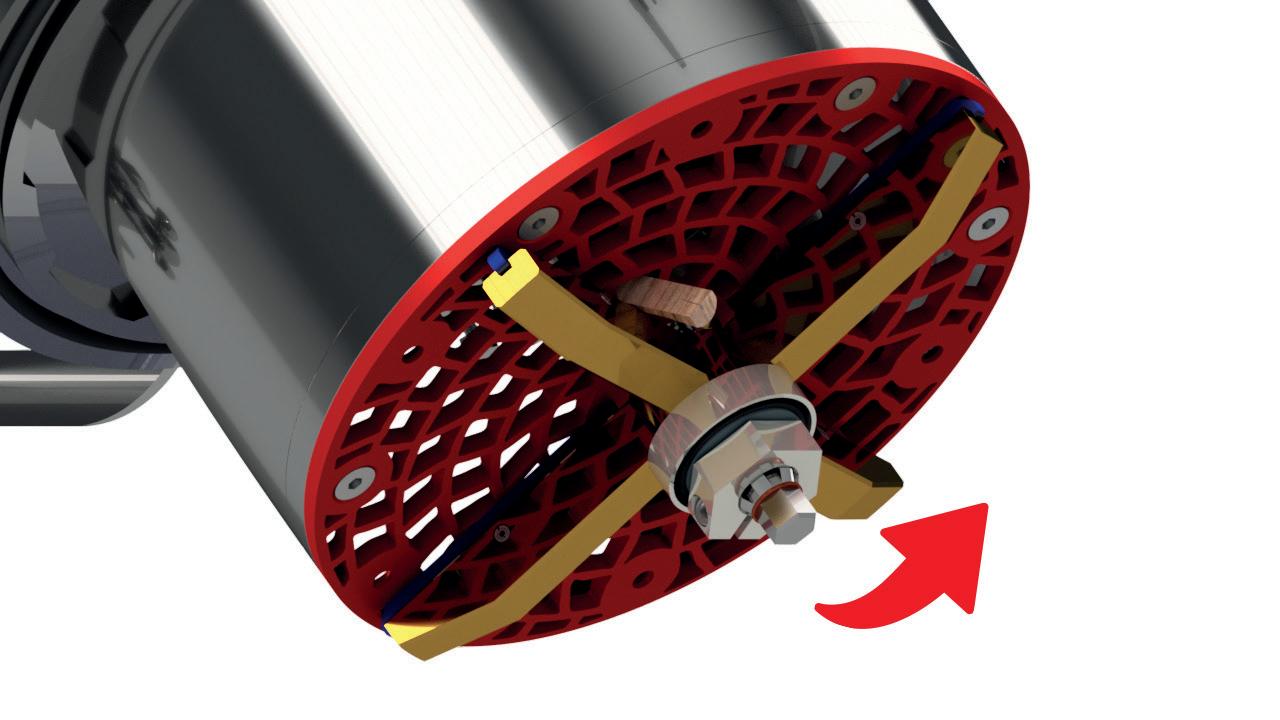

The core function of the BouMatic CYCLONE is to separate out foreign bodies.

CYCLONE shredders combine both separation and shredding functions. They separate, shred and then discharge the material via a pipe. As the fluid flows through the machine, heavy and foreign objects such as stones and metal parts are separated out by gravity and settle at the bottom of the body. The lower part of the body acts as a trap for foreign objects. They can then be easily removed via the cleaning flange. All the floating and suspended substances in the fluid (fibrous materials, wood, grass, straw, etc.) are transported by the flow to the cutting screen and chopped up by the self-sharpening blades. The product is also homogenised in the process.

The system automatically detects blockages caused by contact with coarse, hard foreign objects and reverses the rotation direction of the blade rotor. The shredder also attempts to chop up the disruptive material from the other side. The same process is repeated until the blockage material has been penetrated. The automatic inversion function also helps to maintain the cutting edges used on the sieve and sharpened blades, which enables the user to benefit from optimum cutting performance and reduced energy consumption.

