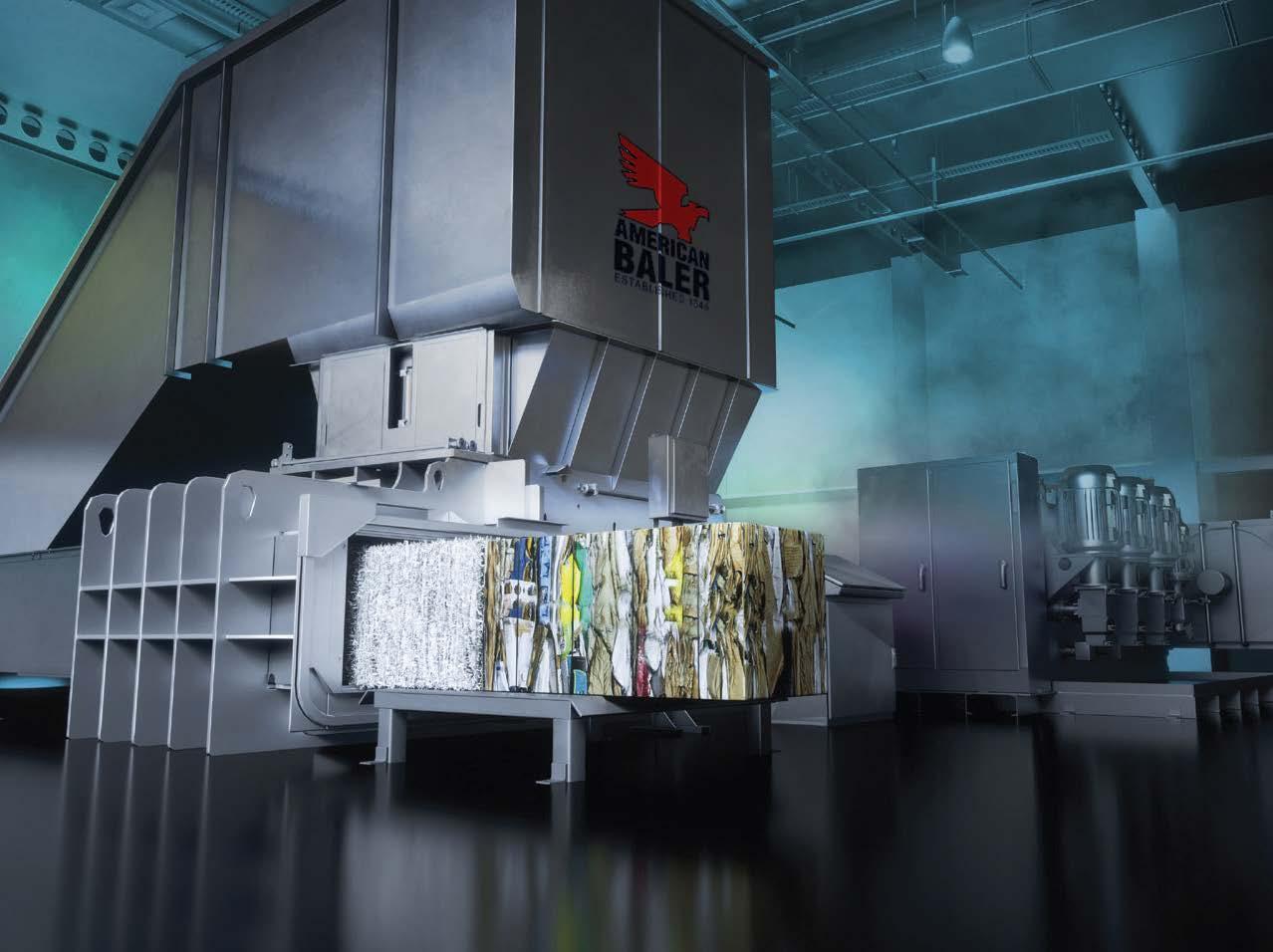

PROUDLY ACHIEVING RESULTS recyclingproductnews.com APRIL 2024 PUBLICATIONS MAIL AGREEMENT NO. 40069270 Special Advertising Feature

Witness the result! EXPERIENCE A COMPLETE SOLUTION, ALL IN ONE PLACE PROVEN SMART MRF SOLUTIONS Unwavering commodity purity through machine interconnectivity AI deployed across the sorting system 50 TPH, 5 manual sorters, up to 99 % purity on all targeted commodities SORTING TECHNOLOGIES EXPERT 1 877 362-3281 machinex technologies.com

APRIL 2024 recyclingproductnews.com HOW TO SELF-AUDIT YOUR RECYCLING FACILITY WASTEEXPO 2024 SHOW PREVIEW Q&A WITH CHRIS HAWN OF MACHINEX

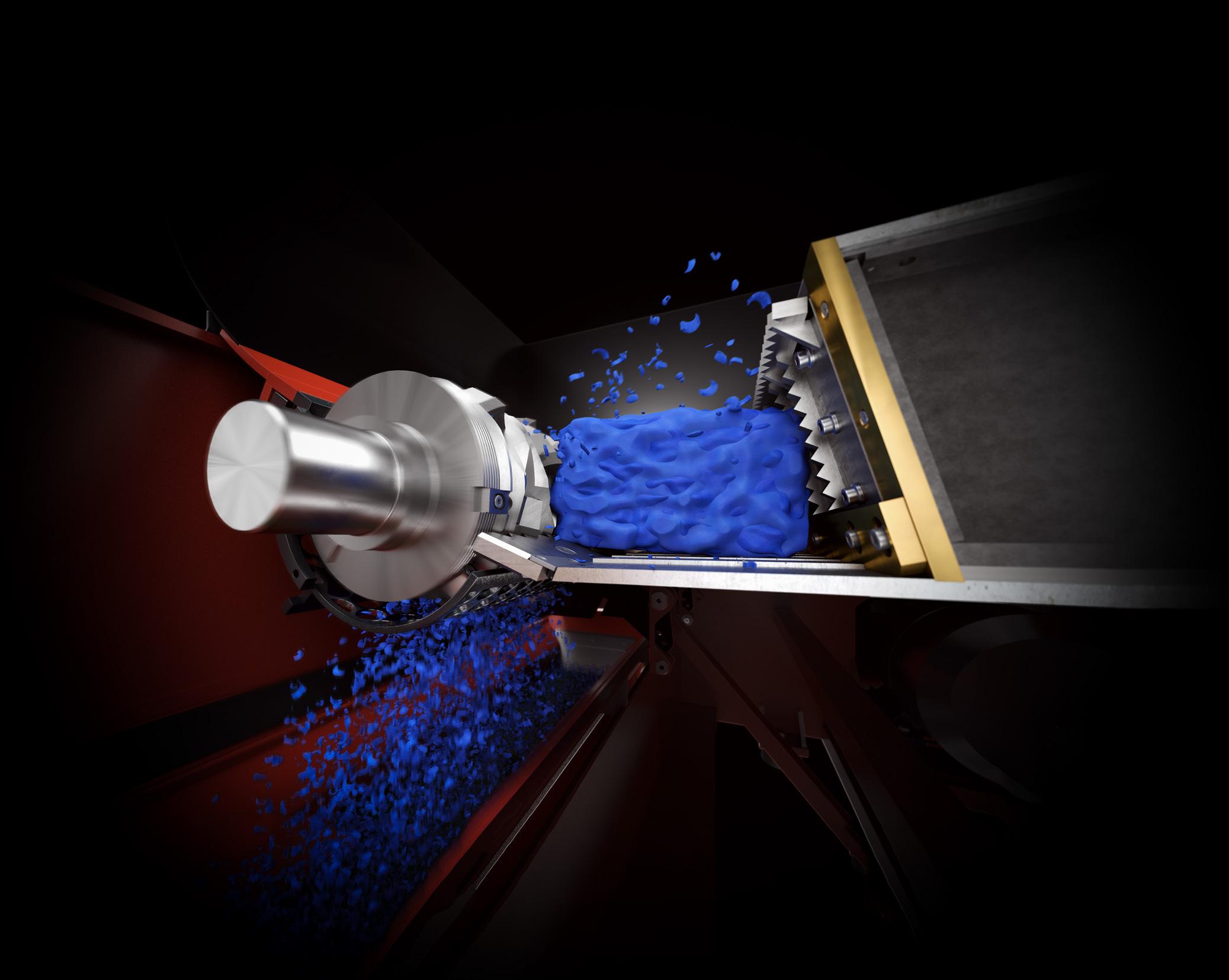

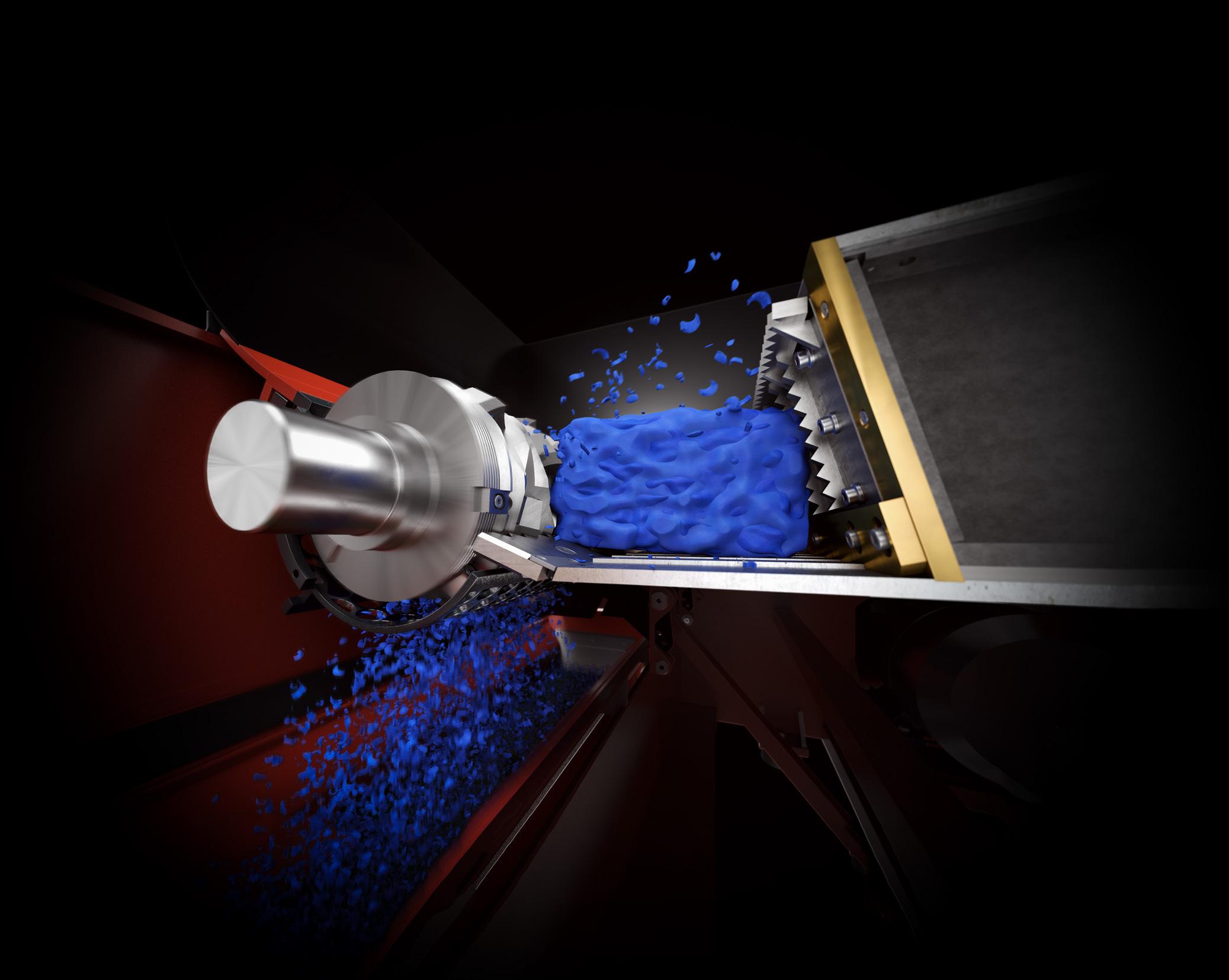

Horizontal depackers offer multiple bulk feed options to process a wide variety of materials and contaminants. Our robust design and unique screening chamber achieves the market’s highest purity organics.