The cutting blades of the BouMatic CYCLONE are wear resistant and have a long service life. If the blades wear out over time, the position of the blade mechanism can be easily adjusted. Thus, the blades can be used until they are completely worn out.

Cutting blade in new state [blue].

Cutting blade close to wear

*Values measured in water

BouMatic’s in-line CYCLONES work with spiral pumps or piston pumps. The CYCLONE is placed downstream of the pump. This enables it to trap foreign bodies to prevent them from damaging the pump or the separator.

The BouMatic CYCLONE comes in three different models, making it the ultimate solution to meet your shredding needs.

Dimensions with cover open

The BouMatic CYCLONE is designed to be easy to maintain. All the wearing parts are easily accessible and can be replaced in very little time.

Protection from foreign bodies for all machines positioned after the CYCLONE.

Perfect shredding of fibrous, coarse materials.

Fully automatic operation, easy maintenance and low servicing requirements.

Reduces the energy required by the pump due to the material being more consistent and fluid.

Energy efficient.

Self-sharpening blade

Reversible cutting grid

Made entirely from stainless steel

Outlet flange

Inlet flange

Cleaning flange

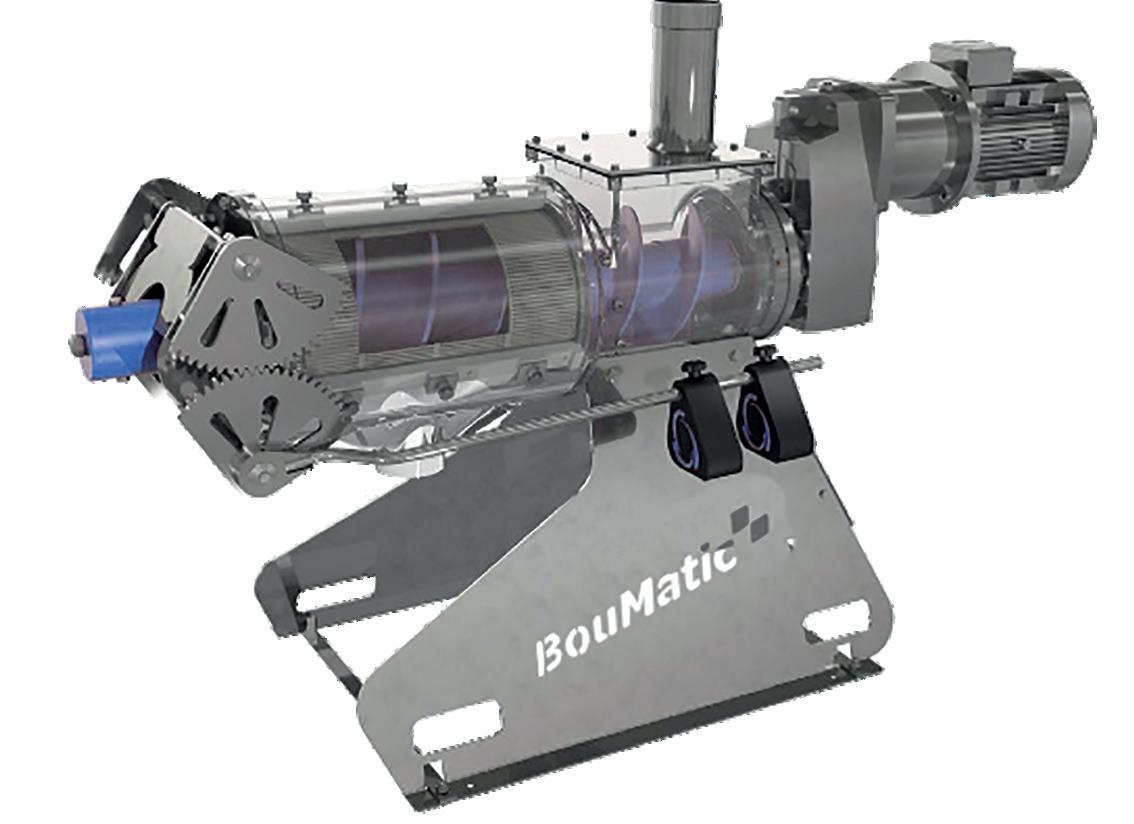

The phase separator forms part of BouMatic’s commitment to an agro-environmental approach

Air pollution is reduced as a result of using the phase separator –phosphorus and nitrogen are concentrated in the solid phase. This reduces the extent to which these two highly polluting components are released into the atmosphere.

BE ENVIRONMENTALLY responsible

Reduction in olfactory pollution.

100% slurry recycling the solid phase is recycled into Reduction in CO2 levels (faster spreading, PM 2.5)

Obtain a dry product that you can store on the headland

Consistency of the compost

30% more storage capacity

Aids transport and spreading

Recycle manure by 100%

Phase separators are designed to separate slurry into 2 elements:

• Solid : Easy to transport, less bulky to store, odour-free, excellent as fertiliser or bedding. The phase separator allows heavily polluting phosphorus and nitrogen to be concentrated in the compost. The resulting product has a dry matter content ranging from 25% to over 40%.

• Liquid : Easy to pump and spread (using a slurry tank or irrigation system). Depending on local regulations, it can enable greater flexibility in spreading.

Sieve available Optional model available: 0,5mm - 1,00mm

Liquid discharge

Weight adjustment on the arms to slow down the compost outlet

Ultra-resistant gear

Adjustment system

Access cover

• Standard : This model is the first choice for farms wanting to gain up to 30% more storage volume in their slurry pit. The solid residue is then used for spreading on crops as a fertiliser.

• HD : The HD model of phase separator is recommended for farms that wish to use the solid material as bedding or compost. In this case, the aim is to obtain a product with a high dry matter content and to have a stable product after fermentation.

Product with a 25 to 30% solid matter content

Product with a 30 to 40% solid matter content

*Sow + offspring (post-weaning and fattening = 18.4 m3/year)

Cattle slurry

If it is not possible to have a return, this tank comes on top of the separator and works with a pressure sensor that regulates the pump (VSD).

Back wash : Allows the sieve to be cleaned automatically.

The phase separator can be placed on a raised platform below which the dry matter can be stored. The platform can contain 1 or 2 separators.

Features

Galvanised steel

Handrail for safety

Trapezoidal type sheets for side walls and roof

Screws and dowels included

Potential for multiple mounting

Option to screw to the mounting area

Disassembled for transport with assembly instructions

Height and dimensions available for single and double separator

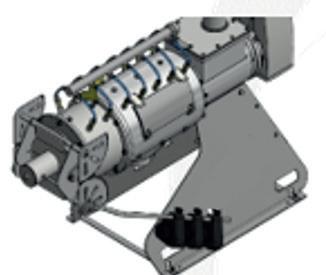

Our composter is a state-of-the-art composting drum that significantly accelerates the aerobic fermentation process. It creates the ideal environment for aerobic bacteria to grow and mineralise organic compounds.

All we do is help natural bacteria do their job - but FASTER!

No external heat is supplied to the system for the fermentation process

The solid matter heats up to 70°C by itself via exothermic aerobic fermentation in line with European regulations on hygienisation.

Low amounts of electricity are required to obtain a high-quality, healthy product.

The BC-series composting system comprises a special heavy-duty (HD) separator that separates solids up to a specific humidity level and a DM content of around 40%.