TURN FOOD WASTE INTO > 99.5% PURE ORGANIC FEEDSTOCK

Preconsumer mixed SSO Postconsumer food waste Preconsumer packaged Beverage containers

203-967-1100 • vdrs.com • info@vdrs.com

San

Santa

Jurupa

British

organic depackers by

Units located in:

Diego

Clara Valley

Valley

Columbia

See a demo unit at Waste Expo booth #2943

24 COVER STORY HOW TO SELF-AUDIT YOUR RECYCLING FACILITY ELECTRIC COLLECTION VEHICLES POWERED BY THE WASTE THEY COLLECT 44 28 MACHINEX CEO CHRIS HAWN DISCUSSES THE MODERN MRF 20 WASTEEXPO PREVIEW

10 From the Editor 12 News Room 18 Spotlight 20 WasteExpo 2024 Show Preview 24 Metals 28 Sorting & Separation 34 Plastics 36 Organics 42 Trucks & Transportation 48 Technology 50 Events Calendar 54 Advertiser Index April 2024 | Volume 32, Number 3 DEPARTMENTS & SECTIONS FEATURES 20 WasteExpo 2024 Show Preview 24 How to self-audit your recycling facility 28 Machinex CEO Chris Hawn discusses the modern MRF 34 Report highlights decreased use of problematic materials in plastic packaging 36 How Ritter Materials turned a disaster into an opportunity for an underserved market 42 Maintaining safe waste collections in growing communities 44 Electric collection vehicles powered by the waste they collect 48 New B2B global marketplace digitizes the metal recycling market

Accent W ire Tie is the largest supplier of baling wire and wire tier technology in the recycling and waste industry. Our leading line of bale packaging equipment includes the Accent 470® W ire Tier, featured on balers around the world and the Envirobale® bagging system for solid waste containment.

Accent W ire Ties’ sales and service technicians teams have hands-on experience and stay up-to-date on the latest industry trends. Accent W ire Tie has forged the strongest ties in the industry since 1986.

Four-wheel drive design for exceptional performance and reliability

Pivot-out or removable parts cartridge cutting maintenance time from hours to minutes

No mechanical or hydraulic adjustments needed, allowing for trouble-free operation

Meets ANSI, CSA standards and is CE compliant TRACK OILER KIT SPARE PARTS

DESIGNED FOR TWO-RAM BALERS A C C E N T ® 4 7 0

PE

. S T

PR ODU C TS . S T

T IE S . 281-255-0703 | PARTS@ACCENTWIRE.COM | AC C ENTWI R E T IE.C O M EQ UIP ME N T & PA R TS TH AT ME E T Y OUR T OUGH E S T BALING APPLI C ATI O N S

S T RONG

OPLE

RONG

RONG

FE A T U RE S & B E N EF IT S

CARTRIDGE

WIRE DUST COVER DEBRIS GUARD

DELIVERED

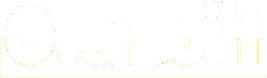

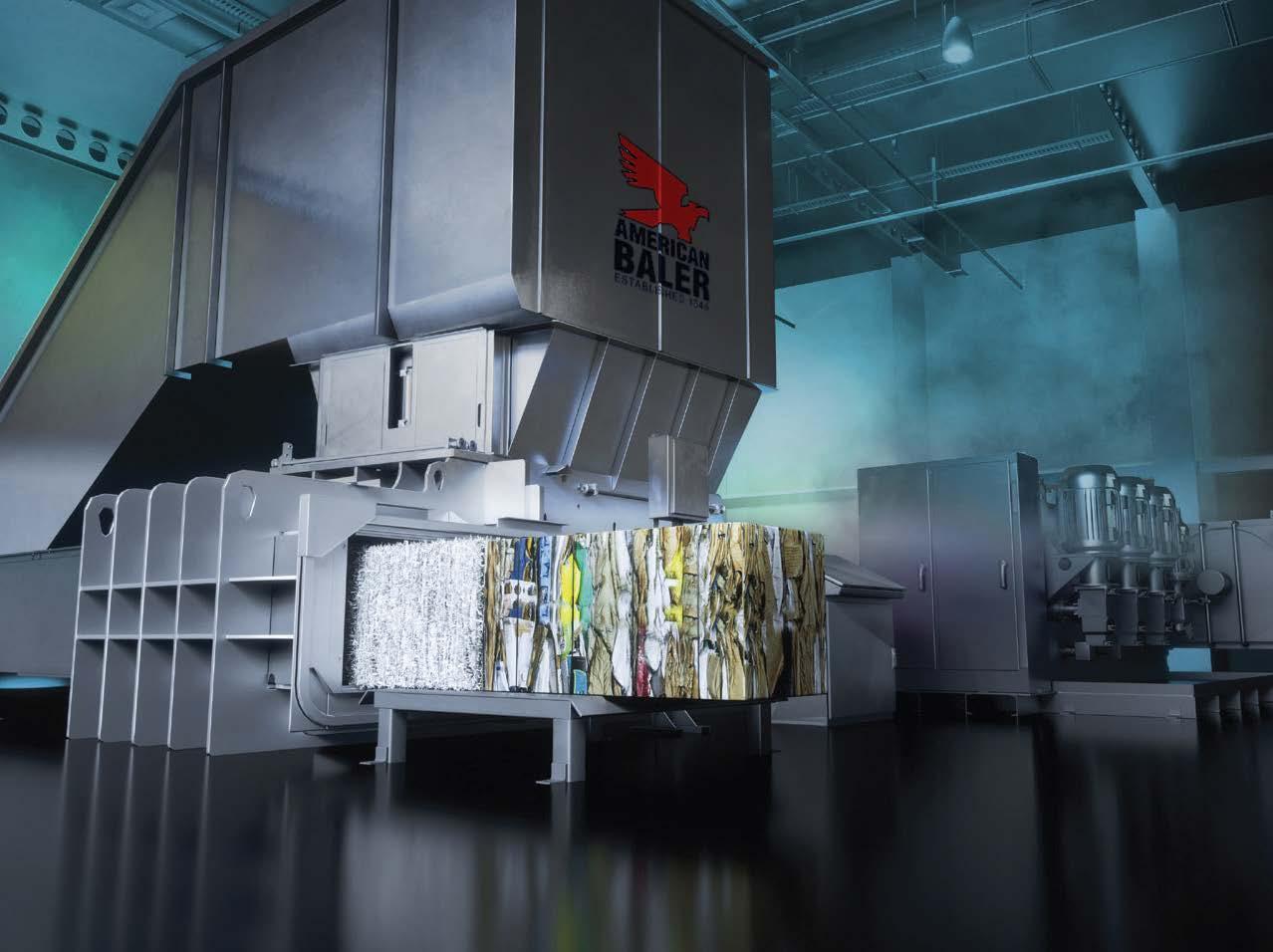

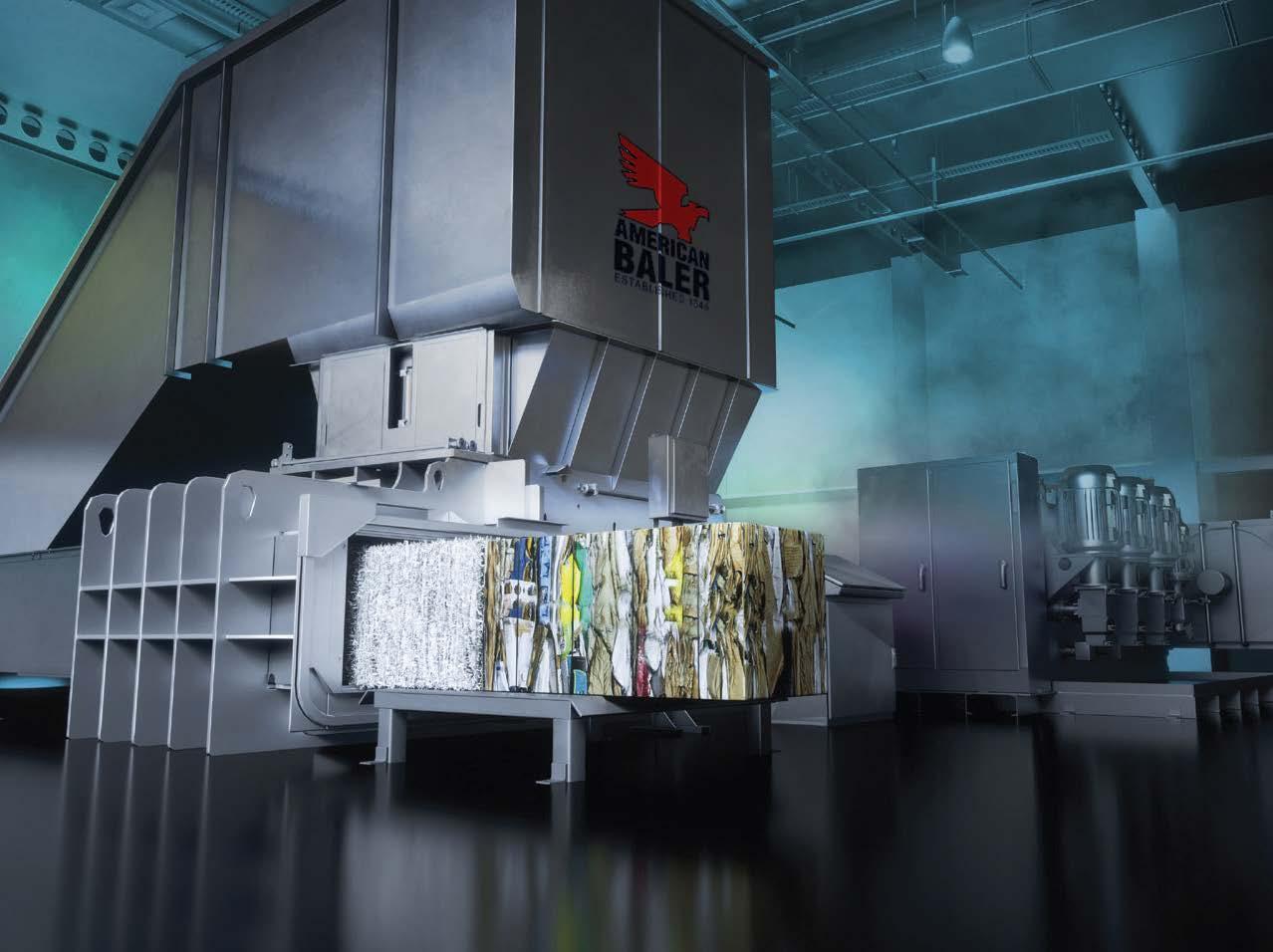

Seven decades of experience sets our balers apart. Engineering refined over the years yields a baling chamber that maximizes geometry and physics, delivering exceptional bale density and integrity. Our proprietary auto-tie design ensures reliability and productivity.

843

AmericanBaler.com 800

7512 PERFORMANCE

The Avis Industrial Recycling & Waste Equipment Division proudly serves customers across the environmental services industry, including: Metals Recycling Facilities | Materials Recycling Facilities (MRF’s) | Auto Recyclers | Converting Plants Box Board Plants | MSW Transfer Stations | C&D Recycling Plants

American Baler takes performance to new heights. American Baler is a proud member of the Avis Industrial Recycling & Waste Equipment Division.

CONNECT WITH US @RecyclingPN Subscription: To subscribe, renew your subscription, or change your address or other information, go to: https://www.recyclingproductnews.com/ mysubscription/subscribe Recycling Product News is published seven times yearly: January/February, March, April, May/June, July/August, September/October, November/ December. Advertising closes at the beginning of the issue month. One year subscription rates for others: Canada $33.50 + 1.68 GST = $35.18; U.S.A. $40; other countries $63.50. Single copies $6.00 + 0.30 GST = $6.30; outside Canada $7.00. All prices are in Canadian funds. Recycling Product News accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd. Copyright 2024 Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers. Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013. PUBLICATIONS MAIL AGREEMENT NO. 40069270. Return undeliverable Canadian addresses to: Circulation Dept., 124-2323 Boundary Road, Vancouver, BC V5M 4V8 email: rpn@mysubscription.ca Toll-free: 1-866-764-0227 We acknowledge the financial support of the Government of Canada. FROM THE COVER An internal audit is a highly effective method for managing risks and minimizing legal liabilities. See more on page 24. WE’D LIKE TO HEAR FROM YOU Do you have a story, equipment, or technology innovation, commentary, or news that our readers in the recycling industry should know about? Drop us a line any time. Contact: Editor Slone Fox at sfox@baumpub.com or 604-291-9900 ext. 335 APRIL 2024 | VOLUME 32 • NUMBER 3 EDITOR IN CHIEF Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330 EDITOR Slone Fox sfox@baumpub.com 604-291-9900 ext. 335 ASSOCIATE PUBLISHER/ VICE PRESIDENT OF SALES Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110 ADVERTISING PRODUCTION MANAGER Tina Anderson production@baumpub.com 604-291-9900 ext. 222 DESIGN & PRODUCTION Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325 PRESIDENT/PUBLISHER Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226 VICE PRESIDENT/CONTROLLER Melvin Date Chong mdatechong@baumpub.com FOUNDER Engelbert J. Baum Published by: Baum Publications Ltd. 124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8 Tel: 604-291-9900 Toll-free: 1-888-286-3630 Fax: 604-291-1906 www.baumpub.com www.recyclingproductnews.com FOR ALL CIRCULATION INQUIRIES Toll-free: 1-866-764-0227 email: rpn@mysubscription.ca @RecyclingPN

A LONG WAY TOGETHER

EARTHMAX SR 41

No matter how challenging your needs, EARTHMAX SR 41 is your best ally when it comes to operations that require extraordinary traction. Thanks to its All Steel radial structure and the special block pattern, EARTHMAX SR 41 provides excellent resistance against punctures and an extended service life. In addition to long working hours without downtime, the tire ensures extraordinary comfort.

EARTHMAX SR 41 is BKT’s response to withstand the toughest operating conditions in haulage, loading and dozing applications.

For info: 514 -792-9220 Discover the BKT Radial Range

FROM THE EDITOR

CURB METAL THEFT THROUGH COLLABORATION

Areader in the oil and gas industry recently contacted me regarding rampant metal theft from their job site and attached photos of other local facilities which had quite literally been torn to shreds by thieves looking for metal to scrap. These repairs often land on the shoulders of businesses and taxpayers, and, as this reader pointed out, even if the thieves are prosecuted, their punishment is usually minimal.

Metal theft is an incredibly common problem with far-reaching consequences: it impacts businesses and communities and undermines legitimate recycling practices. The damage and vandalism caused during theft further compound the issue, while the stolen materials represent lost revenue for legitimate recyclers.

One of the primary concerns surrounding metal theft is the disruption it causes to infrastructure, such as the theft of copper wiring from electrical grids leading to power outages, or stolen metals from construction sites delaying critical projects. In February of this year, thieves made headlines when they stole metal from a railway in Germany, causing the cancellation of both domestic and international trains due to missing materials. According to the national railway company in Germany, it spent over 6.5 million euros on repairs caused by copper thieves in 2022 alone, with stolen materials causing almost 2,700 delays.

Efforts to combat metal theft have been ongoing, with recycling facilities, scrapyards, law enforcement agencies, and policymakers working to implement strategies that address this challenge. Legislation and regulation play an especially crucial role in combatting metal theft: governments can enact laws that regulate the sale and purchase of scrap metals, require proper documentation for transactions, and impose penalties for illegal activities, making it harder for thieves to profit from stolen metals.

For sites with large quantities of metals, the Canadian Association of Recycling Industries (CARI) notes that deterring theft should be the first line of defence, since protecting property is generally far cheaper than repairing damage or replacing stolen materials. While locking up materials and installing video surveillance and alarm systems are the most common solutions, marking your materials can be a useful deterrent as well. Implementing access controls and training employees to identify and report suspicious activities are also effective.

Several years ago, CARI – with the support of ISRI – established www.ScrapTheftAlert.com, a bulletin alert system that aims to combat theft across Canada and the U.S. The alerts

Legislation and regulation play an especially crucial role in combatting metal theft: governments can enact laws that regulate the sale and purchase of scrap metals, require proper documentation for transactions, and impose penalties for illegal activities, making it harder for thieves to profit from stolen metals.

posted on the site cross regions, increasing the chance of recovering material and identifying thieves, while also placing responsibility on recyclers to be vigilant. Blockchain-based systems, GPS-enabled tags, and digital inventory management platforms can also provide real-time insight into the movement of metals, enhancing traceability and accountability within the supply chain.

Despite the challenges posed by metal theft, progress is slowly but surely being made, although there is no one-size-fits-all solution. Vigilance and adaptation are still necessary to combat theft, and the industry needs to continue advocating for measures that safeguard our resources, protect our communities, and uphold the integrity of the recycling sector.

FROM THE EDITOR SLONE FOX Editor sfox@baumpub.com recyclingproductnews.com

10 recyclingproductnews.com | APRIL 2024

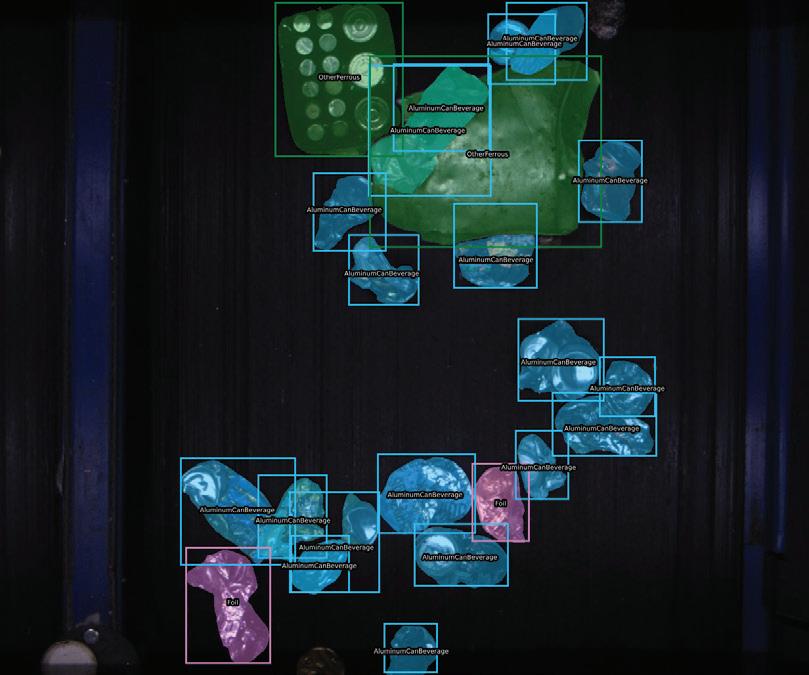

CAGLIA’S NEW ROBOT SORTS PET PLASTIC INTO THREE SPECIALIZED STREAMS

Agrant from The Recycling Partnership’s PET Recycling Coalition has enabled Caglia Environmental to install EverestLabs’ RecycleOS-powered robotic sorters at its Cedar Avenue Recycling & Transfer Station (CARTS). The RecycleOS software is designed to identify #1 PET plastic into three specialized streams then each robot sorts the materials into three different bunkers. Caglia Environmental says that this process is unique as most facilities that recycle PET collect and bale the three streams as one.

Caglia Environmental’s new investments in EverestLabs robotic sorters increase the efficiency of PET plastic recycling and ensure the purity of recycled materials. The facility can now sort clear PET bottles, thermoforms, and pigmented/opaque PET into separate streams, improving the recycling process and output quality.

“EverestLabs is delighted to extend our partnership with Caglia Environmental to increase PET recovery under The Recycling Partnership’s grant from their PET Recycling Coalition,” says JD Ambati, founder and CEO of EverestLabs. “The Caglia team saw right away that RecycleOS-powered robotics and data dramatically improved their bottom line on their Last-Chance line. This overwhelmingly positive experience has led to the expansion of robots on their PET line. We are excited to work with Caglia’s forward-thinking leadership on AI and robotics solutions that drive their recovery and revenue growth while addressing labour challenges.”

This collaborative approach to recycling is expected to have a substantial impact on the recycling capabilities within the San Joaquin Valley and aims to serve as a model for other facilities across the U.S. Caglia Environmental says that the Recycling Partnership’s initiative paired with robots and AI operating systems made by EverestLabs.AI at the Cedar Avenue Recycling and Transfer Station has advanced the PET recovery efforts in Fresno, California.

STAY CURRENT www.recyclingproductnews.com CONNECT WITH US @RecyclingPN NEWS ROOM

12 recyclingproductnews.com | APRIL 2024

VOLVO CE AND MACK TRUCKS ELECTRIFY COASTAL WASTE & RECYCLING

Coastal Waste & Recycling is currently pilot testing a 23-ton EC230 Electric excavator from Volvo Construction Equipment and took delivery of a Mack LR Electric Class 8 refuse vehicle that will operate in residential and specialized commercial applications in southern Florida. The excavator will work at an MRF north of Miami where Coastal sorts and receives recyclable material.

SOLARCYCLE TO BUILD SOLAR PANEL GLASS MANUFACTURING AND RECYCLING PLANT

SOLARCYCLE has invested $344 million in a solar panel glass manufacturing facility in Cedartown, Georgia. The facility will use recycled materials from retired solar panels to make new solar glass. SOLARCYCLE says that this is a first in the U.S.

The EC230 Electric is a medium-sized excavator designed to offer the same performance as its diesel counterpart, while the LR Electric is a heavy-duty truck with all the strength of comparable diesel-powered Mack LR refuse models.

At the MRF, the EC230 Electric is performing the same work as its equivalent diesel model the EC220EL, feeding material into a sorting line.

“Coastal Waste & Recycling has been a great partner and has always been interested in any new technology they can incorporate to drive efficiency and excellence throughout their operations,” says Martin Mattsson, director of key account sales of waste and recycling at Volvo CE. “Testing this electric excavator directly against its conventional equivalent will teach us a lot.”

The big difference between the electric and diesel excavators is zero emissions, but also significantly lower noise and vibration levels. Operators can feel instant torque from the electric motor instead of the slight delay with diesel.

The Mack LR Electric will operate in residential and certain specialized commercial applications. Mack and Coastal worked together to develop favourable routing for the LR Electric to ensure that the collection truck would complete a full day’s work based on the application needs.

Brendon Pantano, CEO of Coastal, says he ordered the Mack LR Electric refuse vehicle because of the company’s long-standing relationship with Mack and Mack’s reputation in the refuse industry.

Nextran Truck Centers in Fort Lauderdale, Florida, will provide service and support for Coastal Waste & Recycling.

SOLARCYCLE currently operates facilities in Odessa, Texas, and Mesa, Arizona – and has inked long-term partnerships with more than 40 solar energy companies to reuse and recycle its solar panels. The company’s recycling technology allows it to extract 95 percent of the value from used solar panels.

“I was proud to help pass the Inflation Reduction Act, and I am thrilled to see Georgians continuing to reap its benefits as solar energy production explodes across the state and country, helping fuel our emerging clean energy economy and create good-paying, local jobs in the process,” says Senator Reverend Warnock.