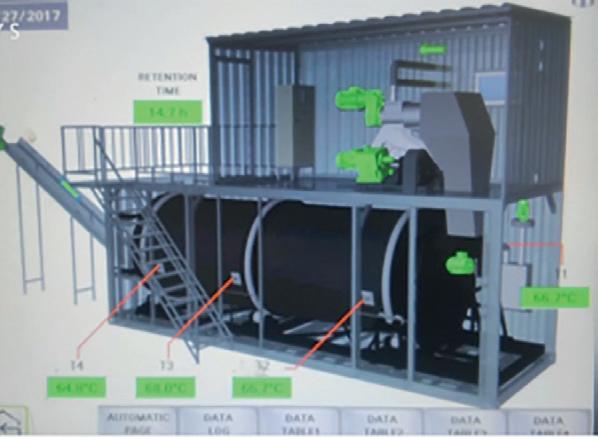

The separated solids are then automatically introduced into the special polymer drum, where they are held for 24 to 72 hours. During this time, the system’s computerised control unit adjusts the temperature, humidity and oxygen levels inside the drum.

The composting parameters can be easily monitored and adjusted from the touchscreen control unit, even via a web browser or smartphone

Control room HDPE drum

Wireless temperature sensor

HD separator

Our system enables compliance with the EU’s hygienisation requirements* without having to invest in a heat treatment system. We use the self-heating fermentation process to reach 70°C while continuously monitoring and recording the temperature.

Whether you are a compost manufacturer or a slurry processor, you can count on the bedding composter for your hygienisation needs.

Dairy farmers are well aware of the advantages of deep beds made up of ergonomic bedding material. Cows are healthier and give more milk when they are on kept on deep bedding. The solid matter obtained from properly composted slurry makes an excellent bedding material as it contains low levels of bacteria, no mastitis-inducing pathogens, and is drier than separated solids. It allows you to make significant savings compared to bought-in straw bedding, which means you can apply more bedding per cow. But above all, cows love it!

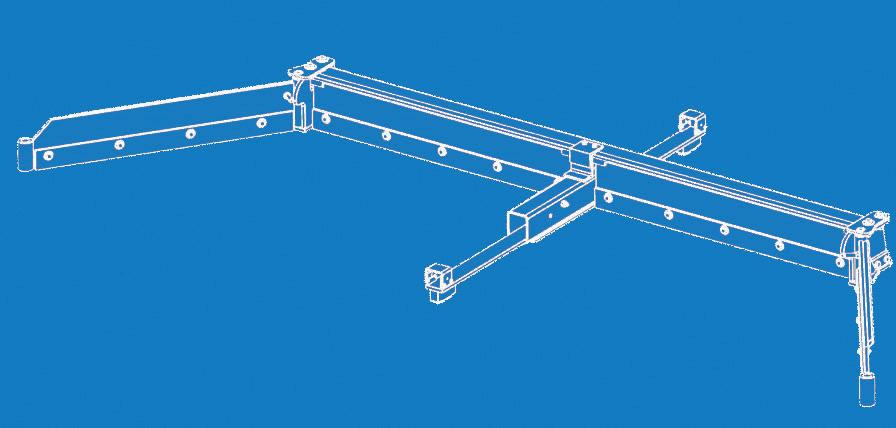

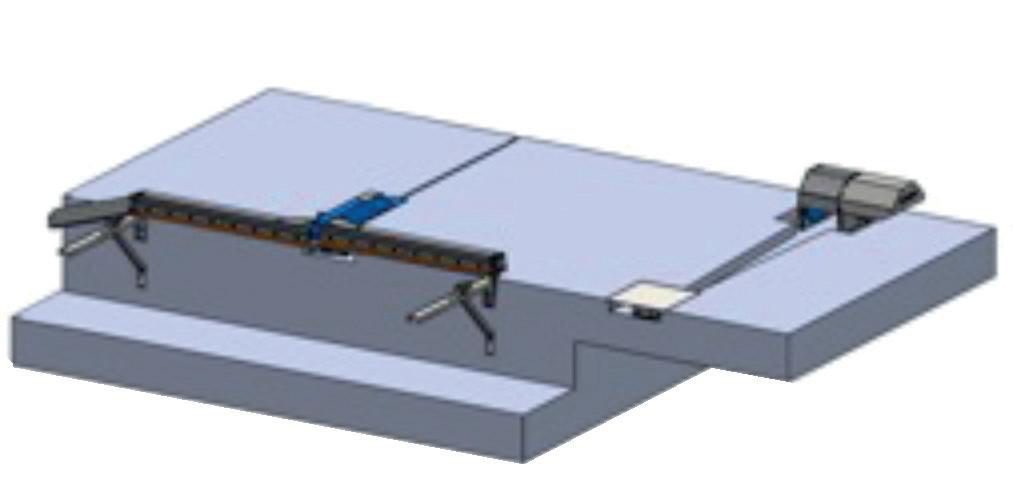

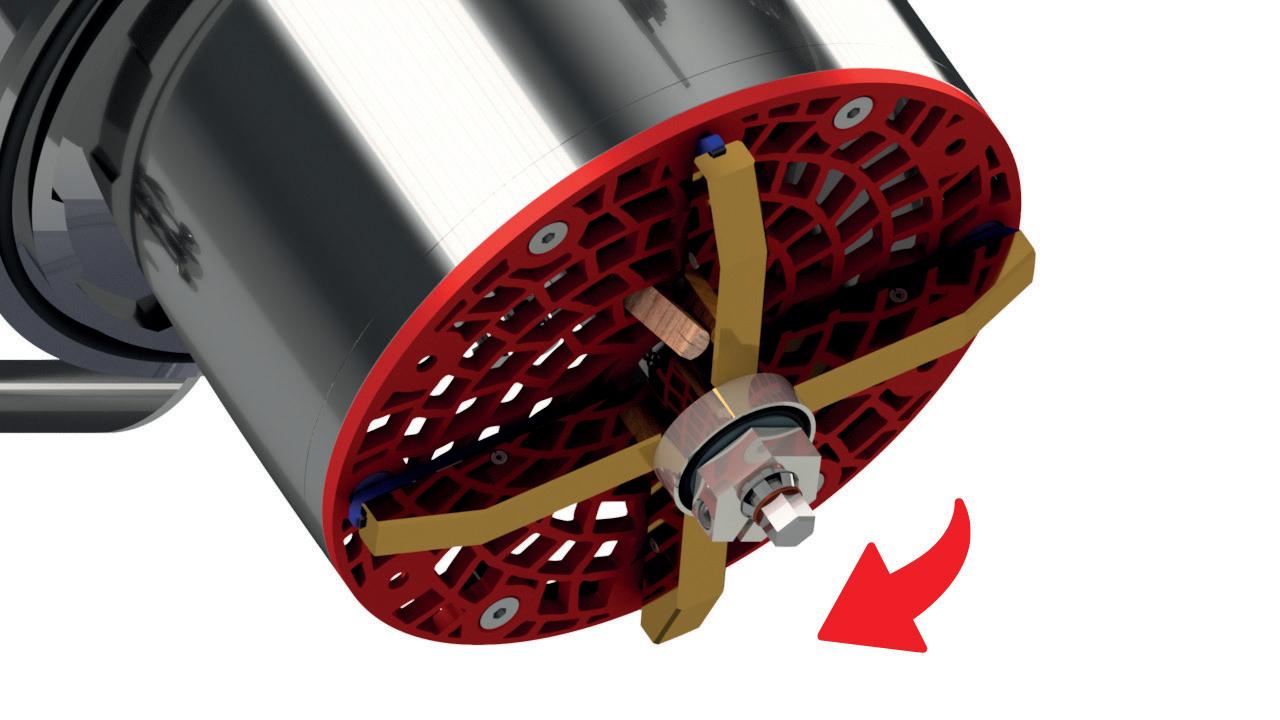

The Falcon cross is capable of pushing the heaviest loads. In a 1.15-m channel for the double row or 0.635-m channel for the single row, it will push the manure that the scraper has discharged. The Falcon cross is used in a compact straw and manure system.