SOLARCYCLE says that its new facility in Georgia will position the company as one of the first manufacturers of specialized glass for crystalline-silicon (c-Si) photovoltaics in the U.S., with the capacity to make five to six gigawatts worth of solar glass every year. The glass will be sold directly back to U.S. solar manufacturers.

SOLARCYCLE will construct a new manufacturing facility located at Cedartown North Business Park. The plant, which will be the first of SOLARCYCLE’s facilities to manufacture glass in addition to recycling solar panels, is scheduled to begin construction in 2024 and will be operational in 2026.

“The United States’ landmark Inflation Reduction Act has spurred unprecedented levels of domestic manufacturing investments,” says Becca Jones-Albertus, director of the U.S. Department of Energy Solar Energy Technologies Office, which has invested $1.5 million in SOLARCYCLE’s research and development efforts. “We are excited to see U.S. solar companies expanding their footprint in the domestic solar supply chain and creating economic opportunities in their communities.”

13 APRIL 2024 | recyclingproductnews.com

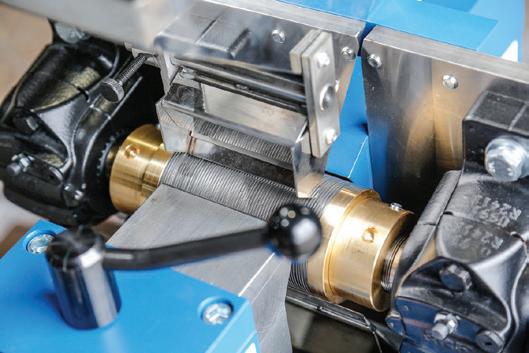

BUNTING’S HIGH-INTENSITY MAGNETIC SEPARATOR FOR BATTERY RECYCLING RESEARCH

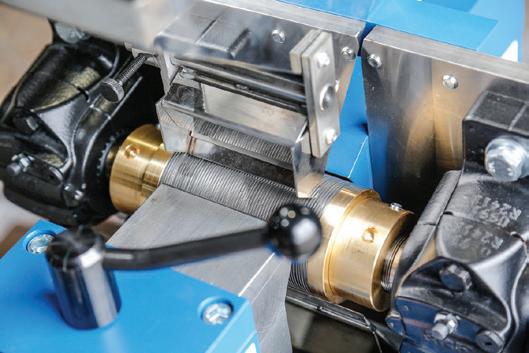

A European mining and technology university has purchased a laboratory-scale bench-induced roll magnetic separator (BIRS) for use in research projects including the recycling of lithium-ion batteries. The BIRS generates high-intensity magnetic fields up to two Tesla, enabling the separation of weakly magnetic particles.

Bunting designed and built the BIRS at its manufacturing facilities in Redditch, just outside Birmingham, and Berkhamsted, both in the U.K.

The induced roll magnetic separator (IRS) uses electromagnetically generated high-intensity magnetic fields to separate paramagnetic particles from non-magnetic materials with a particle size range between -2 millimetres to 45 microns. The IRS comprises of an electro-magnetically induced steel roll positioned between a bridge bar and pole piece.

The adjustability makes the bench version of the IRS ideal for research projects. The three key adjustable features are to vary the magnetic field strength; adjust the roll speed, which balances the centrifugal force against magnetic attraction; and splitter plate settings to create three fractions (magnetics, middlings, and non-magnetics). Regulating the power to the electromagnetic coils varies the magnetic field strength up to a peak of two Tesla. This allows the separation of particles with different magnetic susceptibilities. The final variant is the gap between the induced magnetic roll and the pole, with a smaller gap enabling a higher magnetic intensity. The gap is dependent on the particle size range of the material.

The university research team is assessing physical separation techniques, both dry and wet, to recycle problematic waste such as lithium-ion batteries. Within the scope for dry separation, the team required the BIRS to handle particles between 0.1 and 2 millimetres.

The laboratory-scale induced roll magnetic separator is part of a range of equipment designed specifically for research.

EggersmannNorthAmericaInc.|Contactdetails:ChristopherPickhardt|(646)-391-3177|sales@eggersmann-na.com|www.eggersmann-na.com

aresomeapplicationswhereahigh-torqueshredderisthebetterchoicethanahigh-speedgrinder!Withtheoptionalscreenbaskets (single-shaftshredders)orbreakerbars/screenbaskets(dual-shaftshredders)theseshreddersareabletomakeasizedandconsistentproduct. Checkusoutformoreinformationonshredders,trommelscreensandstarscreensorgetintouchwithoneofourdealersinyourregion. TimberRidgeEquipmentCompanyLLC 55WoodcrestDrive Ephrata,PA,17522 TimMartin (717)-629-3467 Email:tim@timberridgeequip.com CompassEquipmentInc. 4688PacificHeightsRd Oroville,CA95965 RonMoras (530)-864-7986 Email:rmoras@compassequip.com Tired of the daily grind? Just shred it! With Eggersmann high-torque shredders. •Lowfuelcosts»averageof10-15gal/h •Lessfines»betterproductquality •Resistantagainstcontaminants(steel,etc.) •Moreuptime •Lessmaintenancecosts,lesswearandtear QualityFleetService,Inc. 548NewLudlowRd SouthHadley,MA,01075 ErickPoirier (413)-695-6070 Email:erick@qualityfleetservice.com CommonwealthEquipment 36HazletonSt Ashley,PA,18706 DamienDevlin (717)-324-4353 Email:Damien.devlin@commonwealthequipment.com NEWS ROOM

There

14 recyclingproductnews.com | APRIL 2024

Marine Layer, a San Francisco-based apparel brand, and Trashie, a recycling and rewards platform, have partnered to create an expanded clothing recycling service. The partnership unites Marine Layer’s Re-Spun program, which launched in 2018 to give t-shirts a second life,

with Trashie’s Take Back Bag program, which enables an easy way to recycle unwanted clothing, accessories, and linens from any brand.

People can purchase a Re-Spun Take Back Bag for $20 from Marine Layer’s website, fill it with unwanted items, and then mail the bag back to Trashie using a pre-paid shipping label. In exchange, participants receive $40 in credit to spend with Marine Layer.

Marine Layer’s Re-Spun program was initially centred around recycling old t-shirts and has successfully diverted over 500,000 t-shirts from landfills.

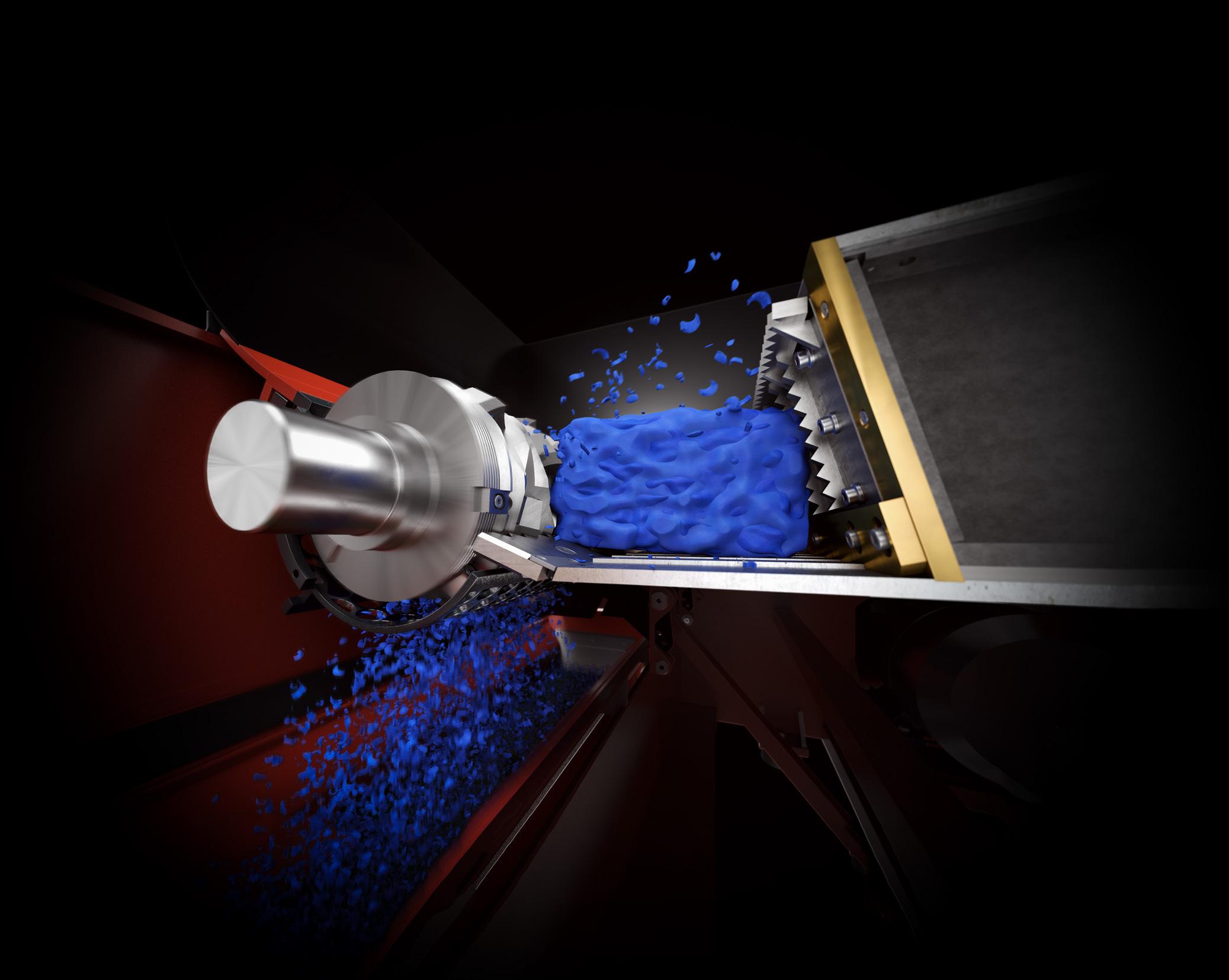

SHRED-TECH PARENT COMPANY ACQUIRES CM SHREDDERS

Shred-Tech’s parent company, The Heico Companies, has acquired Florida-based CM Shredders.

With the acquisition, Shred-Tech is looking to expand its global footprint. CM Shredders’ established presence in tire recycling and markets like Asia and the Middle East will provide Shred-Tech with access to a broader user base.

The acquisition helps increase Shred-Tech’s competitiveness in the marketplace. Shred-Tech says that by combining resources and manufacturing capabilities, the company will help meet the needs of clients and address industry challenges.

15 APRIL 2024 | recyclingproductnews.com

PARTNERSHIP EXPANDS FLEET SAFETY TRAINING PROGRAM TO SMALL HAULERS

Together for Safer Roads (TSR) and the National Waste & Recycling Association (NWRA) have partnered to extend the FOCUS on Fleet Safety Training Program to independent haulers within the waste and recycling industry. This collaboration builds on the success of the program in creating safe and efficient fleet operations.

The FOCUS on Fleet Safety Training Program helps independent fleet operators develop their safety culture with expertise and best practices drawn from TSR’s group of fleets and technol-

ogy companies. The FOCUS program is structured around training and development, safety leadership, and technology, and includes executive coaching and before and after benchmarking. The initiative focuses on:

• Inclusive training that fits the unique characteristics of independent haulers;

• Going beyond compliance to offer practical insights and expertise to establish strong fleet safety programs; and

• Saving lives and creating change, aiming to enhance road safety and foster positive transformations within participating organizations.

REPUBLIC SERVICES EARNS SPOT ON 100 MOST SUSTAINABLE COMPANIES LIST

Republic Services has been named for a sixth year to Barron’s 100 Most Sustainable Companies list. Republic ranks 19th on the 2024 list, which rates companies across 230 environmental, social, and governance performance metrics, from workplace diversity to greenhouse gas emissions.

Republic Services continues to make progress toward its 2030 Sustainability Goals tied to safety, talent, climate leadership, and communities. Republic Services was the first U.S. environmental services provider with a greenhouse gas reduction goal approved by the Science Based Targets initiative.

Brawler HPS Toughsoftjobsride

See us at Booth #2273,

Brawler HPS Solidflex Smooth

Brawler HPS Solidflex Traction

Learn More www.trelleborg-tires.com/en-us TR-152G.indd 1 3/19/24 1:34 PM NEWS ROOM

Brawler HPS Smooth

16 recyclingproductnews.com | APRIL 2024

GLENCORE INVESTS IN LI-CYCLE

Glencore has invested $75 million in Li-Cycle, marking the second investment that Glencore has made in the company. The first was secured in June 2022. Glencore has designated Li-Cycle as one of its preferred recycling partners, and Li-Cycle and Glencore entered into a strategic commercial partnership aimed at creating an integrated platform to supply a global base with both primary and recycled critical battery materials. As part of the partnership, Glencore previously made a $200 million investment in Li-Cycle as well.

ISRI’S 2024 AGENDA FOCUSES ON FIVE PRIORITIES FOR THE RECYCLED MATERIALS INDUSTRY

ISRI has released its 2024 Advocacy Agenda which focuses on strategies to further strengthen and develop legislative, regulatory, and strategic partnerships along with community outreach efforts. ISRI has outlined a series of priorities for the industry to ensure safe, economically sustainable, and environmentally responsible recycling, including:

• Championing environmental stewardship within reasonable regulatory frameworks;

• Maintaining market access, development, and sustained economic growth;

• Ensuring a safe and circular environment in an era of increasing electrification;

• Promoting safe and legal recycling practices; and

• Shaping the future by advancing education, workforce development, and responsible governance.

Improve the productivity of your shredding system by up to 30% and lower power consumption by 20% with our Variable Frequency Drive (VFD). The VFD helps maintain consistent engine speed, minimizing disruptions.

Optimum motor utilization and damping of load peaks

No reduction in rotor speed during the scrap process

Monitoring of motor load quality and speed control

Significant energy savings by higher productivity

Can be retrofitted on all Texas Shredders

High starting torque (approx. 180 % of the full load torque)

Low starting current (freely adjustable, approx. 50 - 100 % of the full load current) 11451

Jones

San

Phone

491

Texas

– Lindemann USA, Inc. lindemann-metalrecycling.com MORE NEWS

Maltsberger Rd

Antonio, TX 78216

+1 210

9521

Shredder

www.recyclingproductnews.com

17 APRIL 2024 | recyclingproductnews.com

SPOTLIGHT

INTRODUCTIONS & UPDATES

M&J Recycling PRE-SHREDDERS

The M&J P250e pre-shredder lineup caters to heavy-duty and lighter applications, emphasizing efficiency, capacity, and minimized energy consumption based on specific operational needs. The series comprises four drivetrain configurations that accommodate different waste types and capacities of up to 100 tph with the possibility to achieve a grain size of 90 percent below 100 mm. The P250e offers a lower total cost of ownership with a patented modular design, facilitating hassle-free wear part replacement. Maintenance procedures are simplified, offering enhanced accessibility for welding and targeted part replacement.

Mecalac

WHEEL LOADER

Mecalac’s AT1050 telescopic wheel loader, part of the AT Series, balances the functionality of a rigid chassis front loader with the maneuverability of an articulated loader. The AT1050 also combines functions, such as material handling and loading, for construction, recycling, and composting applications. The AT1050 delivers heavy-duty performance with a Tier 4 Final 75-hp engine with a DOC emissions control system. This means that there is no DPF or DEF fluid to manage, boosting uptime while mitigating engine issues relating to bypassed regeneration cycles or compromised DEF systems.

Finlay CONVEYOR

Finlay’s TR-80 radial conveyor can be easily integrated into static operations or function as part of a mobile crushing and screening set-up in a diverse range of applications, from heavy-duty primary crushing to light-duty applications. A key feature of the TR-80 is the automated stockpile program that allows operators to stockpile materials in set patterns to suit their operations and site configuration. When operated in conical mode, the TR-80 has a maximum discharge height of 10.18 metres (33 feet 5 inches) and can stockpile 1,811 cubic metres (2,369 cubic yards) of material.

SPOTLIGHT

Electric pre-shredders

Telescopic wheel loader

18 recyclingproductnews.com | APRIL 2024

Radial conveyor

Superior Industries SCALPING SCREEN

Superior Industries has expanded its lineup of Guardian horizontal screens with a heavy-duty scalping model. The HD scalping screen handles a maximum feed size of 18 inches (457 mm). This surpasses its medium-duty predecessor, which maxes out at 14 inches (355 mm). The HD screen is equipped with a perforated top deck, or punch plate, made of heavy-duty 3/4-inch AR steel. A slight slope facilitates the movement of feed material for efficient screening.

ZenRobotics SORTING ROBOT

The Heavy Picker 4.0 robot from ZenRobotics has a compact individual recognition system called ZenBrain to enhance precision and increase efficiency by 60–100 percent compared to the previous system. It features upgraded AI technology with an advanced global recognition database that empowers the robots to identify over 500 waste categories, improved motion control, and the ability to prioritize picking the resource that has the most value to the user. The gripper and manipulator have also been improved with 90 percent new or redesigned components.

Waste sorting robot

19 APRIL 2024 | recyclingproductnews.com

Scalping screen

REIMAGINE

WASTE E XPO 2024

WASTEEXPO 2024 SHOW PREVIEW

RECYCLING AT

Waste Expo returns May 6 – 9 in Las Vegas, NV

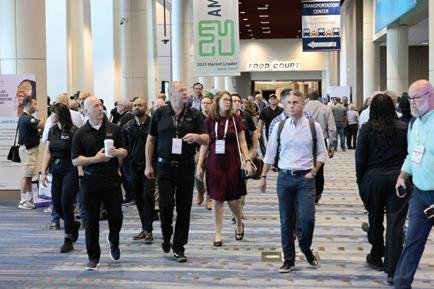

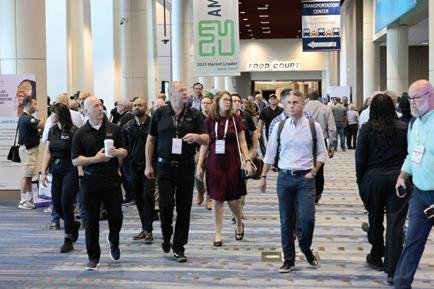

With more than 13,500 participants and over 550 exhibitors, WasteExpo has been one of North America’s largest solid waste, recycling, organics, and sustainability trade shows for over 50 years. Returning for its 2024 edition in Las Vegas from May 6 to 9, the show floor is a place to pursue business opportunities, discover innovative products, and connect with knowledgeable professionals, while the sessions and workshops allow you to sharpen your skills and learn current best practices.

Beyond the show floor, WasteExpo also offers special events packed with activities and business opportunities. Opening night will feature a welcome reception at

1

THE ROLE OF ARTIFICIAL INTELLIGENCE IN FLEET MANAGEMENT

Monday, May 6, 8:30 AM – 9:30 AM

Technological advancements, intelligent transportation systems, and artificial intelligence (AI) have revealed new opportunities to advance both fleet safety and productivity. In this session, industry experts will come together to discuss how the integration of these technologies can improve fleet management; increase return on investment; improve safety, operations, efficiency, and environmental compliance; expand driver knowledge and perception; and improve the capture of data to be utilized, translated, and executed.

2

RECYCLING OPERATIONS IN A POST-EPR WORLD

Monday, May 6, 8:30 AM – 9:30 AM

What do recycling operations look like after extended producer responsibility (EPR) is implemented in the states that have passed legislation in the past several years? Now that implementation is underway in California, Colorado, Maine, and Oregon, this session will dive deep into what impacts, challenges and improvements are coming down the pike for

AREA15, followed by awards ceremonies and a public sector reception on Tuesday. Attendees can also look forward to fun events, such as the TRASHION runway show that highlights eco-conscious fashion made from discarded items, as well as the Women’s Council’s Carts on Display competition that turns bins into artwork.

With technology and innovation as the underlying themes for WasteExpo 2024, the conference program consists of seven education tracks: Operations, Fleet & Safety; Recycling & Landfill; Sustainability Talks; Business Insights & Policy; Technology & Innovation; Food Recovery Forum; and Organics Recycling. Here are eight sessions that you won’t want to miss this year.

U.S. recycling. Learn how EPR differs in each state, how EPR affects recycling operations, and what to expect moving forward as more states consider EPR policies.

3

FEDERAL FOOD LOSS AND WASTE REDUCTION INITIATIVES

Monday, May 6, 12:45 PM – 1:30 PM

During this joint agency session, representatives from the U.S. Department of Agriculture, Environmental Protection Agency, and Food and Drug Administration will share an update on the tools, resources, and funding opportunities regarding food loss and waste reduction. Agency representatives will highlight new and existing federal efforts, such as the Interagency Collaborative, incentivizing food loss and reduction through public-private partnerships, as well as discuss future initiatives.

Speakers: Jean Buzby, USDA Food Loss and Waste Liaison, U.S. Department of Agriculture (Moderator); Lana Suarez, Associate Chief, Materials Management Branch, U.S. Environmental Protection Agency; Priya Kadam, Senior Advisor, Center for Food Safety and Applied Nutrition, U.S. Food and Drug Administration; and Ahmed Kablan Senior Science Advisor: U.S. Agency for International Development.

WASTEEXPO 2024 SHOW PREVIEW

22 recyclingproductnews.com | APRIL 2024

DRIVER ROUNDTABLE: STORIES FROM THE ROAD

Tuesday, May 7, 2:30 PM – 3:30 PM

Drivers from the public and private sides of the waste and recycling industry come together to provide insights and best practices learned from the road. Covering topics such as training, safety procedures, policies for navigating a route, and driving a large truck on narrow roadways with many stops, these drivers share what it takes to be a driver in this dynamic industry.

PATHWAYS TO SUCCESS FOR PLASTIC WASTE

Tuesday, May 7, 2:30 PM – 3:30 PM

Listen to and participate in a lively discussion about plastic waste. The conversation will include how both mechanical and advanced recycling help address the world’s plastic waste problems. Getting plastic waste materials to recycling outlets requires a diverse mix of efforts, including landfill-diversion programs, improved logistics, and innovative technology to identify/analyze materials, sort them, and create pathways/ markets. This requires cooperation with businesses, municipalities, and communities. Hear about real-world examples, including all-plastic collection programs in the City of Houston. The open discussion format encourages all to share their own success stories and get everyone inspired to become active ambassadors for sustainability in their communities.

EMPLOYEE ENGAGEMENT: THE PATH TO SAFETY & PURPOSE

Wednesday, May 8, 10 AM – 11 AM

Employee engagement has long been desirable in corporate America, but in the current business environment, it has become a necessity. Companies with high levels of engagement are flourishing, and those with low levels are struggling. Engagement is most crucial when it comes to safety, making it utterly essential for companies in the waste industry. Learn the science behind the employee engagement imperative, best practices for using recognition/rewards programs to generate long-term engagement and behaviour change, and how you can drive improvements throughout your organization.

UNDERSTANDING MRF PROPOSALS: A GUIDE TO EFFECTIVE ANALYSIS

Wednesday, May 8, 11:30 AM – 12:30 PM

Imagine you have a goal of building a new processing facility. After gathering data and outbound specs, you identify a property and solicit proposals from industry leaders. Now what? You’re faced with the challenge of analyzing these seemingly similar proposals. In this session, you’ll learn how to discern between proposals that align with your facility development and those that fall short, how to sharpen your decision-making skills, how to access diverse technologies from different vendors, and more.