The cylinder pushes and retracts causing the traction rail to move back and forth. The scrapers move forward and backward, allowing the manure to be pushed forward. One-way claws positioned in the races prevent the manure from returning when the scrapers retract.

This allows the manure to be conveyed to the manure pit.

It can be supplied as an add-on to the ELEVATOR.

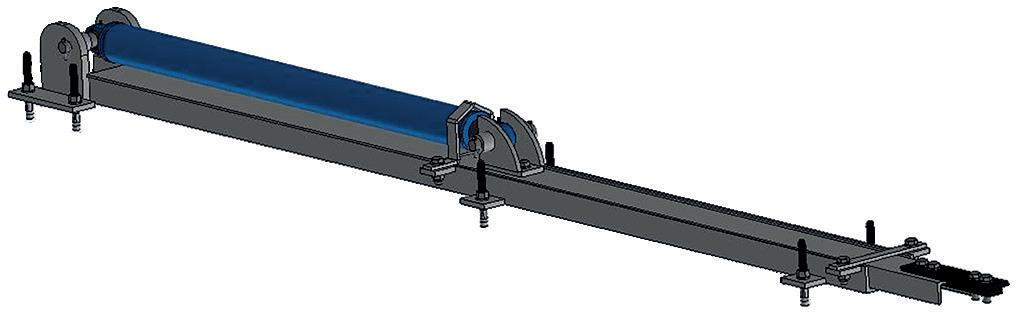

The BouMatic elevator can transport manure up to 70 m. The sturdy square chain and scraper have been tried and tested and will serve you for many years.