ALTERNATIVE FUELS: STABILIZING BUDGETS & PROTECTING AGAINST RISING RATES

Wednesday, May 8, 1:30 PM – 2:30 PM

Learn the basics of fuel hedging, its availability, and how it works; how to stay protected against high fuel prices; how to stabilize and cap fuel budgets; how to mitigate fuel risk to maintain a strong level of profitability; and more.

CHRIS HAWN CEO, MACHINEX

WasteExpo has been, and will continue to be, North America’s leading event bringing our colleagues, customers, new technologies, and education to a location where we can all share our knowledge and experience. Over the years, I feel the show has grown from what was once perceived as an exposition for the private sector to much more of the public sector as well. This is not to say that it cannot be improved upon, and the show owners, management, and leading industry associations strive to continuously grow and consider what the industry wants.

As always, I love to see the new technology that helps drive safety and operational efficiencies within the waste industry, and I also look forward to new education sessions that address topics that are in front of us every day. That all said, the thing I look forward to the most is seeing our friends, colleagues, and even competitors who are dedicated to such a great industry!”

4

5 6 7 8

23 APRIL 2024 | recyclingproductnews.com

HOW TO SELF-AUDIT YOUR RECYCLING FACILITY

ASSESS YOUR OPERATIONS FROM COLLECTION TO DISPOSAL

BY SLONE FOX, EDITOR

For recycling facilities, ensuring operations remain environmentally responsible is paramount. Self-audits play a vital role in this by ensuring compliance with regulations and allowing recyclers to assess their procedures from collection to processing and beyond, identifying areas for improvement and implementing corrective actions where needed. By regularly conducting self-audits, recyclers can mitigate risks associated with non-compliance while simultaneously fostering a culture of continuous improvement and accountability.

An internal audit is a highly effective method for managing risks and minimizing legal liabilities. An audit can identify any current or potential environmental issues and provide a detailed assessment of a facility’s operations, waste management processes, and record-keeping systems. When conducting an internal audit, it’s important to appoint an auditor who is familiar with the facility’s operations and has a solid understanding of environmental regulations. For smaller companies, it can be beneficial to seek assistance from external consultants who specialize in environmental auditing.

According to the Institute of Scrap Recycling Industries (ISRI), the audit process typically involves the following steps: review of legal requirements and liabilities, records review, employee notification, site inspection, and evaluation. Follow their tips below to ensure a smooth and thorough self-audit.

REQUIREMENTS AND LIABILITIES

Before conducting the audit, make sure the auditor understands regulatory obligations and legal liabilities relating not only to the facility itself, but to environmental aspects such as air quality, water management, and land use. Also be sure to determine which local agencies govern the facility’s operations, as local regulations can sometimes be stricter than federal ones.

Following both federal and local laws and regulations ensures the protection of natural resources, minimizes pollution, and promotes sustainable practices within the recycling industry. However, non-compliance may result in fines, penalties, legal action, and broken trust among customers, investors, and the public.

METALS 24 recyclingproductnews.com | APRIL 2024

Self-audits ensure compliance with regulations and allow recyclers to identify areas for improvement.

RECORDS REVIEW

According to ISRI, the following documents should be reviewed thoroughly by the auditor before the inspection:

• Tank testing results

• Inventory records of products and raw materials

• Production schedules

• Purchase records

• Disposal records

• Environmental permits and licenses

• Manifests

• Water discharge inventories

• Material safety data sheets

Existing records offer valuable information about current practices and existing contamination levels, as well as insight into potential issues that may arise in the future. While not all of these records may be available, it’s important to gather as much information as possible ahead of the site audit.

EMPLOYEE NOTIFICATION

During the assessment, the auditor should go over com-

Conducting an internal audit is a highly effective method for managing risks and minimizing legal liabilities. An audit can identify any current or potential environmental issues and provide a detailed assessment of a facility’s operations, waste management processes, and record-keeping systems.

pany policies regarding environmental compliance with all employees to ensure they understand the reasoning behind procedures within the facility. When employees are well-informed, they can offer valuable suggestions and are more likely to adhere to environmentally responsible practices, says ISRI.

INSPECTION

The on-site inspection is the most critical aspect of a self-audit because it provides first-hand insights into the actual environmental practices and conditions within the facility and allows the auditor to verify that all equipment and operations are functioning as intended. If possible, ISRI suggests scheduling the inspection to coincide with critical operations to witness real-time practices, potential emissions, and waste generation.

ISRI recommends recyclers answer these questions to help identify any processes that could be hazardous to the environment:

• Is scrap or waste stored closer than necessary to an adjacent body of water?

• Can you better control used oil?

• Are you screening out sources of potential polychlorinated biphenyl contamination from inbound material?

The auditor should then physically walk through the entire process starting from when materials arrive, following through each step of production until the products and waste are sent off site to customers, storage, or disposal facilities.

EVALUATION

After completing the audit, it’s essential to compile a thorough evaluation of the facility’s environmental practices and performance. This evaluation should include detailed recommendations for future actions that need to be taken to improve compliance and sustainability, as well as a schedule outlining the steps and timelines for implementation. ISRI also offers a list of hotlines and additional resources on its website that can address any technical questions or concerns that arise during the audit process.

25 APRIL 2024 | recyclingproductnews.com

INTERNAL AUDIT CHECKLIST

REDUCE RISKS WITH THESE TIPS

Self-audits play a key role in maintaining the integrity and efficiency of recycling facilities and are essential for identifying areas of improvement, ensuring regulatory compliance and optimizing resource utilization. By conducting regular self-audits, facilities can detect and rectify problems early, minimizing disruptions and enhancing productivity. Use this checklist as a guide to help audit your facility and ensure you’re keeping up with ISRI’s best practices.

MATERIAL HANDLING

Identify each type of material that your facility handles, including inbound materials, processed materials, and any by-products or residue. Next, determine if any of the materials could be hazardous. According to ISRI, a material is considered hazardous under the Resource Conservation and Recovery Act if it exceeds the specific limits for toxicity, corrosivity, flammability, and reactivity; has been named and listed as a hazardous waste; is a mixture containing a listed hazardous waste; or is derived from the treatment of hazardous waste. Some things to look out for include tanks, batteries, and transformers.

USED OIL

When used oil is not managed properly, it can escape into the environment, causing pollution and environmental damage. To mitigate these risks, auditors must identify all points where used oil is released during facility operations, including machinery, storage tanks, and transfer areas where oil may leak or spill. Once identified, measures must be in place to ensure that used oil is collected and controlled effectively. This involves implementing

proper storage and handling procedures, regular maintenance and inspection of equipment to detect leaks or potential issues early on, and having spill containment measures in place to respond quickly to any accidents.

AIR EMISSIONS

The audit should pinpoint every possible air pollution source in your facility, like metal shredding or combustion processes, for example. To ensure you’re following proper protocols, ISRI recommends asking yourself the following questions during the assessment: is a federal, state, provincial, or local permit or authorization required for any of these operations? If so, do you have the permit? Are you in compliance with it?

WATER DISCHARGE

It’s essential to determine if any water discharged from your facility flows into a ditch or other channel that ultimately leads to a body of water, such as a river, lake, or ocean. If so, it’s imperative to ensure that you have the required permits and understand monitoring requirements and reporting obligations. Similarly, if your facility discharges water into a municipal sewer system, there are often specific requirements regarding the quality and quantity of wastewater that can be discharged into it. In some cases, pretreatment may be necessary.

STORAGE TANKS

During your self-audit, it’s paramount to identify and locate all above- and underground storage tank areas, as well as waste and raw material container storage areas. This is essential for ensuring the safety of employees and the environment by implementing proper handling and storage practices to prevent accidents such as spills, leaks, or fires. Moreover, it enables compliance with regulatory requirements concerning storage capacity, material handling, labelling, and emergency response procedures. By managing storage areas effectively, the facility can minimize the risk of contamination to soil, water, and air, as well as enhance operational efficiency by facilitating streamlined inventory management.

RADIATION

Recyclers need to be vigilant about the potential presence of radioactive contaminants in incoming materials by implementing measures to detect radioactive items before they’re received and processed. This typically involves utilizing radiation detection equipment such as Geiger counters during the inspection and sorting processes. Facilities should establish protocols and training programs to ensure employees understand the potential risks associated with handling radioactive scrap, recognize warning signs of radioactive contamination, and know how to respond in case of a suspected radioactive item.

METALS

26 recyclingproductnews.com | APRIL 2024

BATTERIES

If your facility handles lead–acid batteries, it’s important to note that these batteries can pose risks if they are mishandled or improperly disposed of, including soil and groundwater contamination from lead leaching out of the batteries, as well as potential exposure to lead dust during battery dismantling or the recycling process. Lithium-ion batteries, on the other hand, are prone to fire and explosion hazards if mishandled, necessitating strict handling and storage protocols. Employee training is crucial to ensure safe handling practices, as is the use of personal protective equipment and the adoption of best practices for processing hazardous materials.

CONTAMINATED AREAS

In areas where spills have occurred, especially those involving potentially hazardous materials, you must assess whether the soil has been contaminated. This is done by gathering soil samples from the affected areas which then must undergo laboratory analysis to determine the concentration of contaminants at your facility compared to regulatory standards. Depending on the findings, remediation measures ranging from soil excavation and removal to bioremediation or soil washing may be necessary to address contamination and mitigate environmental impacts.

OFF-SITE AREAS

During your audit, don’t forget to inspect off-site areas, particularly waste disposal operations. This includes understanding where your waste ends up and ensuring its proper management. For facilities using haulers to transport waste, confirm that the haulers are indeed delivering to the destination as agreed upon. This includes monitoring hauler activities, maintaining accurate records of waste disposal transactions, and implementing tracking mechanisms to trace waste from generation to disposal. ISRI warns that processors have encountered situations where haulers have disposed of waste at non-designated or improper locations, resulting in legal consequences, financial penalties, and reputational damage. RPN

Want to increase your margins in plastic recycling?

With AUTOSORT™ – the world’s most powerful multifunctional sorting system, you can achieve higher throughput and exceptional purity levels across a variety of polymers and colors. Compact and flexible in design, it complements both new and existing plants.

High-value plastic. From any stream.

how it sorts See us at NPE booth S35185 CA2403_Recycling Product News_Plastics_190,5x123,83mm_v1.indd 1 22.03.24 09:35

See

27 APRIL 2024 | recyclingproductnews.com

BY SLONE FOX, EDITOR

BY SLONE FOX, EDITOR

In your opinion, what are the most notable trends and complications shaping the waste management industry today?

Interestingly enough, we are at a time, in my opinion, where complications are the drivers of many of the trends. Labour shortages have led to increased automation; safety of our workers has led to continuous improvement in designs; and fires as a result of lithium-ion batteries have led to technology and new considerations of producer responsibility and public education. I know I am painting this with a broad brush, but it is something that touches every aspect of the waste industry as a whole.

Q & A

MACHINEX CEO CHRIS HAWN ON THE MODERN MRF

With advancements in automation, robotics, and data analytics, MRFs have become more capable than ever of sorting and separating materials. Through process optimization and strategic investments in equipment, modern MRFs are continuously evolving to meet the demands of a rapidly changing waste management landscape.

I caught up with Chris Hawn, CEO of Machinex, to delve into the factors influencing MRF operations, the role of data analytics in enhancing efficiency, emerging developments in sorting and separation technologies, and key challenges and opportunities on the horizon for the recycling industry.

In recognition of your first question, operators are mostly considering upgrades that will help address labour, safety, material visibility, and technology to help minimize lithium-ion concerns.

The planning at the beginning of the process becomes the foundation that guides every next step. Machinex starts by taking the time to visit with customers to first listen, evaluate operations, and look at ways to implement beneficial and desired technologies. Elements that come into play as we establish a baseline could include increased tonnage or a significant material composition over time; recovery, purity, and efficiency requests; budget; and building limitations.

Through a mutual understanding and concept of the task ahead, Machinex provides solutions that can either be driven by our knowledge and experience of the industry as a whole, our customer’s recommendations stemming from the intricacies of their specific market demands, or, more often than not, a combination of both.

What factors should MRF operators consider when upgrading sorting equipment, and how does Machinex assist in this decision-making process?

SORTING & SEPARATION

SF

Slone Fox

CH

Chris Hawn

28 recyclingproductnews.com | APRIL 2024

Can you discuss the role of data analytics and monitoring systems in enhancing the operational efficiency of MRFs?

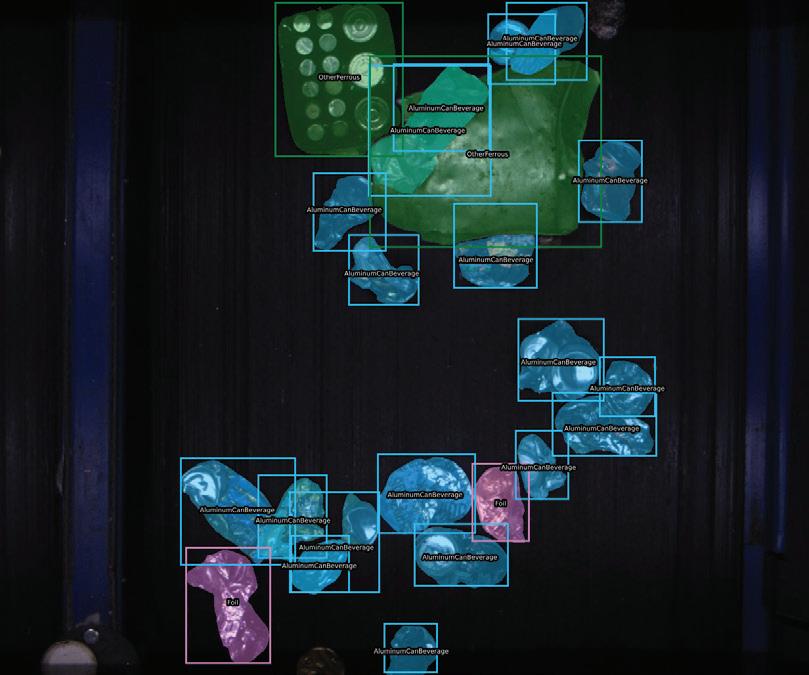

The amount of data now accessible within a MRF has been ever-increasing. Today’s intelligent MRF is the combination of various vision equipment such as optics, robots, and simple cameras to capture data throughout the system and provide SCADA control systems with the information needed to ensure profitable and efficient operations.

Furthermore, the increasing importance of data analytics and monitoring systems has evolved to include even more benefits for MRFs, such as increased recycling rates, the ability to recycle more types of materials, reliability of third parties whether it is related to inbound or outbound material, and sustainability initiatives.

Data capture and analysis within a MRF is definitely a starting point, although in order SF CH

The amount of data accessible within a MRF is ever-increasing.

The amount of data accessible within a MRF is ever-increasing.

29 APRIL 2024 | recyclingproductnews.com

Hawn says the use of optics and robots has skyrocketed.

to maximize its exponential potential, the analyzed data coming from multiple capture points when connected to sorting equipment will have a greater instant impact on the operations. It’s possible to capture an infinite amount of data, but without equipment connectivity, there will be no real improvement in the end.

The technology, when integrated properly, acts like several plant operators constantly looking at different areas of the facility and comparing and optimizing according to what they see.

There are a few developments in the industry that are truly game changers. With the desire to improve upon all of the areas mentioned earlier, front-end equipment such as trommels or auger screens is being used to scalp material that has no business being on the presort lines and can cause excessive work and potential injury.

Automation is another key disrupter. The increased use of high-technology equipment such as optics and robots has skyrocketed. What used to be a MRF with three, four, or five optical sorters that were cleaning up the results of the separation from disc screens has become 12, 13, or more optical sorters without any disc screens and robots to quality control the clean material.

Combining all of this while maximizing the potential of intelligent MRFs and data monitoring has certainly led to the smart MRF of today, and a more flexible MRF for tomorrow as materials change and recovery of new materials is required. SF

What are some emerging or innovative developments in sorting and separation that could potentially disrupt traditional methods in the recycling industry?

SORTING & SEPARATION Scrap Reliable PROCESSING EQUIPMENT FroM A COMPANY YOU CAN TRUST SINCE 1919 GENSCOEQUIP.COM 1-800-268-6797

SCRAP MAGNETS DEPOLLUTION EQUIPMENT ALLIGATOR SHEARS WIRE PROCESSING & STRIPPING

| ATLANTA

GRAPPLES HANDHELD CUTTING TOOLS

TORONTO

30 recyclingproductnews.com | APRIL 2024

CH

In your opinion, what are the biggest challenges and most notable opportunities facing the recycling industry in the coming years?

Hands down, the biggest challenge in the waste and recycling industry is lithium-ion batteries. Technology is being developed, messages are being created, and producer responsibility is being addressed, but unfortunately, there are miles to go. The opportunities are being able to build flexibility within MRF designs to be nimble and adjust to the changing environment around us. Yes, technology was part of that additional flexibility, but it isn’t all about technology. The way the MRF is designed for redundancy, for extra capacity, for future upgrades, etc. are all areas that have become more and more important. RPN

✅ From 720 to 1,375 T of cutting force ✅ The utmost in scrapyard mobility ✅ Patented jam resistant hold down ✅ Full automatic lubrication system TRAX

BOOST YOUR PRODUCTIVITY WITH THE GENUINE PATENTED TRAX ” lefortamerica.com lefort.metal.recycling info@lefortamerica.com + 1 (954) 916-7379

“

SF CH

31 APRIL 2024 | recyclingproductnews.com

Hawn says Machinex visits customers to listen, evaluate operations, and look at ways to implement their desired technologies.

REPORT HIGHLIGHTS DECREASED USE OF PROBLEMATIC MATERIALS IN PLASTIC PACKAGING

THE U.S. PLASTICS PACT HAS RELEASED ITS MOST RECENT DATA FROM MEMBER ORGANIZATIONS

The U.S. Plastics Pact has released its most recent annual report, publishing aggregated 2022 data from its member organizations. The group includes brand, retailer, and converter member organizations (activators) that are collectively responsible for generating 33 percent of all plastic packaging in scope within the U.S. by weight. This equates to the placement of 3.1 million metric tons of plastic packaging in the market.

“Advancing sustainable packaging solutions is as much a systems challenge as a packaging format challenge. The U.S. Pact brings together organizations from every stakeholder group, including government, nonprofits, and for-profits handling the production, use, collection, processing, and disposal of packaging. Facilitating such thoughtful, action-oriented dialogue and goal-setting has been critical to accelerating progress as an industry, and for our own work at Returnity,” says Mike Newman, CEO of Returnity.

Since its inception in August 2020, the U.S. Plastics Pact has grown, more than doubling its membership to over 135 businesses, non-profit organizations, government agencies, and research institutions with the goal of addressing plastic waste at its source through four key targets to be achieved by 2025:

Target 1 Define a list of packaging that is problematic or unnecessary by 2021, and take measures to eliminate items on the list by 2025.

Target 2 100 percent of plastic packaging will be reusable, recyclable, or compostable by 2025.

Target 3 Undertake ambitious actions to effectively recycle or compost 50 percent of plastic packaging by 2025.

Conceding on 2025 commitments will not foster the support still needed to shake the plastics packaging value chain out of the status quo. We must continue to push the boundaries of collaboration and transparency to build the circular economy for plastics packaging.

Emily Tipaldo Executive Director, U.S. Plastics Pact

Target 4 Achieve an average of 30 percent recycled content or responsibly sourced biobased content in plastic packaging by 2025.

Progress since the 2021 report includes:

• A decrease in the amount of plastic packaging placed on the market by U.S. Plastic Pact activators by weight containing items on the U.S. Plastics Pact’s list of problematic and unnecessary materials from 14 percent to 8 percent.

PLASTICS

34 recyclingproductnews.com | APRIL 2024

• An 11.7 percent increase from 36 percent to 47.7 percent in plastic packaging placed on the market by activators being reusable, recyclable, or compostable.

• An increase in the use of post-consumer recycled content (PCR) in plastic packaging from 8 percent to 9.4 percent average PCR or responsibly sourced biobased content used by U.S. Plastics Pact activators.

• Activators commit to ongoing portfolio assessments and annual progress reporting toward these targets through the World Wildlife Fund’s (WWF) Resource Footprint Tracker. The collective progress toward elimination will be documented in future U.S. Pact Annual Reports.

“Global problems can’t be solved without local solutions,” says Erin Simon, vice president and head of plastic waste and business at the WWF. “And that’s why the U.S. Plastics Pact is leading this effort to identify and implement place-based solu tions that will move us closer to a future where plastic pollution no longer harms people or our planet.”

“We must continue to rally activators around our common language and definitions, gathering novel data to model the future potential, and, finally, supporting and inspiring com panies to move toward our circular economy vision,” says Emily Tipaldo, executive director of the U.S. Plastics Pact. “Conceding on 2025 commitments will not foster the support still needed to shake the plastics packaging value chain out of the status quo. We must continue to push the boundaries of collaboration and transparency to build the circular economy for plastics packaging.”

Since its inception, the group has more than doubled its membership. ARE YOUR PROFITS IN THE CAN? Let’s get together! When it comes to our Eddy Current Separators, The Throw Makes The Difference™ Skid Mounted Unit Available Mobile Unit Designs Available Control Packages Vibratory Feeders Rotational speeds up to 3600 RPM Total System Design magnetics.com Industrial Magnetics Inc. » imi@magnetics.com » 231.582.0821 35 APRIL 2024 | recyclingproductnews.com

OPPORTUNITY FOR AN UNDERSERVED MARKET HOW RITTER MATERIALS TURNED A DISASTER INTO AN

Ritter Materials produces mulch, topsoil, and aggregates, and plans to explore coloured mulch as well. ORGANICS

A BUSINESS IS BORN IN THE AFTERMATH OF A TORNADO

BY KENNEDY PHILLIPS

John Ritter, the owner of Ritter Materials in Brookville, Ohio, did not plan on starting a landscaping material company as he approached retirement. Starting early in his career, Ritter helped build a utility company, Ritter Plumbing, that served the local area. That company expanded from a residential plumbing service to a team responsible for replacing water and sewer lines and installing new electrical and gas services. Just as that company evolved with community needs, so did Ritter Materials. John recognized a need and an opportunity to give back to the community that had supported him for many years.

“Memorial Day 2019 is a day everyone in Brookville will remember for a long time,” says Ritter. “An EF4 tornado tore through Montgomery County, leaving a path of destruction spanning 20 miles. When the cleanup effort began, the city needed a location to dispose of over 10,000 cubic yards of organic wood waste. I offered them a piece of land I owned for this purpose.”

A BUSINESS IS BORN

As the piles grew higher, Ritter decided to rent a horizontal grinder to process it all.

“At first, we planned just to spread the mulch around a bit and offer it to people in the community,” Ritter explains. “We quickly realized that there may be a bigger opportunity for us to serve the community than just this one-time venture. That’s when Ritter Materials was started.”

earlier. Ritter Plumbing specializes in horizontal directional drilling, and restoration is always the final step of a project. One of the most challenging aspects of planning that phase is securing clean black dirt to lay down before seeding a work area. To address this challenge, Ritter purchased the piece of land that later became the home of Ritter Materials.

“We bought the land to produce our own topsoil for our utility business,” says Ritter. “To ensure the best quality, we also invested in a Vermeer TR5300 trommel screen to process everything. Soon after, other contractors started asking to buy topsoil from us as well. We did that for a few years and now have incorporated it into the Ritter Materials business.”

OPPORTUNITY TO SERVE

After initially renting a horizontal grinder following the tornado, Ritter decided it was time to invest in one to complement his Vermeer trommel screen. He purchased a Vermeer HG4000 horizontal grinder.