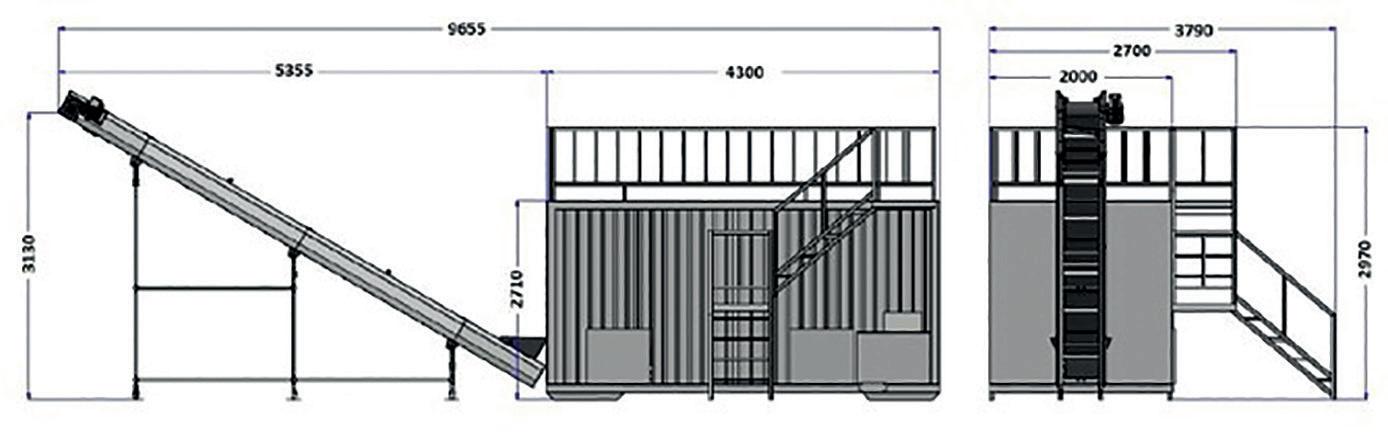

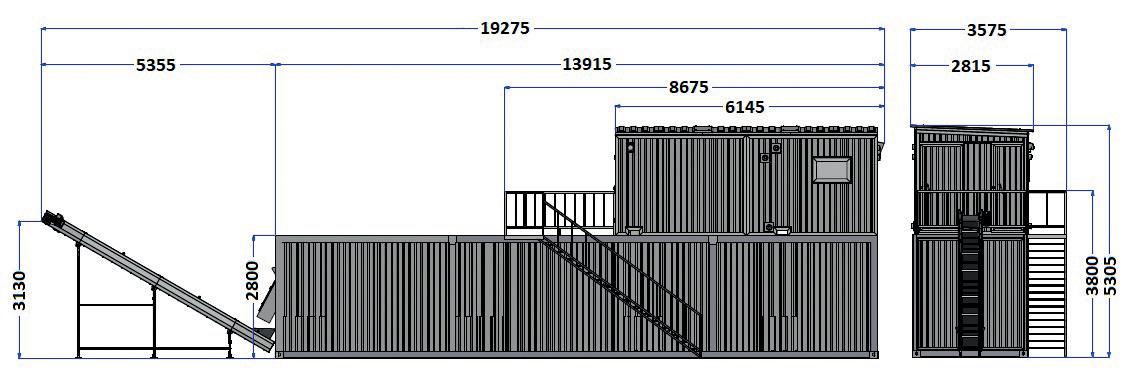

Ramp models from 2 to 12 metres are available. It comprises two 0.5-m parallel gutters separated by a 0.2-m central wall.

The drive is positioned at the top of the ramp to pull the load, which puts less strain on the gearbox. The drive unit has a power rating of 3 kW.

The 180° bevel gearbox pulley is mounted on a high-strength bronze ring. It is located at the end of the gutter and allows the chain to rotate effortlessly. It can be synchronised with the scrapers to automate the transportation of manure.