“We chose a Vermeer grinder because we have been using Vermeer equipment since the 1990s and the team at Vermeer Heartland has always provided excellent support. It’s quite unique to transition from working with utility equipment to working with recycling machines manufactured and supported by the same company.”

These two machines are at the heart of Ritter Materials operations. In addition to storm debris, the yard receives material from tree service and right-of-way clearing contractors. According to Ritter, this gives his team an excellent, sustain-

ORGANICS 38 recyclingproductnews.com | APRIL 2024

To facilitate the transportation of topsoil from the trommel screen to the building, Ritter purchased a Vector VT80 track-mounted conveyor from Vermeer.

At first, we planned just to spread the mulch around a bit and offer it to people in the community. We quickly realized that there may be a bigger opportunity for us to serve the community than just this one-time venture. That’s when Ritter Materials was started.

John Ritter Owner, Ritter Materials

able flow of clean material for making high-quality mulch.

But Ritter Materials doesn’t just produce mulch. There is also a high demand for topsoil and a variety of aggregates. Recently, the company started experimenting with coloured mulch to expand its operations.

“Most of our customers are local property owners, but we sell to a few contractors doing landscaping and general construction work in the area,” says Ritter. “We’re still a pretty new organization, so I think we’ll see that part of the business grow.”

RITTER TURNS WASTE INTO REVENUE

All incoming organic waste is stacked and then processed using the Vermeer HG4000 horizontal grinder. Afterward, Ritter allows the material to sit for approximately a year before replacing the screens on the grinder with smaller ones for regrinding. The material that comes out of the grinder is then passed through the TR5300 trommel screen to minimize the presence of fines in the mulch. This process helps Ritter Materials produce high-quality, uniform, and visually appealing products.

“Product size consistency is important to our customers and something that I think sets us apart from buying some bagged mulch from other bulk producers,” he says. “We are extremely diligent in creating a product that we would be proud to use at our homes and around the community.”

Organic wood waste isn’t the only material finding a new life at Ritter Materials. The company began taking milled asphalt from road repaving projects a few years ago. The team runs the milled material through their Vermeer trommel screen to separate larger, chunky material from the fine-milled asphalt. The chunky material is then further processed until it’s sized appropriately. Afterward, the fine material can be reused to build foundations or pave driveways.

“The ultrafine asphalt that we produce just requires a little heat before it looks like a freshly poured driveway,” says Ritter. “It’s economical and gives the asphalt a second life.”

SPARK DETECTION & EXTINGUISHING SYSTEMS

Reduce

Inside your dust collection & conveying system ducts are hazards that can cause fires & dust explosions. Choose GreCon spark detection and extinguishing systems to help protect your property and personnel while also avoiding costly downtime.

John Ritter, owner of Ritter Materials.

your risk of fire and dust explosions

39 APRIL 2024 | recyclingproductnews.com

fagus-grecon.com

PROCESSING TOPSOIL

As a former contractor, Ritter understands that no construction project is complete until everything is restored to its original condition. This includes growing grass and other vegetation which requires clean and dry topsoil.

“We used to source our topsoil on site by using dirt from a retention pond we built,” he explains. “Now, we mostly obtain dirt from other construction projects. We often collaborate with construction project owners and handle the transportation ourselves, creating a win-win situation. They can control their project expenses, and we can meet the demand of our

Ritter Materials carefully screens all the dirt they receive to remove rocks and other debris. The processed topsoil is stored in a large hoop building to keep it dry.

To facilitate the transportation of topsoil from the trommel screen to the building, Ritter purchased an 80-foot (24.4-metre) Vector VT80 track-mounted conveyor from Vermeer Heartland. This conveyor has greatly improved the efficiency of the entire process by eliminating the need to move the material one bucket load at a time. Instead, they have set up the fines conveyor of the TR5300 to feed into the hopper of the Vector, which transports the material directly to the top of the pile in the hoop building.

“We spend a lot of time moving material and stacking it,” he says. “That can become a lot of work if we only use wheel loaders. The Vector conveyor is on a track, making it easy to reposition and assist with whatever project we’re focused on. We

THROUGHPUT HIGH

The Tigercat 6900 is a heavy duty upswing horizontal grinder designed for high throughput mulch production and material reduction. The 6900 is designed and built for extreme duty, long life and high uptime.

more

www.tigercat.com Scan to learn

ORGANICS

40 recyclingproductnews.com | APRIL 2024

In addition to storm debris, Ritter receives material from tree service and clearing contractors.

use it to stack mulch, load trucks or transport material around the facility. It has helped us get work done with a minimal number of people.”

LOOKING AHEAD

Ritter began working full-time for his father’s plumbing business after graduating from high school in 1978. Over time, he and his brother took over the business, which has undergone significant changes. The company has grown, and its focus has evolved to meet the needs of the communities it serves. Cur-

rently, Ritter’s nephew is in charge of business operations.

Ritter may never have thought he would start a new business in his retirement years, but his commitment to serving his neighbours has never slowed down. Ritter Materials continues to expand to meet the landscaping material needs of property owners and professional contractors working around Brookville.

KENNEDY PHILLIPS is the brand experience lead for Vermeer Corporation.

For the circular economy to have a far-reaching ripple effect.

Welcome to IFAT Munich—the world’s leading trade fair for environmental technologies

Sustainably successful. Being the most important driving force in the global environmental industry, IFAT Munich offers innovative recycling and circular economy solutions for municipalities and industries. To significantly save our resources—including financial ones.

May 13–17, 2024 | Messe München

Get your ticket now: ifat.de/tickets/en

Information: Canada Unlimited Inc. Tel. (905) 813-1051 info@canada-unlimited.com

41 APRIL 2024 | recyclingproductnews.com

A Vermeer TR5300 trommel screen.

MAINTAINING SAFE WASTE COLLECTIONS IN GROWING COMMUNITIES

AS THE NUMBER OF RESIDENTIAL STREETS GROWS, MAINTAINING SAFETY BECOMES MORE DIFFICULT

BY COREY HENISER

Operating a waste and refuse truck isn’t easy. Navigating narrow streets, maneuvering around parked vehicles, and constantly being aware of pedestrians and cyclists nearby are just some of the challenges drivers encounter every day.

The waste and refuse industry is one of the most dangerous occupations in the U.S. Aside from the potential for incidents while out on the road, workers themselves also face risks. According to the most recent statistics published by the Solid Waste Association of North America (SWANA), worker fatalities increased in 2022 by nearly 65 percent.

Reliable and safe waste management is an important part of a community’s infrastructure. However, as the number of residential streets grows, maintaining safety is becoming more and more difficult for operators of waste and refuse services.

According to data from the U.S. Census Bureau and the U.S. Department of Housing, there were more than 1.5 million new residential buildings completed in March 2023 alone, with a further 1.42 million properties started and 1.41 million building permits granted.

This rapid increase in the number of residential dwellings means there is even more potential for waste and refuse trucks to encounter pedestrians as well as domestic animals.

The International Transport Forum reported that since 2000, fatalities in urban areas have increased by 26 percent. In 2019, vulnerable road users (pedestrians, cyclists, and motorcyclists) accounted for more than a third of all road deaths.

The hazards of operating waste and refuse trucks in built-up areas are manifold. People, pets, cyclists, parked cars, and cars pulling in and out of driveways, as well as narrow streets, all contribute to the difficulties drivers face. Factor in a large, heavy vehicle with complex blind spots and limited direct vision from the cab, and the potential for collisions is greatly increased.

Beyond regular training for drivers, commercial vehicle safety devices have proven to be crucial for preventing deaths and injuries. These include camera monitor systems, such as Brigade’s Backeye360, which provides a 360-degree surround view of a vehicle in a single image.

This system provides the driver with instant visibility of the numerous blind spots found on large waste vehicles, allowing operators to quickly see and react to hazards on the ground. This is especially useful in built-up areas where drivers are regularly required to perform low-speed maneuvers in challenging situations, including in darkness or difficult weather conditions.

Artificial intelligence is also improving safety for operators and drivers. AI cameras use artificial intelligence to recognize humans within a predefined detection zone and warn drivers visually and/or audibly before a possible collision occurs, making them ideal for the waste industry.

Successfully navigating routes, including contending with heavy traffic, road works, closures, and incidents can also be a huge obstacle for waste and refuse truck drivers. On any given day, journeys can be affected by complications that cause delays, fatigue, and frustration for drivers.

Remote fleet management is making a huge difference in mitigating the effects of problems that drivers encounter en route. Utilizing a digital video recorder with 4G connectivity, like Brigade’s MDR with BRIDGE, allows fleet managers to live track vehicles.

This includes location tracking so that managers can find their fleet at any time, geo-fencing capabilities so managers can identify when vehicles are entering or leaving specific areas, and trigger warnings that instantly notify fleet managers of incidents. For drivers, they can also send an instant notification in the event of an emergency.

TRUCKS & TRANSPORTATION

42 recyclingproductnews.com | APRIL 2024

Utilizing the latest in safety technology is a crucial step toward preventing deaths and injuries caused by collisions in growing communities.

Corey Heniser CEO, Brigade Electronics

Additionally, when vehicles are involved in an incident, the lack of solid evidence can lead to uncertainty and time-consuming investigations. Research into the benefits of recording camera footage from vehicles has found it encourages driver best practices and acts as an accurate eyewitness providing irrefutable evidence in the event of a collision or dispute.

As the urban landscape changes and workloads increase for waste and refuse drivers, maintaining safety will continue to be a top priority for operators. Utilizing the latest in safety technology is a crucial step toward preventing deaths and injuries caused by collisions in growing communities.

COREY HENISER is the chief executive officer at Brigade Electronics.

43 APRIL 2024 | recyclingproductnews.com

Reliable and safe waste management is an important part of a community’s infrastructure.

ELECTRIC COLLECTION VEHICLES POWERED BY THE WASTE THEY COLLECT

TWO MACK LR ELECTRIC VEHICLES WILL EACH COLLECT 150 CUBIC YARDS OF WASTE PER DAY

WIN Waste Innovations, a Massachusetts-based recycling and waste collector, has recently received two Mack LR Electric Class 8 collection vehicles. WIN Waste is powering these two electric collection vehicles exclusively with the waste each truck collects.

The two Mack LR Electric vehicles will each collect 150 cubic yards of waste per day on service routes in Boston, Massachusetts. The waste will be converted into renewable energy to charge the LR Electric vehicles, as well as provide converted renewable energy to homes and businesses in the region. It is estimated that this will eliminate the need for about 2,000 gallons of diesel fuel per year.

“Mack Trucks looks forward to working with WIN Waste and their customers to help them achieve their environmental goals,” says Jonathan Randall, president of Mack Trucks North America. “Mack is committed to offering solutions that offer zero emissions and help improve sustainability for a cleaner environment.”

WIN Waste operates 50 collection, transfer, and disposal assets, including waste-to-energy facilities, transfer solutions, ash monofils, landfills, and fleets of rail cars and collection vehicles. WIN Waste recycles more than 354,000 tons of plastic, paper, and metals from the waste stream and converts more than 6.4 million tons of post-recycled waste into renewable energy.

“Electric trucks are a natural progression of WIN Waste’s emphasis on sustainability and circularity,” says Dan Mayo, chief executive officer of WIN Waste Innovations. “By recharging our Mack LR Electric trucks using the energy generated from the very waste they collect, we are actively bolstering our own sustainability goals, as well as those of our customers.”

By recharging our Mack LR Electric trucks using the energy generated from the very waste they collect, we are actively bolstering our own sustainability goals, as well as those of our customers.

Dan Mayo CEO, WIN Waste Innovations.

The Mack LR Electric offers a standard 376 kWh total battery capacity for 42 percent more energy and an increased range between vehicle charges. Twin electric motors produce 448 continuous horsepower and 4,051 lb.-ft. of peak torque output from zero RPM.