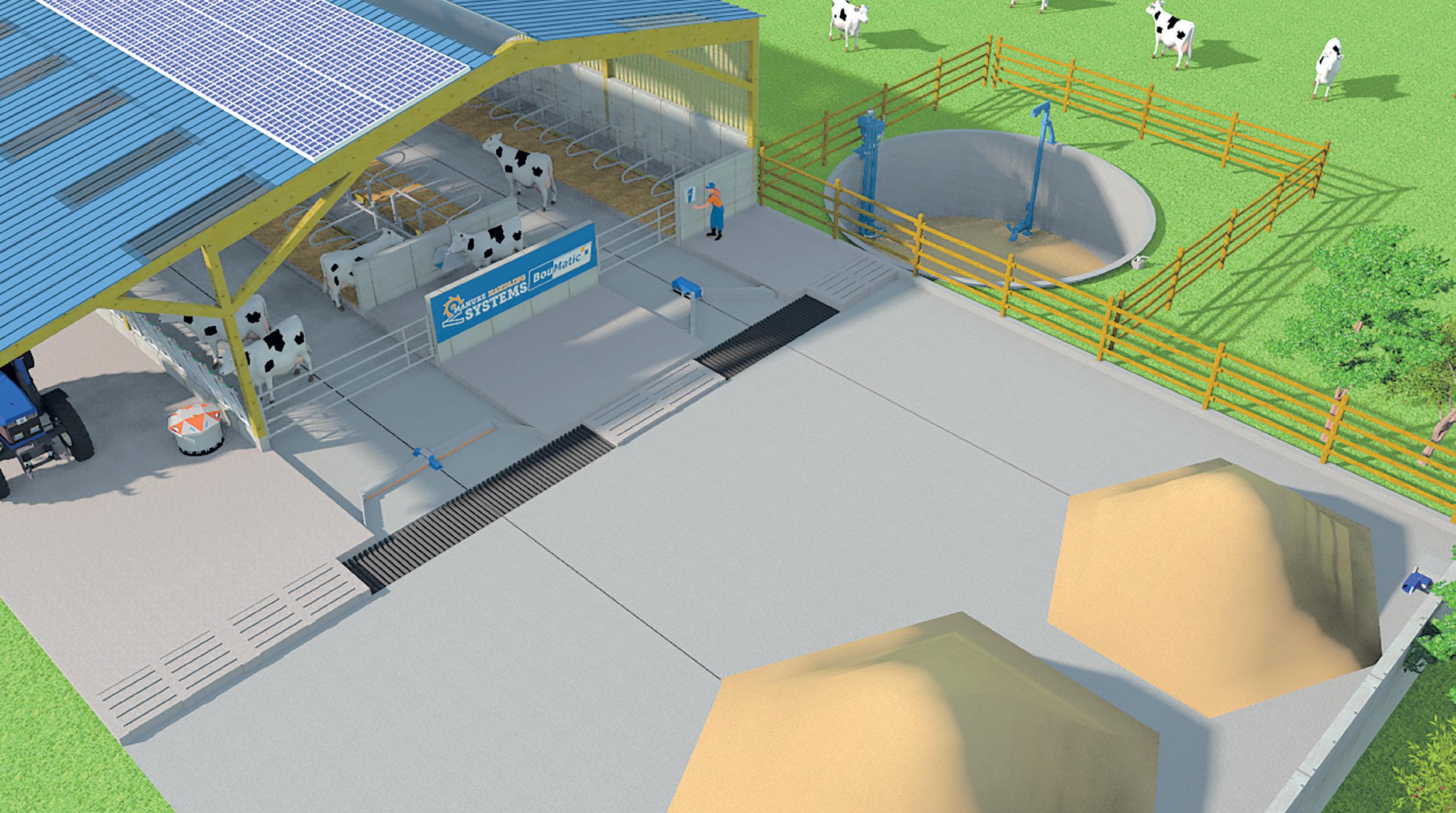

EXAMPLE 1:

Receiving pit:

Two TYPHOON SBC scrapers (brush scrapers).

A slalom receiving pit with AXP mixer.

The slurry is pumped by the piston pump and transferred to the separator.

The separated solid part is stored on the platform and the separated liquid part in the storage pit.

EXAMPLE 2:

Slalom receiving pit:

Two TYPHOON SBC scrapers (brush scrapers).

A slalom receiving pit with AXP mixer.

The slurry is pumped by the piston pump and transferred to the separator.

The separated solid part is stored on the platform and the separated liquid part in the lagoon.

EXAMPLE 3:

Hygienisation:

2 3 4

Installation with a flushing channel and an end receiving pit with a vertical pump for flushing.

Hygienisation of the slurry with the BCS to reuse the compost in the stalls.

A straight TYPHOON scraper and a «V» scraper. A mixer is placed in the brown water pit.

EXAMPLE 4:

Solid-liquid separation:

The separated liquid part falls into the channel and is discharged into the cylindrical pit. In the pit there is a vertical shaft pump for flushing and a mixer to homogenise the slurry. The solid part is pushed onto the platform.

The straight Typhoon scraper is along the feed alley and the V-shaped scraper is between the two rows of cubicles.

At BouMatic, we are proud of the longterm relationships that we have with our users from around the world. As the largest privately-owned company in the sector, we focus all our energy on our customers.

In all our dealings and on all levels, we work for you, our customers, because your success is our success.

OUR PHILOSOPHY

From our modest beginnings, we have always stayed true to the core values of our founders.

Today, as an industry leader, those values have become our guiding principles.

Animal health

Engagement in scientific research

Profitability

The company has access to a global network of dealers. Thanks to them, BouMatic is able to offer its customers the expertise and experience of a multinational combined with the proximity of local experts. Targeted training is offered to customers with each purchase.

Your dealer:

BouMatic A/S

Jernvej 2

Skjern 6900

Danemark

T: 0045 75 26 02 11

BouMatic Europe - Belgique

Rue Jules Mélotte 31 4350 Remicourt

Belgique

T: 0032 (0) 19 54 42 66

F: 0032 (0) 19 54 55 44

Siège social

2001 S Stoughton Rd, Madison, WI 53716

T: (608) 222-3484

F: (608) 222-9314

info@boumatic.com

www.boumatic.com